Wafer inspection method and wafer inspection apparatus

An inspection method and wafer technology, applied in measurement devices, optical devices, testing crystals, etc., can solve problems such as defective products and wafer cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

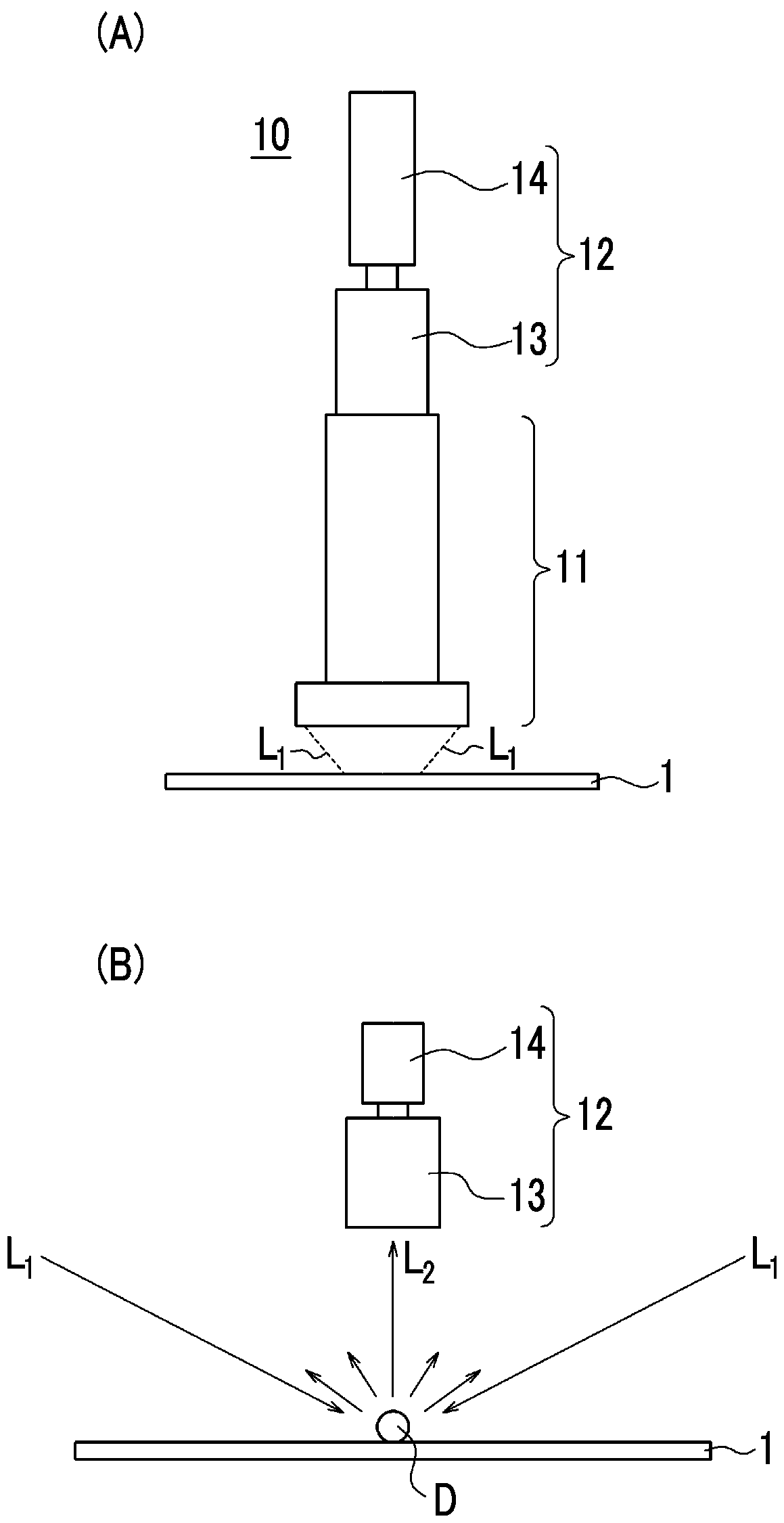

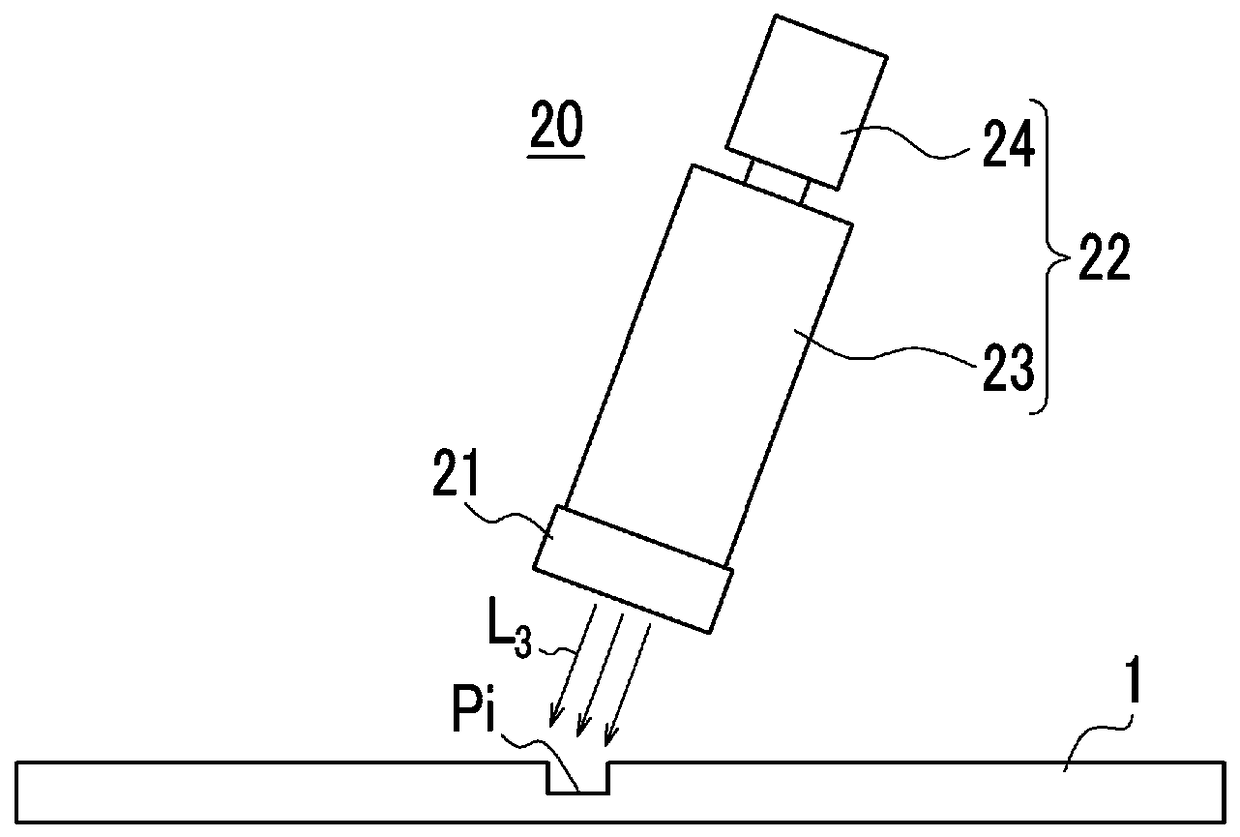

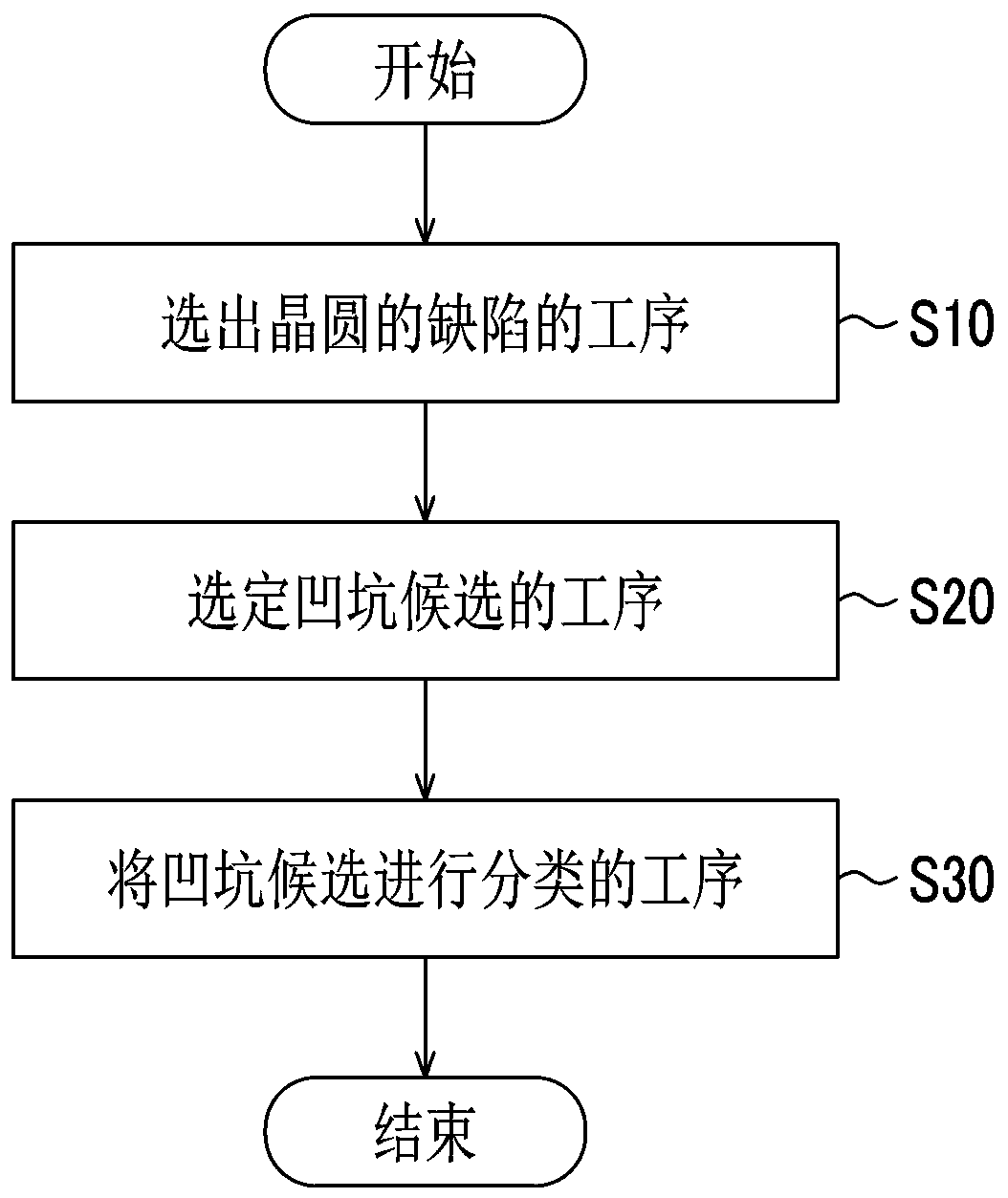

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings. image 3 It is a flowchart of a wafer inspection method based on an embodiment of the present invention, while using the figure 1 The first optical system 10 described in and use Figure 4 The second optical system 20 described later is performed to determine the presence or absence of pits. in addition, Figure 7 It is a schematic diagram of a wafer inspection apparatus 100 according to an embodiment of the present invention, and the wafer inspection apparatus 100 has the above-mentioned first optical system 10 and second optical system 20 .

[0032] (Wafer inspection method)

[0033] like image 3 and figure 1 , Figure 4 , Figure 7 As shown, the wafer inspection method based on one embodiment of the present invention includes: step S10, using the first optical system 10 vertically arranged with respect to the surface of the wafer 1 and equipped with an annular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com