Patents

Literature

118results about How to "Improve sorting index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The method of accurate loading-and-filling ball of two sections of milling mine

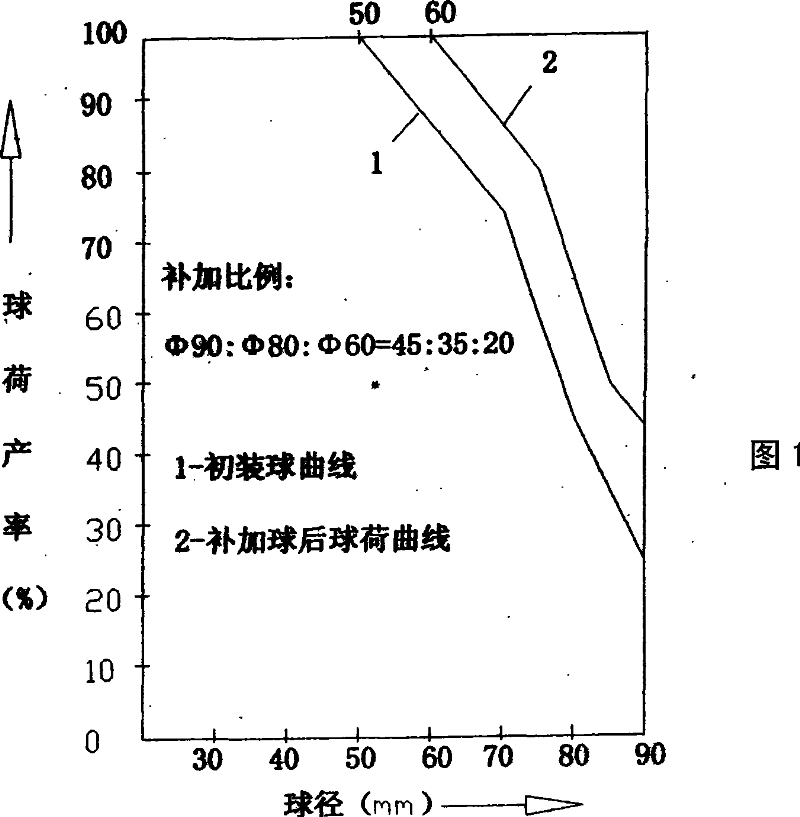

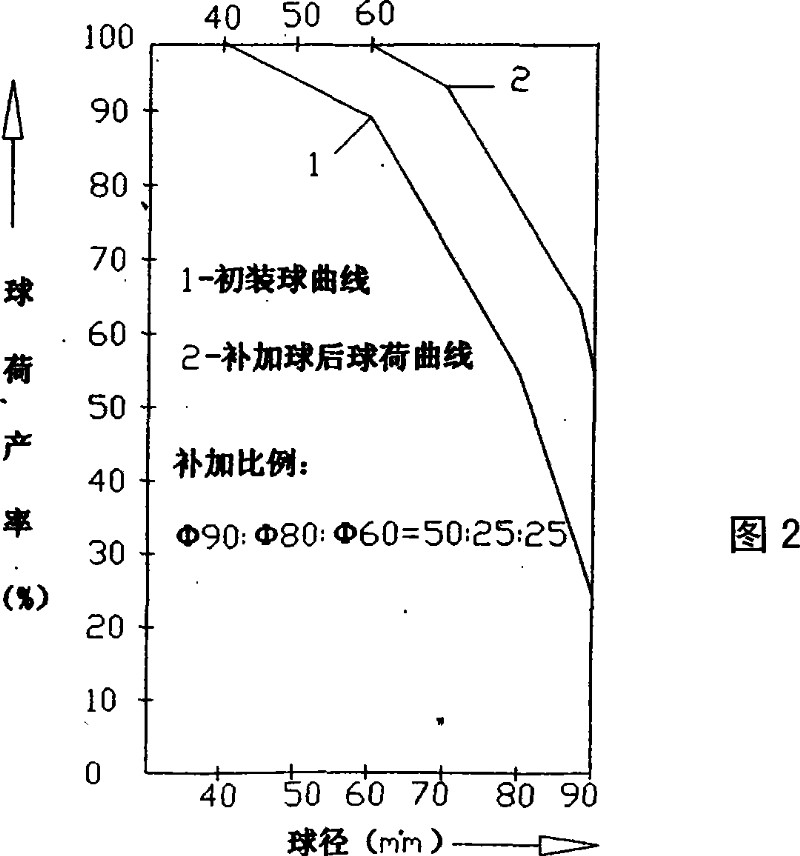

The invention relates to a precise remedy method for two sections of grind, belonging to the ore crash, the mill technical field in the method of preparation. The newly feeding ore with the largest size 25-15 mm is ground to the size smaller than 0.15 mm for two sections, wherein the size smaller than 0.074 mm reaches 70 wt% or thinner product fineness. According to the requirement, the precise makeup remedy method in two sections of grinding suggested in the invention mills the newly feeding mineral grain to the largest size 2-3 mm, wherein the size smaller than 0.074 mm is 20-30wt%, in the second grinding, the size is then ground to smaller than 0.15 mm, wherein the size smaller than 0.074 reaches beyond 70%, to replace the experience remedy method with rude and bad effect in the existing production. The invention not only used in the two section grinding circuit, but also is fit for the three-section grinding circuit, which has good product size characteristic, high sizing index, and can be applied in the grinding technology of the different ore rigidity, different mill specification, different rotating speed mill and different character of ore.

Owner:KUNMING UNIV OF SCI & TECH +1

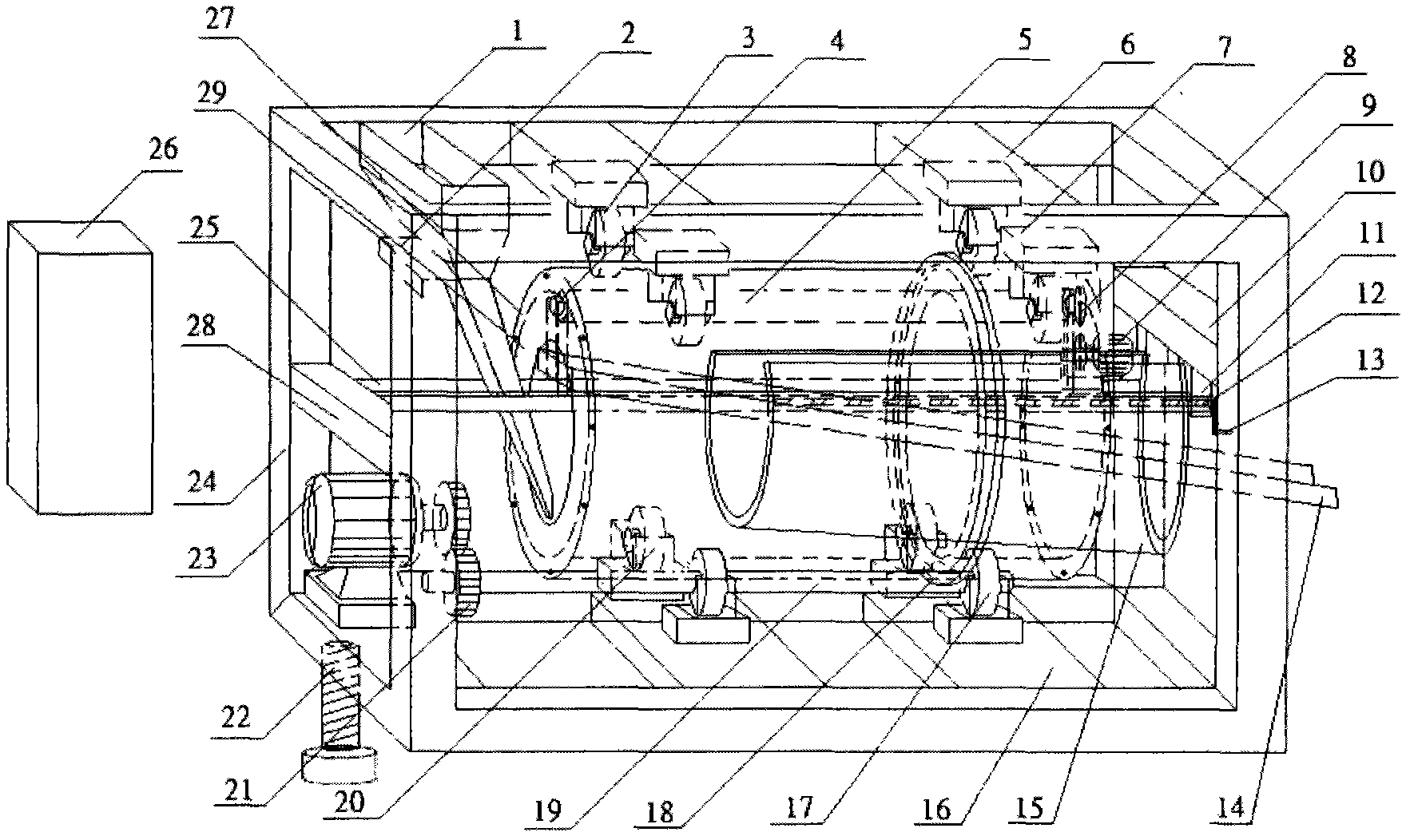

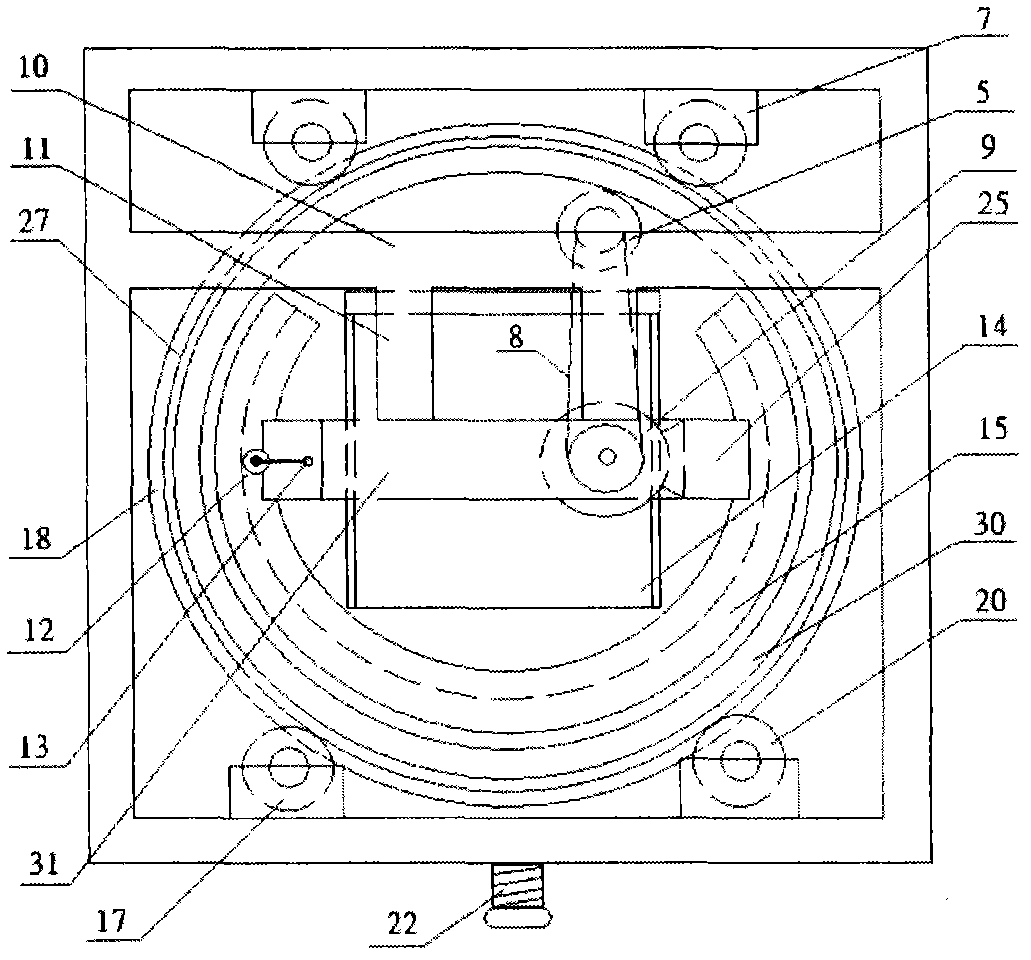

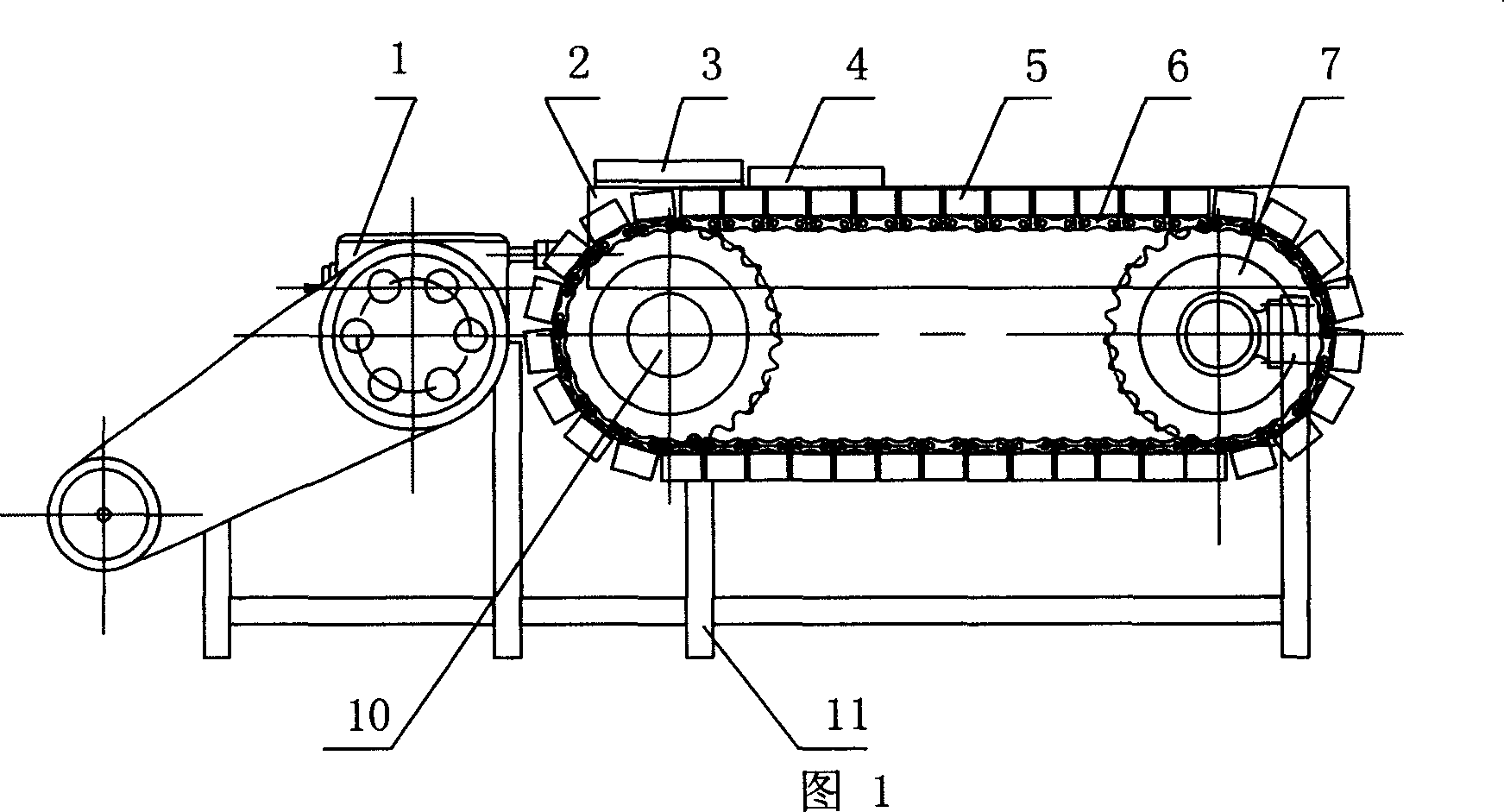

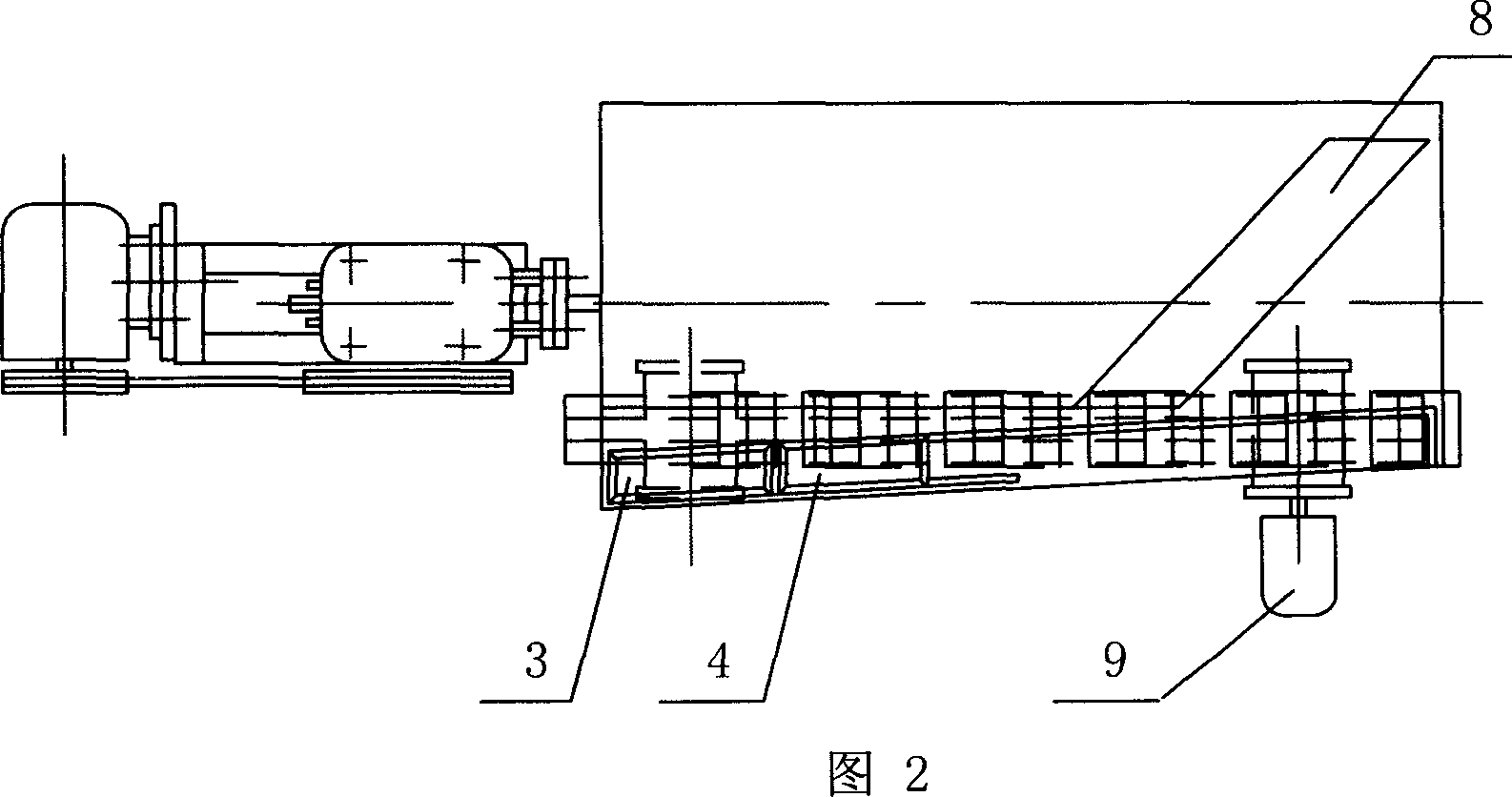

Strong magnetic variation gradient magnetic separator of inner permanent magnetic cylinder

InactiveCN102125889AGood for selectionImprove sorting indexMagnetic separationMagnetic susceptibilityMagnetic field gradient

The invention relates to a strong magnetic variation gradient magnetic separator of an inner permanent magnet cylinder, belonging to the mineral machinery. The strong magnetic variation gradient magnetic separator of the inner permanent magnet cylinder comprises a permanent magnet roller, a control cabinet, an excitation body, a tilt adjusting screw rod of the magnetic separator, a frame, a material discharge box, a material discharging quantity control shutter, a material discharge roller, a roller support idler wheel, an inner bracket beam, a material discharge groove, a bracket, an anti-skid flange plate for the permanent magnet roller, a power motor, an excitation body moving screw rod, and the like. The strong magnetic variation gradient magnetic separator of the inner permanent magnet cylinder has functions of strengthening magnetic field intensity and changing magnetic field gradient, and can further enhance the grade and the yield of the magnetic separation of low magnetic susceptibility mineral power which is difficult to select. The strong magnetic variation gradient magnetic separator has the advantages of compact structure, and convenience for installation and operation, and is suitable for separating various kinds of weak magnetic rare metal mineral powders or exhausting impurities and purifying nonmetal mineral powders. The strong magnetic variation gradient magnetic separator can be separately applied to a dry separation technology or a wet separation technology, and is a permanent magnet high-gradient technical device which can replace an electromagnetic separator with high energy consumption and high gradient.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

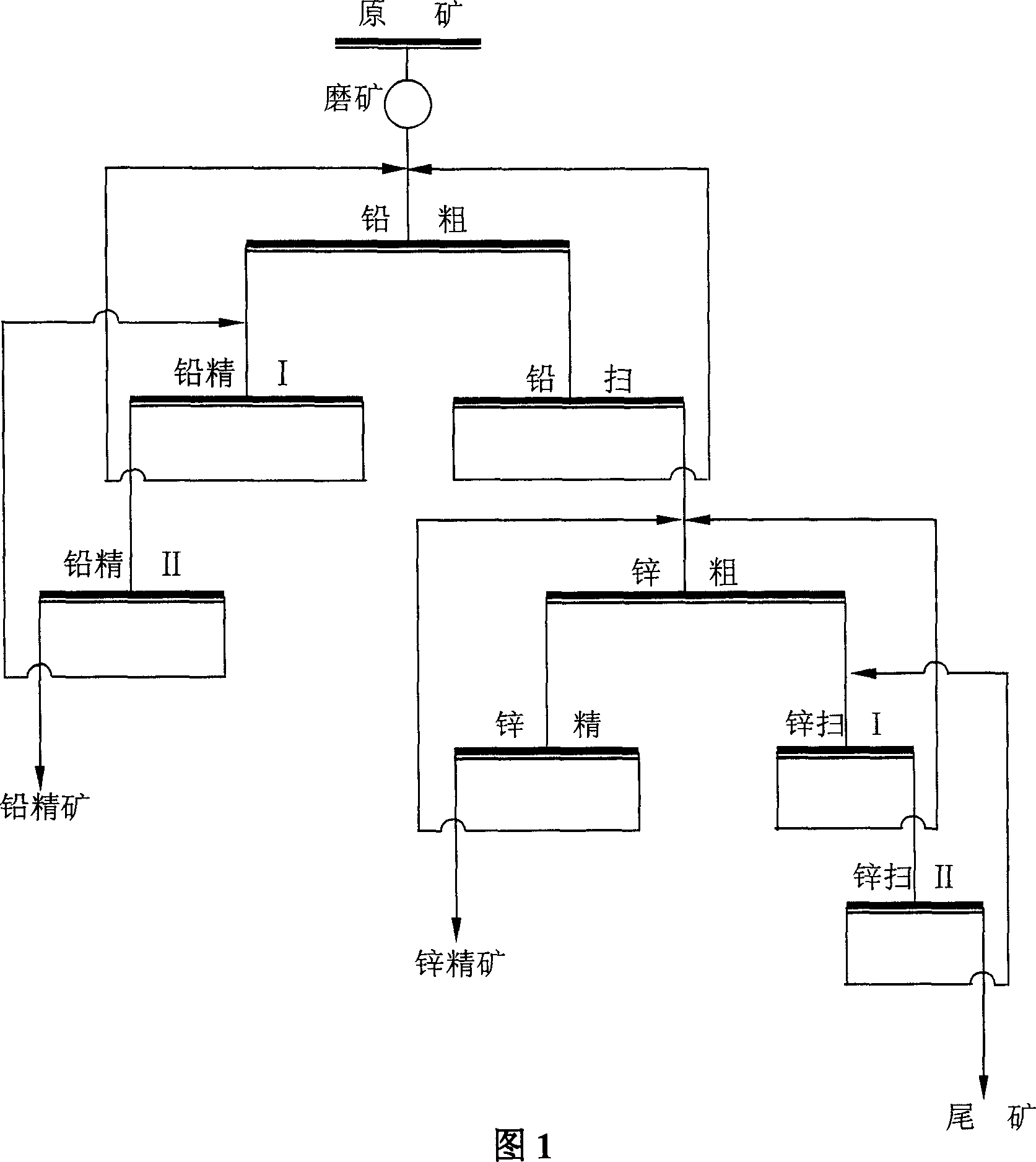

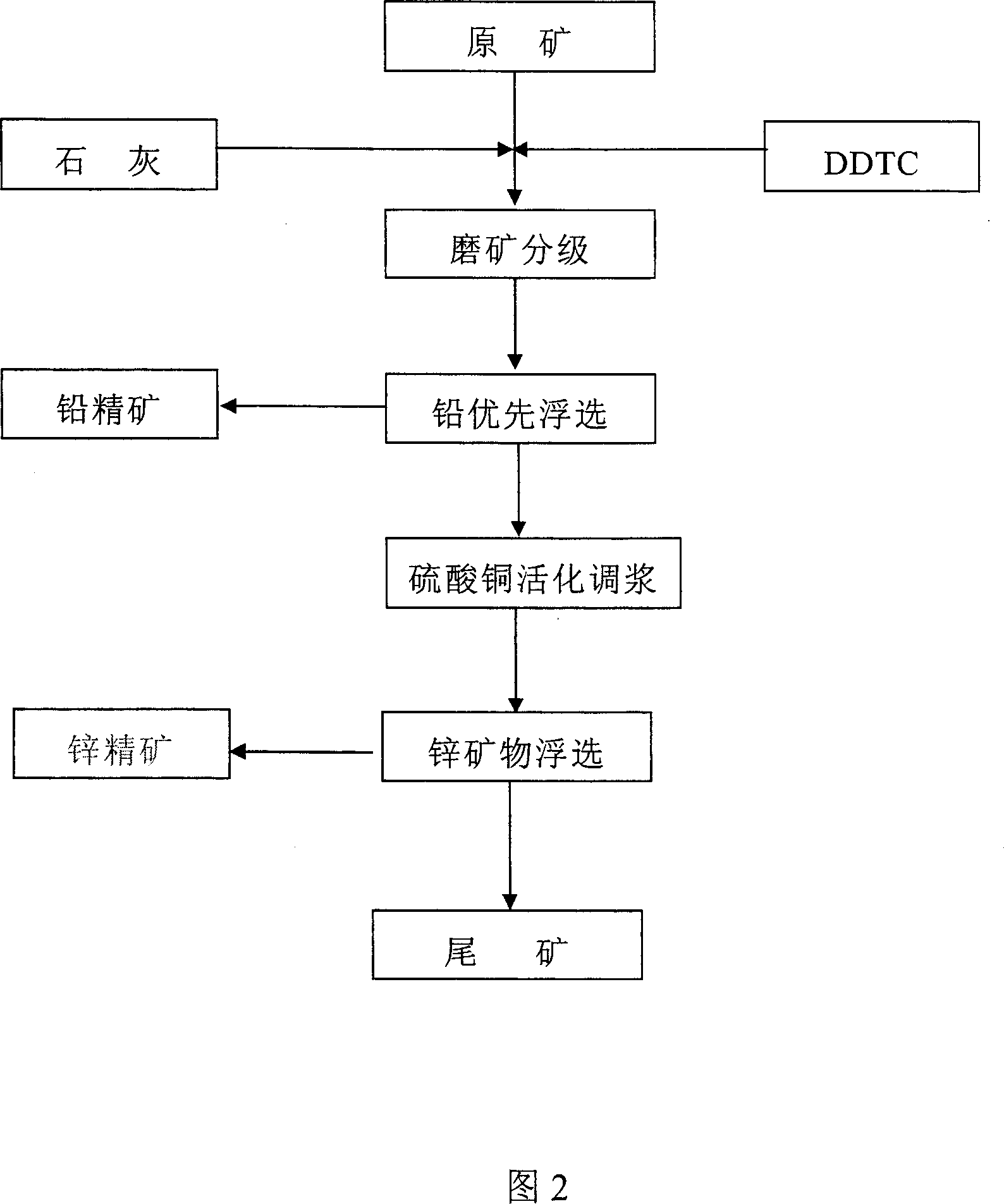

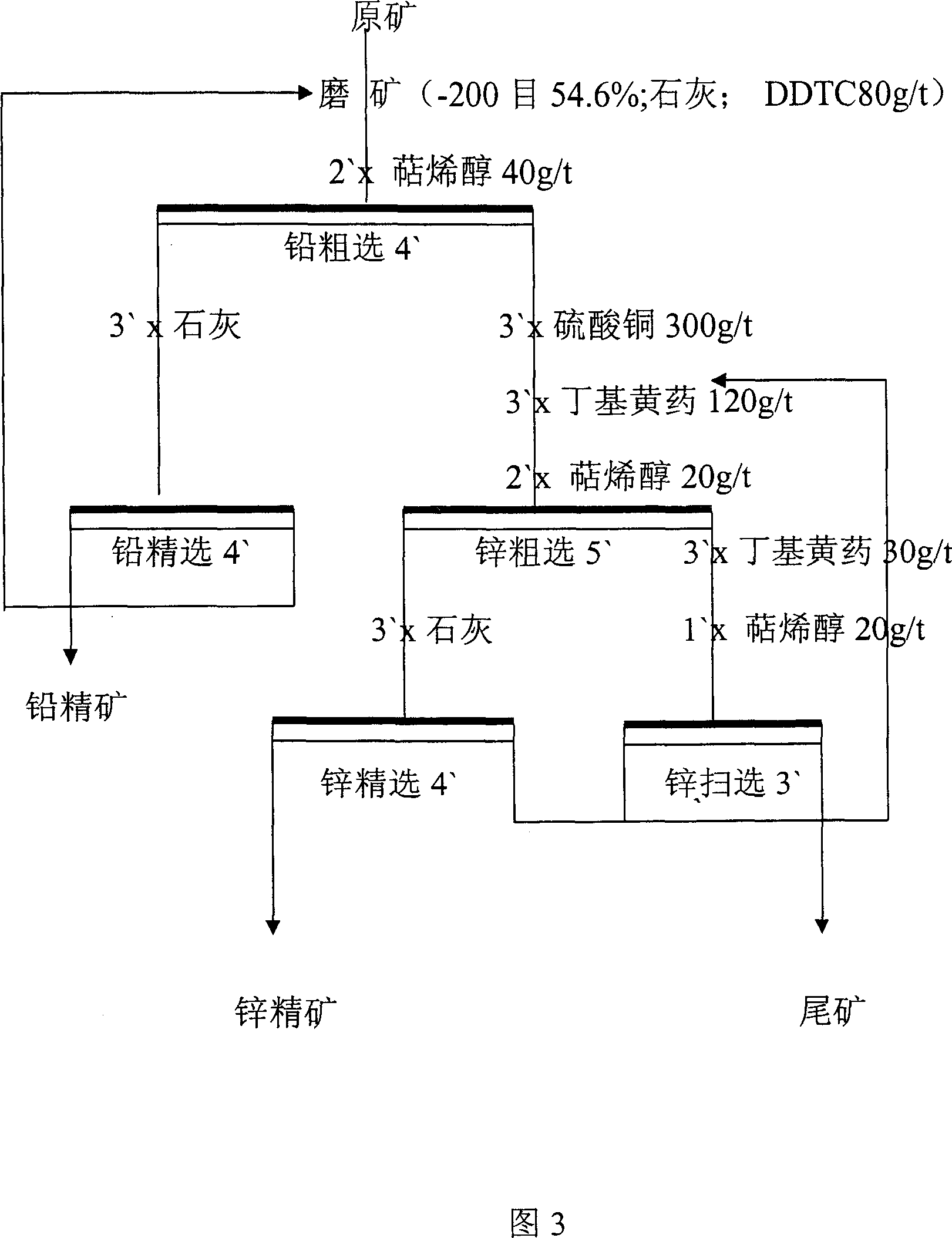

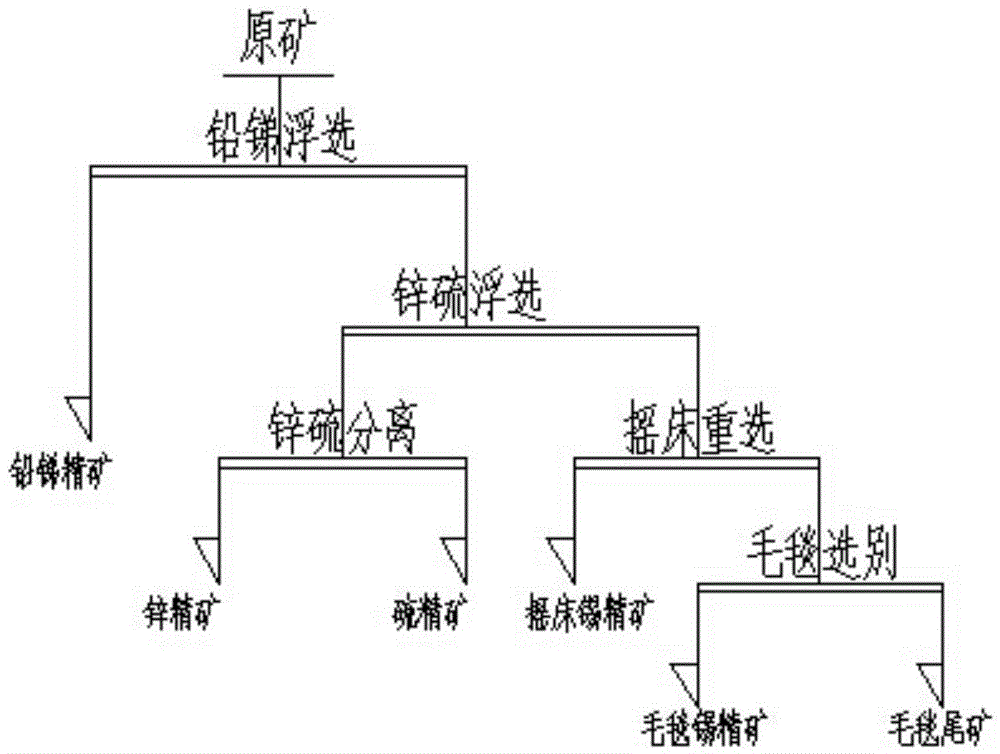

Process for increasing complicated sulfurized-lead-zinc ore dressing recovery rate

The present invention is green process of recovering complicated lead-zinc sulfide ore in high recovering rate. The technological process adopts lime to form high alkalinity and maintain the original potential of lead-zinc sulfide slurry during ore grinding floatation, sodium diethyl dithioamino formate as the selective lead mineral collecting agent, copper sulfate as the sphalerite activating agent and butyl xanthate as the zinc mineral collecting agent for optimized successive fast floatation. The present invention has raised recovering rate, low chemical consumption, simple technological process and low production cost.

Owner:青海西部矿业科技有限公司

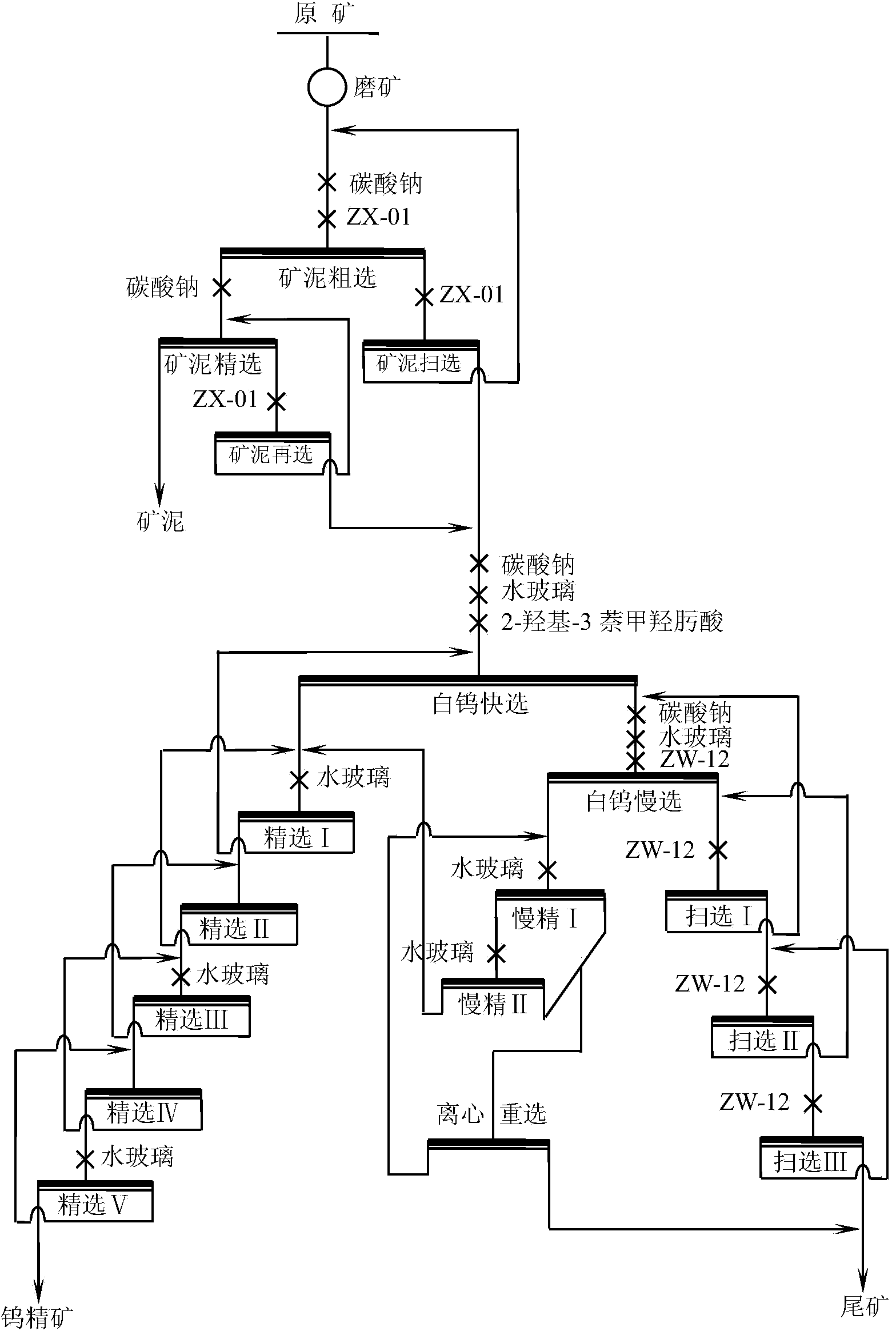

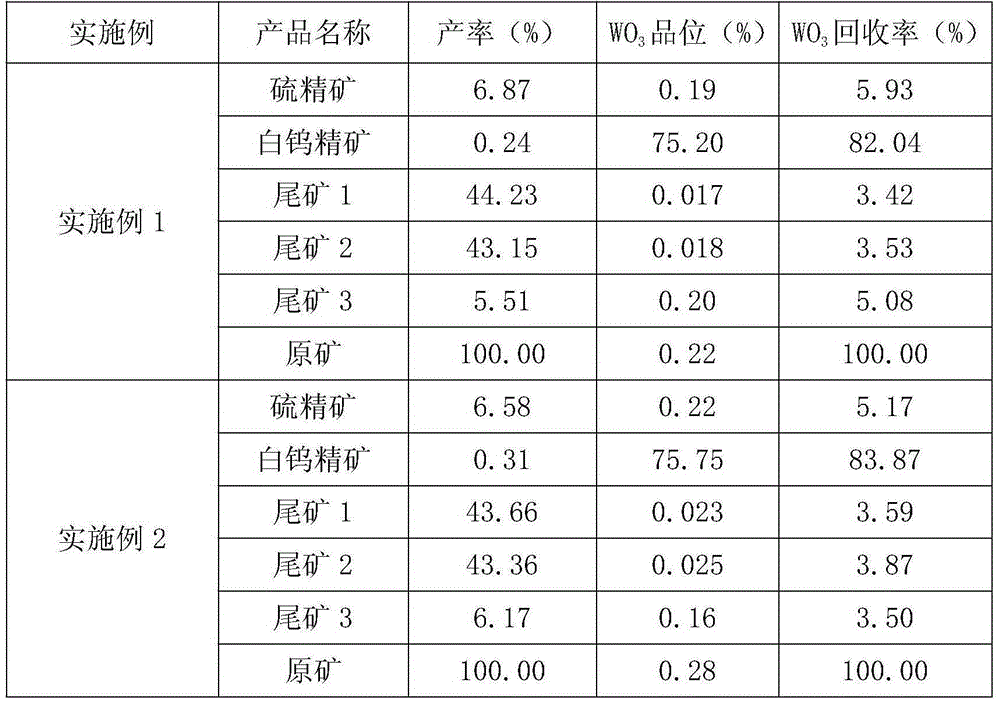

Beneficiation method of refractory low-grade scheelite

ActiveCN104226462AAddressing the Effects of SortingImprove sorting effectFlotationWet separationHydroxamic acidLower grade

The invention provides a beneficiation method of refractory low-grade scheelite. The method adopts slurry collecting agent ZX-01, slurry collecting agent 2-hydroxy-3 naphthoyl hydroxamic acid and slurry collecting agent ZW-12 which have high selective collecting capability; the method comprises the steps of finely grinding raw ore, carrying out slurry flotation, carrying out rapid beneficiation on scheelite, selecting the scheelite, carrying out slow beneficiation on scheelite, slowly selecting the scheelite, carrying out centrifugal reselection on middlings, and the like to finally obtain the scheelite concentrate. The low-grade scheelite sorted by the method is good in sorting indexes; the scheelite concentrate is higher in grade and yield; the beneficiation method of the refractory low-grade scheelite is stable, efficient, good in sorting effect, high in adaptability, high in recovery index and low in production cost, thus being suitable for popularization and application.

Owner:JIANGXI UNIV OF SCI & TECH

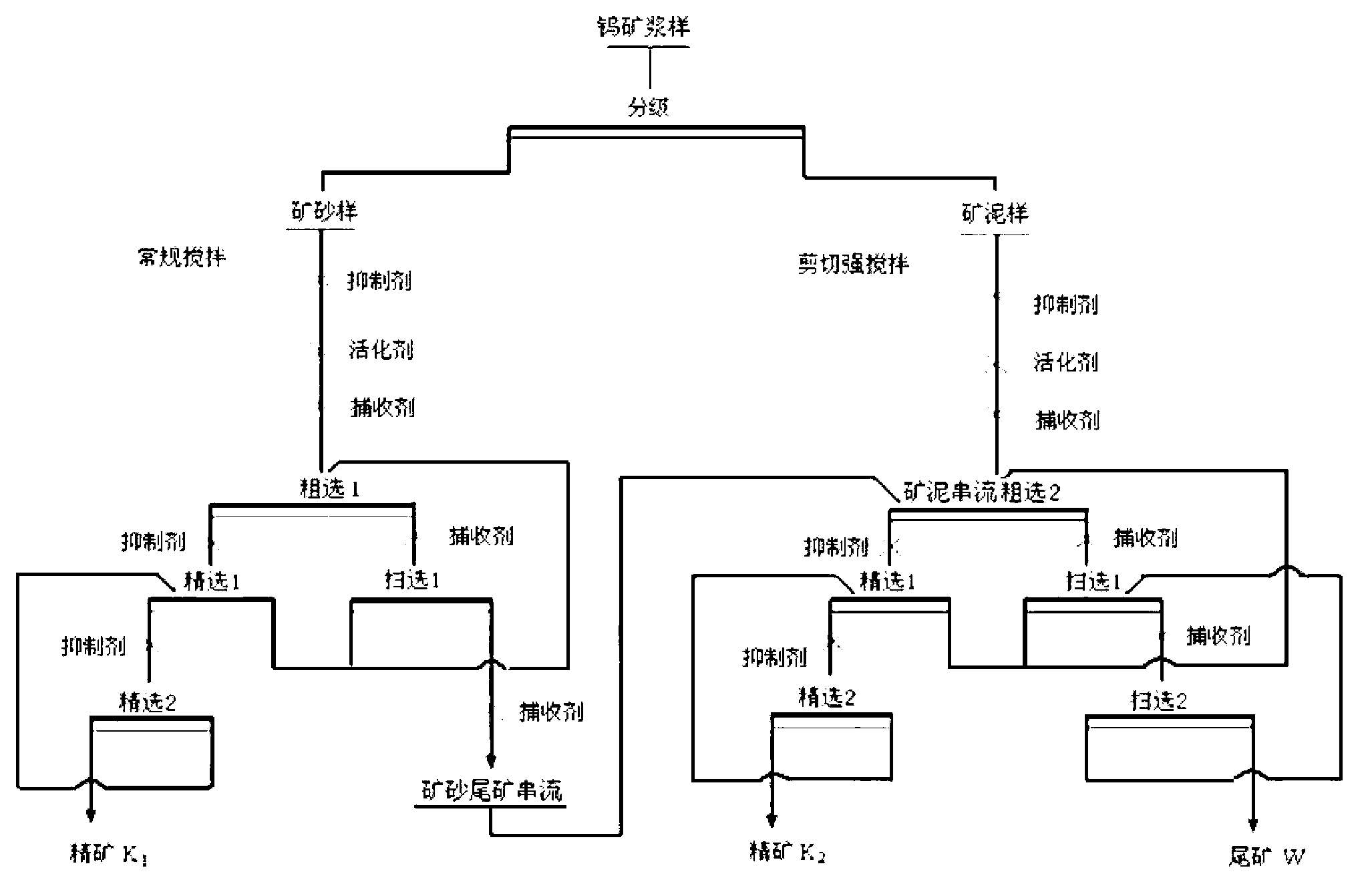

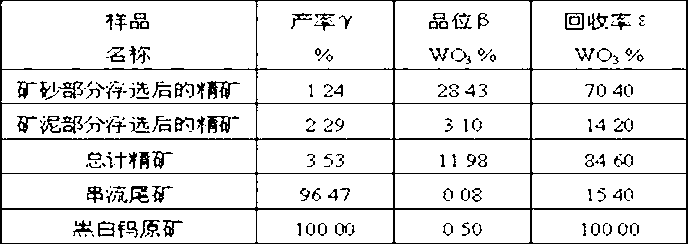

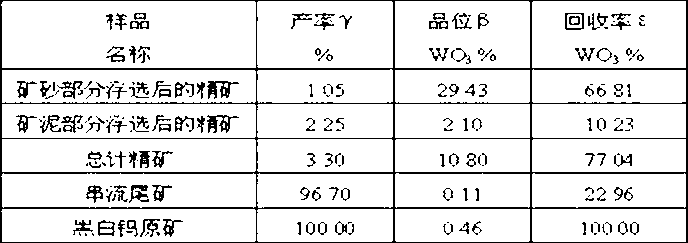

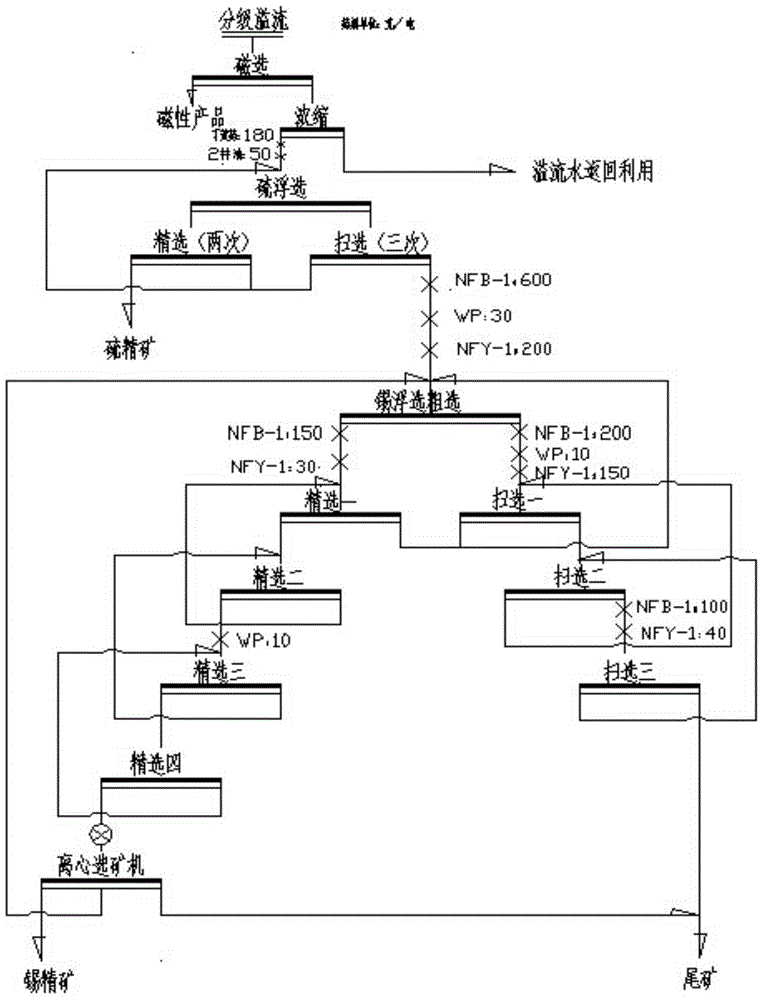

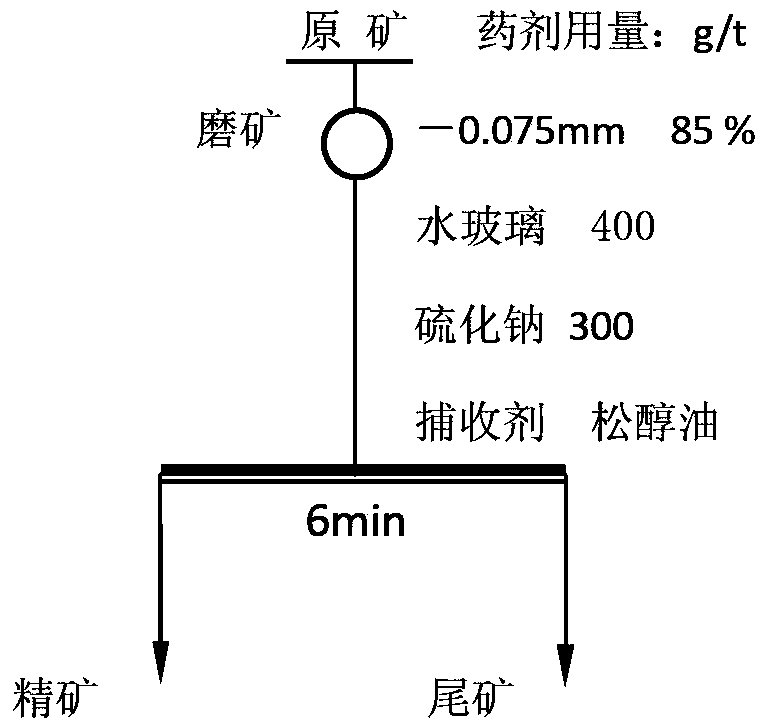

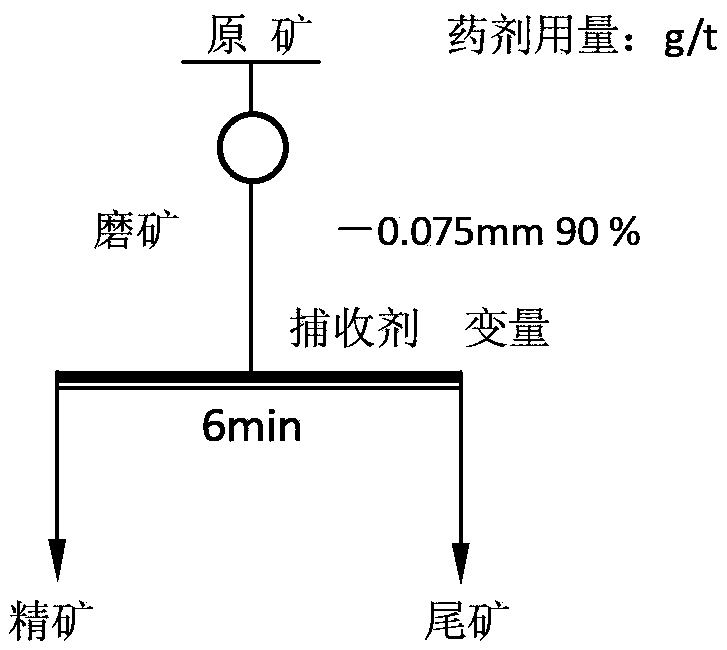

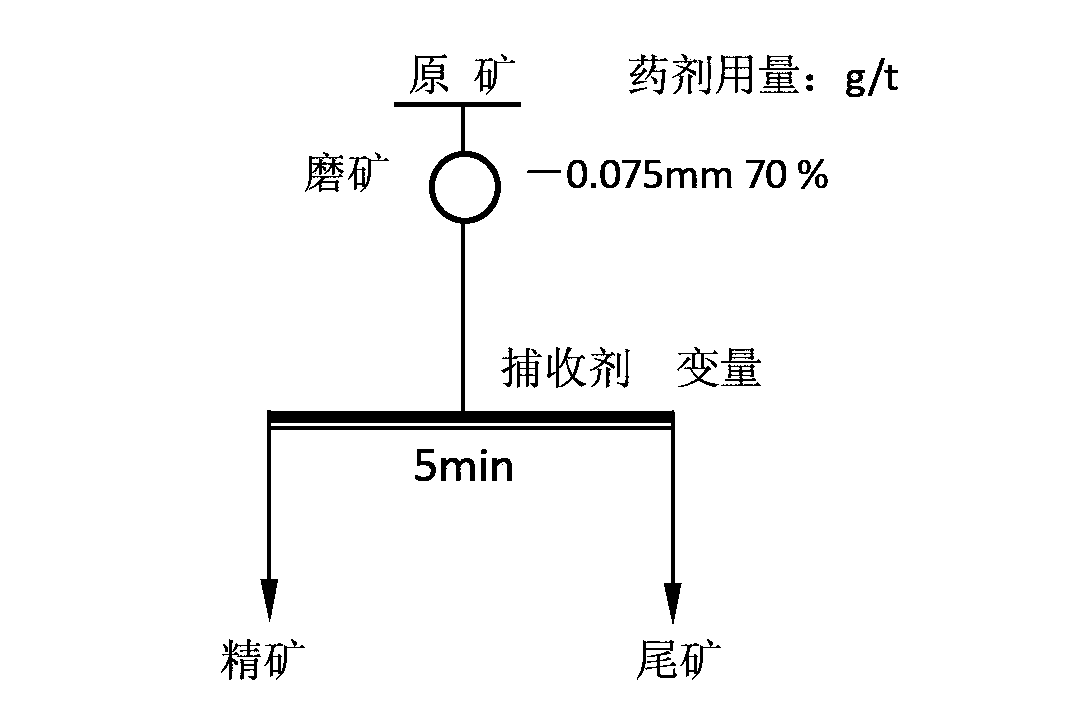

Grading and branching streaming flotation method of tungsten ore

ActiveCN103301946AImprove flotation technical indicatorsImprove sorting indexFlotationRed mudLower grade

The invention discloses a grading and branching streaming flotation method of tungsten ore. The grading and branching streaming flotation method of the tungsten ore comprises the following steps: firstly, finely grinding the tungsten ore; secondly, grading ore pulp of the ground tungsten ore into an ore sand part with a high flotation speed and an ore mud part with a low flotation speed by using grading equipment; thirdly, floating the ore sand part to obtain medium-grade tungsten concentrate and ore sand tailing; and finally, streaming the ore sand tailing to the ore mud part for floating, and obtaining low-grade tungsten concentrate and streamed tailing. By the grading and branching streaming flotation method of the tungsten ore, the size fraction for floating the ore pulp can be improved and the flotation performance and flotation indexes of the ore mud part can be improved.

Owner:中钨共享服务(湖南)有限公司

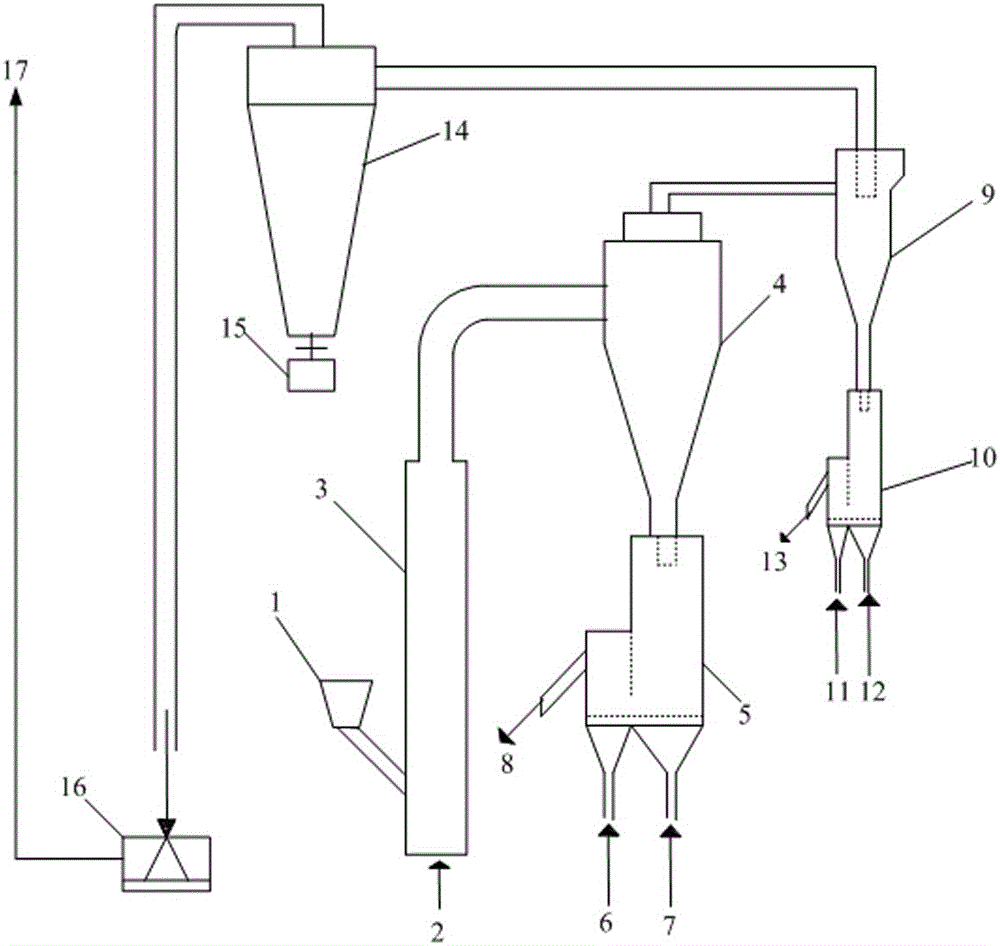

Comprehensive recovery process of intense-weathering poor vanadium titano-magnetite

InactiveCN103157551AImproved flotation indicatorsHigh yieldFlotationWet separationMagnetiteProduct base

The invention provides a comprehensive recovery process of intense-weathering poor vanadium titano-magnetite. The comprehensive recovery process of the intense-weathering poor vanadium titano-magnetite comprises the steps of prescreening, crushing, dry separation, primary grinding, primary magnetic separation, secondary grinding, secondary magnetic separation, strong magnetic separation, floating separation and syrup mixing, and titanium floating separation. The process of titanium floating separation comprises the steps of rough separation, scavenging for two times, and fine separation for four times. According to the comprehensive recovery process of the intense-weathering poor vanadium titano-magnetite, the problems that a throwing tail is high in grade and recovery rate of titanium concentrate is low when an existing process and an existing device are used for processing the intense-weathering poor vanadium titano-magnetite are solved. The index of finished products based on the comprehensive recovery process is that the grade of iron ore concentrate is 64% and yield of the iron ore concentrate is 37%, the grade of the titanium concentrate is 42% and the yield of the titanium concentrate is 41%, and the grade of fine-grain gangue iron is lower than 7% and the grade of titanium is lower than 1%.

Owner:SHANDONG QIANSHUN MINING & METALLURGY SCI

Cassiterite flotation agent composition

The invention provides cassiterite flotation agent composition. The cassiterite flotation agent composition comprises a collecting agent, a combined inhibitor and an optical auxiliary collecting agent, wherein the collecting agent comprises the following ingredients in percentage by weight: 30wt%-50wt% of styryl phosphoric acid, 20wt%-30wt% of aliphatic phosphoric acid (preferably selecting C6-C8 aliphatic series), 10wt%-20wt% of alkyl sulfonated succinic acid and 10wt%-20wt% of alkyl hydroximic acid. The cassiterite flotation agent composition provided by the invention is soluble under normal temperature, non-toxic and tasteless, good in dispersibility, efficient and environment-friendly and good in return water utilizability; mineral processing index of cassiterite flotation can be increased, the agent consumption can be reduced, the agent cost is reduced, and particularly for mineral processing on fine particle cassiterite, a unique effect is obtained; the loss of intermediate products during a tin rough concentrate recycling process is avoided; the industrial application processing capacity can be up to 50-60 tonnage / day, and more preferably, the industrial application processing capacity can be up to 80 tonnage / day; when the flotation ore feeding tin grade is 0.70%-0.80%, good technical indexes of 6%-10% of tin flotation concentrate grade and 60%-70% of operation recovery rate is obtained by agents; the dosage of the agents is greatly reduced.

Owner:临武县南方矿业有限责任公司

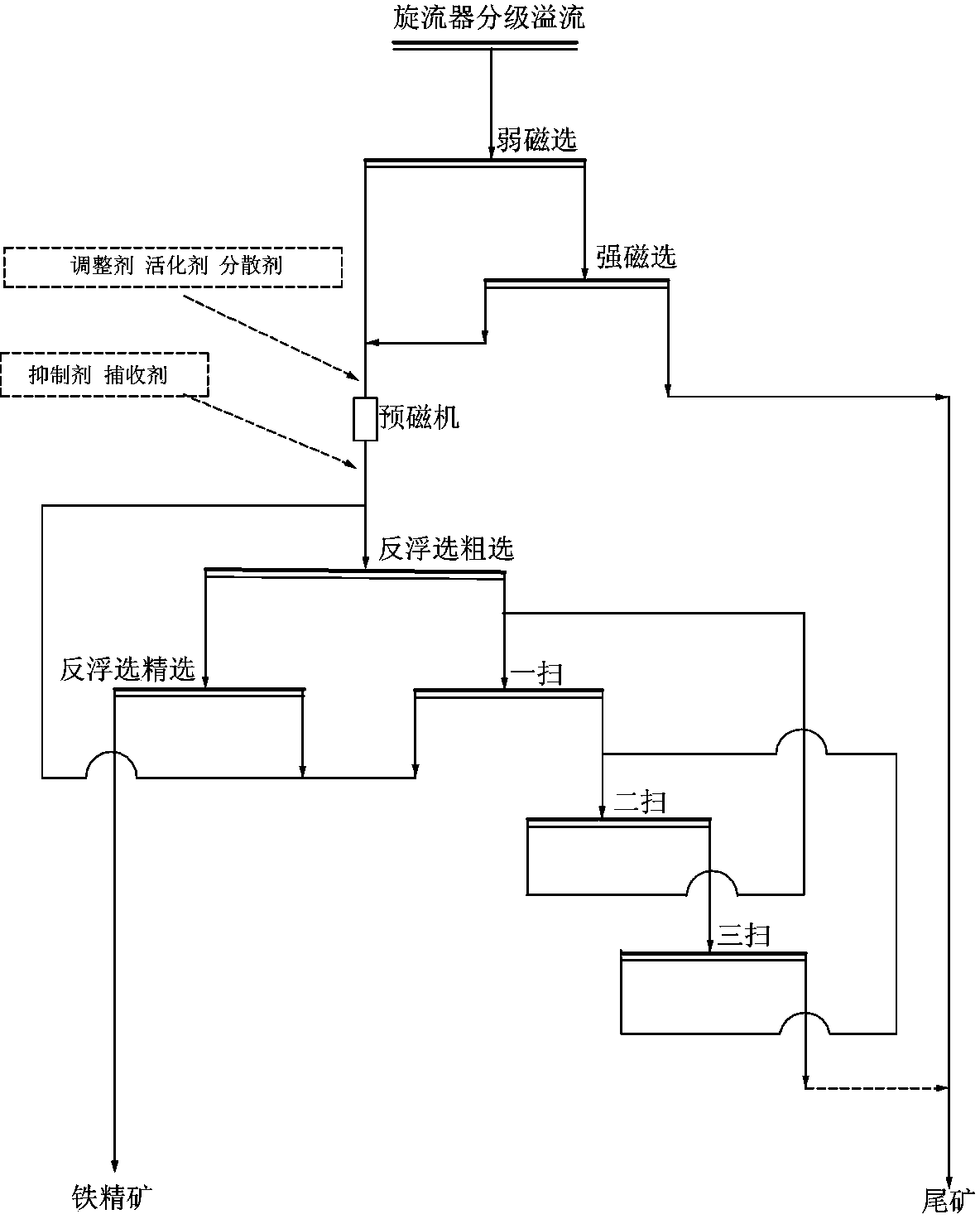

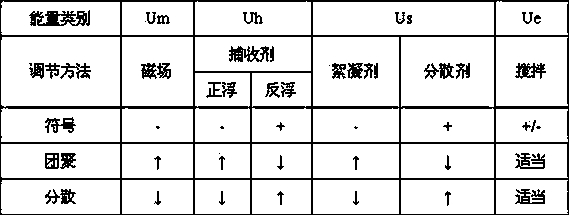

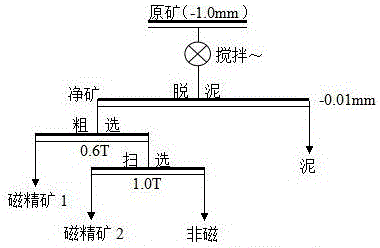

Beneficiation method for micro-fine iron ore

The invention relates to a beneficiation method for micro-fine iron ore. The beneficiation method for the micro-fine iron ore comprises the steps of ore grinding, classification with a hydrocyclone, pre-separation through low-intensity magnetic separation and high-intensity magnetic separation, and hybrid-magnetic-separated iron ore concentrate obtaining. The beneficiation method for the micro-fine iron ore is characterized by further comprising the steps that (1) mixing depression is conducted, wherein the magnetic-separated iron ore concentrate is placed into a stirring groove, a regulator, an activating agent and a dispersing agent are added into the stirring groove, and then mixing depression is conducted; (2) magnetic carrier-pre-magnetization is conducted, wherein a magnetic carrier with the weight being 10%-30% that of fed ore to be separated in a magnetic mode is added into the ore pulp, and then pre-magnetization is conducted through a pre-magnetizing machine; (3) coagulation and reverse flotation are conducted, wherein after an inhibitor and a collecting agent are added into the pre-magnetized ore pulp, reverse flotation which comprises the step of conducting rough concentration once, conducting fine concentration once and conducting scavenging concentration three times is conducted, tailings obtained after scavenging concentration is conducted for the last time serve as final tailings, and concentrate obtained through fine concentration serves as final concentrate. The beneficiation method for the micro-fine iron ore has the advantages that the yield of the finally obtained iron ore concentrate can be increased by 1.5% -3%, the recovery rate of iron can be increased by 5%-10%, energy can be saved greatly, consumption can be reduced greatly, and the grading index can be increased greatly.

Owner:ANSTEEL GRP MINING CO LTD

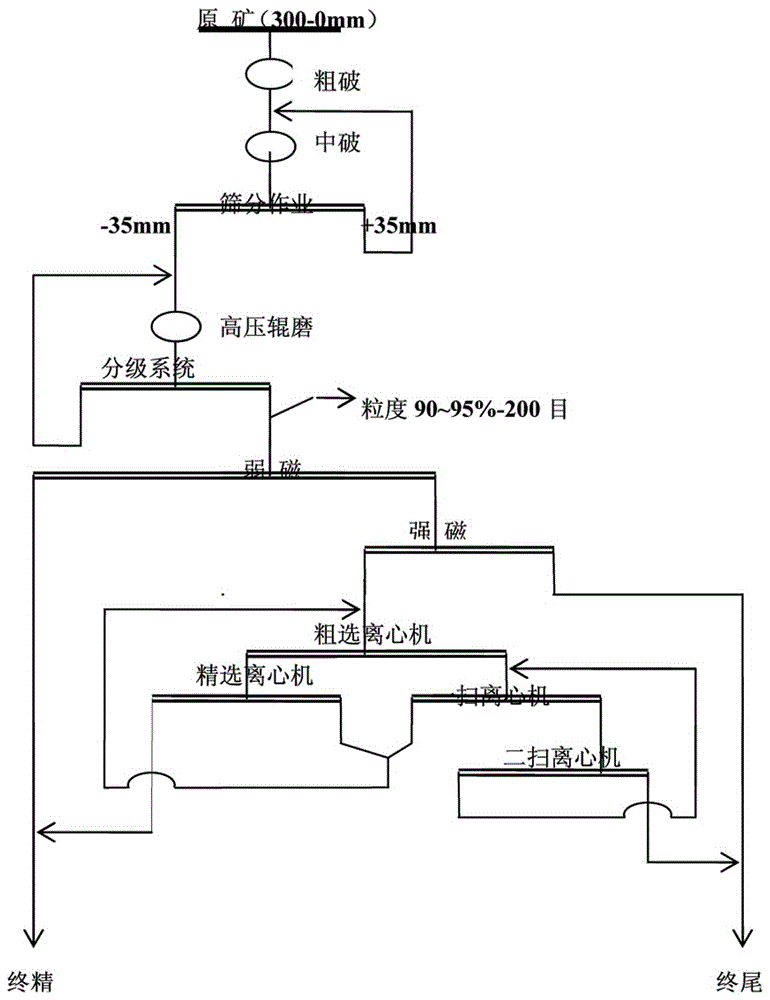

Classifying suspension roasting device for complex refractory iron ore

The invention provides a classifying suspension roasting device for complex refractory iron ore. The device comprises a suspension preheating oxidizing device, two-stage cyclone classifiers, two-stage suspension reducers, a cyclone separator and a draught fan, wherein the suspension preheating oxidizing device communicates with the first-stage cyclone classifier, and the first-stage cyclone classifier communicates with the second-stage cyclone classifier; the second-stage cyclone classifier communicates with the cyclone separator, and the cyclone separator communicates with the draught fan; discharging ports of the first-stage classifier and the second-stage classifier are correspondingly inserted into the first-stage suspension reducer and the second-stage suspension reducer. With the adoption of the device, coarse and fine materials can be classified, magnetized and roasted, and thus the reduction conditions of the materials at different classes can be controlled; in addition, the energy consumption can be greatly reduced, and the optimal technical-economic indicator can be obtained.

Owner:SHANGHAI MILESTONE TECH CO LTD

Method for reverse-floatation mud-removing for bauxite

InactiveCN1947850AImprove sorting indexEasy to separateDifferential sedimentationFlotationSiphonSlurry

A reverse floatation method for removing mud from bauxite includes such steps as grinding crude bauxite, regulating concentration and pH value of ore slurry, stirring, adding catechol, stirring, adding phosphonated starch to flocculate the monohydrated duraluminite, layering, and removing suspended mud by siphon method.

Owner:XIAOYI TIANZHANG ALUMINUM

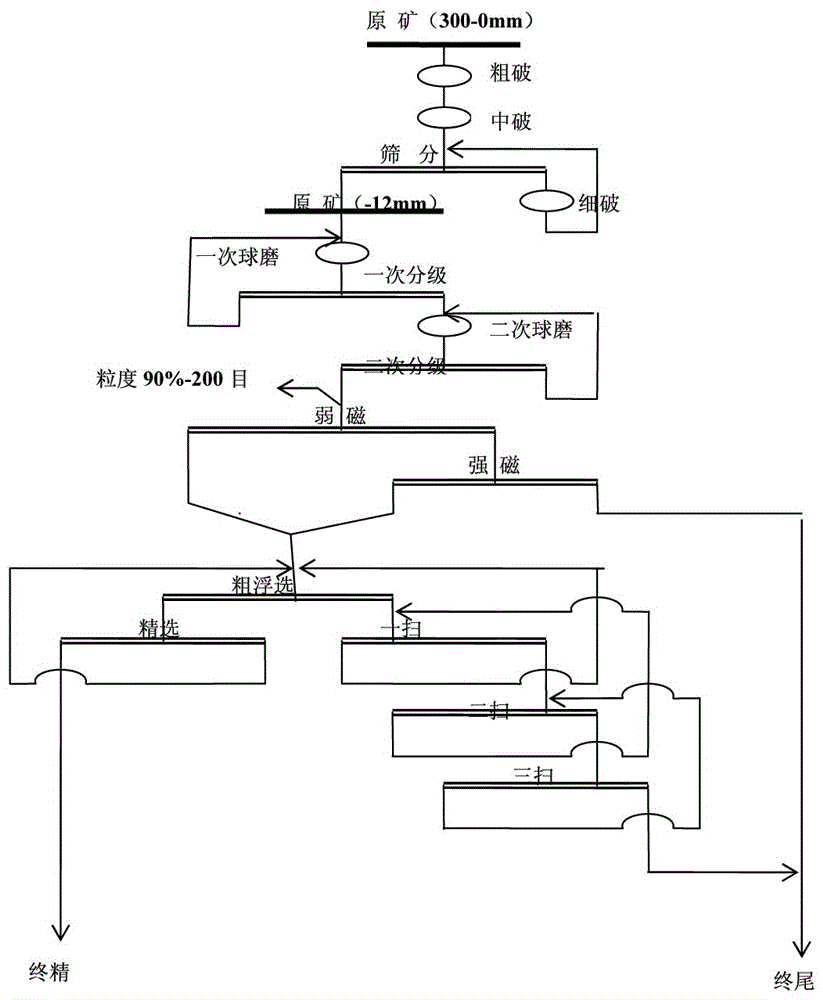

High-pressure rolling and magnetic-gravity separation process for lean hematite

InactiveCN106513163ASimple processReduce the cost of beneficiationWet separationGrade systemHigh pressure

The invention relates to a high-pressure rolling and magnetic-gravity separation process for lean hematite. The high-pressure rolling and magnetic-gravity separation process for lean hematite is characterized by comprising the following steps that after raw ore particles with the particle size of 0-300 mm are subjected to the coarse crushing and intermediate crushing screening operation, the product particle size is 0-35 mm; after the particles pass through a high-pressure roll mill and a wind grading system, the large-particle-size products subjected to wind grading return to the high-pressure roll mill, the small-particle-size products subjected to wind grinding and with the 200-mesh sieve sieving rate being 90%-95% are fed to the technical procedures with low intensity magnetism, high intensity magnetism and a centrifugal machine so as to be graded; concentrate obtained through low intensity magnetic separation and concentrate obtained through the centrifugal machine are combined into final concentrate with the grade being 66.5%-67.5% and the yield being 27%-29%; and the grade of tailings of high intensity magnetic separation is 8.3%-8.8%, the grade of tailings of two-stage scavenging centrifuge is 16%-18%, and the tailings of high intensity magnetic separation and the tailings of two-stage scavenging centrifuge are combined into final tailings with the grade being 10.50%-11% and the yield being 61%-63%. The high-pressure rolling and magnetic-gravity separation process for lean hematite has the advantages that original fine crushing operation and two-stage grinding operation are omitted, the products with the 200-mesh sieve sieving rate being 90%-95% can be directly obtained by the adoption of the high-pressure roll mill and the wind grading system, the process structure is simplified, and the ore separation cost is reduced significantly.

Owner:ANSTEEL GRP MINING CO LTD

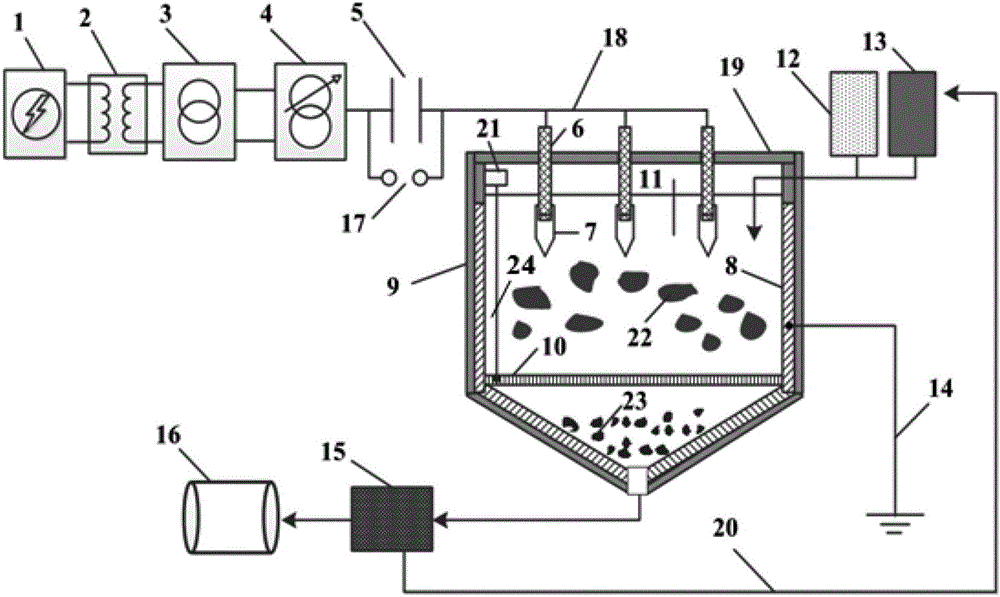

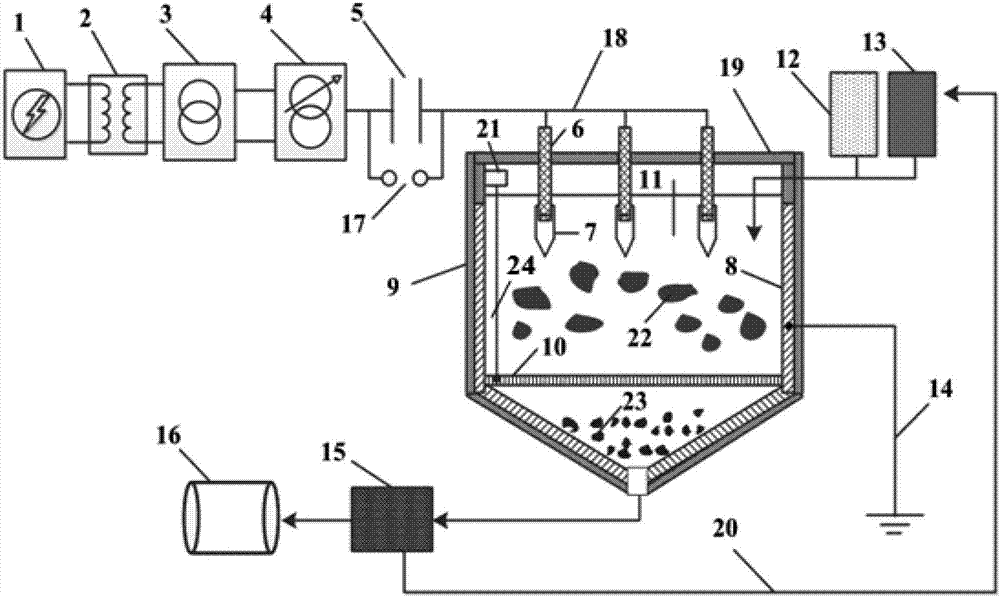

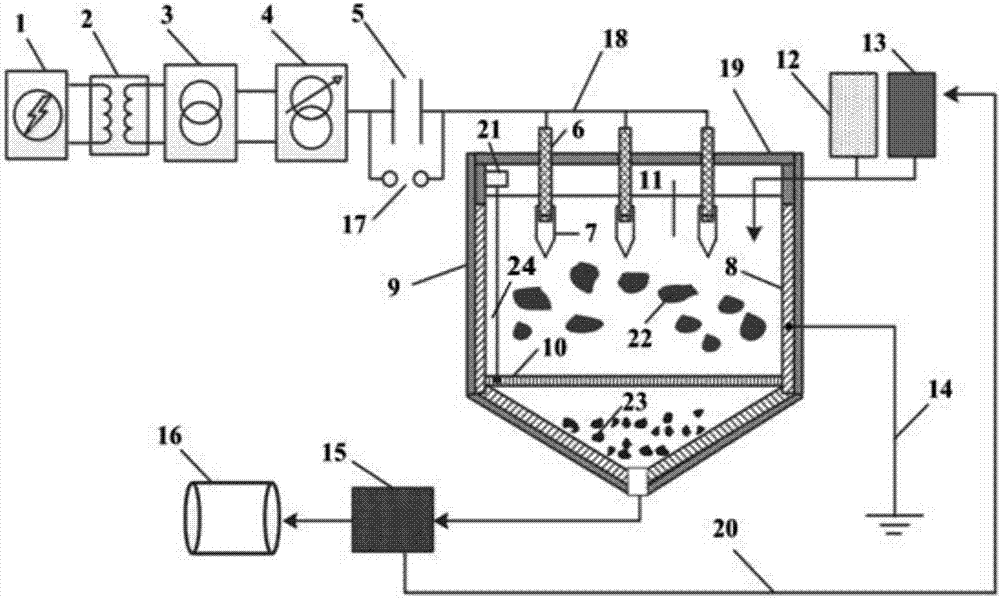

High-voltage electric pulse ore crushing device and method for ore pre-treatment

ActiveCN106824455ADoes not destroy crystal formImproved cleavage propertiesSievingScreeningTransformerCeramic capacitor

The invention discloses a high-voltage electric pulse ore crushing device and a method for ore pre-treatment and belongs to the technical field of ore crushing pre-treatment in mineral processing. The device mainly comprises a power supply, a single-phase voltage regulator, an alternating-current ignition transformer, a six-time-voltage rectification circuit, an ultrahigh-voltage ceramic capacitor, a gas switch, a high-voltage electrode, a conductive barrel body, a discharging and ore crushing bucket, a vibration screen mesh, insulating liquid, a solid-liquid separator, a product collector and the like; all the units are fixedly connected through a lead wire and other auxiliary devices to form a complete equipment system. The ores are treated and then are selectively dissociated and crushed according to different conductive properties of useful metal minerals and non-metal mineral components of gangues, and extension cracks and fissures are generated on mineral interfaces on the ores, so that physical properties of the minerals are improved and subsequent treatment energy consumption is reduced; meanwhile, useful minerals are prevented from excessive abrasion and separation indexes are improved.

Owner:NORTHEASTERN UNIV

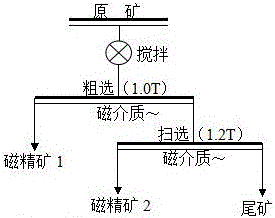

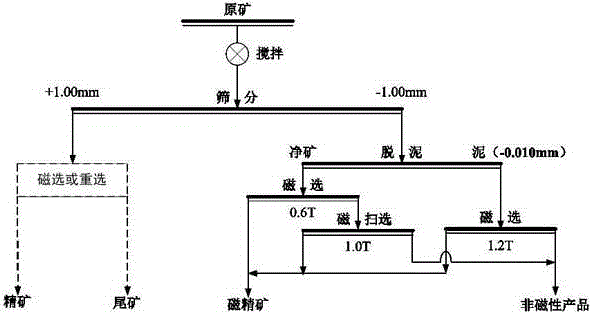

Separation method for low-grade manganese ore with high silicon accompanying a little limonite and psilomelane

InactiveCN104941795ARaise the gradeTo achieve the purpose of comprehensive recycling of resourcesHigh gradient magnetic separatorsKaolin clayPsilomelane

The invention provides a separation method for low-grade manganese ore. The separation method is particularly applied to low-sulfur, low-phosphorous, low-arsenic, low-iron and high-silicon manganese ore with the manganese content lower than 6.5%. The content of a manganese mineral in the ore is lower than 11%, the manganese mineral is mainly the psilomelane with a low crystallization degree and a little pyrolusite, the other metallic oxides are mainly the limonite, and a gangue mineral is mainly quartz and manganese-containing kaolin. The insetting grain size of the psilomelane is small and mainly ranges from 0.005 mm to 0.16 mm, and the insetting grain size of the pyrolusite is relatively beneficial to separation. The low-grade manganese ore with the grain size mainly ranging from 0.005 mm to 0.16 mm enters a high-gradient magnetic separator in a full-dose mode and is separated in a roughing and scavenging alternation mode, the separation magnetic field intensity parameter 1.0 T is adopted for roughing, the separation magnetic field intensity parameter 1.2 T is adopted for scavenging, manganese concentrate can be produced at a time, tailings are thrown out, and then separation of the low-grade manganese ore is completed. The process is simple and effective; when the grade of the original manganese ore ranges from 6.16% to 6.63%, the yield of the manganese concentrate is larger than 14.01%, the grade of the manganese concentrate is larger than 23.22%, the recovery rate is larger than 51.65%, and the separation index is increased.

Owner:马凤祥

Method for automatically monitoring tin ore table beneficiation

ActiveCN103785532AReduce labor costsStable ore concentrationSolid separationAutomatic controlEngineering

The invention relates to a method for automatically monitoring tin ore table beneficiation, and belongs to the technical field of nonferrous metal ore beneficiation automation. The method includes the steps that the table feeding concentration and the table feeding volume are automatically controlled through automatic control over water adding and control flow of a specific gravity concentration meter, a flow meter and linkage control valves; ranges of the coarse sand table jig frequency, the fine sand table jig frequency and a groove carving table jig frequency are controlled through frequency modulation control over a table motor by PLC programming; the optimal washing water flow is controlled in the modes that monitoring is carried out through an automatic camera shooting module, and an adjustment valve is controlled by a PLC; the optimal table body gradient is controlled in the modes that monitoring is carried out through the automatic camera shooting module, and a mechanical component is driven by the PLC and a single shaft control servo motor; the tin concentrate receiving position is controlled in the modes that monitoring is carried out through the automatic camera shooting module, and a mechanical component is driven by the PLC. According to the method, it can be guaranteed that the table feeding concentration and the table feeding volume are stabilized to be in the optimal states, the grading index can be improved, and the labor cost can be greatly reduced.

Owner:云南锡业研究院有限公司研究设计院

Magnetic shaker

InactiveCN101062487AStrong magnetic forceImprove sorting efficiencyMagnetic separationWet separationMagnetic bearingEngineering

The magnetic rocker comprises the bracket with bed head and surface which sets mineral and water supply grooves, magnetic bearing mechanism along the direction of the bed with magnetic system set on the magnetic bearing mechanism. The introduction of compound force field solves the serious issue of mixture, increasing selection efficiency, improving selection index. It meets special requirement for magnetic mineral and non-magnetic mineral separation and nonmetal equipment requirement except iron ones.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

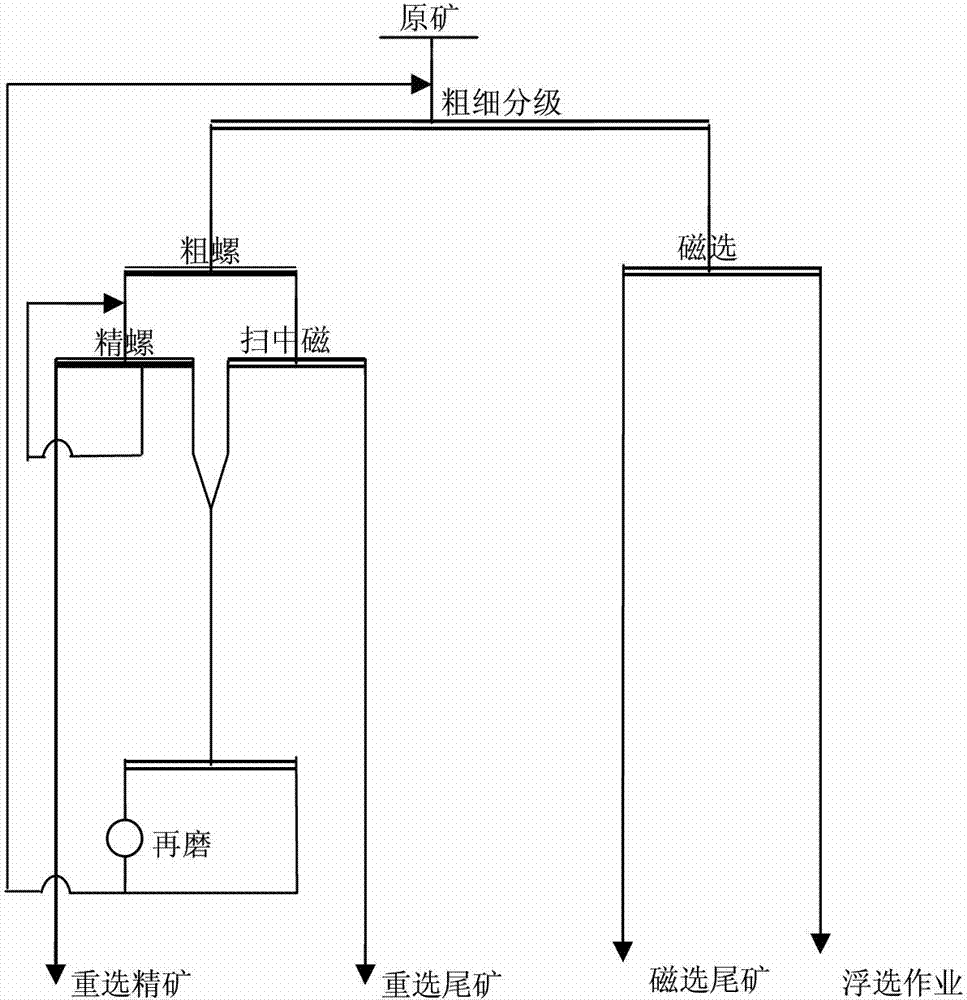

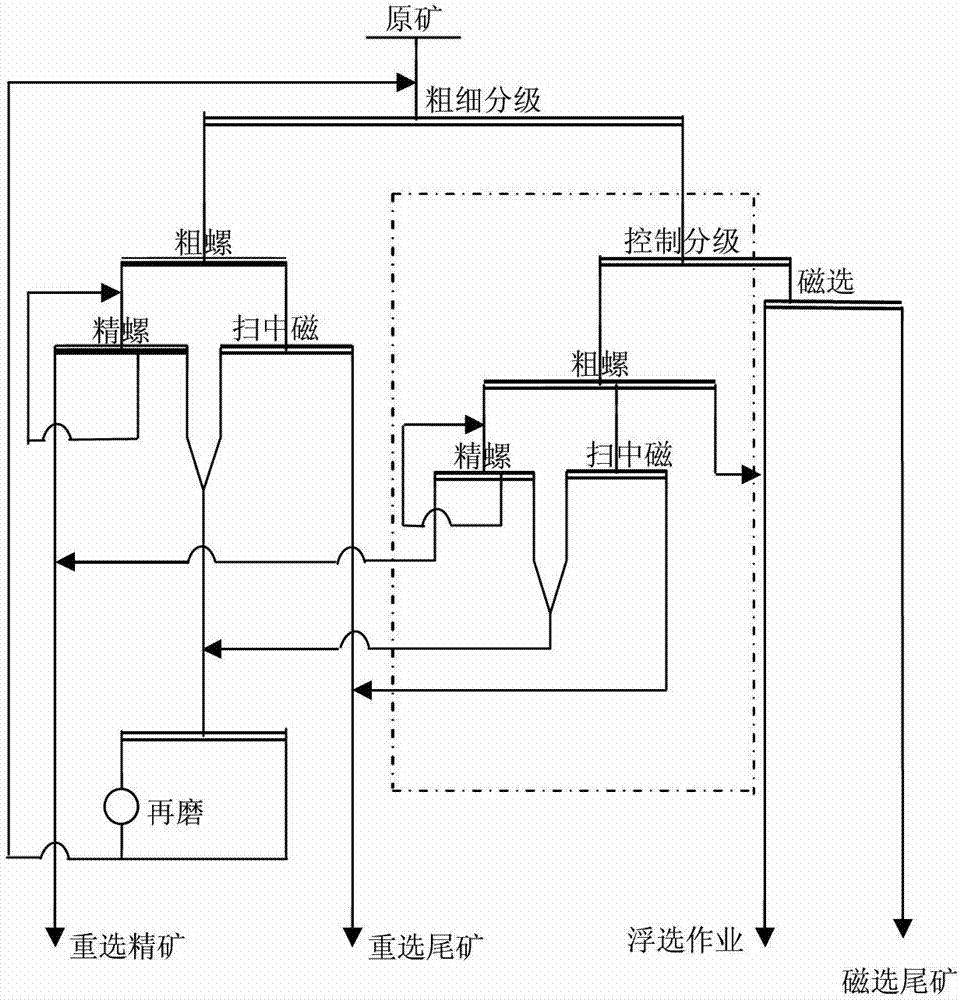

Poor hematite grading level and narrow level sorting process

The invention provides a poor hematite grading level and narrow level sorting process, which is characterized in that three levels of products can be obtained by using a double-section cyclone to grade and reselect a primary ore grinding product and are respectively fed into subsequent selection work to realize grading level and narrow level sorting. The poor hematite grading level and narrow level sorting process comprises the specific steps of: (1) grinding raw ores by a primary ball grinder and grinding the raw ores until the content of a -0.074-micron grain level in primary grading overflowing is 55%; feeding to a cyclone to carry out primary rough-fine grading work to obtain deposited sand of the cyclone of the primary rough-fine grading work; and feeding into primary reselection; (b) feeding the overflowing of the primary rough-fine grading work to secondary rough-fine grading work; and feeding deposited sand of the secondary rough-fine grading work to secondary reselection; and (c) feeding an overflowing product of the secondary rough-fine grading work to magnetic selection work, and feeding concentrate ores of the magnetic selection work to floating selection work, wherein tailings of the magnetic selection work are magnetic selection tailings. The invention provides strengthened rough-fine grading work of a poor hematite ore treatment plant so that the concentrate ore cost is effectively reduced and the iron level of the comprehensive tailings is controlled.

Owner:ANSTEEL GRP MINING CO LTD

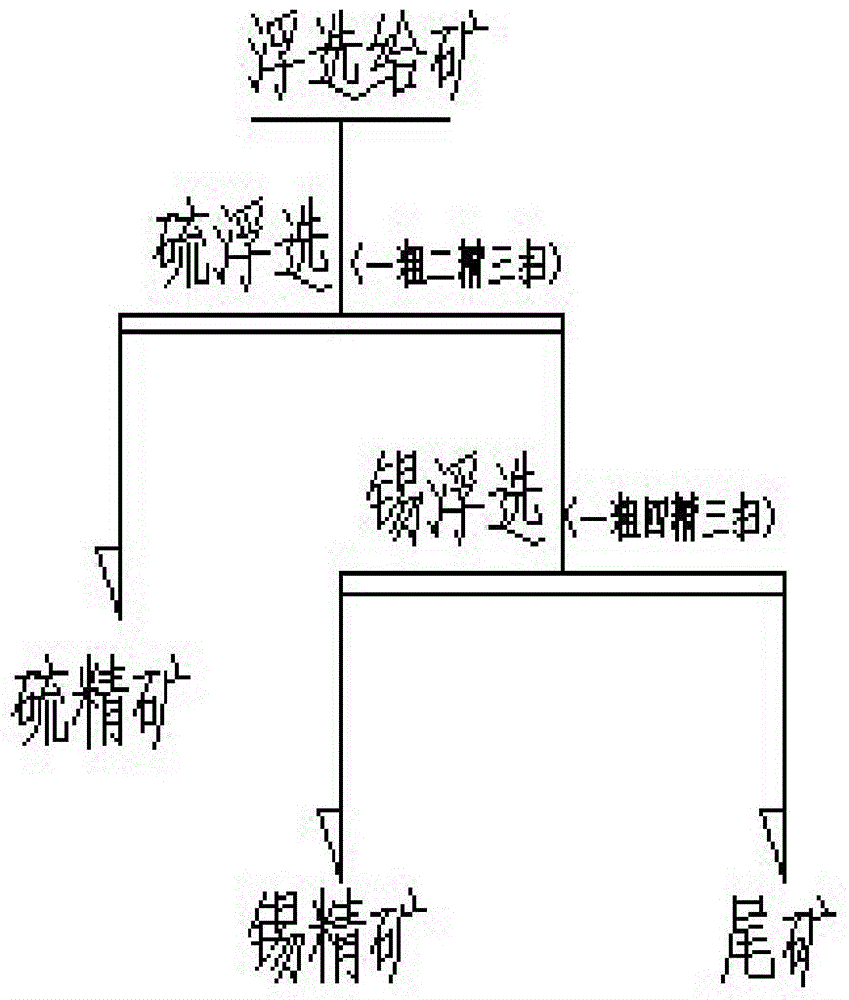

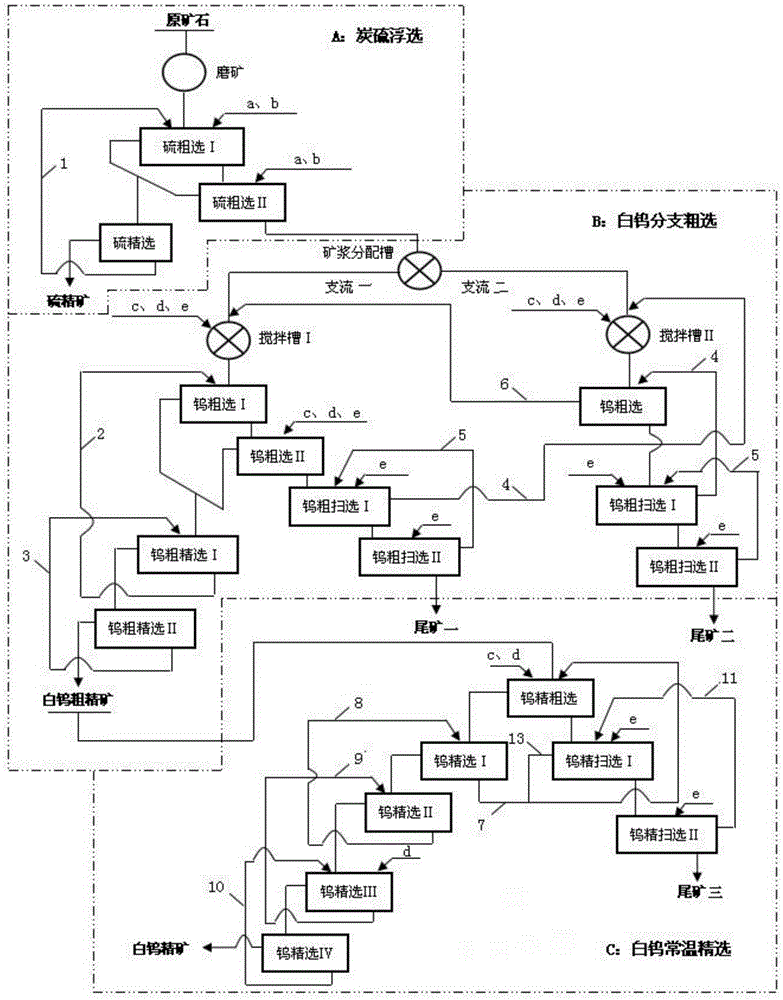

Low-grade scheelite branch floating method

The invention relates to a low-grade scheelite branch floating method. The low-grade scheelite branch floating method includes the following steps and conditions that carbon and sulfur flotation is carried out, namely, kerosene and sulphide ore collecting agents are added into ore pulp based on the weight of dry raw ore for two times of sulfur rougher flotation, and sulfur concentration is carried out on sulfur rough concentrate without any chemicals to obtain sulfur concentrate; scheelite branch rougher flotation is carried out, namely, sulfur rougher tailing pulp is fed into a distribution tank I and a distribution tank II and then evenly divided into a branch flow I and a branch flow II, sodium carbonate is added respectively to adjust the pH value of the ore pulp, modified sodium silicate and 731 oxidized paraffin soap are added, stirred and mixed into the pulp, then wolfram grab picking is carried out, the 731 oxidized paraffin soap is added into wolfram rougher tailings to carry out two times of wolfram rough scavenging, and then two times of wolfram rough concentration are carried out, so that scheelite rough concentrate and tailings are obtained; and scheelite normal-temperature concentration is carried out, namely, sodium carbonate is added into the scheelite rough concentrate to adjust the pH value of the ore pulp, then modified sodium silicate is added to carry out wolfram concentrate rougher flotation, the tailings obtained after wolfram concentrate rougher flotation are subjected to two times of wolfram concentrate scavenging, the tailings are separated out, then middlings obtained after wolfram concentrate rougher flotation are subjected to four times of wolfram concentrate scavenging, and scheelite scavenging concentrate is obtained. The low-grade scheelite branch floating method has the advantages of being short in process, easy to operate, high in adaptability, low in processing cost, good in dense settlement effect, easy to industrialize and the like, and is suitable for floating application of low-grade scheelite.

Owner:ZIJIN MINING GROUP

Magnetic iron ore beneficiation method

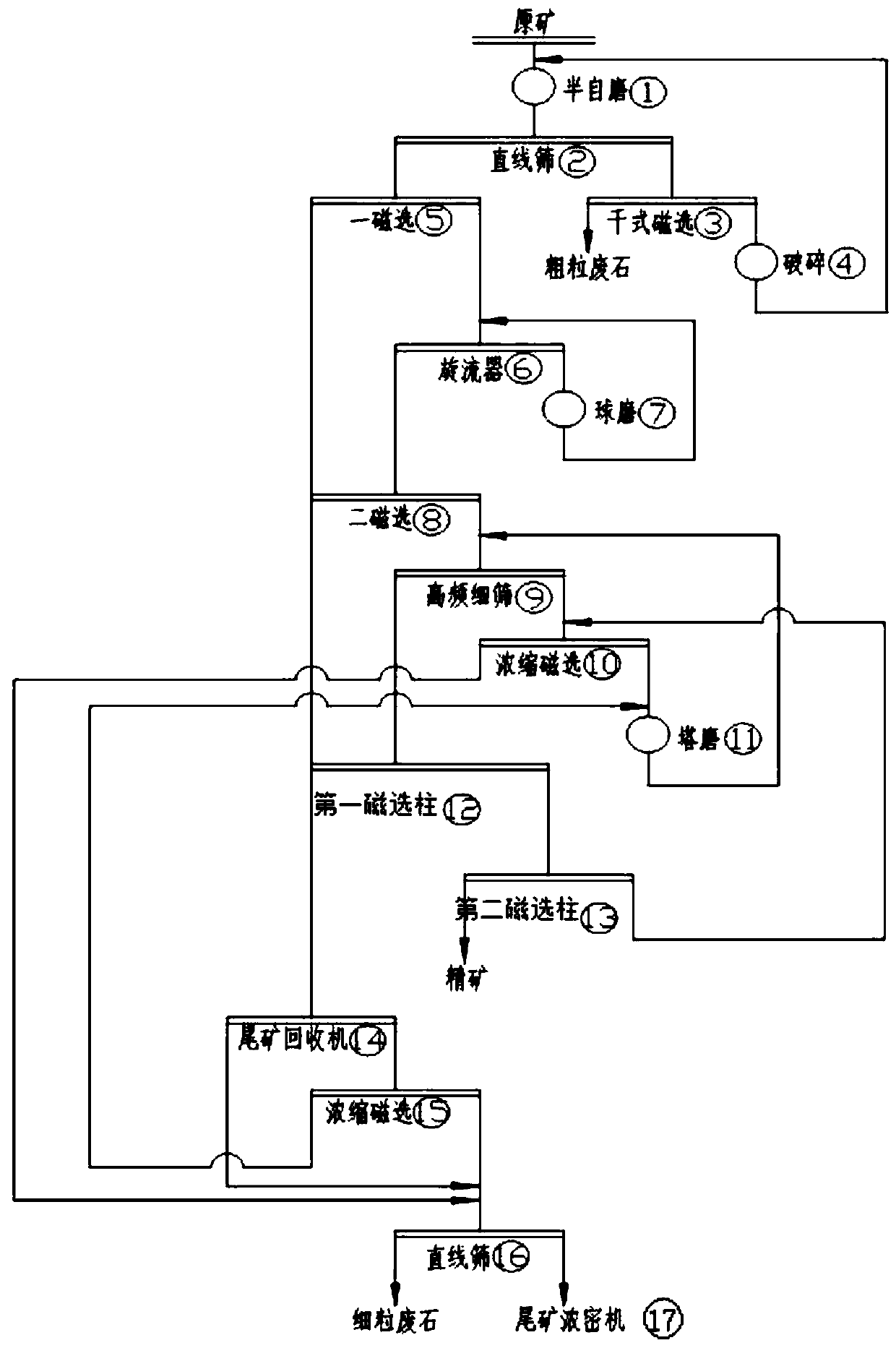

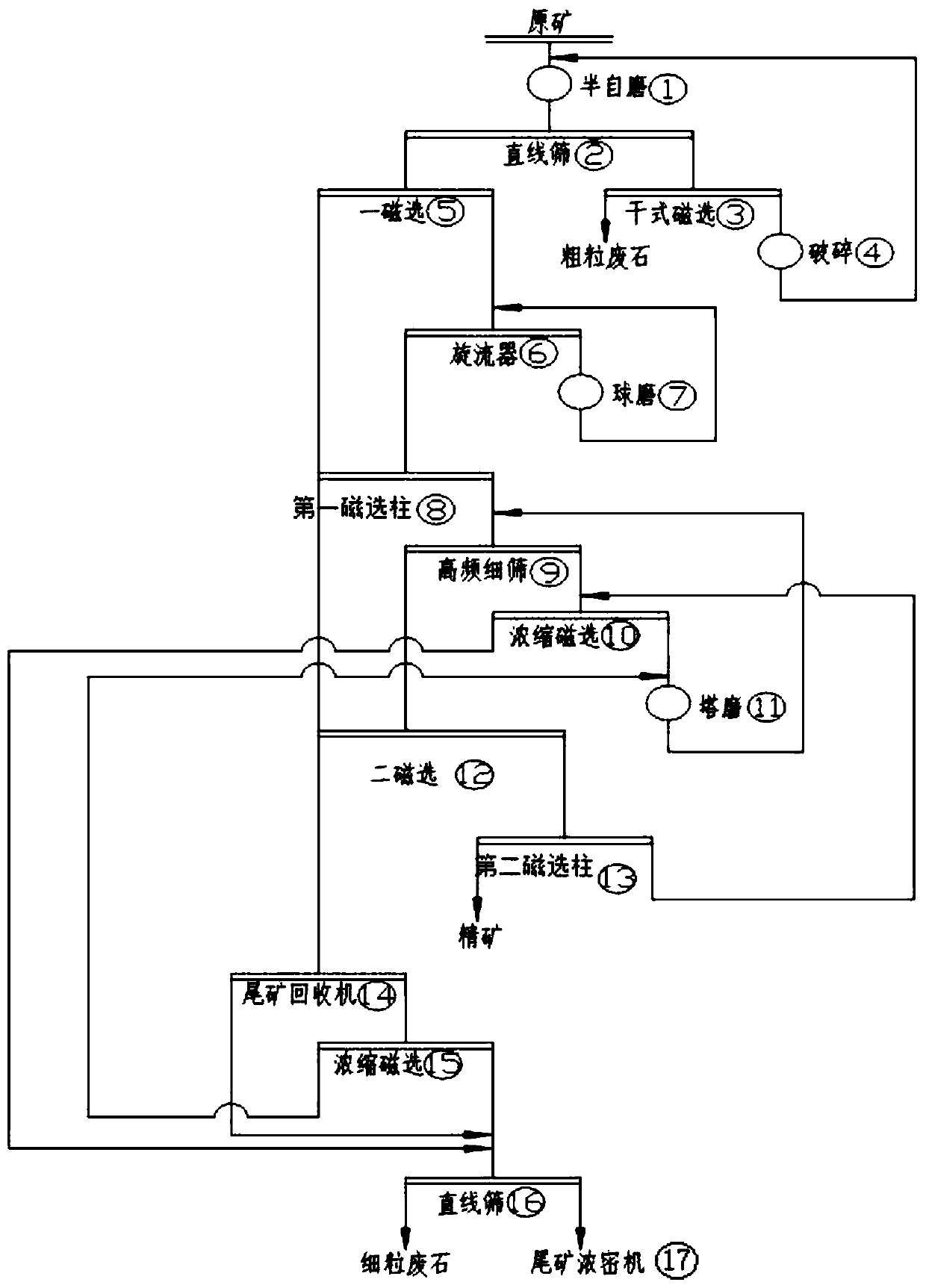

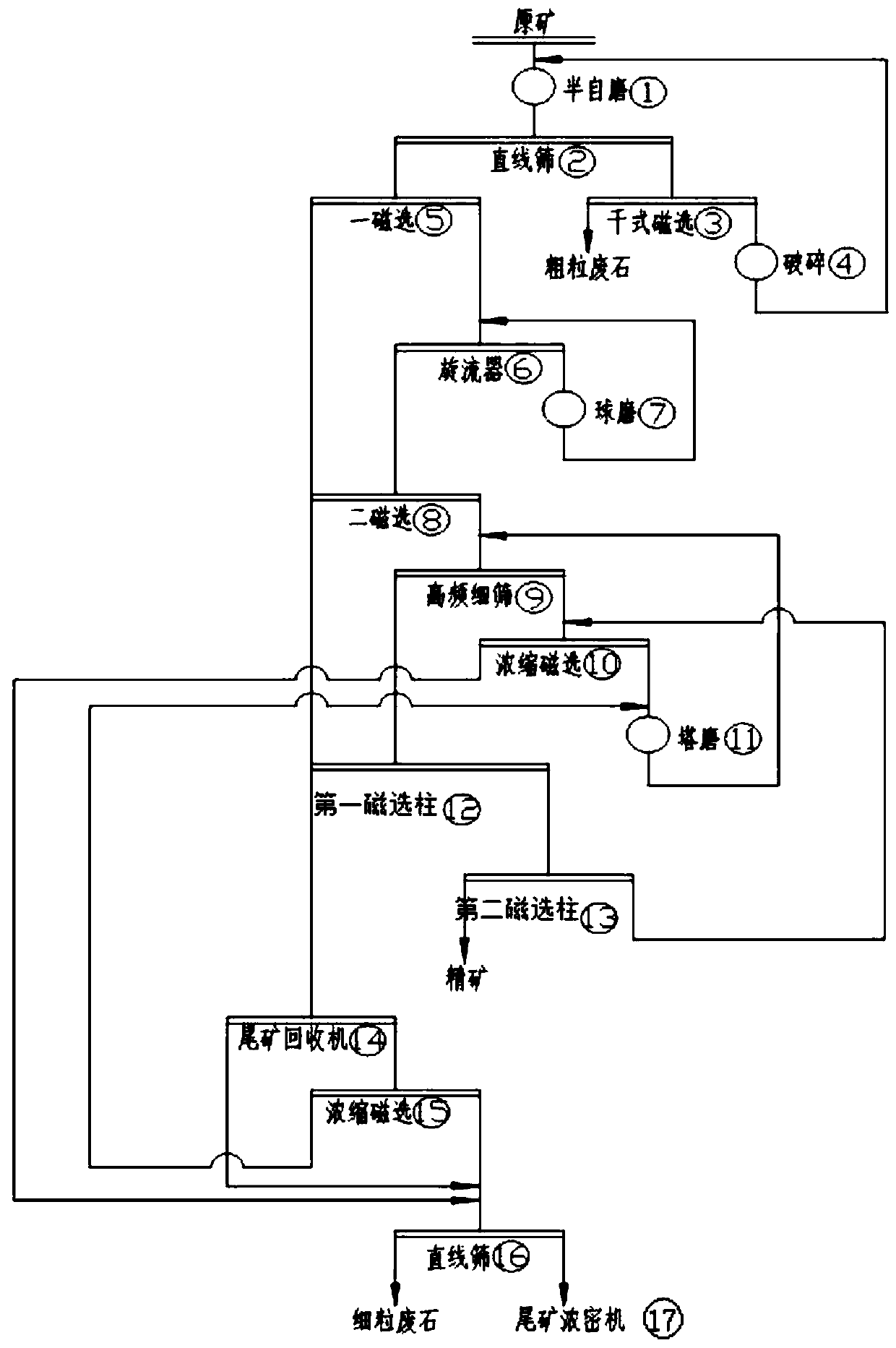

The invention discloses a magnetic iron ore beneficiation method which comprises the steps of utilizing a semi-autogenous grinding or autogenous grinding mill for replacing crushing operation with a long flow, so that the crushing operation efficiency is improved, meanwhile, the failure rate of the crushing operation is reduced, and advanced waste abandoning can be realized; adopting a two-stage ore grinding process comprising ball milling and tower milling for grinding and separating operation, so that the ore grinding efficiency is improved; adopting two-stage low intensity magnetic separation, high-frequency fine screening, a first magnetic separation column and a second magnetic separation column for separation operation, so that a separation index is improved; scavenging, recovering and concentrating stage tailings, and returning to ore grinding and recleaning, so that the metal recovery rate is improved; and grading primary and secondary magnetic tailings through a linear screenso as to obtain building materials for sale. According to the ore beneficiation method provided by the invention, the process flow is shortened, meanwhile, the process stability and the separation precision are greatly improved, and the production efficiency is improved.

Owner:MASTEEL GRP MINING CO LTD

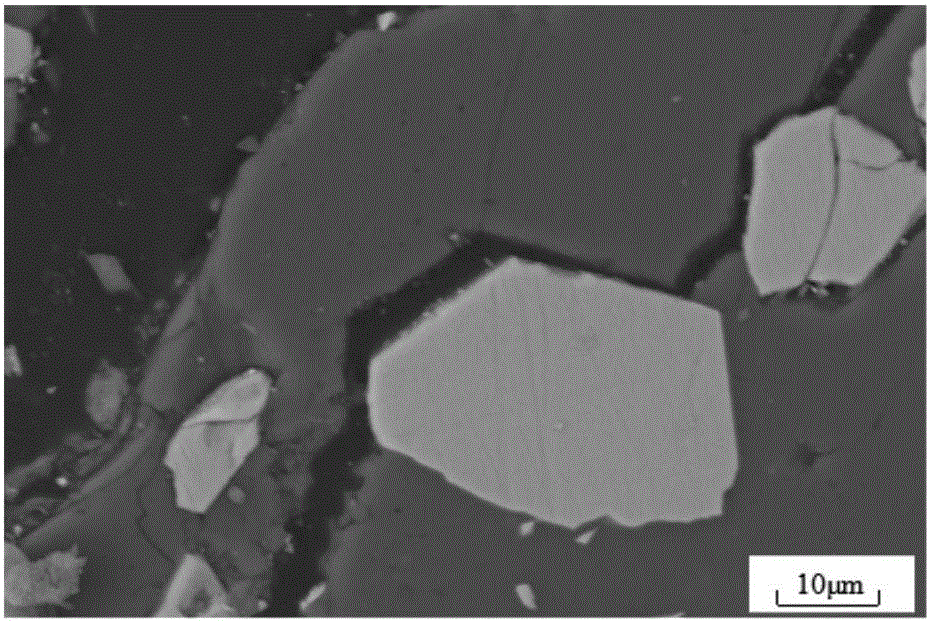

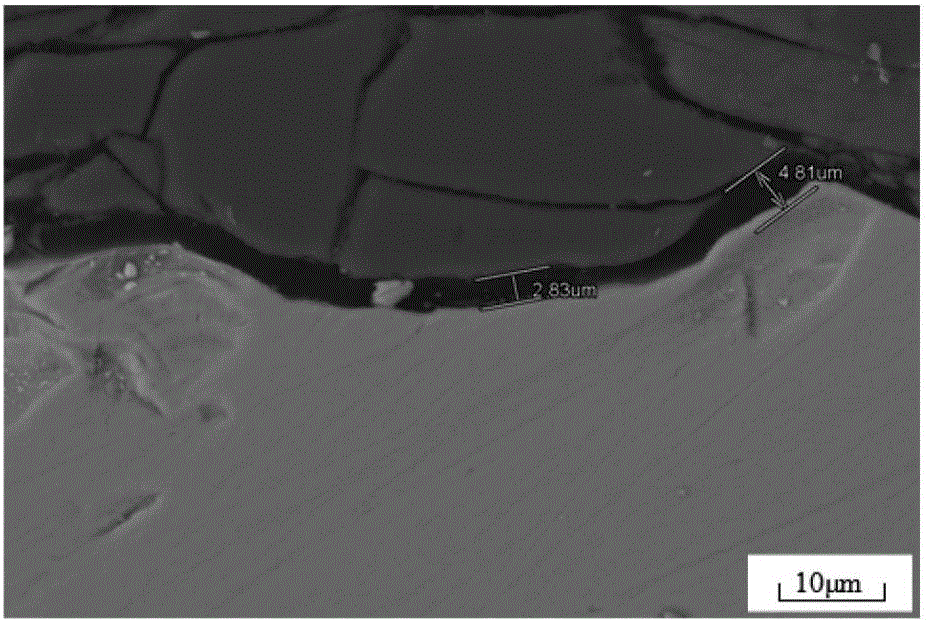

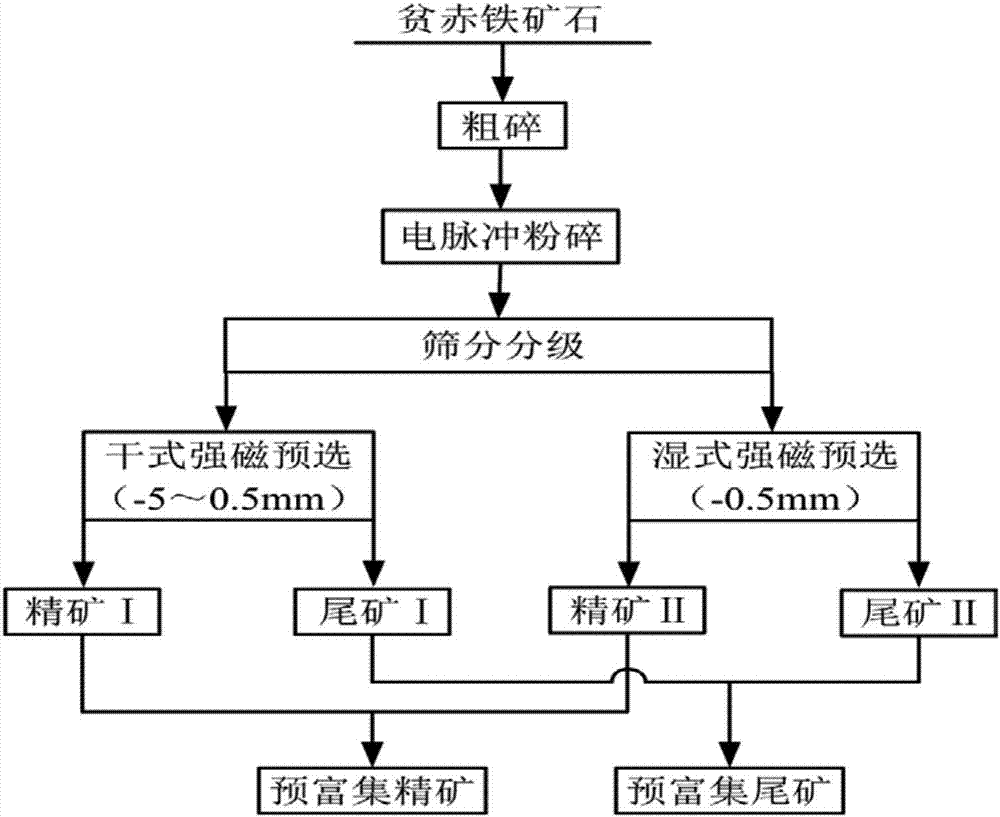

High-voltage electric pulse selective pulverizing and pre-enriching method for lean hematite ores

ActiveCN106984412ADoes not destroy crystal formImproved cleavage propertiesSievingScreeningElectrical impulseHigh pressure

The invention discloses a high-voltage electric pulse selective pulverizing and pre-enriching method for lean hematite ores. The method is characterized in that high-voltage electric pulse pulverizing pretreatment is realized by utilizing dielectric property difference of different minerals in ores, energy with extremely high power density is output by high-voltage pulses, and the energy is discharged onto the lean hematite ores through a high-voltage electrode; valuable mineral hematite, gangue mineral quartz and the like in the ores form a plurality of micro cracks among interfaces, so that selective dissociation for hematite and gangue minerals is realized; and pre-enriched concentrate is obtained through strong magnetic separation. The method improves beneficiation feed grade of the ores, and is beneficial for improving follow-up grading and sorting indexes.

Owner:NORTHEASTERN UNIV

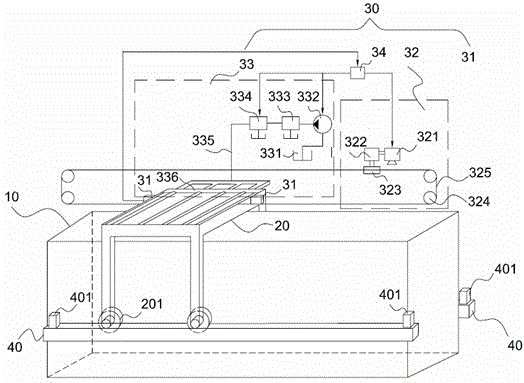

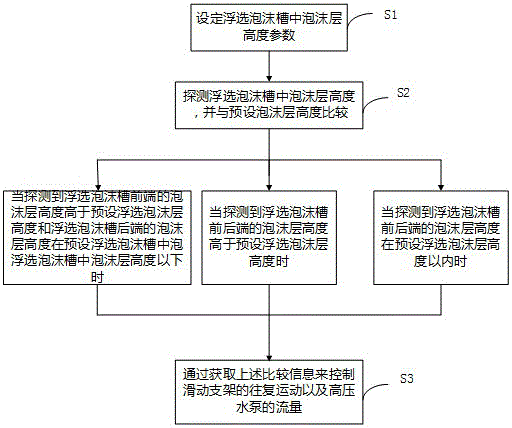

Self-adaptive flotation foam de-foaming device and de-foaming method

ActiveCN104147813ADone successfullyReduce liquidityFoam dispersion/preventionMineral SourcesReciprocating motion

The invention relates to the field of mineral processing flotation equipment, and specifically discloses a self-adaptive flotation foam de-foaming device and a de-foaming method. The device comprises a flotation foam tank, a sliding support arranged on the flotation foam tank, and a self-adaptive control de-foaming system used for controlling the reciprocating movement of the sliding support on the flotation foam tank. According to the invention, the de-foaming method is an advanced, high-efficiency, pollution-free and continuous novel flotation foam removing method. With the device and the method, a foam control difficulty caused by large foam amount, viscous foam, and low foam fluidity when a collecting agent such as amine is used in mineral flotation is solved. With the method, flotation process work can be completed smoothly, sorting index can be improved, and high-efficiency processing and comprehensive utilization of the type of mineral resource can be realized.

Owner:KUNMING UNIV OF SCI & TECH

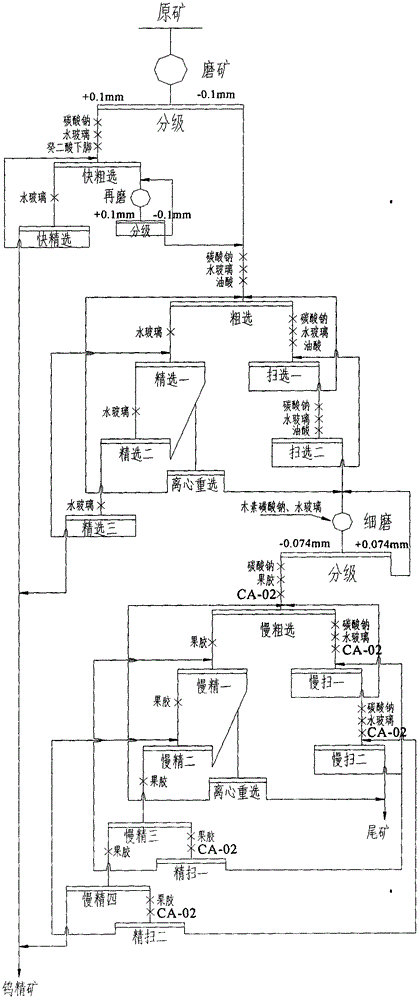

Skarn type tungsten ore beneficiation method

InactiveCN104785355AImprove sorting effectSolve for uniformityWet separationCoarse particleMaterials science

The invention discloses a skarn type tungsten ore beneficiation method. Tungsten concentrates are finally obtained through the steps of raw ore levigation, quick floatation of coarse particles, middling regrinding, quick scheelite flotation, medium grain floatation, fine grinding, fine grain floatation, centrifugal reselection of middlings and the like. Separation indexes of separated skarn type tungsten ore are good, and the grade and recovery rate of the tungsten concentrates are high. The skarn type tungsten ore beneficiation method is stable, efficient, good in separation effect, high in adaptability, high in recovery index, capable of achieving low production cost and suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

Efficient composite collector for copper sulfide minerals and application of collector

The invention relates to an efficient composite collector for copper sulfide minerals and application of the collector. The collector is characterized by comprising ethyl isopropylxanthogenic formate, isopropyl ethyl thiocarbamate, terpenic oil, kerosene and industrial heptane. A preparation method includes: injecting a certain amount of the isopropyl ethyl thiocarbamate into a container at the temperature of 15-30 DEG C, then sequentially adding the ethyl isopropylxanthogenic formate, the erpenic oil, the kerosene and the industrial heptane under the condition of stirring, stirring for 60 minutes to allow the components to be totally dissolved, and finally subjecting the materials to standing to obtain a brownish red transparent liquid product, namely the efficient composite collector for the copper sulfide minerals. Practical application proves that the collector has the advantages of good selectivity, high in copper sulfide mineral collecting capability, simple production process and no other hazardous substances.

Owner:SHENYANG RES INST OF NONFERROUS METALS

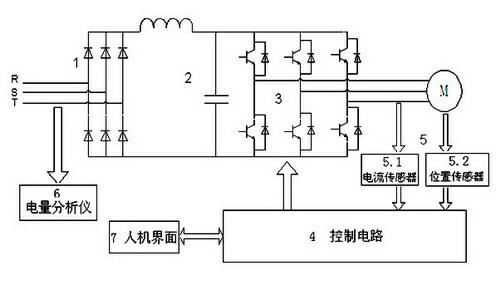

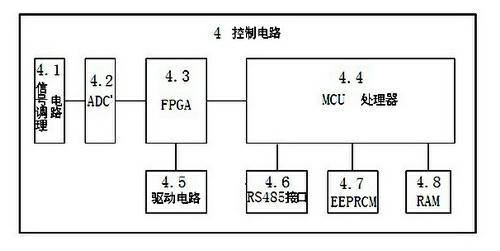

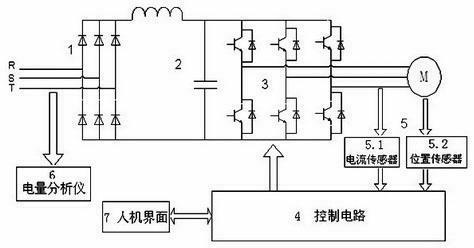

Variable frequency speed regulation control device and variable frequency speed regulation control method for flotation machine

InactiveCN102624301AConvenient speed adjustmentEfficient startAC motor controlSingle motor speed/torque controlHuman–machine interfaceDrive motor

The invention relates to a variable frequency speed regulation control device and a variable frequency speed regulation control method for a flotation machine. The device comprises a rectification circuit, a filtering circuit, an inversion circuit, a control circuit, a sensor, an electric quantity analyzer and a human-computer interface, wherein the rectification circuit is connected with the inverter circuit through the filtering circuit; the permanent magnet motor M is connected with the inversion circuit; the control circuit is connected with the permanent magnet motor M through the sensor, and is also connected with the inversion circuit and the human-computer interface ; and the electric quantity analyzer is connected with the rectification circuit. The control method comprises the following steps of: setting rotating speed, detecting a position signal, detecting a current signal, regulating the rotating speed and performing failure alarming and processing. The device and the method have the advantages that: the permanent magnet direct drive motor of the flotation machine is controlled to be randomly regulated within a rotating speed range, and optimal flotation rotating speed can be conveniently set according to actual conditions by a user; and the most power-saving economical rotating speed of the device can be realized by regulating output current under a material-free light-load working condition, and remarkable energy-saving effects can be achieved.

Owner:武汉长海电气科技开发有限公司

Selective flocculation desiliconisation method against low aluminum silicon ratio bauxite

InactiveCN101439316AImprove sorting indexGood separation effectDifferential sedimentationSodium carbonateAluminium

The invention discloses a method of selective flocculating settling desiliconization from alumyte with low ratio of silicate to aluminium by using a polymeric flocculant. The method comprises: the alumyte with low ratio of silicate to aluminium is ground to be fine, and is added with sodium carbonate when in the milling grinding process; the mixture is added with fresh water to be stirred, and then is settled for desliming after being fully scattered; the first part of alumyte having the qualified ratio of silicate to aluminium is separated; modified starch is added in a section of desliming tail mine; then, the desliming tail mine which is added with flocculant is fully stirred and scattered, and then is settled for desliming; the second part of alumyte concentrated ore having the qualified ratio of silicate to aluminium is separated. The sorting method has high target, good separating effect, simple process flow and low cost. By adopting the method, when the alumyte with the ratio of silicate to aluminium of 5.6-5.8 of crude ore is processed, the alumyte concentrated ore having the recovery rate of 85.51% and the ratio of silicate to aluminium of 9.02 is obtained; when the alumyte with the ratio of silicate to aluminium of 4.88 of crude ore is processed, the alumyte concentrated ore having the recovery rate of 86.74% and the ratio of silicate to aluminium of 6.63 is obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

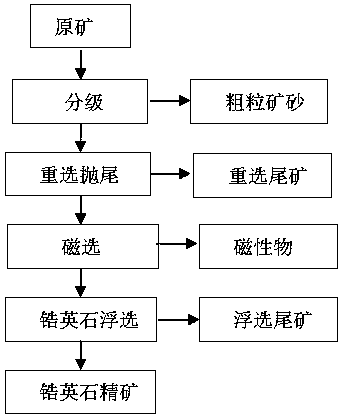

A kind of zircon beneficiation combination agent and beneficiation method

The invention discloses a zircon beneficiation composite reagent and a beneficiation method. Each ton of reagents for adding to crude ore comprises, by weight, 100-2000 g of sulfuric acid, 0-500 g of inhibitors and 100-1000 g of collecting agents. The inhibitors are sodium silicate, the collecting agents comprise petroleum sodium sulfonate and hydroximic acid, and a mass ratio of the petroleum sodium sulfonate to the hydroximic acid is 1:1-10. The zircon beneficiation composite reagent and the beneficiation method has the advantages that the zircon beneficiation composite reagent is good in zircon collecting property and selectivity, and the grade and the recovery of zircon concentrate can be further improved; the sodium silicate can be added to materials to be used as the inhibitors for fine silt or clay minerals when the materials contain few fine silt or clay minerals during flotation operation.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

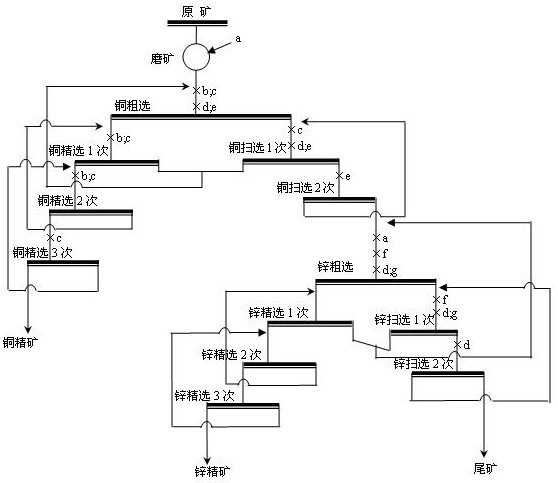

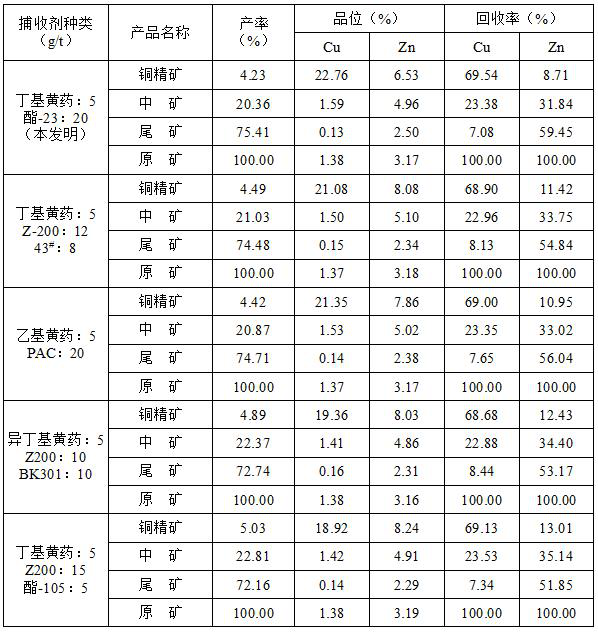

Flotation separation method for high-sulfur copper-zinc ore

The invention relates to a flotation separation method for high-sulfur copper-zinc ore, which comprises the steps of (1) grinding crushed high-sulfur copper-zinc raw ore to obtain ore pulp; (2) under the condition that the pH value of the ore pulp is 7-8, adding inhibitors, namely, sodium sulfite and zinc sulfate, a collecting agent, namely, butyl xanthate and a collecting foaming agent, namely, ester-23 for copper roughing, and respectively obtaining copper rough concentrate ore pulp and roughing tailing ore pulp; (3) enabling the copper rough concentrate pulp to be subjected to three-time concentration operation, and obtaining copper concentrate; (4) conducting copper scavenging operation on the roughing tailing pulp twice, and obtaining copper scavenging tailings; (5) sequentially adding lime, copper sulfate, butyl xanthate serving as a collecting agent and 2 # oil into the copper scavenging tailings for zinc roughing, and respectively obtaining zinc rough concentrate ore pulp and zinc roughing tailing ore pulp; (6) carrying out three times of concentration operation on the zinc rough concentrate pulp to obtain zinc concentrate; and (7) conducting zinc scavenging operation on the zinc roughing tailing pulp twice, and obtaining zinc scavenging tailings. Efficient flotation separation of copper and zinc is achieved, and copper flotation return water and zinc flotation return water are recycled.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

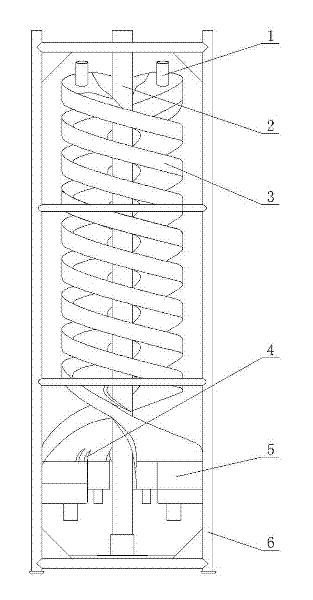

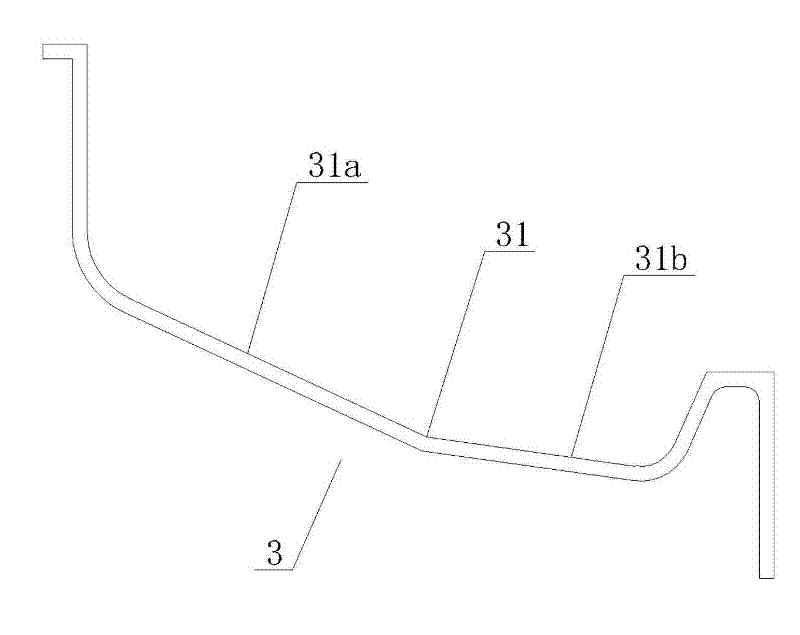

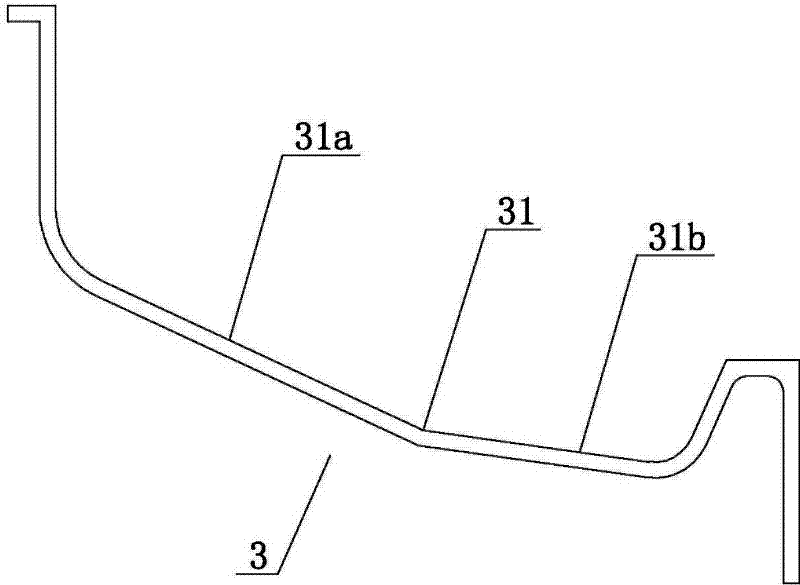

Spiral concentrator

The invention relates to a spiral concentrator comprising a stand, a central tube, a spiral groove, an ore feeding bucket and an ore receiving bucket, wherein the central tube is arranged on the stand; the spiral groove is fixedly connected with the central tube; the ore feeding bucket is arranged on the upper end of the spiral groove; the ore receiving bucket is arranged on the lower end of the spiral groove; the cross section of the separation surface of the spiral groove is formed by a straight line near an outer edge and a straight line near an inner edge, and the straight line near the outer edge and the straight line near the inner edge respectively downwards incline from outside to inside. According to the spiral concentrator disclosed by the invention, because the separation surface of the spiral groove is set to be formed by two inclined planes with different transverse inclination angles, after ore pulp is delivered into the separation surface, ore pulp distribution of thinner ore pulp near the inner edge and thicker ore pulp near the outer edge is formed, the thinner ore pulp flows in a laminar flow manner, and the thicker ore pulp flows in a weak turbulent flow manner, and therefore, transverse circulation action is higher and then the recovery of rough-grain and medium-grain heavy ores is facilitated; when the spiral concentrator disclosed by the invention is in use, water does not need to be added, zonation is distinct, operation is convenient, and the production cost of users is reduced; and in addition, the separation surface is of an integral structure, and therefore the spiral concentrator disclosed by the invention has the advantages of simple and reliable structure, high abrasion-resistant property and long service life.

Owner:广州粤有研矿物资源科技有限公司

Method for improving ore grinding efficiency through electric pulse ore pretreatment

The invention discloses a method for improving ore grinding efficiency through electric pulse ore pretreatment, and belongs to the technical field of mineral processing. According to the method, high-voltage electric pulse crushing pretreatment is achieved through dielectric property differences of different minerals in ore, high-voltage pulse outputs energy with the extremely high power density, electricity is discharged to ore through a high-voltage electrode, multiple microcracks are formed on the interfaces between gangue minerals and useful minerals in ore, accordingly, the strength of ore is lowered, the dissociation characteristic is improved, the ore grinding efficiency can be improved, energy consumption can be reduced, and separation indexes can be modified and improved.

Owner:NORTHEASTERN UNIV

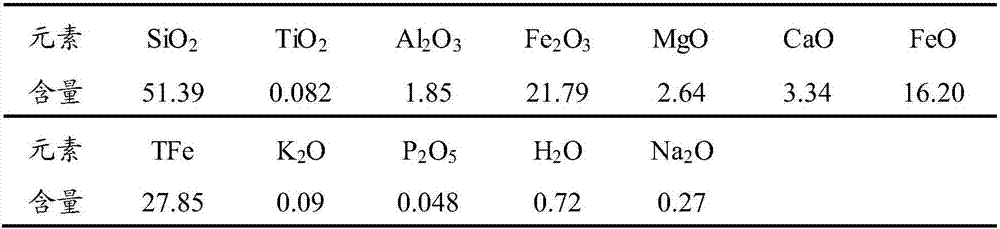

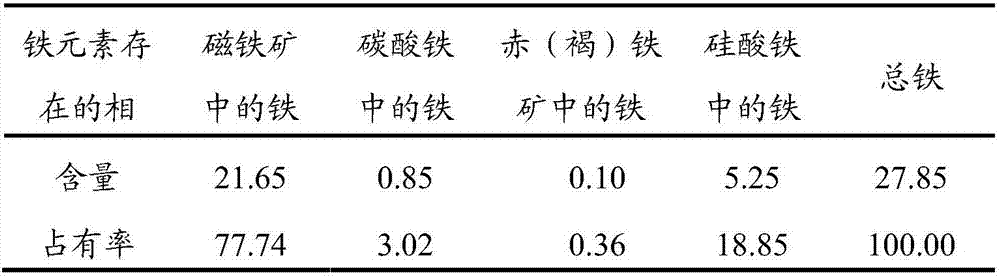

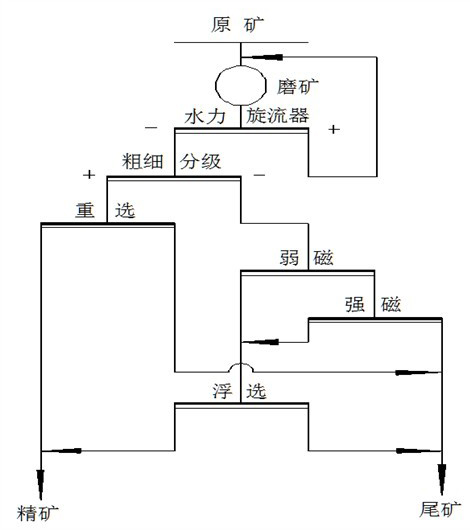

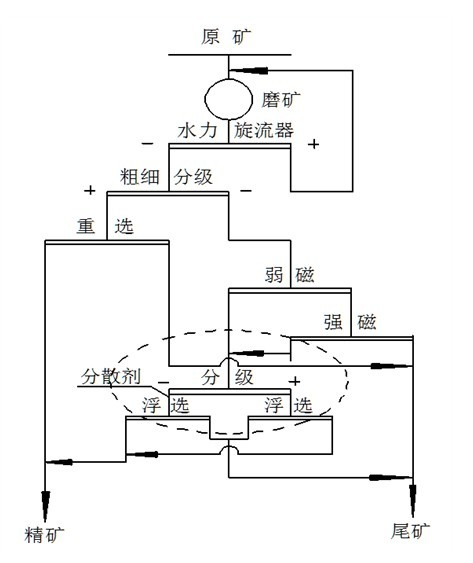

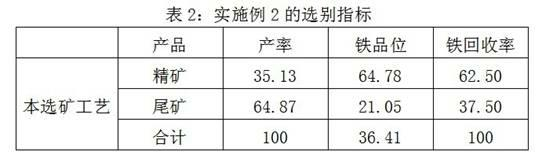

Mineral processing technology of hematite containing chlorite

The invention discloses a mineral processing technology of hematite containing chlorite, which comprises the processes of stage grinding, classification of crudeness and fineness, gravity separation of coarse grains, magnet weakening of small particles to obtain essence, strong magnet separation and flotation, and the process of flotation and classification is arranged between the strong magnet separation and flotation; the flotation and classification is to classify the flotation feedings, and a second flotation is respectively carried out for classified coarse grains and small particles. According to the technology, a classified flotation is creatively proposed, i.e. the classification of crudeness and fineness is carried out for the flotation feedings, the affect to flotation caused by small particles of gangue minerals can be effectively eliminated, and the separation index is increased. According to the technology, the defect of the flotation index deterioration by chlorite is overcome, low-graded hematite containing argillaceous gangue minerals can be effectively utilized, the theoretical and practical basis is provided for the separation and the flotation of hematite containing chlorite, and the affect to surrounding environment by store-up minerals is eliminated.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

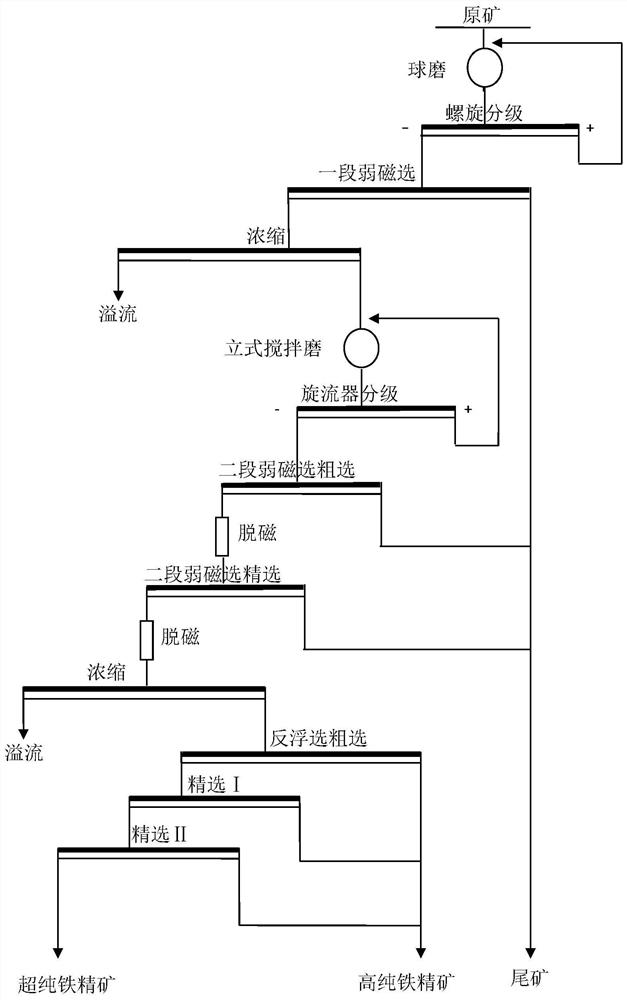

Beneficiation method for preparing ultra-pure iron ore concentrate by adopting magnetite concentrate

ActiveCN112090578ASimple systemWide variety of sourcesFlotationGrain treatmentsOre concentrateMineralogy

The invention discloses a beneficiation method for preparing ultra-pure iron ore concentrate by adopting magnetite concentrate. First-stage ore grinding-grading-first-stage low-intensity magnetic separation, first-stage low-intensity magnetic separation concentrate concentration and dehydration, second-stage ore grinding-grading, second-stage low-intensity magnetic separation roughing-demagnetization-second-stage low-intensity magnetic separation concentration, second-stage low-intensity magnetic separation concentration concentrate demagnetization-concentration operation are separately adopted; demagnetization treatment is carried out on the obtained second-stage low-intensity magnetic separation concentration concentrate, and then concentration and reverse flotation operation are carriedout; and finally, the ultra-pure iron ore concentrate with the TFe content larger than 72.0%, the SiO<2> content smaller than or equal to 0.20% and the acid insoluble matter content smaller than or equal to 0.17% and the high-purity iron ore concentrate with the TFe content larger than 70.7% are obtained. A reverse flotation operation collecting agent is prepared by heating and modifying dodecylamine and a glacial acetic acid solution according to the mass ratio of 4: 1. The method has the advantages of flexible and variable beneficiation process flow, stability, reliability, high applicability, high efficiency and energy conservation. A flotation reagent is simple in system, raw materials are wide in source, small in dosage, good in selectivity and very environment-friendly.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com