Separation method for low-grade manganese ore with high silicon accompanying a little limonite and psilomelane

A technology of low-lean manganese ore and beneficiation method, applied in chemical instruments and methods, high gradient magnetic separator, magnetic separation, etc., can solve the problems of poor production and operation efficiency, poor separation effect, etc., and achieve reduced production and separation. The effect of process flow, improving grade and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

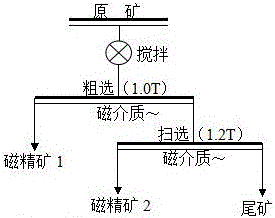

[0057] Such as figure 1 As shown, (1) Low-poor manganese ore with high silicon associated with a small amount of limonite and a small amount of manganese ore, the manganese content is 6.16%, and the content of ore particles with a particle size range of 0.005-0.16mm is greater than 70%;

[0058] (2) Stir the minerals for 60 minutes to fully dissociate the manganese minerals and gangue minerals.

[0059] (3) The ore pulp with a raw ore concentration of 20% is subjected to full-size magnetic separation roughing, and the whole amount enters a high-gradient magnetic separator. The roughing magnetic field strength is 1.0T. After obtaining the magnetic concentrate, continue to sweep. The sweeping magnetic field strength is 1.2T, after one rough and one sweep separation, manganese concentrate can be produced at one time, and the tailings can be thrown out to complete the separation of low-poor manganese ore. The process is simple and effective.

[0060]

[0061] Full-size mag...

Embodiment 2

[0066] The test results of the magnetic field strength of the whole particle size magnetic roughing

[0067]

[0068] It can be seen from the results that: with the increase of the magnetic field intensity, the recovery rate of manganese concentrate increases, but the grade of concentrate decreases. When the magnetic field strength is 1.0T, the manganese concentrate grade of 28.51% and the recovery rate of 46.70% can be obtained. It is suitable to choose the magnetic field strength of the coarse selection of the whole grain class as 1.0T.

Embodiment 3

[0070] The test results of magnetic field strength for full-size magnetic separation

[0071]

[0072] The test results show that the 2 grade of magnetic concentrate decreases with the increase of the magnetic field intensity, but the recovery rate increases. Considering comprehensively, the magnetic field intensity of 1.2T is suitable for scanning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com