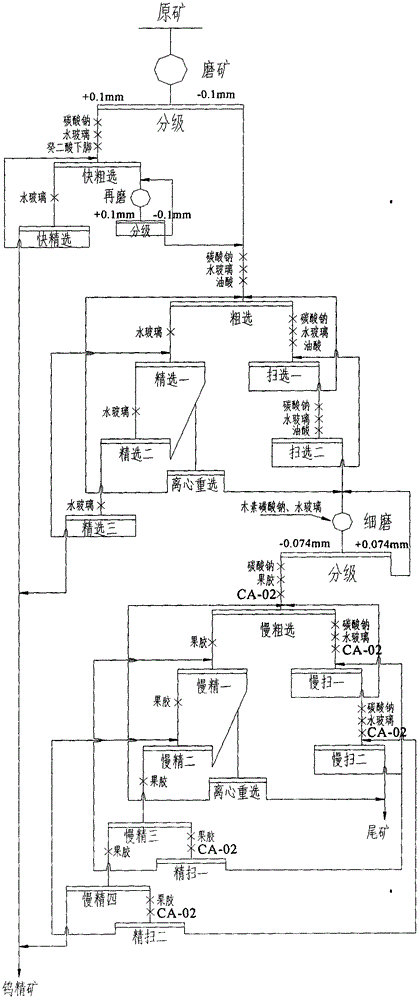

Skarn type tungsten ore beneficiation method

A beneficiation method and skarn technology are applied in the field of beneficiation of skarn-type tungsten ore, which can solve the problems of large influence of gangue minerals, high sorting difficulty and low sorting efficiency, and achieve efficient recovery and sorting effects. Good, avoid the effect of excessive mudding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Mix 150g 2-hydroxy-3-naphthohydroxamic acid, 100g 1,1,2-octyl tricarboxylic acid, 100g 1-phenyl-2-mercaptobenzimidazole, use a beaker as a container at normal temperature and pressure, and magnetically stir Stir for 100-120 minutes to obtain collector CA-02.

Embodiment 2

[0051] Mix 250g 2-hydroxy-3-naphthohydroxamic acid, 100g 1,1,2-octyl tricarboxylic acid, 100g 1-phenyl-2-mercaptobenzimidazole, use a beaker as a container at normal temperature and pressure, and magnetically stir Stir for 100-120 minutes to obtain collector CA-02.

Embodiment 3

[0053] Mix 200g 2-hydroxy-3-naphthohydroxamic acid, 100g 1,1,2-octyltricarboxylic acid, 100g 1-phenyl-2-mercaptobenzimidazole, use a beaker as a container at normal temperature and pressure, and magnetically stir Stir for 100-120 minutes to obtain collector CA-02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com