Method for displaying original austenite grain boundary of 85Cr2MnMo liner steel

A technology of austenite grain boundary and lining plate, which is applied in the field of heat treatment quality inspection, can solve problems such as unsatisfactory display effect, and achieve the effect of clear display effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

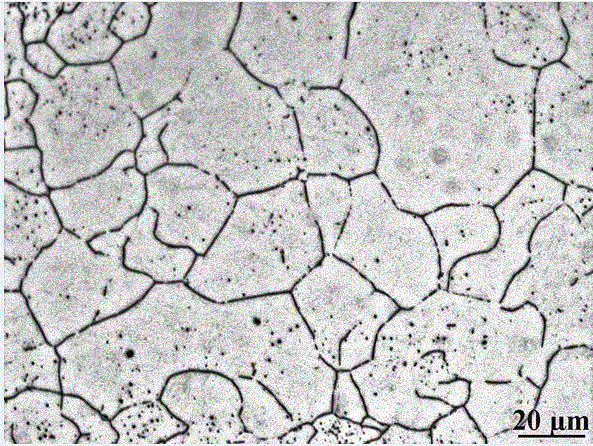

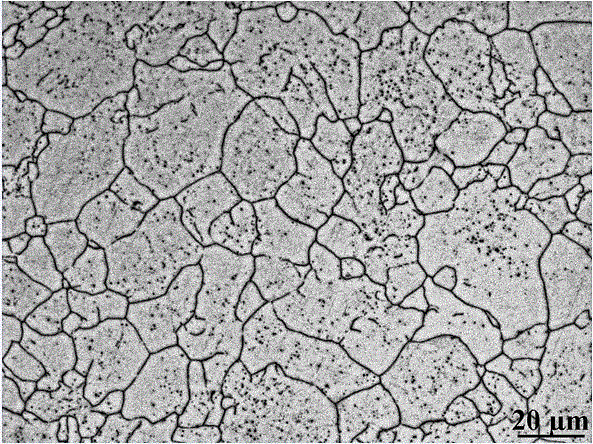

Embodiment 1

[0021] The chemical composition of the sample in this example is C: 0.83%, Si: 0.43%, Mn: 0.77%, Cr: 1.91%, Mo: 0.34%, Ni: 0.12%, P: 0.035%, S: 0.028%, The rest is Fe and unavoidable impurities. Specific steps are as follows:

[0022] A. sample. Cut two heat treatment test blocks with a size of 10×10×15mm and three thermal expansion samples with a size of ϕ4×10mm from an industrially produced liner. The roughness of the two ends of the thermal expansion sample is Ra0.8, and the two ends must be parallel to each other and perpendicular to the axis of the round rod.

[0023] B. Measure the critical point. According to the parameters stipulated in the standard "YB / T 5127-93" for determining the critical point of steel by dilation method, its Accm (cementite and carbide are completely dissolved into austenite) temperature is measured to be about 835 °C.

[0024] C. Quenching treatment. Put the samples into the heating furnace in batches and place them as close as possible ...

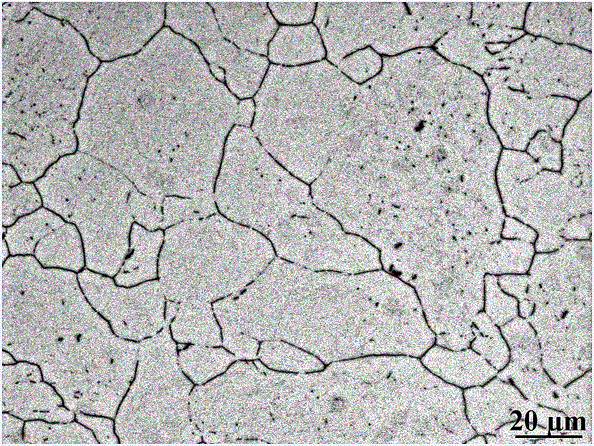

Embodiment 2

[0027] The chemical composition of the sample in this example is C: 0.79%, Si: 0.39%, Mn: 0.85%, Cr: 1.90%, Mo: 0.36%, Ni: 0.10%, P: 0.029%, S: 0.014%, Nb: 0.1%, the rest is Fe and unavoidable impurities. Specific steps are as follows:

[0028] A. Sample preparation. Cut two heat treatment test blocks with a size of 10×10×15mm and three thermal expansion samples with a size of ϕ4×10mm from an industrially produced liner. The roughness of the two ends of the thermal expansion sample is Ra0.8, and the two ends must be parallel to each other and perpendicular to the axis of the round rod.

[0029] B. Measure the critical point. According to the parameters stipulated in the standard "YB / T5127-93" for determining the critical point of steel by dilation method, its Accm (cementite and carbide are completely dissolved into austenite) temperature is measured to be about 835 °C.

[0030] C. Quenching treatment. Put the samples into the heating furnace in batches, and place them as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com