A beneficiation process for producing chemical-grade chromite concentrate

A technology for chromite and concentrate, which is applied in the field of beneficiation and recovery of high-grade chromite ore, can solve the problems of interference with magnetic separation and shaking table separation effect, large differences in physical properties, and low chromite content, etc. The effect of improving the beneficiation efficiency, simple process and high recovery rate of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

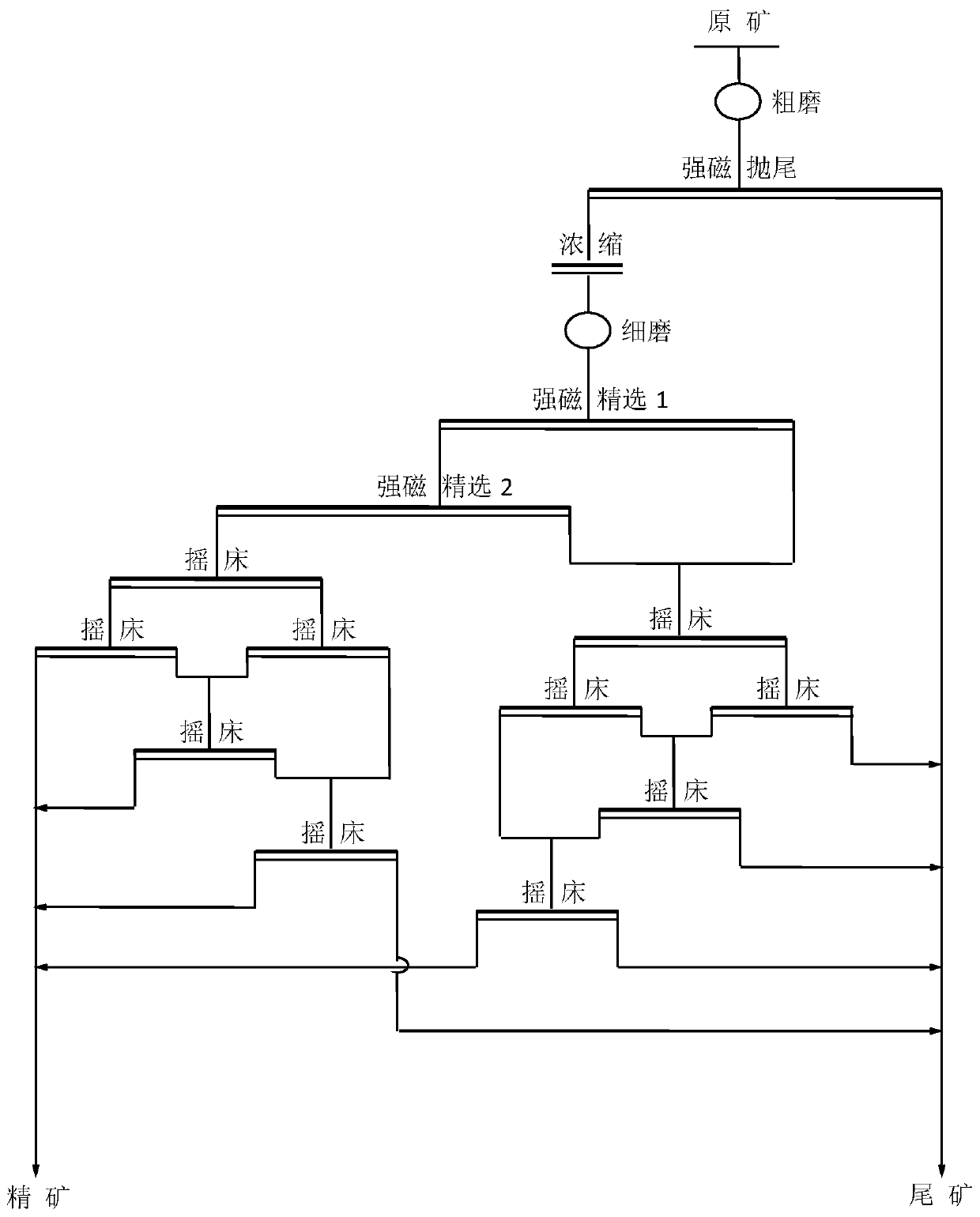

[0027] The ore sample is a certain chromite ore in Xinjiang, the raw ore Cr 2 O 3 The content is 32.55%, SiO 2 The content is 12.63%. The study of technological mineralogy shows that the chromium minerals in the ore are mainly chromite, and a small amount of chromium-rich spinel: the gangue minerals are mainly talc, and the second is serpentine and carbonate minerals. For the ore, use such as figure 1 The process flow shown is selected, and the specific process parameters are as follows:

[0028] a. After rough grinding the raw ore with a rod mill, the mineral size in the slurry is -0.074mm, and the mass fraction is 65%;

[0029] b. The magnetic separation intensity when the strong magnetic tail is thrown is 1.1T, the stroke is 23mm, and the stroke frequency is 300 times / min;

[0030] c. After the coarse concentrate obtained after strong magnetic tailing is finely ground by the Isa mill, the mineral size in the slurry is -0.045mm, and the mass fraction is 85%, of which the mineral c...

Embodiment 2

[0035] The ore sample is a certain chromite ore in Tibet, the raw ore Cr 2 O 3 The content is 30.12%, SiO 2 The content is 13.88%. The study of technological mineralogy shows that the chromium minerals in the ore are mainly aluminum chromite, with a small amount of chromium-rich spinel; the gangue minerals are mainly serpentine, followed by forsterite and carbonate minerals. For the ore, use such as figure 1 The process flow shown is selected, and the specific process parameters are as follows:

[0036] a. After rough grinding the ore with a rod mill, the mineral size in the slurry is -0.074mm, and the mass fraction is 60%;

[0037] b. The magnetic separation intensity when the strong magnetic tail is thrown is 1.4T, the stroke is 26mm, and the stroke frequency is 300 times / min;

[0038] c. After the coarse concentrate obtained after strong magnetic tailing is finely ground by the Isa mill, the mineral size in the slurry is -0.045mm, and the mass fraction is 87%. The mineral content...

Embodiment 3

[0043] The ore sample is a certain chromite ore in Tibet, the raw ore Cr 2 O 3 The content is 43.60%, SiO 2 The content is 9.20%. The study of technological mineralogy shows that the chromium minerals in the ore are mainly aluminum chromite, followed by chromite and a small amount of chromium-rich spinel; the gangue minerals are mainly forsterite and secondly serpentine , A small amount of chlorite and quartz. For the ore, use such as figure 1 The process flow shown is selected, and the specific process parameters are as follows:

[0044] a. After rough grinding the ore with a rod mill, the mineral size in the slurry is -0.074mm, and the mass fraction is 58%;

[0045] b. The magnetic separation intensity when the strong magnetic tail is thrown is 1.2T, the stroke is 18mm, and the stroke frequency is 240 times / min;

[0046] c. After the coarse concentrate obtained after strong magnetic tailing is finely ground by the Isa mill, the mineral size in the slurry is -0.045mm, and the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com