Patents

Literature

175results about How to "Paste effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

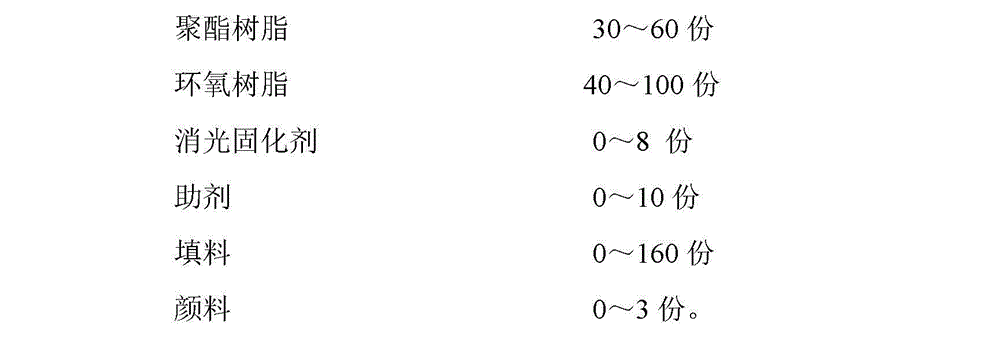

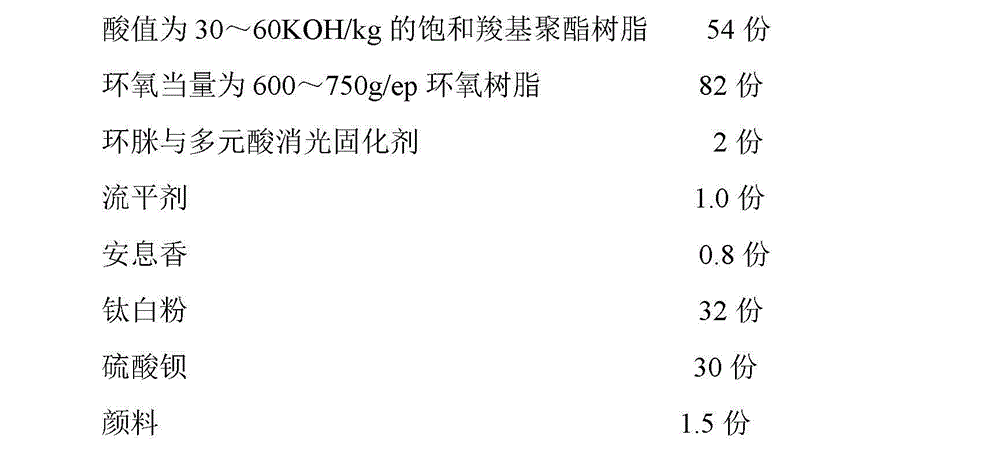

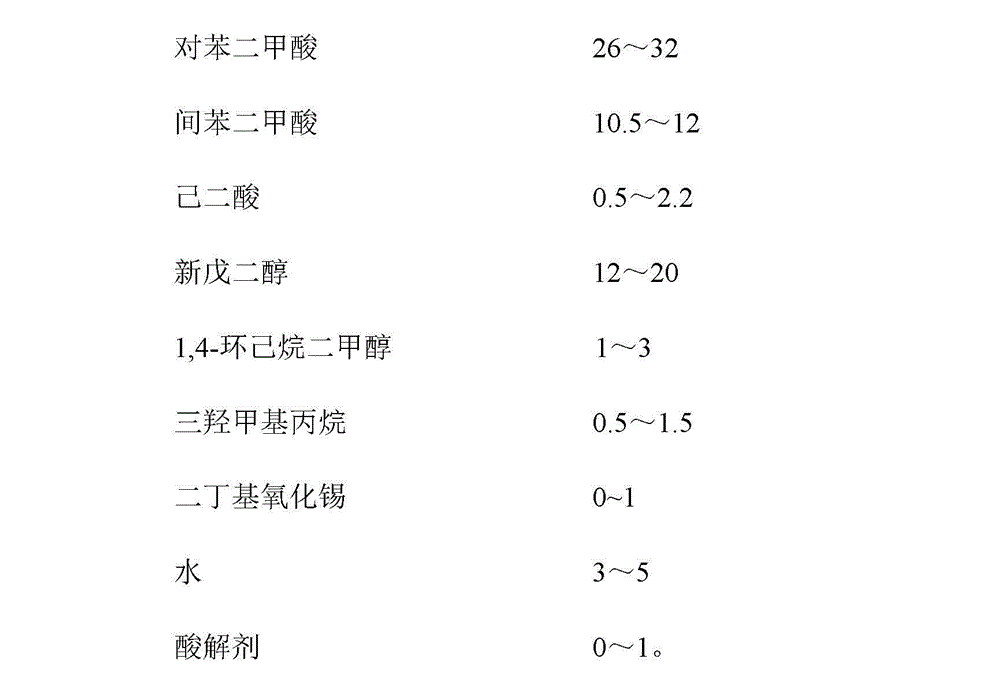

Special primer paint for medium and high grade automobile aluminum hubs and preparation method of primer paint

ActiveCN102911585ANon-toxic and environmentally friendlyImprove the level ofPowdery paintsEpoxy resin coatingsEpoxyPolyester resin

The invention discloses special primer paint for medium and high grade automobile aluminum hubs. The primer paint comprises, by weight, 30-60 parts of polyester resin, 40-100 parts of epoxy resin, 0-8 parts of matting and curing agents, 0-10 parts of additives, 0-160 parts of packing and 0-3 parts of pigment. The invention further discloses a preparation method of the paint. Once a coating of the paint is solidified, the paint has good leveling property, breathability and chemical resistance.

Owner:GUANGZHOU KINTE IND

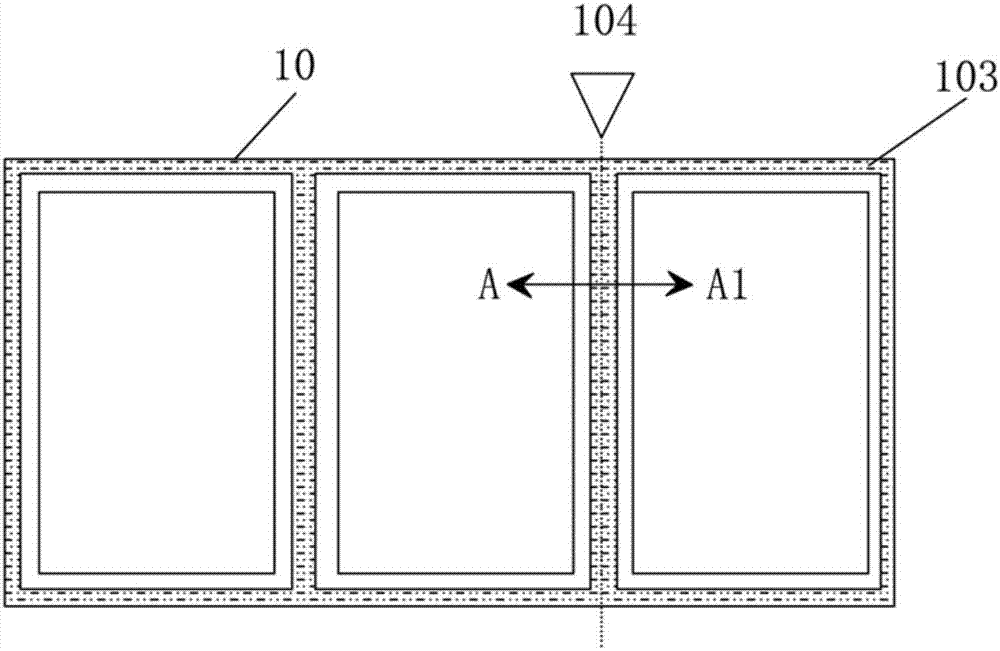

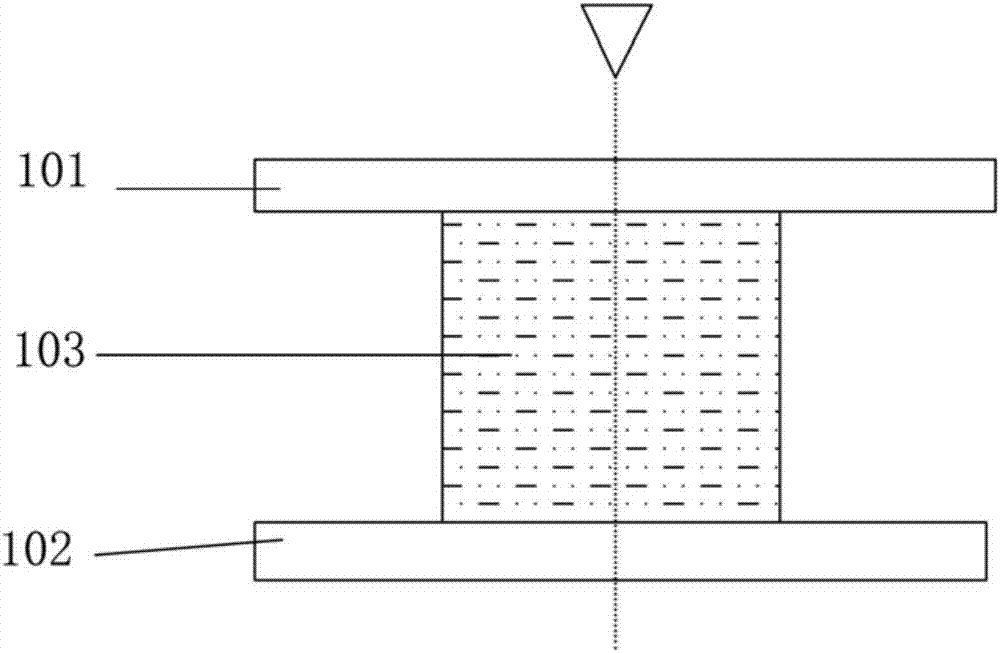

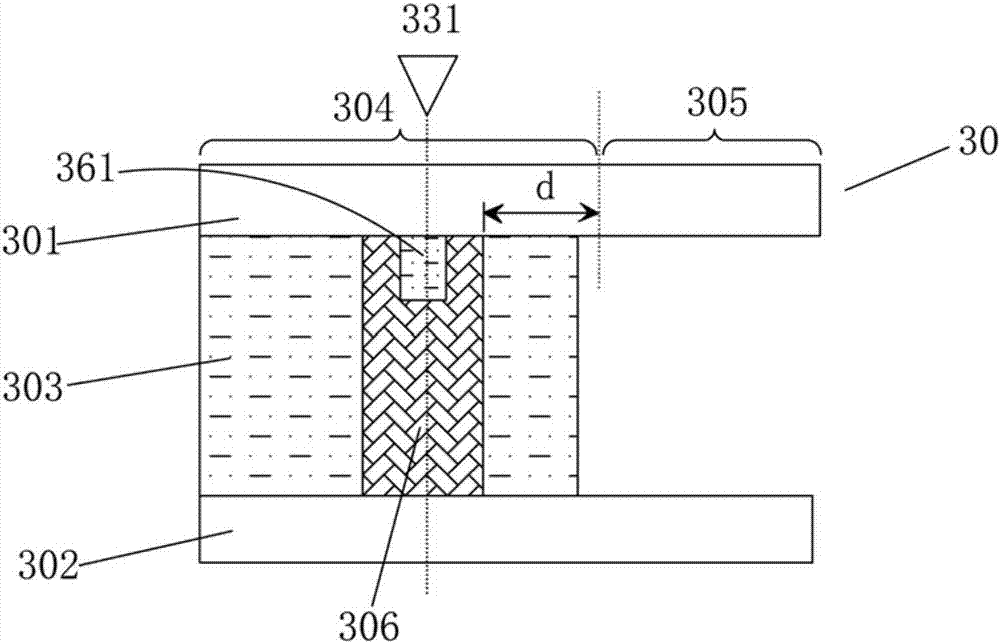

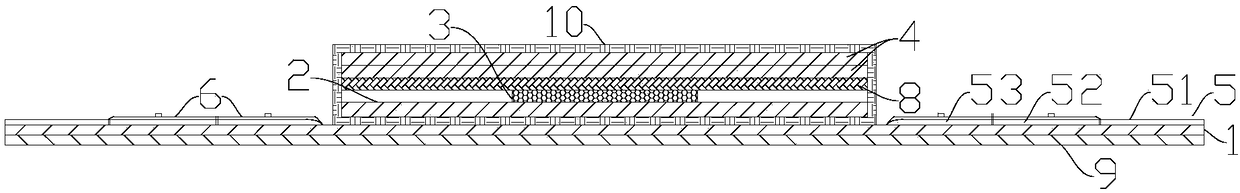

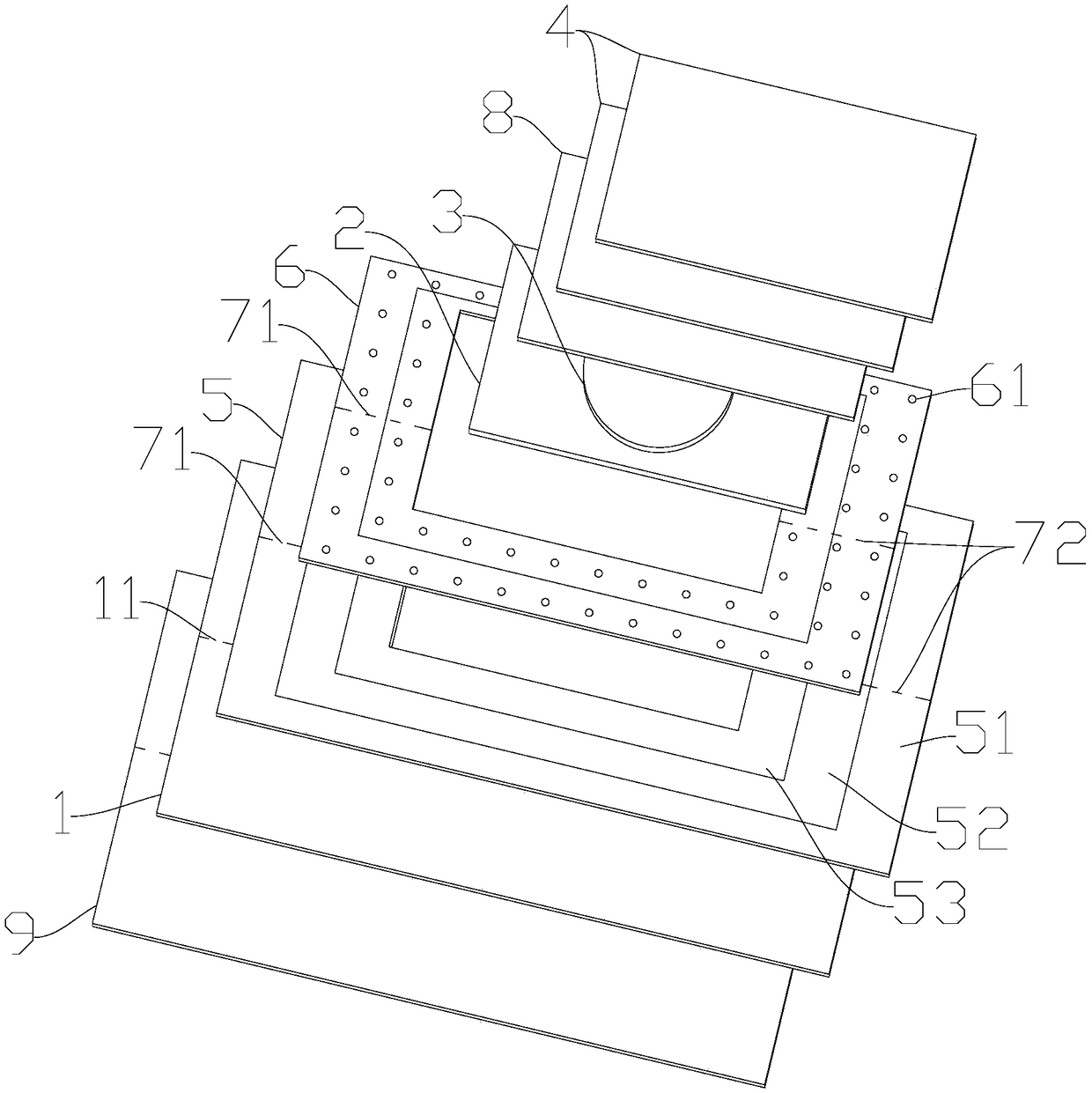

Display panel

ActiveCN106990620AReduce widthPaste effect is goodNon-linear opticsRetaining wallElectrical and Electronics engineering

The invention provides a display panel. The display panel includes a first substrate, a second substrate and frame glue located between the first substrate and the second substrate and further includes a display region and a non-display region, and the frame glue is located in the non-display region and surrounds the display region; the frame glue is internally provided with at least one first retaining wall, the first retaining walls at least partially make contact with the first substrate and the second substrate, the end portions, near the first substrate, of the first retaining walls are provided with grooves with openings facing the first substrate, and first trenches are formed. By forming the first trenches in the first retaining walls, the trench regions are filled in the frame glue coating process, the adhesion between the first retaining walls and the substrates corresponding to the first trenches is improved, the width of the frame glue in the non-display region is reduced, and the narrow bezel design is easily achieved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

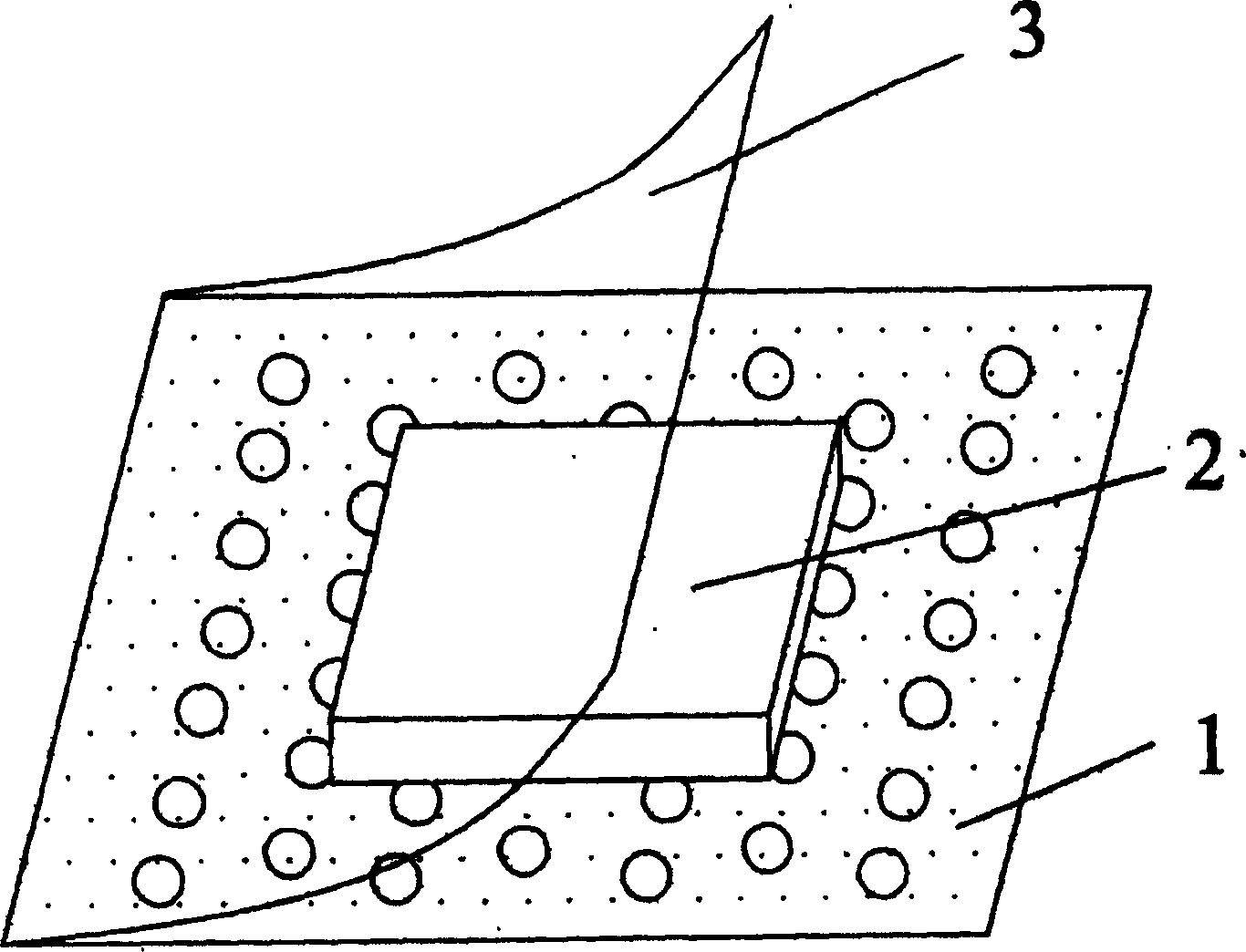

Foamed reinforcing material

The invention discloses a foamed reinforcing material. The foamed reinforcing material is characterized by comprising the following components by mass: 5-20% of synthetic rubber, 5%-20% of an epoxy resin, 0.5%-5% of a hardening agent, 0.5%-5% of a foaming agent, 27%-33% of an inorganic filling material and 40%-50% of a light calcium carbonate. The foamed reinforcing material is foamed and hardened by a chemical reaction of the epoxy resin and the hardening agent and the heat during a baking process of electro-coating. A gas generated by a decomposition effect of the foaming agent allows the epoxy resin filling with bubbles, thereby forming a light-weight resin hardener and adhere with a steel plate and integrating an automobile steel plate and reinforced resin, so that the strength of the steel plate is enhanced. The foamed reinforcing material is simple in structure, good in adhesivity, high in strength and obvious in reinforced effect of the automobile steel plate.

Owner:IIDA FOSHAN IND

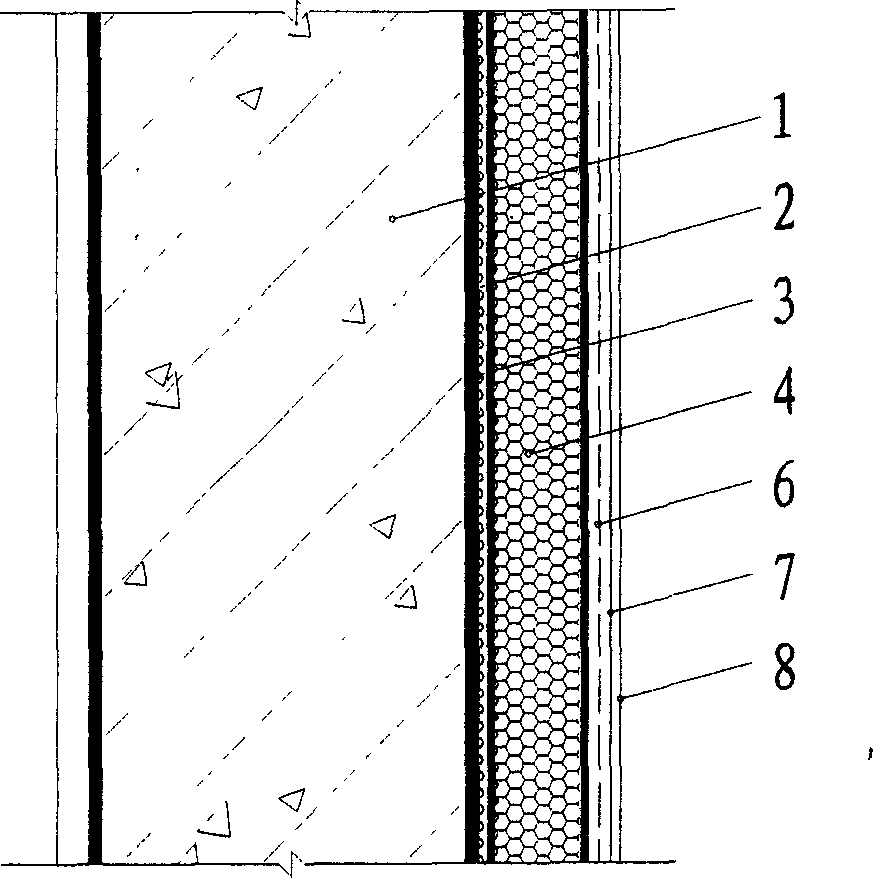

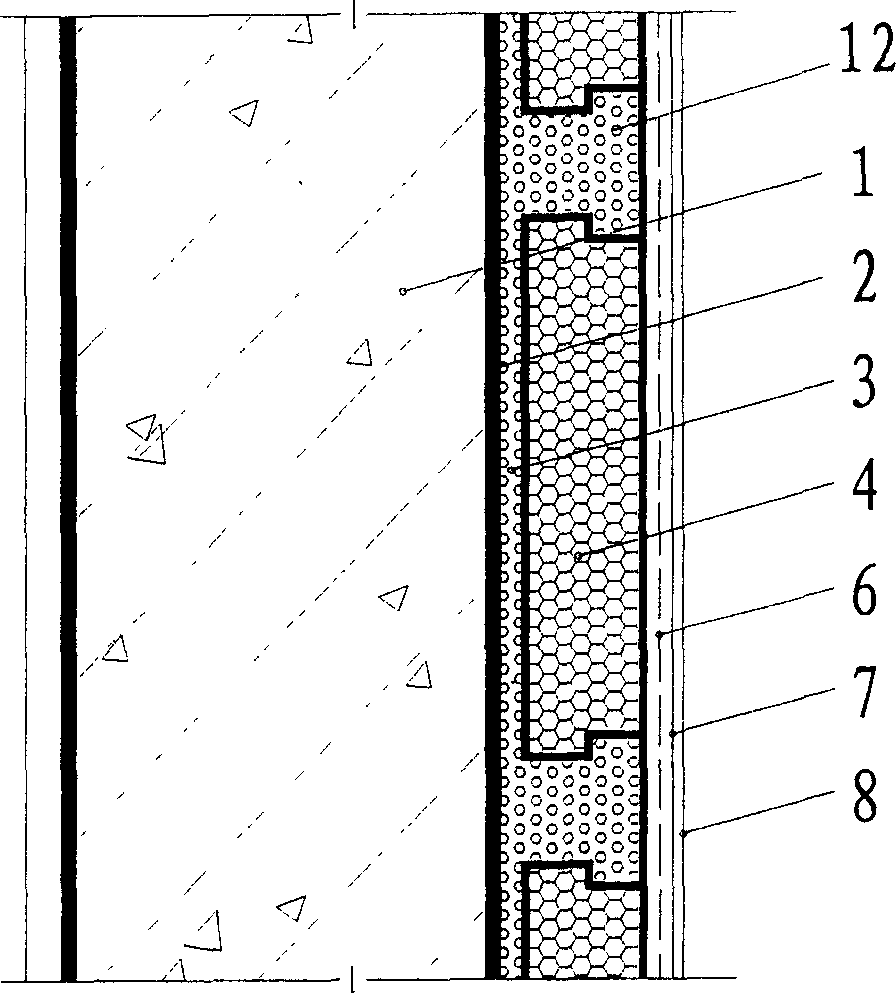

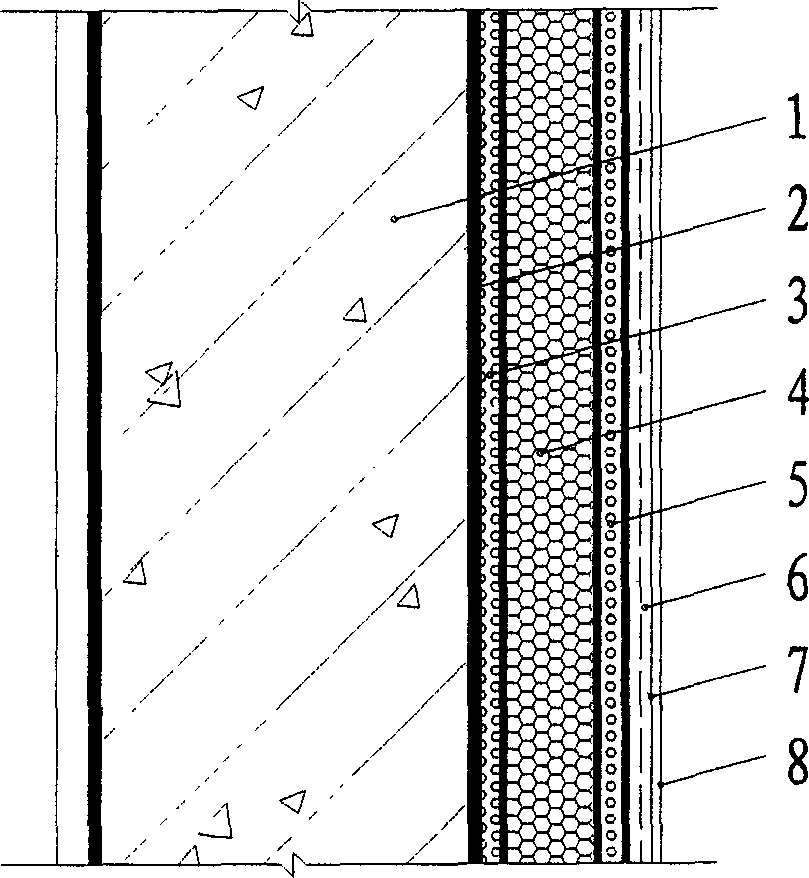

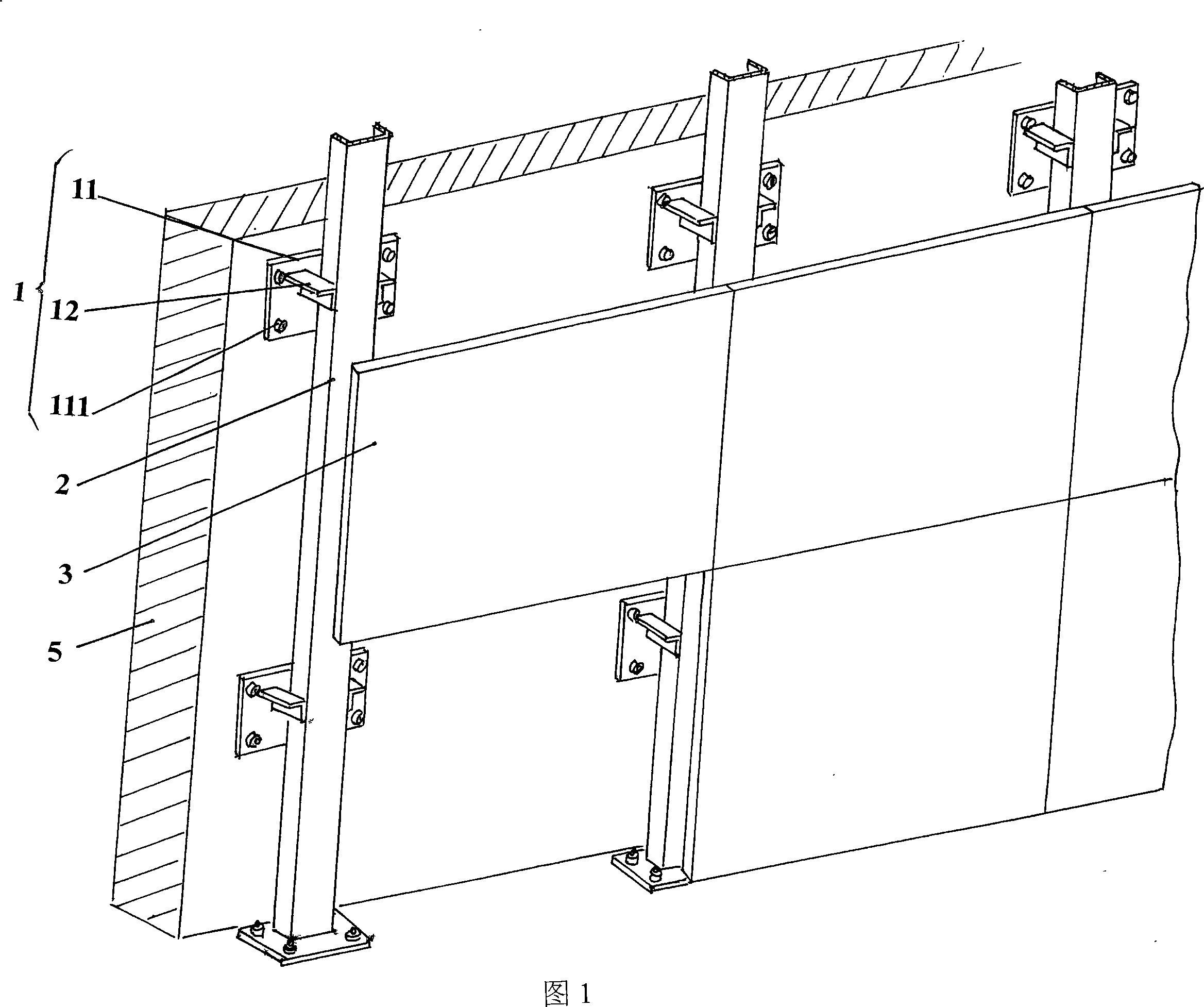

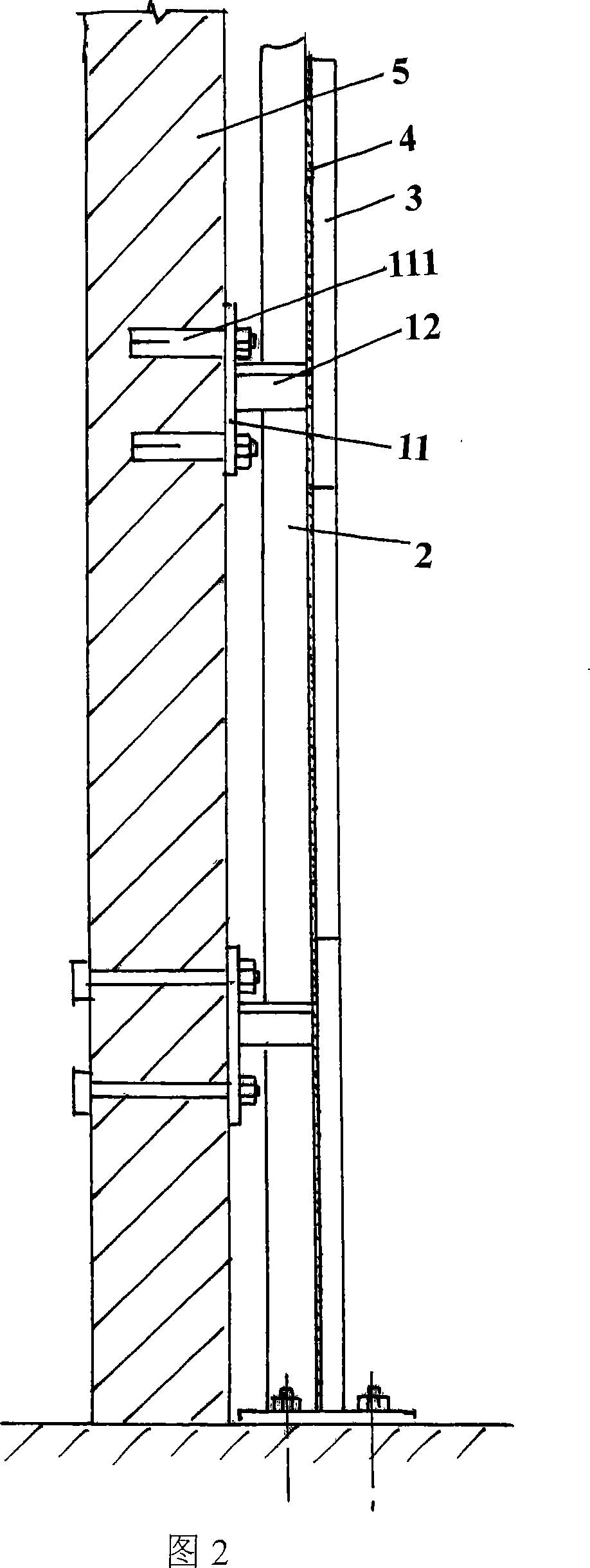

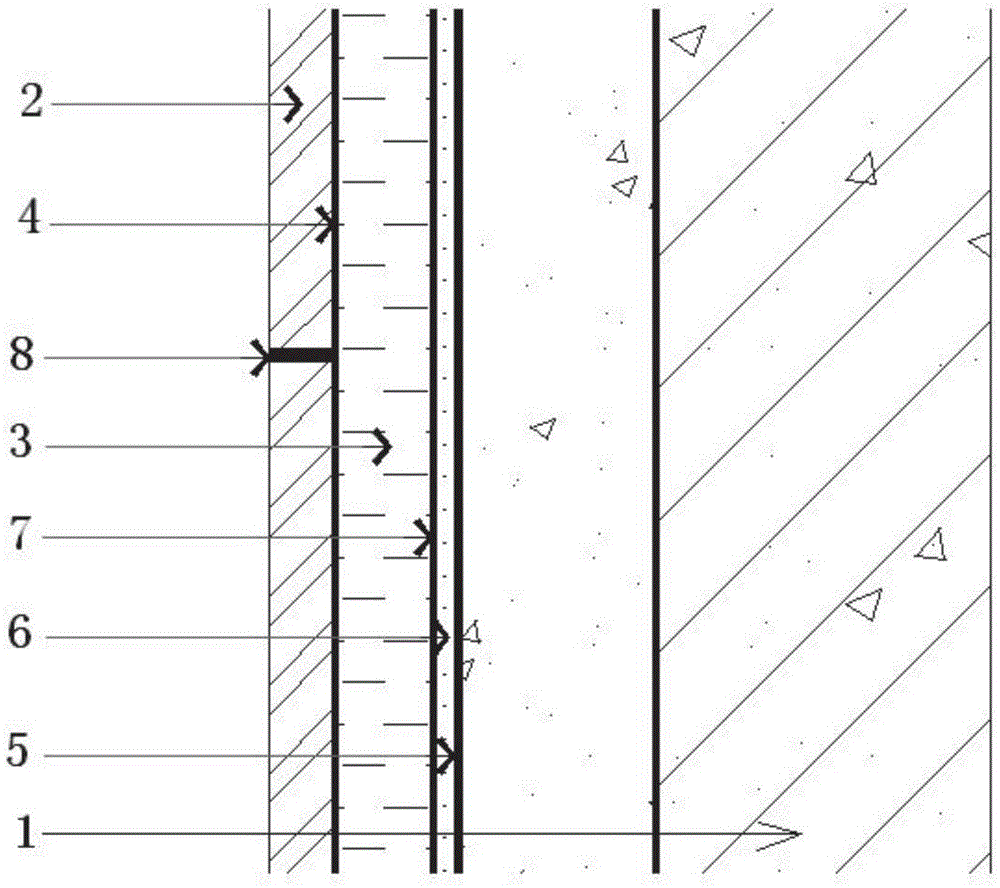

Polyphenyl board composite thermal insulative wall and constructing process

InactiveCN1584236AImprove stabilityImprove insulation effectHeat proofingInsulation layerMechanical engineering

The present invention relates to a polypenyl plate composite heat-insulating wall body and its construction process. Said wall body has base layer wall body, boundary surface mortar layer, adhesive coating, polyphenyl plate, anticrack mortar layer and finishing coat from interior to exterior successively. Its polyphenyl plate is adhered and fixed on the base layer wall body by means of heat-insulating mortar, on the polyphenyl plate there are some air-permeable plug-holes, if necessary, the polyphenyl plate can be strengthened and fixed by using plastic expanding anchor, and according to the requirements it can be leveled by using heat-insulating mortar. Said invention can raise heat-insulating effect and construction speed.

Owner:黄振利

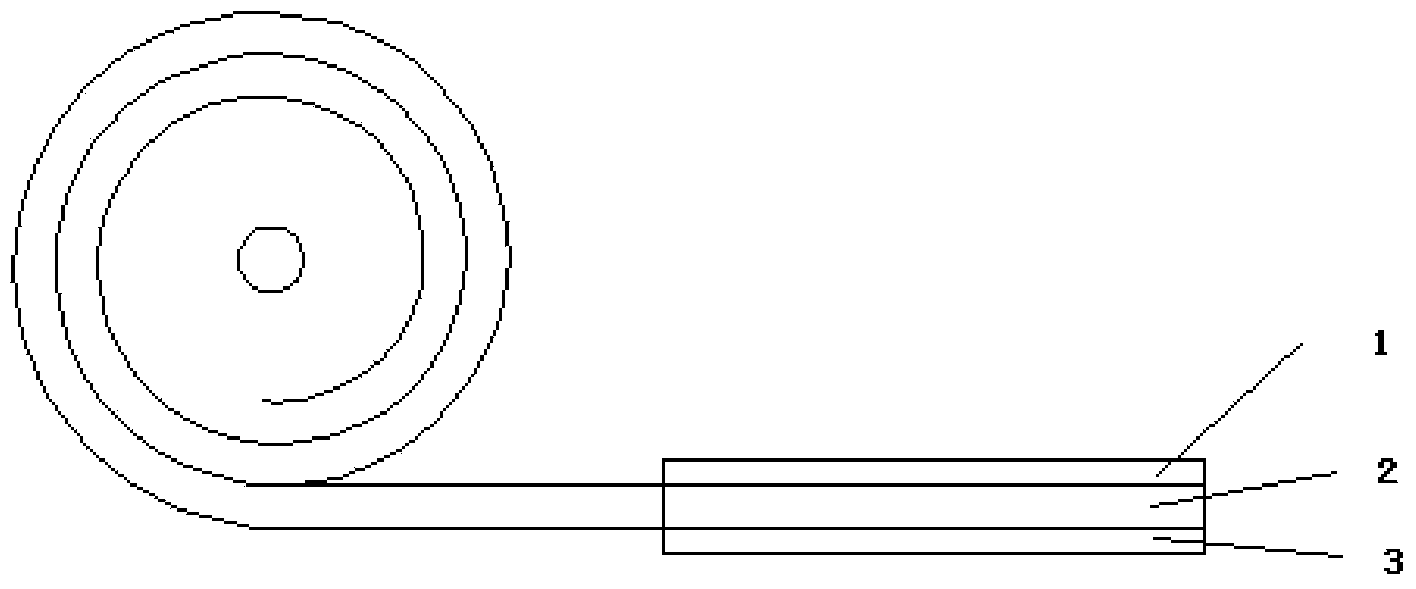

Aging-resistant adhesive tape used for protecting edge of film photovoltaic module and preparation method of adhesive tape

ActiveCN103614088AEasy to operateIncrease productivityFilm/foil adhesivesAcid polymer adhesivesAging resistanceThermoplastic polyurethane

The invention relates to an aging-resistant adhesive tape used for protecting the edge of a film photovoltaic module, and a preparation method of the adhesive tape. The adhesive tape consists of a release layer, a pressure sensitive adhesive layer coated on the release layer, and a substrate compounded on the pressure sensitive adhesive layer, wherein the release layer is made of a single-side release material which is resistant to 100-120 DEG C; the thickness of the pressure sensitive adhesive layer is 50-60mu m; the ingredient of the pressure sensitive adhesive layer is crylic acid-butyl acrylate polymer; the substrate is a black thermoplastic polyurethane elastomer film with the thickness of 140-160mu m. By adopting the preparation method, the aging-resistant adhesive tape has the advantages of good adhesion effect for different adhering surfaces, aging resistance, softness, elasticity and the like, practical operation in production of the module is easy to carry out, and after primary adhesion and fixation, a procedure of adding an aluminum rim is not needed but entering a next procedure directly, so that the efficiency in producing the module is improved.

Owner:YANTAI DARBOND TECH

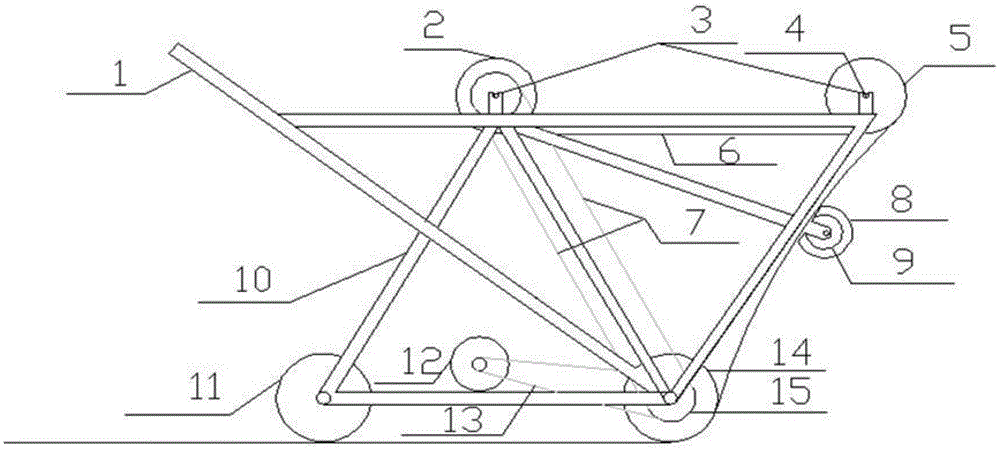

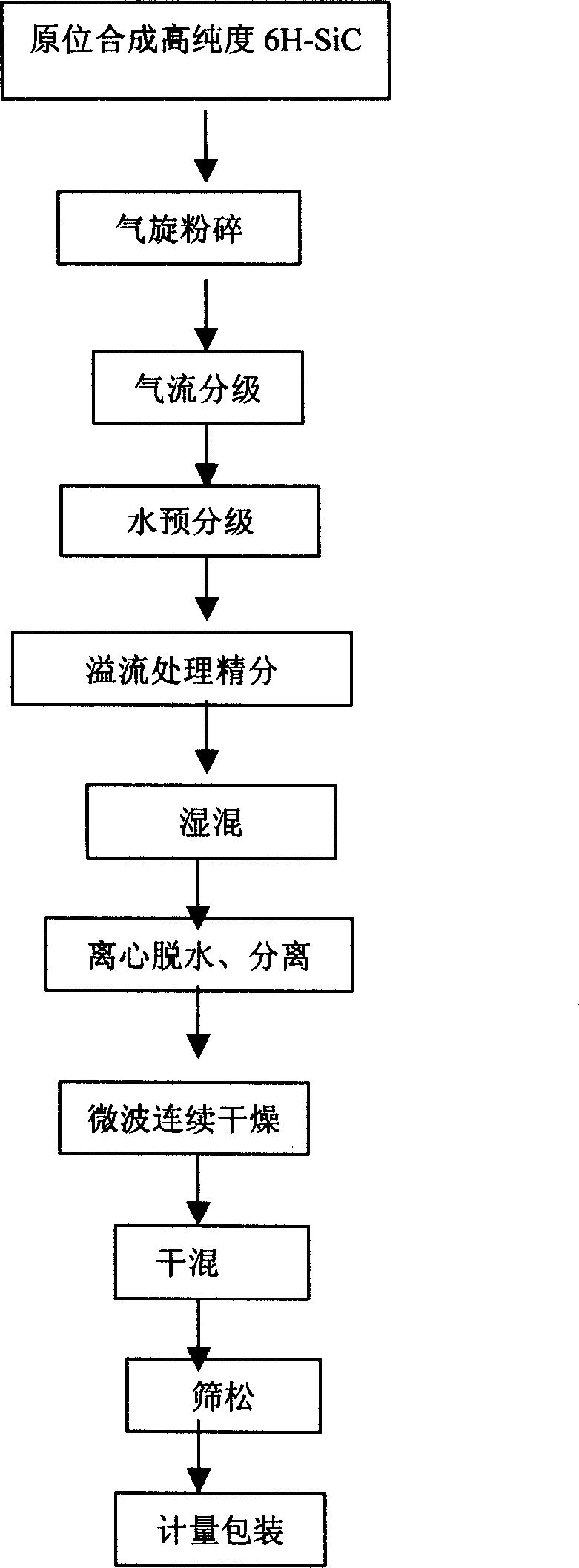

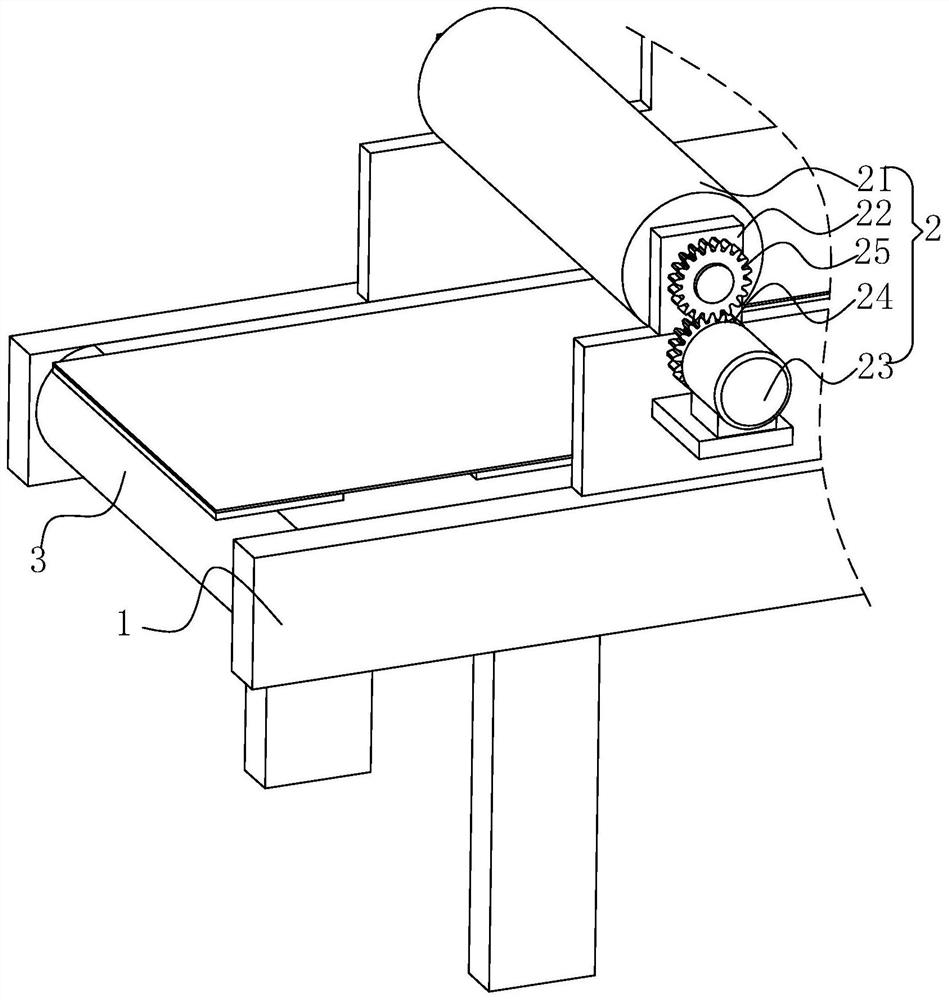

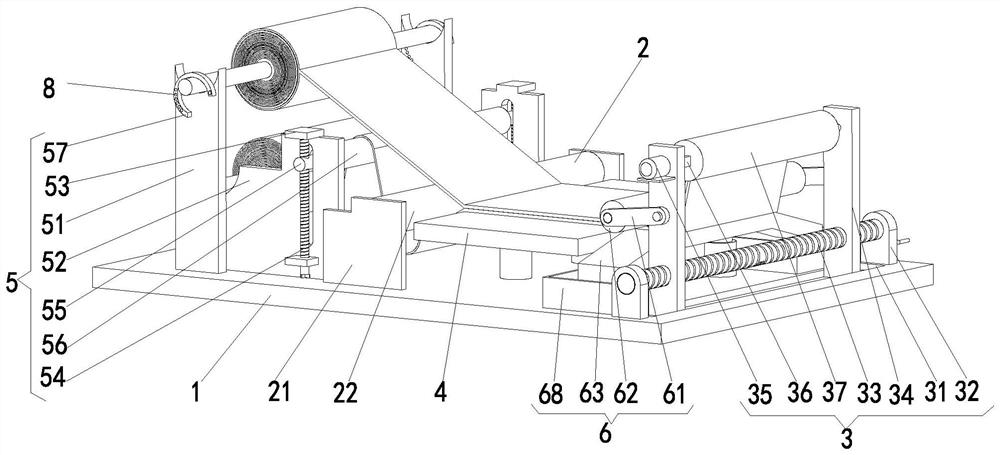

Self-adhesive waterproof coiled material paving machine

InactiveCN105484775ASimple structureEasy to operateUnderground chambersRoof toolsVehicle frameMotor drive

The invention discloses a self-adhesive waterproof coiled material paving machine which comprises a frame and a motor. The upper end of the frame is provided with a feeding roller and a recycling roller, the middle of the frame is provided with a tightening roller, and the lower end of the frame is provided with a compressing roller and walking wheels; one side of the recycling roller and one side of the compressing roller are each provided with a belt pulley, the two belt pulleys achieve transmission through a first belt, and the compressing roller rotates to drive the recycling roller to rotate; the motor drives the compressing roller to rotate through a second belt; the tightening roller is provided with a detachable cutter used for longitudinally cutting a self-adhesive waterproof coiled material when the width of a self-adhesive waterproof coiled material needing to be paved is smaller than that of the whole self-adhesive waterproof coiled material; the frame is provided with handrails. According to the self-adhesive waterproof coiled material paving machine, operation is easy, after the self-adhesive waterproof coiled material is paved by using the self-adhesive waterproof coiled material paving machine, effective bonding between the self-adhesive waterproof coiled material and a waterproof surface can be guaranteed, and therefore the bonding effect of the self-adhesive waterproof coiled material and the waterproof surface is good.

Owner:WUHAN ENGINEERING CO LTD OF CHINA RAILWAY SEVENTH GROUP

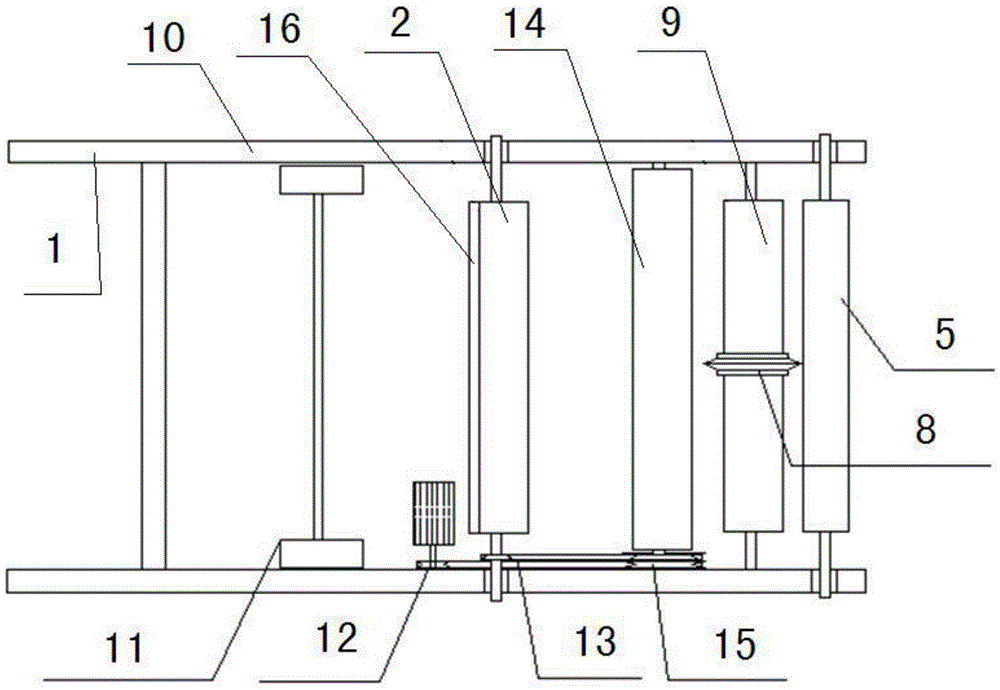

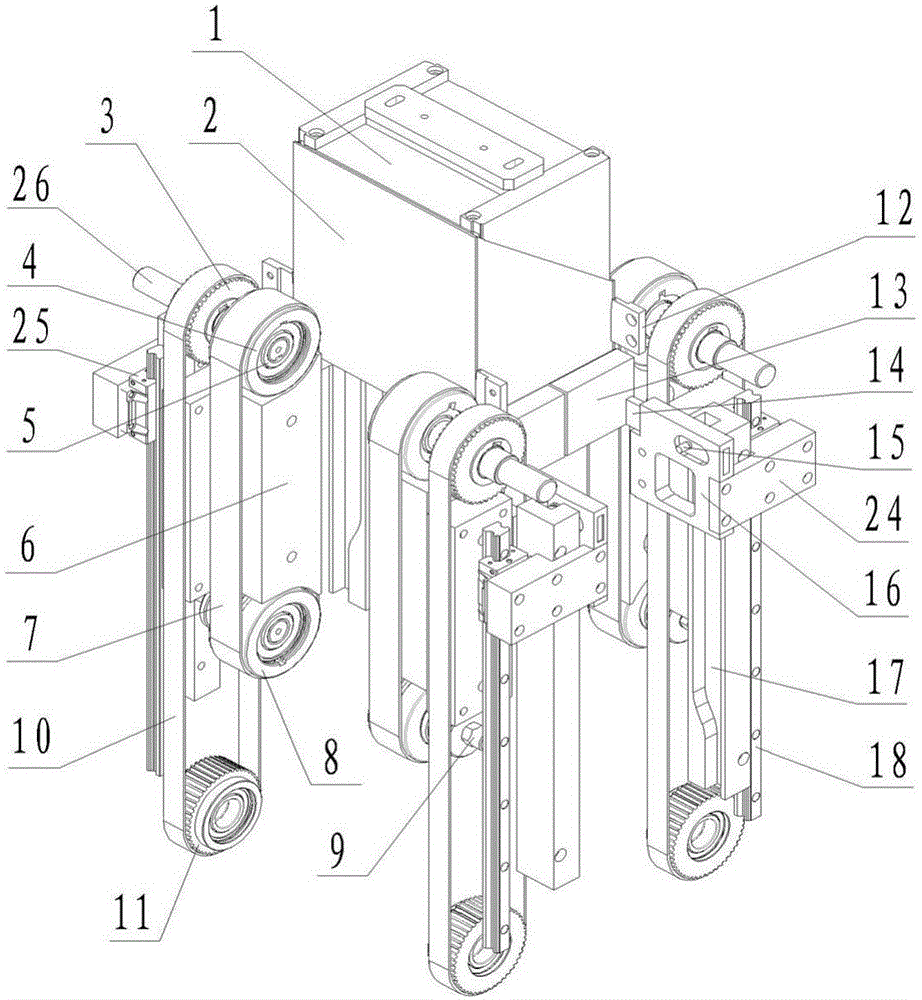

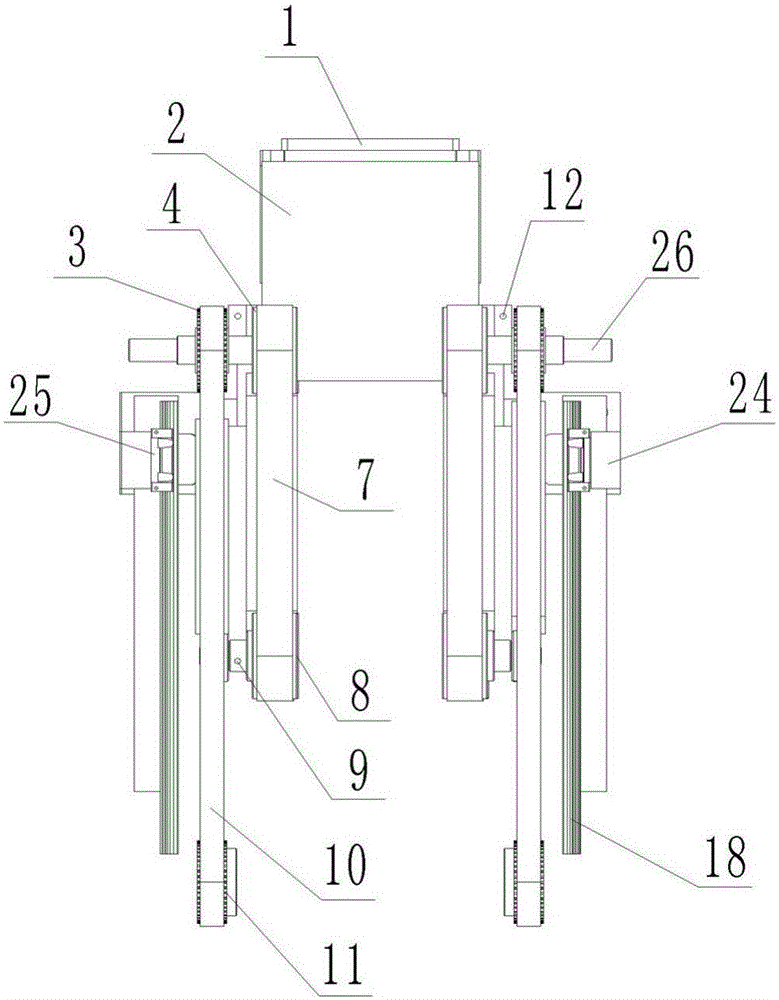

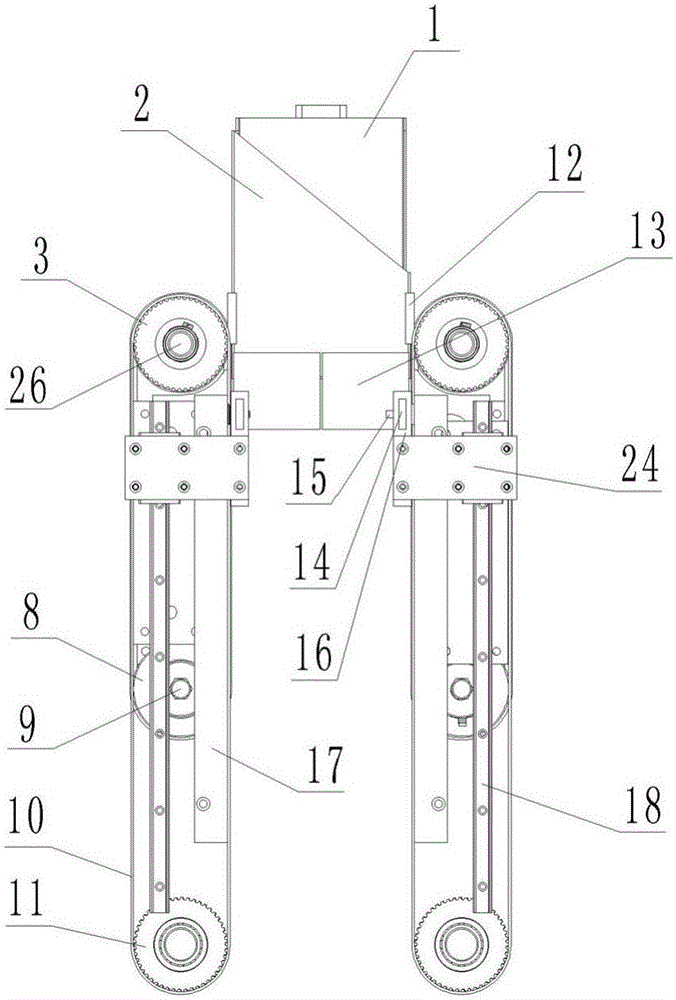

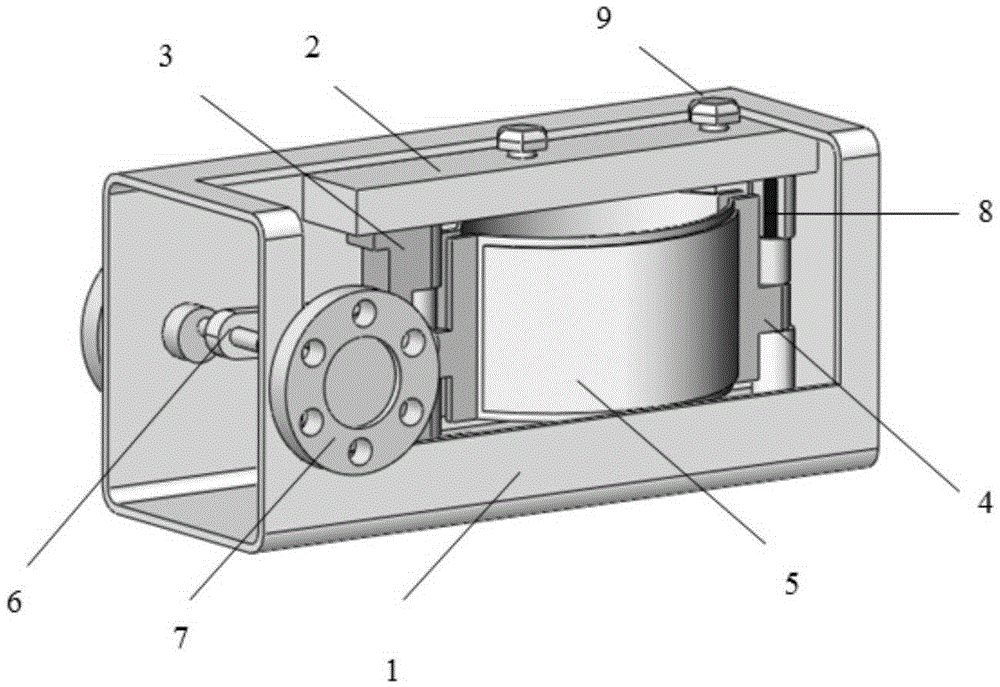

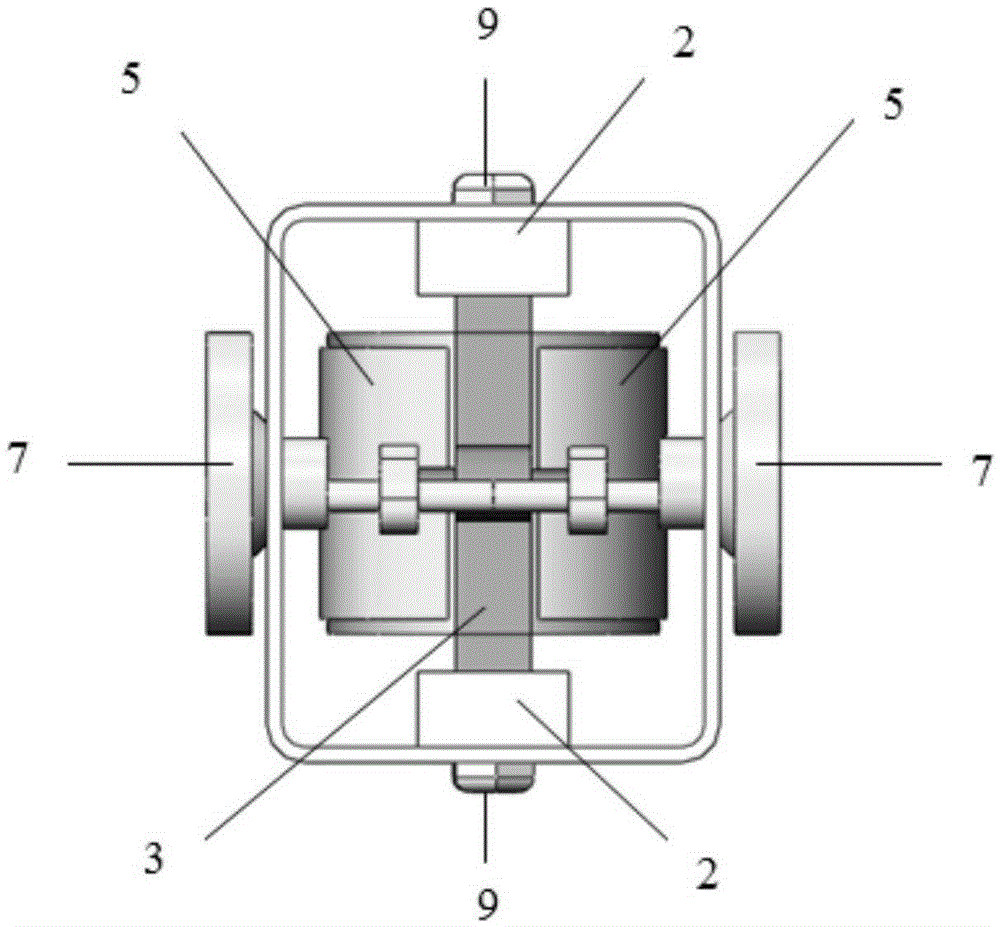

Cavity mechanism

ActiveCN105150595AGood glue spray effectSpray glue sticking effect is goodBoxes/cartons making machineryDrive shaftEngineering

Owner:WENZHOU GAOSHENG MACHINERY CO LTD

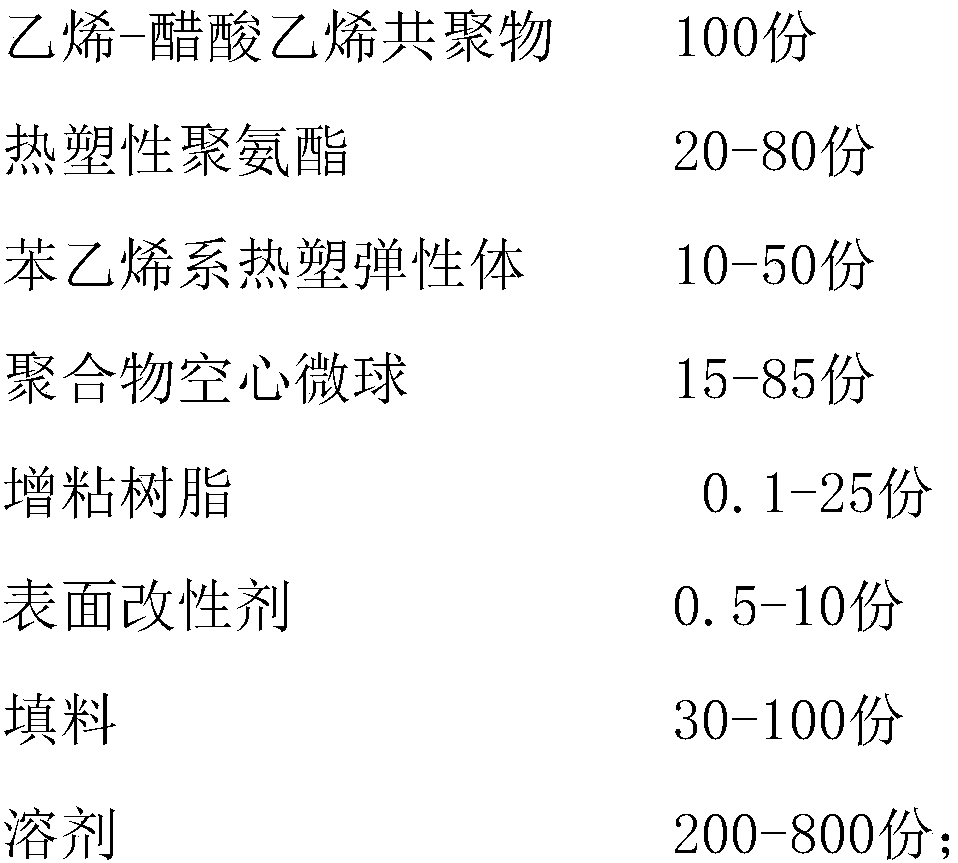

Waterproof buffer glue, and preparation method and application method thereof

InactiveCN108264869ASimple coating processSuitable for mass productionLiquid surface applicatorsNon-macromolecular adhesive additivesPolymer scienceFoaming agent

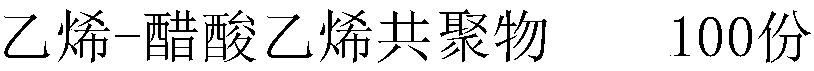

The invention relates to the technical field of adhesives, concretely relates to a waterproof buffer glue, and a preparation method and an application method thereof. The waterproof buffer glue comprises, by weight, an ethylene-vinyl acetate copolymer, thermoplastic polyurethane, a styrene thermoplastic elastomer, polymeric hollow microspheres, tackifying resin, a surface modifier, a filler and asolvent, wherein the polymeric hollow microsphere are foamed expanded microspheres having a core-shell structure. The waterproof buffer glue is prepared by adding the foamed and expanded microspheresinto raw material without an azo chemical foaming agent, air is evenly distributed in the waterproof buffer glue, and the waterproof buffer glue is used for producing waterproof buffer glue tapes having various thicknesses, especially ultrathin waterproof buffer adhesive tapes with a thickness of 100 [mu]m or less. The application method has the advantages of simple coating process and no harsh production conditions or devices, and the waterproof buffer glue is especially suitable for mass production, and has good economic benefits.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Dedicated blade materials for line cutting of semiconductor materials

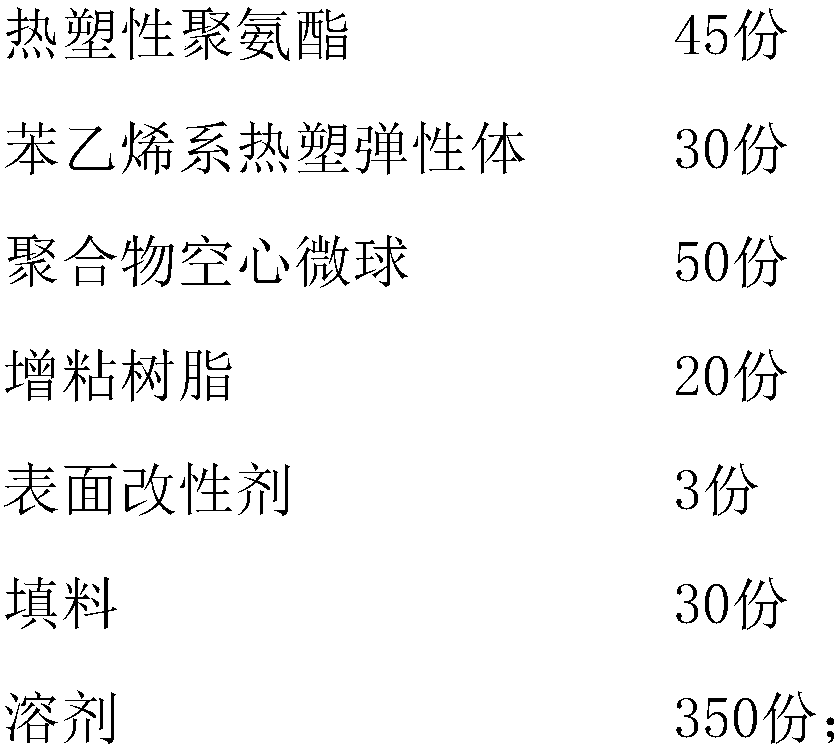

InactiveCN1884067AStrong resistance to crushingSharp particle shapeGrain treatmentsWet separationCycloneMicrowave

The invention discloses a specific cutting knife-material of semiconductor material wire (6H-SiC), which comprises the following steps: 1. grinding through cyclone; grading flow; 2. grading water pretreatment; grading finely for overflow; 3. wetting to blend; dehydrating eccentrically; separating; 5. drying through microwave continuously; 6. blending dryly. The invention is compatible with flexibility of black carbofrax, which improves anti-grinding property obviously.

Owner:河南晟道科技有限公司

Stoneware sheet and preparation method thereof

ActiveCN101898892AImproves Strength and ToughnessElasticConstruction materialTemperature resistanceRadioactive contamination

The invention provides a stoneware sheet and a preparation method thereof. The stoneware sheet comprises the following chemical components in percentage by weight: 55-68% of SiO2, 14-28% of Al2O3, 0.5-1.8% of Fe2O3, 0.2-1.5% of TiO2, 1-12% of CaO, 0.3-1% of MgO, 2-5% of K2O and Na2O and 5-30% of fiber reinforcer. The preparation method comprises the following steps: independently ball-milling and pulping the fiber reinforcer, mixing with other pulping raw materials, carrying out spray granulation, and dry-pressing to obtain the green body. The stoneware sheet has the advantages of favorable adhesiveness, high strength, favorable flatness, high resilience and flexibility, high abrasive resistance, favorable anti-fouling performance, fire resistance, high temperature resistance, long service life, no radioactive contamination, light weight and the like.

Owner:MONALISA GRP CO LTD

Efficient film laminating machine

PendingCN112959791APaste firmlyRealize the heating effectLaminationLamination apparatusMechanical engineeringEngineering

The invention relates to an efficient film laminating machine and belongs to the technical field of film laminating machines, the efficient film laminating machine comprises a rack and a conveying assembly, the rack is connected with an unwinding assembly used for providing a film, and the unwinding assembly is located above the conveying assembly and located at the conveying tail end of the conveying assembly; a gluing assembly for gluing the film is arranged on the side, close to the conveying starting end of the conveying assembly, of the unwinding assembly, the gluing assembly is located above the unwinding assembly, an adjusting roller is arranged between the gluing assembly and the unwinding assembly, and the adjusting roller is rotationally connected with the side wall of the rack; and a heating assembly used for heating glue is arranged on the side, close to the conveying starting end of the conveying assembly, of the gluing assembly, a pressing and pasting assembly used for pressing and pasting a film and an object with a film is arranged below the heating assembly, a guide roller is arranged between the pressing and pasting assembly and the heating assembly, and the guide roller is rotationally connected with the side wall of the rack. The efficient film laminating machine has the advantages of being obvious in pasting effect and stable in pasting.

Owner:杭州良晟塑业有限公司

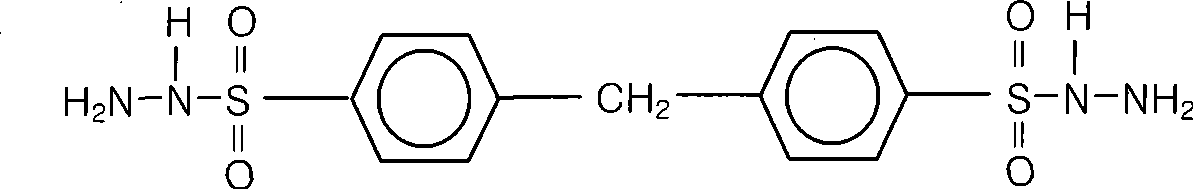

Removable traceless glue and manufacturing process thereof

InactiveCN105131852AImprove adhesionFlat surfaceNon-macromolecular adhesive additivesFilm/foil adhesivesXylylenePolymer science

The invention relates to removable traceless glue and a manufacturing process thereof, which belong to the technical field of sticky glue. The removable traceless glue comprises a sticking layer and a base material layer, wherein the sticking layer is prepared from polyurethane synthetic resin which comprises the following raw materials in parts by weight: polyether polyol resin, acrylic resin, unsaturated polyester resin, tung oil, amino resin, rosin resin, epoxy resin, chemigum, phenolic resin, xylene, calcined kaolin, zinc oxide, an antioxidant, a stagnation agent, an anti-ultraviolet agent, a curing agent, a light stabilizer, a photoinitiator, organophosphorus, a vulcanizing agent, an anti-aging agent and a tackifier. According to the matching of the removable traceless glue, the whole preparation of the raw materials of the polyether polyol resin is environmental friendly and the raw materials are low in price, and no harm to human bodies is generated, and secondary pollution to the environment cannot be caused, in addition, the removable traceless glue can be recycled through reproduction, and any residual glue cannot be left after long-term sticking and use, and the removable traceless glue can be repeatedly torn and used, and the surface of the removable traceless glue can be directly cleaned with tap water or a detergent when dust is adhered to the surface.

Owner:东莞市万高电子材料有限公司

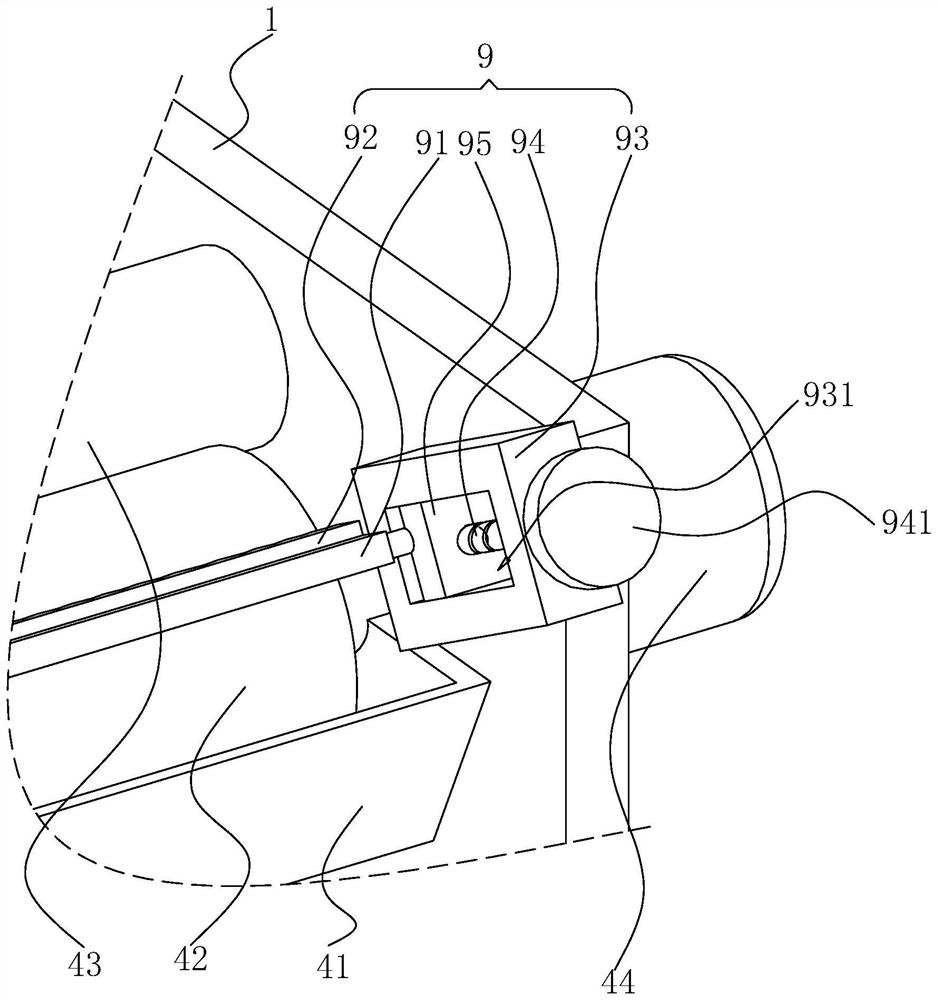

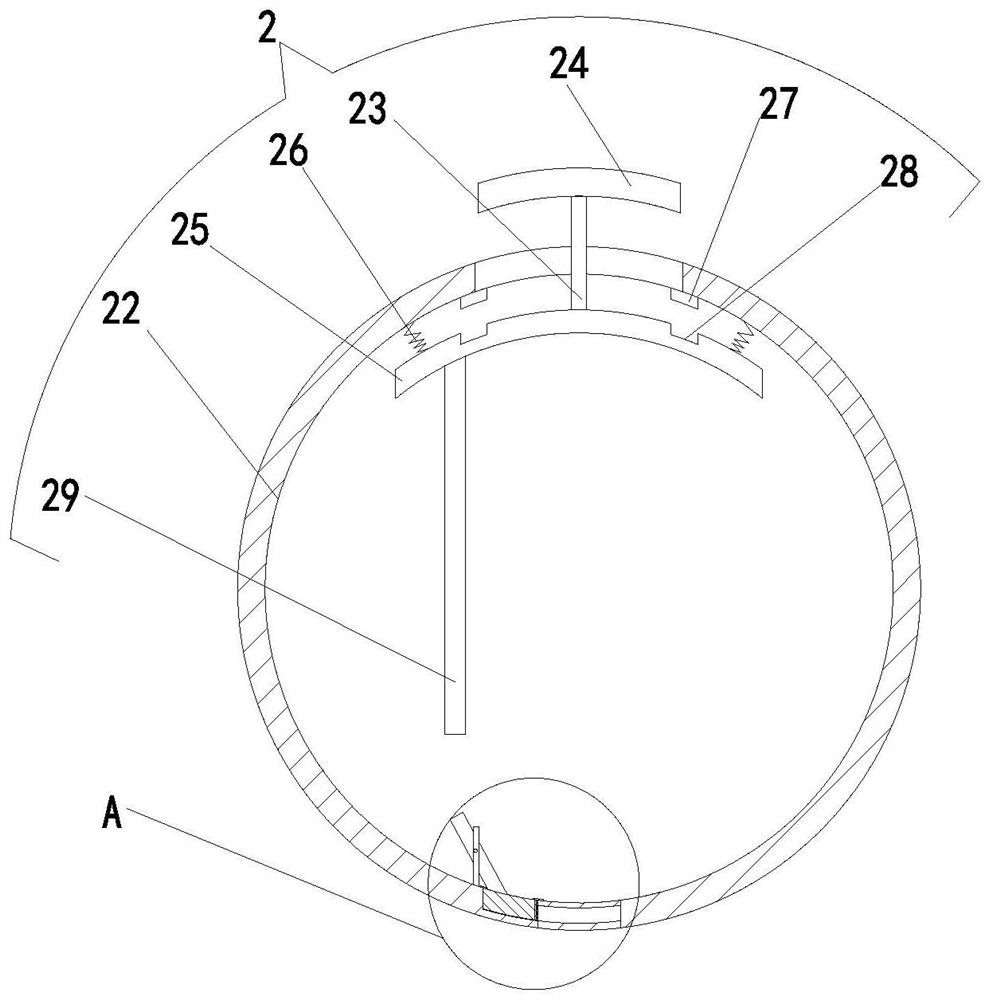

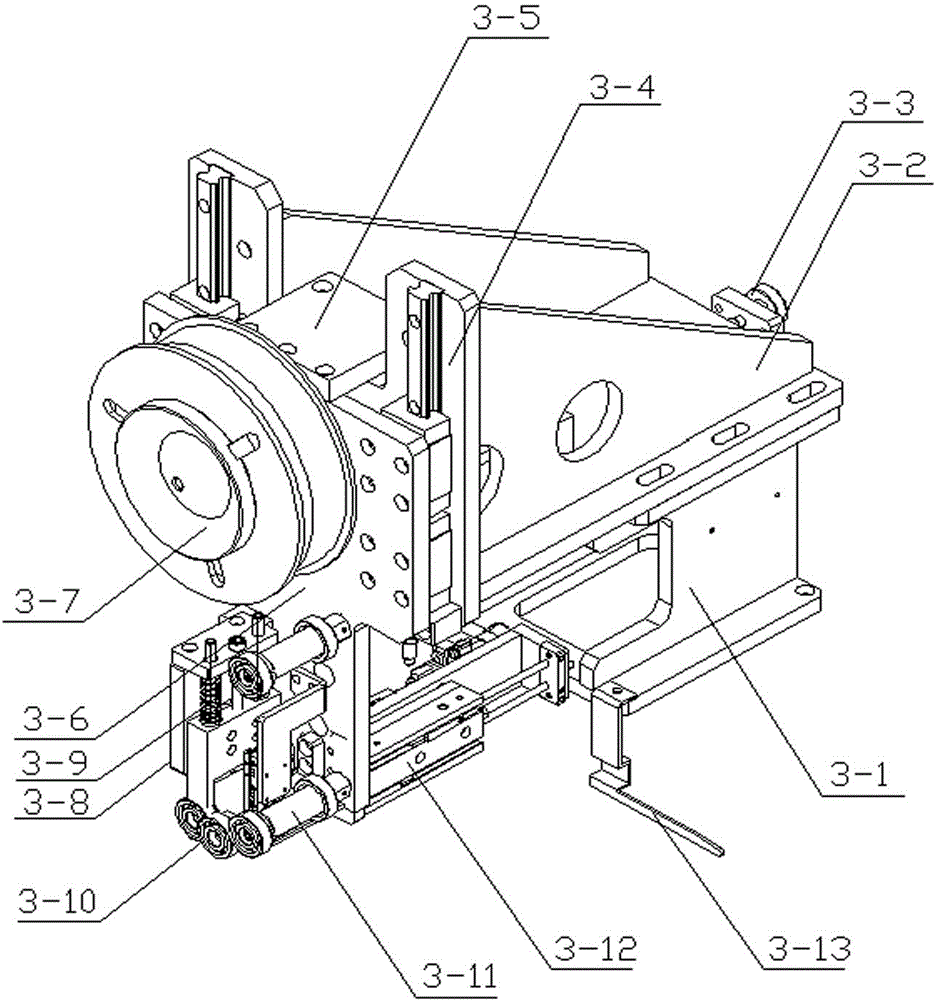

Rotary actuator based on piezoelectric crude fibers and slider-crank mechanism and actuating method thereof

ActiveCN105406757AAvoid small displacementAvoid interferencePiezoelectric/electrostriction/magnetostriction machinesFiberElectricity

The invention discloses a rotary actuator based on piezoelectric crude fibers and a slider-crank mechanism and an actuating method thereof. The actuator is composed of the piezoelectric crude fibers, an arc panel, pin bolts, a sliding block, a connecting rod, a flywheel, a guide rail, screws and an outer framework; the piezoelectric crude fibers are adhered to the arc panel; the two ends of the arc panel are connected with the sliding block and the guide rail respectively through the pin bolts; the two ends of the sliding block are located in the guide rail, the middle shaft is connected with one end of the connecting rod, and the other end of the connecting rod is connected with the shaft of the flywheel; the flywheel is arranged on the outer framework; the guide rail is fixed in the outer framework by adopting the screws; the sliding block, the connecting rod and the flywheel compose the in-line slider-crank mechanism; electricity for the piezoelectric crude fibers is put through and cut off in sequence; and the piezoelectric crude fibers and the arc panel are bent and restored together to enable the sliding block to do reciprocating motion, thereby pulling the connecting rod and driving the flywheel to rotate. Therefore, outputting of rotary motion and torque is realized. The rotary actuator based on the piezoelectric crude fibers and the slider-crank mechanism disclosed by the invention has the characteristics of resistance to electromagnetic interference, continuous rotation, good flexibility and durability, small volume and light weight.

Owner:XI AN JIAOTONG UNIV

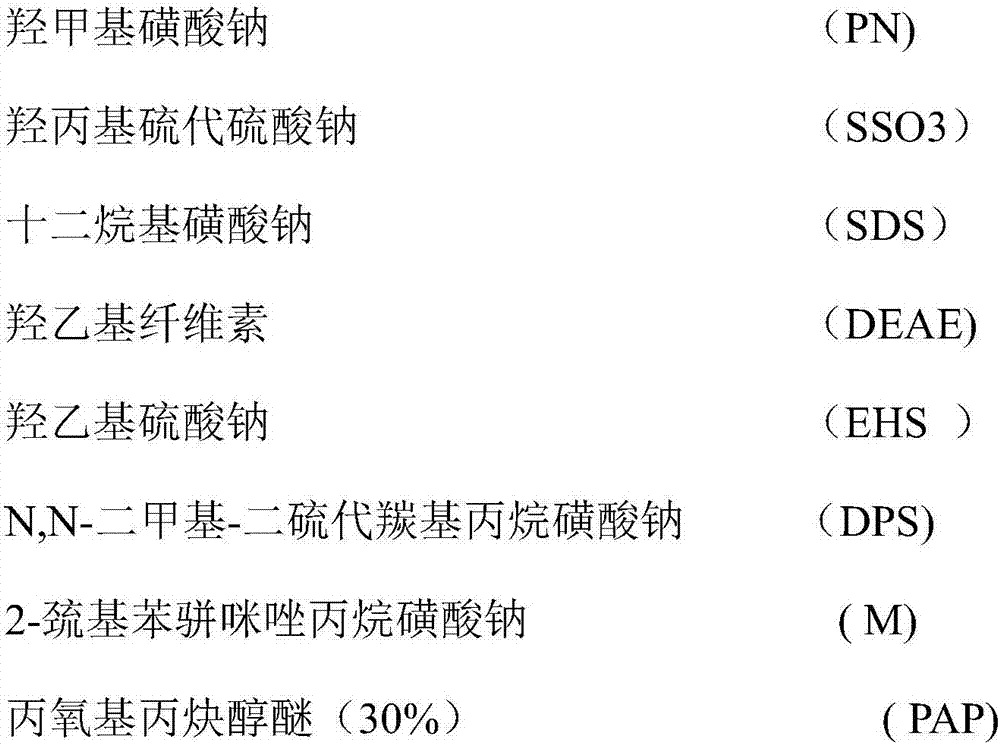

Preparation method, product and application of additive for high-end flexible porous electrolytic copper foil

The invention discloses a preparation method, a product and an application of an additive for high-end flexible porous electrolytic copper foil. The additive for the high-end flexible porous electrolytic copper foil is prepared from raw materials as follows: PN, SSO3, SDS, DEAE, EHS, DPS, M and PAP (30%). An electrodeposition technology is adopted, an electrolyte direct-current electrodeposition technology is included, the additive is added and mixed in the electrolytic process; in the electrolytic process, an electrolyte has the copper content being 80-120 g / L and the sulfuric acid content being 90-130 g / L, the temperature is controlled to range from 45 DEG C to 60 DEG C, the additive is added to the electrolyte, the flow of the electrolyte ranges from 60 m<3> / H to 90 m<3> / H, and direct-current electrodeposition is performed under the condition that the current density ranges from 4,500 A / M<2> to 6,500 A / M<2>.

Owner:安徽华威铜箔科技有限公司

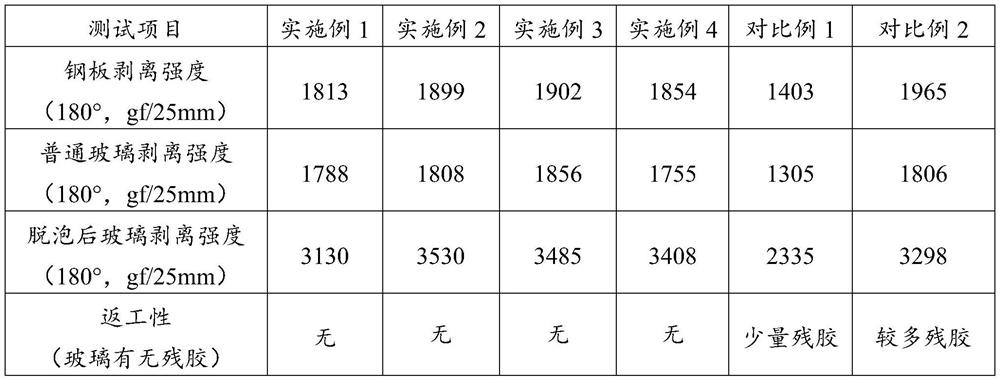

Preparation method and application of acrylate pressure-sensitive adhesive

PendingCN112552842AHigh glass transition temperatureLow initial viscosityAmide/imide polymer adhesivesEster polymer adhesivesAdhesive cementPolymer science

The invention discloses a preparation method and application of an acrylate pressure-sensitive adhesive. The acrylate pressure-sensitive adhesive is mainly prepared from the following components by weight: 30-60 parts of an acrylic acid soft monomer, 30-60 parts of an acrylic acid hard monomer and 5-20 parts of an acrylic acid functional monomer. By optimizing the formula of the acrylic monomer, increasing the glass transition temperature of the acrylate polymer and reducing the initial adhesion, the acrylate pressure-sensitive adhesive with high viscosity, high light transmittance, high adhesive force and easiness in reworking is prepared, and is used for preparing an explosion-proof membrane with high stripping force, high adhesive property, excellent visual effect and touch feeling.

Owner:CROWN TAICANG ADHESIVE PROD CO LTD

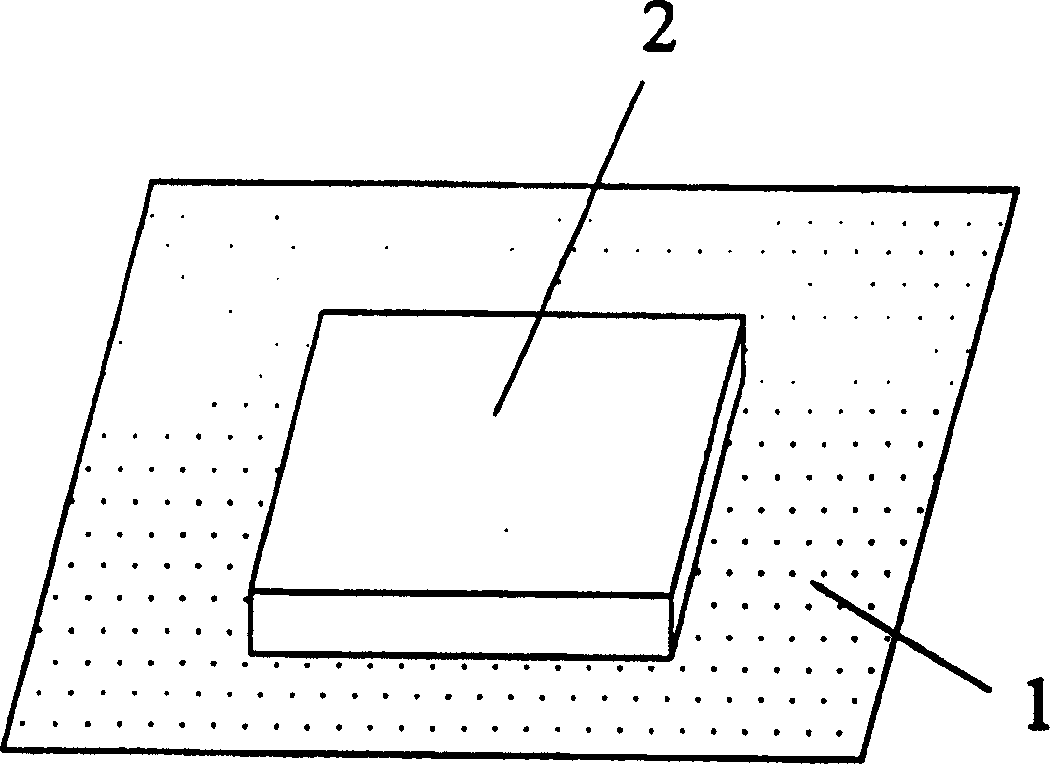

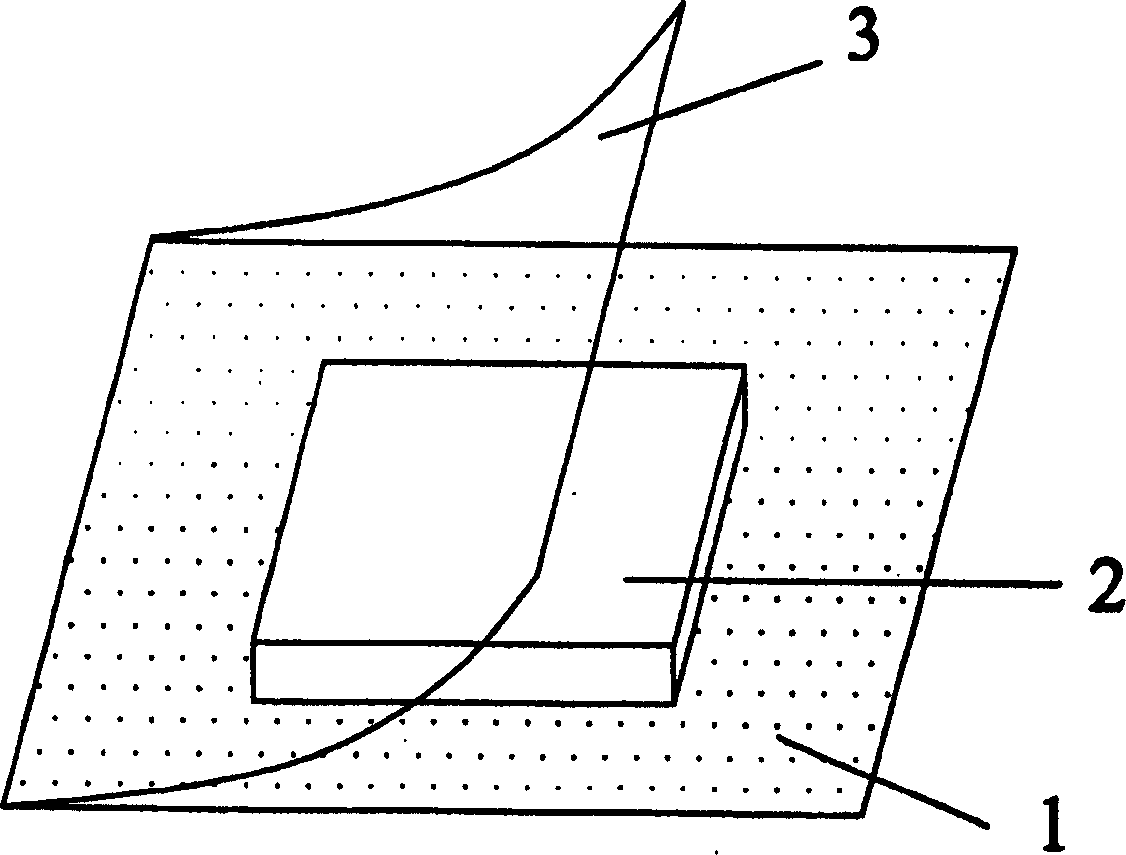

Sticking method for decorative brick

The invention relates to a method for adhering facing tiles, and belongs to the architectural decoration technical field. The method comprises the following steps: firstly, first holding pieces protruding the surface of a wall are arranged on the wall at intervals; secondly, second holding pieces are fixed and connected on the first holding pieces; thirdly, the facing tiles are adhered on the second holding pieces by using adhesion agent; fourthly, joint pointing treatment is performed to the joint positions among the facing tiles; fifthly, the surfaces of the facing tiles are cleaned finally. The invention has the advantages that the wet method adhesion in the prior art is changed into the dry method adhesion, the cement slurry and dust pollution is not existed in an operation site, thereby ensuring the environment of the construction site to be clean and sanitary; the adhering efficiency is improved by three times than the prior art; the adhering effect is ideal, and the post cleaning is simple.

Owner:常熟市金龙装饰有限责任公司

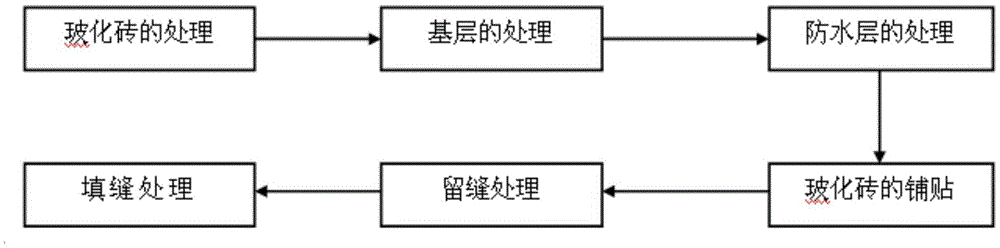

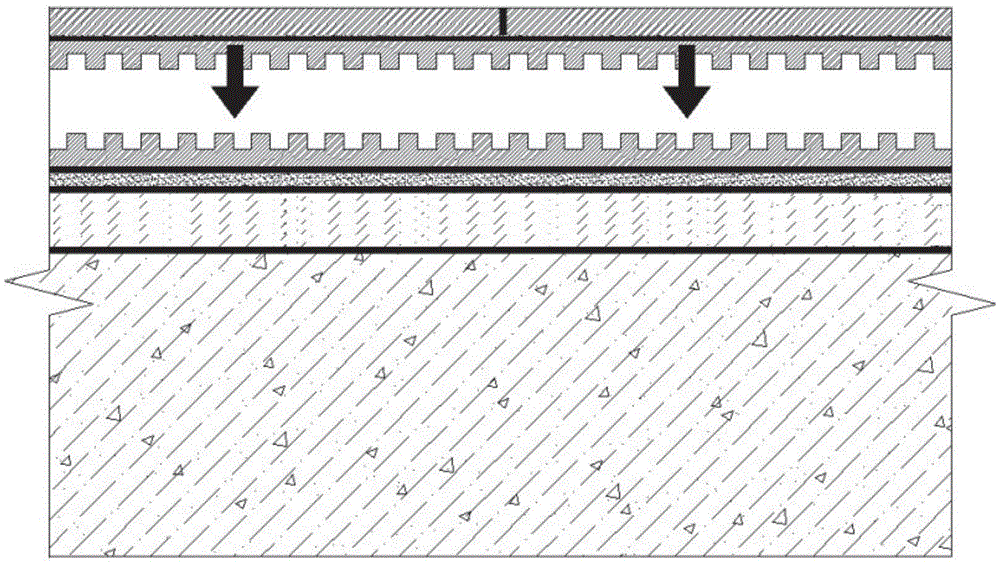

Vitrified tile paving structure and paving method thereof

ActiveCN105625669AReduce material costsSolve prone to surface chalkingCovering/liningsBuilding material handlingUltimate tensile strengthVitrified tile

The invention discloses a vitrified tile paving structure and a paving method thereof.The vitrified tile paving structure comprises a base layer, a vitrified tile layer is arranged on the base layer and formed by paving multiple vitrified tiles, the vitrified tile layer is arranged on the base layer through a bonding layer, a back gum layer is arranged between the vitrified tile layer and the bonding layer, the bonding layer is connected with the base layer through a wall curing processing agent layer, and a waterproof layer is arranged between the bonding layer and the wall curing processing agent layer.The paving method comprises the steps of vitrified tile processing, base layer processing and vitrified tile paving.According to the vitrified tile paving structure and the paving method thereof, by additionally arranging the back gum layer on the bonding layer, firm bonding can be formed between the vitrified tile layer and the bonding layer, the bonding strength is increased by 80% or above, and the cost of a bonding layer material can be saved by 50%; through the wall curing processing agent layer, the advantages of being little in using quantity per unit area, high in sealing and curing speed and permeability, good in closing property, high in strength and the like.

Owner:GOLD MANTIS CONSTR DECORATION

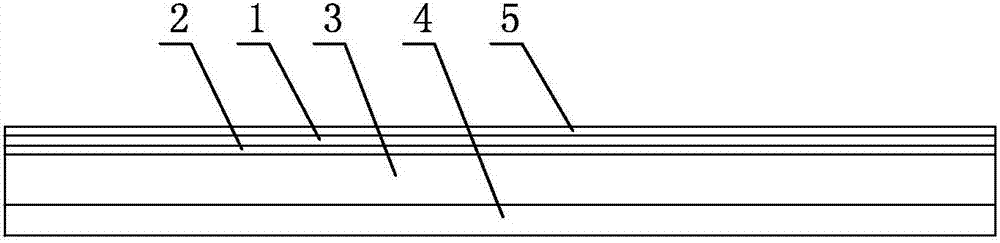

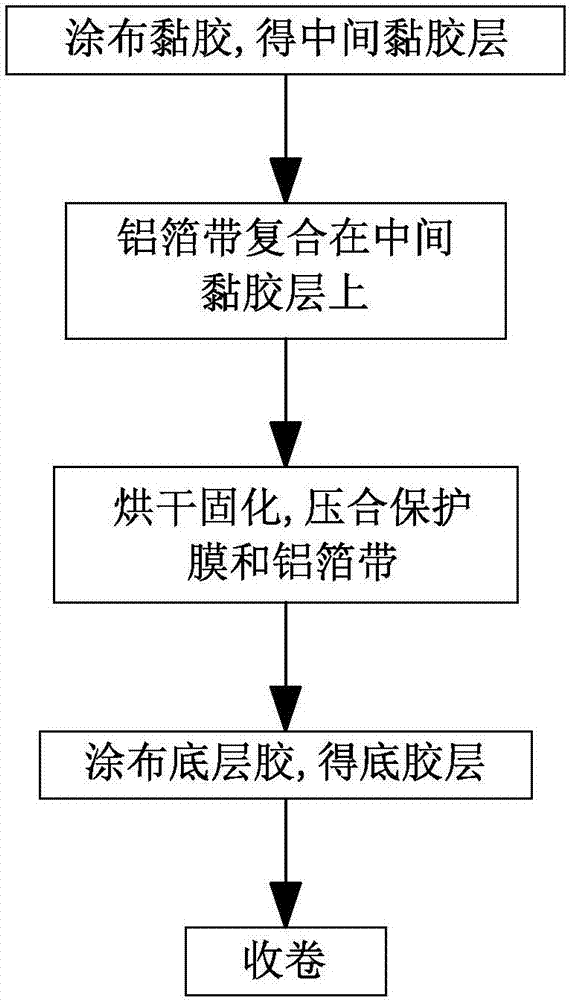

Wear-resistant aluminum foil adhesive tape and manufacturing method thereof

InactiveCN106978099AImprove protectionPaste effect is goodFilm/foil adhesivesTectorial membraneWear resistant

The invention discloses a wear-resistant aluminum foil adhesive tape and a manufacturing method thereof. the wear-resistant aluminum foil adhesive tape sequentially comprises a protection film, a middle adhesive layer, an aluminum foil belt and a bottom adhesive layer from outside to inside, wherein the protection film comprises a film body formed by a plastic film; the middle adhesive layer comprises a layer body formed by aqueous plastic-plastic composite adhesives; the bottom adhesive layer comprises a layer body formed by pressure-sensitive adhesives, acrylic adhesives and hot melt adhesives or flame retardant adhesives. The manufacturing method comprises the following steps of 1, coating the adhesives on the back side of the protection film to obtain the middle adhesive layer; 2, compounding the aluminum foil belt onto the middle adhesive layer; 3, performing temperature rise drying; pressing the protection film and the aluminum foil belt; 4, coating a bottom layer glue on the back side of the protection film aluminum foil belt to obtain the bottom adhesive layer; 5, performing coiling to obtain the wear-resistant aluminum foil adhesive tape. The wear-resistant aluminum foil adhesive tape has the advantages of abrasion resistance, stretching resistance and long service; the use cost is greatly reduced; the use requirements of customers can be met.

Owner:合肥梦飞电器有限公司

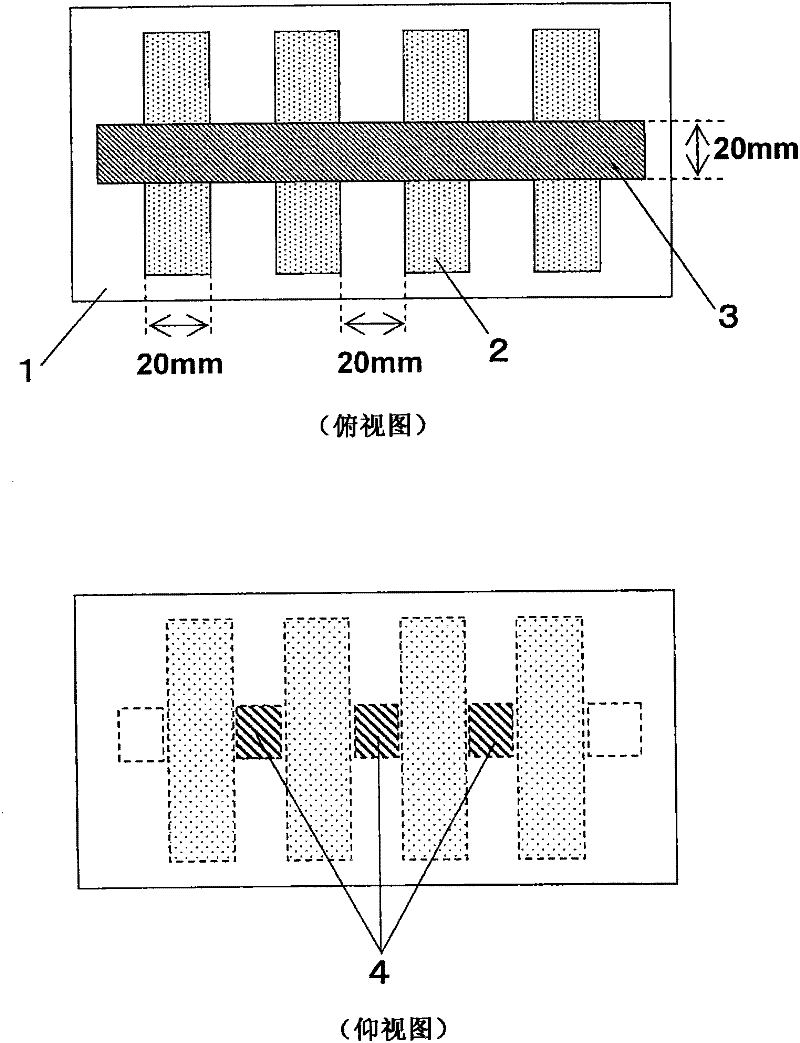

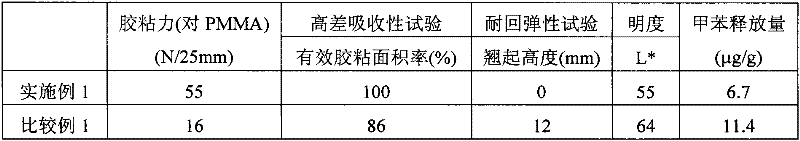

Double-faced pressure-sensitive adhesive tape for affixing decorative panel

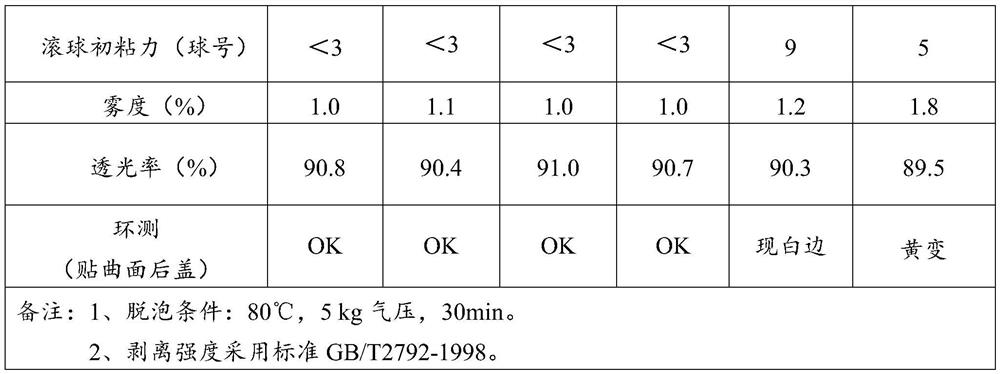

InactiveCN102239226AGood followabilityExcellent VOC suppressionEster polymer adhesivesThin material handlingMicrosphereEngineering

The invention provides a double-faced pressure-sensitive adhesive tape for affixing decorative panels, characterized by having a pressure-sensitive adhesive layer containing bubbles and / or hollow microspheres. It is preferable that the pressure-sensitive adhesive layer be constituted of an acrylic pressure-sensitive adhesive, in particular, an acrylic pressure-sensitive adhesive curable with actinic energy rays. The double-faced pressure-sensitive adhesive tape for affixing decorative panels preferably has a toluene emission of 15 [mu]g / g or less. It is preferable that a surface of the adhesive tape have an L* (lightness) of 60-30. The double-faced pressure-sensitive adhesive tape for affixing decorative panels has excellent conformability to curved surfaces or surfaces having a difference in level, resistance to resilience, and adhesion. The adhesive tape can hence show excellent adhesive properties when a decorative panel is adhered to an adherend of a complicated shape having a curved surface or a difference in level and even when a slender decorative panel is adhered.

Owner:NITTO DENKO CORP

Gluing process and material formula by two-step method in the same pot

InactiveCN101029211AHigh viscosityLow viscosityNon-macromolecular adhesive additivesStarch adhesivesBoraxChemistry

A gluing process by two-step method and its raw-material formula are disclosed. The raw material formula consists of total water 68-76wt%, total starch 24-32wt%, sheet base 1.5-3.2wt% of total starch and borax 1-2wt% of total starch. The process is carried out by adding into carrier water 30-45wt% of total water, heating to 30-45degree, adding into carrier starch 8-16wt% of total starch, adding into sheet base, agitating while shearing to obtain carrier, adding residual water into water, agitating, adding into residual starch and borax and agitating to obtain the final product. It's simple, cheap and controllable, has fast permeating and curing speed.

Owner:颜水平 +2

Preparation method for hydrophilic trauma dressing made from polyurethane

InactiveCN1202785CImprove hydrophilicityNo foreign body reactionAdhesive dressingsAbsorbent padsWound dressingPolyethylene glycol

A hydrophilic polyurethane wound dressing is composed of hydrophilic polyurethane soft foam slices and a moisture-permeable, breathable, waterproof and bacteria-isolating polyurethane film. Preparation method: Stir polyethylene glycol, toluene diisocyanate (TDI-80) and glycerol evenly at room temperature, then raise the temperature to 80-90°C and react for 90-120 minutes to prepare a polyurethane prepolymer; stir the polyurethane prepolymer at room temperature. Mix polyether, organotin catalyst, tertiary amine catalyst, pore opening agent, stabilizer and water evenly, then add polyurethane prepolymer, stir evenly, foam at room temperature, and mature for at least 24 hours into slices to obtain polyurethane soft foam slices; Prepare the polyurethane prepolymer into an acetone or / and N,N-dimethylformamide solution with a concentration of 40.0 to 55.0%, then add water, cast it to form a film, then remove the solvent at 40 to 80°C, and freeze at room temperature. The polyurethane film can be obtained after curing reaction for 16 to 24 hours.

Owner:SICHUAN UNIV +1

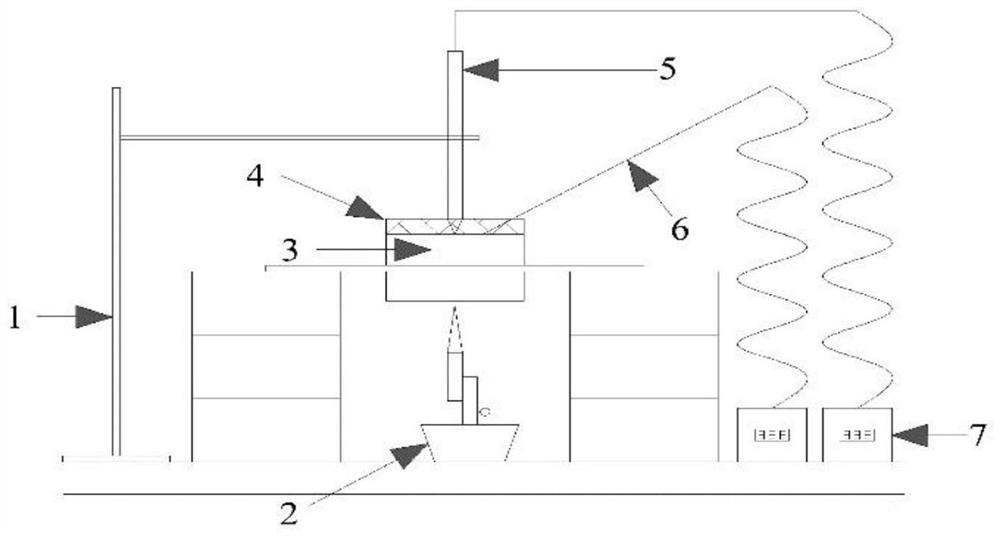

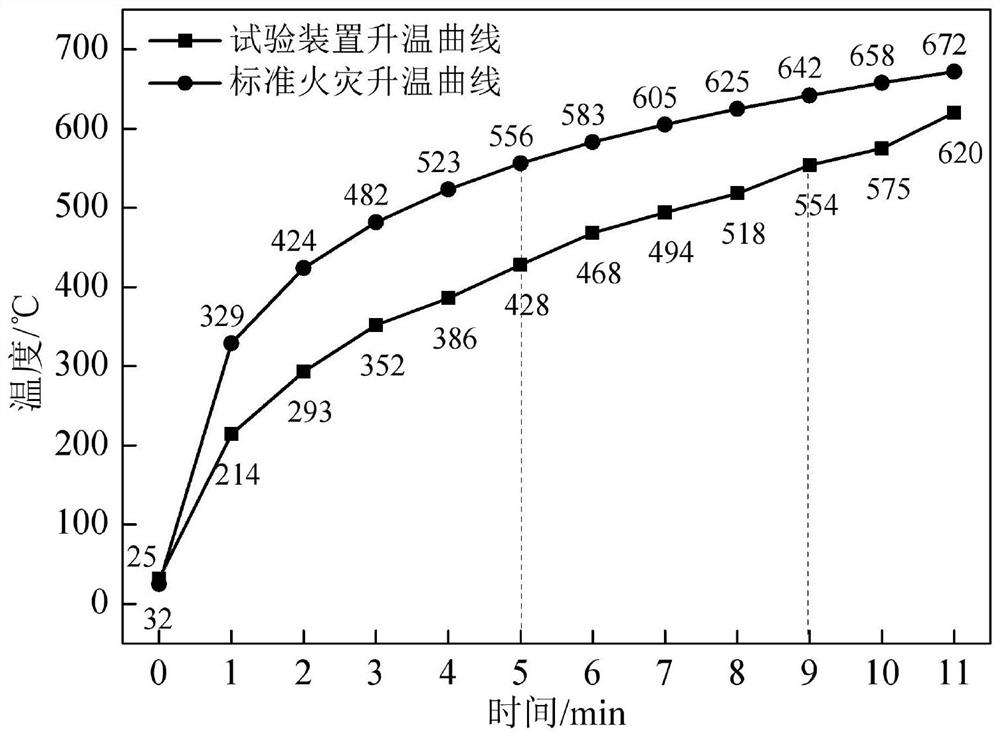

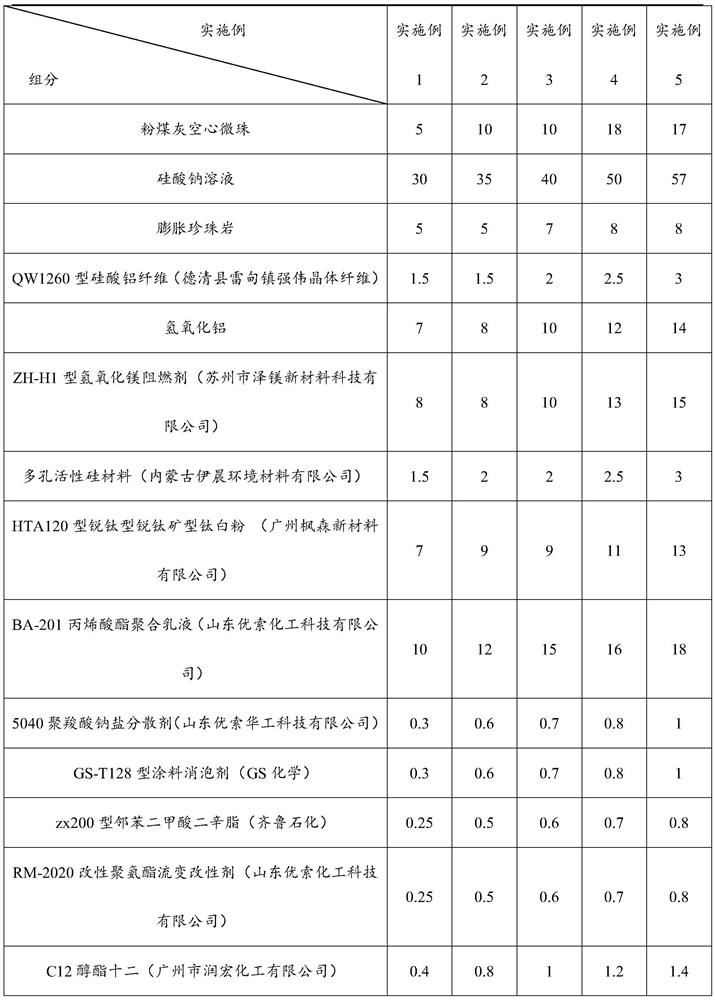

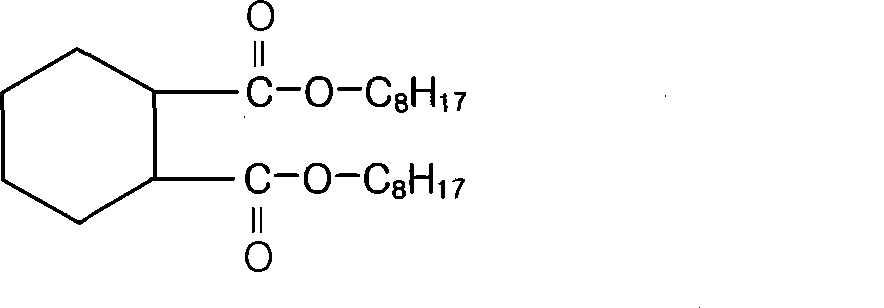

Indoor thick steel structure fireproof coating and preparation method thereof

ActiveCN112251057AImprove flame retardant performanceGood chemical stabilityFireproof paintsAlkali metal silicate coatingsEmulsionPlasticizer

The invention provides an indoor thick steel structure fireproof coating, which relates to the technical field of fireproof coatings, and comprises the following components by mass: 5-20 parts of flyash hollow microspheres, 20-60 parts of a sodium silicate solution, 5-10 parts of expanded perlite, 1-3 parts of aluminum silicate fiber, 5-15 parts of aluminum hydroxide, 5-15 parts of magnesium hydroxide, 1-3 parts of a porous active silicon material, 5-15 parts of titanium dioxide, 10-20 parts of apure acrylic emulsion, 0.2-1 part of adispersive agent, 0.2-1 part of an antifoaming agent, 0.2-1part of a plasticizer, 0.2-1 part of a leveling agent, 0.2-1.5 parts of a coalescing agent and 20-60 parts of water. According to the invention, the small-particle-size hollow microspheres are used asa filler, and the sodium silicate solution prepared from the screened residual large-particle-size hollow microspheres is used as a binder of the coating, so that the resource reutilization is realized, and the fireproof coating has excellent physical and chemical properties and heat insulation and flame retardancy under the condition of not using cement.

Owner:INNER MONGOLIA UNIV OF TECH

Production method of foamed concrete dry powder composite mortar

The invention discloses a production method of foamed concrete dry powder composite mortar. The foamed concrete dry powder composite mortar is prepared from fine tailing sand, sulfoaluminate cement, quicklime, fly ash, glass beads, a foaming agent and lightweight aggregate as raw materials. The production method is characterized in that quicklime and fly ash are used as binders and initiators; a surfactant is used as the foaming agent; and fine tailing sand, glass beads and sulfoaluminate cement are uniformly suspended in a material and the mixture is cured into the foamed concrete dry powder composite mortar in a short time. The foamed concrete dry powder composite mortar has low density, good thermal insulation performances and high affinity, is convenient for slurry coating and construction, is not delaminated, does not crack, has high strength, can be prepared by one step, and satisfies wall later decoration requirements.

Owner:山东隆济时节能科技股份有限公司

Dry-baked spicy peanuts and production method thereof

InactiveCN107712788AEvenly wrappedPaste effect is goodSugar food ingredientsFood ingredient as taste affecting agentCooking & bakingDeep frying

The invention discloses dry-baked spicy peanuts. According to the technical scheme, the dry-baked spicy peanuts are characterized in that 12-18 parts of coating liquid and 23-27 parts of a seasoning are added into each 45-55 parts of peanuts; the coating liquid is prepared from the following components in parts by weight: 5.0-6.0 parts of edible gelatin, 2.8-4.0 parts of sugar, 4.0-6.0 parts of anedible essence, 20-25 parts of table salt and 60-70 parts of hot water; and the seasoning is prepared from the following components in parts by weight: 25-30 parts of basic powder, 27-32 parts of chili flakes, 2.5-3.0 parts of chili powder and 40-45 parts of a flavoring agent; and the dry-baked spicy peanuts have the advantages of low sugar and fat and spicy and crispy taste. The invention further provides a production method of the dry-baked spicy peanuts. By utilizing a dry-baking process, the deep-frying is not required, and the peanuts are low in sugar and fat and are spicy and crispy.

Owner:青岛胶平食品有限公司

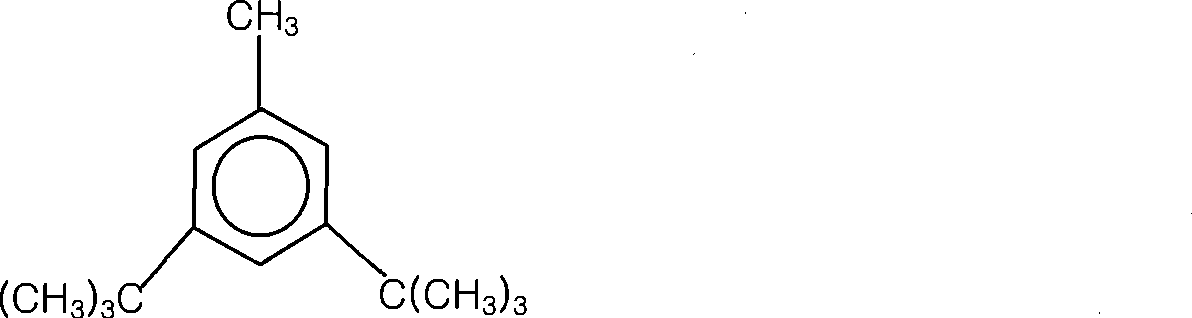

Foaming type sealant for filling space

ActiveCN101440271AImprove noiseImprove initial adhesionOther chemical processesAdhesive processes using foamed adhesivesNitrile rubberFoaming agent

The invention discloses a foaming sealant for space filling, which can improve the initial adhesion and the foaming rate. The foaming sealant comprises the following components by weight percentage: 25 to 30 weight percent of nitrile rubber, 10 to 15 weight percent of OBSH foaming agent, 15 to 20 weight percent of calcium carbonate filling agent, 20 to 30 weight percent of plasticizer, 1 to 5 weight percent of antiager, 5 to 10 weight percent of adhesion imparting agent, and 1 to 4 weight percent of vulcanizing agent. The foaming sealant improves the initial adhesion through the self-expansion phenomenon of the sealant, enlarges space filling force by improving the foaming rate, enlarges filling effect, and effectively improves the generation of noises during the driving of automobiles.

Owner:张家港市凤凰科技开发有限公司

Making method of composite plastic woven bag

InactiveCN112644086ARealize double-sided gluingEasy to adjustBag making operationsPaper-makingAdhesive glueEngineering

The invention relates to a making method of a composite plastic woven bag. Gluing and winding equipment is used in the making method, and comprises a base, a double-sided gluing device, a winding device, an operating platform, a supporting device and an extrusion adjusting device. When a gluing arc-shaped plate moves downwards, a glue overflowing plate is driven to be pressed downwards through a sliding rod, and an outer bag at the lower part of a gluing roller is sufficiently smeared with glue while the sliding rod of the gluing arc-shaped plate drives the glue overflowing plate to be pressed downwards, so that double-sided gluing on an inner bag and the outer bag of the woven bag is realized; a winding motor is started, so that the winding roller is driven to rotate for winding; during adjustment of the tightness of the inner bag and the outer bag before winding operation, a loosening and tightening rod rotates to drive a loosening and tightening roller to rotate, so that the tightness of the inner bag and the outer bag clamped in the loosening and tightening roller can be adjusted, and the sticking effect is better; and the glue adhered to the inner bag and the outer bag is effectively extruded through an extrusion roller, so that the inner bag and the outer bag are smoother after being adhered, redundant glue is extruded out, and the glue is recycled.

Owner:尤晨曦

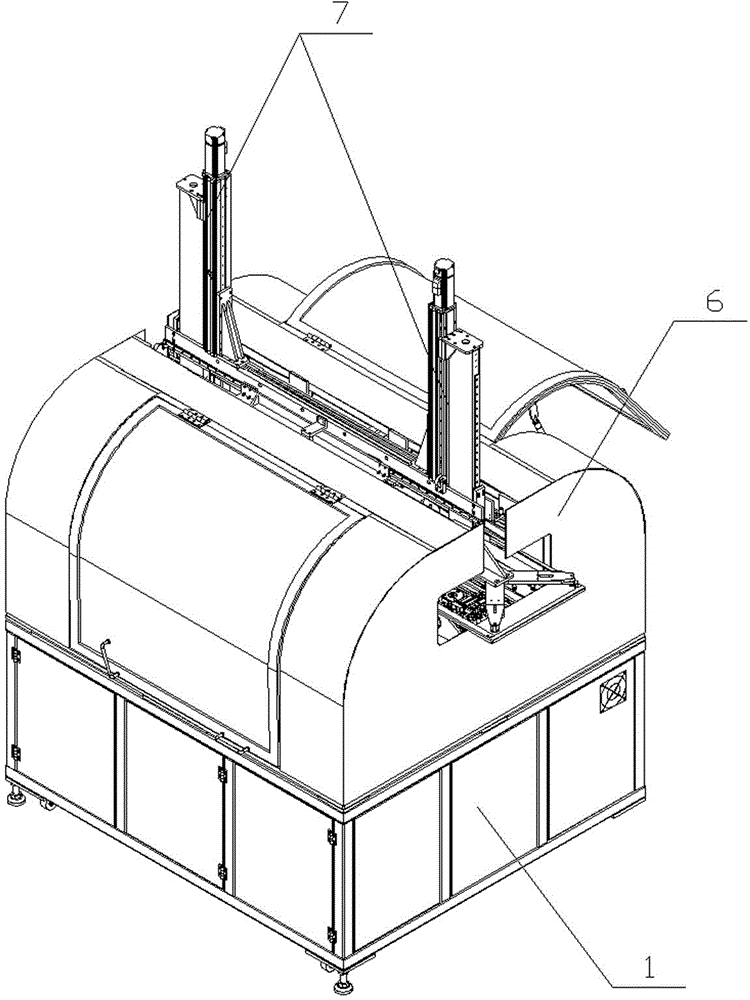

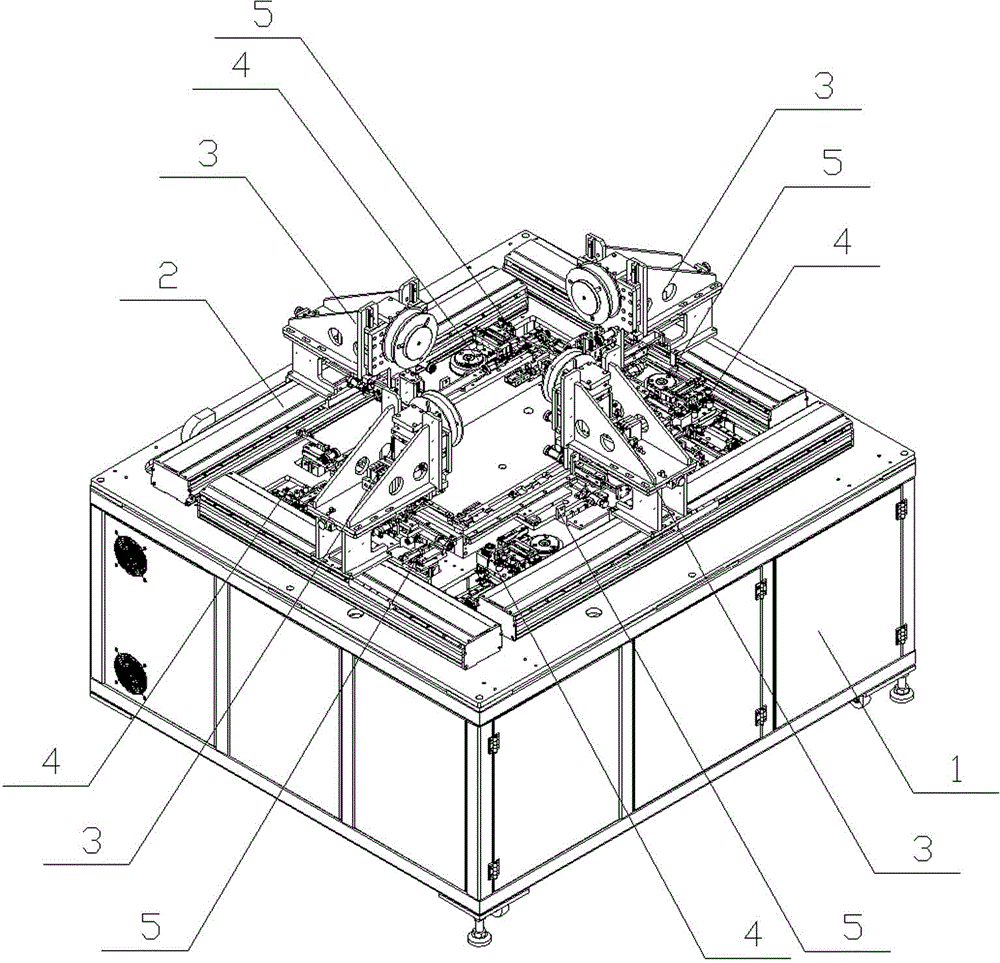

Two-in-one automatic laminating machine for front frame of flat-panel TV

ActiveCN105291541AReduce wasteReasonable structural designLaminationLamination apparatusEngineeringMechanical equipment

The invention discloses a two-in-one automatic laminating machine for the front frame of a flat-panel TV and relates to the field of mechanical equipment. A jig frame is arranged on a machine body rack; four lamination heads are respectively arranged at the four edges of the jig frame; a rubberizing head and a laminating device are correspondingly arranged below each of the four lamination heads on the inner side of the jig frame; an arc-shaped upper cover is arranged above the machine body rack; a material taking telescopic manipulator and a material placing telescopic manipulator are arranged on the arc-shaped upper cover. The two-in-one automatic laminating machine is reasonable in structural design, simple to mount and operate, convenient to use and small in size, does not occupy space, can realize automatic feeding and discharging, automatic lamination and automatic rubberizing and corner wrapping, has a good gluing effect, not only reduces the product defective rate but also reduces the waste of both resources and manpower, and meets the use requirements of people.

Owner:惠州同兴自动化工业设备有限公司

Non-gumming wear-resistant sole and preparation method thereof

The invention relates to a non-gumming wear-resistant sole by regulating the formula and process of various components of the sole. The non-gumming wear-resistant sole contains the following components in parts by weight: 30-50 parts of EVA (Ethylene-Vinyl Acetate), 10-20 parts of calcium stearate, 5-10 parts of nano calcium carbonate, 5-10 parts of zinc stearate, 20-30 parts of butadiene styrenerubber, 10-15 parts of ethylene-propylene-diene monomer, 5-8 parts of nano-titanium oxide, 1-3 parts of a vulcanizing agent, 2-5 parts of a bridging agent, 5-10 parts of a compatilizer, 2-8 parts of an anti-aging agent, 5-15 parts of epoxy resins, 5-15 parts of polyacrylate, 20-30 parts of polyvinyl alcohol and 2-5 parts of a foaming agent. Therefore, the prepared sole is excellent in mechanical property and excellent in high temperature resistance. The polyvinyl alcohol can achieve an excellent bonding effect, has high heat resistance, and achieves an excellent bonding effect when matched with polyacrylate.

Owner:浙江薪然鞋业集团有限公司

Woundplast

PendingCN108056856AUse diversificationPaste effect is goodElectrotherapyAdhesive dressingsChinese charactersEngineering

The invention relates to a woundplast. The woundplast includes viscose cloth, blood sucking cotton, a magnetic sheet and an anti-adherent film. The blood sucking cotton, the magnetic sheet and the anti-adherent film are sequentially arranged on the middle of the viscose cloth from bottom to top; the periphery of the viscose cloth is provided with release paper, the release paper includes a first release-paper segmented piece, a second release-paper segmented piece and a third release-paper segmented piece; the first release-paper segmented piece, the second release-paper segmented piece and the third release-paper segmented piece are in a shape like the Chinese character 'hui'. The release paper is composed of several release-paper segmented pieces, a user can selectively uncover the outermost first release-paper segmented piece according to the skin characteristics when the user uses the woundplast, the first release-paper segmented piece and the second release-paper segmented piece are uncovered or the first release-paper segmented piece, the second release-paper segmented piece and the third release-paper segmented piece are uncovered, and the woundplast is more diverse in use.Meanwhile, the release-paper segmented pieces are in a shape like the Chinese character 'hui', the sticky area on the viscose cloth torn down from the release-paper segmented pieces is distributed onthe periphery of the woundplast, and the sticky effect is good.

Owner:武汉明康医疗器械有限公司

Paste preparation technique

InactiveCN103145861AIt has the effect of making paste and suspendingEasy to operateStarch adhesivesWarm waterStarch paste

The invention provides a paste preparation technique, relating to the technical field of starch paste. The paste preparation technique is characterized by comprising the following steps: (1) mixing, stirring and shearing 455 parts by weight of warm water, 50 parts by weight of starch, 9 parts by weight of alkali and 0.5 part by weight of borax for 8-10 minutes; (2) pouring 630 parts by weight of water, 300 parts by weight of starch and 5 parts by weight of borax into the mixture obtained in the step, and mixing and stirring for 8-12 minutes; and (3) pouring 14 parts by weight of binding agent into the mixture obtained in the step (2), and thoroughly mixing. The invention simple to operate, and has the advantages of less equipment, lower production cost, favorable paste preparation effect and sufficient paste viscosity.

Owner:安徽天诺包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com