Preparation method, product and application of additive for high-end flexible porous electrolytic copper foil

An electrolytic copper foil and additive technology, applied in the electrolytic process, electroforming and other directions, can solve the problems of low composite rate of finished products, hidden dangers of downstream product quality and safety, production of copper scraps and particulate copper powder, etc., to ensure product quality and efficiency. , Good paste effect and characteristics, the effect of a wide range of process applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of an additive for high-end flexible porous electrolytic copper foil provided in this embodiment includes the following steps:

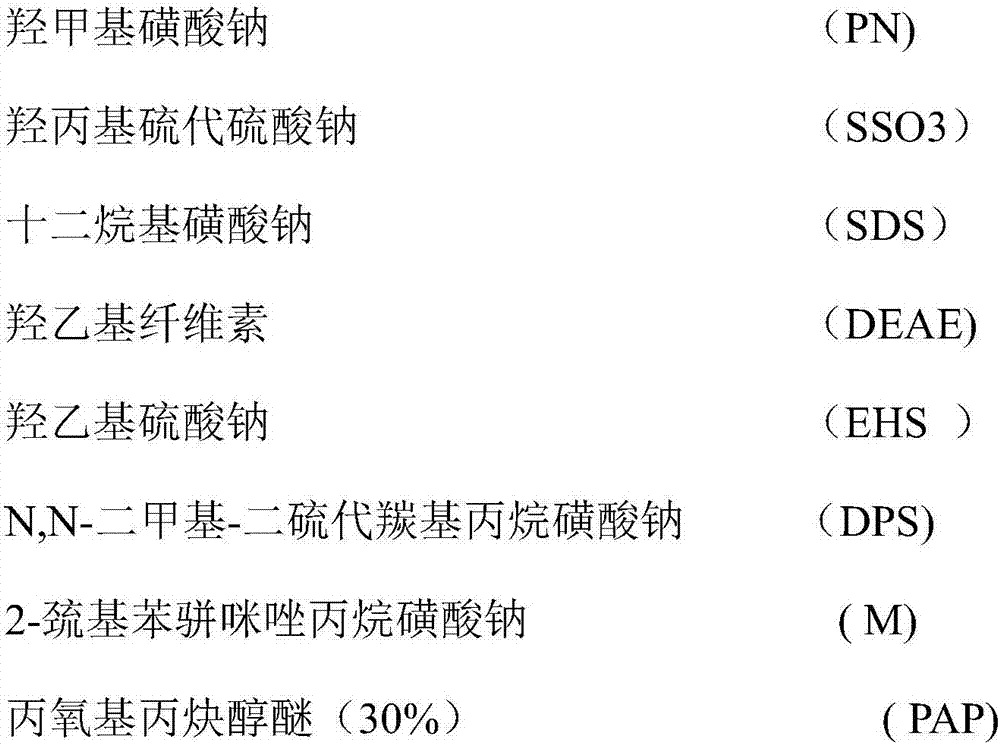

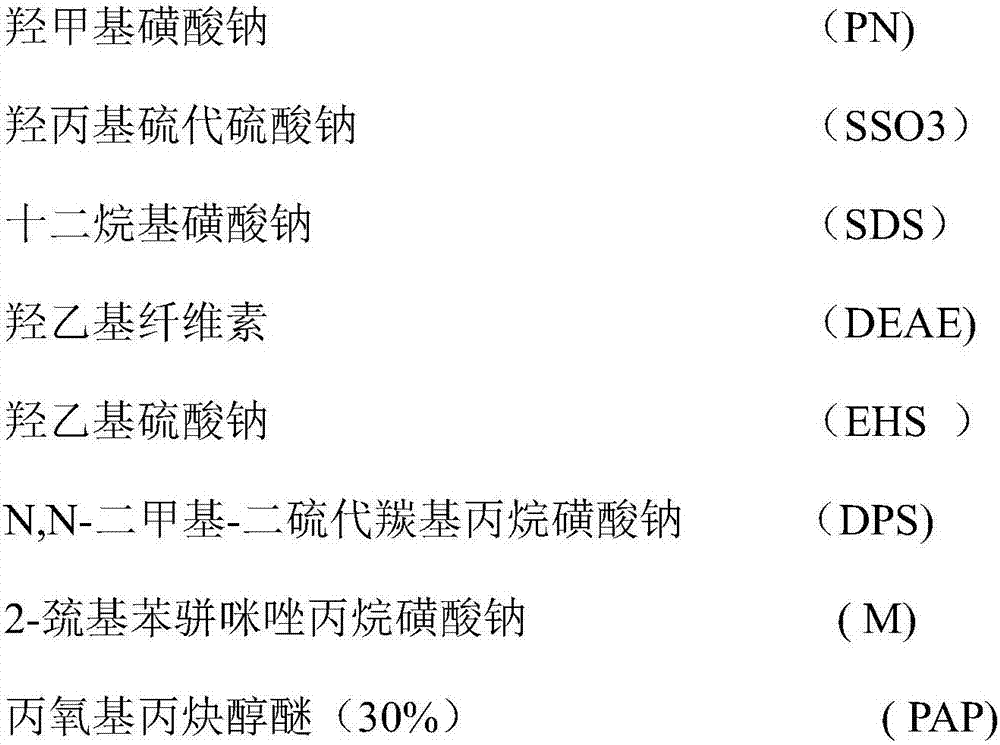

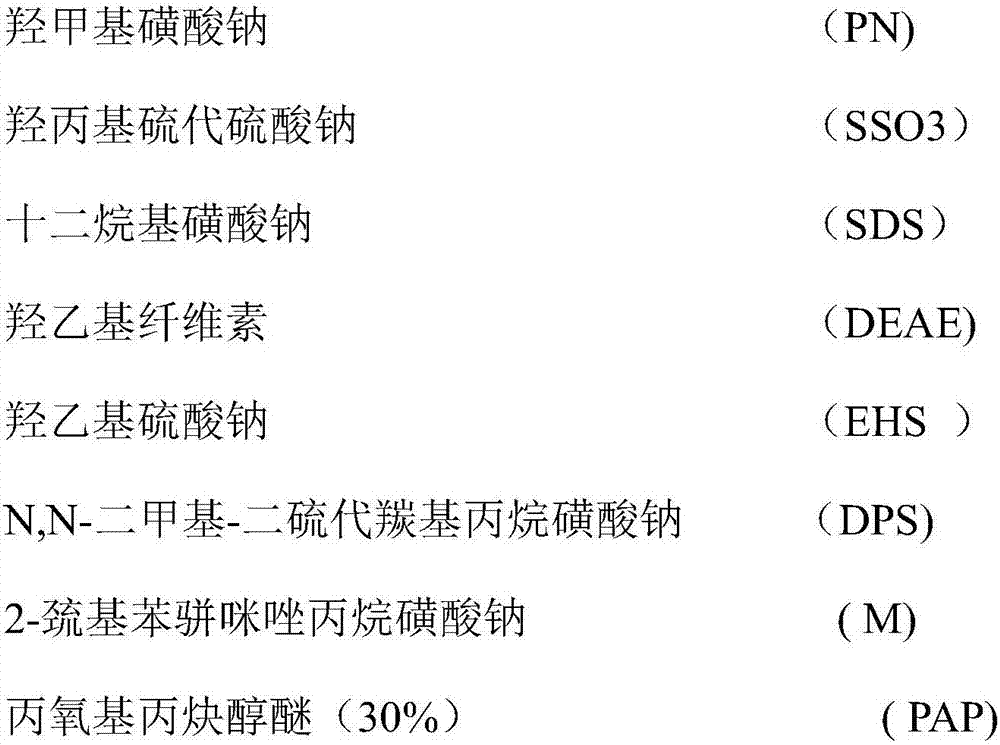

[0023] (1) Prepare the following raw materials:

[0024]

[0025] Its mass ratio is 1.5:1:0.5:2:0.5:1:0.5:0.25;

[0026] (2) Take sodium hydroxymethanesulfonate, sodium hydroxypropylthiosulfate, sodium dodecylsulfonate, hydroxyethylcellulose, sodium hydroxyethylsulfate, N,N-dimethyl-disulfide Sodium carbonylpropane sulfonate, sodium 2-mercaptobenzoimidazole propane sulfonate, and propoxypropynyl alcohol ether (30%) were dissolved in 250mL deionized pure water to obtain solution A, solution B, solution C, and solution respectively. D, solution E, solution F, solution G, solution H;

[0027] (3) Add solution A, solution B, solution C, solution D, solution E, solution F, solution G, and solution H prepared in step (2) into a 5L constant temperature stirring cup, then add 2L deionized water, and Stir at a constant temp...

Embodiment 1

[0035]

example 1

[0036] The copper foil parameters obtained in Example 1 are as follows:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com