A high-voltage electric pulse pretreatment method for strengthening magnetite crushing and sorting

A high-voltage electric pulse and magnetite technology, applied in the field of high-voltage electric pulse pretreatment, strengthening the crushing and sorting of magnetite, can solve the problems of fine embedded particle size, large energy consumption, and many associated components, etc. Achieve the effect of increasing the content of useful minerals, increasing the content of fine particles, and increasing the degree of monomer dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

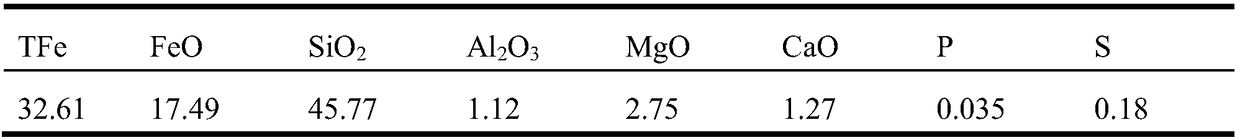

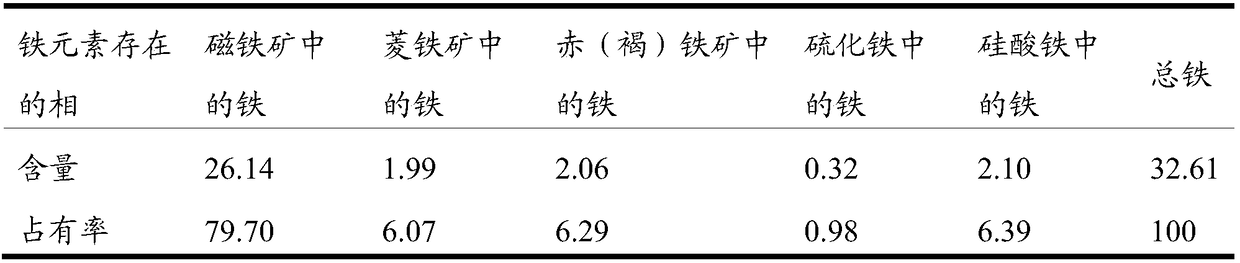

[0026] The ore sample used in this embodiment is Dagushan magnetite, and its main chemical composition is shown in Table 1. It can be seen from Table 1 that the valuable element in the raw ore is iron, the grade of TFe is 32.61%, and the content of FeO is 17.49%; the main impurity is SiO2, accounting for 45.77%; the content of harmful impurities S and P is low. The chemical phase analysis of raw ore Fe element is shown in Table 2. From Table 2, it can be seen that iron in the ore mainly exists in the form of magnetite, and the iron occupancy rate in magnetite reaches 79.70%, followed by siderite and red (brown) iron ore. It exists in the form of iron silicate and a small amount in the form of iron sulfide.

[0027] Table 1 Chemical composition analysis of raw ore / %

[0028]

[0029] Chemical phase analysis results / % of iron element in table 2 ore

[0030]

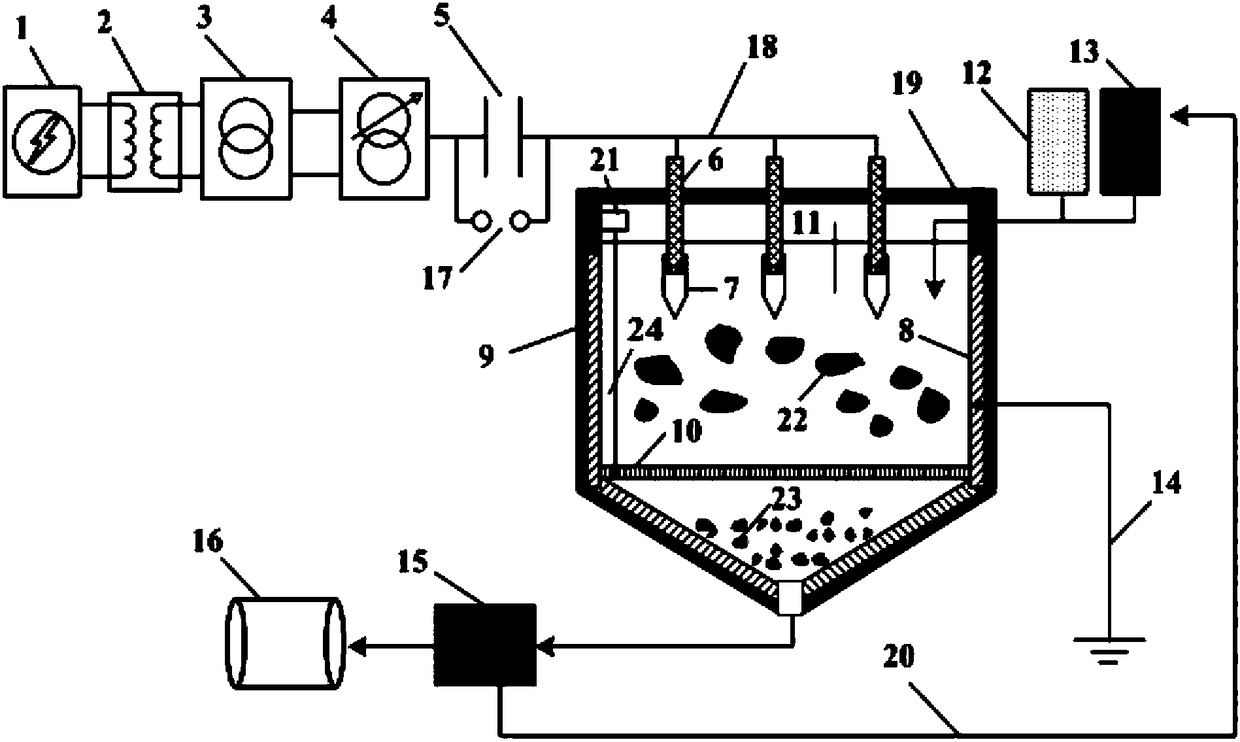

[0031] Add the magnetite ore of the above composition into the high-voltage electric pulse crushing device, and o...

Embodiment 2

[0038] The ore sample used in this example is taken from the mixed magnetic concentrate of the ore dressing plant of Anqian Mining Industry Co., Ltd., and its main chemical composition is shown in Table 4. It can be seen from Table 4 that the mineral composition of the ore sample is relatively simple. The main iron-containing minerals are magnetite and hematite, while the gangue minerals are mainly quartz, with a TFe grade of 47.70% and a SiO2 content of 33.012%. The content of other minerals with industrial value is very low, and the utilization value is not great.

[0039] Table 4 Analysis of raw ore chemical composition / %

[0040]

[0041] Raw ore TFe grade is the magnetite of 47.70%, adopts the same process and parameter of embodiment 1 to carry out test production, analyze the productive rate of untreated common ore product and the small particle magnetite product that is processed through high-voltage electric pulse ore crushing device , grade, and three indicators o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com