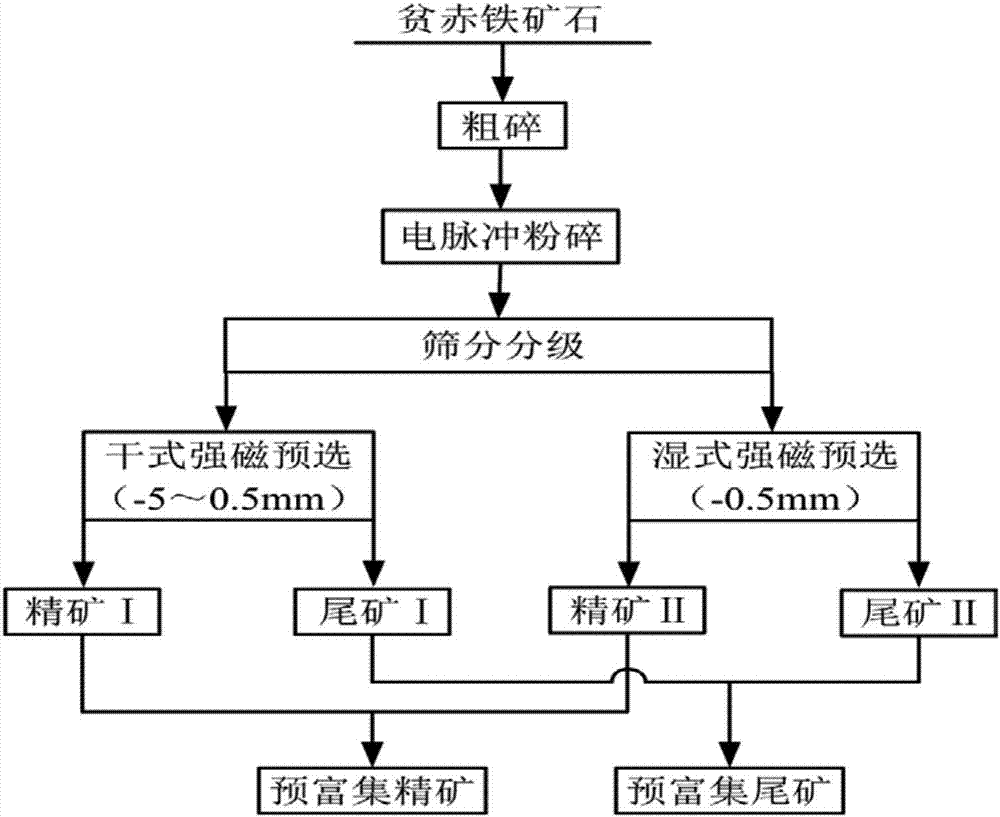

High-voltage electric pulse selective pulverizing and pre-enriching method for lean hematite ores

A high-voltage electric pulse and pre-enrichment technology, applied in chemical instruments and methods, solid separation, filtration, etc., can solve the problem of poor hematite pre-enrichment without considering the ore crushing process, poor selective dissociation effect of ore It is difficult to further improve the set index and achieve the effect of increasing the dissociation degree of the monomer, benefiting energy consumption and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Use lean hematite ore with an iron grade of 20%;

[0034] The ore is roughly crushed to a particle size of -30mm by a jaw crusher;

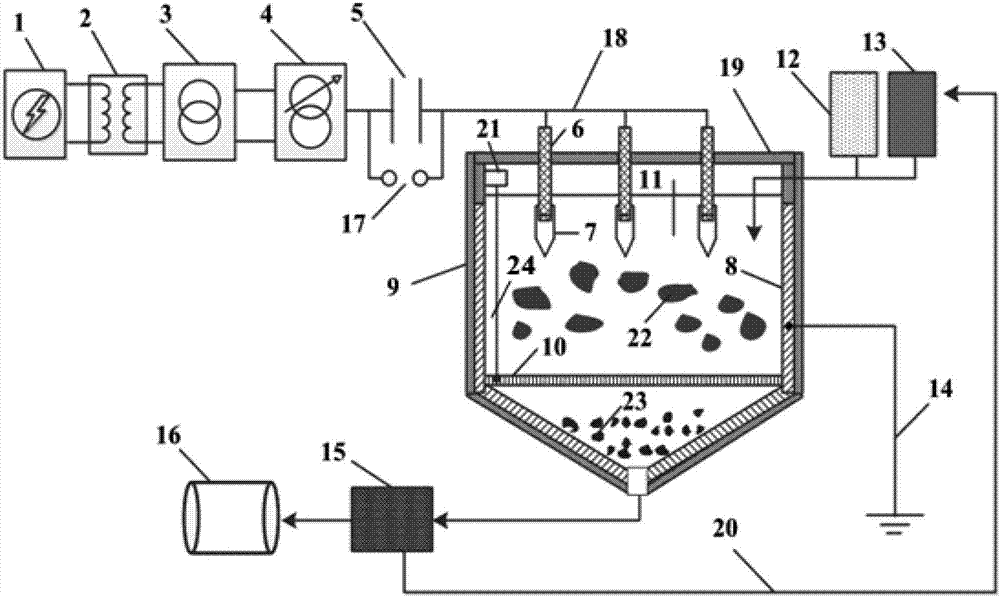

[0035] Under the conditions of voltage 150kV, frequency 5Hz, and electrode spacing 25mm, the coarsely crushed material with a particle size of -30mm is crushed to a particle size of -5mm by a high-voltage pulse crusher;

[0036] Use a sieve with a sieve hole of 0.5mm to sieve the -5mm electric pulverized material into -5 ~ +0.5mm particle size material and -0.5mm particle size material;

[0037] The material with a particle size of -5 ~ +0.5mm is subjected to dry strong magnetic separation through a roller permanent magnet strong magnetic separator with a magnetic field strength of 950kA / m to obtain pre-enriched concentrate I and tailings I;

[0038] The material with a particle size of -0.5mm is subjected to wet strong magnetic separation through a vertical ring strong magnetic separator with a magnetic field strength of 400kA / m to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com