Method forpreparing iron concentrate for making iron from phosphorus-containing oolitic hematite

A technology for oolitic hematite and iron concentrate, applied in the direction of improving process efficiency, etc., can solve the problem of low iron grade and recovery rate of iron concentrate, unexplored iron concentrate for ironmaking, complicated intercalation relationship, etc. problem, to achieve the effect of improving the sorting effect, low cost and good dephosphorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

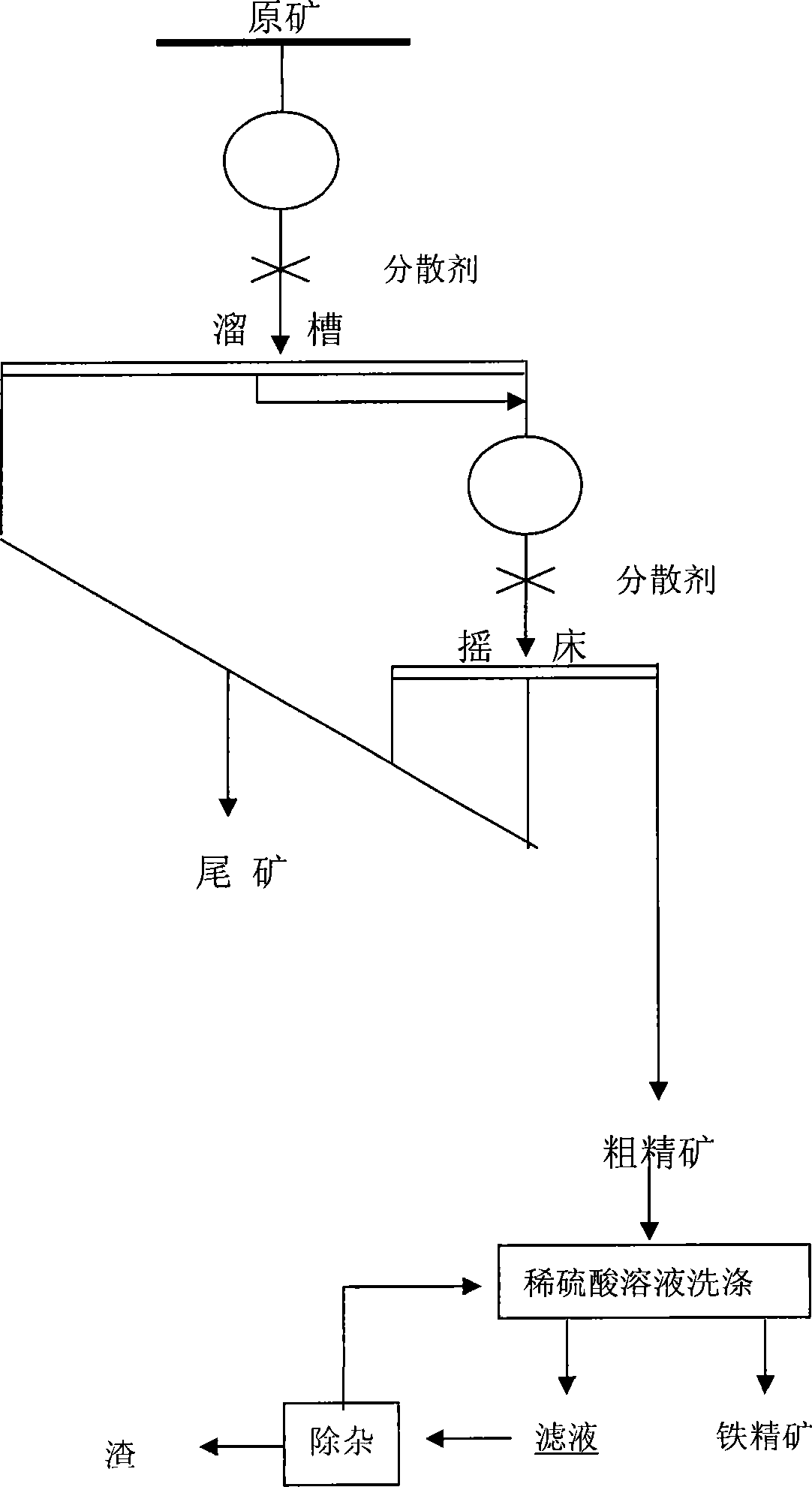

[0012] Example 1, referring to the accompanying drawings, the "Ningxiang type" oolitic hematite with a TFe of 35.27% and a P of 0.82%, is wet-ground to a particle size of less than 0.074mm and accounts for 40% of the mass percentage of the whole hematite %, adjust the pulp concentration to 20%, add water glass with an amount of 0.5kg / t as a dispersant and stir to fully disperse the pulp, use spiral chute for sorting, and regrind the obtained primary concentrate until the particle size is less than 0.074mm, accounting for 80% About 0.2kg / t of water glass is added as a dispersant, and the shaker is used for separation. The obtained iron concentrate is dephosphorized by leaching with 0.5% sulfuric acid for 5 minutes, and the obtained iron grade is 62.21%, and the recovery rate is 52.30%. Iron concentrate with a P content of 0.058%.

Embodiment 2

[0013] Embodiment 2, see accompanying drawing, TFe is 35.27%, P is the oolitic hematite of 0.82%, and the hematite of grain size less than 0.074mm accounts for about 50% of the mass percentage of whole hematite by wet grinding, adjusts the slurry When the concentration reaches 25%, add 0.7kg / t of water glass as a dispersant and stir to fully disperse the ore pulp. Use spiral chute for separation, and then grind the obtained primary concentrate until the particle size is less than 0.074mm, accounting for about 80%. The added amount is 0.3kg / t water glass is used as dispersant, separated by shaking table, and the obtained iron concentrate is dephosphorized by leaching with 1.0% sulfuric acid for 10 minutes. The obtained iron grade is 63.12%, the recovery rate is 51.50%, and the P content is 0.055%. of iron concentrate.

Embodiment 3

[0014] Example 3, referring to the accompanying drawings, TFe is 37.51%, P is oolitic hematite of 0.88%, wet grinding until the hematite with particle size less than 0.074mm accounts for about 60% of the mass percentage of the whole hematite, adjust the slurry When the concentration reaches 30%, add water glass at an amount of 1kg / t as a dispersant and stir to fully disperse the ore pulp, and use a spiral chute for separation. kg / t of water glass as dispersant, separated by shaking table, the obtained iron concentrate is dephosphorized by leaching with 1% sulfuric acid for 10 minutes, and the grade of iron can be 63.35%, the recovery rate is 50.89%, and the P content is 0.050%. iron concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com