Patents

Literature

218results about "Investigating crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

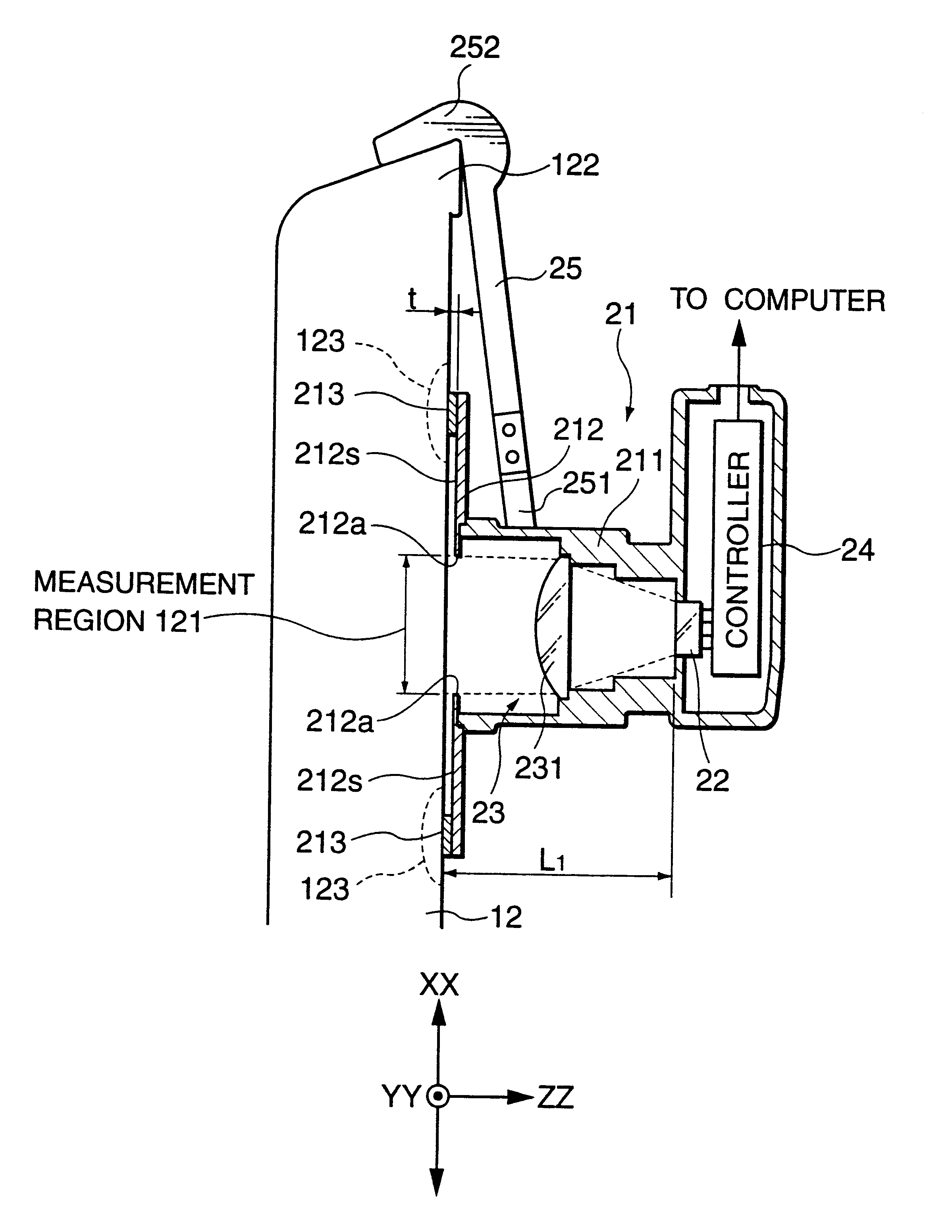

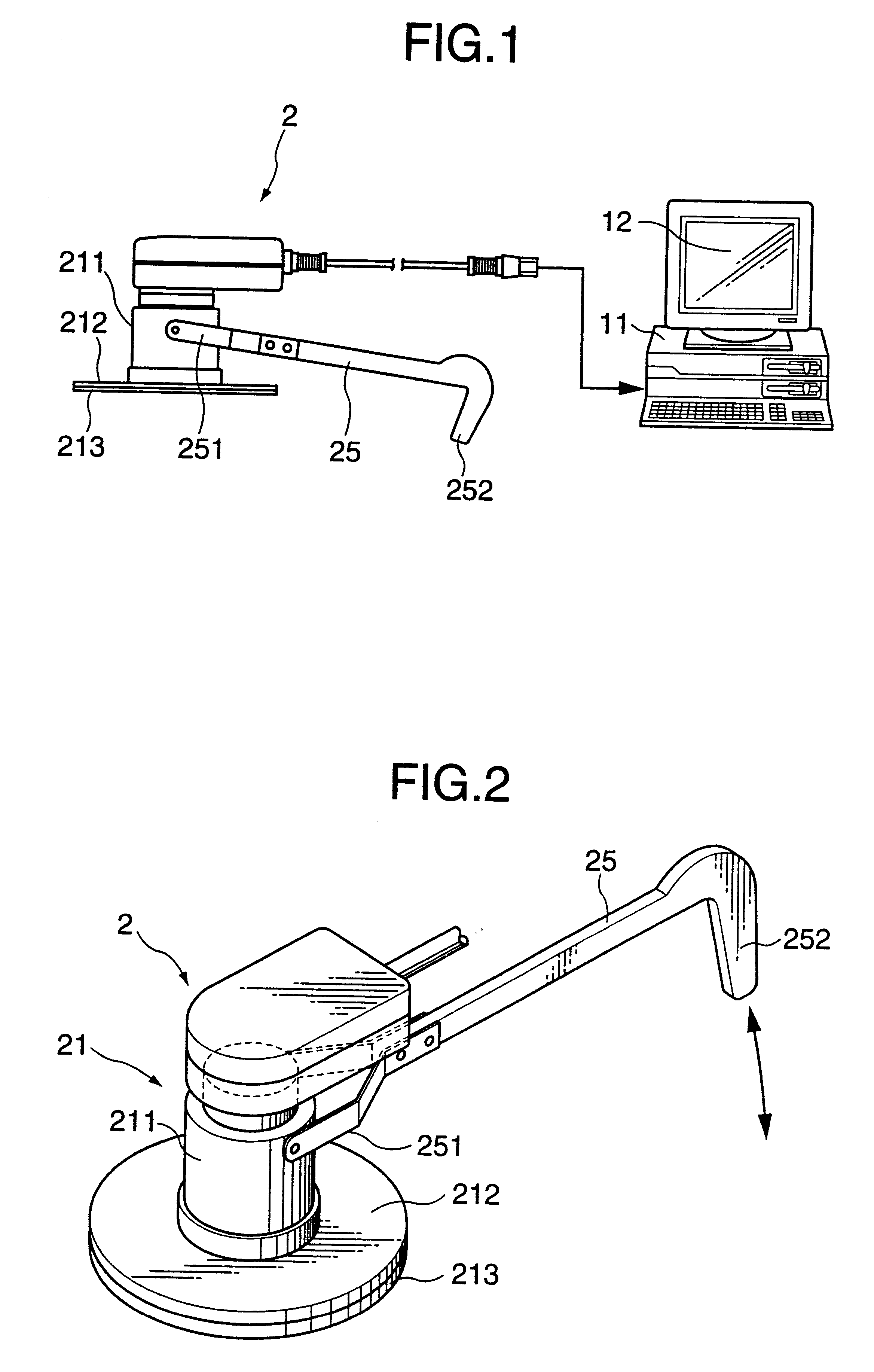

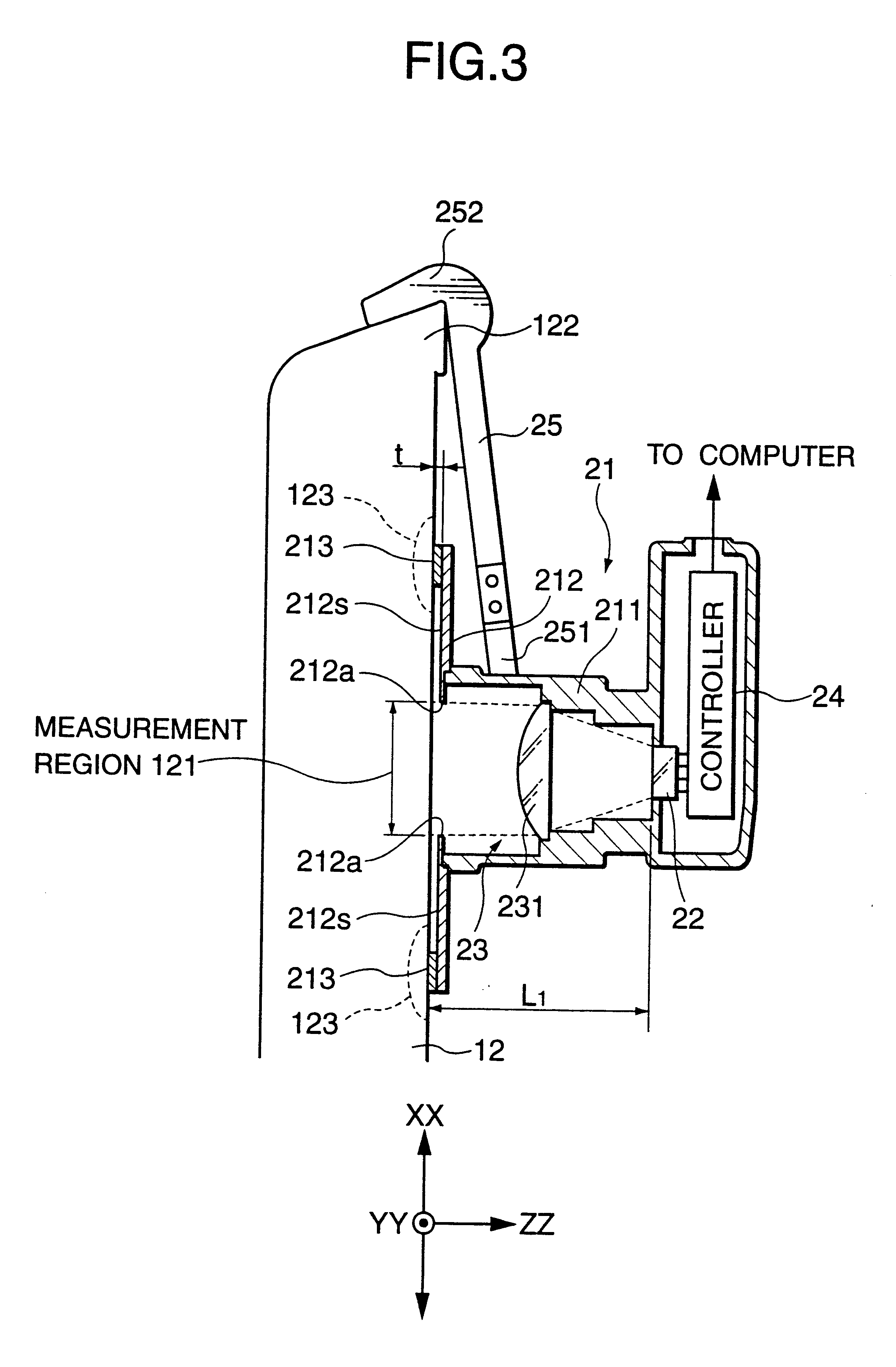

Optical measuring apparatus

InactiveUS6320652B1Accurate measurementRadiation pyrometryInvestigating crystalsAmbient lightingOptical property

An optical measuring apparatus used for measuring optical characteristics of a liquid crystal display panel (LCD panel) in a calibration thereof comprises a housing having a contacting portion directly contacting a surface of the LCD panel and disposed far from a region on the LCD panel to be measured. An optical system and a photosensor is provided in the housing with a predetermined positional relation, so that ambient illumination is shielded by the housing and stray rays emitted from the LCD panel and having exit angles larger than a predetermined maximum exit angle alpha are restricted by the optical system.

Owner:MINOLTA CO LTD

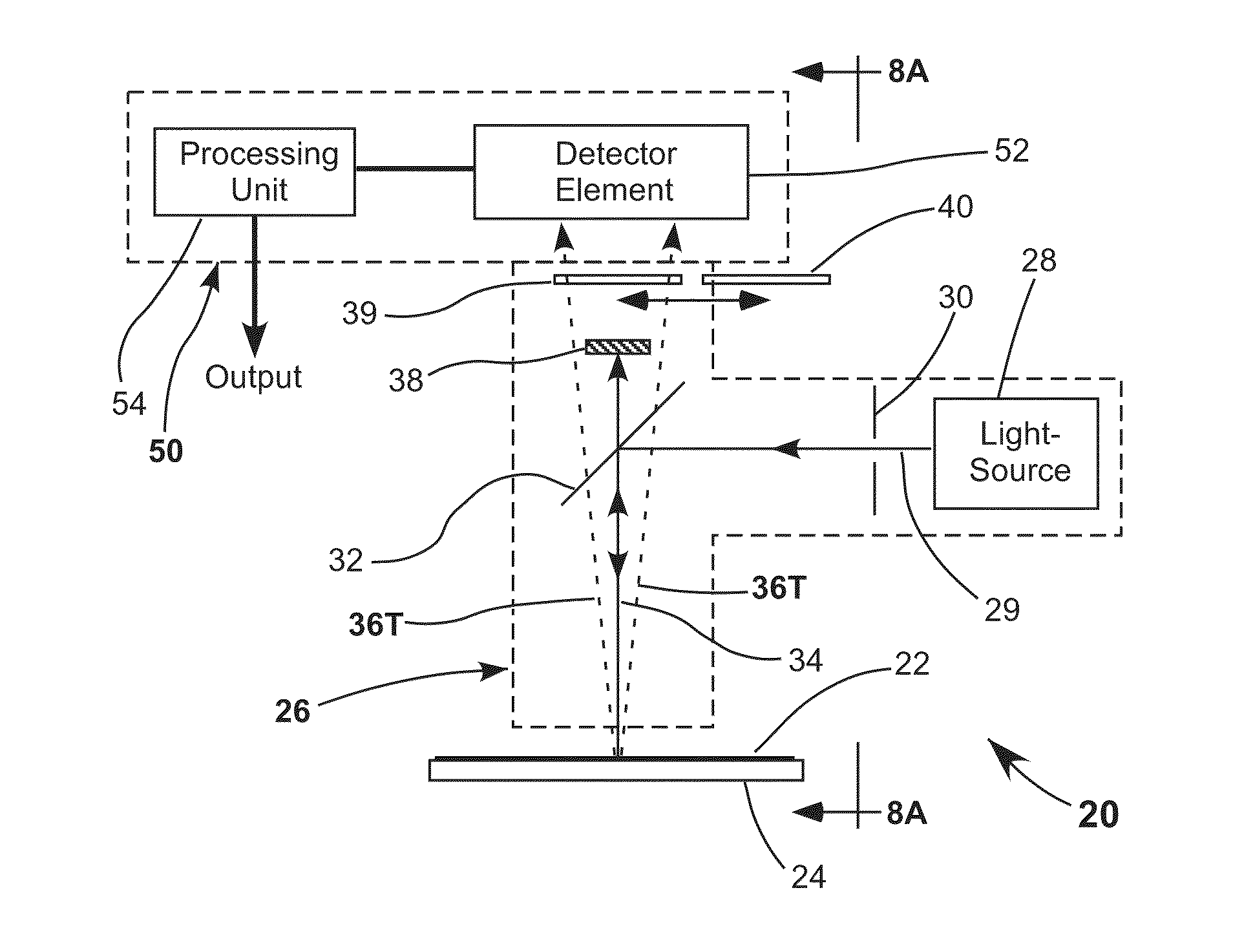

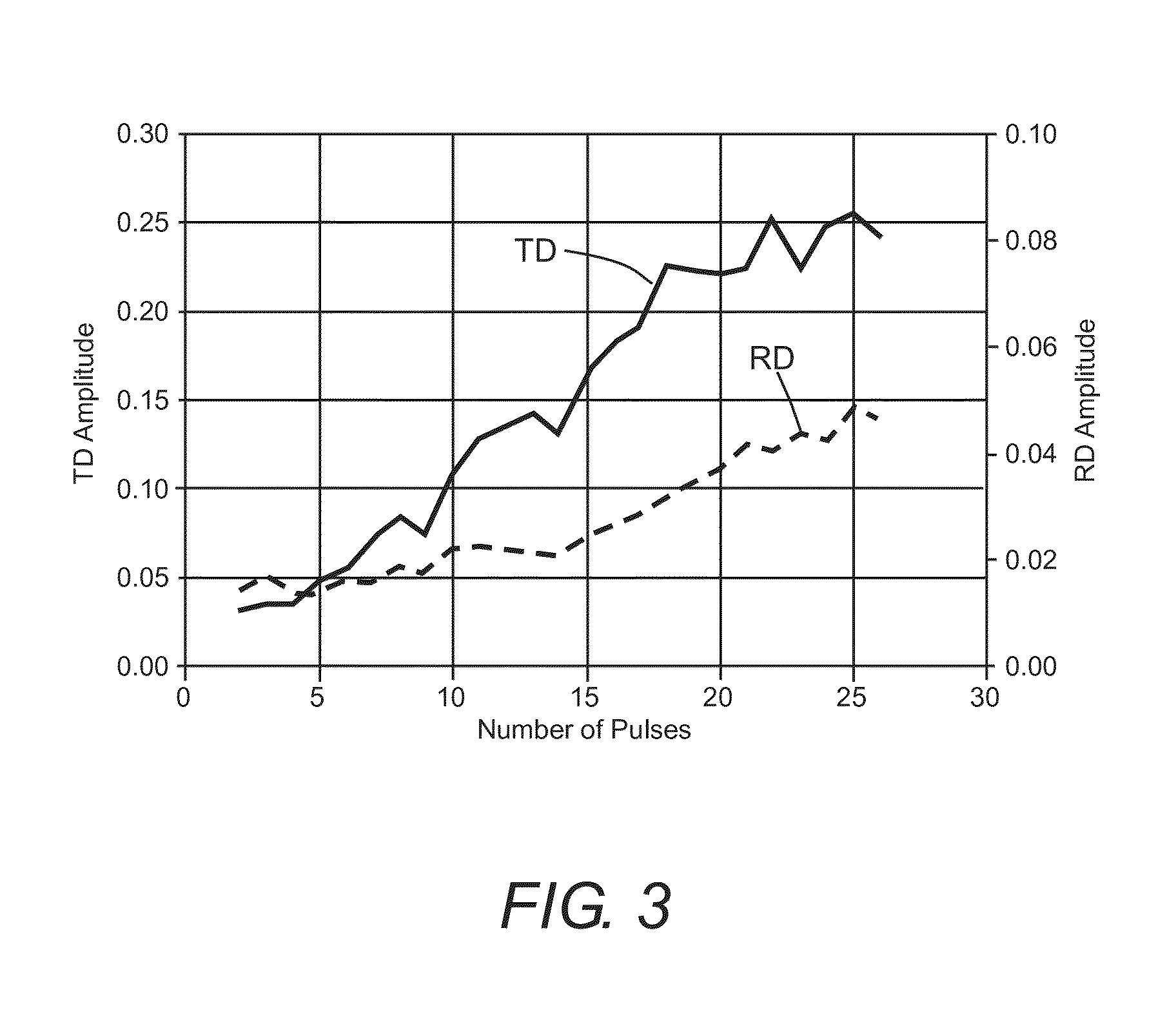

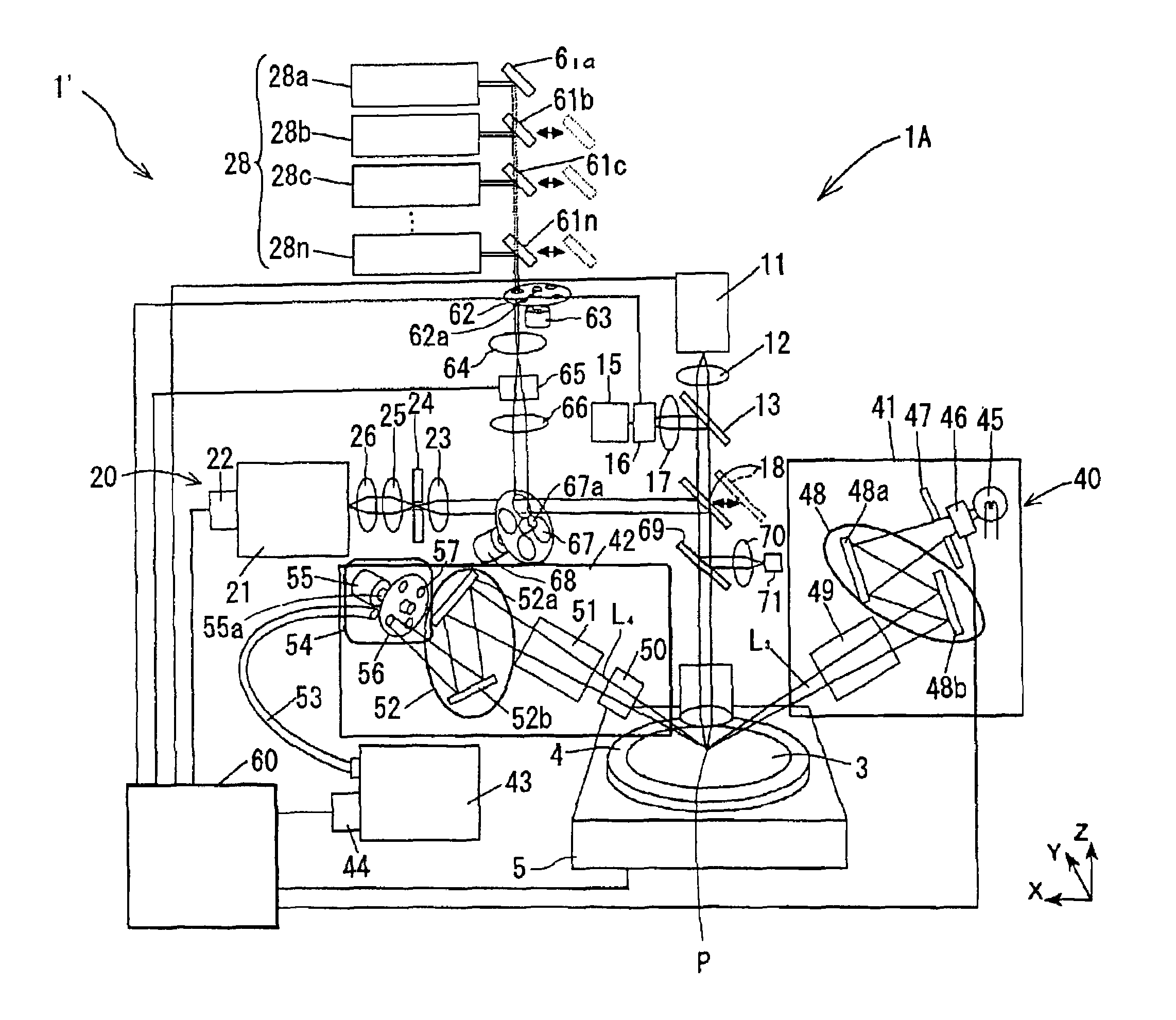

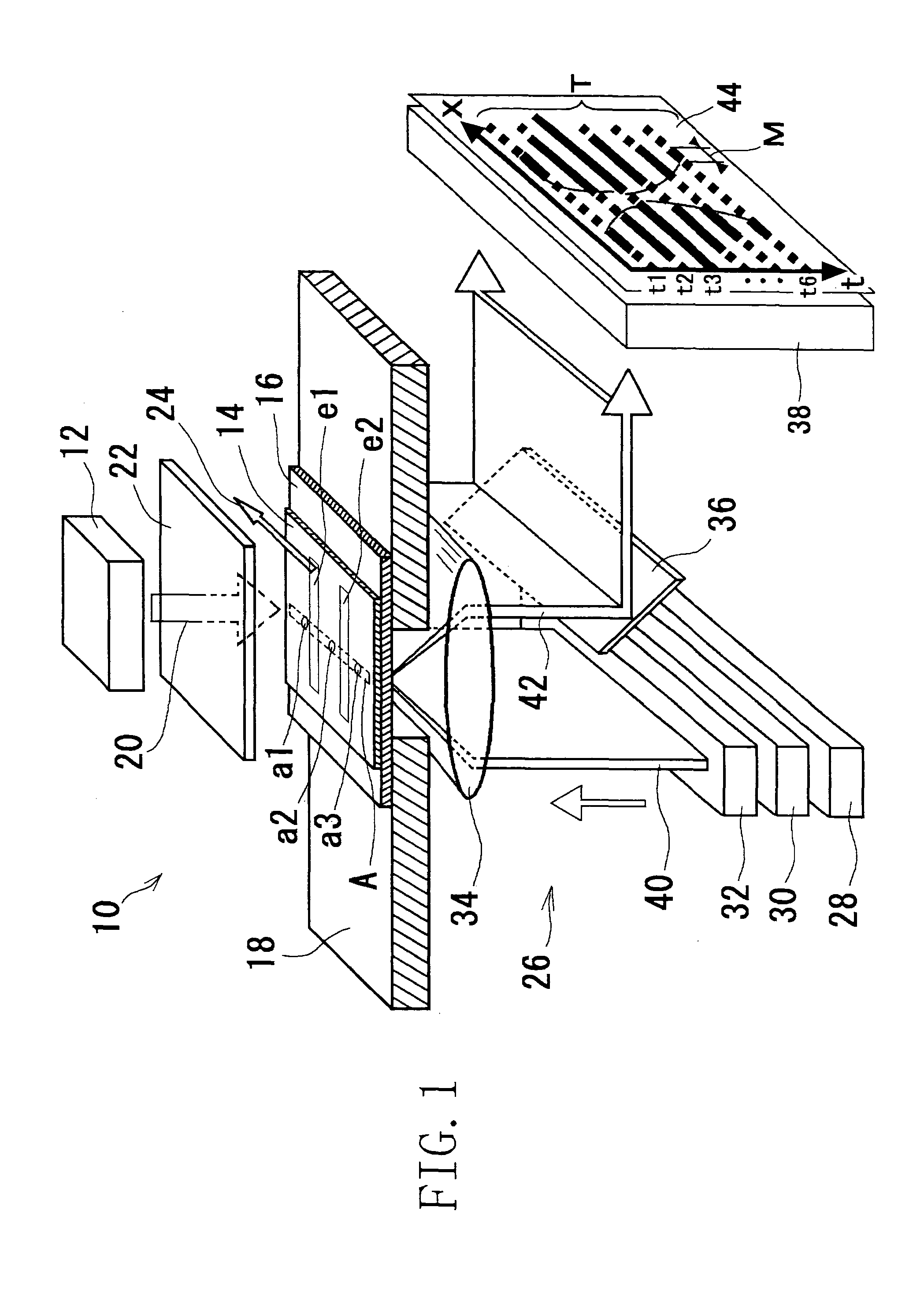

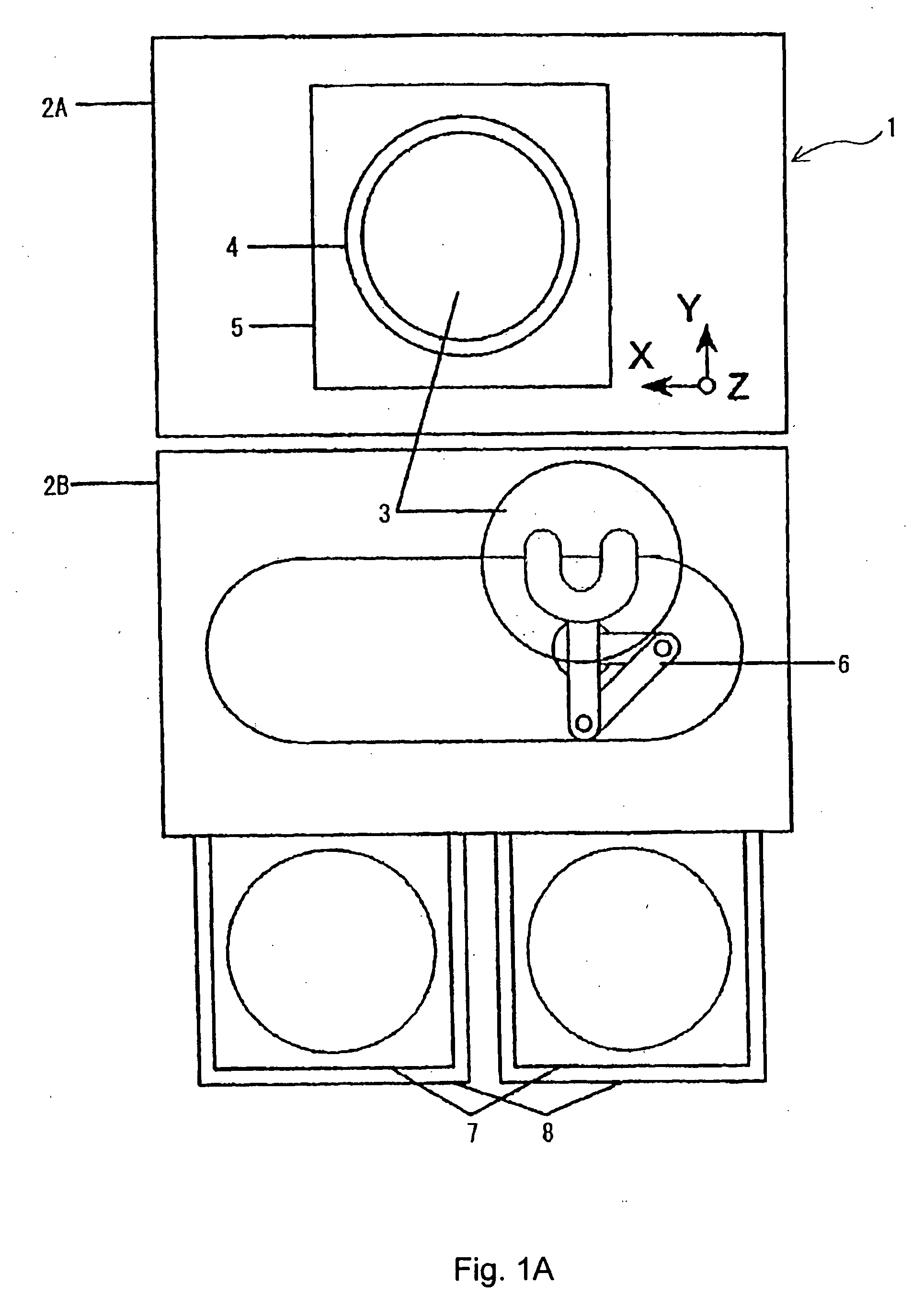

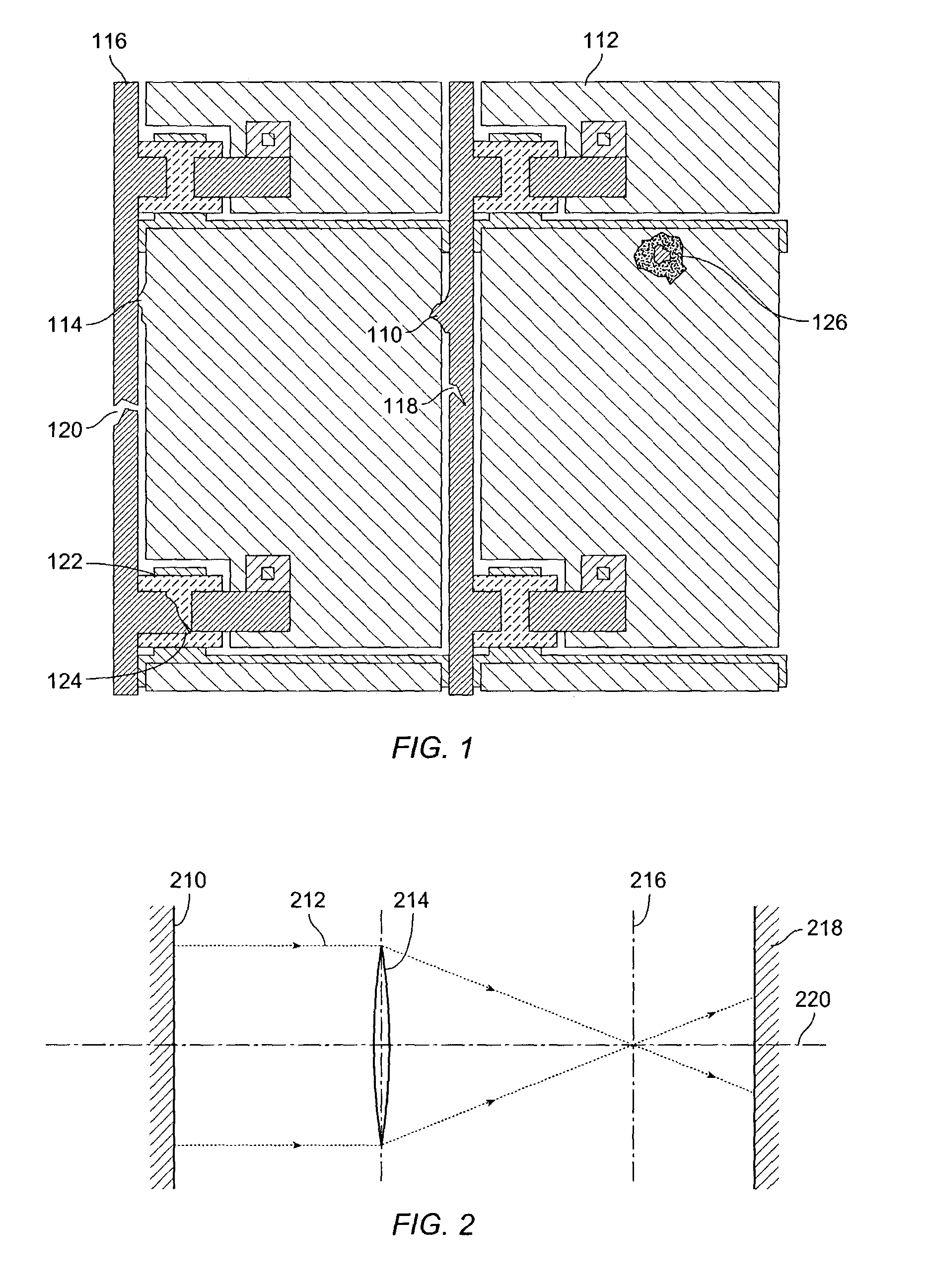

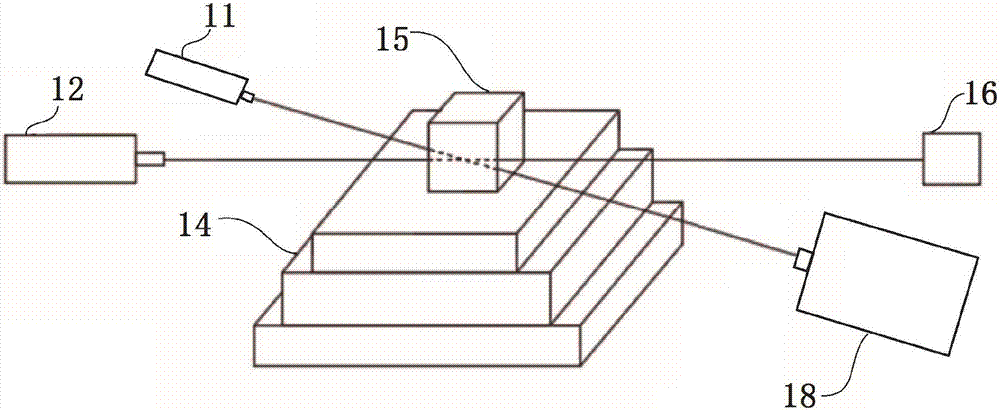

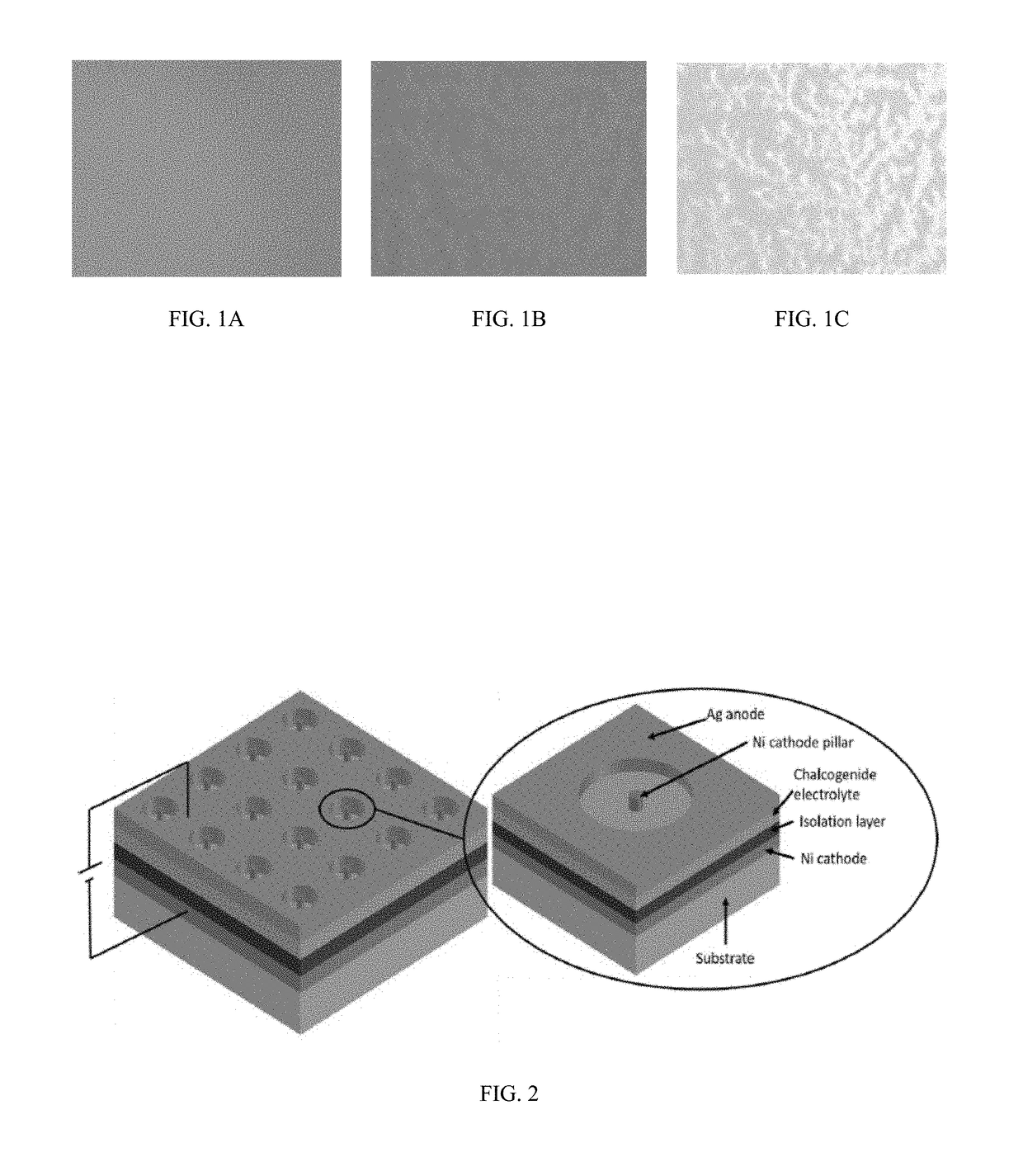

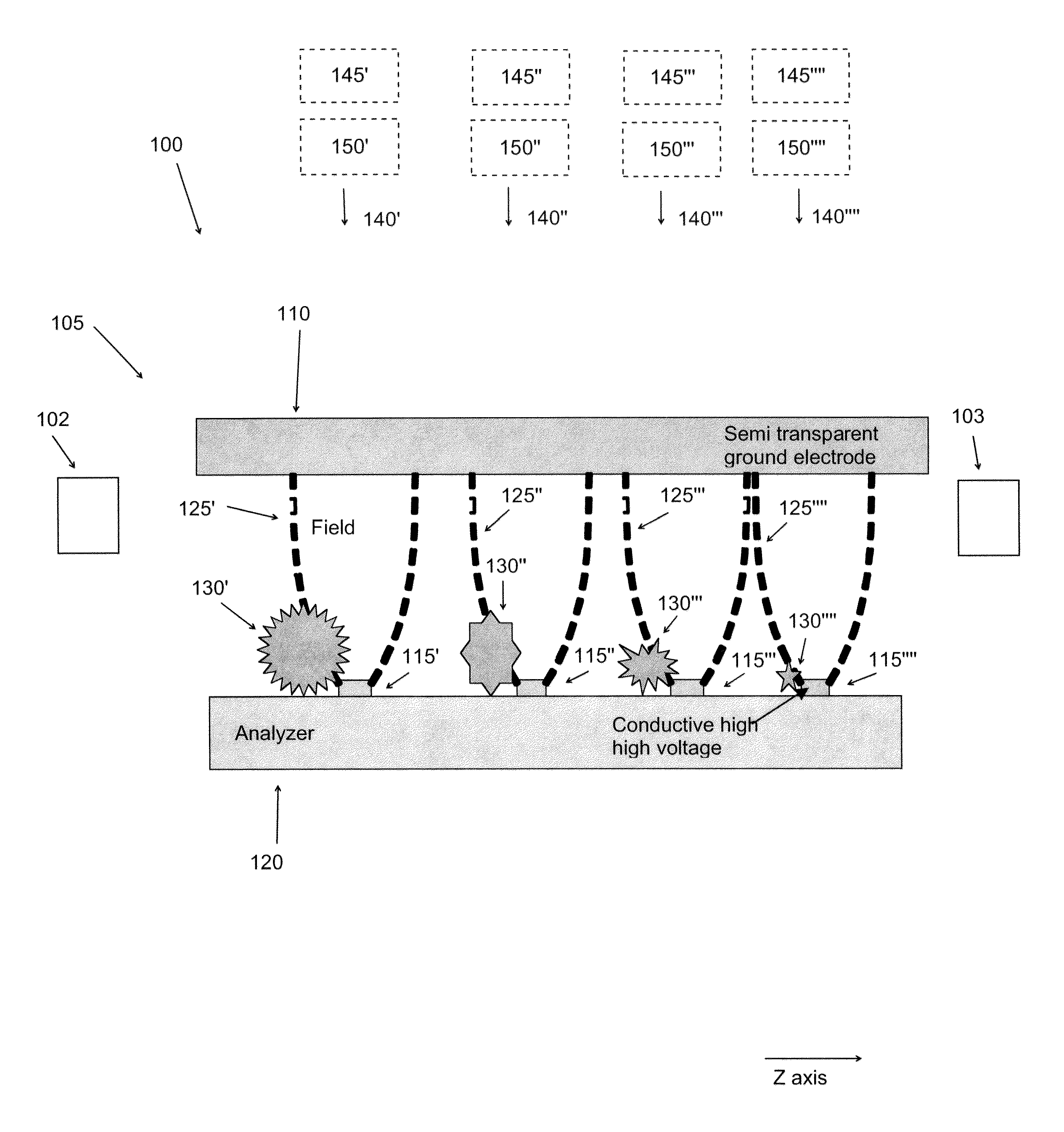

Monitoring method and apparatus for excimer laser annealing process

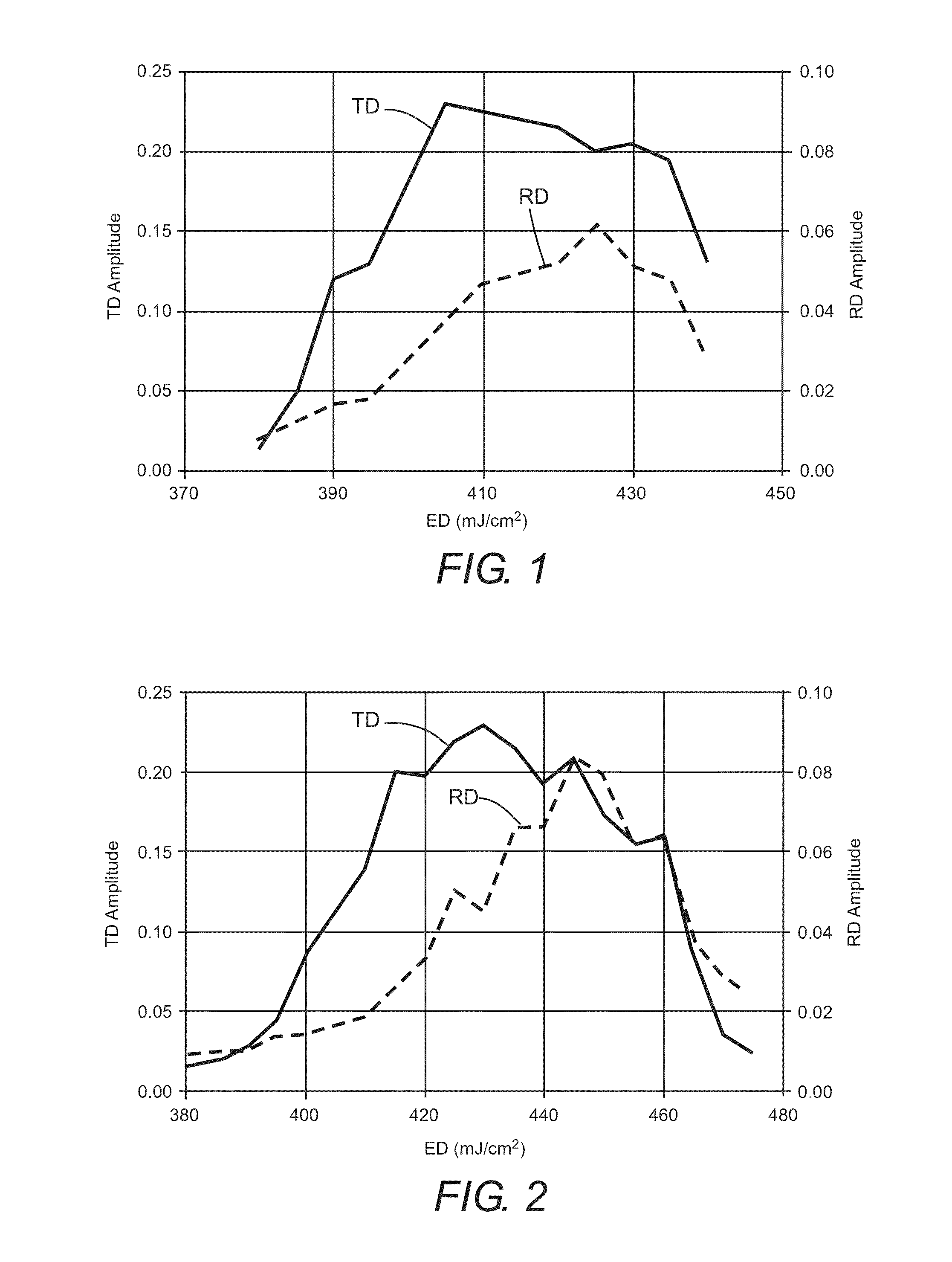

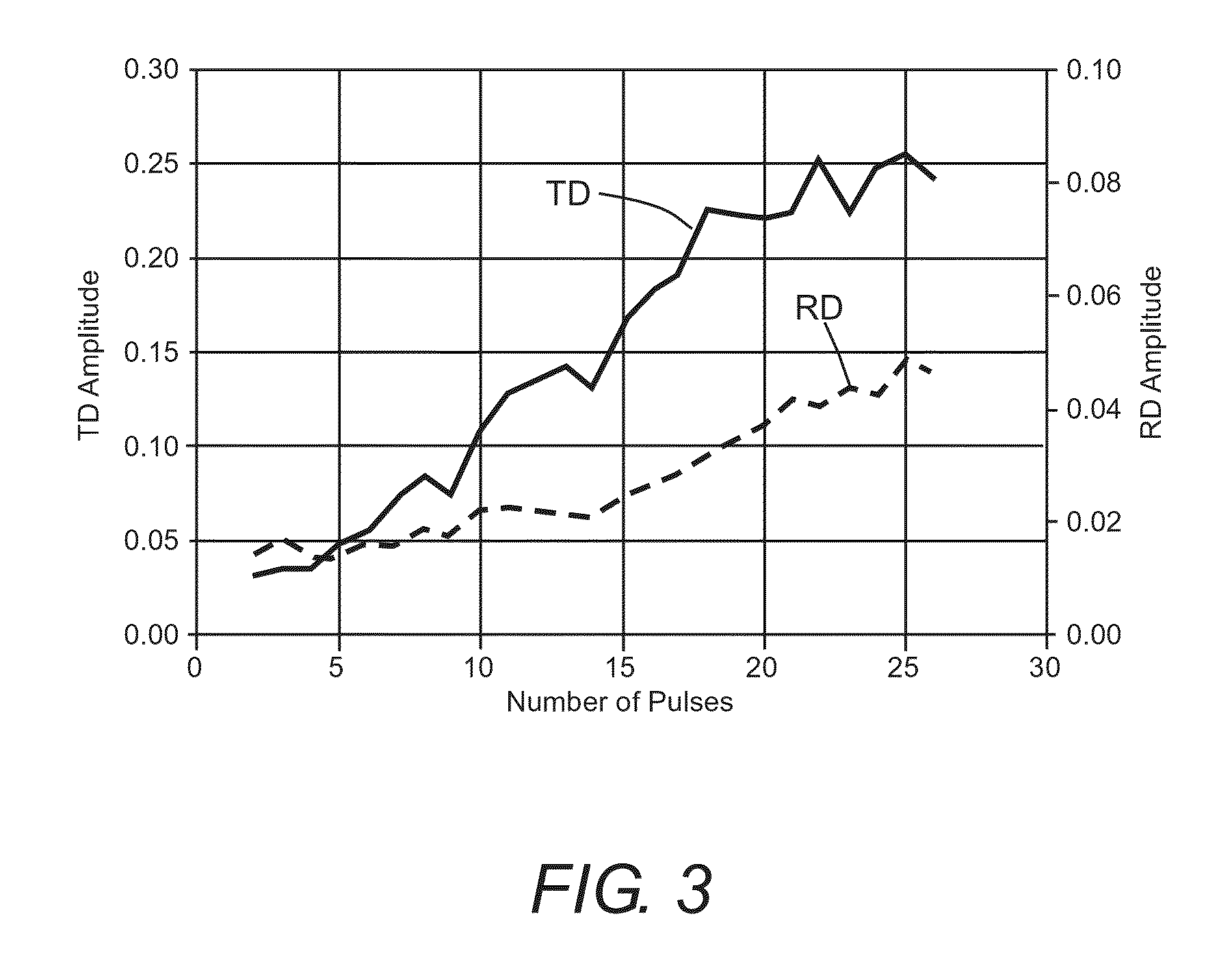

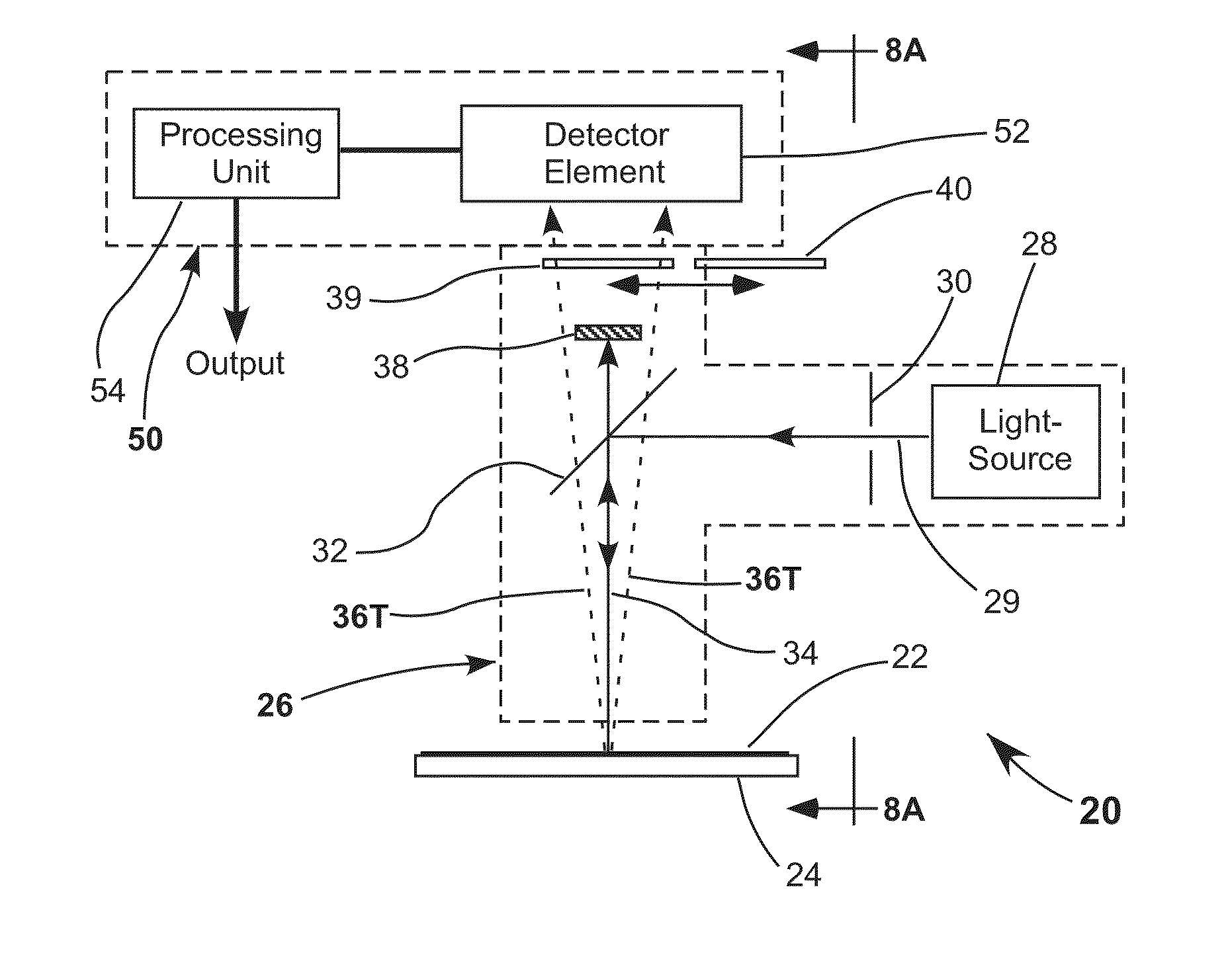

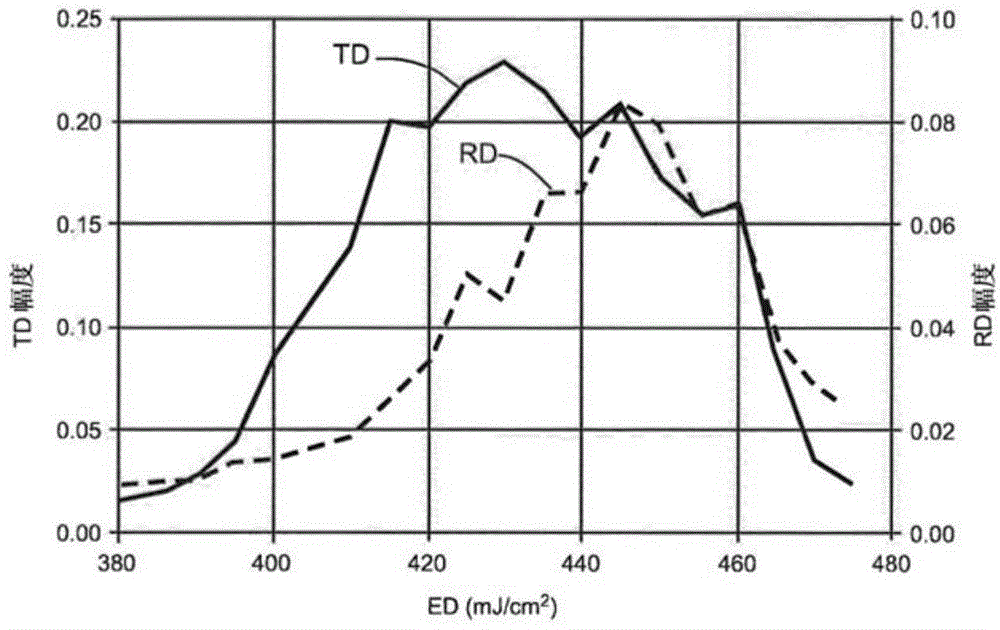

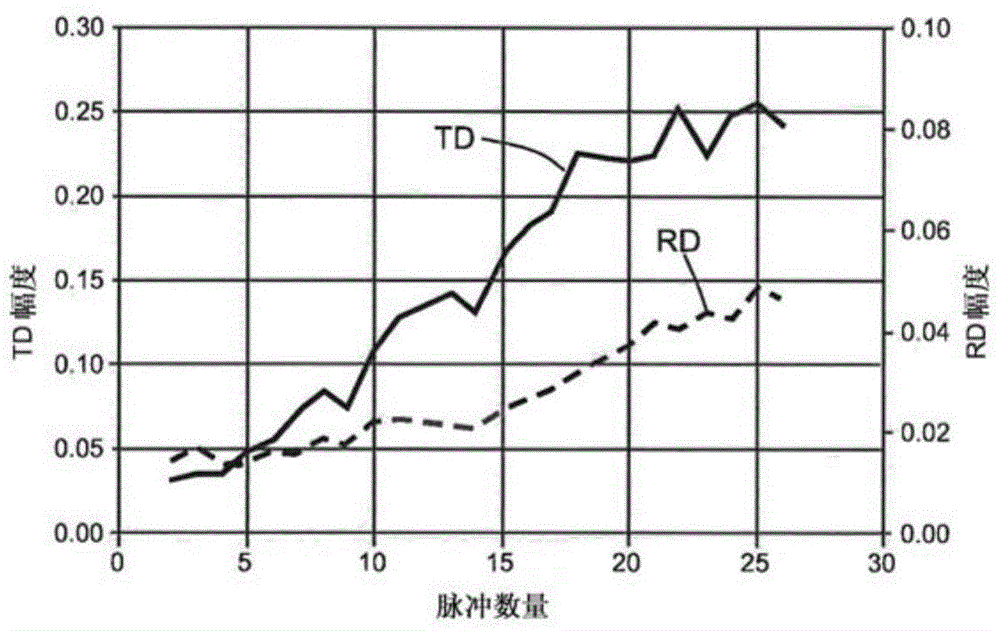

InactiveUS20130341310A1Investigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

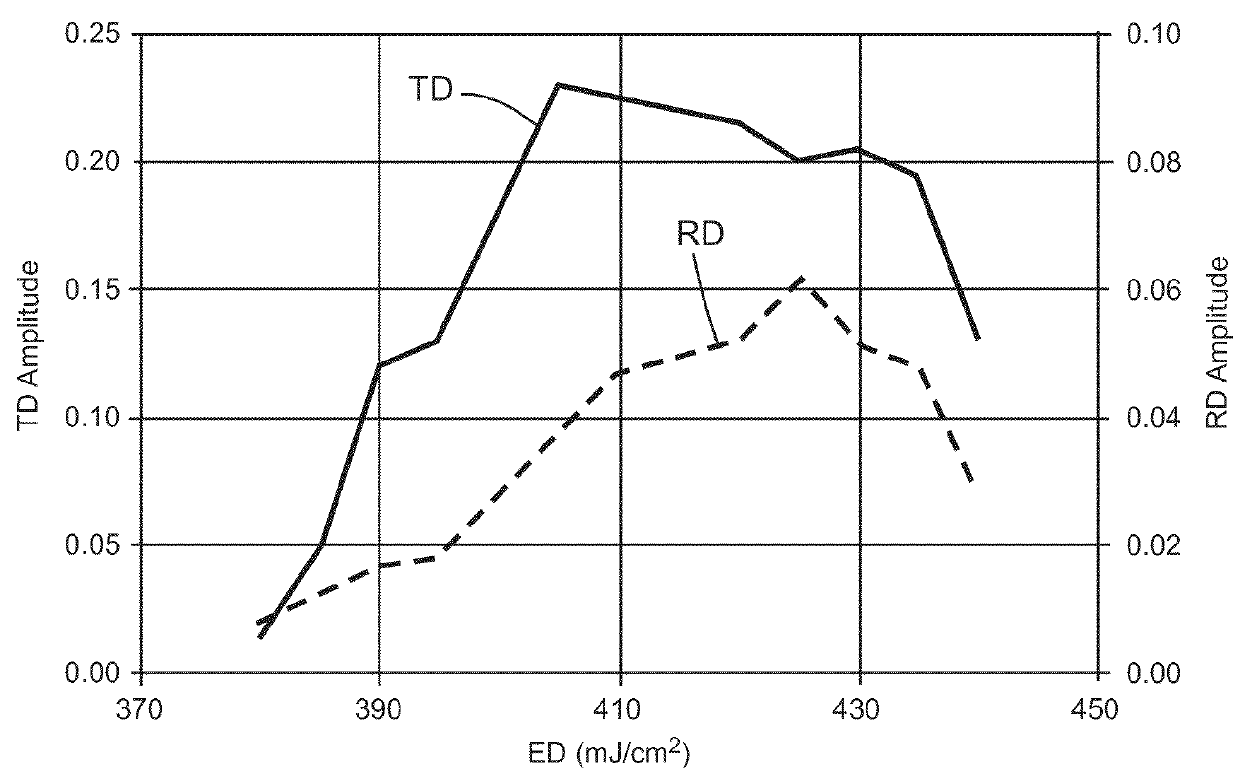

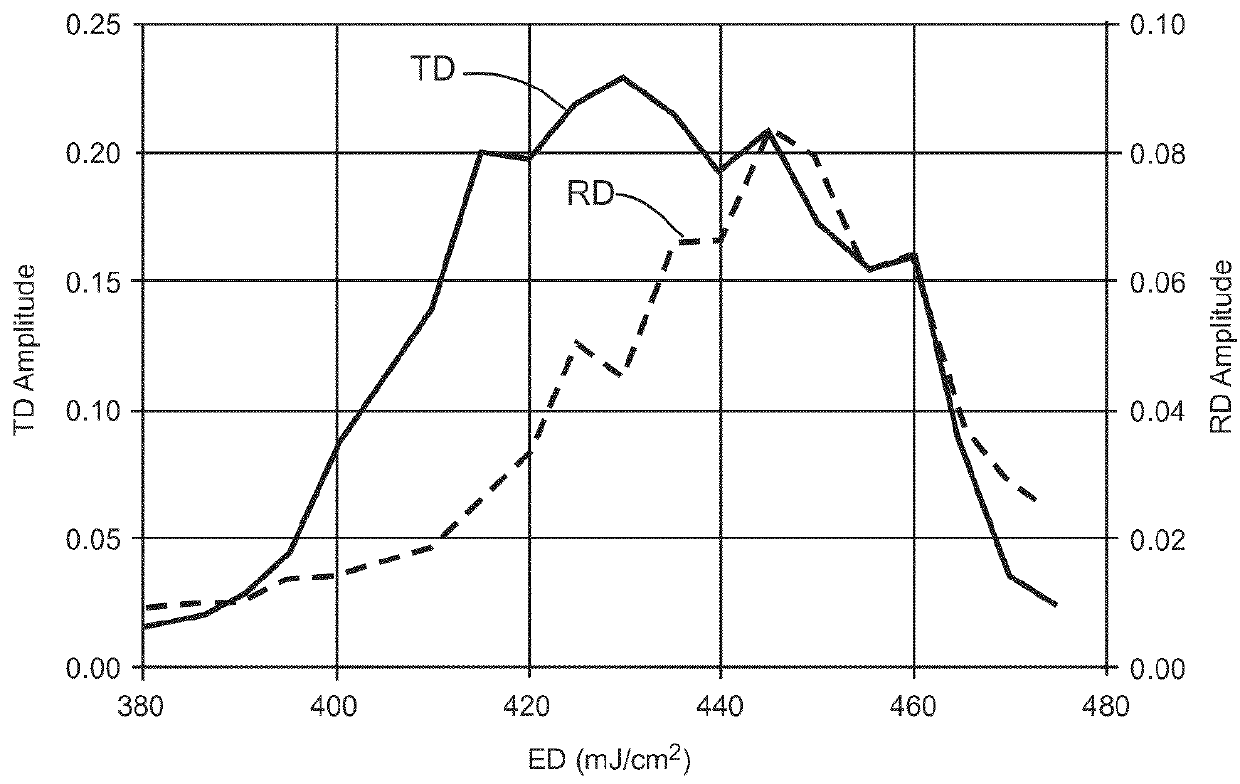

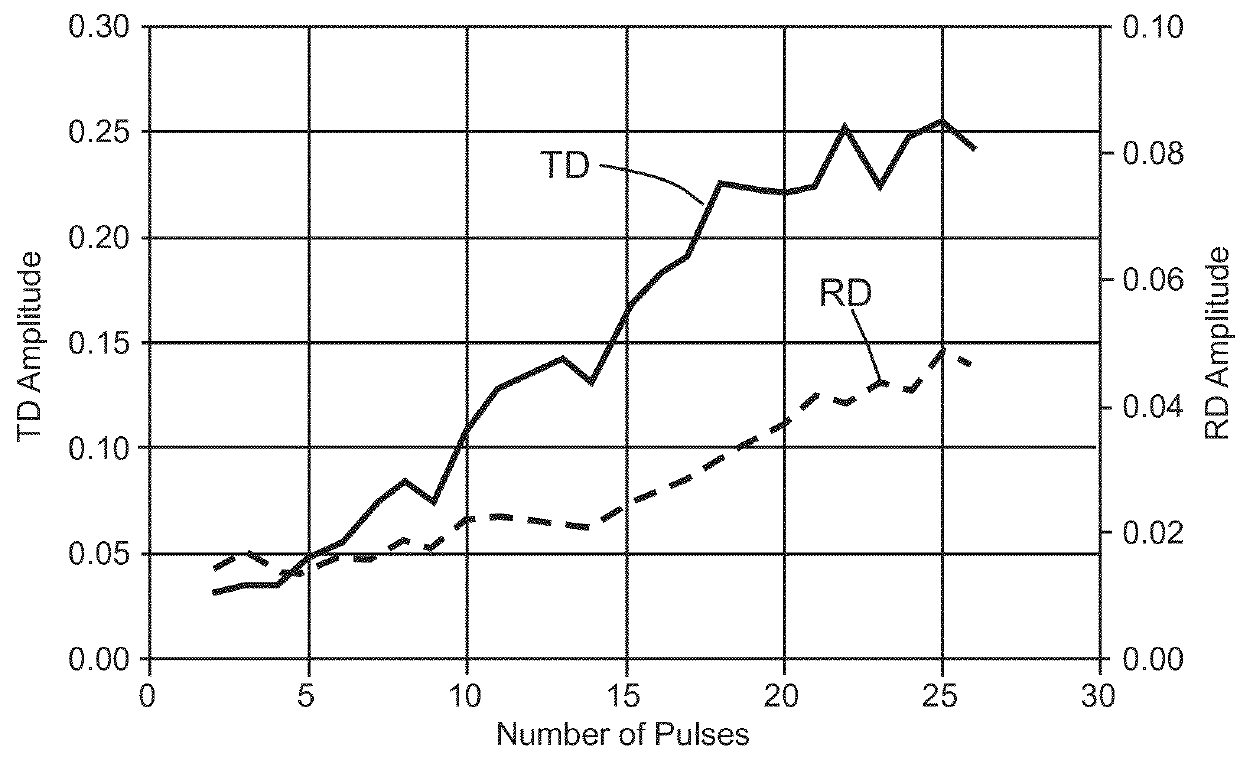

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A detector is arranged to detect light diffracted from the illuminated area and to determine from the detected diffracted light the energy density in the pulses to which the layer has been exposed.

Owner:COHERENT LASERSYST

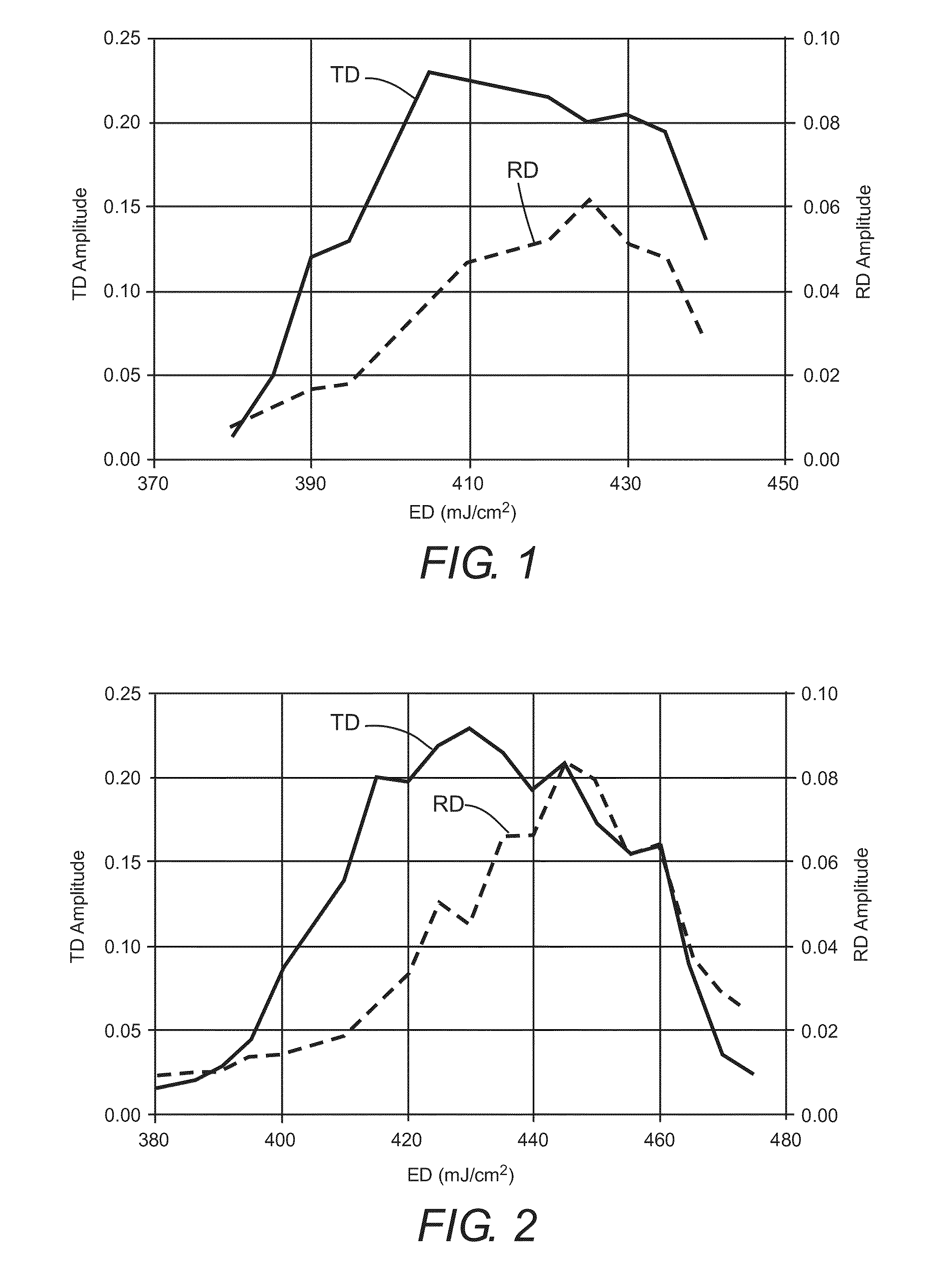

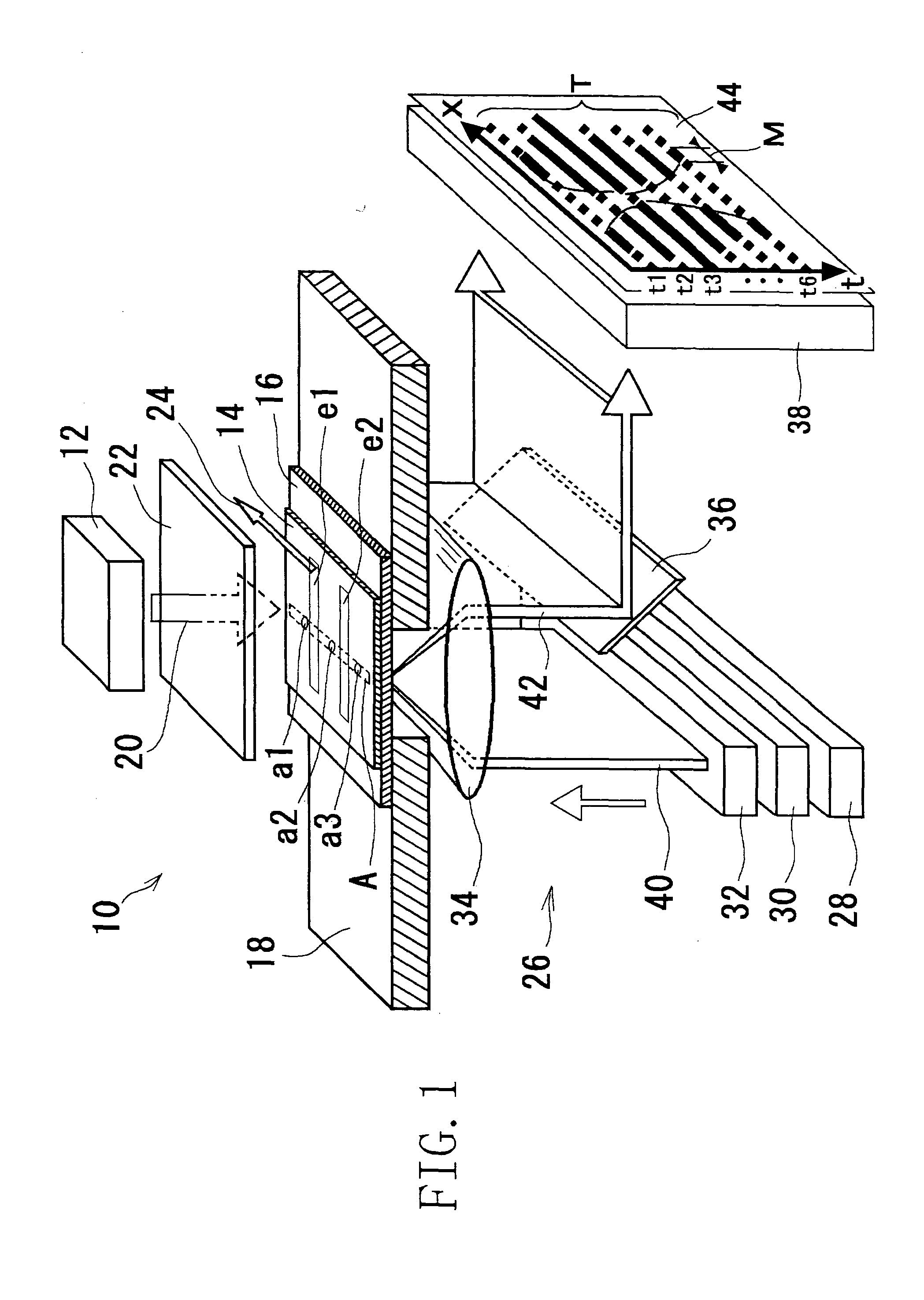

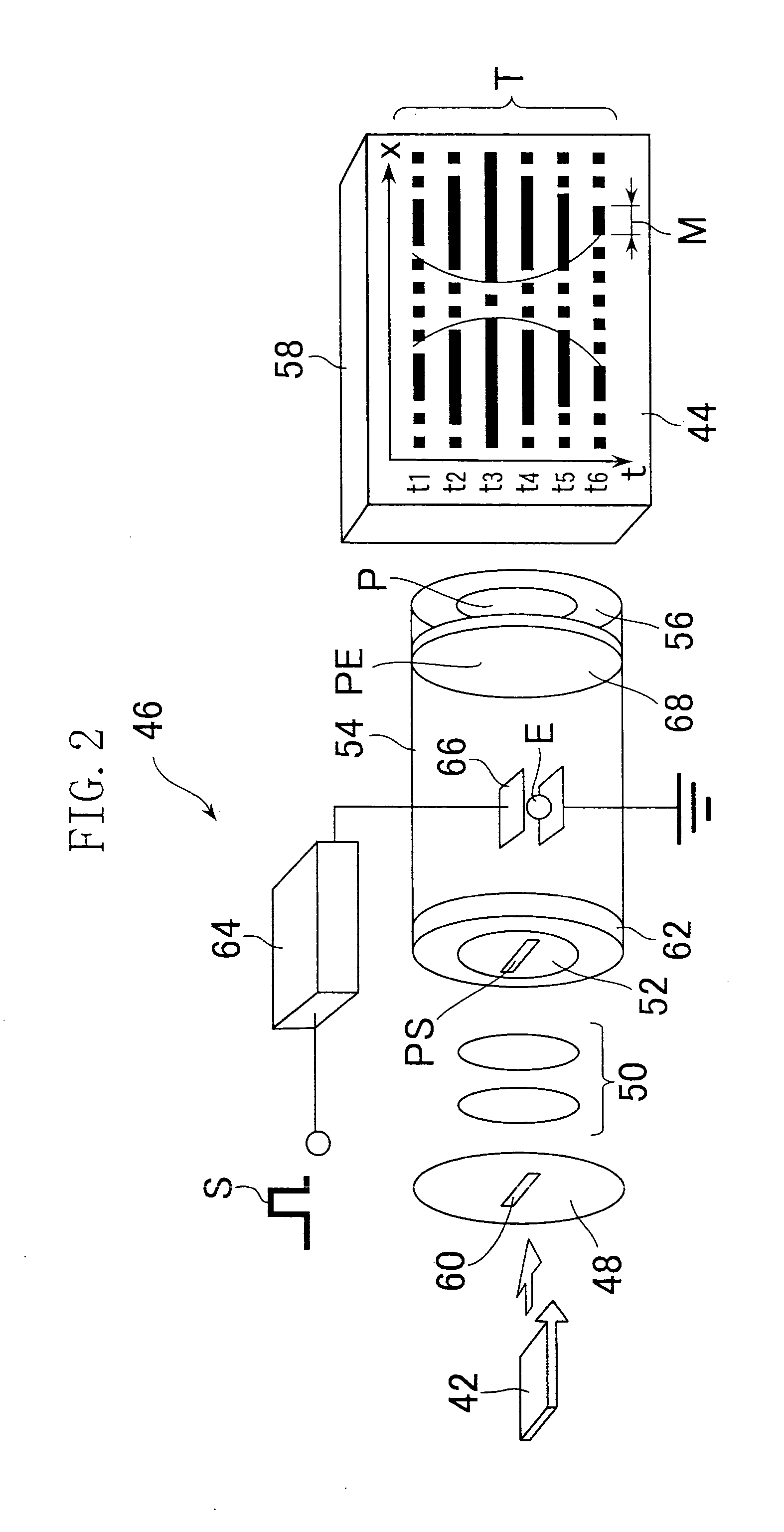

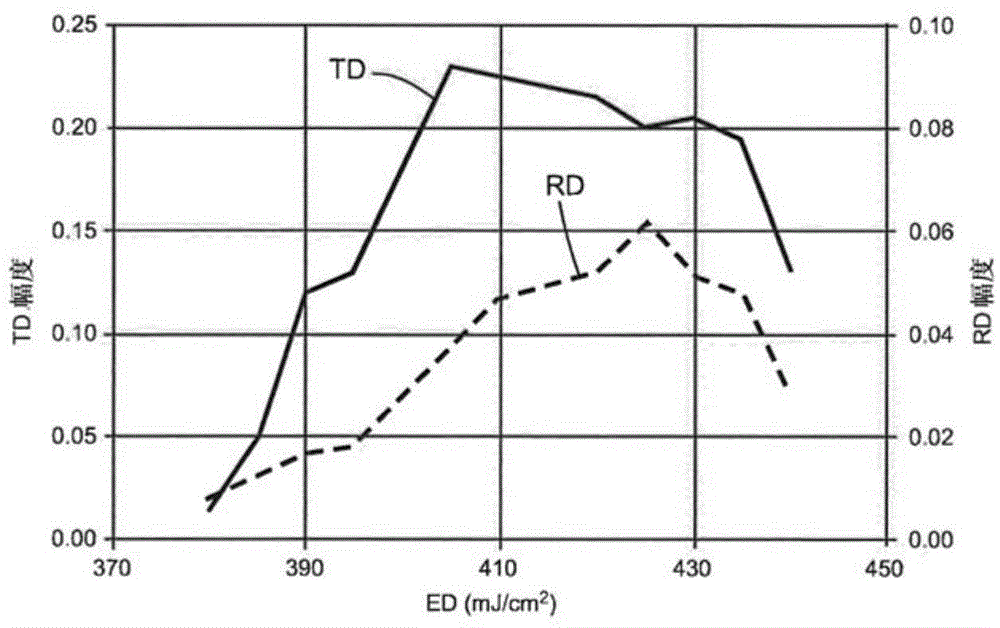

Monitoring method and apparatus for control of excimer laser annealing

ActiveUS20150247808A1Investigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density ED in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A microscope image of the illuminated area is made from light diffracted from the illuminated are by the periodic features. The microscope image includes corresponding periodic features. The ED is determined from a measure of the contrast of the periodic features in the microscope image.

Owner:COHERENT LASERSYST

Method of and apparatus for measuring stress of semiconductor material

InactiveUS7295307B2Accurate measurementHigh precisionRadiation pyrometryInvestigating crystalsSemiconductor materialsLength wave

The present invention provides a method of and a device for measuring the stress in a semiconductor material. An excitation light is irradiated on a semiconductor material formed with a silicon germanium layer and a strained silicon layer in a multilayer structure on a single crystal silicon substrate from the direction of the strained silicon layer. An internal stress of the semiconductor material is measured from peak position information of the Raman spectrum of scattered light from the irradiating point, wherein light having a wavelength capable of reaching the single crystal silicon substrate is used as the excitation light, a temperature of the semiconductor material is estimated from a shift amount of the peak position of the Raman spectrum of the scattered light from the substrate in accordance with the irradiation of the excitation light and the shift amounts of the peak positions of the Raman spectra in the strained silicon layer and in the silicon germanium layer are corrected by means of the estimated temperature, The internal stresses of the strained silicon layer and the silicon germanium layer are calculated from the corrected peak position information of the Raman spectra in the respective layers.

Owner:HORIBA LTD

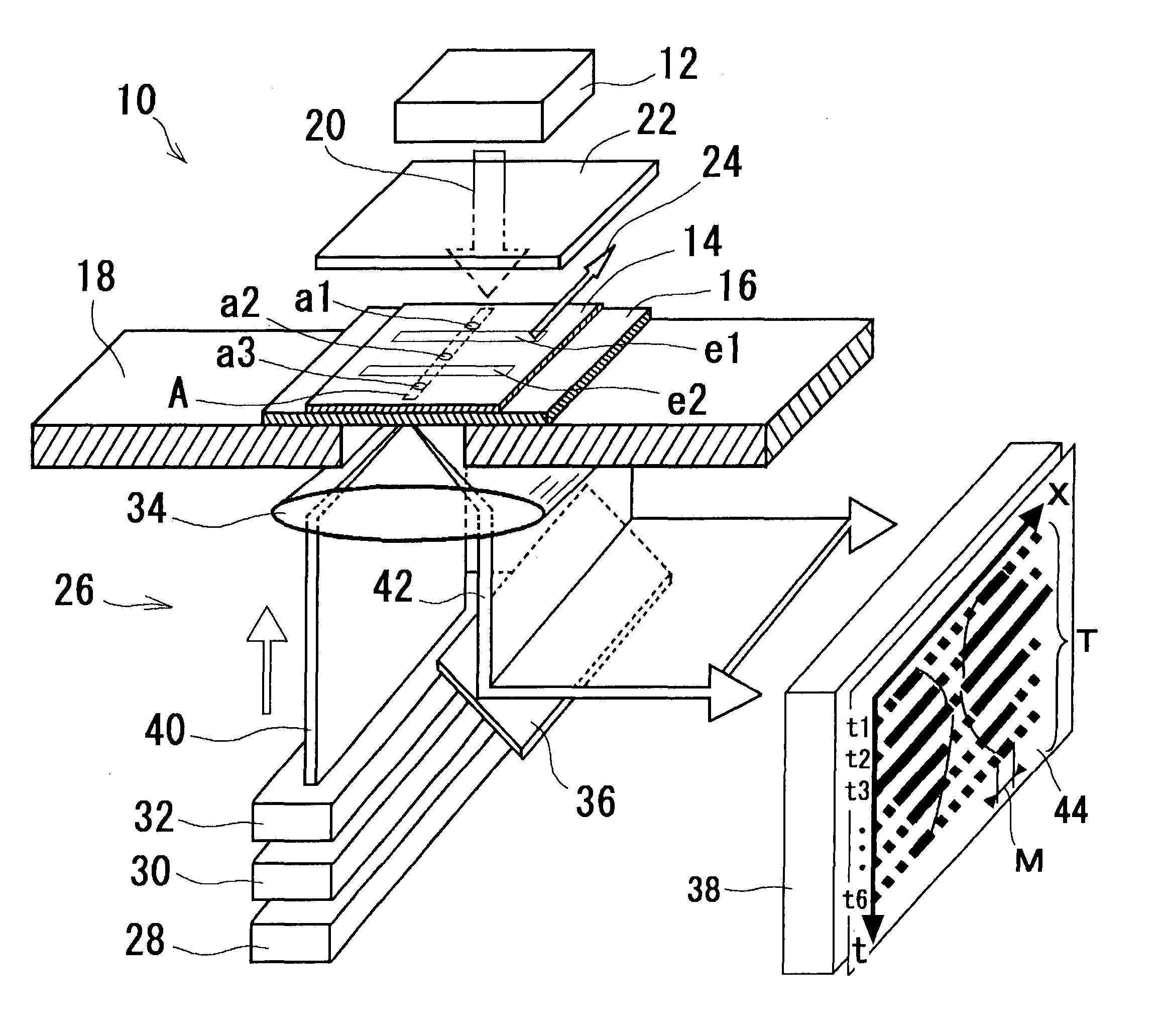

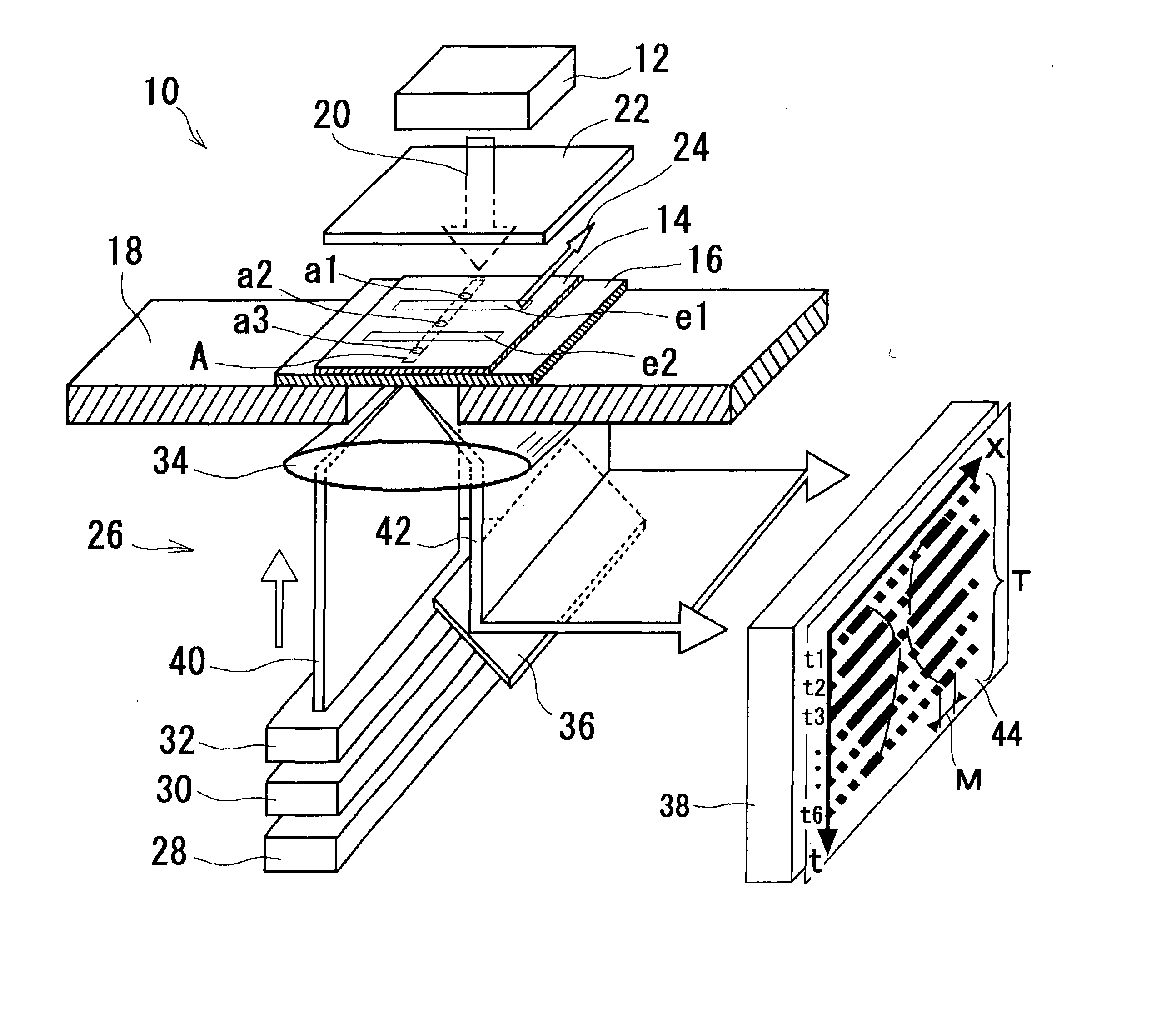

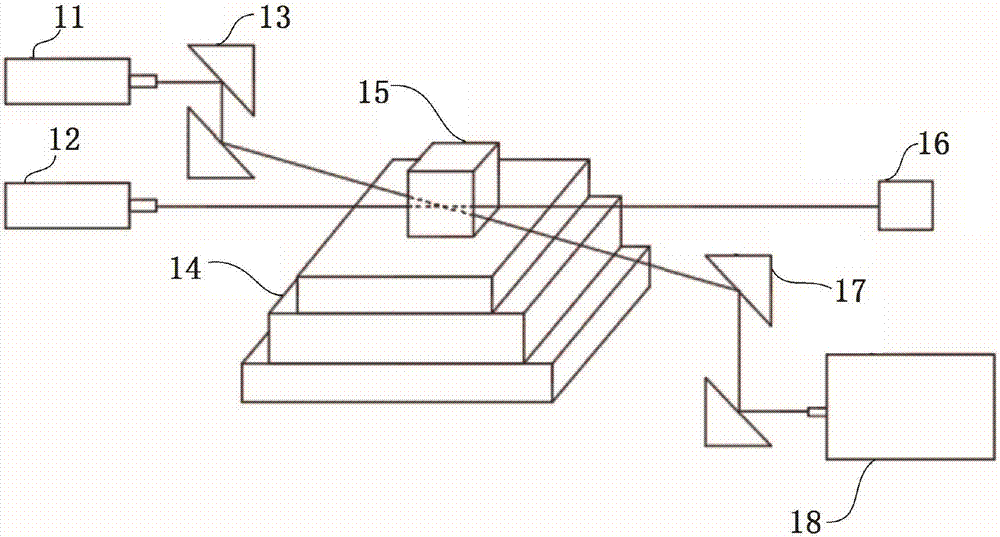

Method of in-situ monitoring of crystallization state

InactiveUS7102750B2Accurate observationEasy to controlSemiconductor/solid-state device testing/measurementInvestigating crystalsTemporal changeOptoelectronics

A method of in-situ monitoring of a crystallization state is used for laser anneal processing for applying an energy line irradiation for at least one of crystallization of a thin film and promotion of the crystallization. The method of in-situ monitoring of a crystallization state is characterized by irradiating simultaneously at least a plurality of monitoring places in a region having a predetermined area of at least one of the surface and the underside of the thin film by a monitor light for monitoring a crystallization state of the thin film at least during or after of before, during and after the energy line irradiation directly or through a substrate, and measuring a temporal change of the intensity of at least one of a reflected light and a transmitted light, from the surface or the underside of the thin film, of the monitor light as a light intensity distribution related to the positions of the monitoring places.

Owner:ADVANCED LCD TECH DEVMENT CENT

Method of and apparatus for measuring stress of semiconductor material

InactiveUS20060049480A1Accurate measurementHigh precisionRadiation pyrometryInvestigating crystalsSemiconductor materialsPeak value

The present invention provides a method of and a device for measuring the stress in a semiconductor material. An excitation light is irradiated on a semiconductor material formed with a silicon germanium layer and a strained silicon layer in a multilayer structure on a single crystal silicon substrate from the direction of the strained silicon layer. An internal stress of the semiconductor material is measured from peak position information of the Raman spectrum of scattered light from the irradiating point, wherein light having a wavelength capable of reaching the single crystal silicon substrate is used as the excitation light, a temperature of the semiconductor material is estimated from a shift amount of the peak position of the Raman spectrum of the scattered light from the substrate in accordance with the irradiation of the excitation light and the shift amounts of the peak positions of the Raman spectra in the strained silicon layer and in the silicon germanium layer are corrected by means of the estimated temperature, The internal stresses of the strained silicon layer and the silicon germanium layer are calculated from the corrected peak position information of the Raman spectra in the respective layers.

Owner:HORIBA LTD

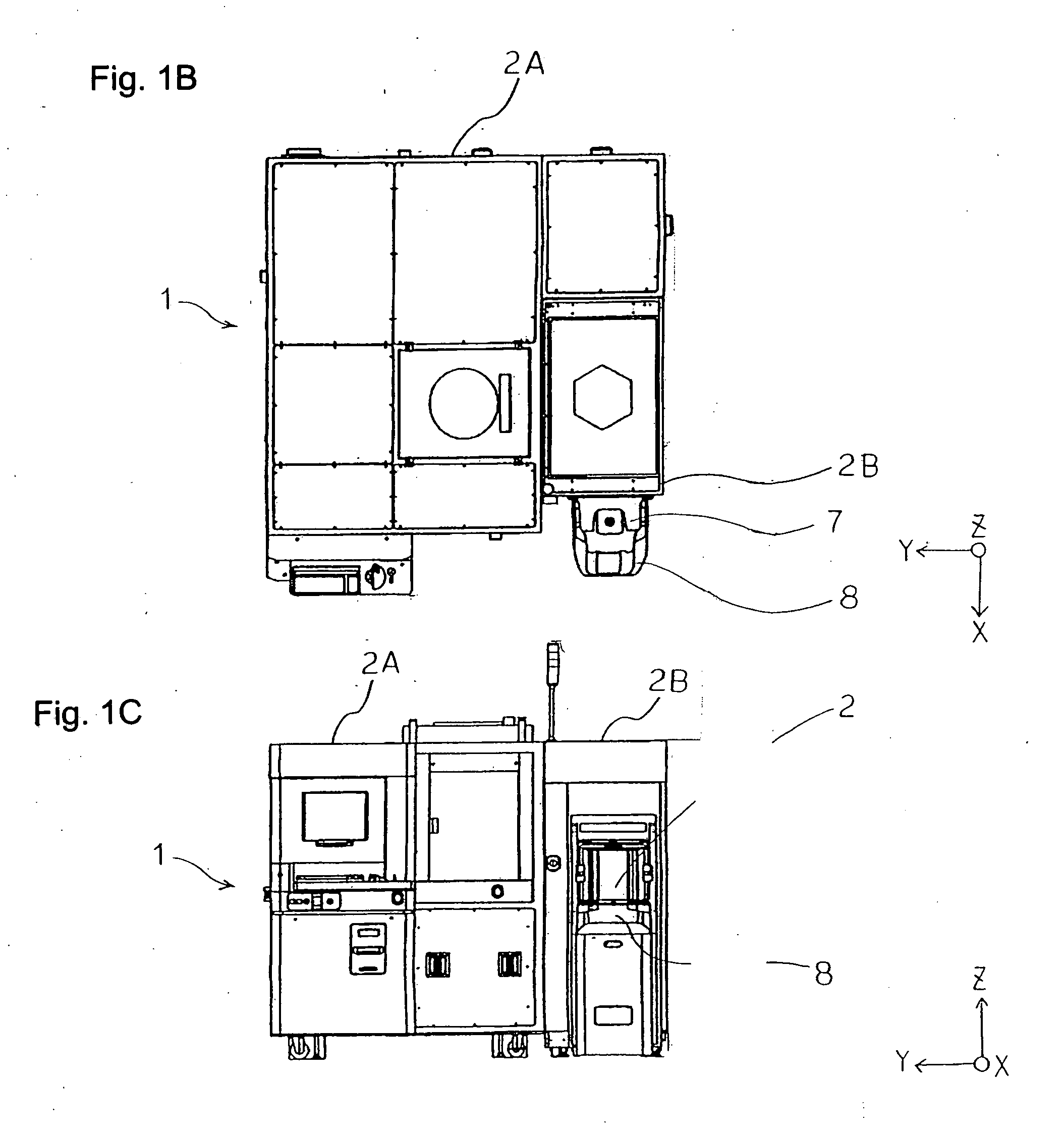

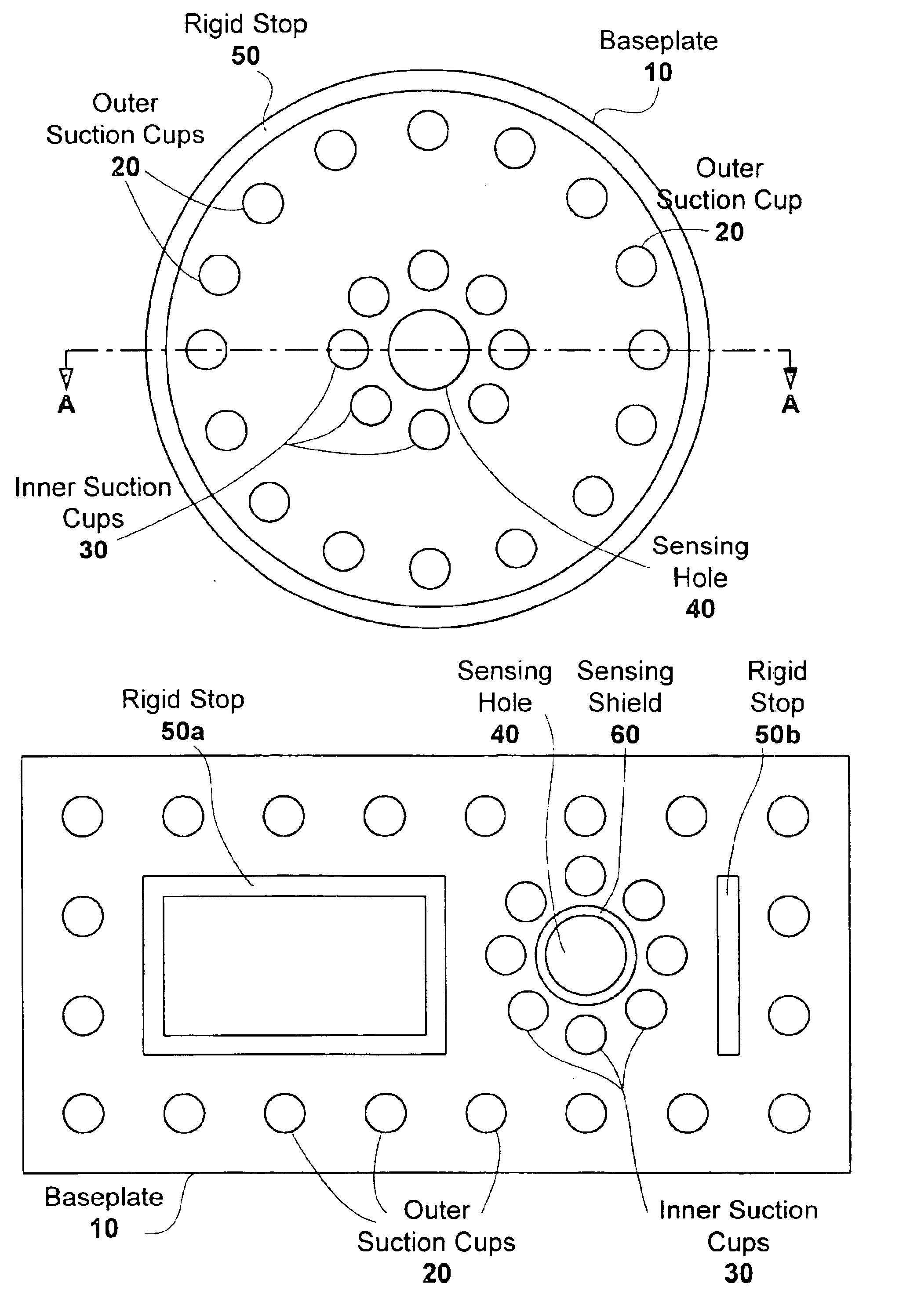

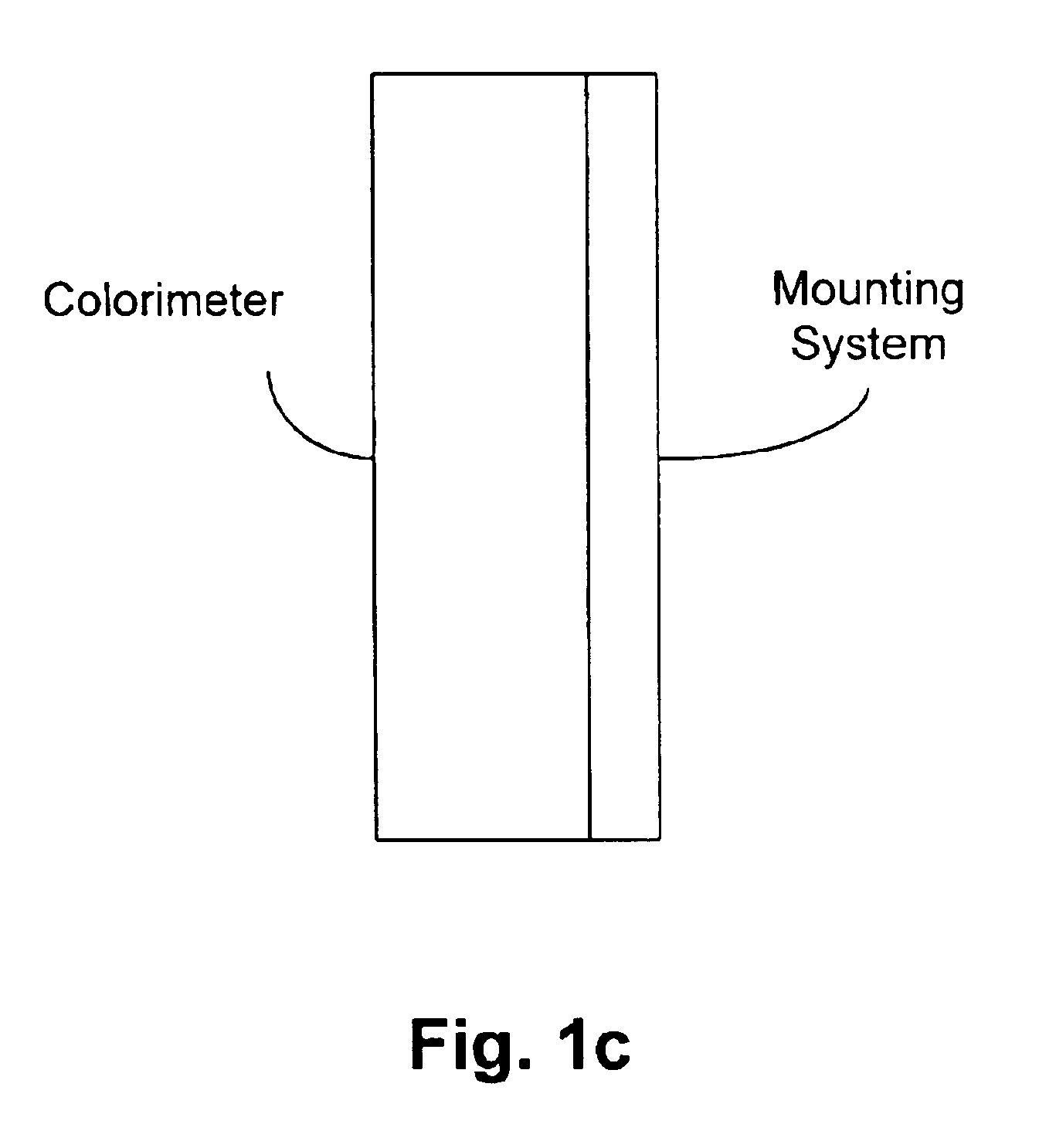

Sensor with suction cup array mount

ActiveUS6880790B2Enabling positional stabilityRadiation pyrometryColor measuring devicesMeasurement deviceManufacturing technology

A sensor mounting system having a suction cup array is disclosed. In one application, the system eases the initial positioning of the calorimeter on the screen to be measured, minimizes the force applied to the screen upon which it is mounted, and minimizes the distortion in the mounted area of the screen surface. In addition, the mounting system can be configured so that the distance from the colorimeter sensor to the screen will not significantly change over time. Such positional stability operates to improve SNR. The mounting system is further adapted for ease of removal from the screen upon which it is mounted. Applications not only include a mount for low to high accuracy calorimeters, but also for other measurement devices that can benefit from advantages of the present invention. Injection molding manufacturing techniques can be employed in fabrication of the system.

Owner:X RITE SWITZERLAND +1

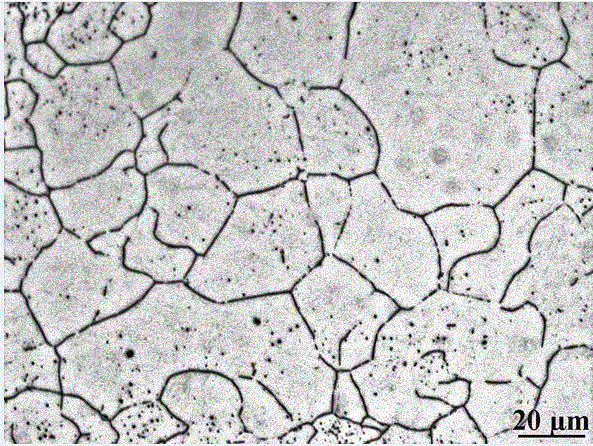

Corrosive for displaying heat-resistant steel original austenite grain-boundary and displaying method thereof

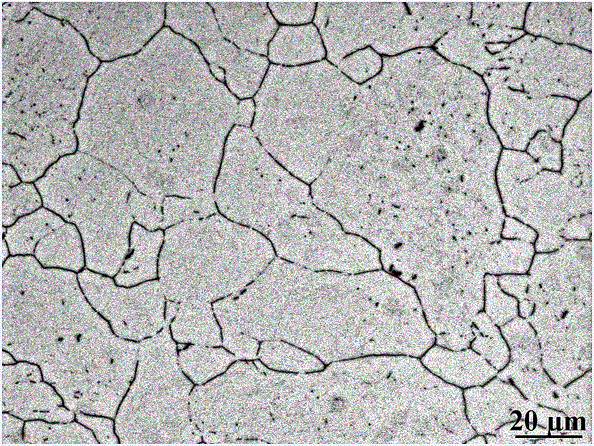

ActiveCN109187152AAccelerated corrosionThe preparation process is simpleInvestigating crystalsPreparing sample for investigationAustenite grainDistilled water

The invention relates to a corrosive for displaying heat-resistant steel original austenite grain-boundary and a displaying method thereof, belongs to the technical field of gold-phase sample preparation, and solves the problems of unclear display and complicated displaying method for heat-resistant steel original austenite grain-boundary. The corrosive is prepared from potassium permanganate, concentrated sulfuric acid and distilled water. The displaying method comprises the following steps: S1, preparing, grinding and polishing a sample; S2, preparing corrosive and performing chemical corrosion; and S3, observing the original austenite grain-boundary. The corrosive can quickly and easily display the original austenite grain-boundary of heat-resistant steel and determine the performance by analyzing and determining whether the original austenite grain-boundary has thick grains or not, and provides important accordance to constitution of the production process.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Method of in-situ monitoring of crystallization state

InactiveUS20050078298A1Accurate observationEasy to controlSemiconductor/solid-state device testing/measurementInvestigating crystalsTemporal changeOptoelectronics

A method of in-situ monitoring of a crystallization state is used for laser anneal processing for applying an energy line irradiation for at least one of crystallization of a thin film and promotion of the crystallization. The method of in-situ monitoring of a crystallization state is characterized by irradiating simultaneously at least a plurality of monitoring places in a region having a predetermined area of at least one of the surface and the underside of the thin film by a monitor light for monitoring a crystallization state of the thin film at least during or after of before, during and after the energy line irradiation directly or through a substrate, and measuring a temporal change of the intensity of at least one of a reflected light and a transmitted light, from the surface or the underside of the thin film, of the monitor light as a light intensity distribution related to the positions of the monitoring places.

Owner:ADVANCED LCD TECH DEVMENT CENT

Monitoring method and apparatus for excimer laser annealing process

ActiveCN104641460AInvestigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A detector is arranged to detect light diffracted from the illuminated area and to determine from the detected diffracted light the energy density in the pulses to which the layer has been exposed.

Owner:COHERENT LASERSYST

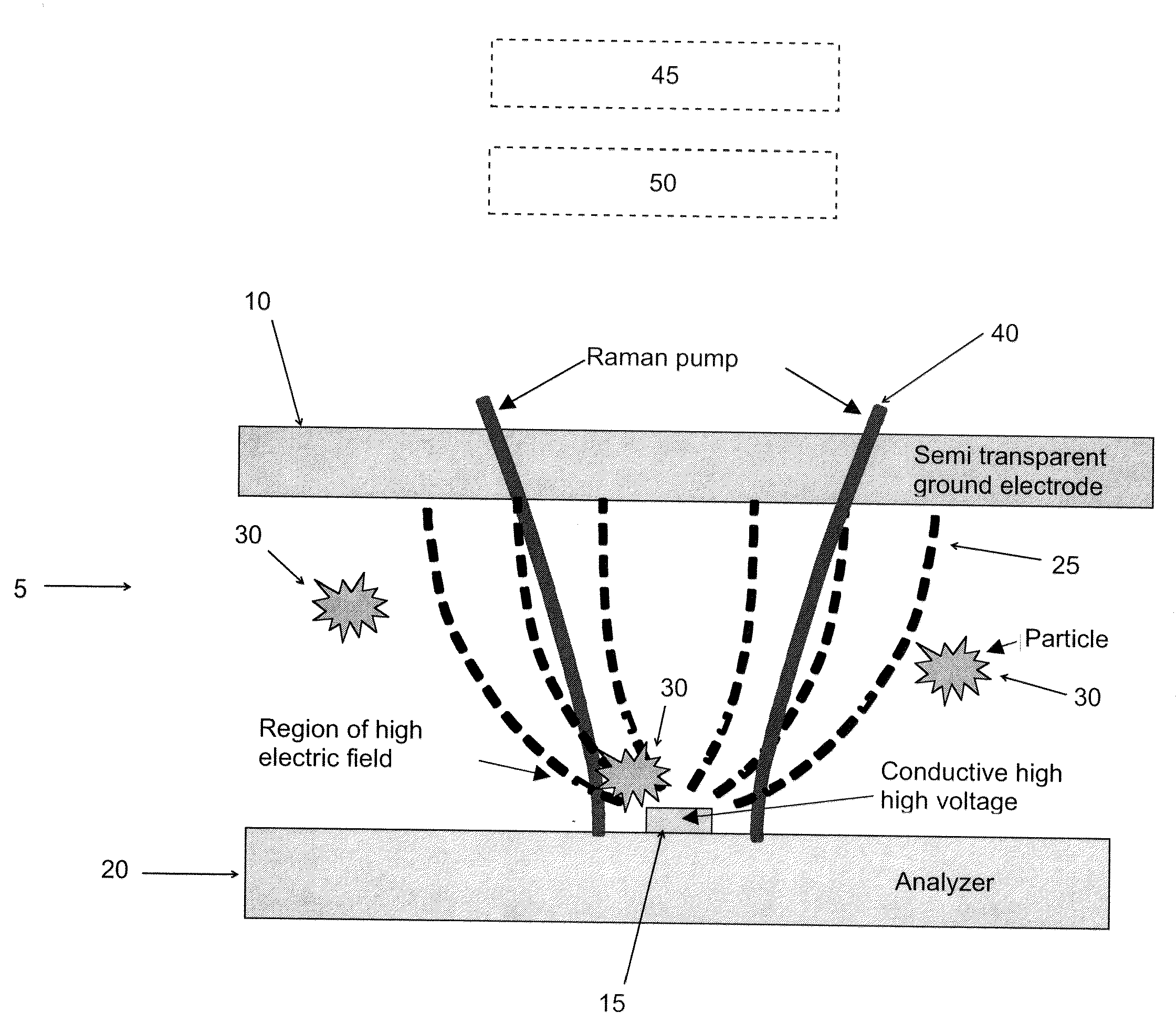

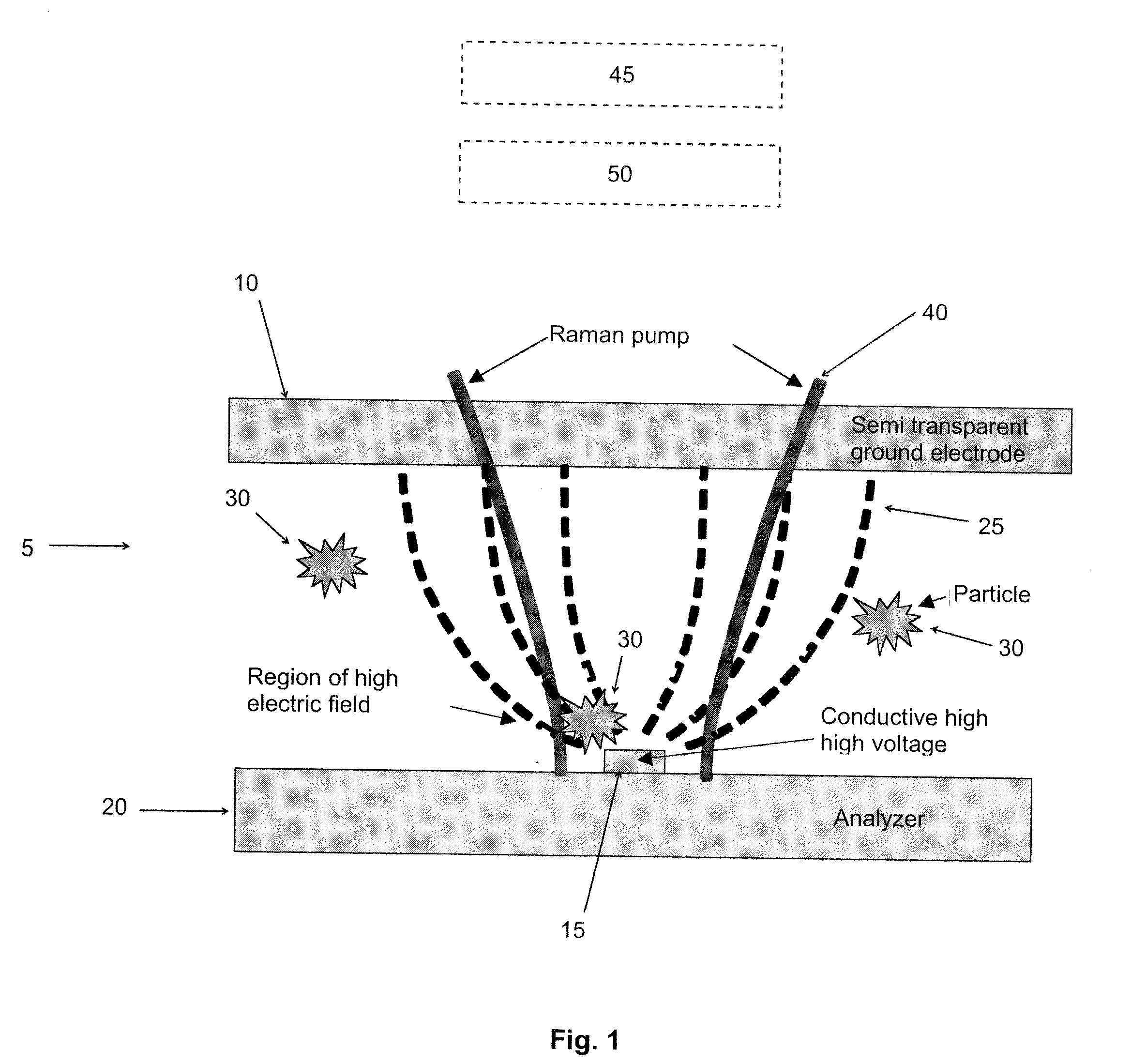

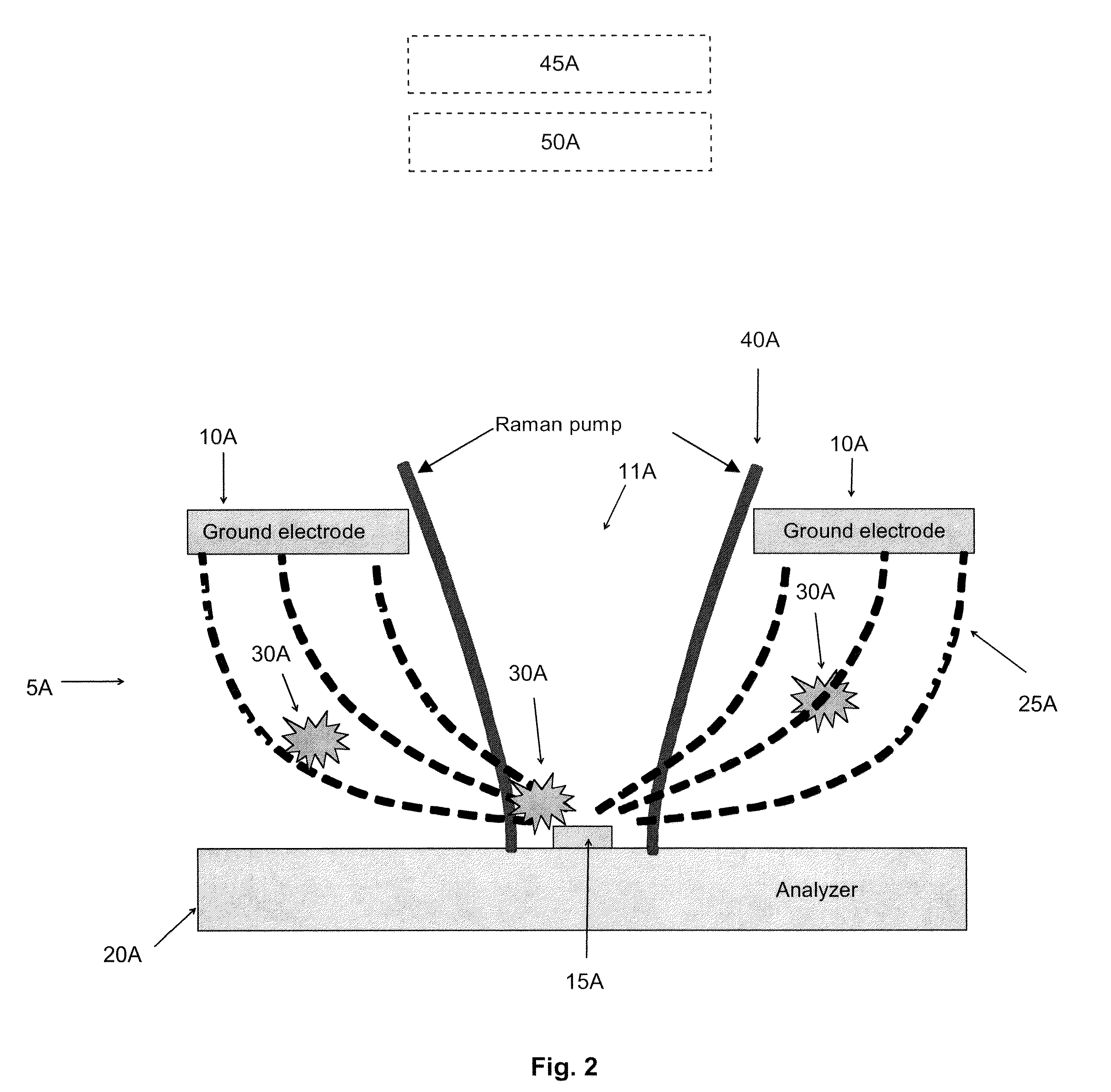

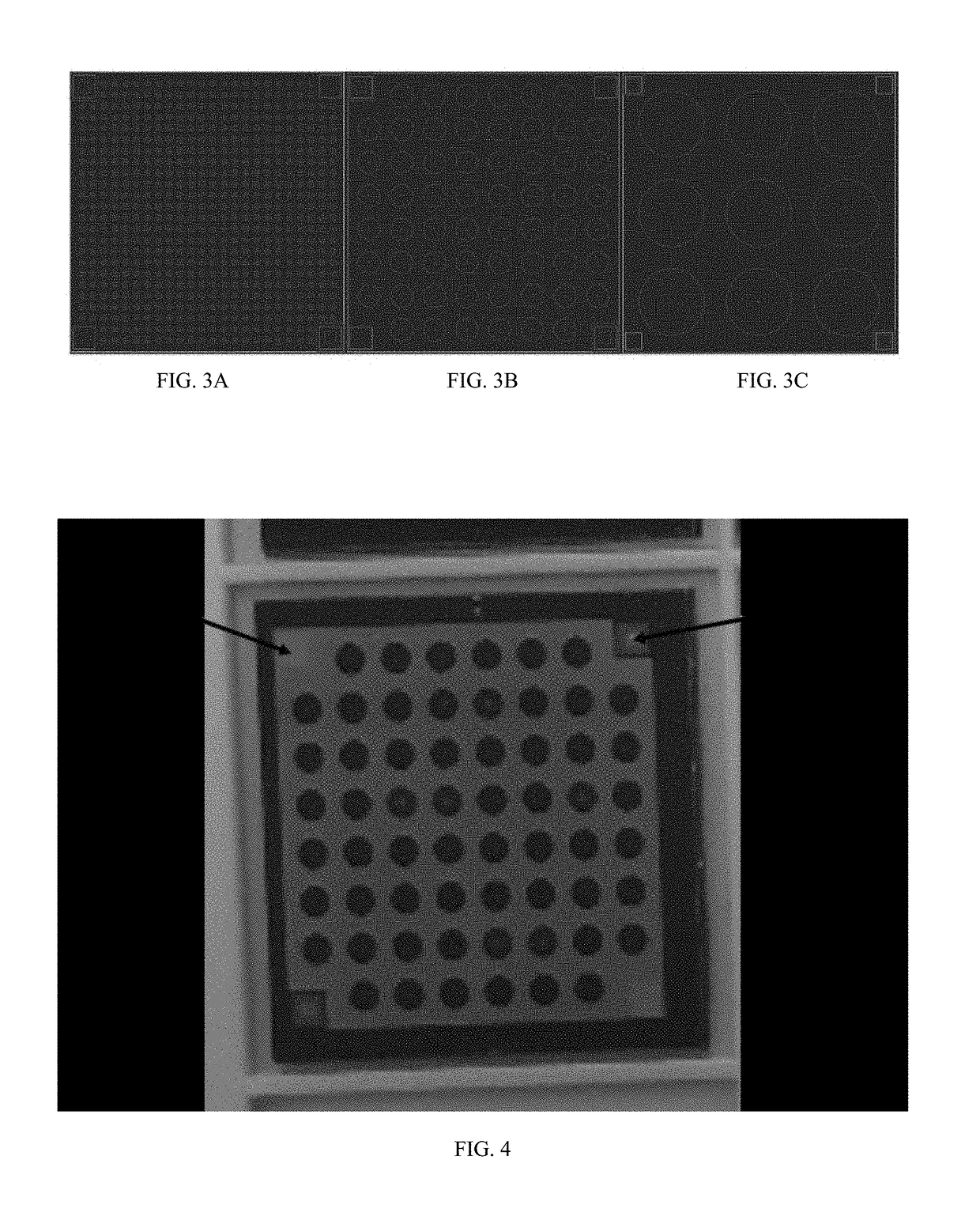

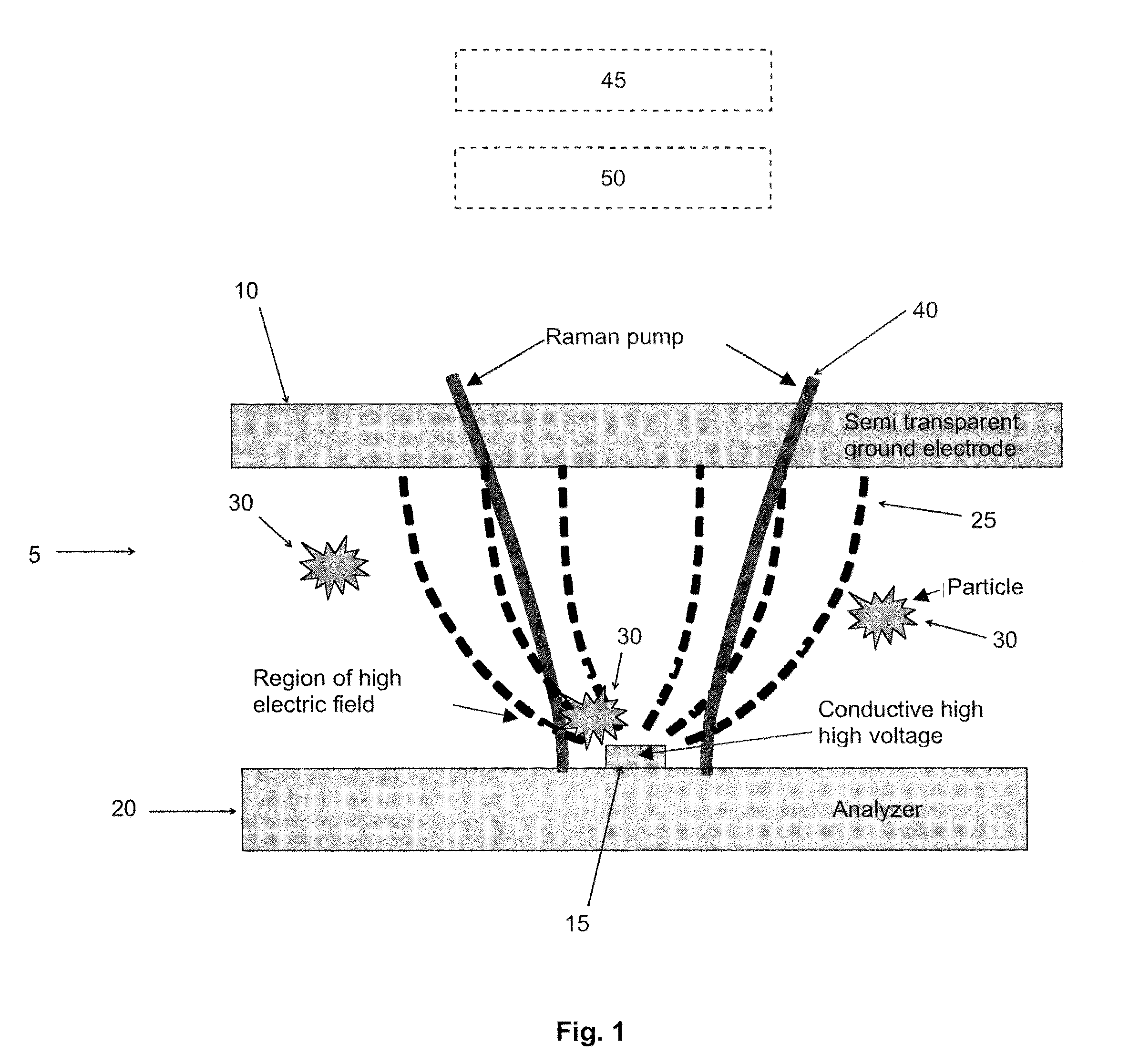

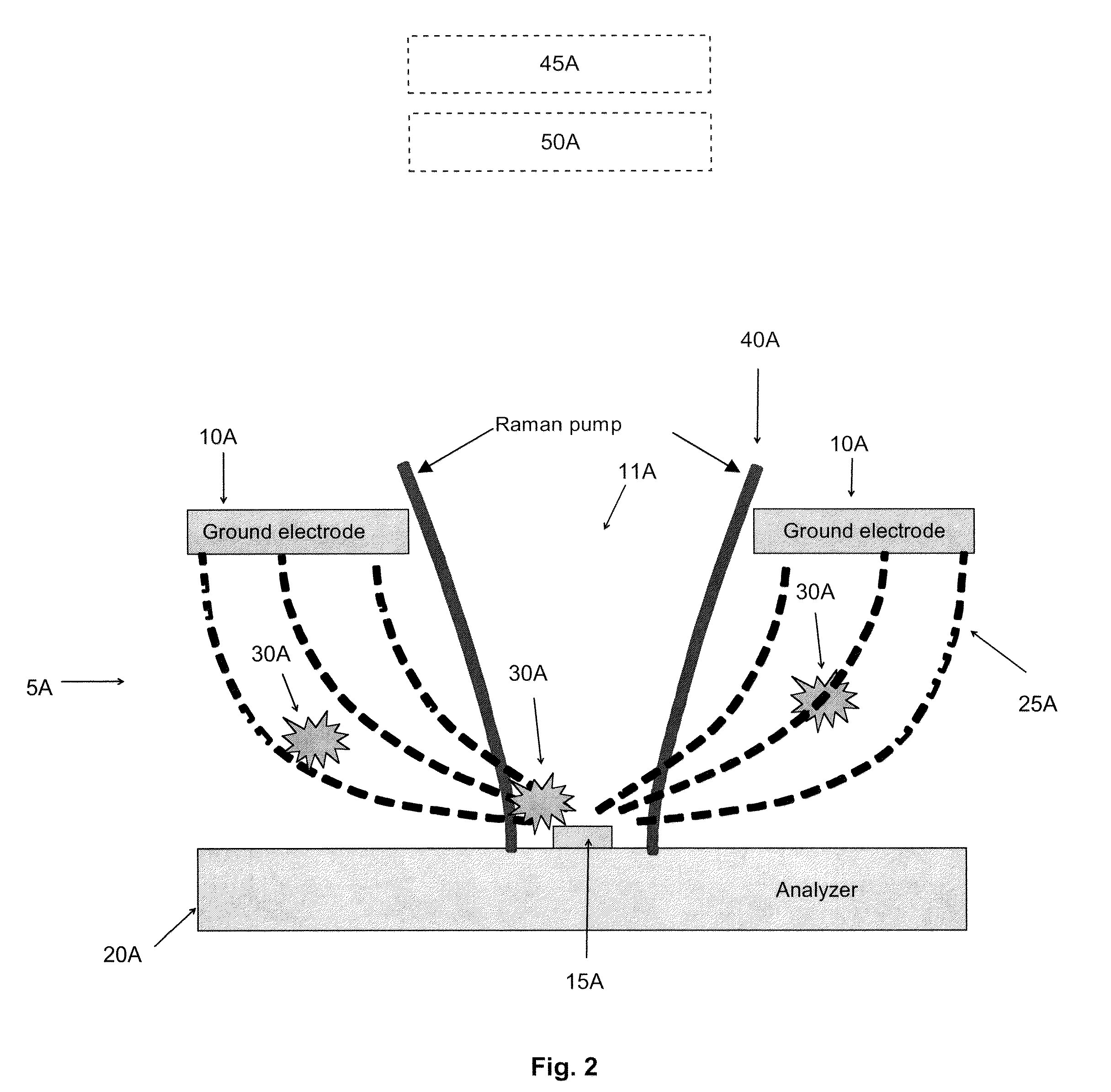

Method and apparatus for incorporating electrostatic concentrators and/or ion mobility separators with Raman, IR, UV, XRF, LIF and LIBS spectroscopy and /or other spectroscopic techniques

ActiveUS20090014646A1Reliably and accurately detectingReliably and accurately and identifyingSpectral/fourier analysisRadiation pyrometrySpectroscopyEngineering

The present invention provides a novel approach for reliably and accurately detecting and identifying airborne particles. This is done by providing a novel system which incorporates electrostatic concentrators and / or ion mobility separators with Raman, IR, UV, XRF, LIF and LIBS spectroscopy and / or other spectroscopic techniques.

Owner:AHURA SCI +1

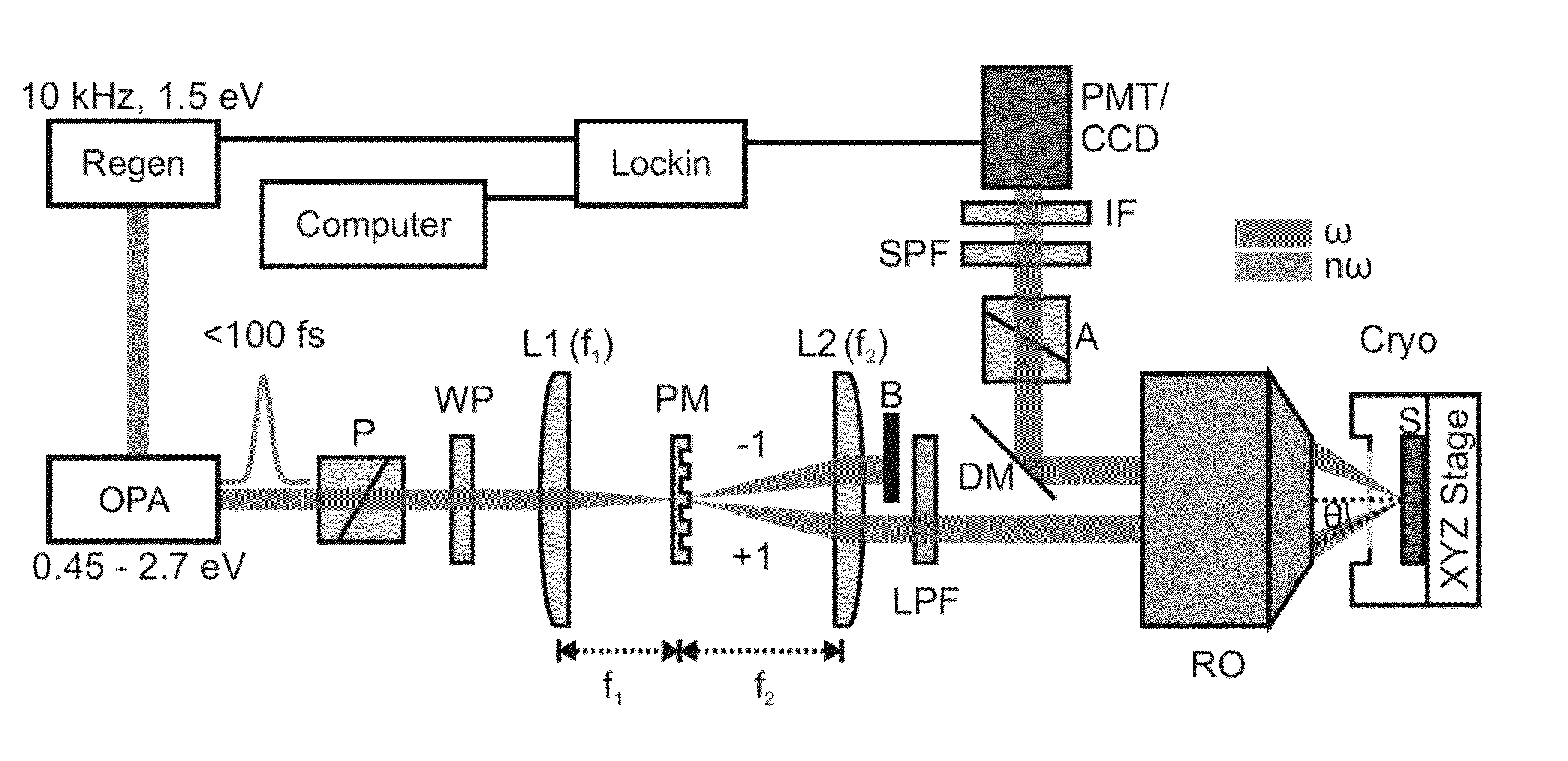

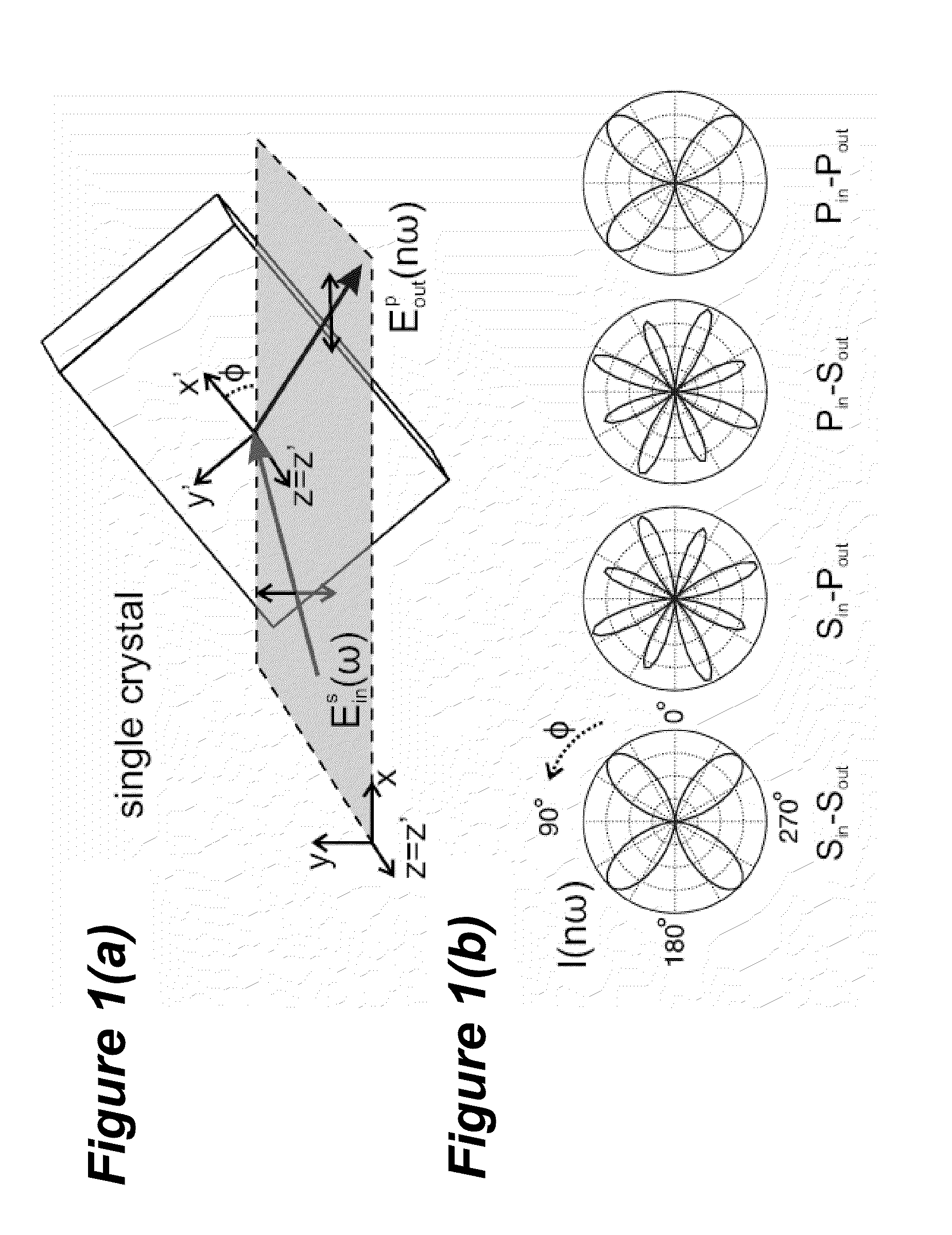

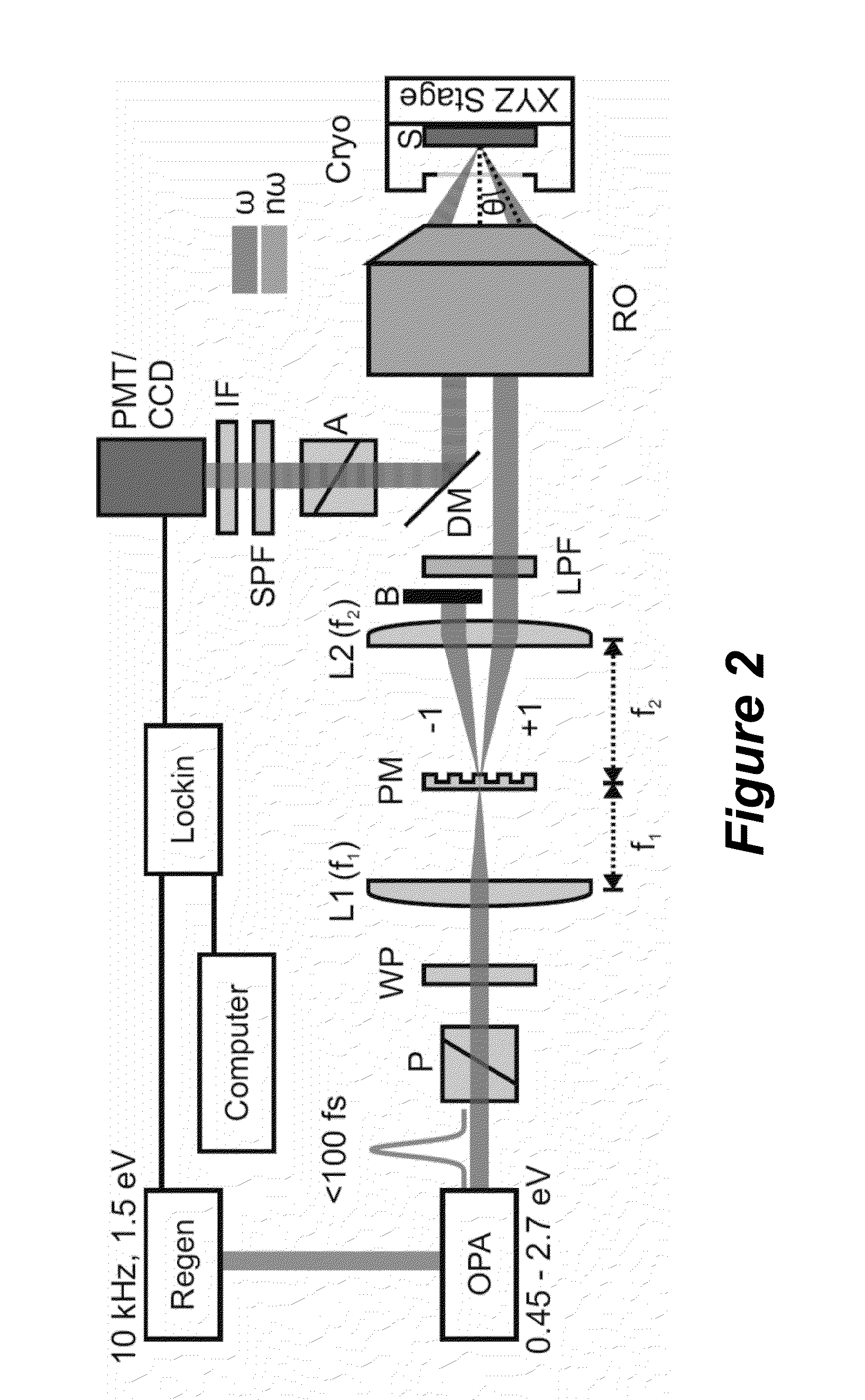

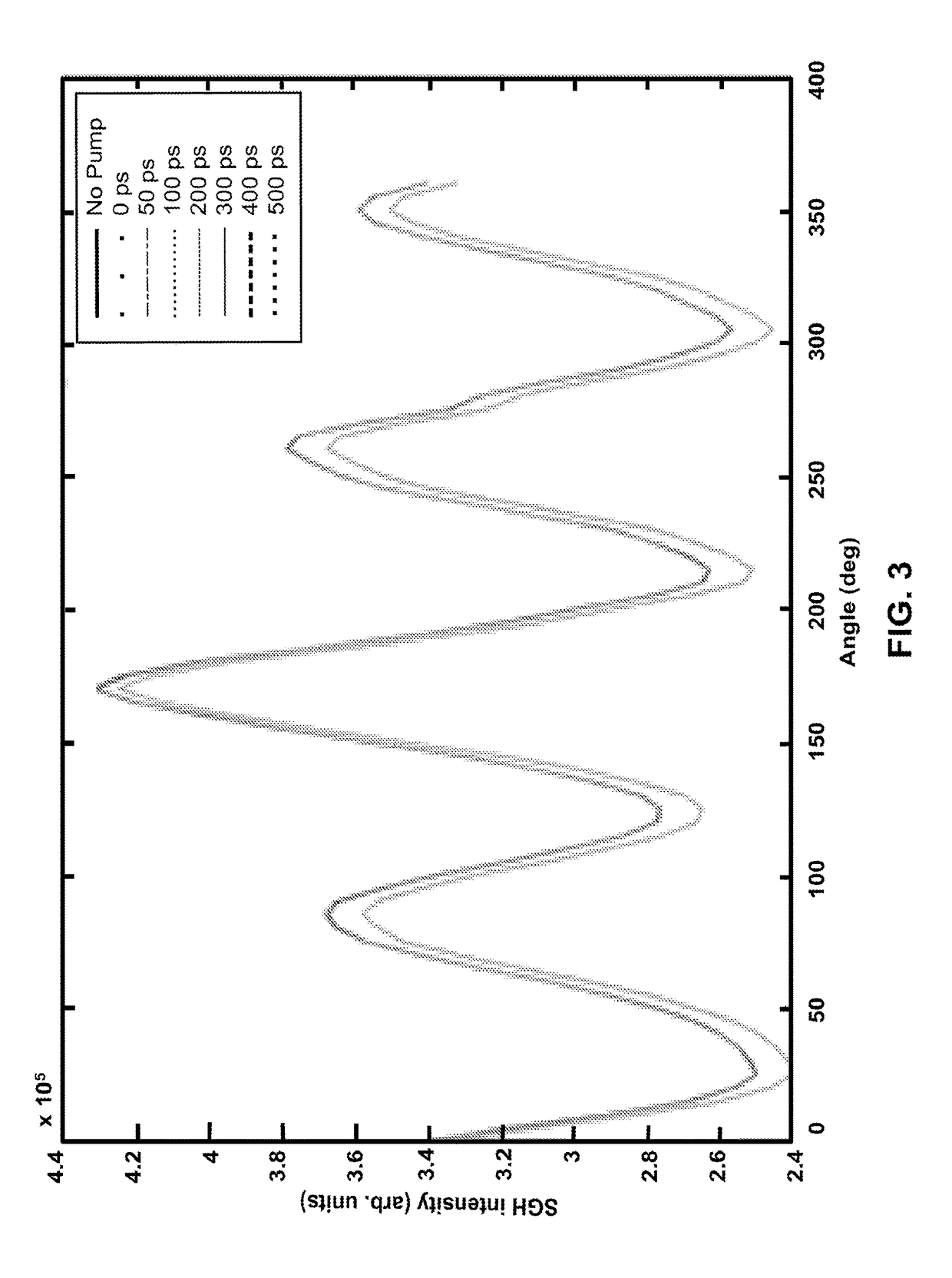

Rotating scattering plane based nonlinear optical spectrometer to study the crystallographic and electronic symmetries of crystals

InactiveUS20150355098A1Challenge can be overcomeInvestigating crystalsScattering properties measurementsNonlinear opticsNonlinear radiation

A method for measuring nonlinear Electromagnetic (EM) radiation emitted by a material, comprising rotating a beam of EM radiation to form a rotating beam; irradiating a surface of a material with the rotating beam at an oblique angle with respect to the surface, wherein the rotating irradiates a plurality of scattering planes in the material; and detecting nonlinear radiation emitted by the material in response to the rotating beam, such that the nonlinear radiation generated by each of the scattering planes is detected by the detector. This method opens the possibility of applying nonlinear optics as a probe of lattice and electronic symmetries on small bulk single crystals in ultra low temperature, high magnetic field or high pressure environments, which can greatly complement diffraction based techniques.

Owner:CALIFORNIA INST OF TECH

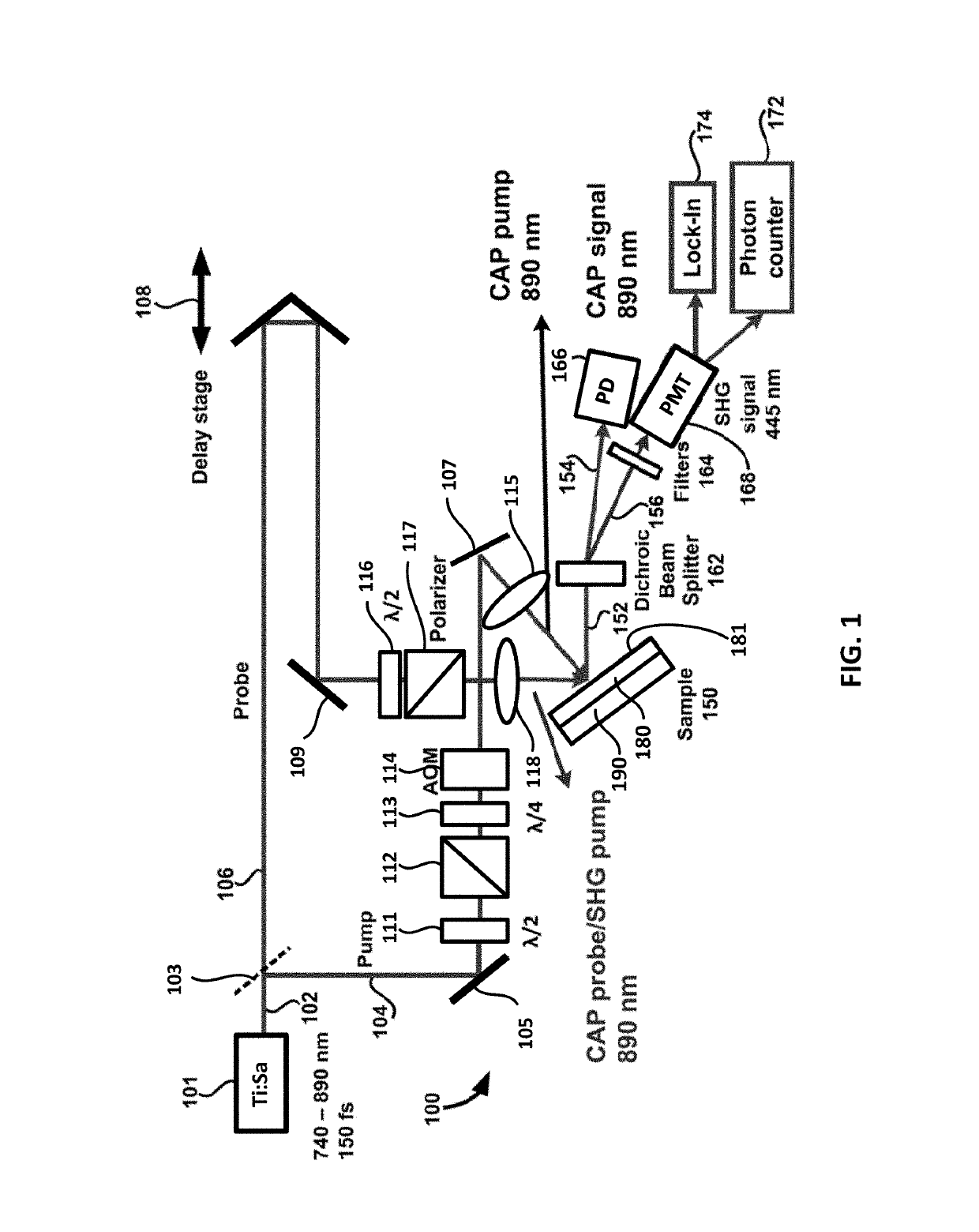

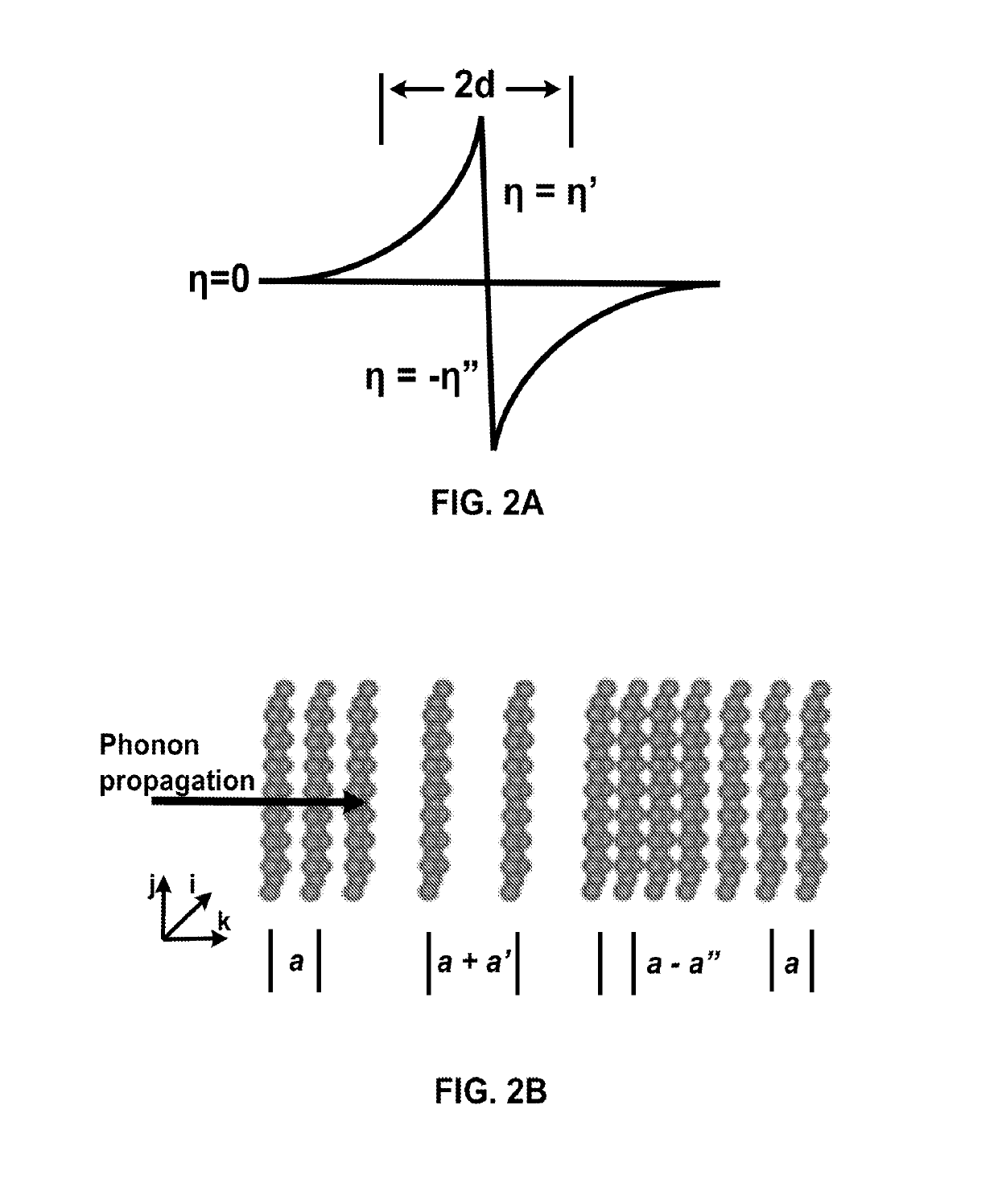

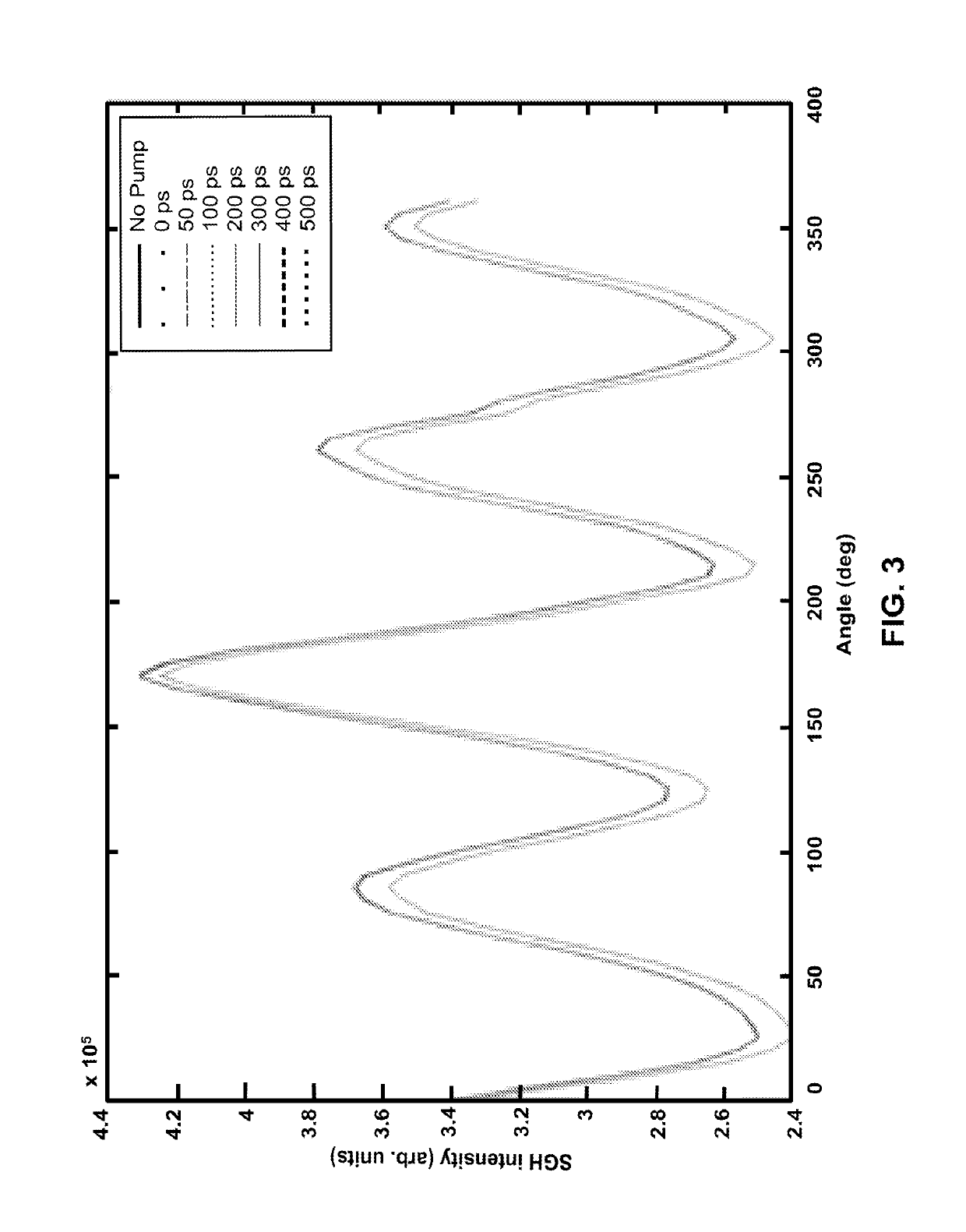

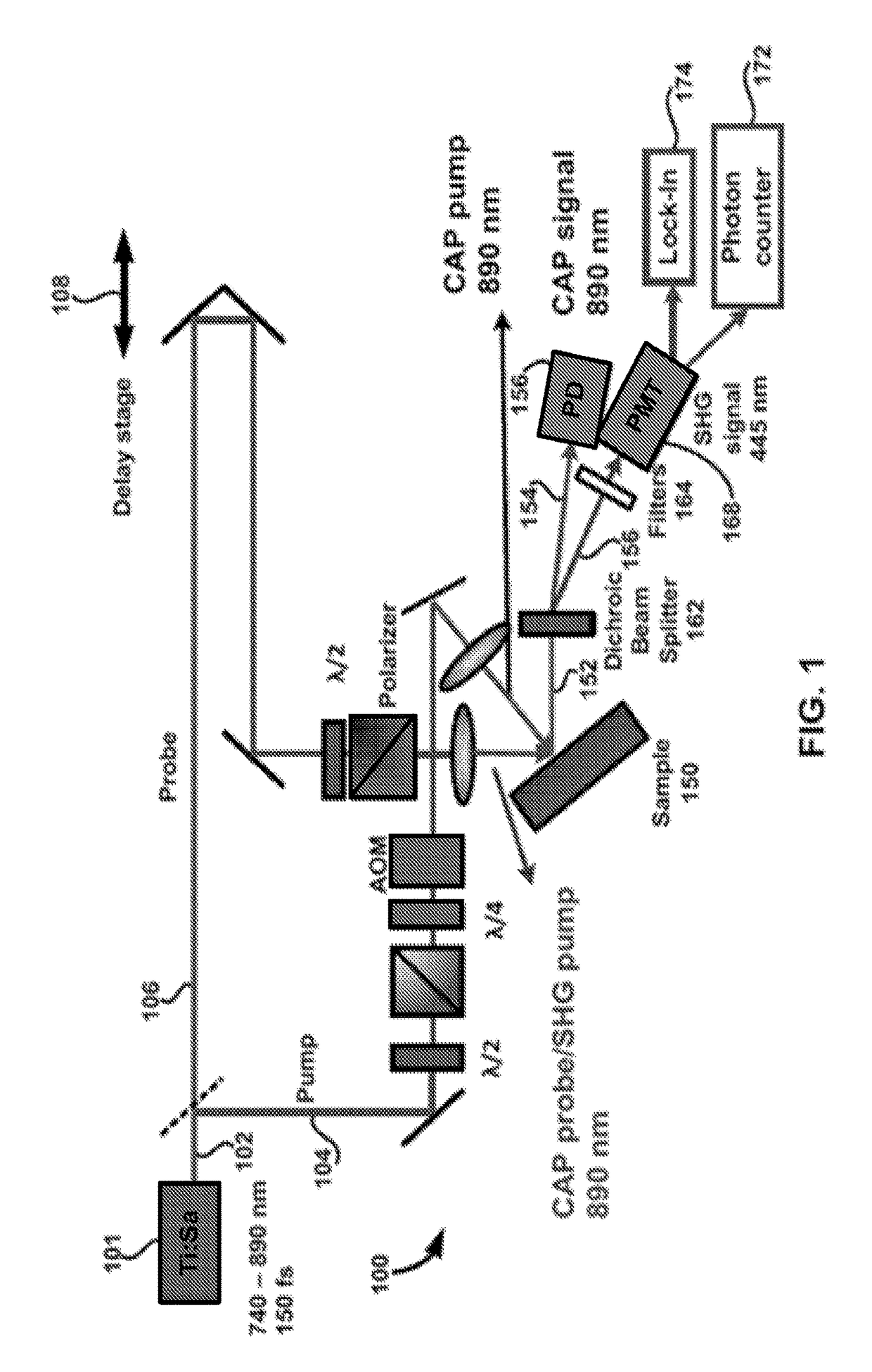

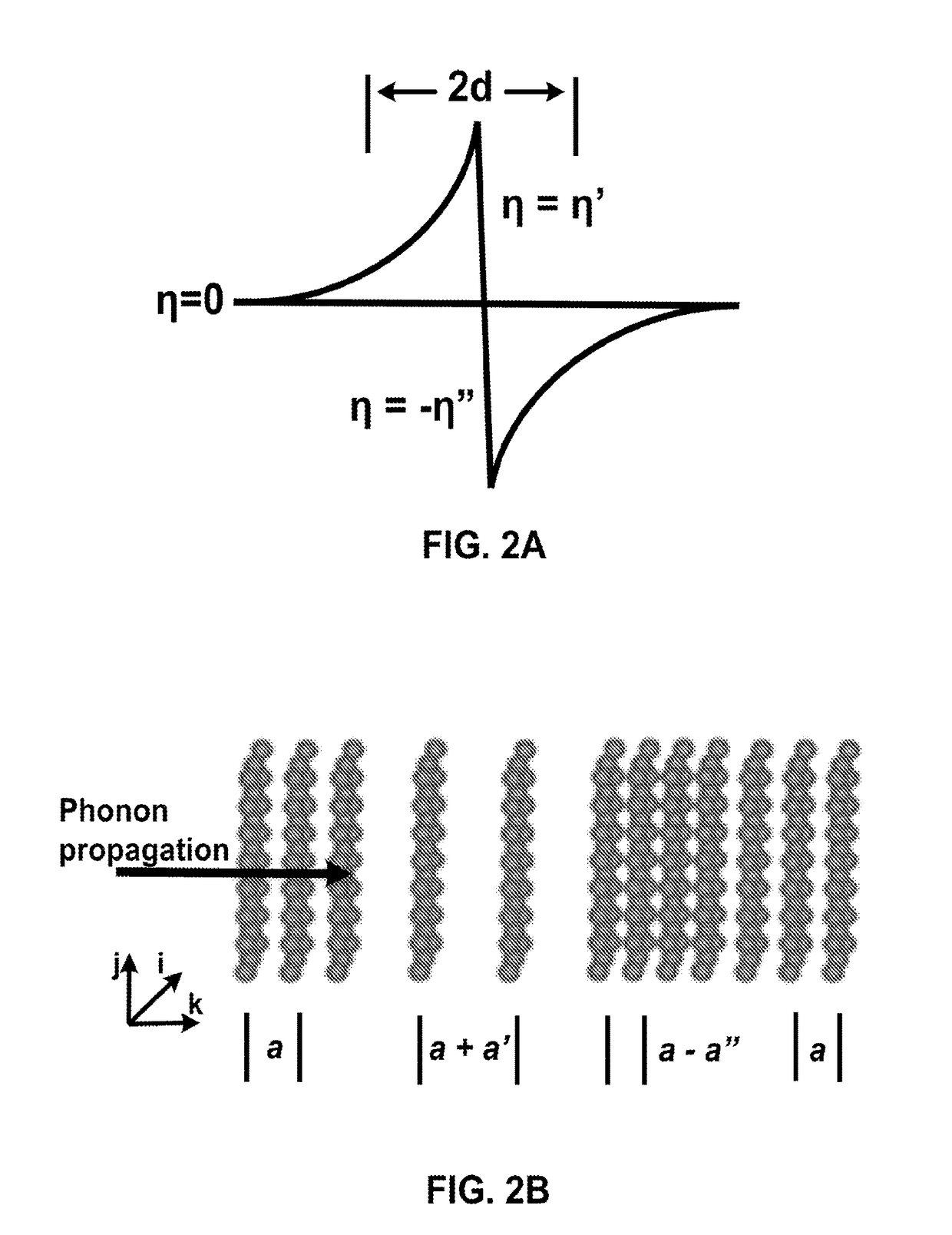

Apparatus and methods for probing a material as a function of depth using depth-dependent second harmonic generation

ActiveUS10371668B2Analysing solids using sonic/ultrasonic/infrasonic wavesInvestigating crystalsHarmonicDepth dependent

A method for non-invasively probing at least one physics property of a solid material. In one embodiment, the method has the steps of splitting a photon beam into a first photon beam and a second photon beam, exposing the solid material to the first photon beam to generate a coherent acoustic phonon wave in the solid material at time t, and exposing the solid material to the second photon beam at a time t+Δt, where t+Δt≥t, to generate corresponding second harmonic generation signals, where from the corresponding second harmonic generation signals, the at least one physics property of the solid material is determinable.

Owner:VANDERBILT UNIV

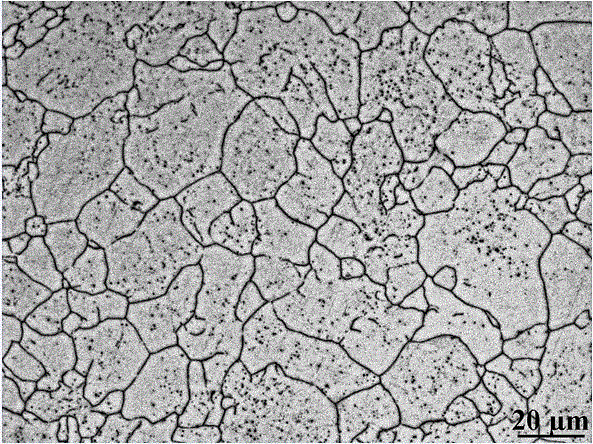

Method for displaying original austenite grain boundary of 85Cr2MnMo liner steel

ActiveCN105865881AImprove efficiencyDisplay clearInvestigating crystalsPreparing sample for investigationWater bathsThermal expansion

The invention discloses a method for displaying the original austenite grain boundary of 85Cr2MnMo liner steel. The method comprises the following steps: (1) sample preparation; (2) determination of phase transition temperature, wherein Accm (complete dissolution of cementite and carbide into austenite) temperature of the 85Cr2MnMo liner steel is 835 DEG C according to results of thermal expansion measurement; (3) quenching: heating a sample to 860 to 920 DEG C, maintaining the temperature for 60 min and then rapidly quenching the sample in machine oil No. 10; and (4) corrosion: mixing 100 ml of deionized water, 4 g of picric acid, 2 g of Aiou shampoo paste and 0.1 g of CuCl2.2H2O to prepare a corrosive agent, putting the corrosive agent in a water-bath pot with a temperature of 55 to 60 DEG C for heat preservation, putting the quenched, ground and polished sample in the corrosive agent for corrosion for 50 to 60 s, taking the sample out, wiping the sample with absorbent cotton dipped with alcohol so as to remove reaction products on the surface of the sample, cleaning the sample through flushing and then subjecting the sample to blow-drying. As the sample is observed with an optical microscope, the original austenite grain boundary of 85Cr2MnMo liner steel can be clearly displayed and matrix structure is not displayed, so bases are provided for accurate rating of the grain size of austenite.

Owner:SHANGHAI UNIV

Apparatus and methods for probing a material as a function of depth using depth-dependent second harmonic generation

ActiveUS20170205377A1Analysing solids using sonic/ultrasonic/infrasonic wavesInvestigating crystalsHarmonicDepth dependent

A method for non-invasively probing at least one physics property of a solid material. In one embodiment, the method has the steps of splitting a photon beam into a first photon beam and a second photon beam, exposing the solid material to the first photon beam to generate a coherent acoustic phonon wave in the solid material at time t, and exposing the solid material to the second photon beam at a time t+Δt, where t+Δt≧t, to generate corresponding second harmonic generation signals, where from the corresponding second harmonic generation signals, the at least one physics property of the solid material is determinable.

Owner:VANDERBILT UNIV

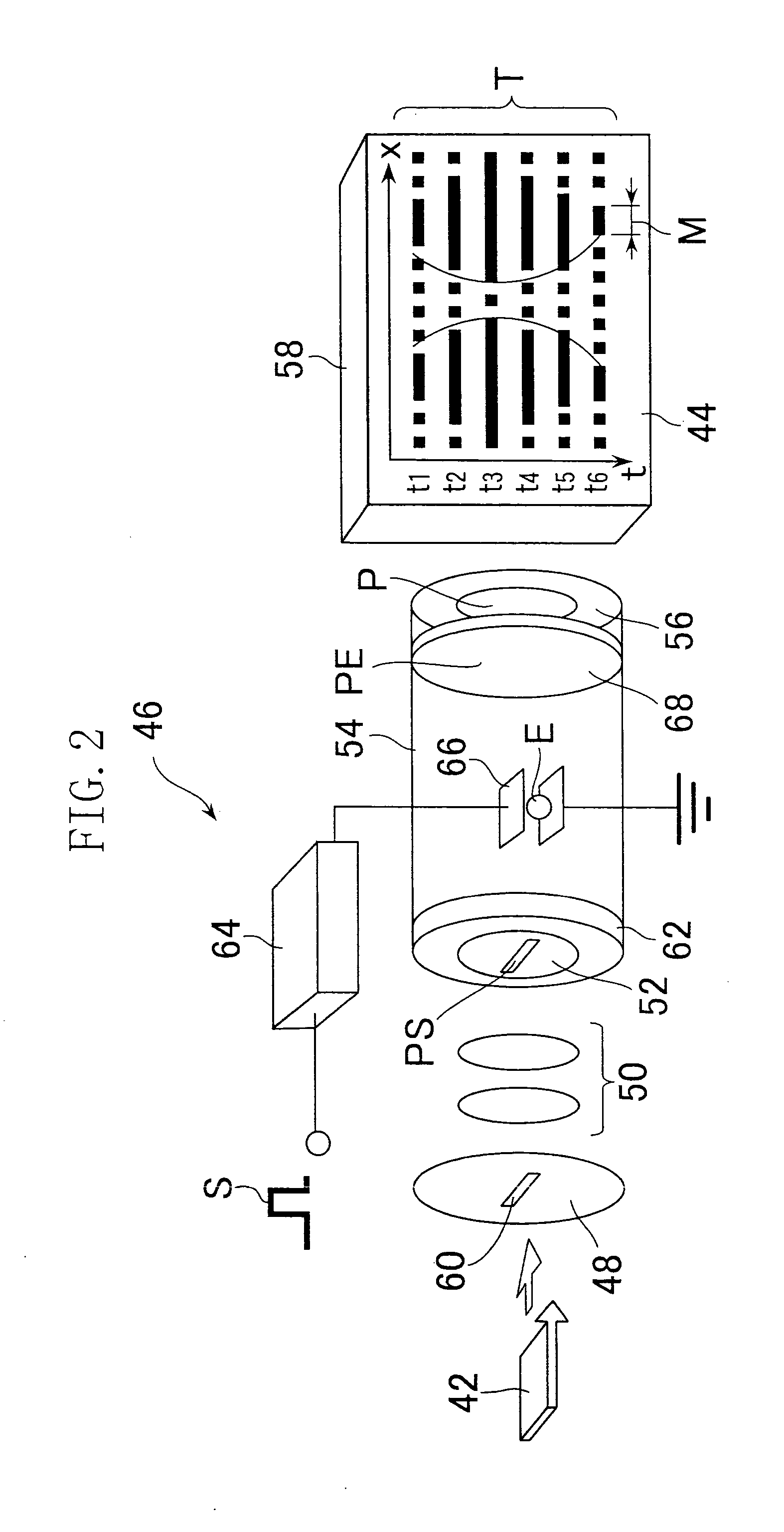

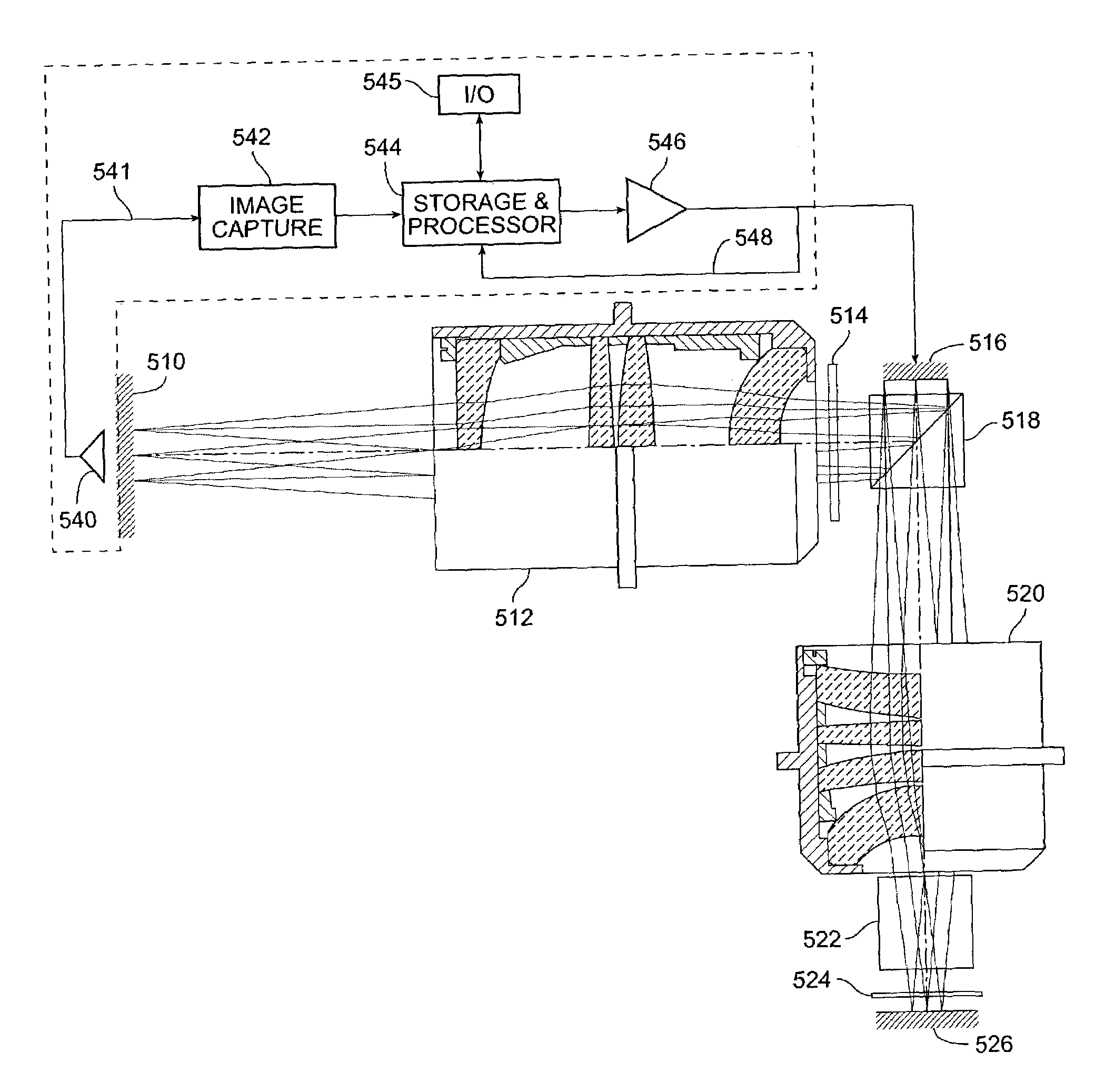

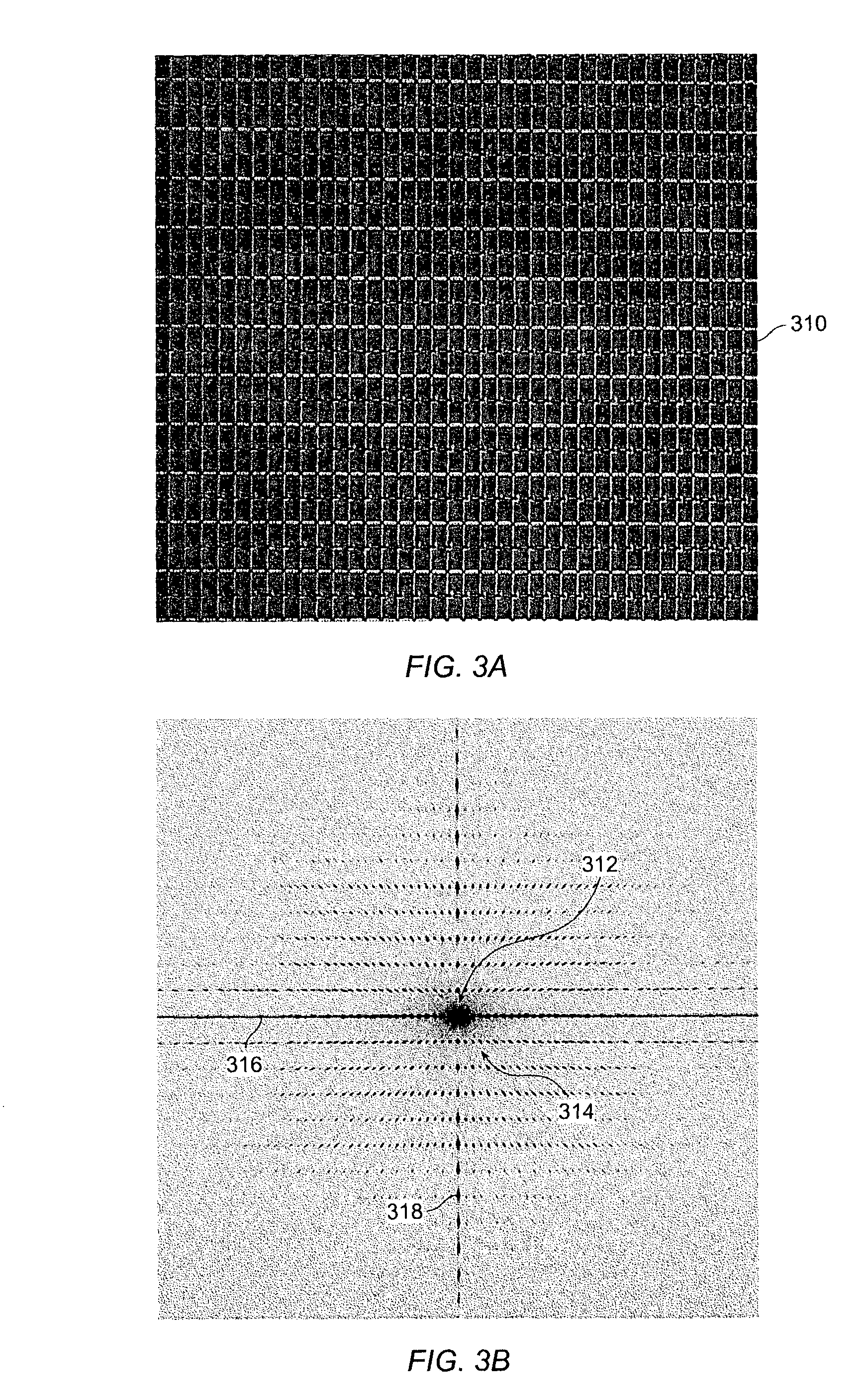

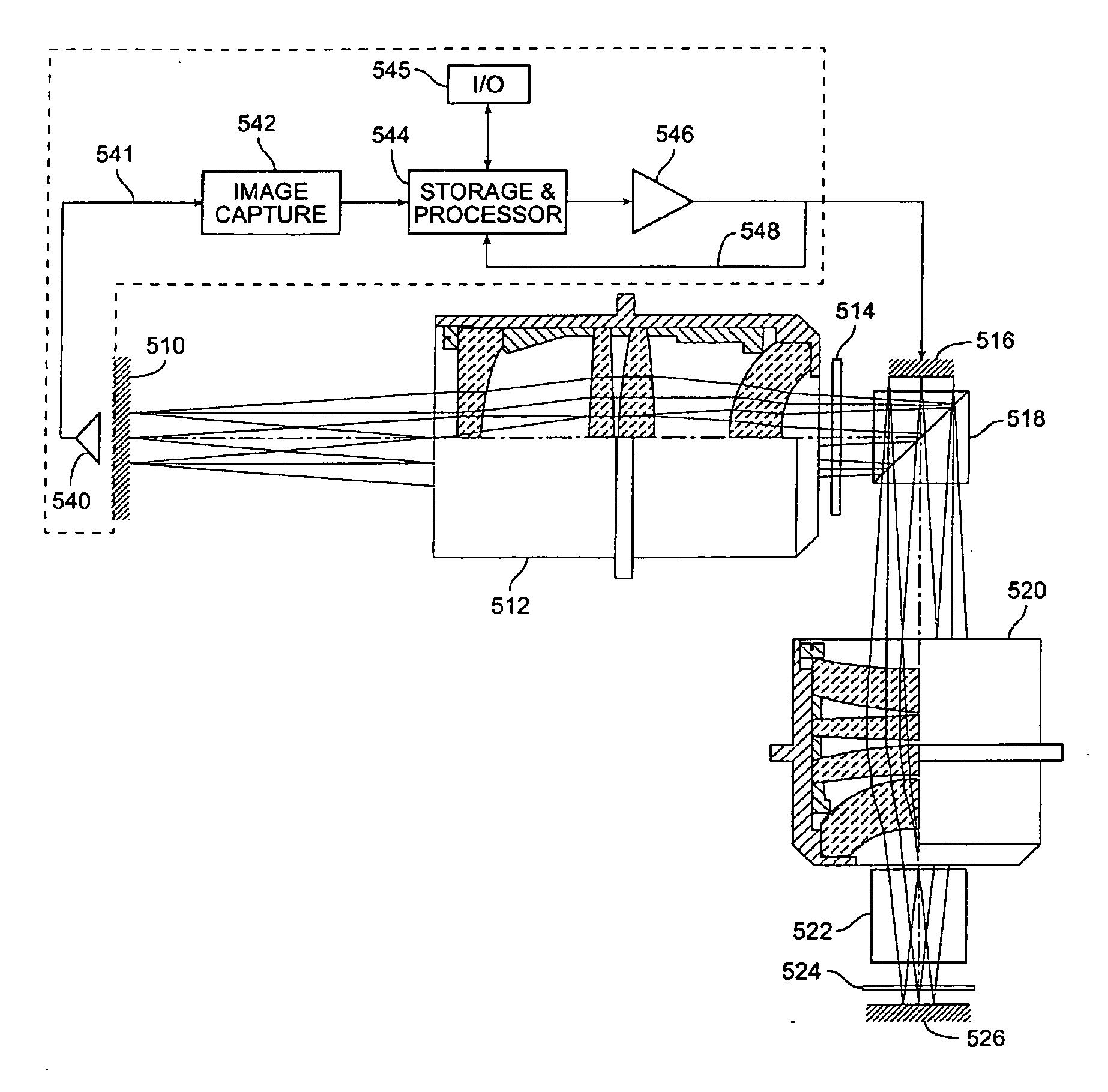

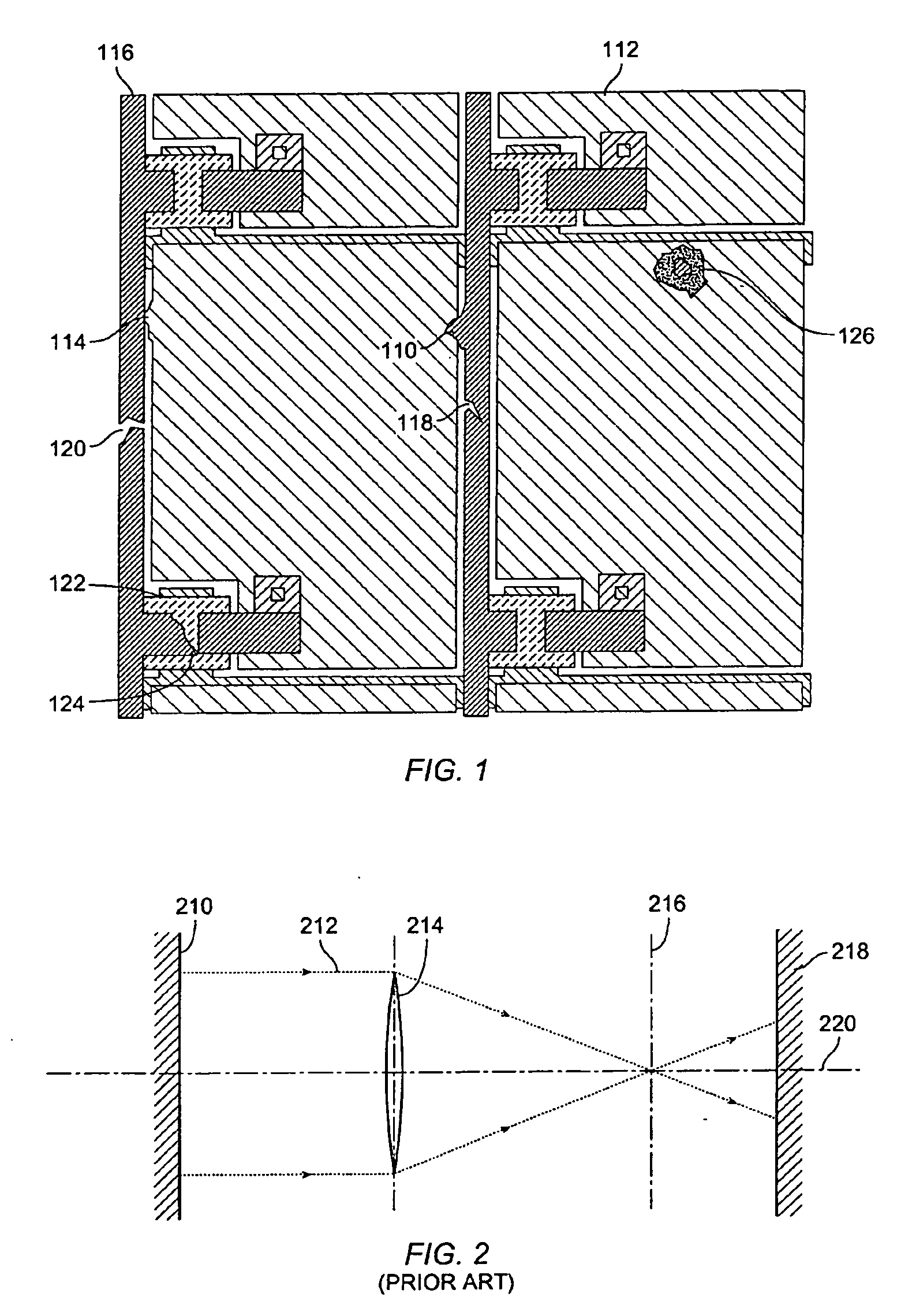

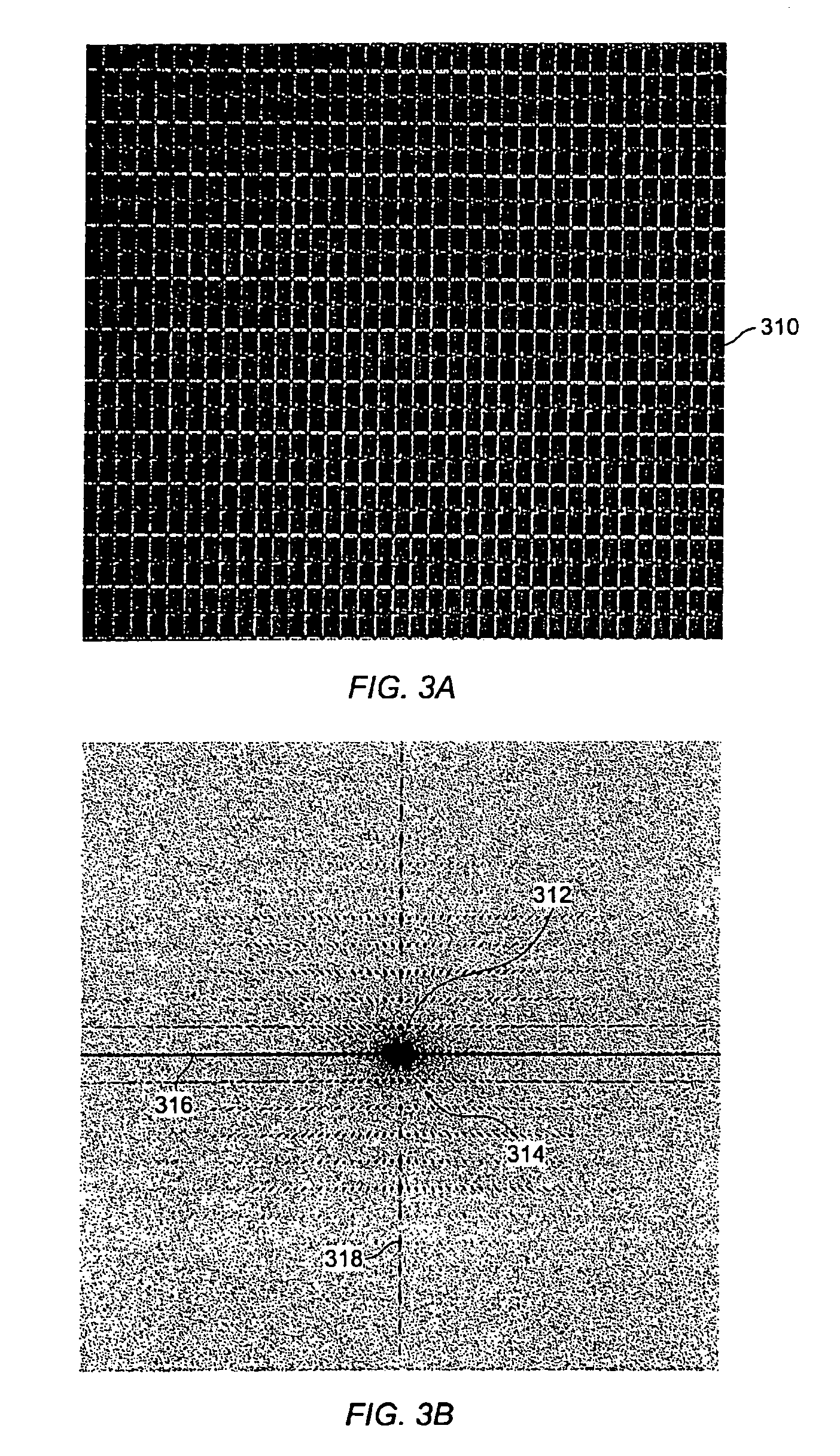

Method and apparatus for high-throughput inspection of large flat patterned media using dynamically programmable optical spatial filtering

InactiveUS7041998B2Reduce resolutionLimiting detection of defectAutomatic control devicesInvestigating crystalsSignal-to-noise ratio (imaging)Optical space

In an inspection system for planar objects having periodic structures, programmable optical Fourier filtering in the focal plane of a telecentric lens system is used to directly identify physical phenomena indicative of non-periodic defects. Lens assemblies and a coherent optical source are used to generate and observe a spatial Fourier transform of a periodic structure in the Fourier plane. Optical Fourier filtering (OFF) is performed in the focal plane using an electrically programmable and electrically alignable spatial light modulator. The spatial light modulator with high signal to noise ratio is electrically reconfigurable according to a feedback-driven, filter construction and alignment algorithm. The OFF enhances any non-periodic components present in the Fourier plane and final image plane of the object. A system having a plurality of inspection channels provides high-throughput inspection of objects with small non-periodic defects while maintaining high detection sensitivity.

Owner:PHOTON DYNAMICS

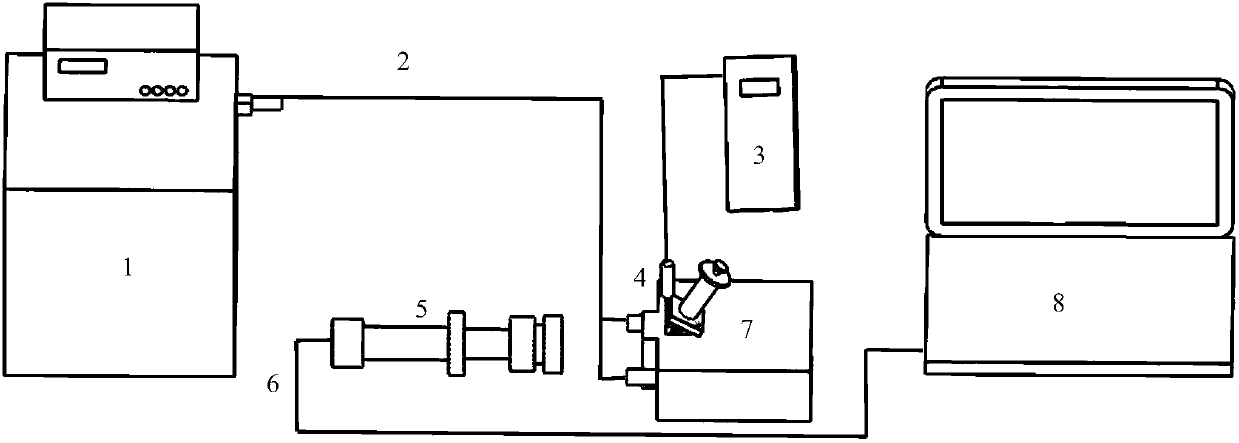

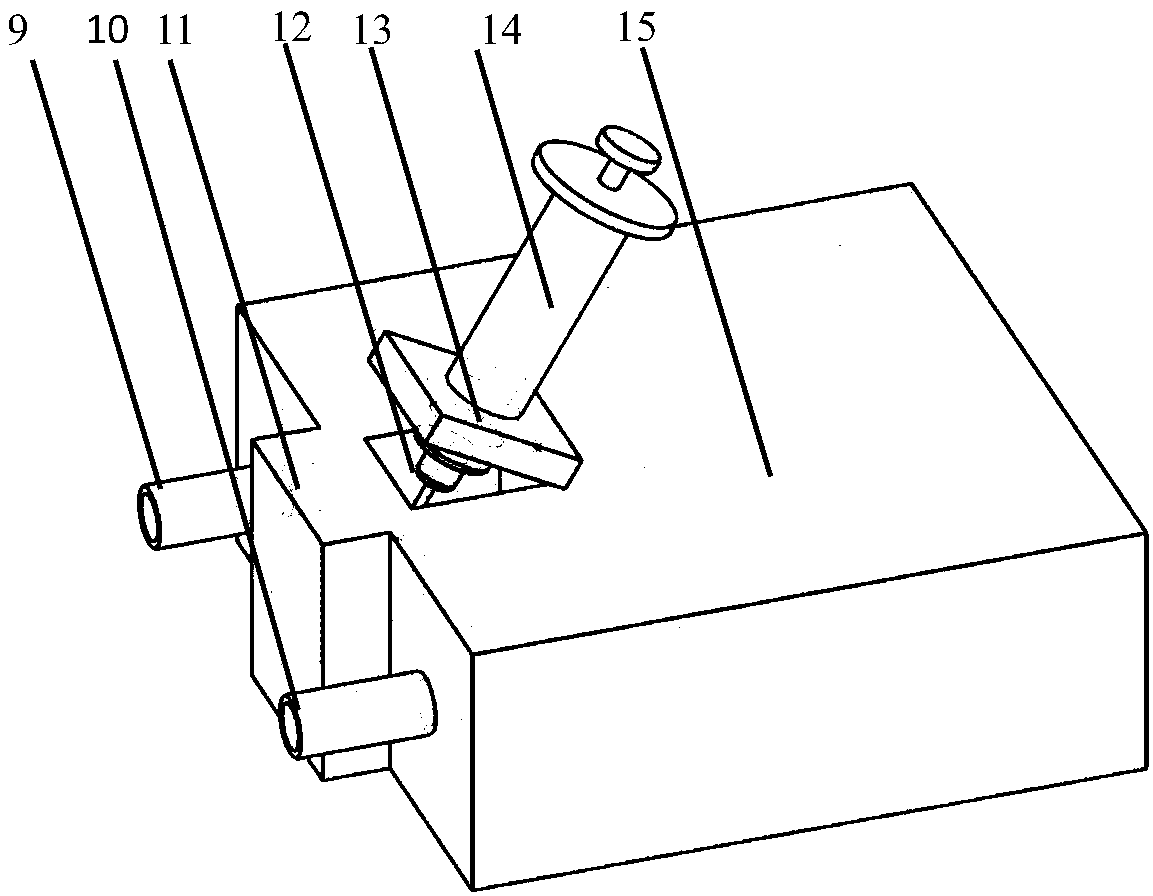

Photo-thermal common-path interference module and method for measuring crystal defect

InactiveCN107121395AHigh measurement accuracyLarge measuring rangeInvestigating crystalsScattering properties measurementsAbsorption capacityCommon path

The invention discloses a photo-thermal common-path interference module which is applied to a crystal defect measurement instrument. The crystal defect measurement instrument based on a module is characterized in that pump laser and detection laser are focused at the same point of a sample to test a dynamical mesoscopic defect of the sample; a dynamic defect three-dimensional distribution map of the sample is obtained through movement of the sample. The photo-thermal common-path interference module disclosed by the invention comprises a pumping light source, a detection light source, a converging light path, a sample frame, a measurement light path, a laser power meter, and a wave-front detector, wherein a test point is heated through the pump laser; remaining laser is received by the laser power meter; the detection laser passes through the heated test point; interference is changed in front of waves according to the temperature distribution of the test point; weak laser passing through the sample passes through the measurement light path, and is irradiated into the wave-front detector; changed wave-front information is measured, and the heating condition and absorption capacity of an irradiation point are obtained through comparative calculation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

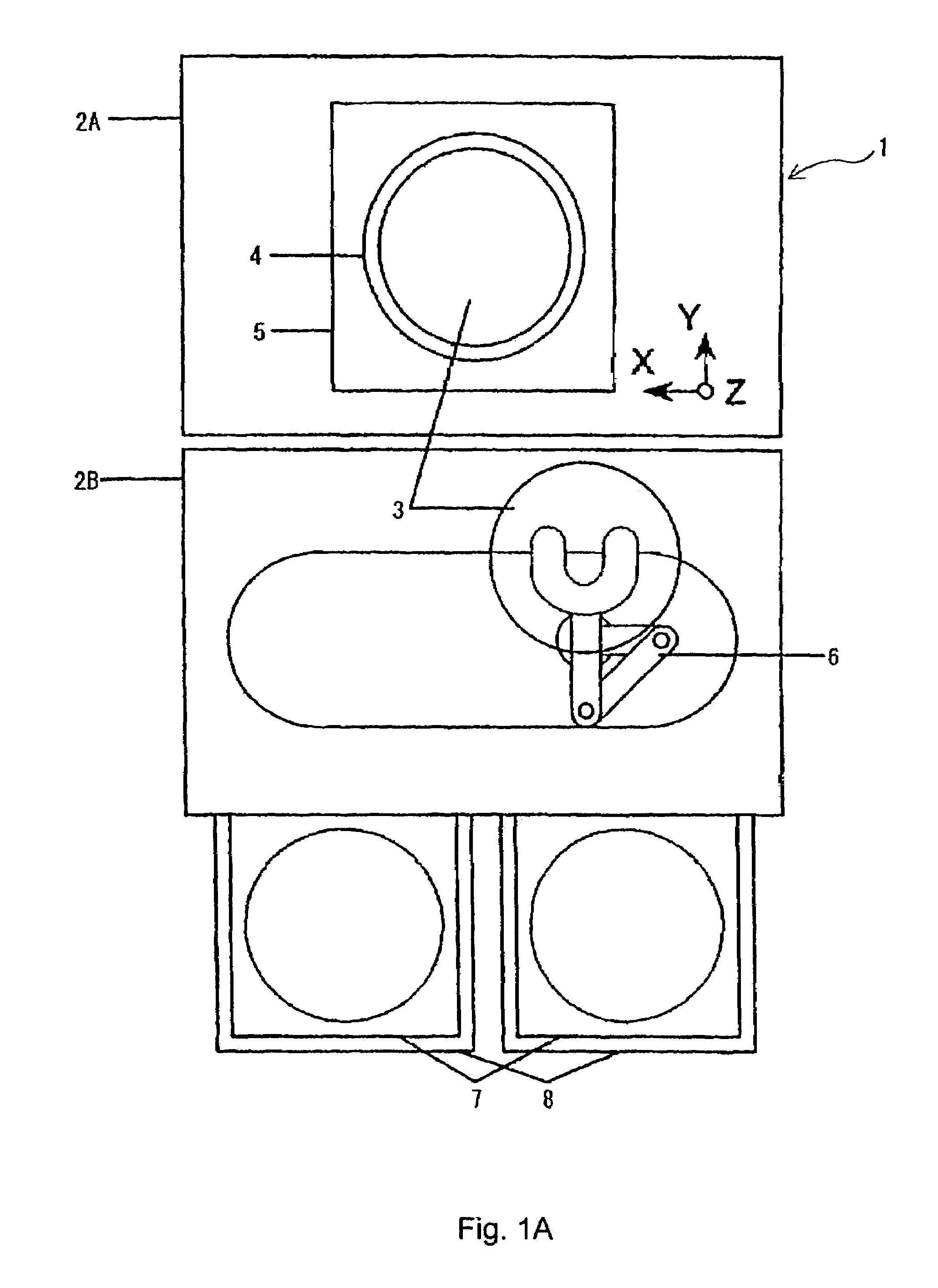

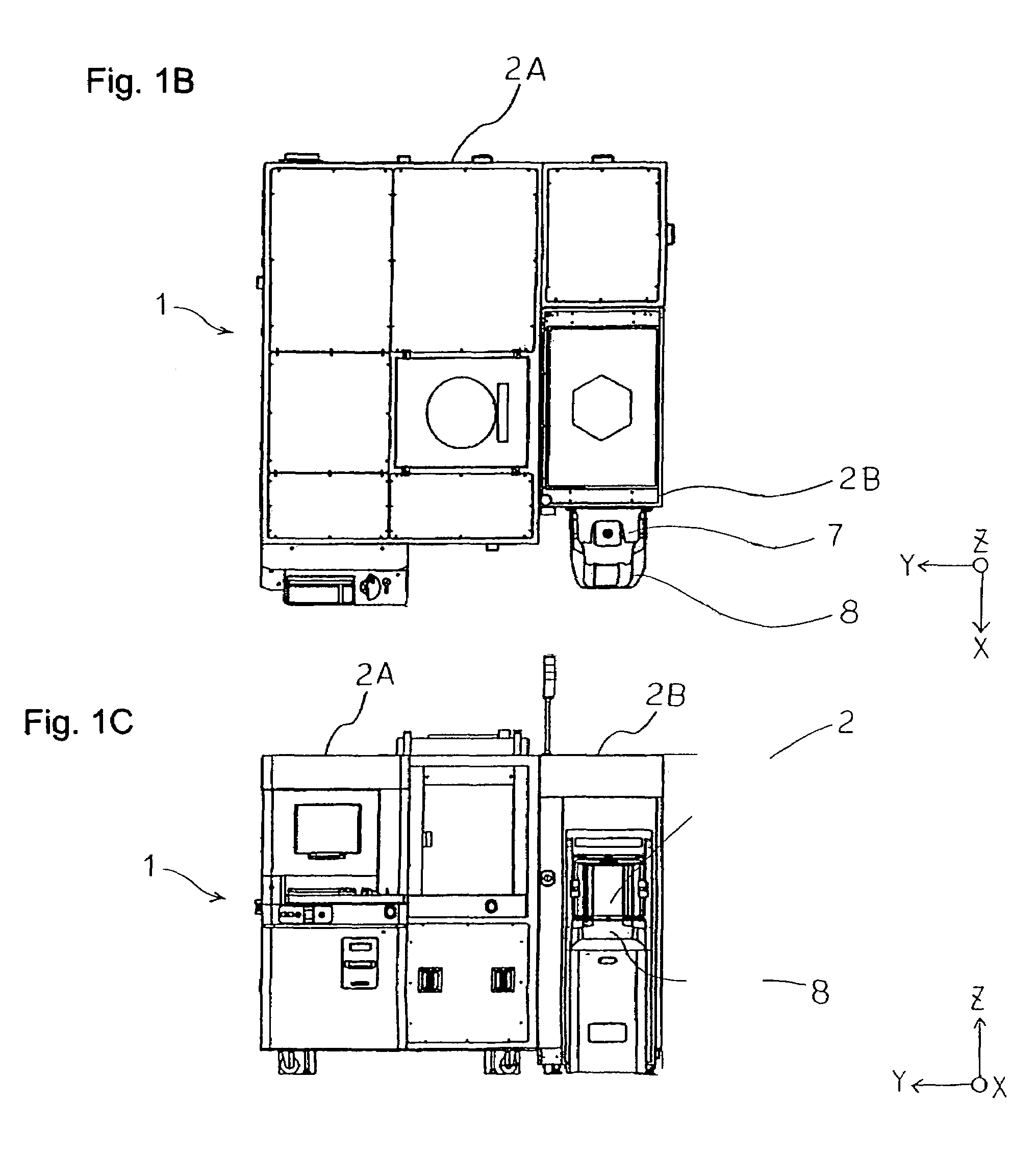

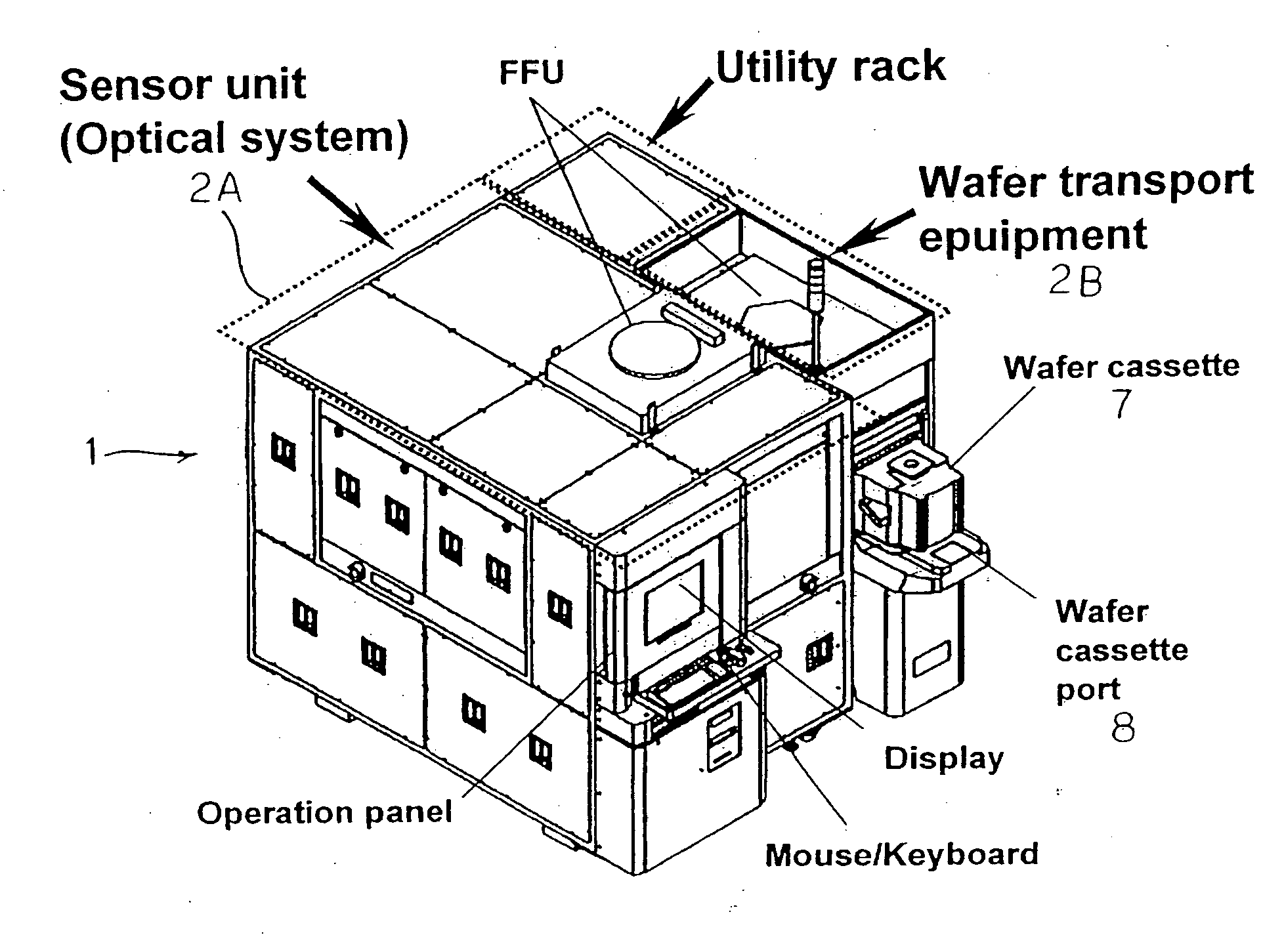

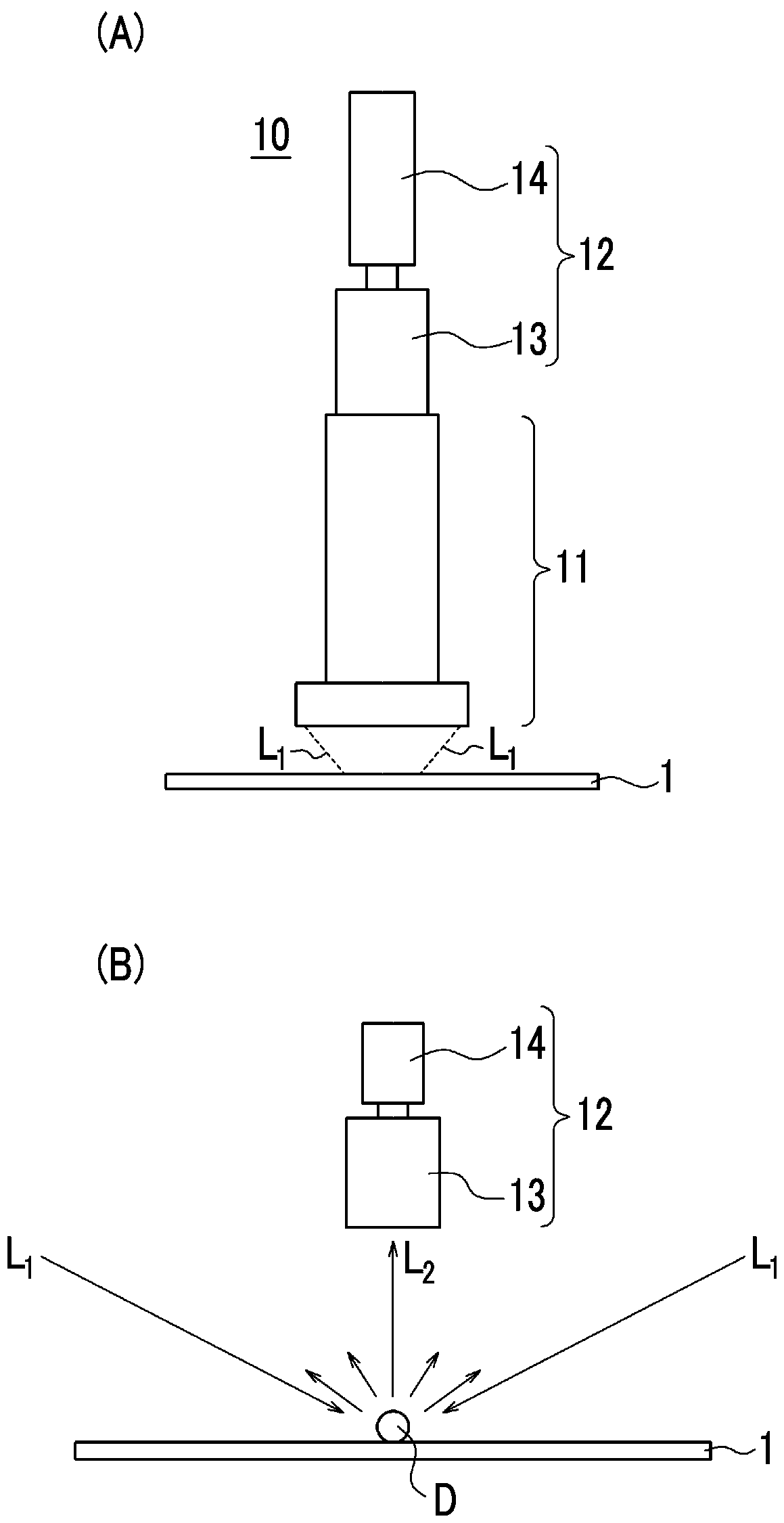

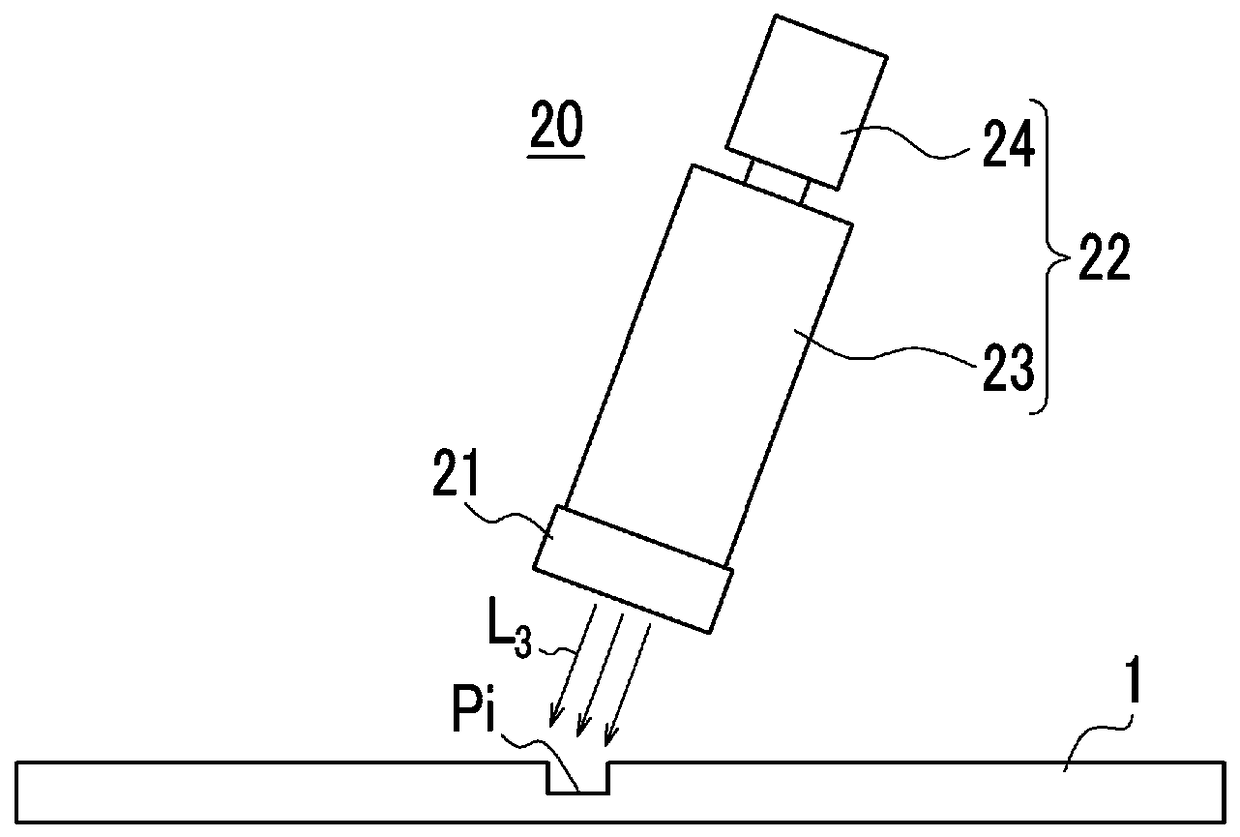

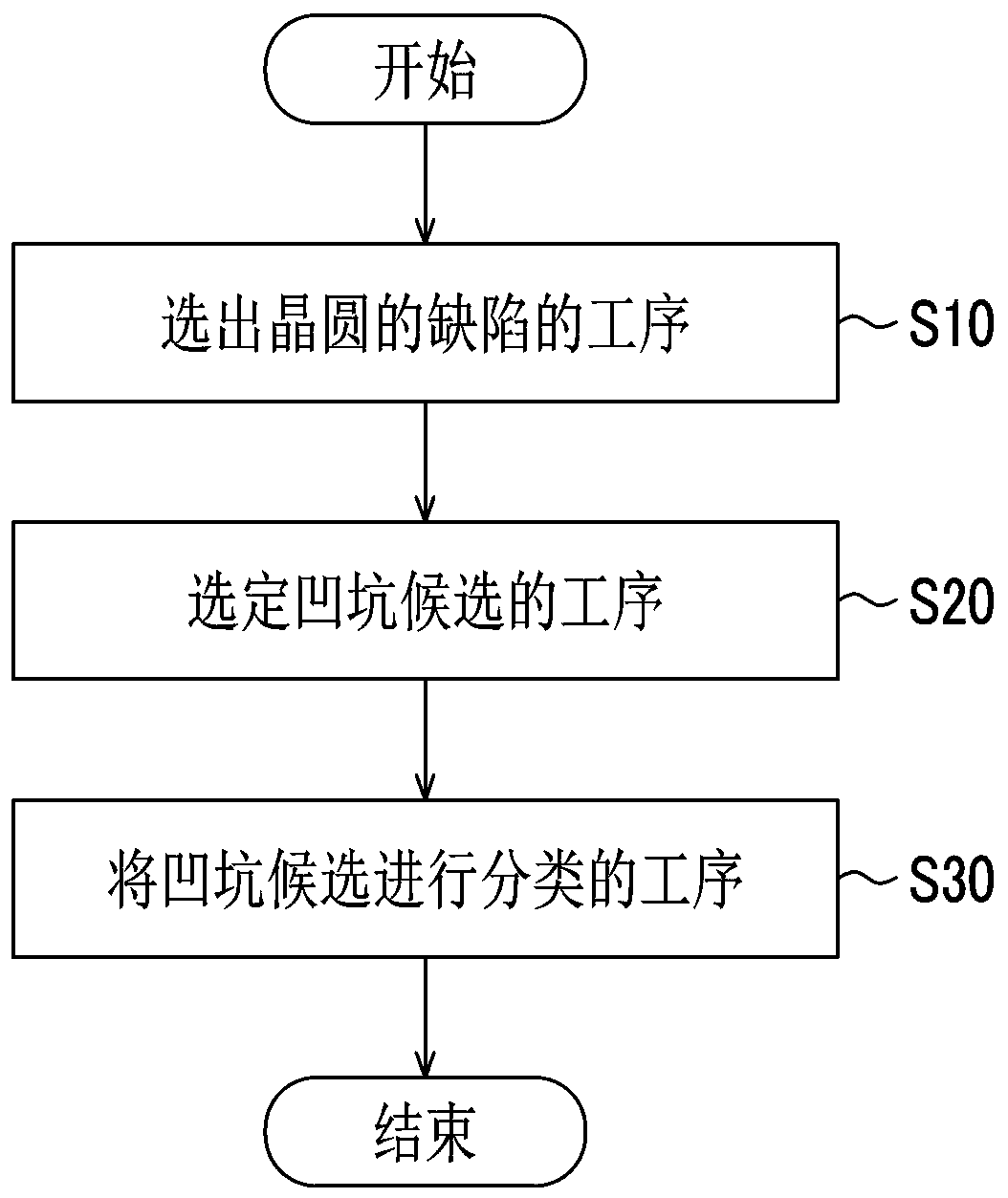

Wafer inspection method and wafer inspection apparatus

ActiveCN108351311ASemiconductor/solid-state device testing/measurementInvestigating crystalsEngineeringElectrical and Electronics engineering

Provided is a wafer inspection method whereby whether there is a pit in a wafer surface can be inspected. This wafer inspection method is characterized by including: a step for picking up defects of awafer (1) using a first optical system (10); a step for selecting pit candidates from among thus picked up defects; and a step for classifying the pit candidates into a group of pit defects and a group of defects other than the pit defects using a second optical system (20).

Owner:SUMCO CORP

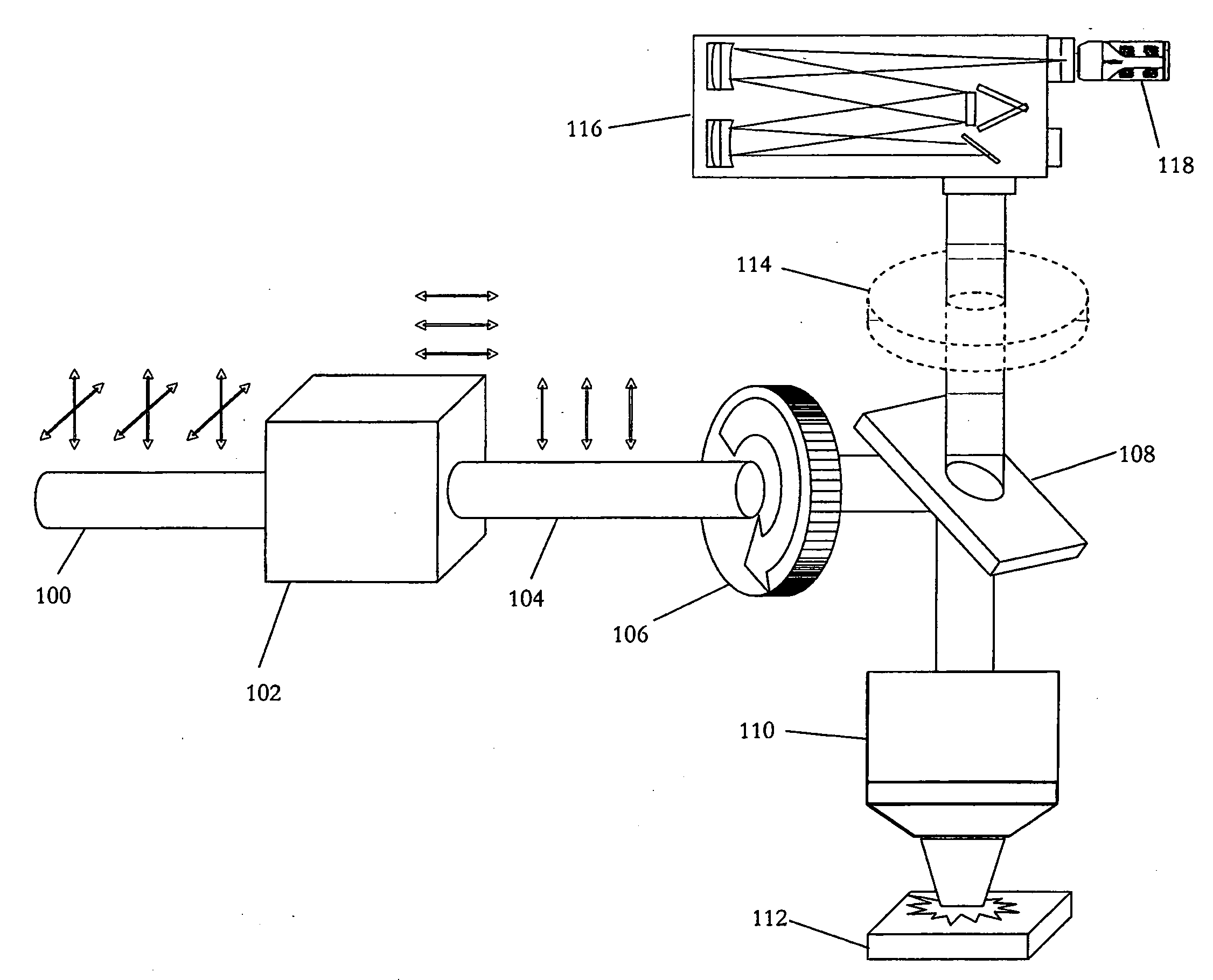

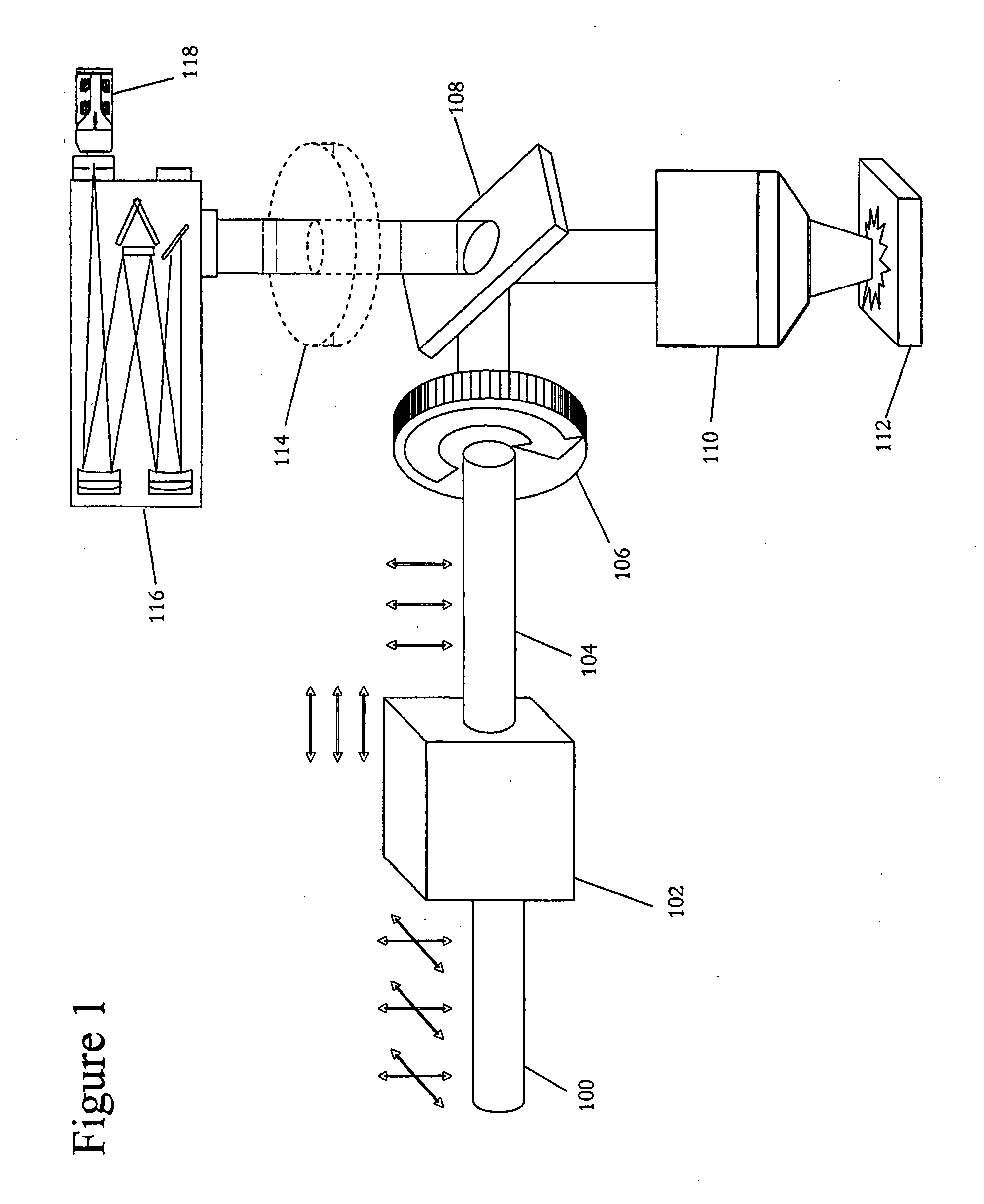

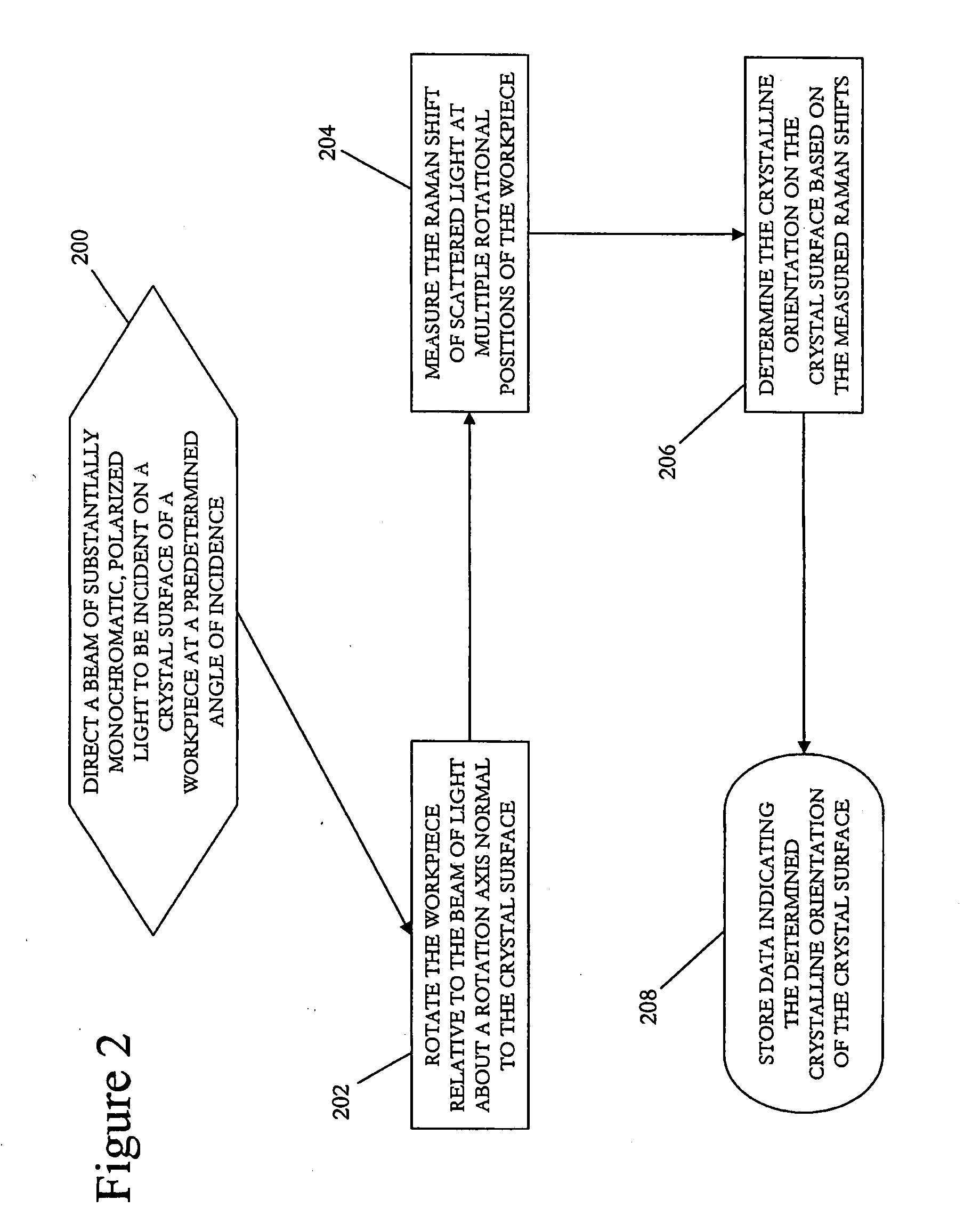

Method for determining crystalline orientation using raman spectroscopy

A method of determining the crystalline orientation of a crystal surface of a workpiece using Raman spectroscopy. A beam of substantially monochromatic light is directed to be incident on the crystal surface at a predetermined angle of incidence. The beam of light is substantially polarized. The workpiece is rotated relative to the beam of light about a rotation axis substantially normal to the crystal surface. A Raman shift of scattered light is measured at each of a number of rotational positions during the rotation of the workpiece. The crystalline orientation of the crystal surface is determined based on the measured Raman shifts. Data indicating the determined crystalline orientation of the crystal surface is stored.

Owner:PANASONIC CORP

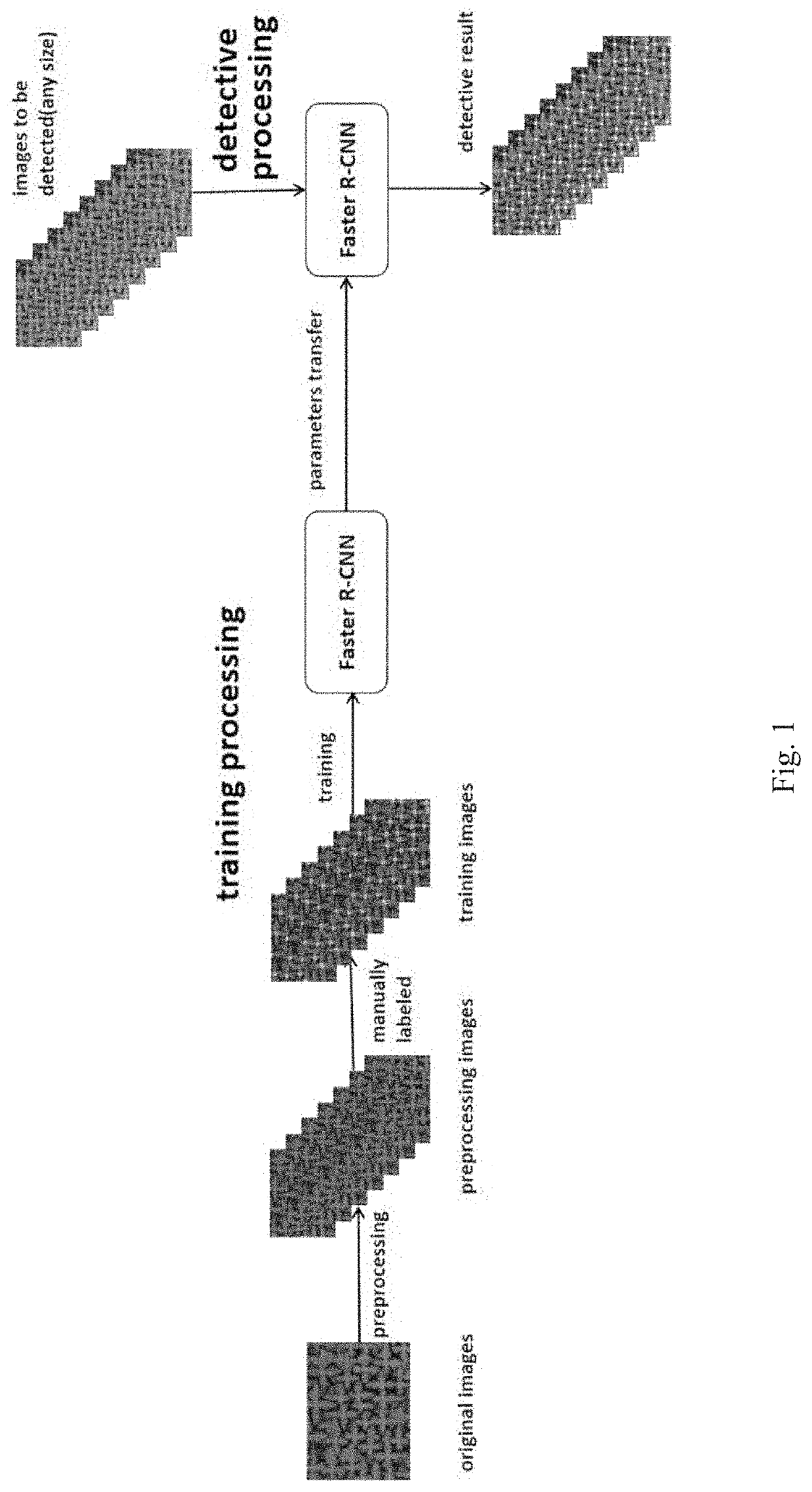

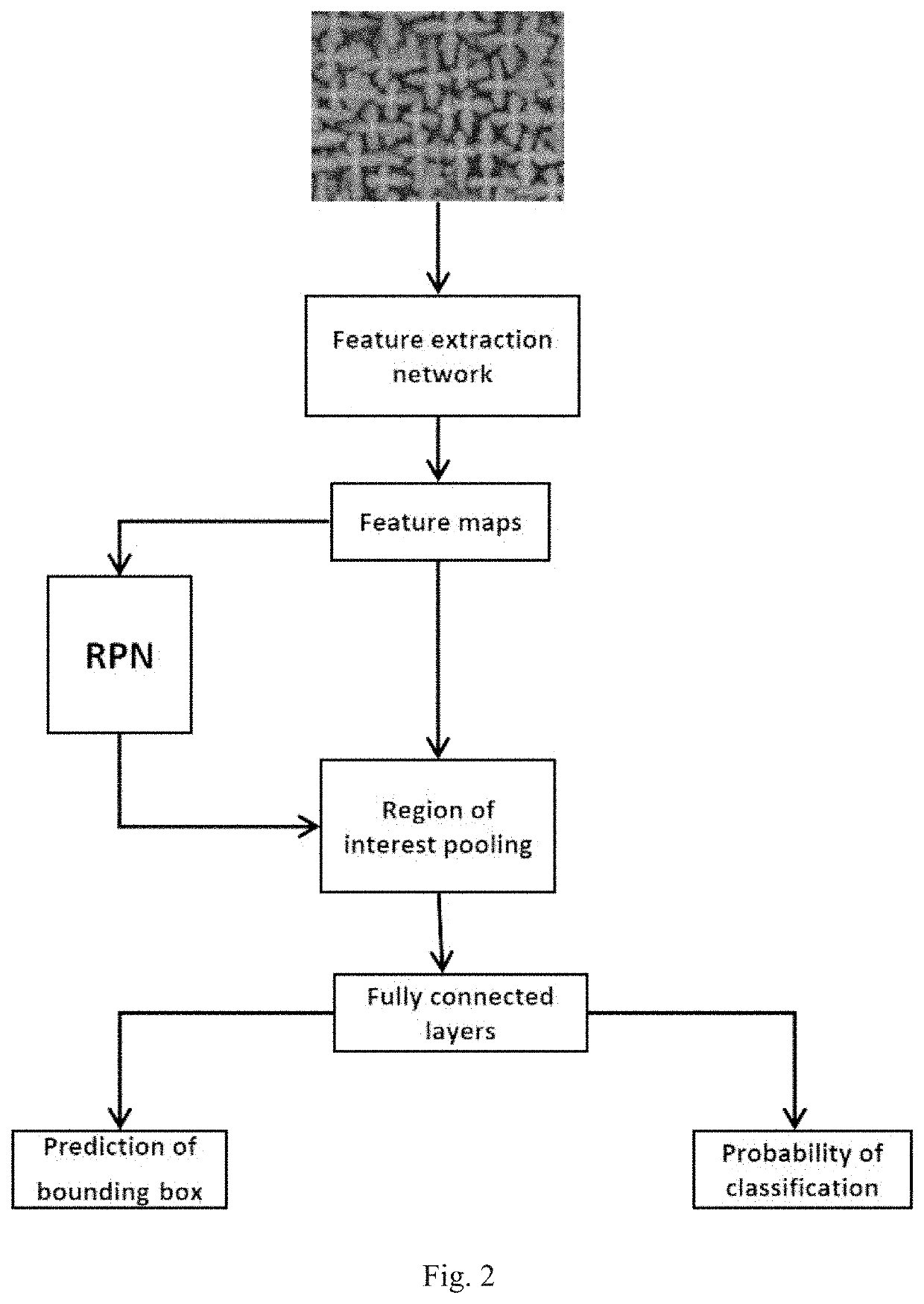

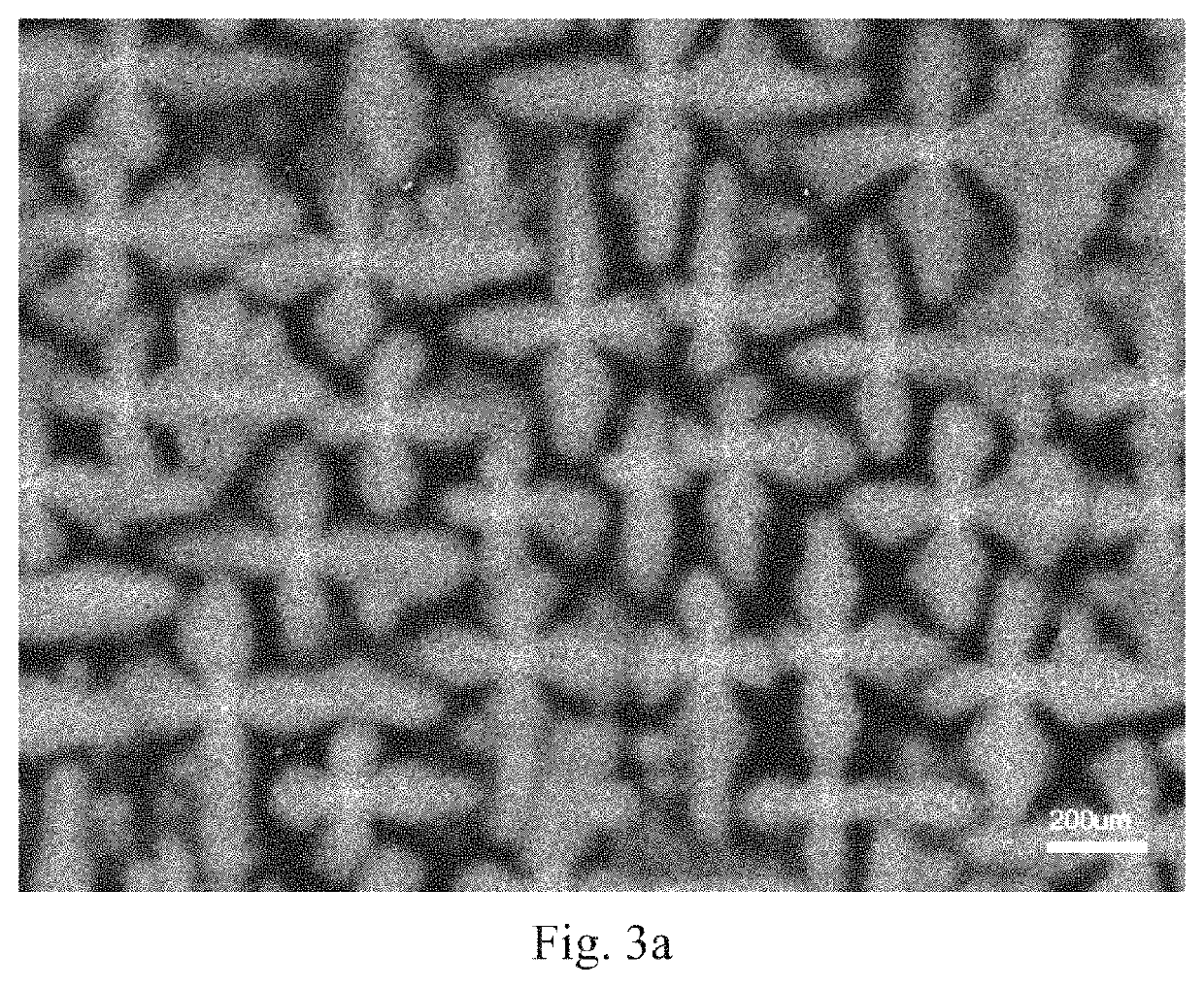

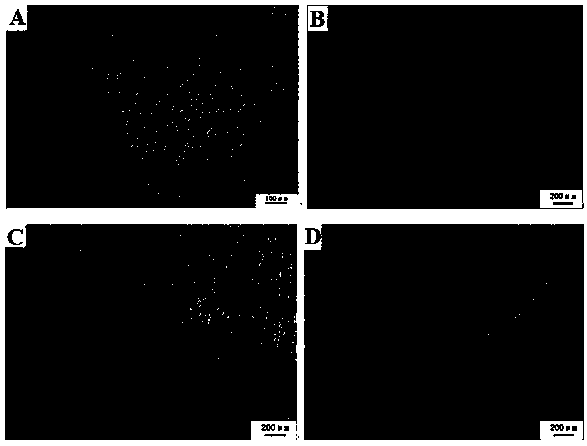

Method for automatic quantitative statistical distribution characterization of dendrite structures in a full view field of metal materials

ActiveUS20210063376A1Improve detection efficiencyHeavy workloadImage enhancementImage analysisFeature DimensionImaging processing

The invention belongs to the technical field of quantitative statistical distribution analysis for micro-structures of metal materials, and relates to a method for automatic quantitative statistical distribution characterization of dendrite structures in a full view field of metal materials. According to the method based on deep learning in the present invention, dendrite structure feature maps are marked and trained to obtain a corresponding object detection model, so as to carry out automatic identification and marking of dendrite structure centers in a full view field; and in combination with an image processing method, feature parameters in the full view field such as morphology, position, number and spacing of all dendrite structures within a large range are obtained quickly, thereby achieving quantitative statistical distribution characterization of dendrite structures in the metal material. The method is accurate, automatic and efficient, involves a large amount of quantitative statistical distribution information, and is statistically more representative as compared with the traditional measurement of feature sizes of dendrite structures in a single view field.

Owner:THE NCS TESTING TECH CO LTD

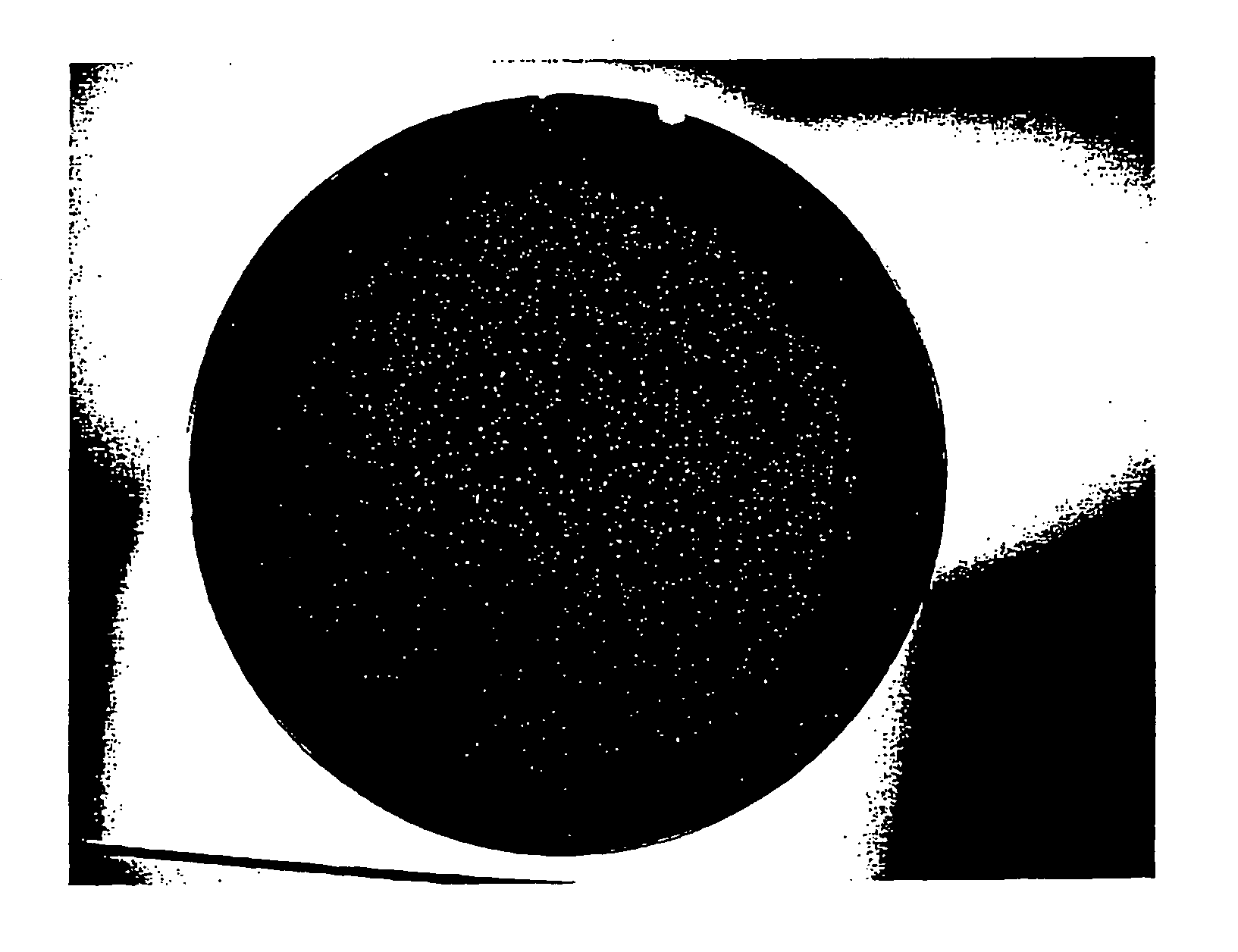

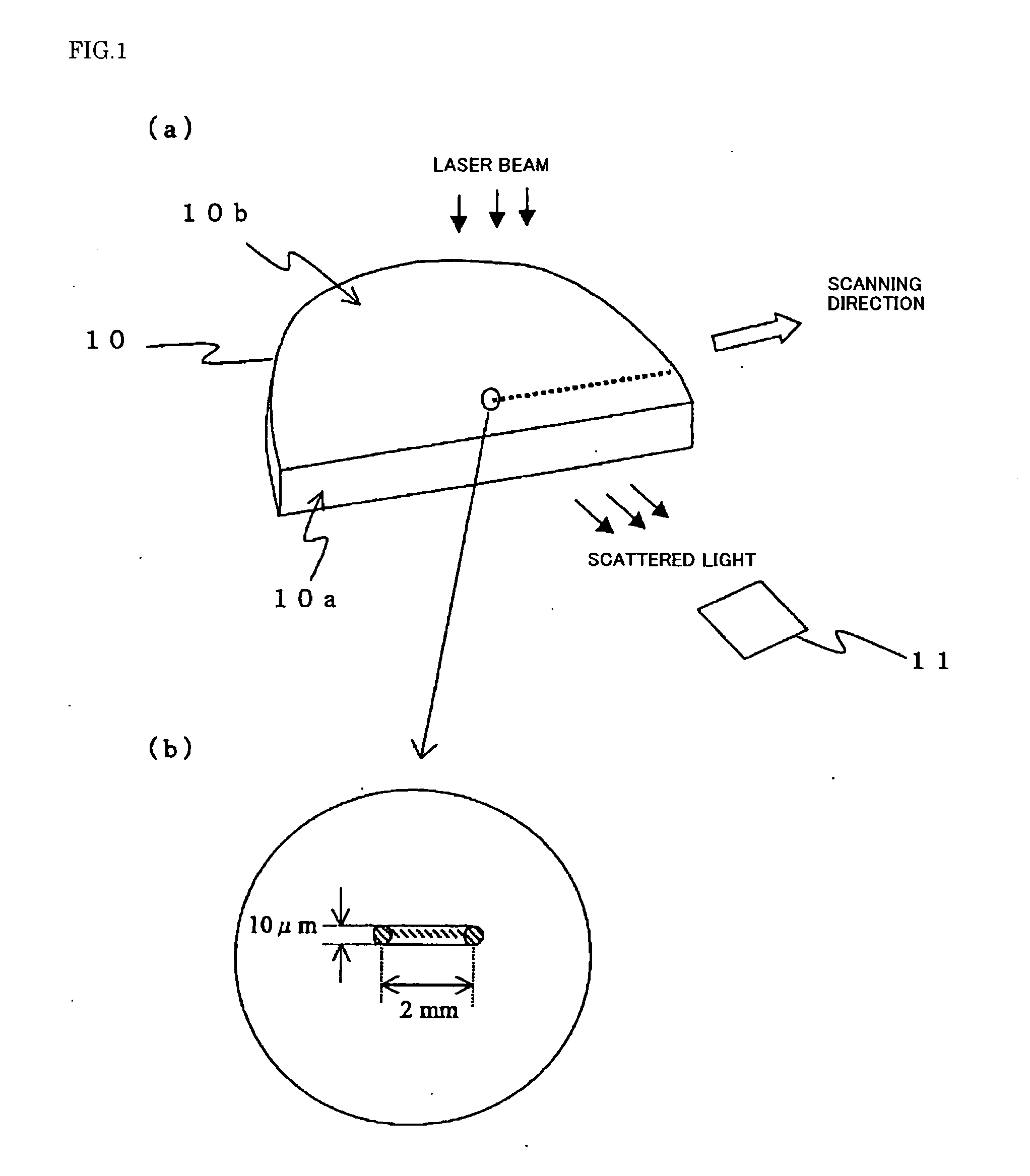

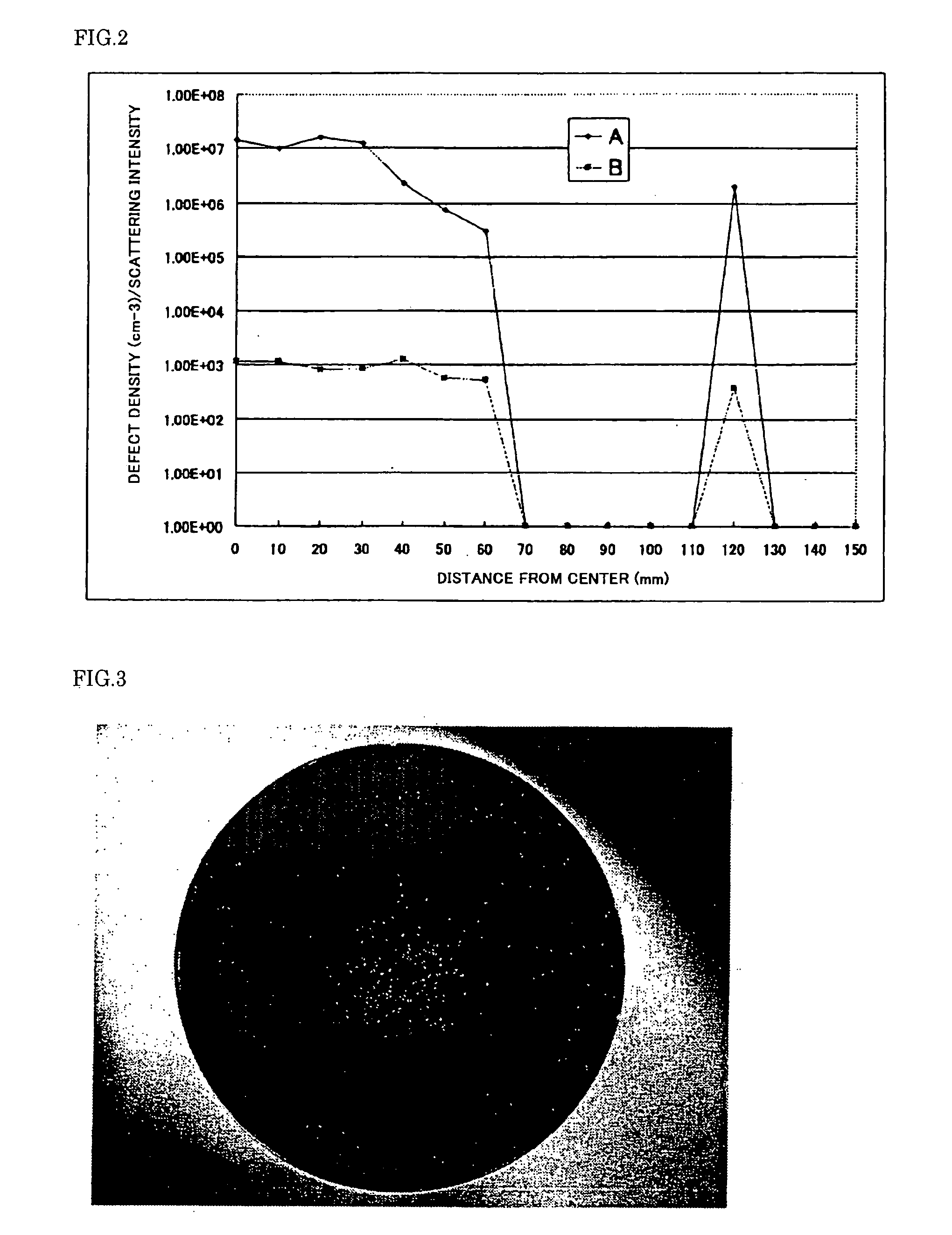

Evaluation Method for Crystal Defect in Silicon Single Crystal Wafer

InactiveUS20080153186A1Short timeLow costSemiconductor/solid-state device testing/measurementInvestigating crystalsLaser scatteringSingle crystal

The present invention provides an evaluation method for a crystal defect in a silicon single crystal wafer based on an infrared laser scattering tomograph method, wherein at least, the silicon single crystal wafer is irradiated with a laser beam, and light that enters the silicon single crystal wafer is scattered by a crystal defect, and the scattered light is detected to evaluate a Direct Surface Oxide Defect (DSOD) and a void defect smaller than the DSOD in the silicon single crystal wafer. As a result, the evaluation method for a crystal defect in a silicon single crystal wafer that can simply and precisely evaluate, e.g., a small DSOD, which can be conventionally evaluated based on a Cu deposition method alone, without requiring a wasteful cost.

Owner:SHIN-ETSU HANDOTAI CO LTD

Method and device for detecting crystal direction of silicon slice

The invention provides a method and device for detecting the crystal direction of a silicon slice. The method includes the steps that an image pickup device which comprises a light source and one or more image pickup probes rotates in different angular directions to irradiate the silicon slice, corresponding reflection strength is acquired, and a reflection curve of interested crystal particles in a polar coordinate system is drawn; pixel brightness extreme values are marked in the reflection curve, the normal directions of three or more faces of regular octahedrons of the crystal particles <111> are determined, then normal vectors of all the regular octahedrons are calculated, and therefore the crystal directions of the interested crystal particles can be calculated.

Owner:TRINA SOLAR CO LTD

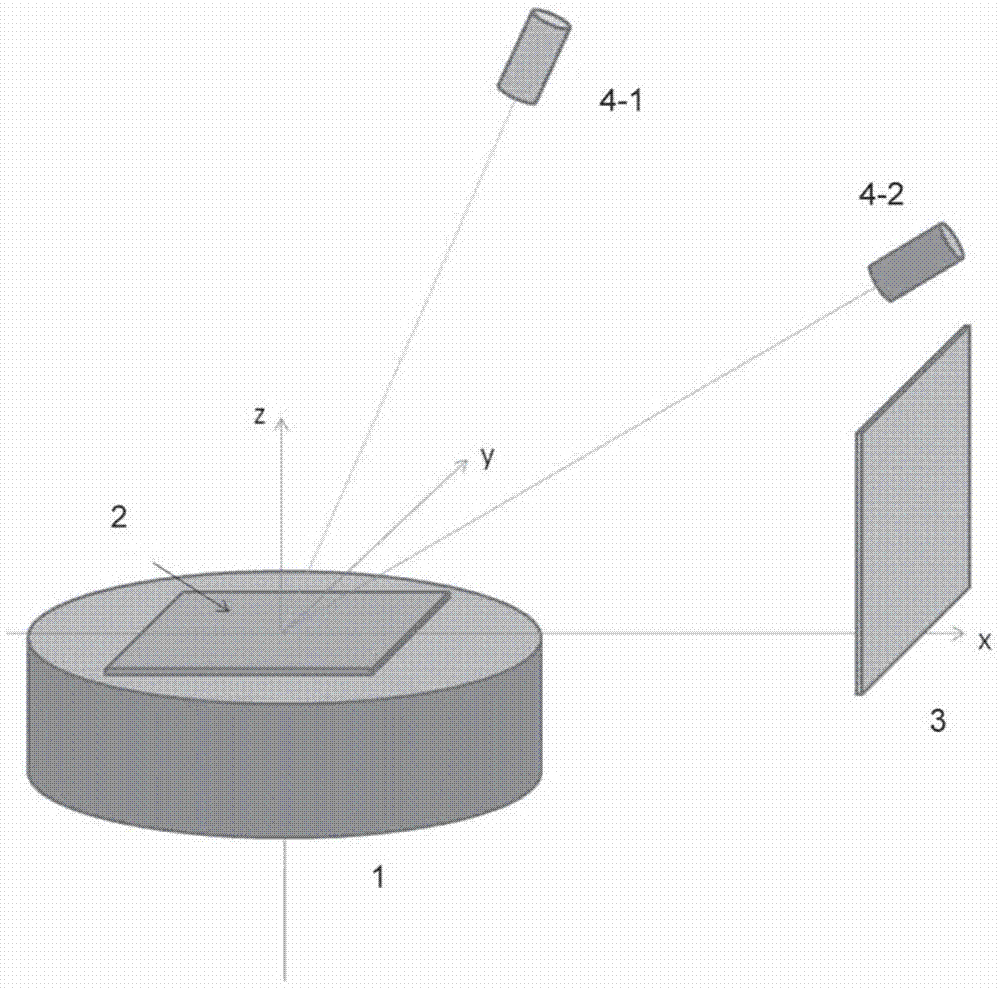

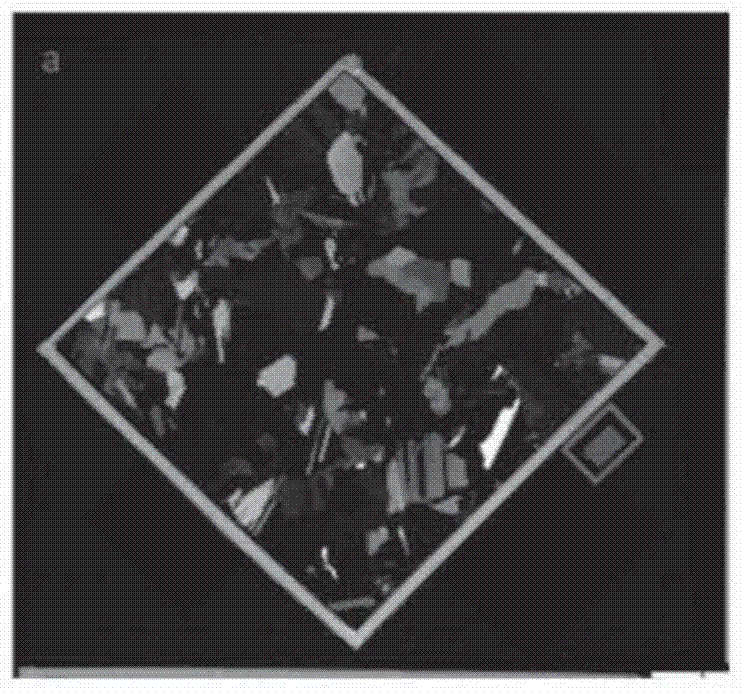

Monitoring method and apparatus for control of excimer laser annealing

ActiveUS9335276B2Investigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystallized layer dependent on the number of and energy density ED in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A microscope image of the illuminated area is made from light diffracted from the illuminated are by the periodic features. The microscope image includes corresponding periodic features. The ED is determined from a measure of the contrast of the periodic features in the microscope image.

Owner:COHERENT LASERSYST

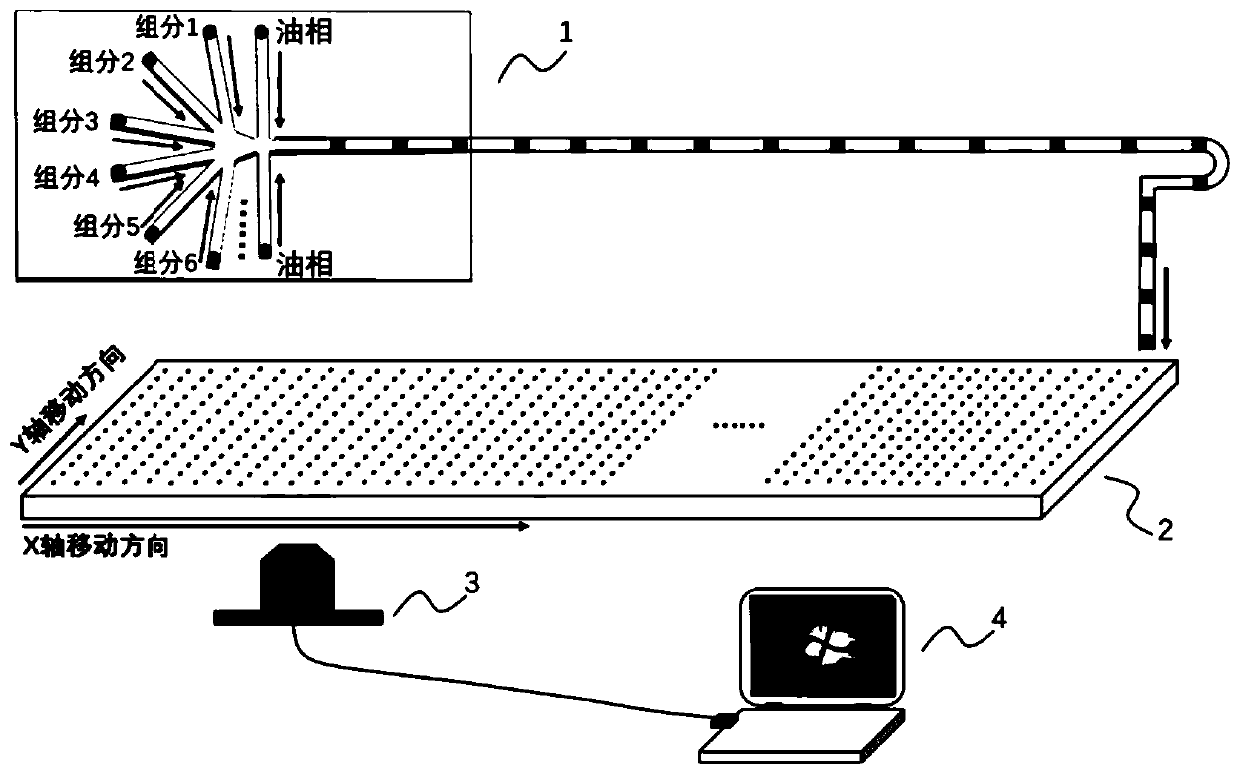

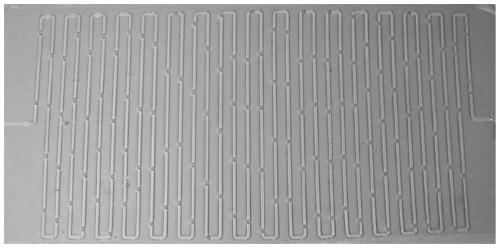

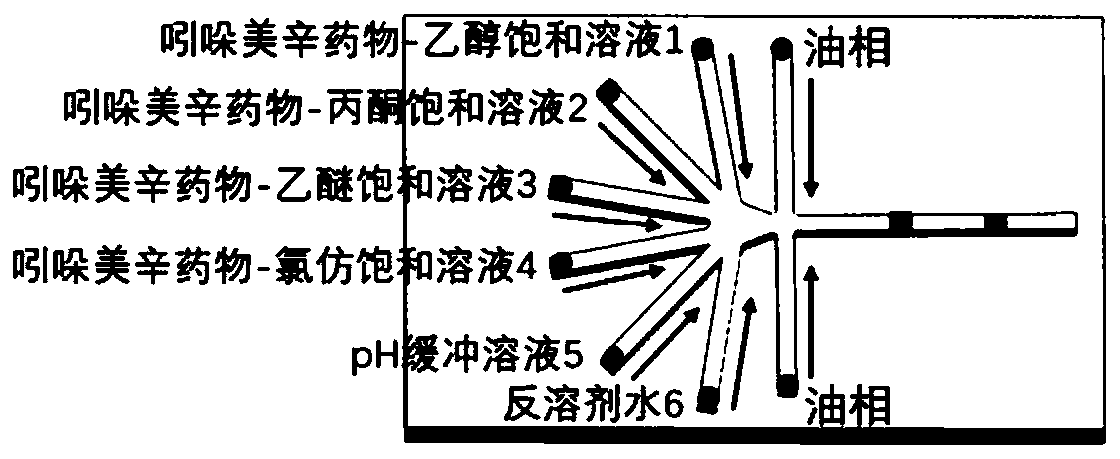

Ultrahigh-flux platform for screening crystal generation conditions and screening method

PendingCN111135883ANo cross contaminationReduce consumptionMaterial crystallisationMaterial analysis using wave/particle radiationCrystal morphologyMicrofluidics

The invention discloses an ultrahigh-flux platform for screening crystal generation conditions and a screening method. The platform comprises a micro-fluidic droplet chip, a micro-droplet collection chip and a characterization-analysis system, wherein the micro-fluidic droplet chip is used for generating crystallized droplets at ultrahigh flux; the micro-droplet collection chip is used for collecting the crystallized droplets generated by the micro-fluidic droplet chip; and after the micro-droplet collection chip collects the crystallized droplets, the characterization-analysis system characterizes and identifies the morphology of crystals in the crystallized droplets, and analyzes and screens out crystallization conditions corresponding to the optimal crystal morphology according to the characterized and identified morphology of the crystals. The ultrahigh-flux platform provided by the invention provides a good solution for rapid screening of crystal generation conditions. The screening method for screening the crystal generation conditions provided by the invention is based on the ultrahigh-flux platform, can quickly screen out excellent and stable crystallization conditions, andis convenient and accurate.

Owner:SUN YAT SEN UNIV

Fluorescent dendritic tags

A method of detecting a covert marking including applying a fluorescent ink to a dendritic structure to generate an ink-coated dendrite and imaging the ink-coated dendrite with a device to visualize the ink-coated dendrite. A method of detecting a covert marking on an object including applying UV light to an object including a dendritic structure and illuminating the dendritic structure with the UV light. A dendritic structure including a unique metallic structure at least partially coated with a fluorescent ink that is not visible to the naked eye in ambient light and is visible to the naked eye when exposed to UV light.

Owner:ARIZONA STATE UNIVERSITY

Method and apparatus for incorporating electrostatic concentrators and/or ion mobility separators with Raman, IR, UV, XRF, LIF and LIBS spectroscopy and/or other spectroscopic techniques

ActiveUS7838825B2Reliably and accurately detecting and identifyingSpectral/fourier analysisRadiation pyrometrySpectroscopyEngineering

The present invention provides a novel approach for reliably and accurately detecting and identifying airborne particles. This is done by providing a novel system which incorporates electrostatic concentrators and / or ion mobility separators with Raman, IR, UV, XRF, LIF and LIBS spectroscopy and / or other spectroscopic techniques.

Owner:AHURA SCI +1

Visualization device and method for multidirectional observation of hydrate generation and decomposition

ActiveCN107064145AAvoid high pressure and low temperature conditionsSolve the problem of water mistInvestigating crystalsTemperature controlAcquisition apparatus

The invention relates to a visualization device and method for multidirectional observation of hydrate generation and decomposition. The visualization device comprises a low-temperature constant-temperature control system, a normal-pressure visualization reaction device, a temperature acquisition apparatus and a CCD imaging system, wherein the normal-pressure visualization reaction device comprises a temperature control circulating tank, a reaction tank, a circulating liquid inlet and a circulating liquid outlet; the reaction tank is arranged in the temperature control circulating tank; the tank wall of the temperature control circulating tank is communicated with the circulating liquid inlet and the circulating liquid outlet; a two-layer organic glass window is arranged on one side tank wall of the reaction tank, and comprises an observation window and an organic glass window in turn from inside to outside; the observation window and the organic glass window are both made of organic glass. According to the visualization device and method provided by the invention, the two-layer organic glass window is adopted, and is totally closed inside, air is dry, and the heat conductivity is low; the temperature of the outer-layer organic glass is close to room temperature, and the problem of water mist is solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

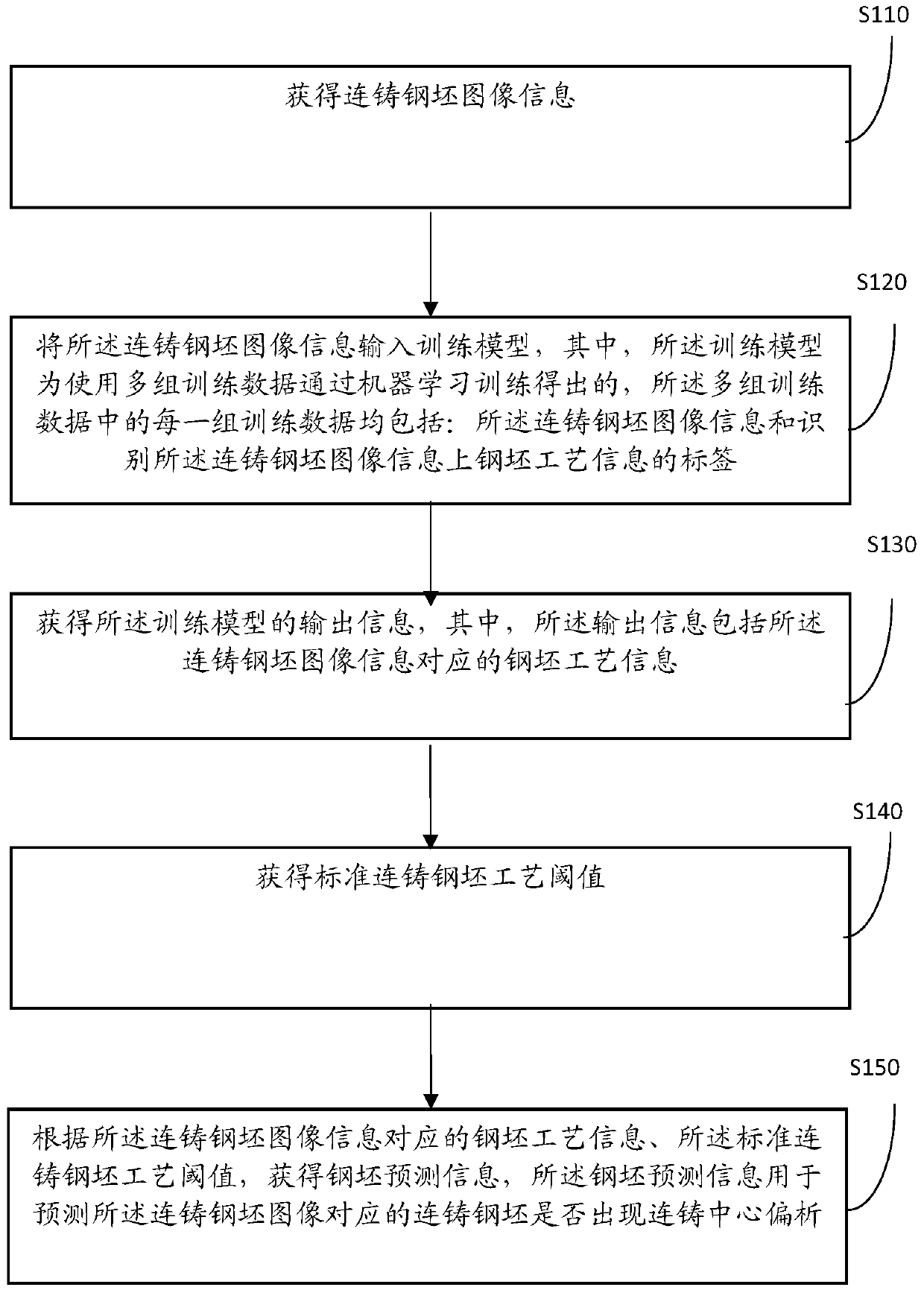

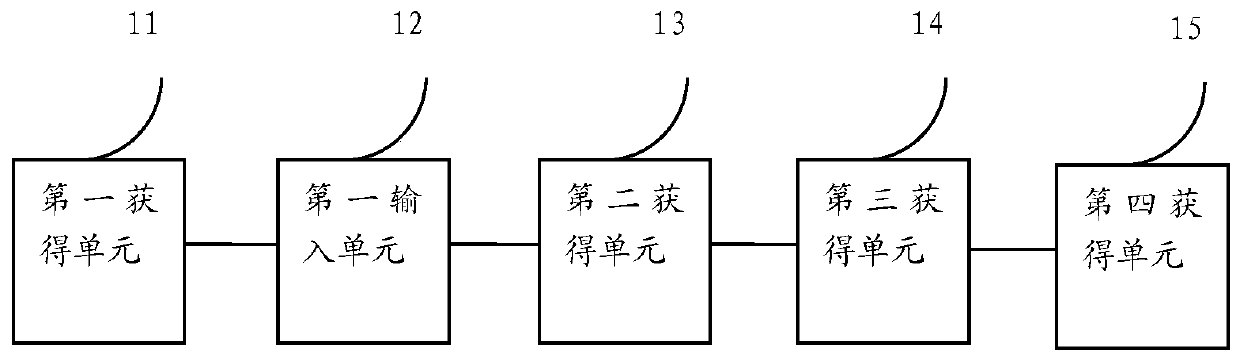

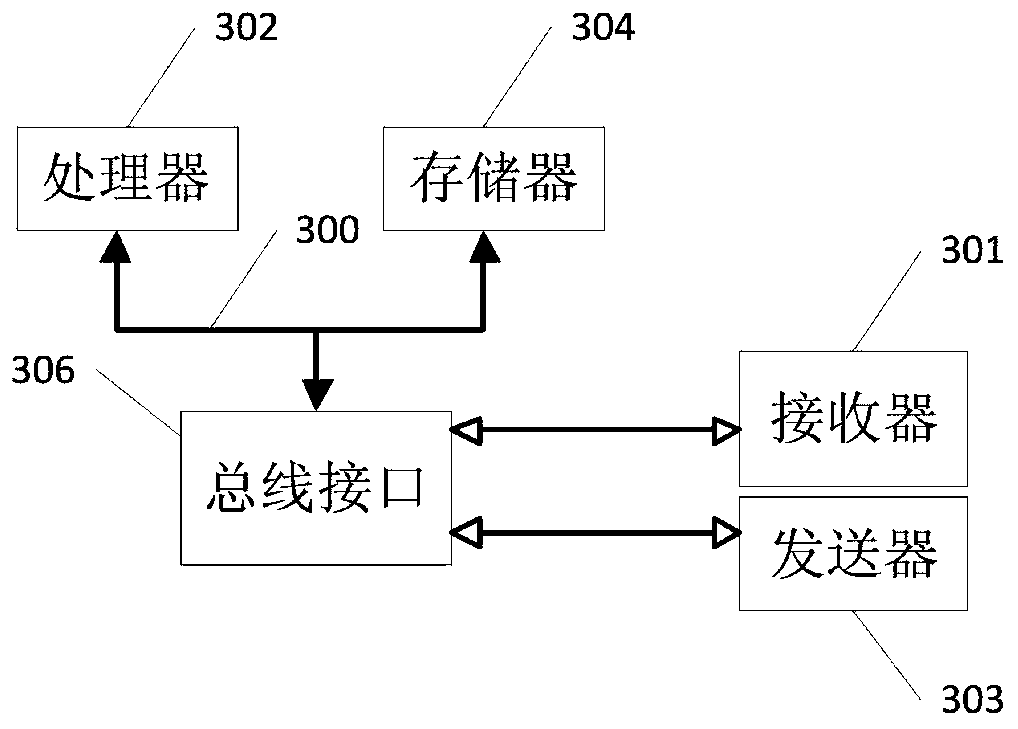

Prediction method and device for continuous casting center segregation

InactiveCN110490259AQuality improvementInhibition of segregationInvestigating crystalsCharacter and pattern recognitionPrediction methodsData processing

The invention provides a prediction method and device for continuous casting center segregation. The method comprise: obtaining continuous casting billet image information, and inputting the continuous casting billet image information into a training model, wherein the training model is obtained by training multiple sets of training data, and each set of training data comprises the continuous casting billet image information and a label for recognizing billet process information on the continuous casting billet image information; obtaining output information of the training model, wherein theoutput information comprises billet process information corresponding to the continuous casting billet image information; and according to the billet process information corresponding to the continuous casting billet image information and the standard continuous casting billet process threshold, obtaining billet prediction information, and predicting whether the billet corresponding to the continuous casting billet image is subjected to center segregation. The technical problems that in the prior art, a casual inspection mode is adopted, judgment cannot be conducted one by one, and center segregation of continuous casting billets cannot be predicted in advance are solved. The technical effects that intelligent data processing is conducted on all steel billets in the continuous casting equipment, the risk of center segregation is predicted in time, the accuracy is high, and the quality of the steel billets is improved are achieved.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

Etchant for displaying 690 nickel-base alloy deposited metal grain boundary and etching method thereof

ActiveCN110389129ALow costComposition is stableInvestigating crystalsPreparing sample for investigationLiquid wasteProcess quality

The invention discloses an etchant for displaying a 690 nickel-base alloy deposited metal grain boundary and an etching method thereof. The etchant comprises ferric chloride, EDTA, deionized water andconcentrated hydrochloric acid. The surface of the 690 nickel-based alloy deposited metal surface is successively wiped with the etchant and a nitric acid ethanol solution. Thus, it is possible to intuitively observe that the surface of a sample changes from bright to frosty during an etching process, and the weld bead can be clearly observed by naked eyes in order to better control the degree ofcorrosion, completely and clearly show the grain boundaries of the deposited metal sample grains, and avoid the covering by corrosion products. The etched different grains have different shades due to different orientations. The columnar crystal structure can be clearly observed and the grain boundaries are clear and complete. The etchant is made of simple raw materials, nontoxic, environmentallyfriendly, convenient in liquid waste disposal, low in cost, and stable and easy to control in a reaction process. The etching method is simple and easy to use, and provides detection basis for the process quality control, the process plan and the quality analysis of nuclear welding deposited layer, and has very important practical significance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

Method and apparatus for high-throughput inspection of large flat patterned media using dynamically programmable optical spatial filtering

InactiveUS20060186361A1Reduce resolutionAutomatic control devicesBeam/ray focussing/reflecting arrangementsSpatial light modulatorSpatial fourier transform

In an inspection system for planar objects having periodic structures, programmable optical Fourier filtering in the focal plane of a telecentric lens system is used to directly identify physical phenomena indicative of non-periodic defects. Lens assemblies and a coherent optical source are used to generate and observe a spatial Fourier transform of a periodic structure in the Fourier plane. Optical Fourier filtering (OFF) is performed in the focal plane using an electrically programmable and electrically alignable spatial light modulator. The spatial light modulator with high signal to noise ratio is electrically reconfigurable according to a feedback-driven, filter construction and alignment algorithm. The OFF enhances any non-periodic components present in the Fourier plane and final image plane of the object. A system having a plurality of inspection channels provides high-throughput inspection of objects with small non-periodic defects while maintaining high detection sensitivity.

Owner:PHOTON DYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com