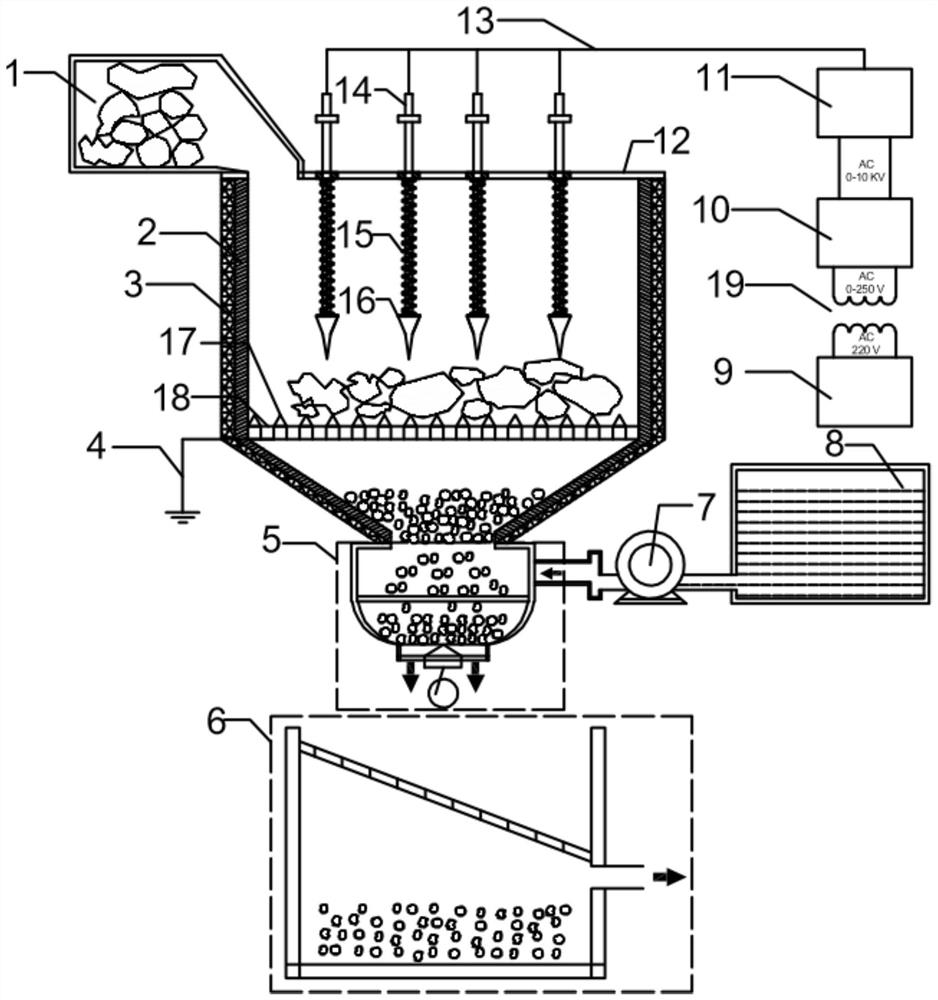

A method for pretreatment of tourmaline electric pulse by using high-voltage electric pulse device

A high-voltage electric pulse and device pair technology is applied in the field of electric pulse pretreatment of tourmaline by using a high-voltage electric pulse device, which can solve the problems of increased cost of tourmaline, long grinding time, low efficiency, etc. efficiency, short processing time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

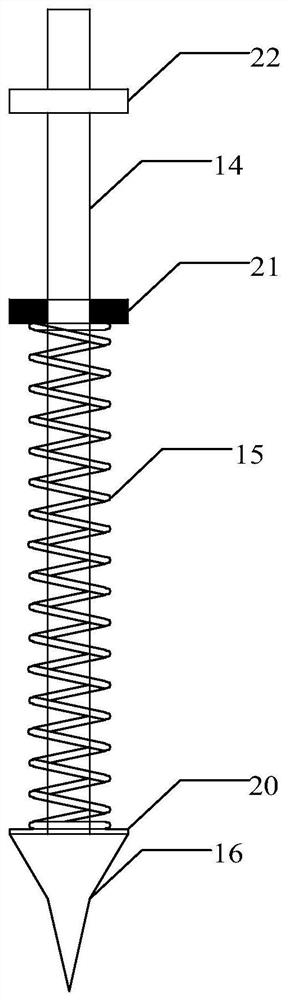

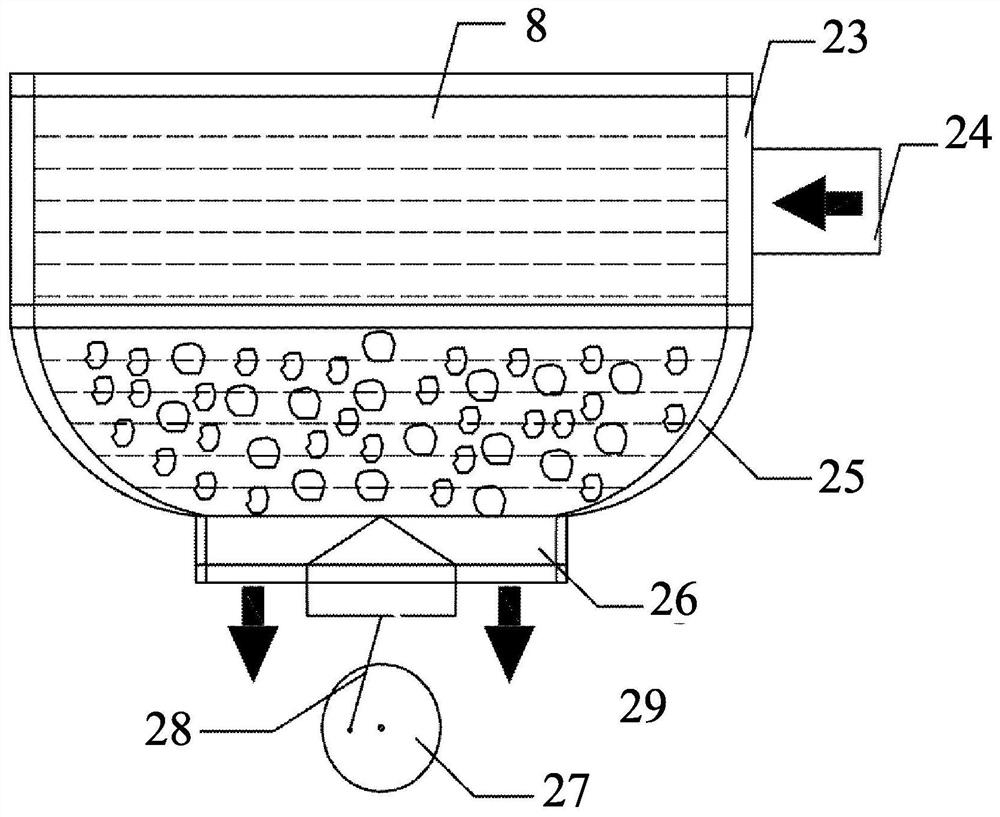

Method used

Image

Examples

Embodiment 1

[0080] The tourmaline raw ore used comes from Chifeng, Inner Mongolia, and the chemical elements are shown in Table 1 by mass percentage;

[0081] Table 1

[0082] components B 2 o 3

SiO 2

al 2 o 3

TF MgO CaO Na content / % 7.27 50.05 18.60 11.37 3.33 1.76 0.95 components TiO 2

FeO P K S Burn out content / % 0.84 0.25 0.078 0.058 <0.004 1.98

[0083] The main content of tourmaline raw ore is SiO 2 , accounting for 50.05%, followed by Al 2 o 3, accounting for 18.60%; total iron content is 11.37%, of which magnetic iron accounts for 0.25%, B 2 o 3 The content of magnesium oxide is 7.27%, and the content of magnesium oxide is 3.33%. The scanning electron microscope analysis results of the ore are as follows: Figure 8 and Figure 9 shown;

[0084] The method is:

[0085] Start the water pump so that water continuously enters the pulsating insulation cylinder of the pulsation device and is...

Embodiment 2

[0098] The tourmaline raw ore used comes from Xinjiang Altai, the particle size is 2-12mm, the color is dark gray, and the chemical formula is NaFe 3 al 6 Si 6 o 18 (BO 3 ) 3 (OH) 4 ;Using EPMA-1720 electronic probe to detect the chemical composition of the sample, the accelerating voltage is 15kV, the beam current is 2×10-8, and the beam spot diameter is 0.5μm; the chemical composition is shown in Table 2 by mass percentage;

[0099] Table 2

[0100] main component SiO 2

al 2 o 3

MgO TF content / % 38.45 29.67 9.89 3.29

[0101] The main component of ferrite tourmaline is SiO 2 、Al 2 o 3 , MgO and FeO;

[0102] Method is with embodiment 1, and difference is:

[0103] The processing time of ore subjected to high-voltage electric pulse is 30 minutes, and the grinding time is 30 minutes.

[0104] Laser particle size detection and scanning electron microscope analysis were carried out on the tourmaline powder obtained by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com