Patents

Literature

135results about How to "Wide range of processing applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

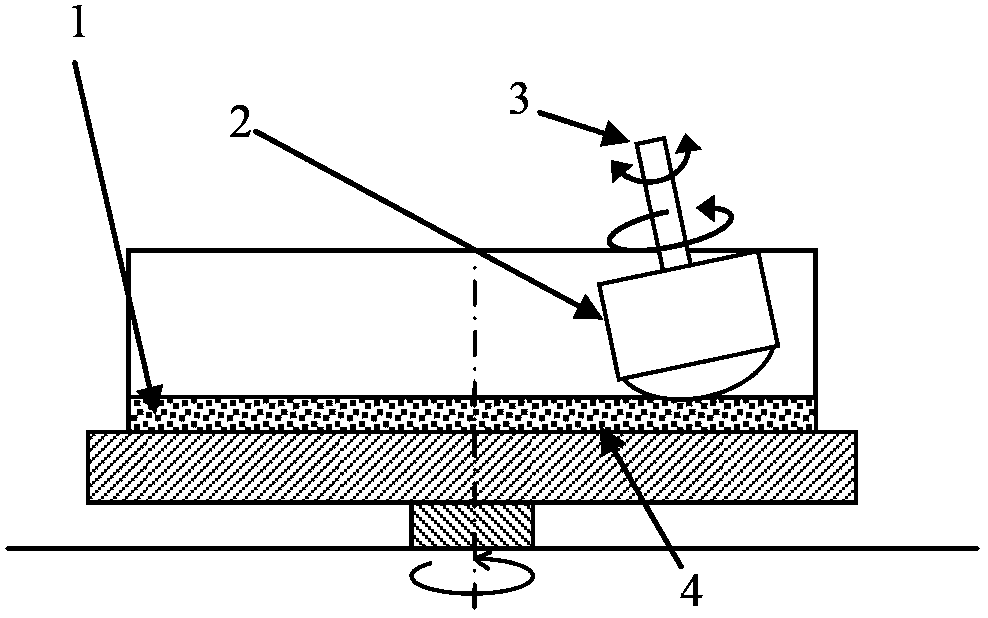

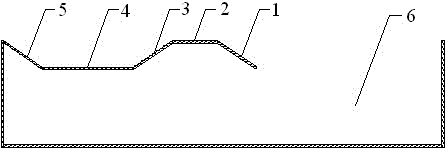

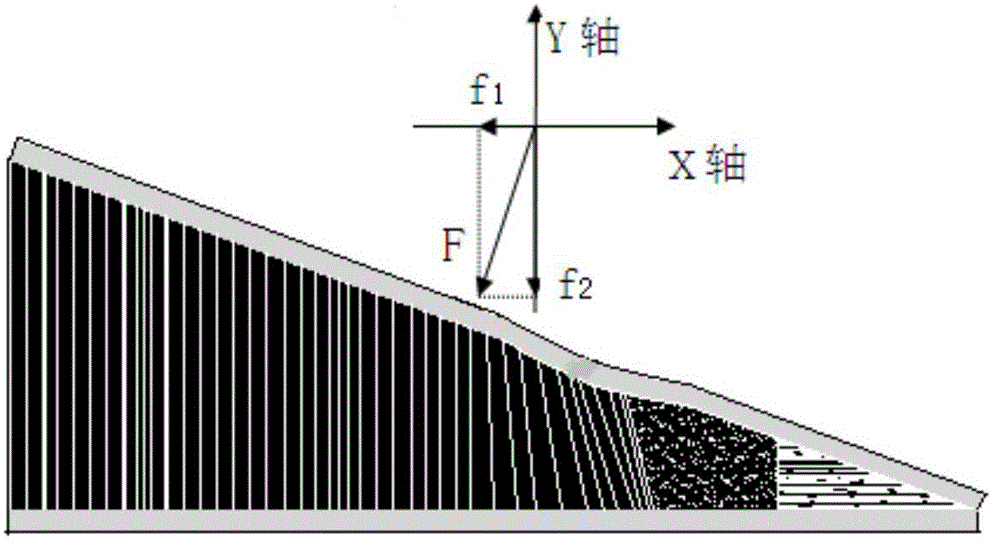

Lost foam casting vibration clotting method

The invention relates to a vibration solidification method of lost mold casting, pertaining to the precision casting field, which aims at fining the organization of castings of the lost mold casting, reducing the cost and enhancing the performance of castings. The invention comprises three steps of: production of foamy mold, imbedding the foamy mold into a casting box for filling and compacting sand as well as casting of molten metal; the invention is characterized in that: before and during the period of casting molten metal, during the solidification period, or the solidification period after the period of casting molten metal, casting box filled with foamy mold and scattered sand is vibrated at the frequency ranging from 10 to 100Hz and the amplitude ranging from 0.1 to 3.0mm, and rotation speed of a vibration motor that drives the vibration is 750 to 3000 rpm, and the vibration is stopped after the solidification of casting is completed. The invention has the advantages of low cost, easy operation and control, obvious fining effect of casting organizations, greatly improving performance and no environmental pollution, which is both suitable for the casting of the lost molds of nonferrous metals components, such as aluminum alloy, magnesium alloy, copper alloy, etc., and is also suitable for the casting of the lost mold of ferrous metal components, such as cast iron, cast steel and so on.

Owner:HUAZHONG UNIV OF SCI & TECH

High-solid content waterborne polyurethane emulsion with particle size polydispersity and preparation method thereof

The invention relates to a high-solid content waterborne polyurethane emulsion with particle size polydispersity and a preparation method thereof, belonging to the technical field of high polymer materials. The preparation method comprises the following steps of: preparing a polyurethane prepolymer, diluting the synthesized polyurethane prepolymer by adding a solvent, then dividing the diluted polyurethane prepolymer into a plurality of portions, respectively adding different doses of sulfonate hydrophilic chain extender to the different portions of polyurethane prepolymer for remixing, dispersing the mixtures to deionized water, carrying out secondary chain extension and removing the solvent from the emulsion in vacuum, thus obtaining the waterborne polyurethane emulsion with the solid content being higher than or equal to 50%. The preparation method has the advantages that a catalyst is not needed, the production time is short, and the process is simple and easy to control. The prepared waterborne polyurethane emulsion is relatively wide in particle size distribution and relatively low in viscosity and can be applied to the fields of environment-friendly coatings, adhesives and the like.

Owner:SOUTH CHINA UNIV OF TECH

Nickel-cobalt-manganese core-shell structure precursor, preparation method thereof and positive electrode material

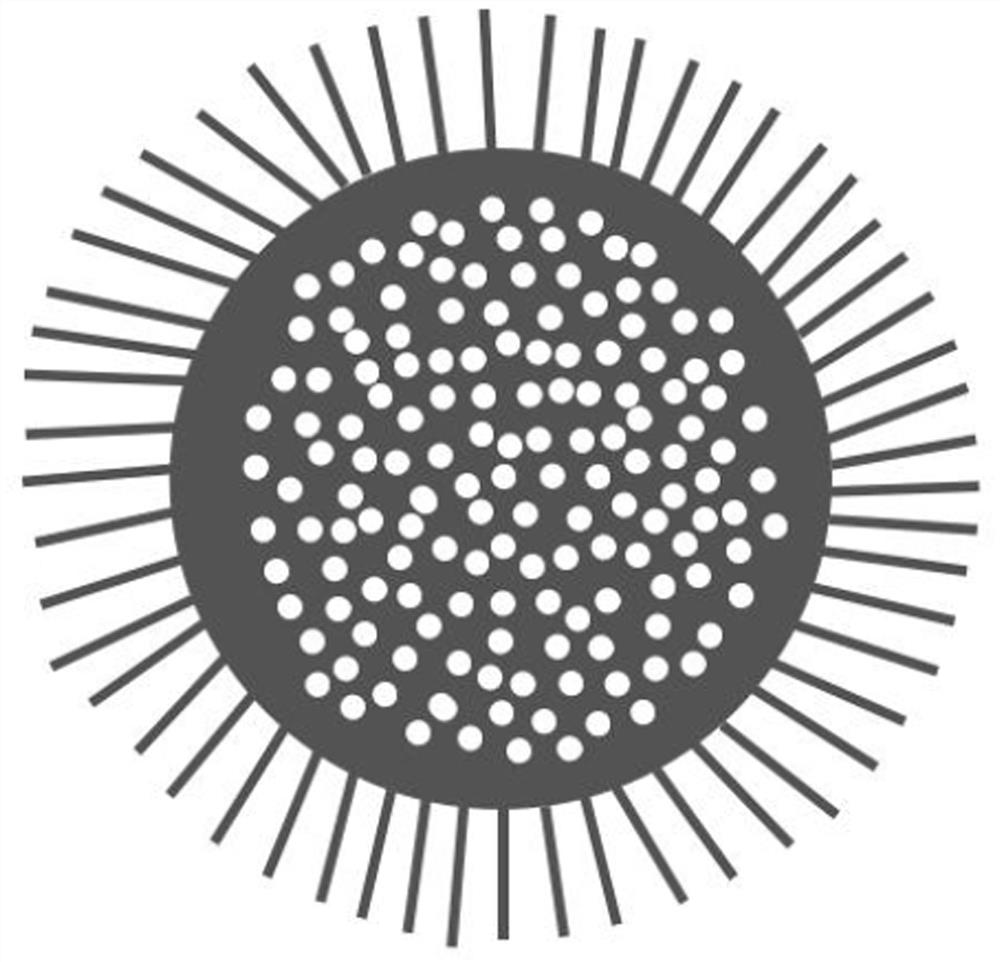

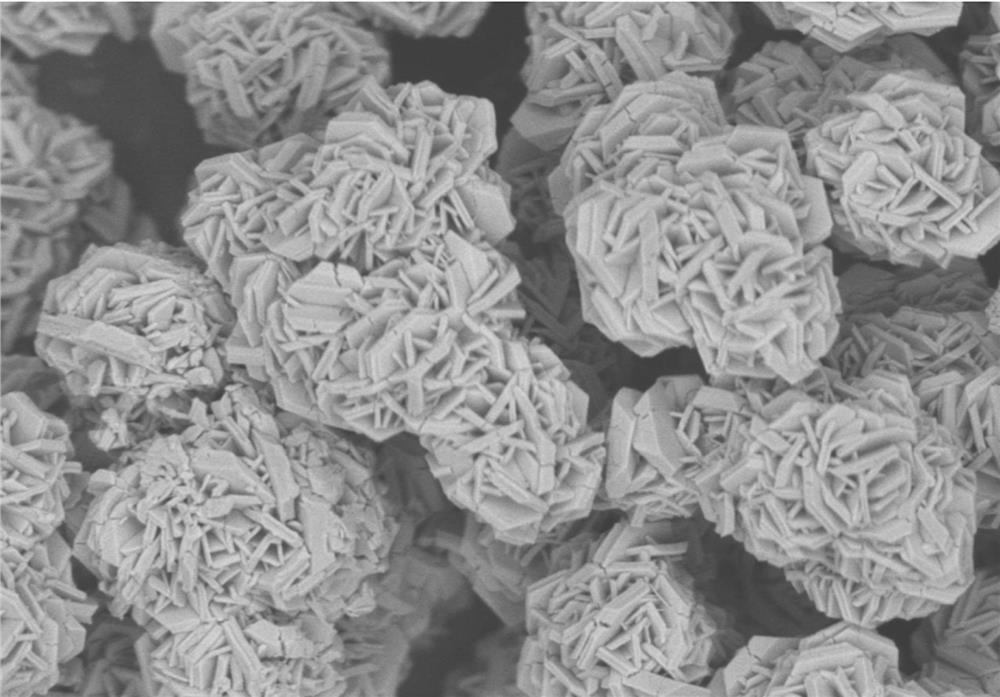

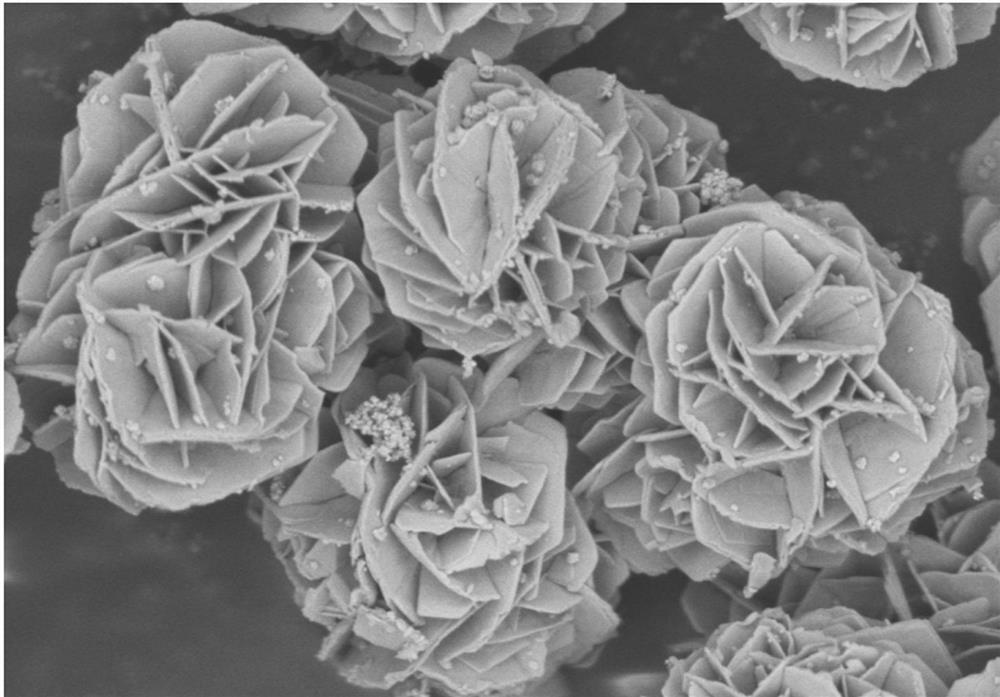

The invention provides a nickel-cobalt-manganese core-shell structure precursor and a preparation method thereof. The precursor is compact in inner core and has pores; the shell is loose, and the primary particles are radially arranged on the inner core. The precursor structure is beneficial to diffusion of Li ions and permeation of an electrolyte in the lithium mixing and sintering process, provides a rapid migration channel for the Li ions in the charging and discharging process, and meets the structural requirements of tap density and porosity. The precursor is synthesized by adopting a wetmethod, the reaction process is divided into a first stage and a second stage, the switching point of the first stage and the second stage is determined according to the size requirement of the innercore part of the precursor, and the reaction conditions are adjusted. The preparation method is simple in process control, free of newly increased cost, wide in process application range, good in product crystallinity, low in impurity Na and S content and adjustable in precursor kernel size on the basis of an existing mainstream intermittent method process.

Owner:JINCHI ENERGY MATERIALS CO LTD +1

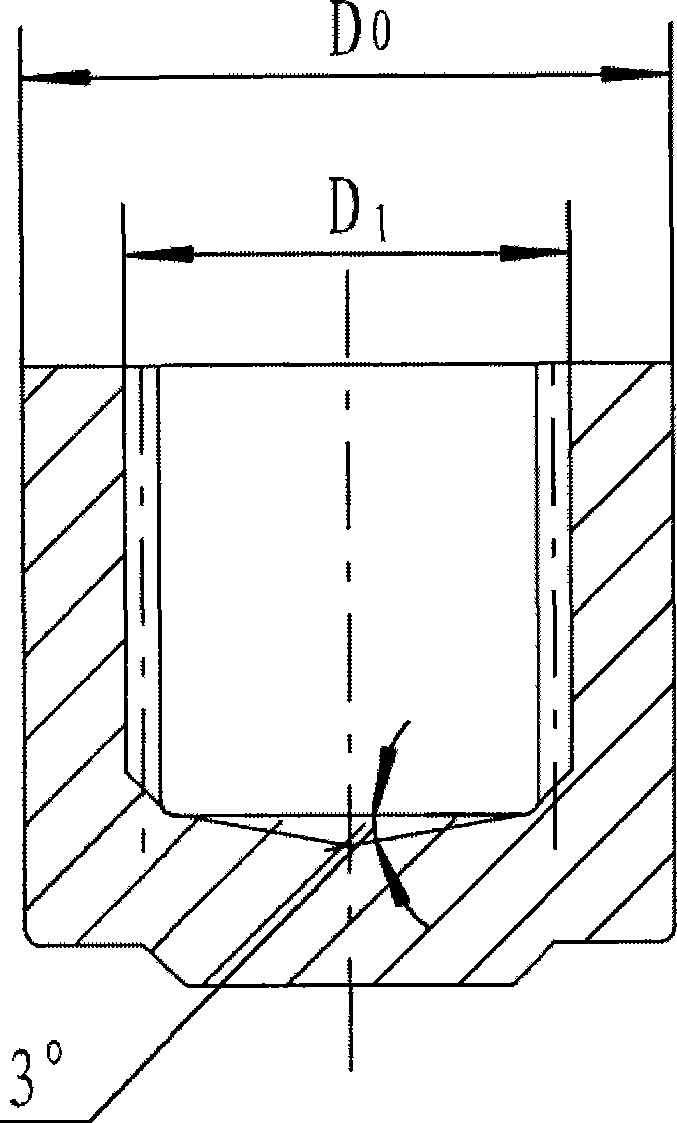

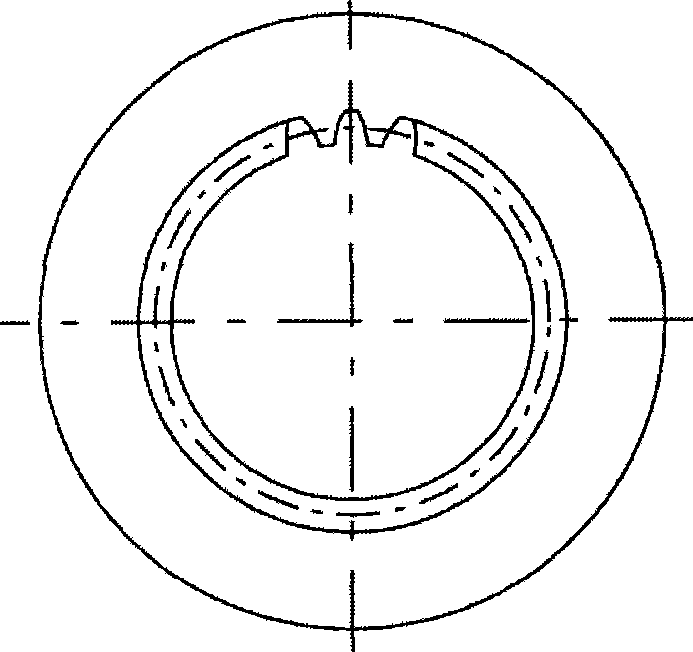

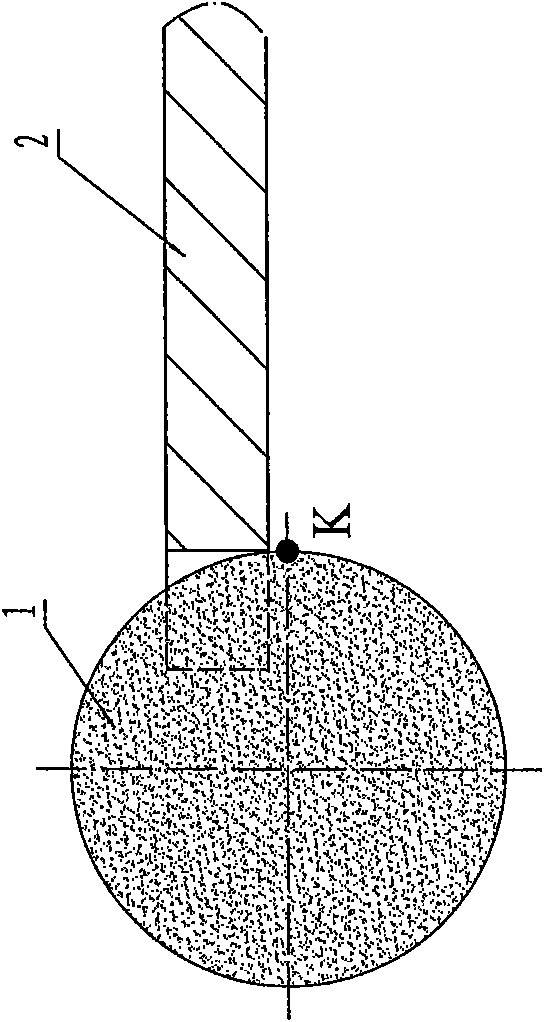

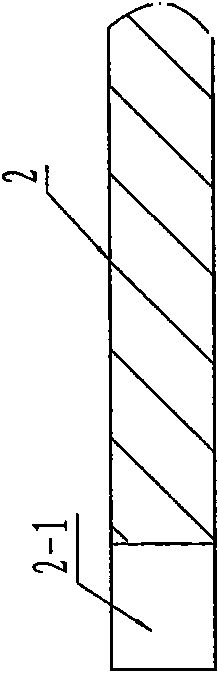

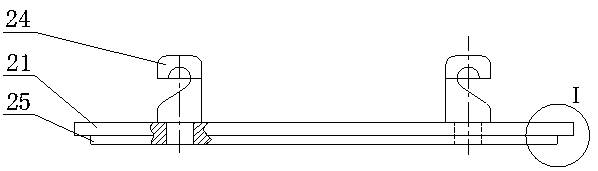

Reverse cold extrusion mold for car rear transversal stabilizer bar casing tube

InactiveCN101502855ASave materialThe whole length of the working section is tooth-shaped, and the structure is simplePunchingRound table

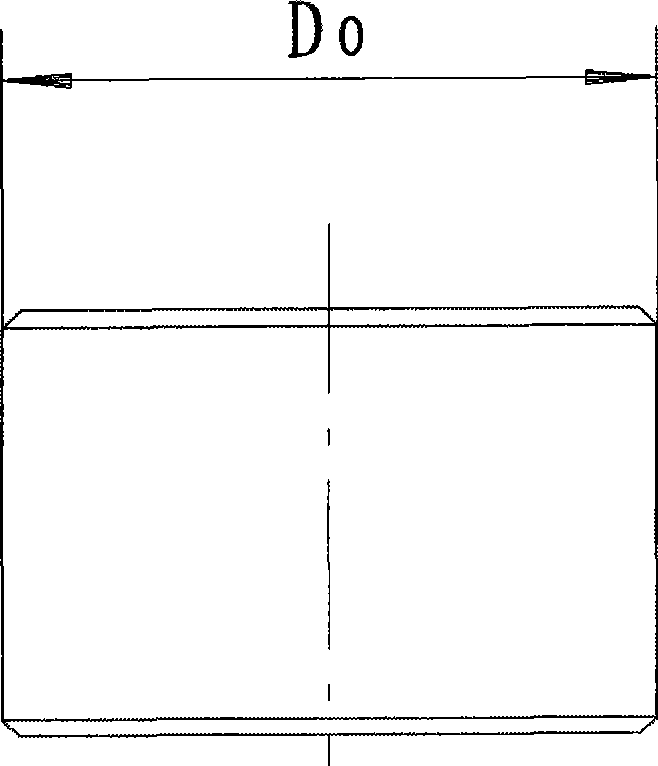

A rear transverse stabilizer rod bushing reverse cold extrusion die is disclosed, belonging to plastic forming die of metallic material and solving the problems that the current extrusion convex die has complex structure, large variation of cross section, large processing difficulty, low service life, inconvenient installation and regulation, excessive required materials of the die and high expenditure. The invention comprises a reverse extrusion concave die, an ejection device, a reverse extrusion convex die and a guide device; a punching head of the reverse extrusion convex die is sequentially divided into a punching head lower end, a working section and a fixation section, the punching head lower end is a cone, the entire working section is tooth-shaped; the diameter, the spline module and the number of teeth thereof are equal to relative parameters of the bushing to be formed; the fixation section is cylindrical; a conical clamping ring of the reverse extrusion convex die is a round table having an inner hole, the side thereof has an axial incision, and the inner hole has annular channels that are distributed equidistantly. The invention is convenient in manufacturing, installation, regulation and usage, stable and reliable in operation, wide in application range of the technology and long in service life; the die expenditure is lowered due to quite few materials required for manufacturing the convex die.

Owner:湖北天轮机械有限公司 +1

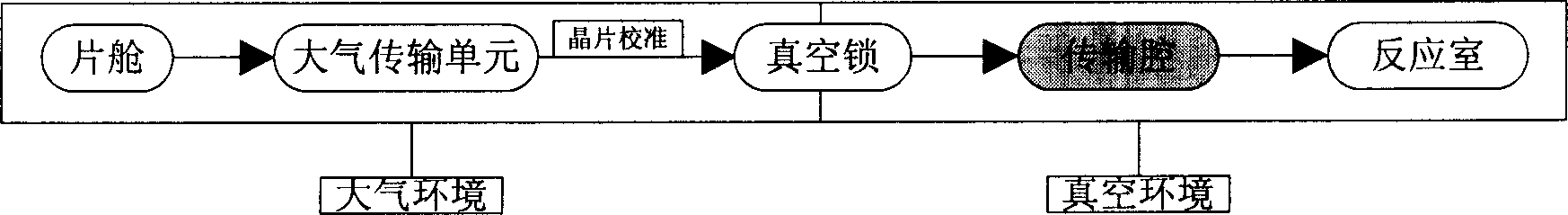

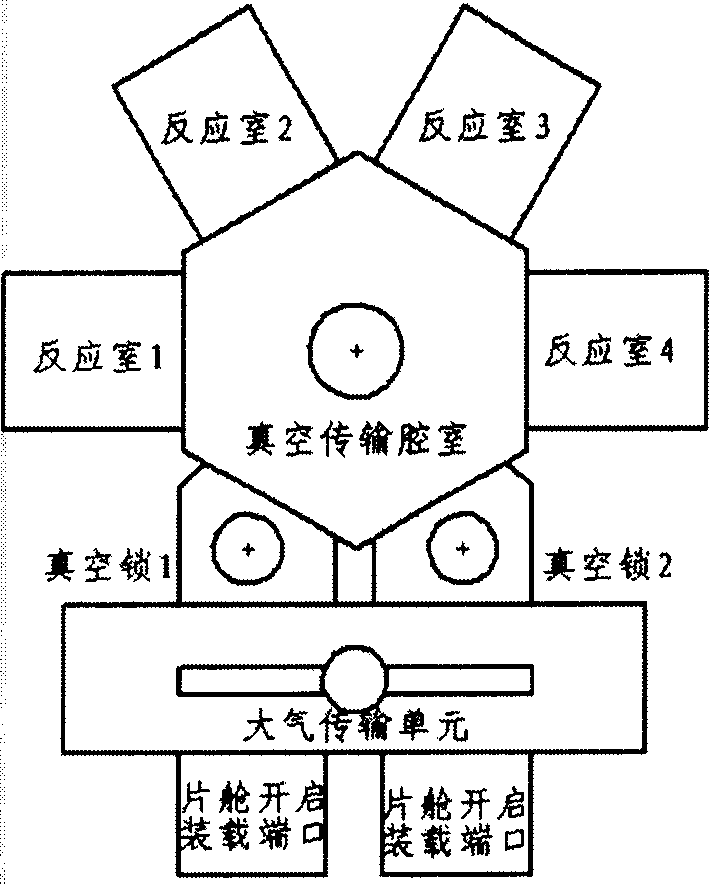

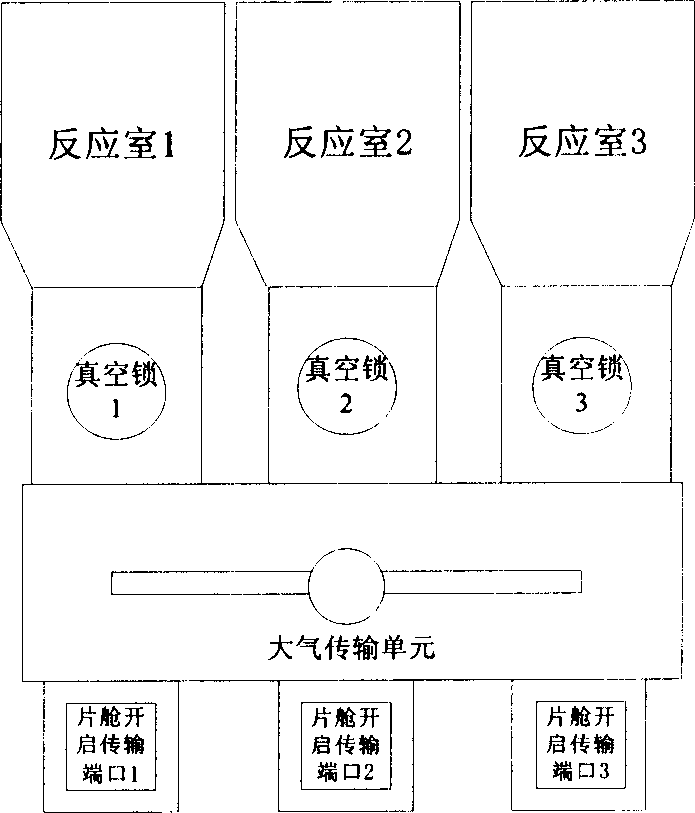

Transmission platform for semiconductor wafer processing

The related transmission platform for a semiconductor wafer processing comprises: a port for wafer-cabin opening and loading, some reaction chambers, and a vacuum axisymmetrical polygonal transmission cavity. Wherein, arranging some vacuum manipulators, some wafer temporary areas, two vacuum locks on nearby polygonal edges, and the reaction chambers on other edges; applying the manipulators near the lock for transmission among the lock, nearest chamber and the temporary area, and other manipulators for transmission among the near areas and chambers. This invention has more wide application area and well compatibility.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Preparation method for wear-resisting metal ceramic composite material

The invention discloses a preparation method for a wear-resisting metal ceramic composite material. The preparation method comprises the steps of uniformly mixing ceramic particles or ceramic particles being subjected to surface preprocessing with self-fluxing alloy powder by polyvinyl alcohol to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, wherein a 2-10mm common steel gasket is arranged at the bottom of the cavity in advance, and the mixture bears 50-70MPa from the pressing machine; after molding and demolding, putting both a biscuit and the gasket into a drying box of 150 DEG C to be drying for 2 hours; putting the dried biscuit and the gasket into a vacuum furnace to be sintered for 30-90 minutes, wherein the temperature of the vacuum furnace is 1000-1300 DEG C, and the vacuum degree is 0.1-1.0Pa; and cooling down and taking out of the furnace to obtain the wear-resisting metal ceramic composite material. The composite material is prepared by pressing and has the relatively high compactness after being sintered; if being compounded on the surface of a wear-resisting part, the wear-resisting part has the relatively long friction durability; the mixture does not contain an adhesive agent, so that the composite material does not generate slag inclusion and pores after being sintered.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Contaminated acid concentrating and recycling method

ActiveCN104909507AImprove the utilization rate of sulfur resourcesReduce consumptionMultistage water/sewage treatmentSulfur-trioxide/sulfuric-acidSulfidationArsenic

The invention discloses a contaminated acid concentrating and recycling method. The method comprises the following steps: adding a contaminated acid solution and a vulcanizing agent solution into a negative pressure reaction kettle according to an amount ratio of 1L:(10-30)g, reacting under the condition of 60-70 DEG C for 25-40 minutes, performing filter pressing on the reacted materials by using a filter press, and treating the filtrate in the next step; adding the filtrate and the vulcanizing agent solution into another negative pressure reaction kettle according to an amount ratio of 1L:(20-48)g, reacting at room temperature for 80-100 minutes, precipitating by using a thickener, performing filter pressing by using the filter press, treating the obtained contaminated acid filtrate by virtue of a dynamic wave scrubbing tower to remove lots of ions F<-1> and Cl<-1>, thereby obtaining the 50-60% industrial sulfuric acid. The contaminated acid is treated by combining two-stage vulcanization and evaporation and concentration, the heavy metals and arsenic are effectively removed by controlling the time and temperature during two-stage vulcanization, the sulfur and metal elements are comprehensively recycled, the cost is low, and the economic benefits are high.

Owner:河南菲迪泰环境科技有限公司

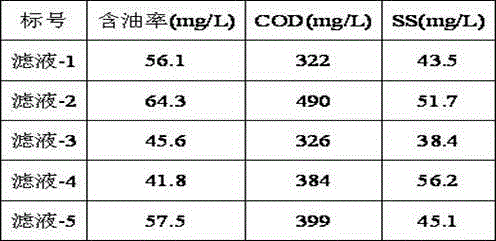

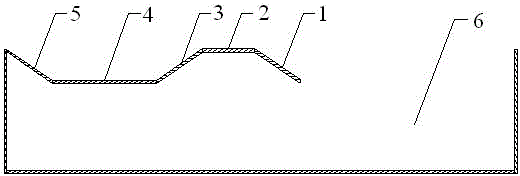

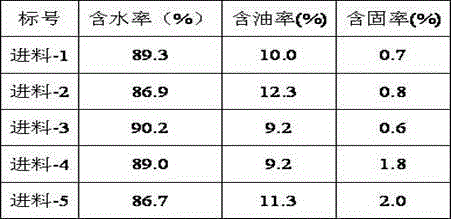

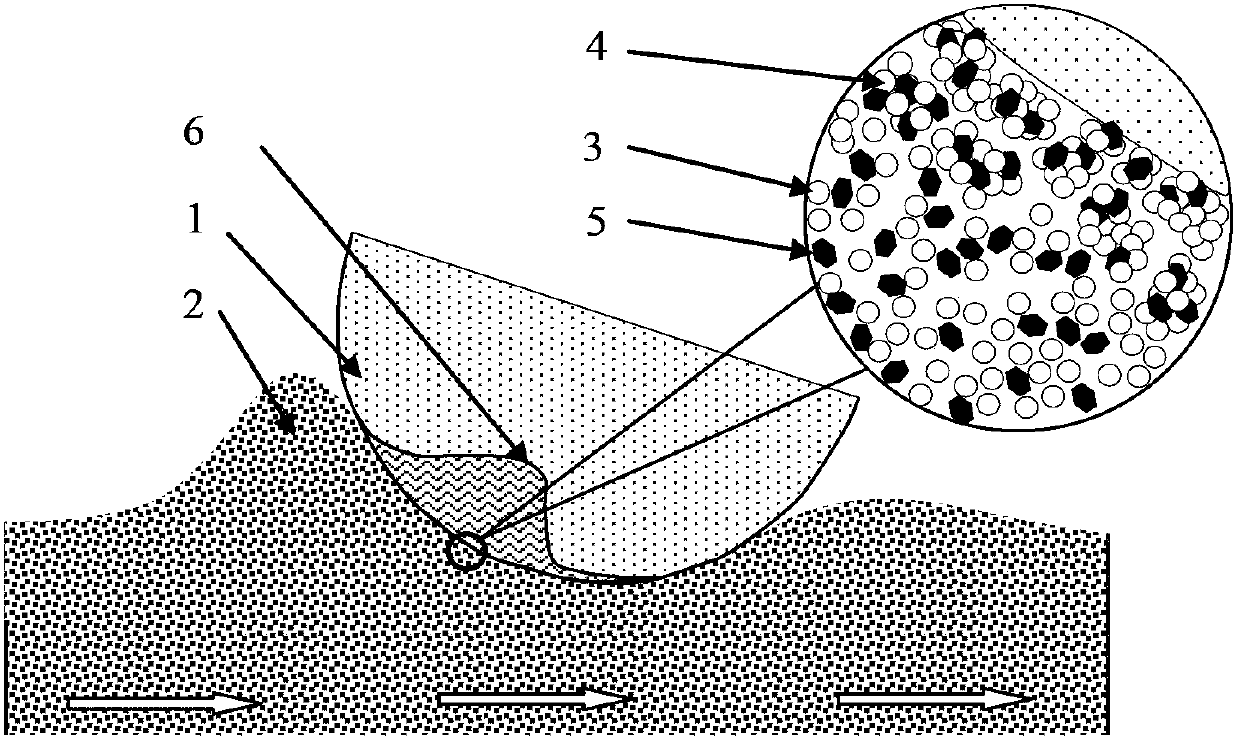

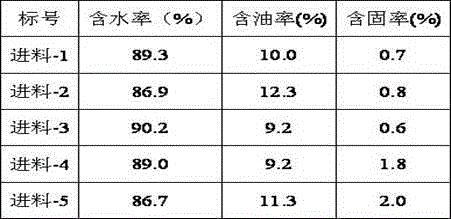

Oily sludge advanced treatment technology

ActiveCN104649563AGood demulsification effectGood biodegradabilitySludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesPetroleumSludge dewatering

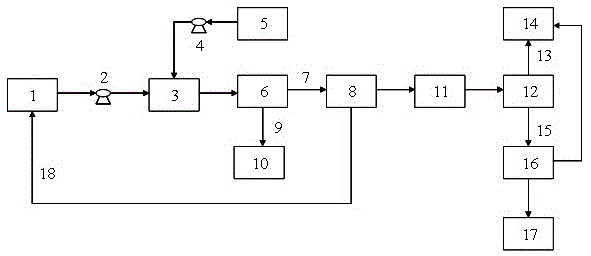

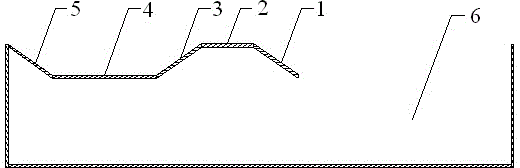

The invention discloses an oily sludge advanced treatment technology which comprises the following contents: oily sludge in a raw material storage sludge-tank enters a sludge mixing tank; a demulsifier is added to carry out demulsification treatment; demulsified oily sludge enters screw-type sludge dewatering equipment to undergo solid-liquid separation so as to obtain a filtrate and sludge cake; the filtrate enters a two-phase cyclone to be separated; after two-phase separation, excess sludge at the lower layer flows back to the raw material storage sludge-tank, a mixed liquor at the upper layer is sent into a gas-liquid mixing tank to be mixed with the air and then enters a separation pond to carry out primary separation of sump oil and sewage; sump oil is recovered to a sump oil tank by the use of a sludge scraper; sewage enters a filter to separate suspended particles and residual sump oil in the sewage from water; sump oil separated from the top of the filter is recovered to a sump oil recovery tank; and sewage discharged from the filter is sent to a sewage treatment plant to undergo subsequent processing. By the technology, water content of the oily sludge can be reduced from 80-98% to about 50%, and most crude oil in the oily sludge can be recovered. Thus, sludge subsequent processing difficulty is greatly reduced. The technology provided by the invention has a wide range of application, is especially suitable for processing of oily sludge at the bottom of an oil-tank, dross and activated sludge as well as processing of various oily sludge generated from oil exploitation and storage transportation enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

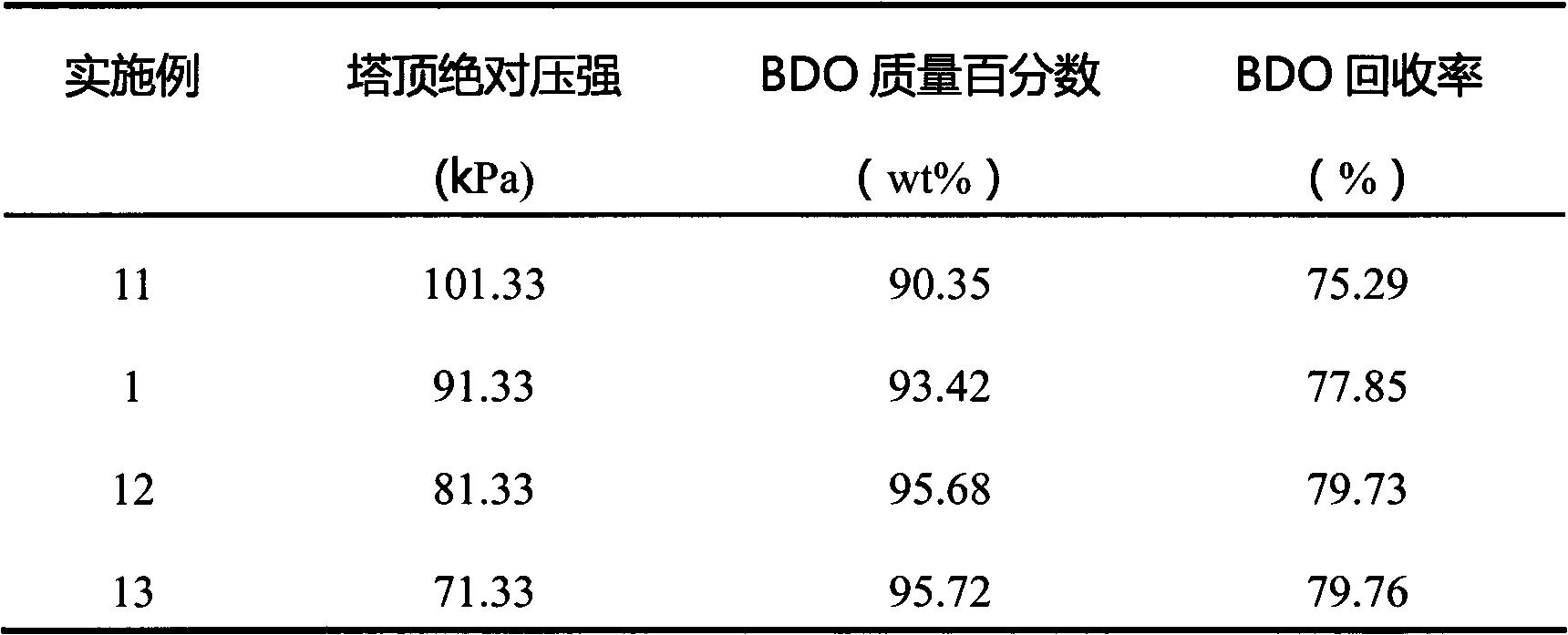

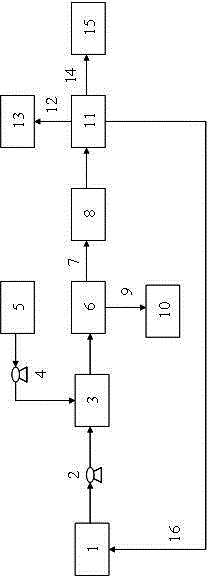

Process for recovering distillation waste liquid generated by producing 1,4-butanediol

InactiveCN103274898AHigh recovery rateImprove overall recoveryOrganic compound preparationHydroxy compound preparationDistillationButanediol

The invention relates to a process for recovering distillation waste liquid generated by producing 1,4-butanediol and belongs to the technical field of recycling of organic waste liquid in the industrial production. According to the invention, the distillation waste liquid generated in the process of producing 1,4-butanediol by a Reppe method is used as a raw material; drained wastewater is used as an extracting agent; sodium sulfate is used as a salting-out agent; sulfuric acid is used as a catalyst for depolymerizing reaction; and by a circulating process of salting-out-extraction, reduced pressure batch distillation separation and depolymerizing reaction, various products in the distillation waste liquid, such as 1,4-butanediol, butanol and 3-tetrahydrofurfuryl alcohol are recovered. The process disclosed by the invention has the characteristics that various products can be recovered, the recovery rate of the products is high and the recovery economic benefits are good; the process sufficiently utilizes waste liquid resources and is beneficial to environment protection; the process is simple, reaction conditions are mild, equipment is conventional and recovery cost is low; and the process has a wide application range and is convenient to popularize and apply. The process can be widely applied to recycling of the organic waste liquid in the industrial production and is particularly suitable for recycling the waste liquid generated in the process of producing 1,4-butanediol by the Reppe method.

Owner:CHONGQING UNIV

Enzymatic preparation method of low molecular pectin

ActiveCN104419737ALow degree of esterificationReduce molecular weightFermentationPolymer scienceFiltration

The invention discloses an enzymatic preparation method of low molecular pectin. The method comprises the following steps: carrying out enzymolysis and de-esterification on high molecular high ester pectin by virtue of one or more of pectinase, cellulase, galacturonase and pectinesterase; and carrying out alkali liquor neutralization, filtration and drying and grinding on the product to obtain a pectin product with targeted molecular weight and degree of esterification. According to the method disclosed by the invention, the high molecular high ester pectin is hydrolyzed by adopting a multienzyme compound hydrolyzing technology so as to extract pectin with different molecular weights and degrees of esterification, high content of galacturonic acid and excellent taste from natural pectin. The low molecular pectin powder prepared by the preparation method meets the USP30 standard, various chance elements in the prior art are avoided, and the purity and success rate for extracting the low molecular pectin are improved. Meanwhile, the method is short in process flow, strong in capability of industrialization and suitable for being popularized on a large scale.

Owner:ZHEJIANG GUOYUAN KANGPIN BIOTECH CO LTD

Treatment process for oily sludge

ActiveCN104556595AImprove surface activityLess irritatingSludge treatment by de-watering/drying/thickeningEmulsionProcess engineering

The invention discloses a treatment process for oily sludge. The treatment process comprises the following steps: putting the oily sludge in a raw material storage sludge basin into a sludge mixing tank, adding an emulsion breaker for emulsion breaking, putting the oily sludge subjected to emulsion breaking into a stacked type sludge dewatering machine for solid-liquid separation to obtain filtrate and mud cakes, putting the filtrate into a settling tank for settling separation, recycling waste oil discharged from the top of the settling tank, conveying the sludge at the bottom of the settling tank into the raw material storage sludge basin, feeding middle-layer mixed liquid into an air-liquid mixing tank for mixing with air to obtain a mixture, enabling the mixture to enter a separation basin for oil-water separation, recycling separated waste oil, putting sewage into a biochemical device for treatment, and discharging the sewage after the sewage meets the standard. According to the process, three-phase separation and treatment on oil, water and sludge of the oily sludge can be effectively realized, and most raw oil in the oily sludge can be further recycled; after being treated, the sewage meeting the standard can be discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

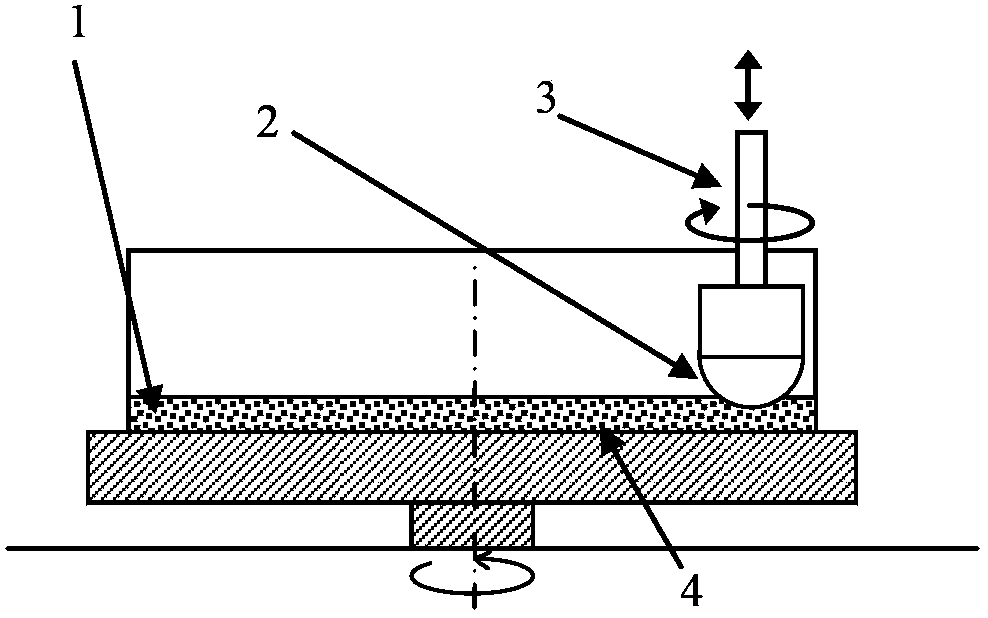

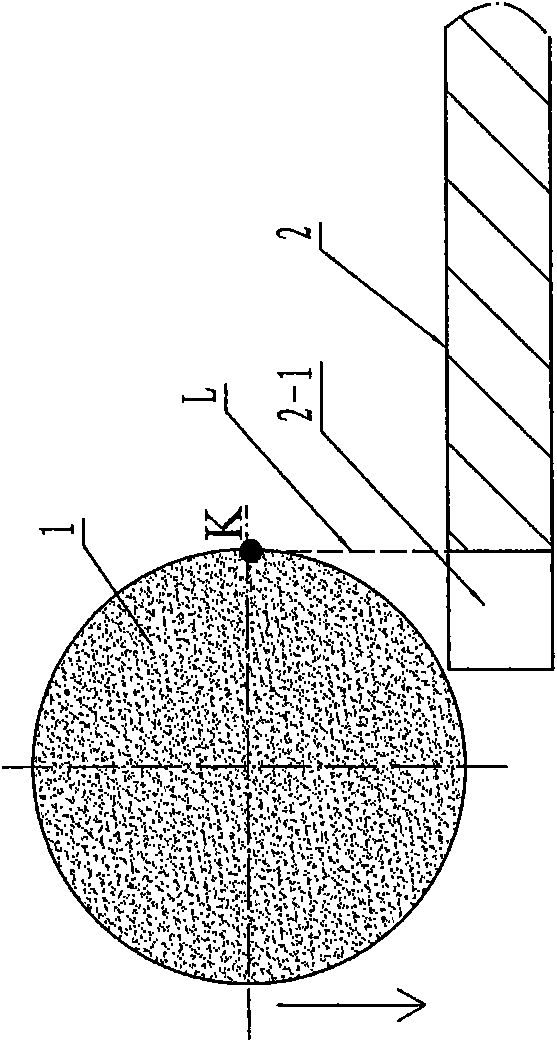

Ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect

ActiveCN102717325BImprove surface qualityImprove processing efficiencyPolishing machinesOther chemical processesSocial benefitsSurface finish

The invention discloses an ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect. The method includes: adding abrasive particles or micropowder into non-Newtonian fluid with shear thickening effect to prepare non-Newtonian fluid polishing solution, wherein the non-Newtonian fluid accounts for 50%-90% of the mass of the polishing solution, the abrasive particles or the micropowder account for 10%-50% of the mass of the polishing solution, and the particle size of the abrasive particles or the micropowder ranges from 0.05 micrometer to 50 micrometers. Relative motion is generated between a workpiece and the polishing solution during polishing, shear thickening is generated at a contact portion of the polishing solution and the workpiece under shearing action, viscosity of the polishing solution in the contact area is increased to enhance holding force to the abrasive particles or the micropowder, and removal of workpiece surface materials is achieved under the micro cutting or chemical mechanical action of the adding abrasive particles or micropowder with polishing effect in the polishing solution on the workpiece, so that polishing of the workpiece surface is achieved. The ultra-precise curved surface finishing method based on the non-Newtonian fluid shear thickening effect can achieve efficient and high-quality polishing to various curved surfaces, in particular to complex curved surfaces and has great economic and social benefits.

Owner:ZHEJIANG UNIV OF TECH

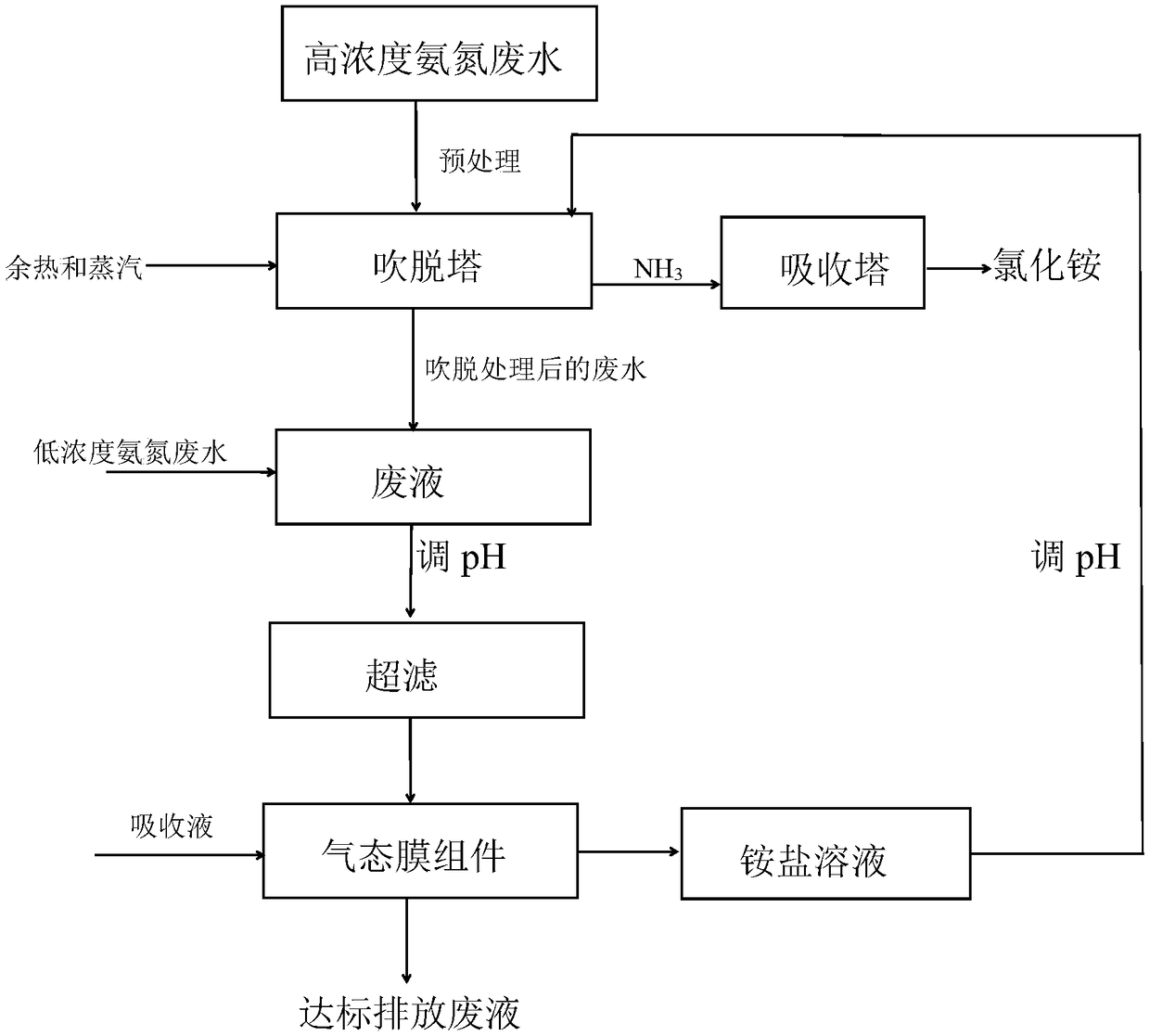

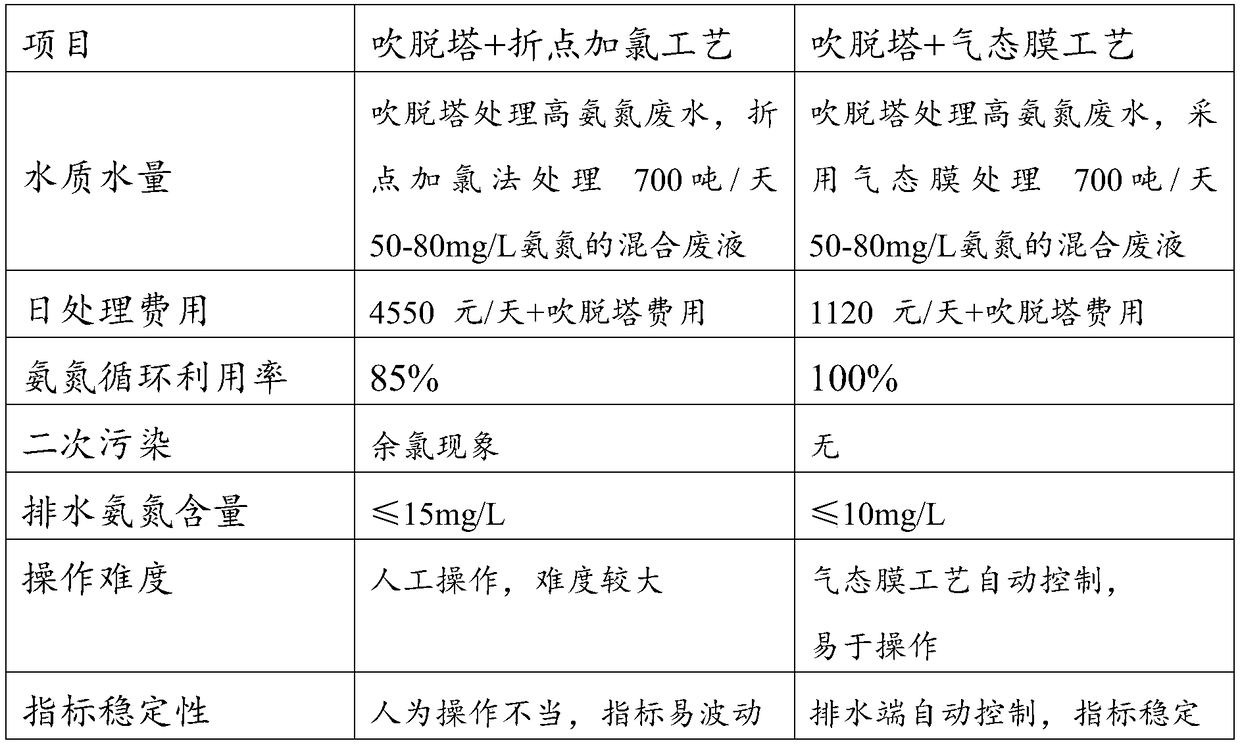

Process for treating ammonia nitrogen wastewater by gas-state membrane

ActiveCN109319976AExtended service lifeAvoid cloggingWater contaminantsDispersed particle separationHigh concentrationLiquid waste

The invention relates to a process for treating ammonia nitrogen wastewater by a gas-state membrane. The process comprises the following steps: adopting a composite discolouring agent and a heavy metal catcher to pre-treat high-concentration ammonia nitrogen wastewater, feeding high-concentration ammonia nitrogen wastewater into an air stripping tower to perform ammonia nitrogen removal, introducing stripped ammonia gas into a hydrochloric acid absorption tower to generate ammonium chloride; mixing stripped wastewater with low-concentration ammonia nitrogen wastewater to obtain waste liquor, regulating the pH value of the waste liquor to be 10.5 or more, performing ultrafiltration, introducing ultra-filtered waste liquor and absorbing liquor into the gas-state membrane assembly, controlling flow speed andthe temperature, removing ammonia nitrogen to obtain an ammonia salt solution and waste liquor with ammonia nitrogen content lower than 10 mg / L; feeding the ammonia salt solution to the air stripping tower after regulating the pH value, passing through the hydrochloric acid absorption tower to obtain ammonium chloride. The process has an ammonia nitrogen removal rate higher than 99%; the treated waste liquor meets discharge standards. In a process, the gas-state membrane is good in stability, does not generate osmotic distillation of water; and a gas-state membrane process canbe continuously performed, so that industrial implementation is facilitated.

Owner:江西铜鼓有色冶金化工有限责任公司

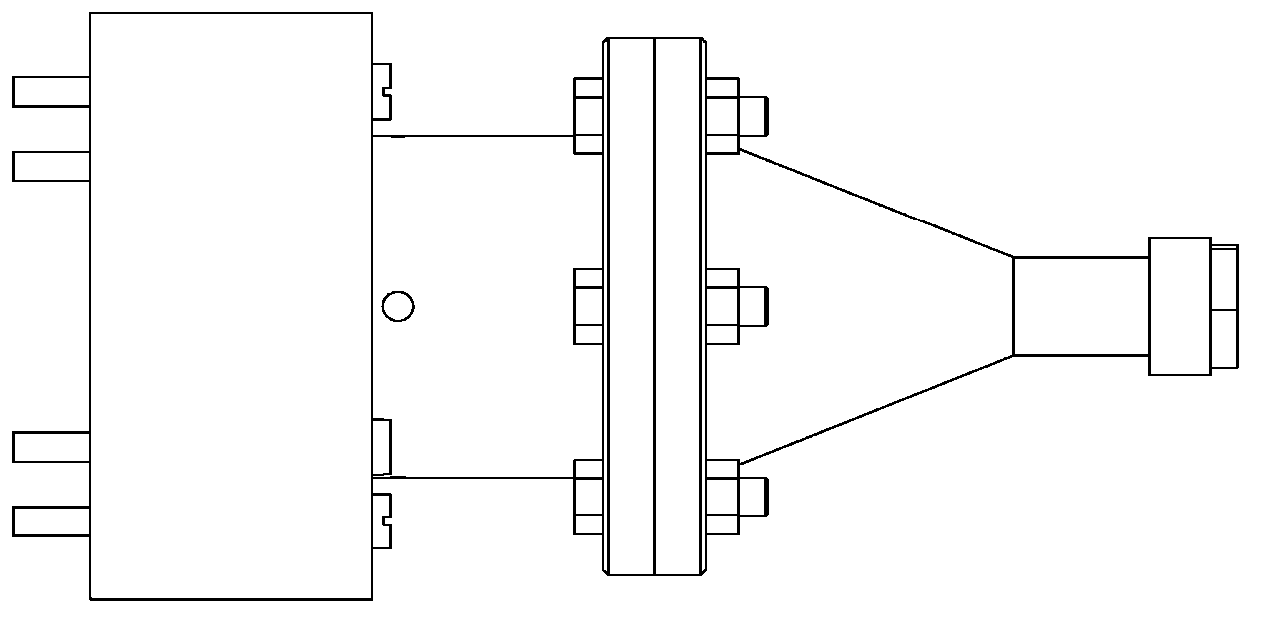

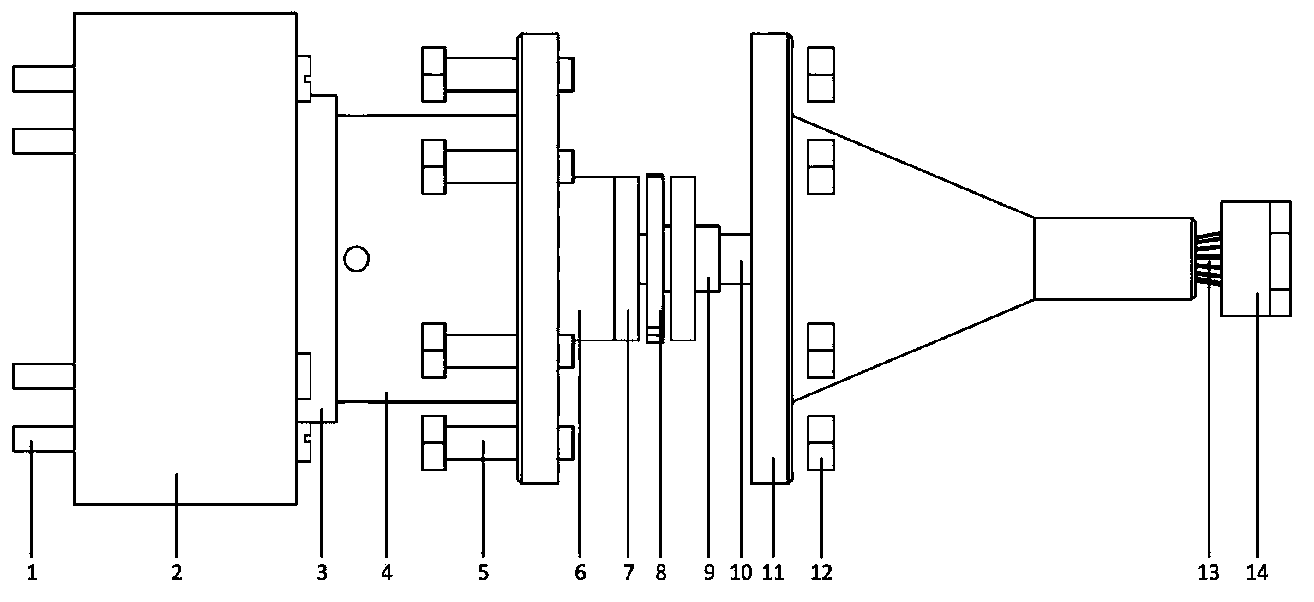

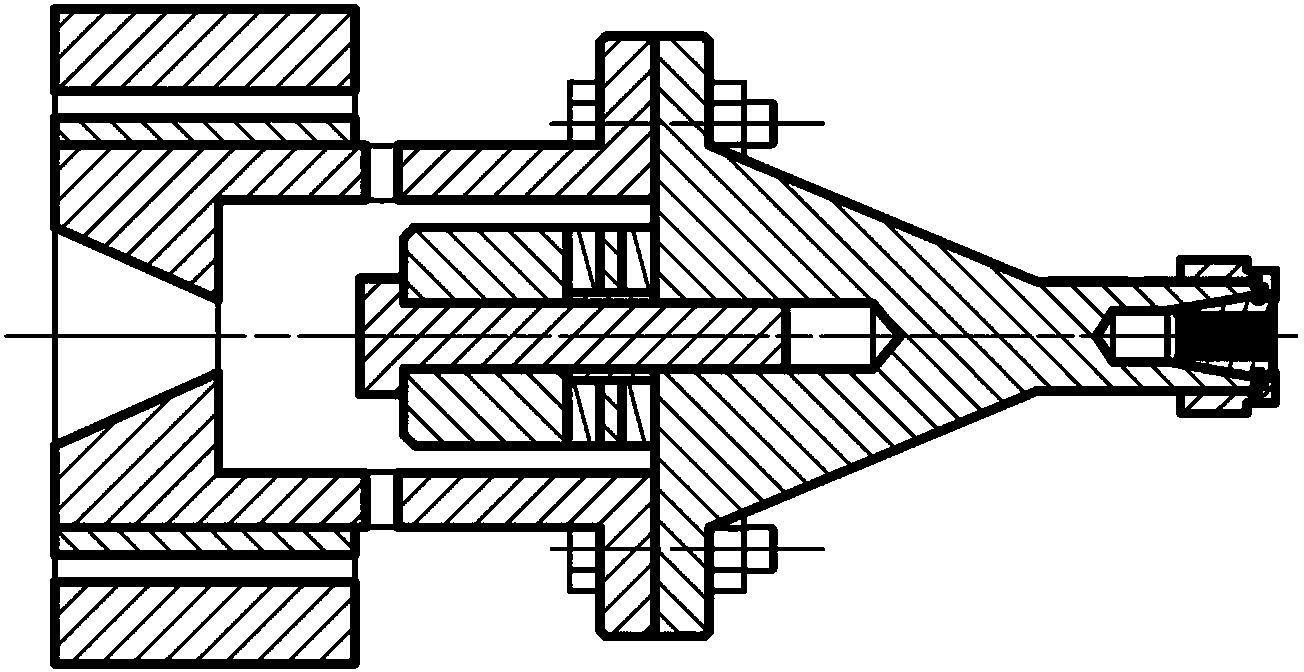

High-speed ultrasonic vibration assistant air drill

InactiveCN103406567AImprove cutting performanceReduce drilling forceMechanical vibrations separationPortable drilling machinesSmall amplitudeElectricity

The invention discloses a high-speed ultrasonic vibration assistant air drill which is composed of an ultrasonic generator, an ultrasonic wireless power transmission mechanism, a connection mechanism, an ultrasonic energy conversion mechanism, an ultrasonic amplitude varying mechanism and a drill bit clamping mechanism. The ultrasonic generator generates an ultrasonic frequency electric signal and provides ultrasonic frequency electric excitation for a system; the ultrasonic wireless power transmission mechanism achieves effective transmission of electric energy and dynamic and static transition; the connection mechanism is fixedly connected with the ultrasonic energy conversion mechanism, and the ultrasonic energy conversion mechanism is located at the front portion of the connection mechanism and used for converting the ultrasonic frequency electric signal into ultrasonic frequency mechanical vibration; the ultrasonic amplitude varying mechanism is fixed at the front end of the ultrasonic energy conversion mechanism and used for converting small-amplitude mechanical vibration into large-amplitude mechanical vibration; the drill bit clamping mechanism is installed at the front end of the ultrasonic amplitude varying mechanism and used for clamping a drill bit. As ultrasonic vibration is used for assisting in drilling, a traditional continuous drilling mode is removed, and average drilling force of drilling is decreased. By the utilization of the ultrasonic vibration for assisting in drilling, the cutting performance of materials difficult to machine is improved, and application range of drilling machining is made to be wider.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Necking process used for aluminum alloy liner of hydrogen storage cylinder

InactiveCN102310153AGood fatigue performanceGood consistencyHollow articlesAluminium alloyHydrogen storage

The invention relates to a necking process used for an aluminum alloy liner of a hydrogen storage cylinder. The process comprises a necking preheating temperature, the number of feeding tools of a numerical control necking machine, the angle of a roller of the numerical control necking machine, temperature compensation in a necking process, and the thickness of aluminum alloy tubes. Compared with the prior art, the necking process has the advantages that: product yield is high, the arc shape of cylinder body is good, the outer surface of the cylinder body is smooth and clean, and the concordance rate of the cylinder body is high.

Owner:上海康巴赛特科技发展有限公司

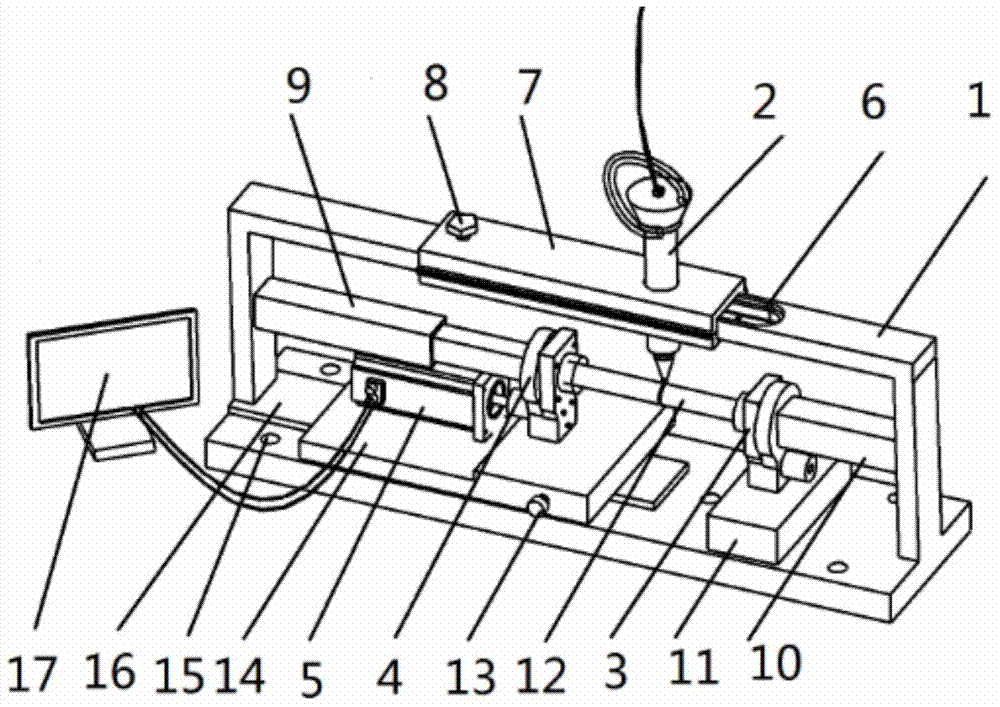

Device and method for ultrasonic impact strengthening of shaft type part welding seams

The invention relates to a device and a method for ultrasonic impact strengthening of shaft type part welding seams. An ultrasonic impact gun and a detachable and movable sliding block are arranged together on a chute; the chute provided with the detachable and movable sliding block are fixed on a top layer supporting beam of a supporting frame mechanism; a left hollow shaft rotary platform is positioned with a movable platform by virtue of a second layer left end telescopic supporting beam of the supporting frame mechanism, and the left-right movement of the left hollow shaft rotary platform, the second layer left end telescopic supporting beam and the supporting frame mechanism is realized by virtue of the rotation of a turning handle; a right hollow shaft rotary platform is positioned with a fixed platform by virtue of a second right end fixed supporting beam of the supporting frame mechanism; an AC (alternating-current) servo motor is fixed on the movable platform, and a rotating shaft of the AC servo motor is connected with the left hollow shaft rotary platform by virtue of a spring coupling; the movable platform is arranged on a guide rail which is arranged on a base of the supporting frame mechanism; and a shaft type workpiece is connected with the right hollow shaft rotary platform and the left hollow shaft rotary platform by virtue of the spring coupling. The device and the method provided by the invention are used for performing impact strengthening treatment on shafts with different length sizes and welding seams thereof.

Owner:WENZHOU UNIVERSITY

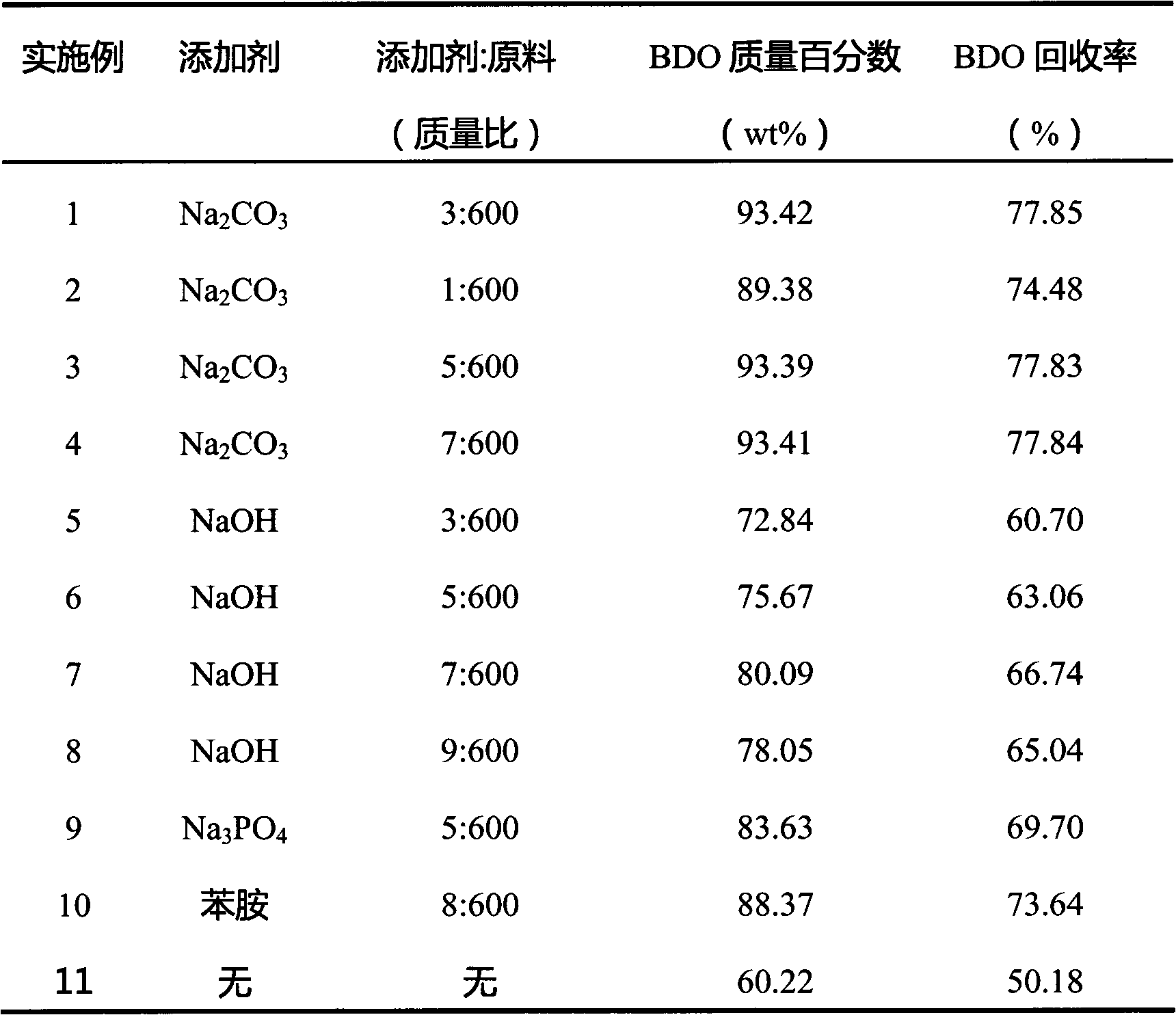

Method for recovering 1,4-butanediol from waste liquor generated in production of 1,4-butanediol through Reppe method

InactiveCN102659515ATake advantage ofEmission reductionOrganic compound preparationHydroxy compound preparation1,4-ButanediolMass ratio

The invention discloses a method for recovering 1,4-butanediol from a waste liquor generated in production of 1,4-butanediol through a Reppe method. The method comprises the following steps: (1) adding an alkaline substance serving as an additive into a raw material, namely the waste liquor generated in production of 1,4-butanediol, ensuring that the mass ratio of the additive to the raw material is (1-9):600, and stirring and mixing uniformly; and (2) putting the mixture into an intermittent rectifying tower for intermittent rectification, and recovering the 1,4-butanediol. The method has the advantages that: (1) a small amount of additive is added, so that the mass percentage of a 1,4-butanediol product and the recovery rate of the 1,4-butanediol are obviously improved; (2) only one piece of intermittent rectifying equipment is used, and the technological operation is flexible, simple and convenient; (3) the additive is cheap and readily available, low in recovery cost and high in economy; (4) the process application range is wide, the method is suitable for recovering and purifying the 1,4-butanediol from waste liquors in different concentration generated in the production of the 1,4-butanediol through the Reppe method, and the recovery rate can reach 80 percent; and (5) the waste liquor resource is fully utilized, the waste emission is reduced to the greatest extent, and the method is favorable for protecting environment and convenient to promote and apply.

Owner:XIANGTAN UNIV

Oil-containing sludge resourceful treatment technology

ActiveCN104418473APromote degradationGood demulsification effectSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesActivated sludgeOil sludge

The invention discloses an oil-containing sludge resourceful treatment technology, which comprises the following steps: oil-containing sludge in a raw material sludge storage pond is introduced in a sludge mixing tank for demulsification treatment, the oil-containing sludge after demulsification is introduced in a spiral sludge dewatering machine for solid-liquid separation to obtain a filtrate and mud cakes, the filtrate is introduced in a gas-liquid mixing tank for mixing with air, a mixture is introduced in a separation tank for oil, water and mud three-phase separating. According to the technology, water content of the oil-containing sludge is decreased from 80-98% to about 50%, most crude oil in the oil-containing sludge can be recovered, and subsequent processing difficulty of sludge can be greatly reduced. The technology has the advantages of wide application scope, and is especially suitable for treatment of oil sludge at bottom of pot, scum and activated sludge, and can be used for treating various kinds of oil-containing sludge generated by petroleum exploitation, storage and transportation enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of polytetrafluoroethylene granular powder

The invention discloses a production method of polytetrafluoroethylene granular powder, comprising the following steps of: (a) preparing polytetrafluoroethylene crude granules by using a suspension method to polymerize; (b) crushing, washing and drying the polytetrafluoroethylene crude granules to obtain polytetrafluoroethylene micro powder; (c) contacting the polytetrafluoroethylene micro powder obtained by the step (b) with the atomized organic liquid in a mixer so that the organic liquid is coated on the polytetrafluoroethylene micro powder; and (d) granulating in a water phase of a granulating groove. The method has the advantages of high continuous degree, low energy consumption, uniform granularity and favorable product performance.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

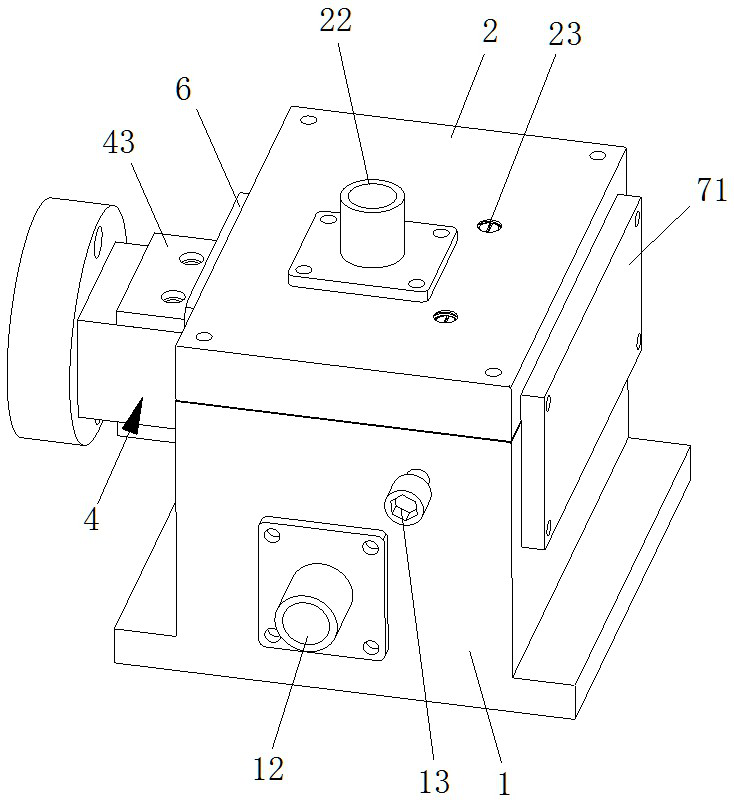

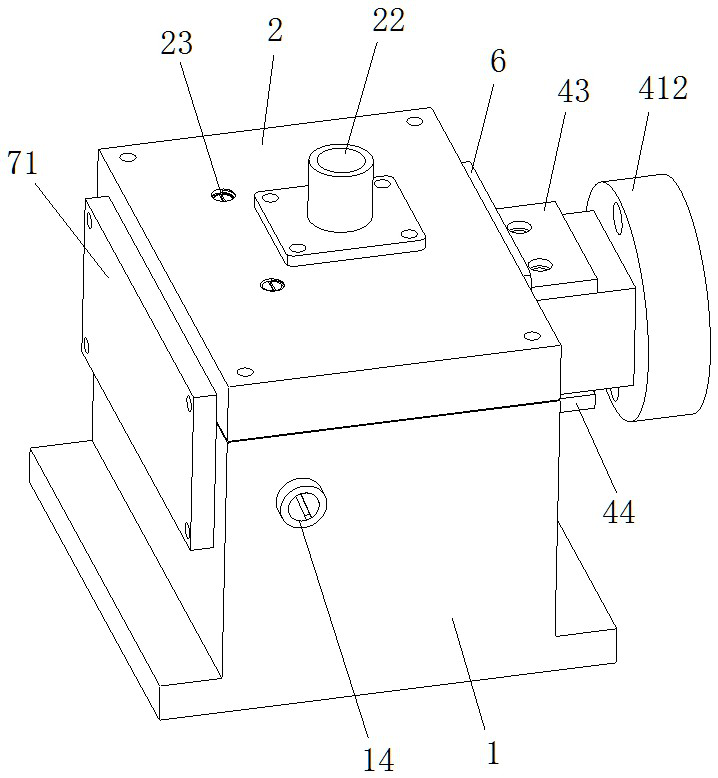

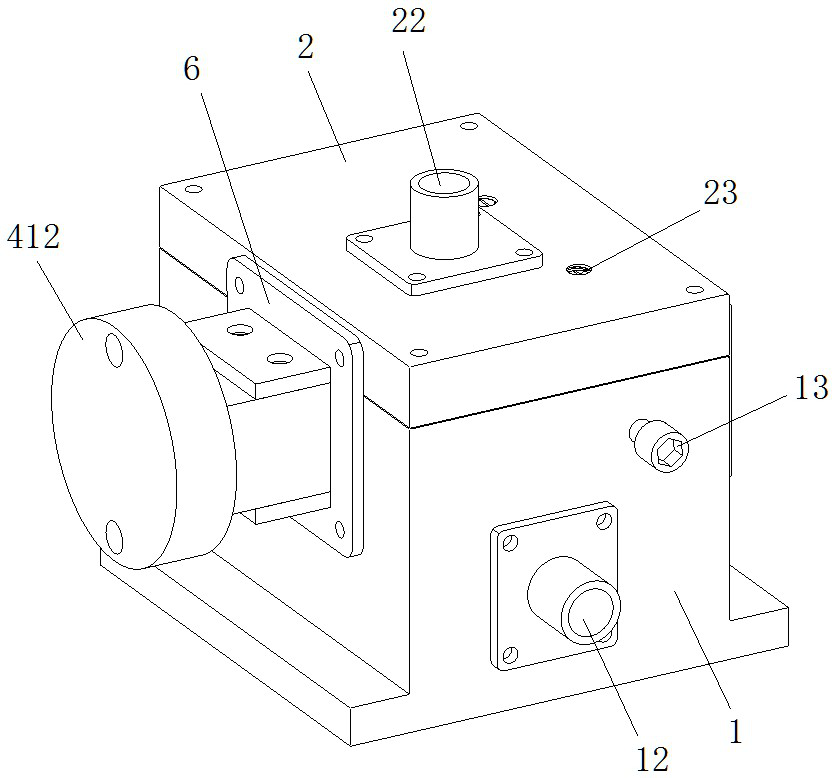

Electrolytic machining tool used for flexible part

ActiveCN112025011AAvoid deformationPrevent leakageElectrochemical machining apparatusElectrolytic agentMachined surface

The invention relates to an electrolytic machining tool used for a flexible part. The electrolytic machining tool comprises a base and a cover plate, a groove body penetrating through the left side face and the right side face of the base is formed in the base, the groove body comprises a first groove body matched with an electrolytic machining cathode and a second groove body matched with a to-be-machined assembly, the to-be-machined assembly is limited by a positioning and clamping device to move and rotate in the second groove body, a sealing plate is arranged on the left side face of the base, a fixing plate is arranged on the right side face of the base, the groove body forms a closed cavity under matched connection of the sealing plate, the fixing plate, the cover plate and the base,the cover plate and the base are provided with an electrolyte inlet channel and an electrolyte outlet channel respectively, the electrolytic machining cathode is connected with a transmission shaft of a mechanical vibration feeding mechanism in an insulating mode, and the transmission shaft drives the electrolytic machining cathode to horizontally feed along the direction limited by the first groove body, so that a cathode cutter on the electrolytic machining cathode is used for carrying out electrolytic machining on the to-be-machined assembly. The electrolytic machining tool has the advantages of wide machining range, high machining efficiency, good machined surface quality and the like.

Owner:HEFEI UNIV OF TECH +1

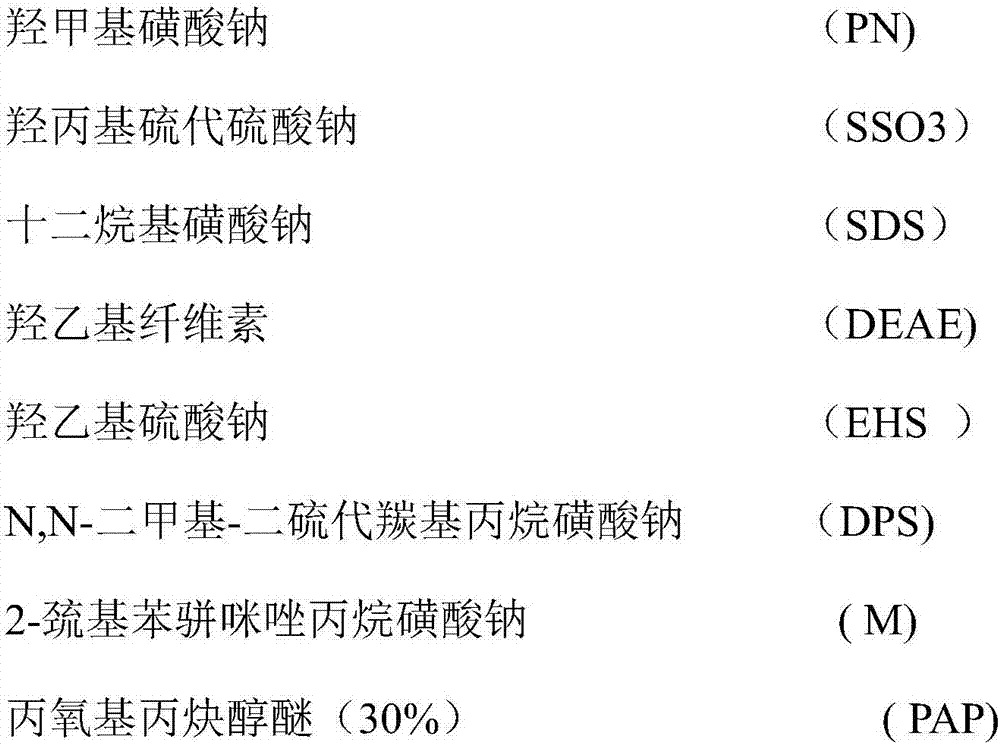

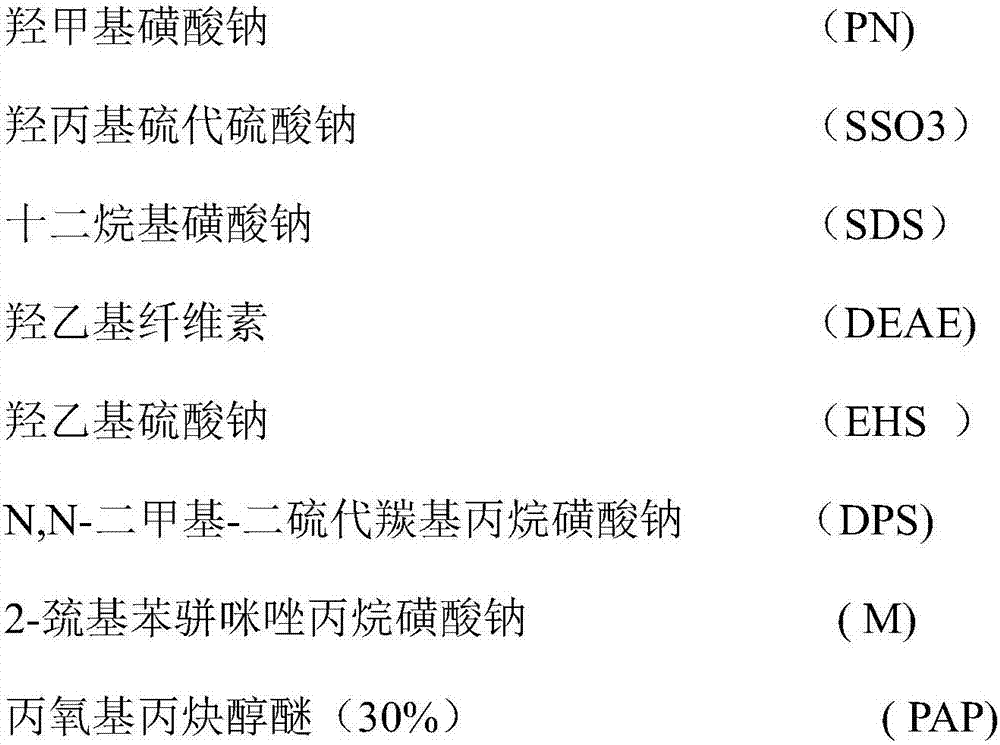

Preparation method, product and application of additive for high-end flexible porous electrolytic copper foil

The invention discloses a preparation method, a product and an application of an additive for high-end flexible porous electrolytic copper foil. The additive for the high-end flexible porous electrolytic copper foil is prepared from raw materials as follows: PN, SSO3, SDS, DEAE, EHS, DPS, M and PAP (30%). An electrodeposition technology is adopted, an electrolyte direct-current electrodeposition technology is included, the additive is added and mixed in the electrolytic process; in the electrolytic process, an electrolyte has the copper content being 80-120 g / L and the sulfuric acid content being 90-130 g / L, the temperature is controlled to range from 45 DEG C to 60 DEG C, the additive is added to the electrolyte, the flow of the electrolyte ranges from 60 m<3> / H to 90 m<3> / H, and direct-current electrodeposition is performed under the condition that the current density ranges from 4,500 A / M<2> to 6,500 A / M<2>.

Owner:安徽华威铜箔科技有限公司

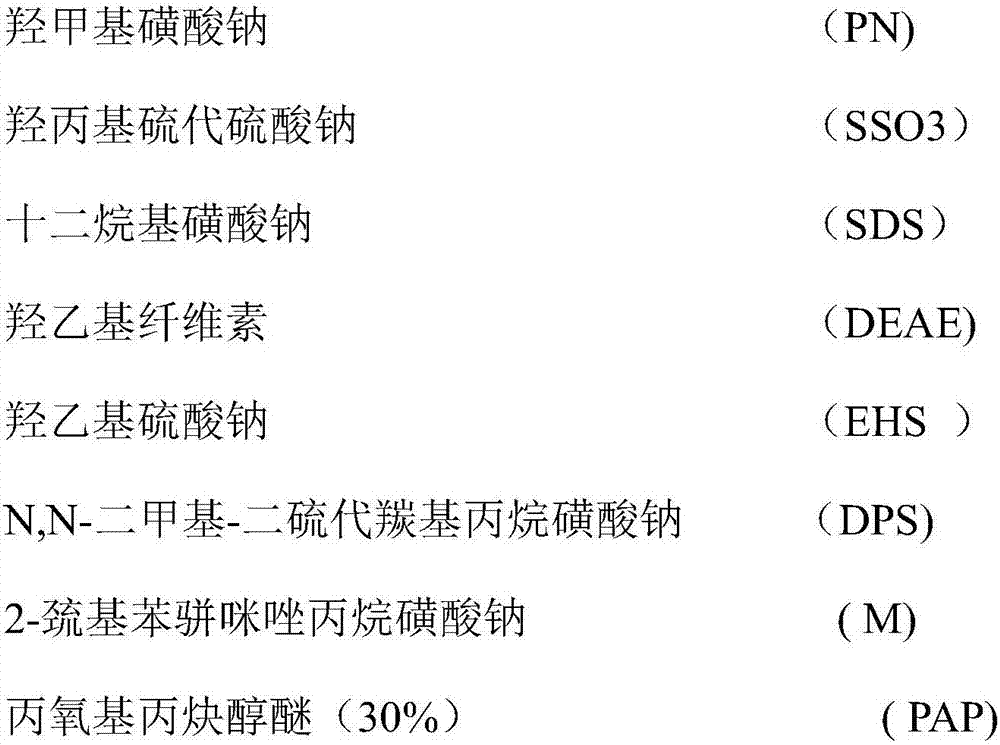

Processing method for inclined planes and inclined plane hole systems of V-shaped machine engine body

InactiveCN107350748AImprove processing efficiencyLow costOther manufacturing equipments/toolsLarge fixed membersNumerical controlEngineering

The invention discloses a processing method for inclined planes and inclined plane hole systems of a V-shaped machine engine body. The method is characterized in that the inclined planes and the inclined hole systems of a marine V-shaped diesel engine body are processed by a numerical-control gantry boring and milling machine, a universal angular joint and a V-shaped engine body boring and milling tool; a V-shaped engine body is mounted on the V-shaped engine body boring and milling tool and then is integrally placed onto a working platform of the numerical-control gantry boring and milling machine for being pressed, so that the inclined planes of the V-shaped machine engine body form angles alpha with the XZ plane of the numerical-control gantry boring and milling machine; the universal angular joint is rotated, so that the universal angular joint form an angle beta with the axis of the numerical-control gantry boring and milling machine; sum of the angles alpha and the angle beta is equal to 90 degrees; and a coordinate zero point is deviated, and programming is performed to complete processing for the inclined planes and the inclined plane hole systems of the V-shaped machine engine body. With the adoption of the technical scheme, planes and hole systems of different angles can be processed without manufacturing a special machine tool and a clamp; and in a product trial-manufacturing process and a small-batch production process, cost can be effectively reduced, and labor intensity can be reduced.

Owner:青岛淄柴博洋柴油机股份有限公司

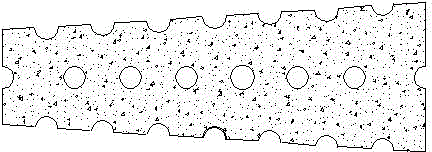

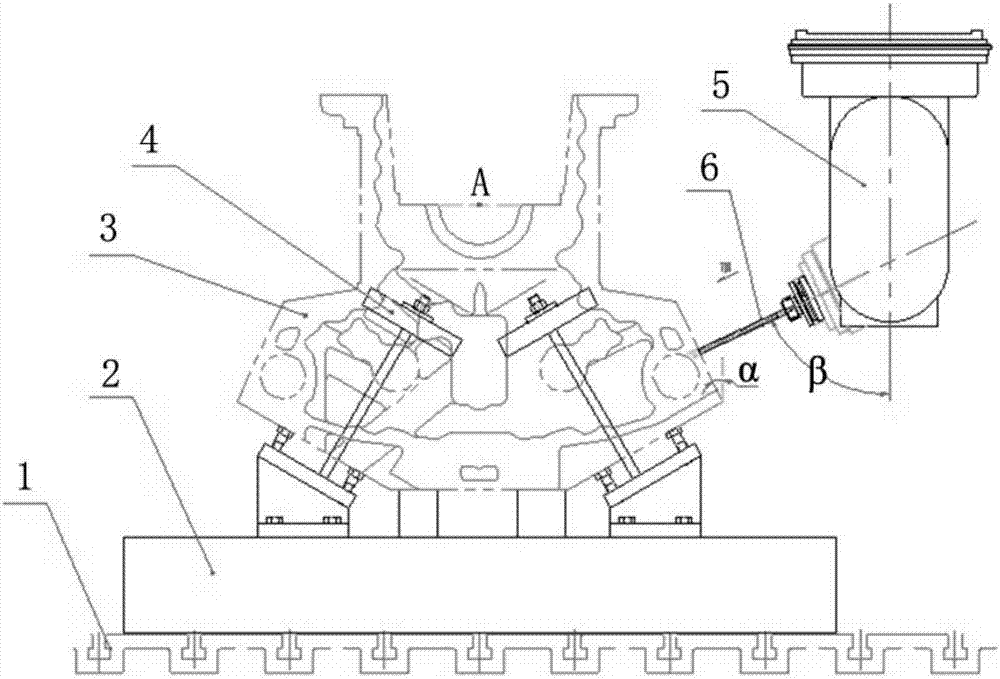

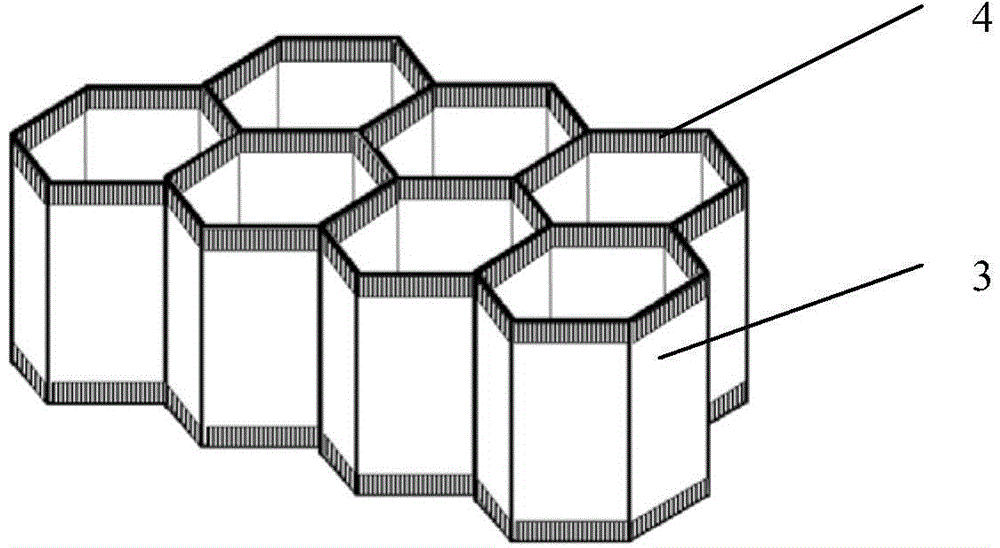

Method for reinforcing surface stability of core of honeycomb-like porous structure by hot film blowing and breaking method

ActiveCN104553238ALess weight gainThe process is simple and easy to operateLamination ancillary operationsLaminationHoneycombAerospace

The invention belongs to the technical field of composite materials, and relates to a technological method for reinforcing the surface stability of a core of a honeycomb-like porous structure in the manufacturing process of a honeycomb core sandwich structure in an aerospace craft, and particularly relates to a method for reinforcing the surface stability of the core of a honeycomb-like porous structure by a hot film blowing and breaking method. The method comprises the following steps: before manufacturing the sandwich structure, firstly, sticking an adhesive film on the surface of the honeycomb-like porous structure, breaking pores of the adhesive film by a hot film blowing and breaking method and sticking on the side wall of a honeycomb core hole cell, and then carrying out heating and curing treatment so that the adhesive film forms an adhesive stream and shaped on the wall of the core of the honeycomb-like porous structure. An organic integer is formed on the surface of the honeycomb core by the method, and the intensity and rigidity of the surface of the honeycomb core are reinforced. When the structure is pressed, the pressure can be transferred and dispersed timely, so that the possibility of buckling failure of a partial weak region is reduced, the surface stability of the structure is reinforced effectively, and the integral pressure resistant capability is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

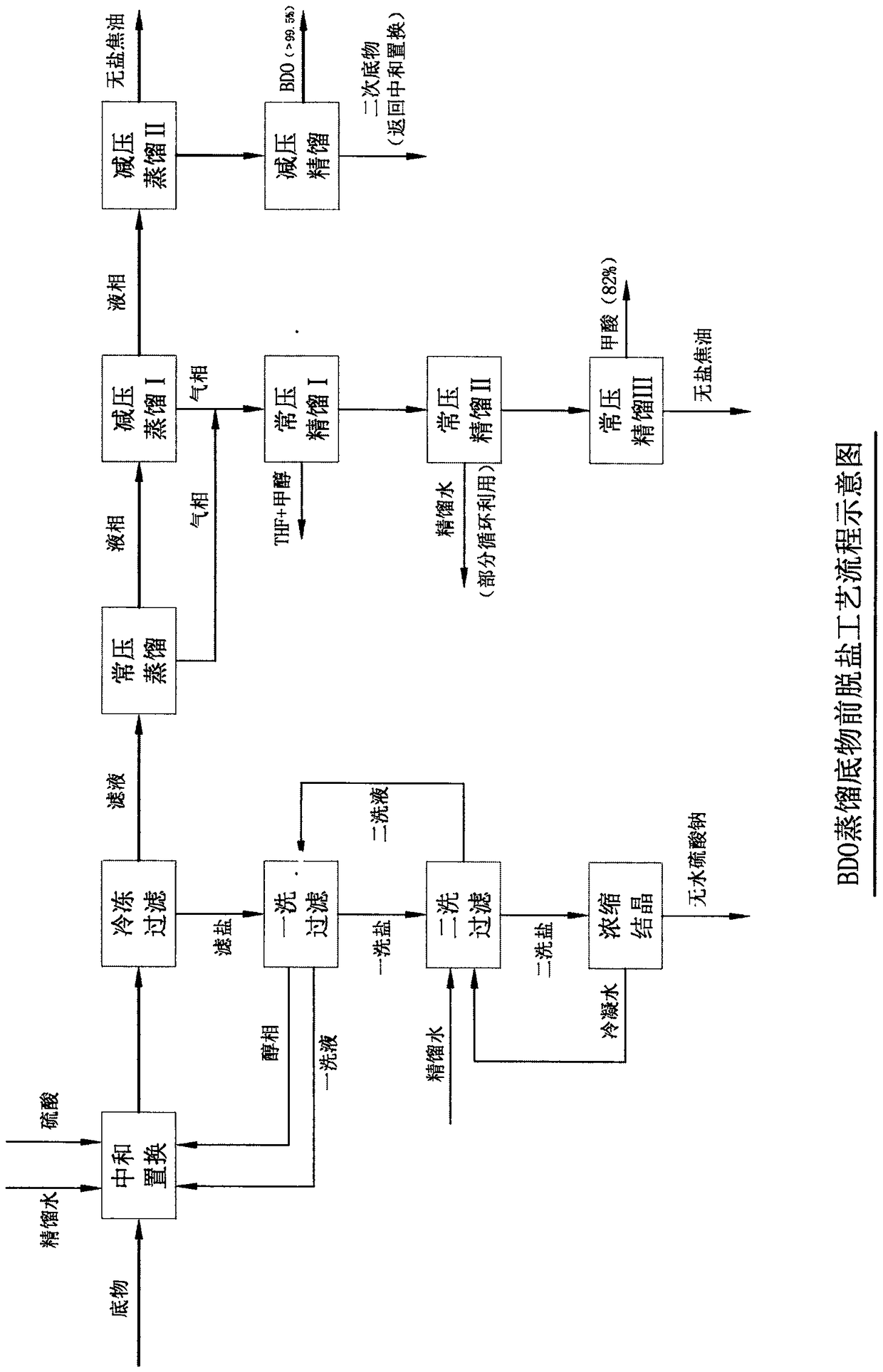

Continuous desalination technology before steaming for resource utilization of BDO device waste liquid

InactiveCN109336736AHigh recovery rateImprove product added valuePreparation from carboxylic acid saltsOrganic compound preparationSalt freeResource utilization

The invention discloses a continuous desalination technology before steaming for resource utilization of BDO device waste liquid, and belongs to the technical field of organic waste liquid recycling in industrial production. According to the technology, the BDO device waste liquid is mixed with return salt-leaching water, and sodium formate in the mixed liquid is completely displaced with sodium sulfate through neutralization and displacement of sulfuric acid; a displacement solution is frozen and filtered, and filter salt is washed and concentrated twice to obtain anhydrous sodium sulfate; filter liquor is subjected to atmospheric concentration and first-stage reduced pressure membrane scraping distillation, light components in the filter liquor is steamed out, and low boiling alcohol, water and a formic acid water solution are separated from the light components through third-stage rectification; a remaining solution after the first-stage reduced pressure membrane scraping distillation is subjected to second-stage reduced pressure membrane scarping distillation, a BDO product with the content of 99.5% or more than 99.5% is obtained after rectification of the distilled coarse BDO,and a distillation substrate is salt-free tar which can be used for oil burning boiler byproduct steam. The technology has the advantages that various products can be recycled, the product recycle rate is high, waste liquid resources are utilized sufficiently, the environmental protection is facilitated, the recycle cost is low, the applicable range of the technology is wide, the technology is convenient for popularization and application and the like.

Owner:CHONGQING UNIV

Metal cold hot cut circular saw blade sawtooth grinding method

InactiveCN101596622AEliminate the phenomenon of easy wear or chipping of the sawtoothImprove sawing resultsSawing tools dressing arrangementsMetalworkingEngineering

A metal cold hot cut circular saw blade sawtooth grinding method belongs to the metal processing technical field and is used for solving the problem that a sawtooth grinding radial feed method can cause tipping or easy wearing of arc at the blade of the sawtooth. The method includes the following steps: a, a saw blade to be ground is installed, and the installed saw blade can freely rotate; b, a grinding wheel matched with the sawtooth type of the saw blade to be ground is selected and installed; c, the grinding wheel rotates to grind each sawtooth of the saw blade to be ground one by one, and the grinding wheel feed direction is along the axial direction of the saw blade to be ground during grinding; d, the sawtooth type after grinding is checked, and the saw blade is discharged after meeting technical requirement. In the method of the invention, the sawtooth is ground by the grinding wheel in axial feed manner, the sawtooth blade and root after grinding are in straight line, thus eliminating tipping or easy wearing of sawtooth caused by arc at the blade, effectively improving sawing effect of a repaired saw blade and prolonging the service life of the saw blade.

Owner:TANGSHAN METALLURGICAL SAW BLADE

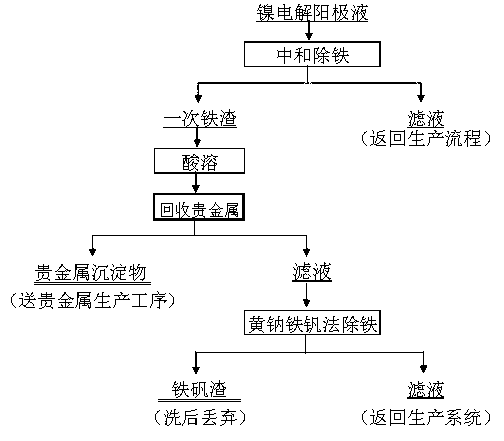

Method for recovering platinum group metal from ferrous nickel electrolysis anolyte

ActiveCN102994773ASolve difficult to recycleRealize enrichment recoveryProcess efficiency improvementElectrolysisSlag

The invention relates to a method for recovering platinum group metal from ferrous nickel electrolysis anolyte, which comprises the following steps of: firstly neutralizing the nickel electrolysis anolyte to remove iron; returning the filtrate to a production system; performing acid dissolution on the obtained primary iron slag at 20-50 DEG C, and then adding a vulcanizing agent; performing precision filtering, wherein over 96% of precious metal is enriched in the filter residue; and removing iron of the filtrate by a sodium jarosite method, wherein the content of precious metal in the obtained sodium jarosite slag is less than 1.0g / t. The method provided by the invention solves the problem that precious metal is lost in anolyte and hard to recover in an electrolytic refining process of a nickel anode containing precious metal, prevents influence on the existing production, and can guarantee the quality of electrolytic nickel; and moreover, the technology is simple, the production cost is low, and the implementation is easy.

Owner:JINCHUAN GROUP LIMITED

Production process for producing natural pigments through microorganisms

InactiveCN106191130AGood compatibilityWide range of processing applicationsNatural dyesFermentationMicroorganismDissolution

The invention discloses a production process for producing natural pigments through microorganisms. The production process includes the steps of strain culture, temperature setting, time setting, mycelium inactivation, pigment dissolution, pigment testing, crudely-extracted pigment dissolution, refined pigment purifying and concentration. Compared with the prior art, the process is wide in application range and easy to operate, product quality is good, and production efficiency is high; the process is low in production cost, and more profits are generated; during the production flow of the process, resources are saved, pollution is avoided, and environmental compatibility is good; the process can meet laboratory research requirements and also meet the requirements for enterprise industrial production. The problems, about how to increase the yield, how to purify refined pigments and how to reduce cost, usually generated when the natural pigments are produced through microbial fungi, actinomycetes and bacteria are solved to a certain degree, and the basic problems about the requirements for the stability and safety of the produced pigments are solved to a certain degree.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

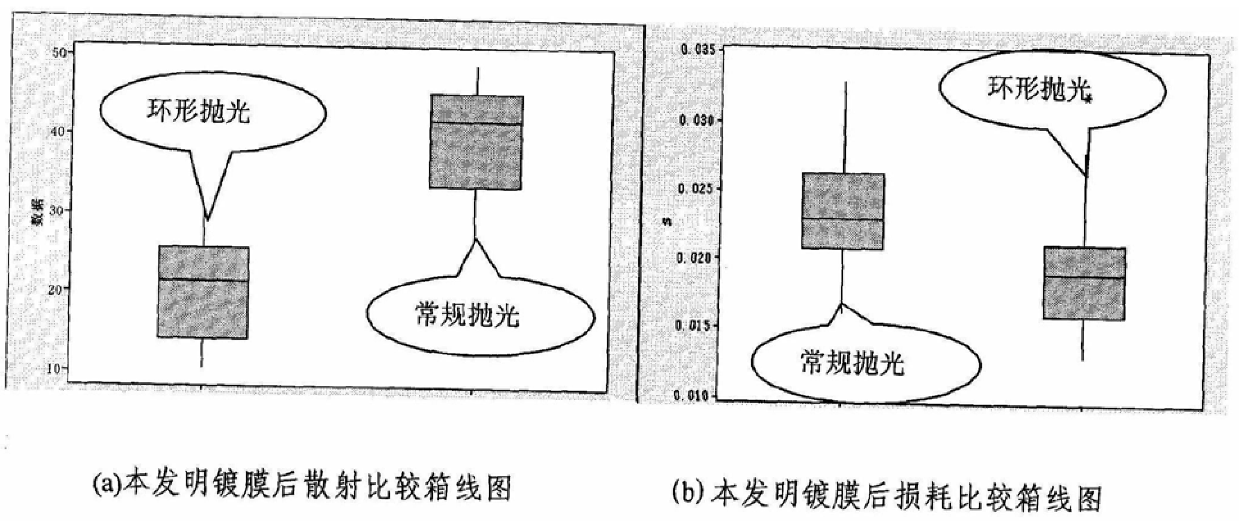

Ring Polishing Disc Correction Method and Pitch Formula for Ultra-Low Scattering Mirror of Laser Gyroscope

InactiveCN106507726BMeet the requirements of coatingImprove processing efficiencyOptical surface grinding machinesAbrasion apparatusGyroscopeMechanical engineering

The invention relates to a method for correcting an annular polishing disc and its asphalt formula, in particular to a method for correcting an annular polishing disc suitable for a high-precision laser gyroscope with extremely low scattering mirrors and its asphalt formula. The present invention adopts mechanical turning tool to turn asphalt surface, groove shape determination, correction parameter control, etc., to form a set of methods for correcting polishing discs; adopt the asphalt with grades 82# and 73# produced by Global Optics in the United States, and the required asphalt ratio Be 82#: 73#=1 / 3~3 / 5. Apply the polishing disc made by the asphalt formula of the present invention and apply it in the technological process of annular polishing in combination with the ring polishing disc correction method, the Rq of the processed parts is as follows; N=0.2; ΔN=0.1; the surface defect is 0 grade; Very low scattering substrate coating requirements are met. It has played a positive role in improving the accuracy, reliability and stability of high-precision laser gyroscopes.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

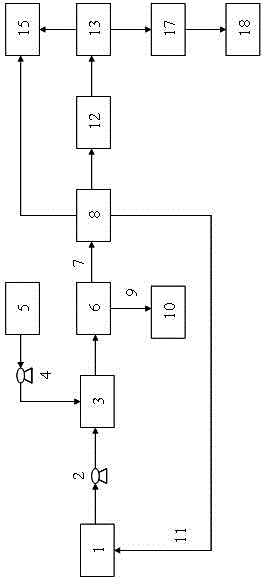

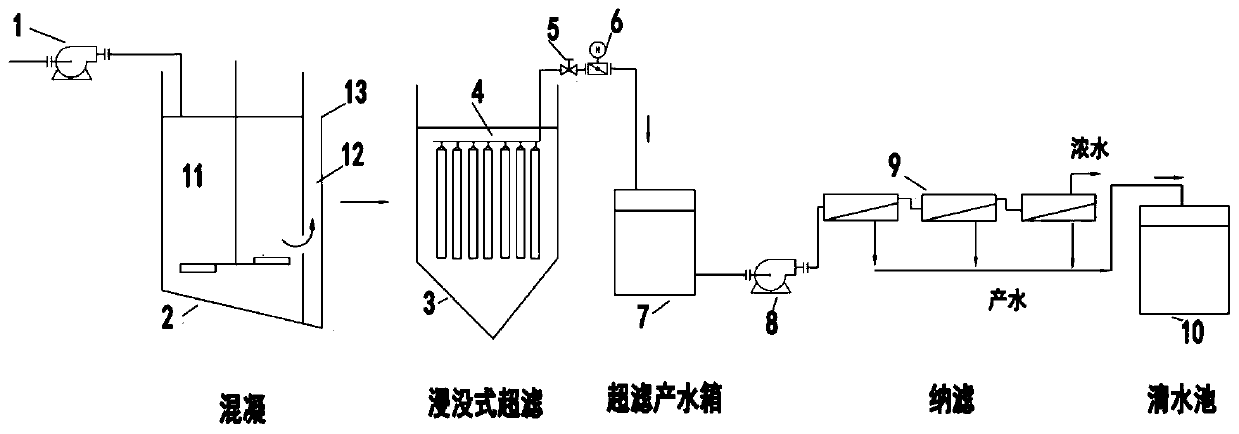

Method for preparing high-quality drinking water

PendingCN111087095AGuarantee the quality of produced waterWide range of process applicationsWater contaminantsWater/sewage treatmentRaw waterPollutant

The invention provides a method for preparing high-quality drinking water, and belongs to the technical field of feed water advanced treatment. A conventional treatment process is combined with a membrane technology, wherein raw water enters a coagulating basin through a lifting pump, and after coagulation treatment, the raw water directly enters an immersed ultrafiltration membrane basin from anoverflow weir at the upper part of the coagulating basin for ultrafiltration treatment; ultrafiltration produced water enters the nanofiltration device, so that trace organic pollutants in the water are removed while inorganic salt is reserved; the nanofiltration device is of a one-stage three-section design with in-section internal reflux, and the nanofiltration produced water is high-quality drinking water. According to the method, the surface water is treated by adopting a coagulation-short process ultrafiltration-nanofiltration combined process, wherein trace organic matters harmful to a human body are removed, most of inorganic salt is reserved, and the produced water conforms to the current concept of healthy water; the system recovery rate is high, no chemical agent (scale inhibitor) needs to be added in the nanofiltration operation process, the produced water quality is stable, the technological process is simple, membrane method treatment is adopted, occupied land is saved, the device integration degree is high, the occupied area is small, and the operation cost is low.

Owner:BEIJING ORIGINWATER TECH CO LTD +1

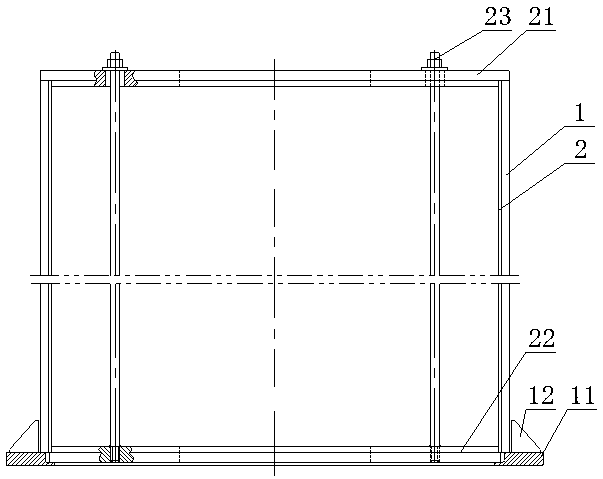

High-precision superposition technology of shrink fit cylinder for pressure container

ActiveCN109396745AQuality improvementGuaranteed coincidenceMetal working apparatusSwelling capacityFree cooling

The invention discloses a high-precision superposition technology of a shrink fit cylinder for a pressure container. The high-precision superposition technology comprises manufacturing an outer cylinder, manufacturing a lining cylinder and shrink fit, wherein the shrink fit comprises the followings: A, positioning and pre-assembling: adopting a lining hoisting tool to hoist and fix the lining cylinder, pre-assembling the lining cylinder and the outer cylinder on a base tool, and marking the best shrink fit station; B, heating: heating the outer cylinder and the base tool until the internal diameter swelling capacity D reaching (0.4-0.6)% of the outer cylinder; C, superposition: moving a flat car to the marked part in the step A, slowly and perpendicularly putting down the lining cylinder,and carrying out natural cooling; and D, checking the indicator to meet the requirement of the related standard. According to the high-precision superposition technology, the base tool and the lininghoisting tool are matched for application, so that shrink fit of the outer cylinder and the lining cylinder can be rapidly and precisely carried out; the application range of the technology is wide; and in addition, the metallographic structure and the performance of the material of the outer cylinder are not damaged, the entire operating process is simple, convenient and fast, the manufactured shrink fit cylinder is stable in quality and reduced in rejection rate.

Owner:云南大为化工装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com