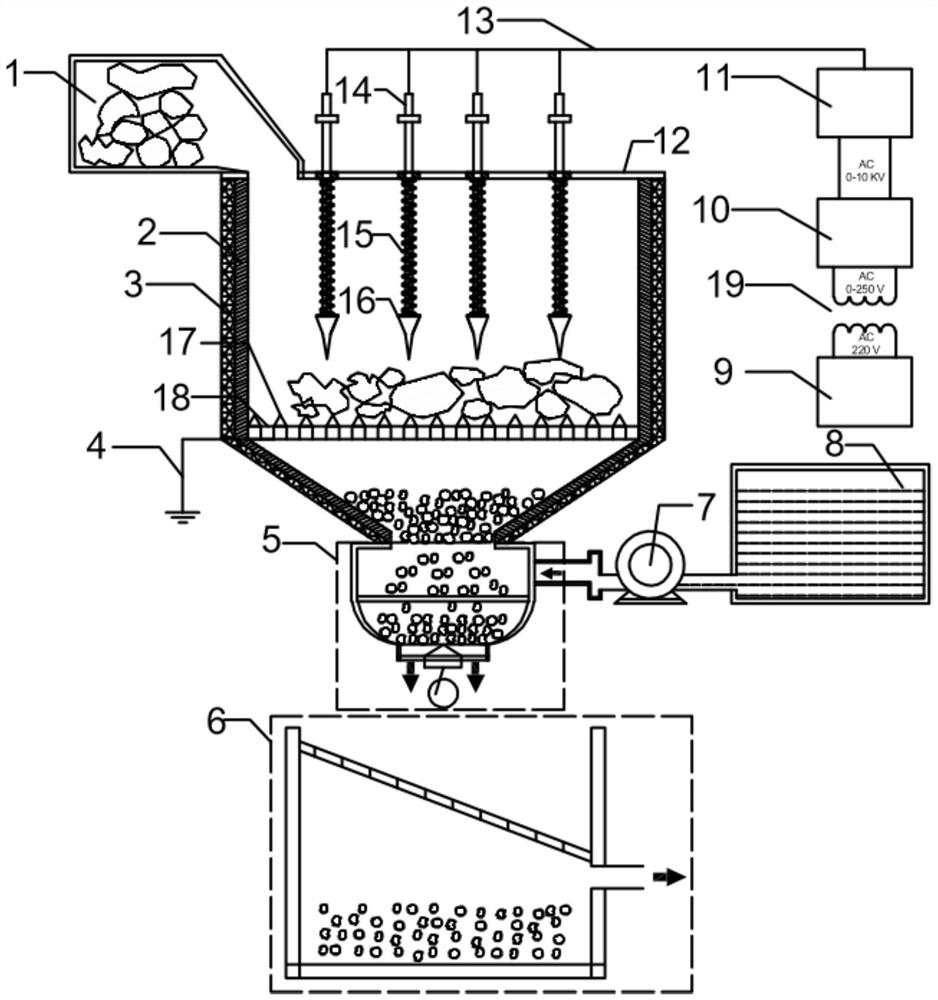

A high-voltage electric pulse pretreatment method for strengthening chalcopyrite crushing and sorting

A high-voltage electric pulse, chalcopyrite technology, applied in the field of mineral processing, can solve the problem that useful minerals and gangue minerals cannot be effectively separated, and achieve the effects of reducing the ineffective electric crushing process, ensuring the discharge channel, and improving the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The chalcopyrite ore sample adopted is a high-magnesium copper ore in Jinchuan, and its main chemical composition is shown in Table 1 by mass percentage;

[0072] Table 1

[0073] element Cu Ni Fe MgO CaO SiO 2

al 2 o 3

content 0.33 0.23 10.99 29.11 3.26 36.16 2.28 element S Na 2 o

K 2 o

TiO 2

Cr Pt* Pd* content 2.37 0.39 0.29 0.32 0.22 <0.02

<0.03

[0074] Chemical phase analysis results are shown in Table 2 by mass percentage;

[0075] Table 2

[0076] form of copper Gallbladder free copper oxide bound copper oxide Sulfide and others sum content / % <0.01

<0.01

<0.01

0.32 0.33 Proportion / % 1.01 1.01 1.01 96.96 100

[0077] It can be seen from the table that copper and nickel in the ore are the main valuable elements, and the content of the harmful impurity gangue MgO is as high as 29.11%; the content of the associated benefic...

Embodiment 2

[0095] The chalcopyrite ore sample adopted is the raw ore provided by a certain copper mine in Yunnan, and the chemical composition is as shown in Table 4 by mass percentage;

[0096] Table 4

[0097] element Cu S SiO 2

Al 2 o 3

Fe2O3 MgO CaO content 1.43 0.59 82.98 2.12 8.23 1.34 1.23

[0098] Chemical phase analysis results are shown in Table 5 by mass percentage;

[0099] table 5

[0100] form of copper Sulfate free copper oxide bound copper oxide copper sulfide sum content / % 0.04 0.32 0.15 0.92 1.43 Proportion / % 2.80 10.49 22.38 64.34 100

[0101] It can be seen from the table that the ore sample contains 1.43% copper and 0.59% sulfur, and the recovery object is copper, of which the Au and Ag contents are small and have no recovery value; the occupancy rate of copper sulfide in this ore sample is 64.34%, and the oxidation rate is as high as 35.66%, of which the combined copper ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com