Method for extracting and separating scandium-iron solution by using microchannel reactor

A micro-channel reactor, micro-reactor technology, applied in the direction of instrument, process efficiency improvement, special data processing application, etc., can solve the problems of difficult separation and few process parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A method for extracting and separating scandium iron solution in a microchannel reactor, comprising the following steps:

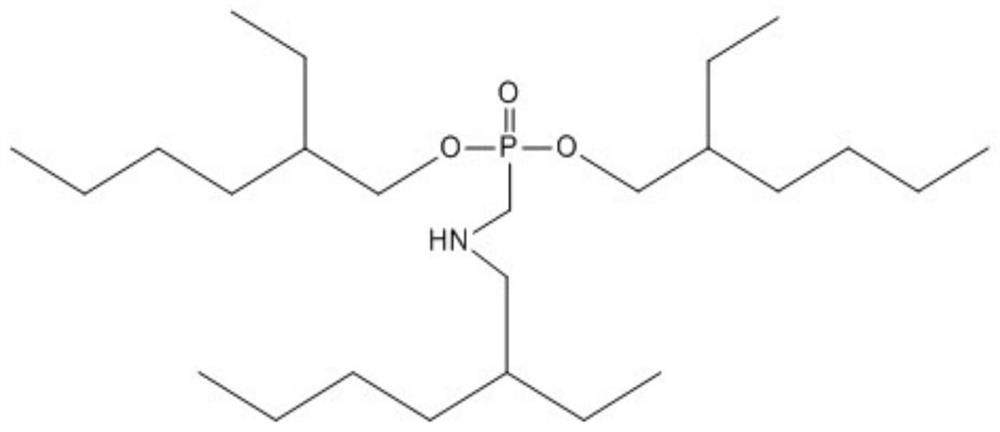

[0077] S1 put the extractant and the diluent in the microchannel reactor, and at the same time put the standard scandium iron solution in the microchannel reactor for reaction, the reaction starts, count the various process parameters in the reaction stage, and analyze the effect of the process parameters on the scandium extraction rate. Effect, Effect of Iron Extraction Rate and Separation Coefficient; Standard Solution Configurations:

[0078] Calculate and weigh the required contents of scandium sulfate and ferric sulfate, add deionized water to dissolve in a beaker, stir until completely dissolved, transfer the solution to a volumetric flask for constant volume, and adjust the pH to 2.00 with concentrated sulfuric acid to obtain Standard solution with scandium ion concentration of 99.99mg / L and iron ion concentration of 428.36mg / L;

[0079] In ...

Embodiment 2

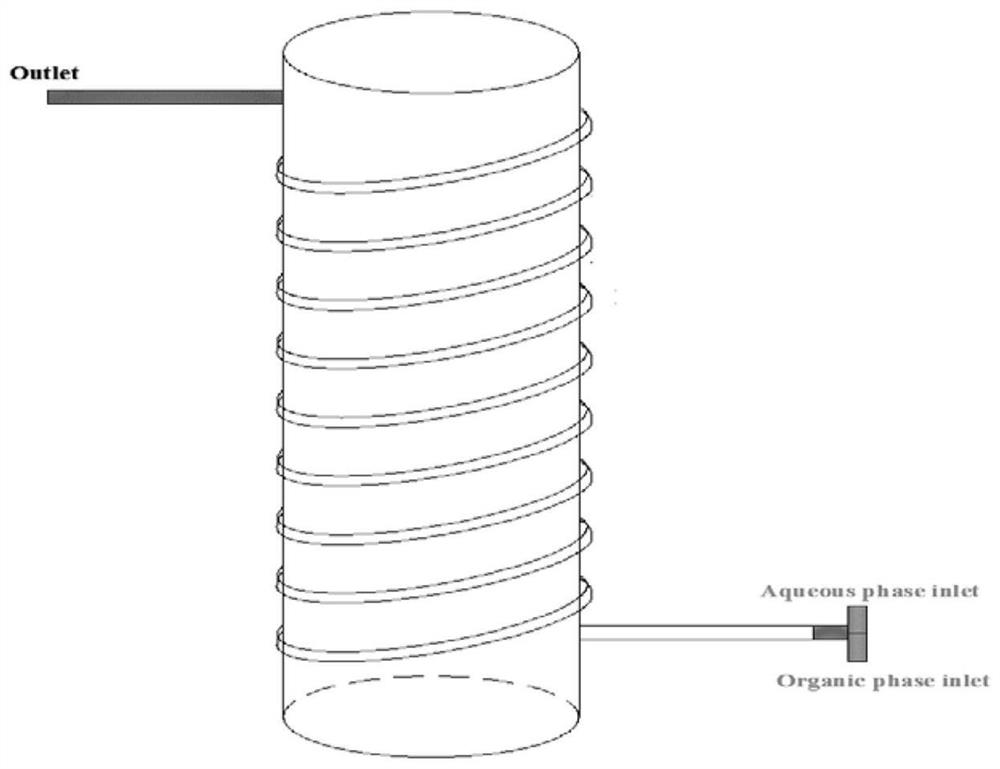

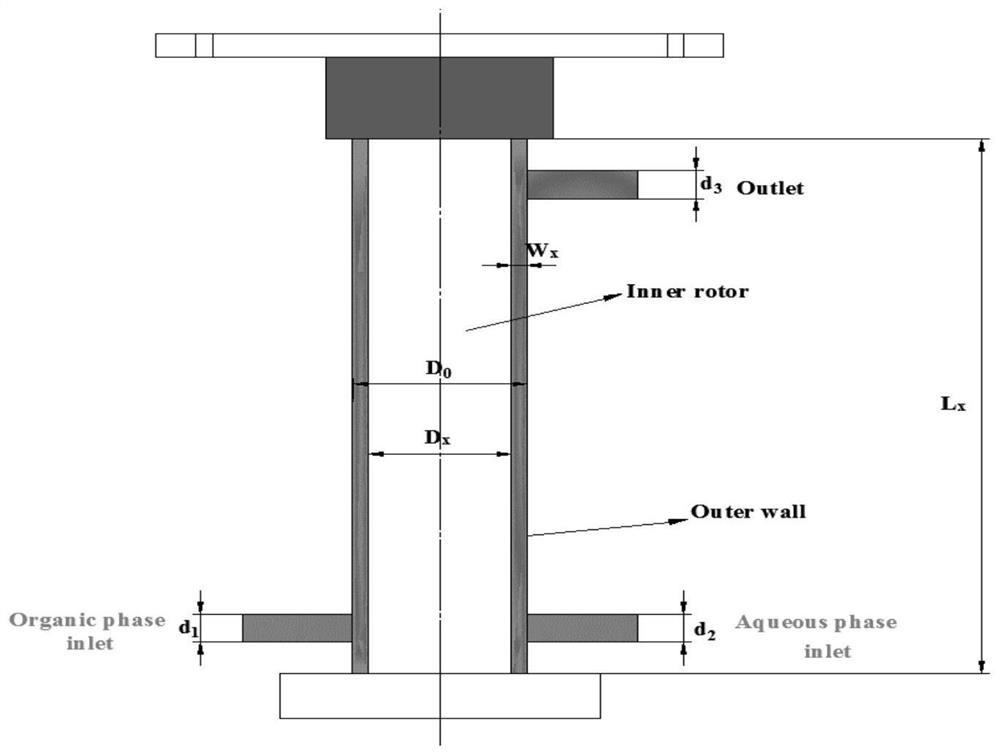

[0185] The microchannel reactor is selected as figure 2 For the shown co-current rotating wiped-film microchannel reactor, the specific structure can refer to "A Lengthened Wiped-Film Type Rotating Microchannel Enhanced Extraction Equipment" with Application No. 201822159540 and "A Wiped-Film Type Rotating Microchannel with Application No. 20182215347". The difference is that the liquid outlet is arranged side by side at the bottom end, and the rest of the structure is the same; the process parameters include rotational speed, flow rate, ratio (O / A), tube length, inner tube diameter; the remaining steps and formula are the same as in Example 1.

[0186] data analysis:

[0187] Depend on Figure 5 In Figure (1), it can be seen that the extraction rate of scandium shows a trend of first increasing and then stable with the increase of the rotation speed of the inner cylinder rotor, and reaching a stable state when the rotation speed is 200 rpm, indicating that the extraction o...

Embodiment 3

[0203] The optimal process parameters obtained by the above-mentioned "T" shaped inlet spiral microchannel reactor and co-current rotating wiped film microchannel reactor were carried out back extraction experiments. When the "T" shaped inlet spiral microchannel reactor was used :

[0204] Depend on Image 6 Figure (1) in the figure shows that deionized water can strip 41.52% of iron in the organic phase. The addition of sulfuric acid can significantly improve the stripping rate of iron. When the concentration of sulfuric acid reaches 0.1 mol / L, the extraction amount of iron tends to increase. It is stable at 72.49%, indicating that 0.1mol / L sulfuric acid solution is the HSO provided by the system 4 - The saturated amount of back-extraction has been reached. Continue to increase the concentration of sulfuric acid solution, and the improvement of the iron back-extraction rate becomes smaller. Therefore, 0.1 mol / L sulfuric acid solution is selected as the back-extraction agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com