Efficient composite collector for copper sulfide minerals and application of collector

A composite collector and copper sulfide technology, which is applied in the field of flotation reagents and high-efficiency composite collectors, can solve problems such as poor collection capacity, fluctuations in production indicators, and difficulty in improving copper grade, and achieve simple production process and clean environment Friendly, good emulsifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

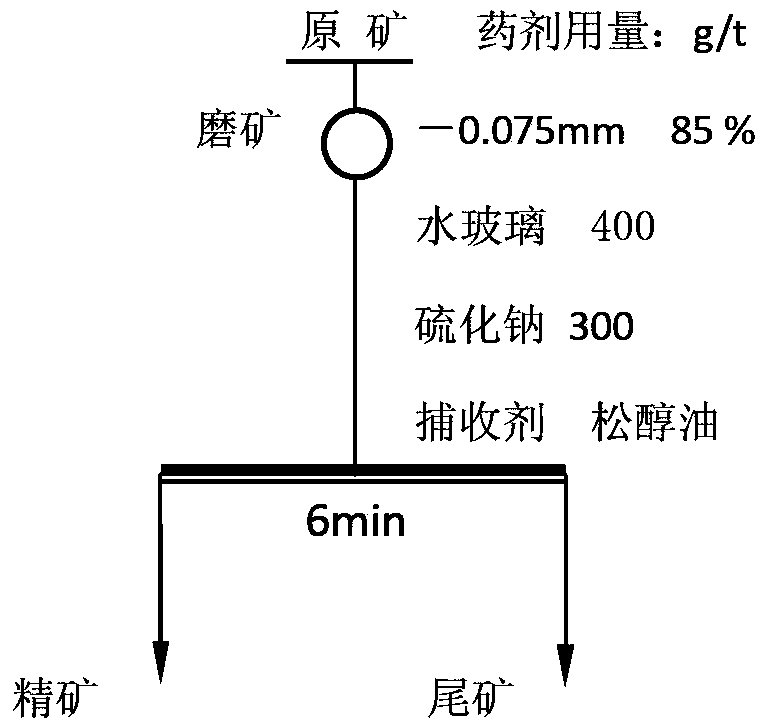

[0028] Embodiment 1: copper smelting reverberatory slag flotation copper:

[0029] The copper sulfide mineral high-efficiency composite collector using reflective slag flotation copper is composed of: isoamyl xanthate ethyl formate 20%, isopropyl ethyl thiocarbamate 65%, pine oil 5% , kerosene 5%, industrial heptane 5%.

[0030] The reverberatory furnace copper slag can be roughly divided into four phases under the microscope, which are metal sulfide phase, magnetite phase, iron silicate phase and glassy phase, of which iron silicate, glassy and magnetite are mostly contained , the metal sulfide content is less, mainly including chalcopyrite, bornite, copper blue, chalcocite, blue chalcocite, sulfur cobalt ore, sulfur copper cobalt ore, pyrrhotite, etc., among which the recyclable elements are copper.

[0031] Metal sulfides are mostly in the form of pellets and drops, and a small amount of them are small and irregular. They are often concentrated in the slag, and the partic...

Embodiment 2

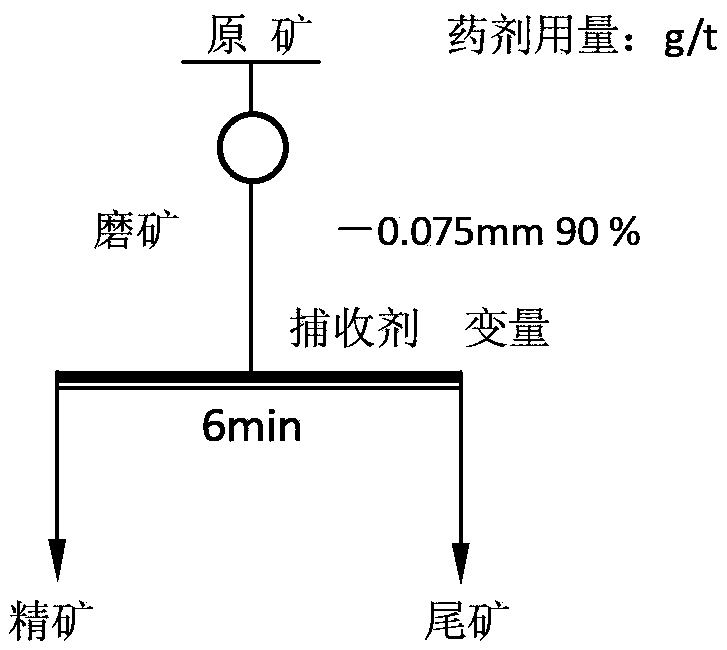

[0038] Example 2: Flotation of copper with converter slag from a certain copper smelting

[0039] Copper sulfide mineral high-efficiency composite collector for flotation copper smelting converter slag is composed of: 30% isoamyl xanthate ethyl formate, 45% isopropyl ethyl thiocarbamate, terpineol oil 10%, kerosene 8%, industrial heptane 7%.

[0040] The copper sulfide minerals in a copper smelting converter slag are mainly chalcocite, followed by a small amount of bornite and copper blue. Chalcocite mostly forms copper sulfide particles alone, and a small amount intersperses bornite in a grid pattern to form aggregates of copper sulfide, and the boundary between bornite and bornite is not clear; Crystals form copper sulfide. Copper sulfide is mainly distributed in the slag in the shape of pellets and drops of varying thickness, and a small amount is in small irregular shape, which is often dispersed in the slag. Spherical natural copper and fine-grained cuprous oxide are o...

Embodiment 3

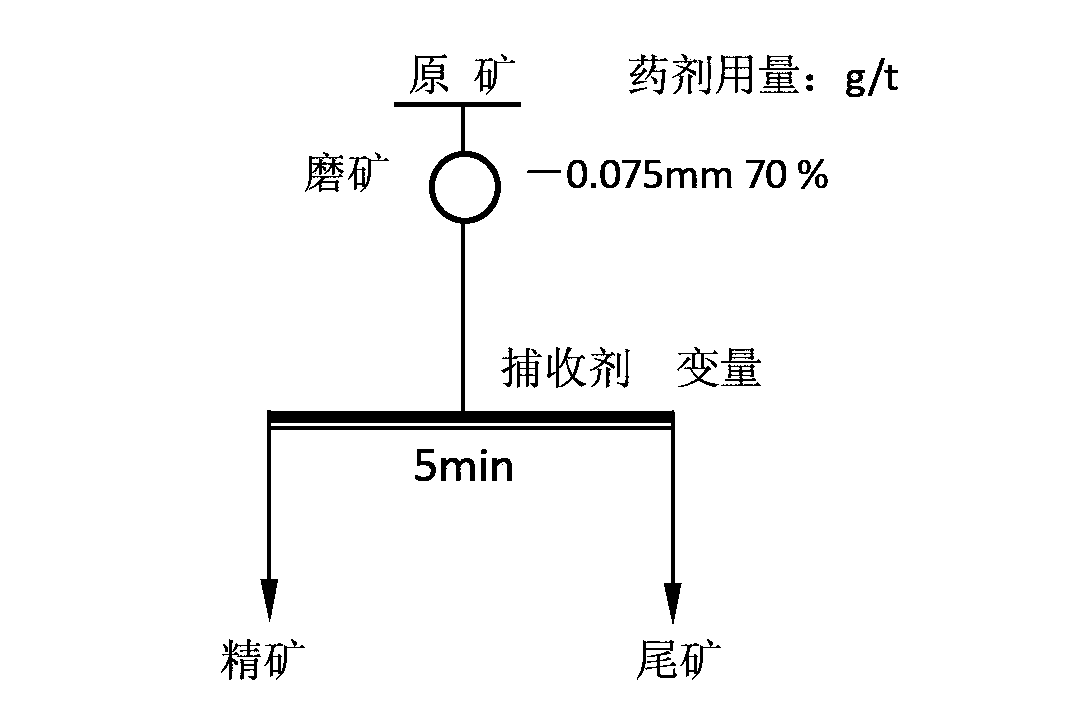

[0044] Embodiment 3: certain copper-zinc ore sorting

[0045] The copper sulfide mineral high-efficiency composite collector using the copper-zinc ore is composed of: isoamyl xanthate ethyl formate 10%, isopropyl ethyl thiocarbamate 70%, pine oil 5%, Kerosene 10%, industrial heptane 5%.

[0046] The copper-zinc ore belongs to skarn-type copper-zinc sulfide ore. The main metal minerals in the ore are chalcopyrite, sphalerite, pyrite, limonite, followed by copper blue, malachite, etc.; the gangue minerals are mainly quartz, tremolite, olivine, pyroxene and carbonate etc.; precious metal minerals are natural silver, a very small amount of silver-gold mine and gold-silver mine. The raw ore contains 1.45% copper and 2.50% zinc; the oxidation rate of copper is 5.88%, and the oxidation rate of zinc is 6.65%.

[0047] The experimental research adopts the priority sorting process. When the grinding fineness is -0.075mm and accounts for 70%, the copper recovery rate of this collector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com