Mineral processing technology of hematite containing chlorite

A mudstone hematite and iron ore technology, which is applied in the beneficiation process of chlorite-containing hematite, can solve the problems of lower recovery rate, easy mudification and separation of chlorite, so as to eliminate the influence of the surrounding environment and improve the separation process. Indicators, the effect of concentrate grade improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

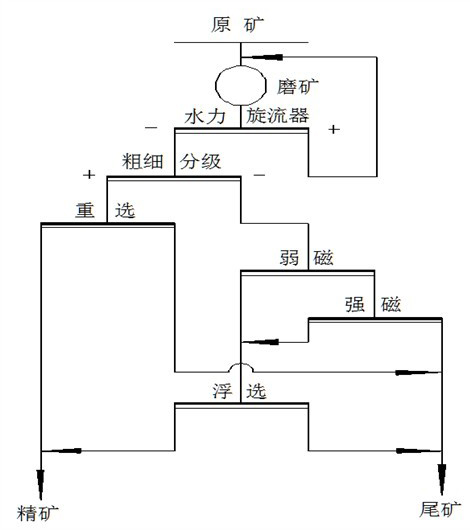

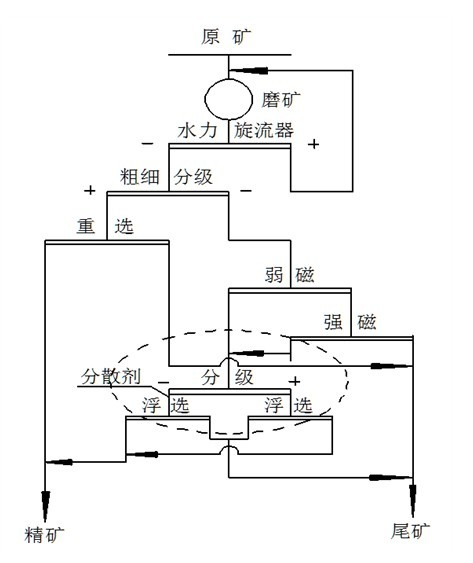

[0024] Embodiment 1: as figure 2 As shown, the beneficiation process of this chlorite-containing hematite adopts the following process steps.

[0025] Raw material: select the ore mined by Sijiaying. Among them, the useful minerals are mainly hematite, half-false hematite, magnetite and a small amount of limonite, with an iron grade of 36.71%; the muddy gangue minerals are mainly chlorite, mica, calcite, hornblende, From stone, etc., iron silicate accounts for about 1.42% of the total iron.

[0026] Process steps: (1) Stage grinding: grind the above-mentioned ore by ball mill, wherein the first stage of grinding fineness -200 mesh accounts for 50-65wt%, and the second stage of grinding to -200 mesh accounts for more than 90wt%; then Classification is carried out through the cyclone group; the classified grit returns to the ball mill for grinding again, and the classified overflow enters the coarse and fine classification process;

[0027] (2) Coarse and fine classification...

Embodiment 2

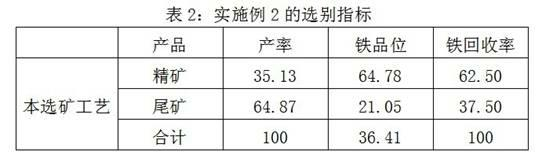

[0033] Embodiment 2: The beneficiation process of this chlorite-containing hematite adopts the following process steps.

[0034] Raw material: The ore mined from Yanshan Iron Mine is selected. Among them, the useful minerals are mainly hematite, half-false hematite, magnetite and a small amount of limonite, with an iron grade of 36.41%; the muddy gangue minerals are mainly chlorite, mica, calcite, hornblende, and Starting stone, etc., iron silicate.

[0035] Process step is with embodiment 1. The classification index of this embodiment is shown in Table 2.

[0036]

Embodiment 3

[0037] Embodiment 3: The beneficiation process of this chlorite-containing hematite adopts the following process steps.

[0038] Raw material: The ore extracted from the Sijiaying surface mine is selected. Among them, the useful minerals are mainly hematite, pseudo-semi-pseudo-hematite, magnetite and a small amount of limonite, with an iron grade of 36.68%; the muddy gangue minerals are mainly chlorite, mica, calcite, hornblende, Starting stone, etc., iron silicate.

[0039] Process step is with embodiment 1. The sorting index of this embodiment is shown in Table 3; the sorting index of the original process of Sijiaying reverse flotation is shown in Table 4.

[0040]

[0041]

[0042] From the sorting indexes obtained in Examples 1-3, it can be seen that this mineral processing process can improve the concentrate grade by 2 to 3 percentage points, and increase the recovery rate by 3 to 5 percentage points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com