Ultrahigh-flux platform for screening crystal generation conditions and screening method

A conditional and high-throughput technology, applied in the field of microfluidic screening, can solve the problems of time-consuming, low throughput, low efficiency and throughput, and achieve the effects of low reagent consumption, large screening range and fast experimental speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

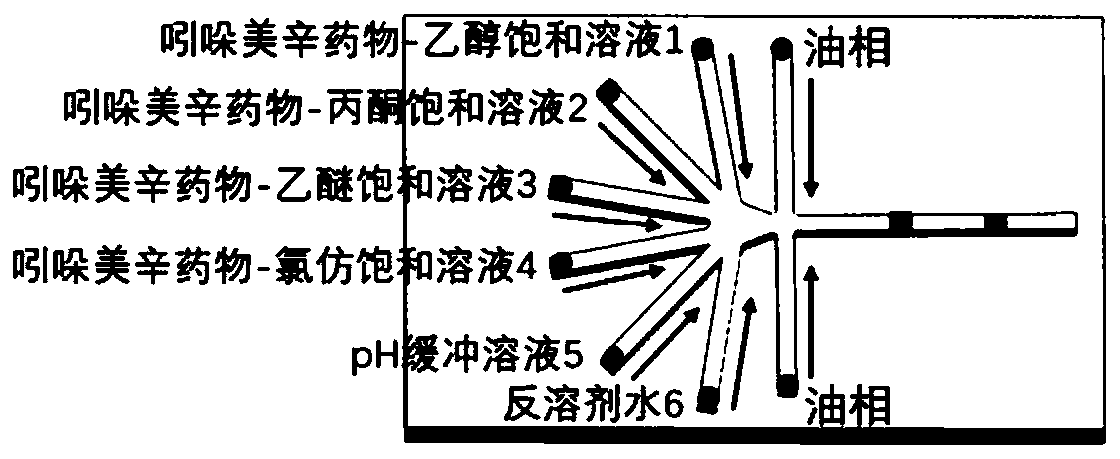

[0054] The crystallization condition screening of drug crystals-indomethacin drug crystals, the specific steps are as follows:

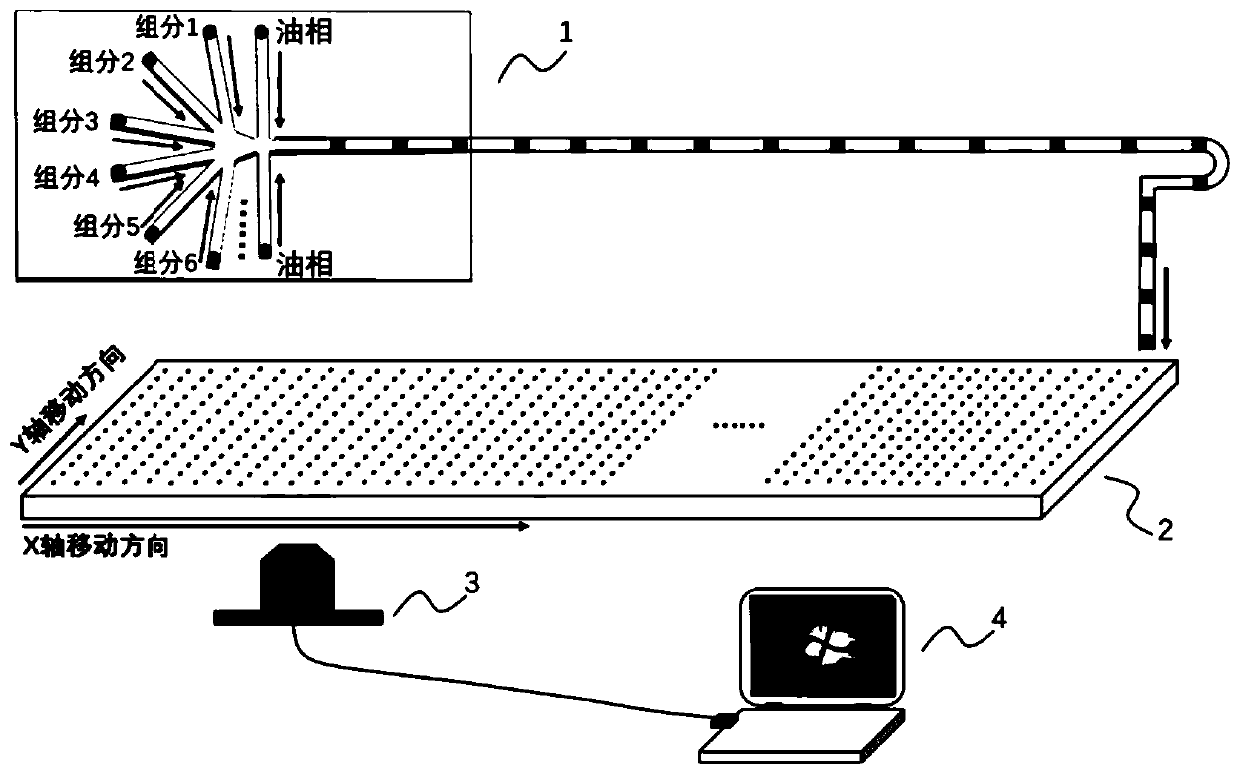

[0055] S1. Microfluidic droplet ultra-high-throughput droplet generation experiment

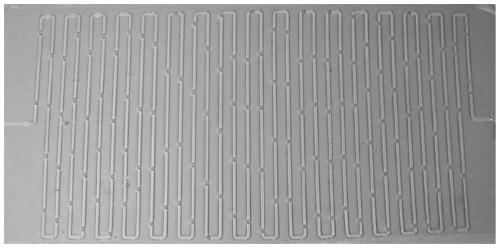

[0056] S11. Fabrication of the microfluidic droplet generation chip: according to the co-flow focusing microchannel structure of the microfluidic droplet chip, the microfluidic droplet chip is fabricated, and the chip manufacturing method is selected from the molding method;

[0057] Preparation of microfluidic droplet chip: using PDMS (polydimethylsiloxane) and aluminum sheet as materials;

[0058] (1) Use SolidWorks2017 software to design the co-flow focusing microchannel structure generated by droplets, and then use a high-resolution and high-power laser engraving machine to engrave the channel structure on the aluminum sheet, and control the engraving depth of the channel by grasping the engraving time. Polishing treatment reduces the surface roughness of the a...

Embodiment 2

[0077] The crystallization condition screening of inorganic crystals-calcium carbonate crystals, the specific steps are as follows:

[0078] S1. Microfluidic droplet ultra-high-throughput droplet generation experiment

[0079] S11. Fabrication of the microfluidic droplet generation chip: the fabrication method is the same as that of S11 in Example 1.

[0080] S12, Preparation of 0.5 mol / L and 0.05 mol / L calcium chloride solution: Weigh 5.55 g of calcium chloride powder, place it in a 100 mL volumetric flask, add water to make it 100 ml, and place it in an ultrasonic cleaner Sonicate for 10 min to dissolve calcium chloride completely, and prepare 0.5 mol / L calcium chloride solution. Weigh 0.555 g of calcium chloride powder, place it in a 100 mL volumetric flask, add water to make the volume to 100 ml, then place it in an ultrasonic cleaner for 10 minutes to dissolve calcium chloride completely, and prepare 0.05 mol / L chlorine calcium solution.

[0081]S13, Preparation of 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com