Preparation method for hydrophilic trauma dressing made from polyurethane

A hydrophilic polyurethane and wound dressing technology, which is applied in the fields of adhesive dressings, dressings, medical science, etc., can solve the problems such as the introduction of the preparation of non-absorbent foam layers and matrix materials, and achieves good adhesiveness, good biocompatibility, and improved The effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

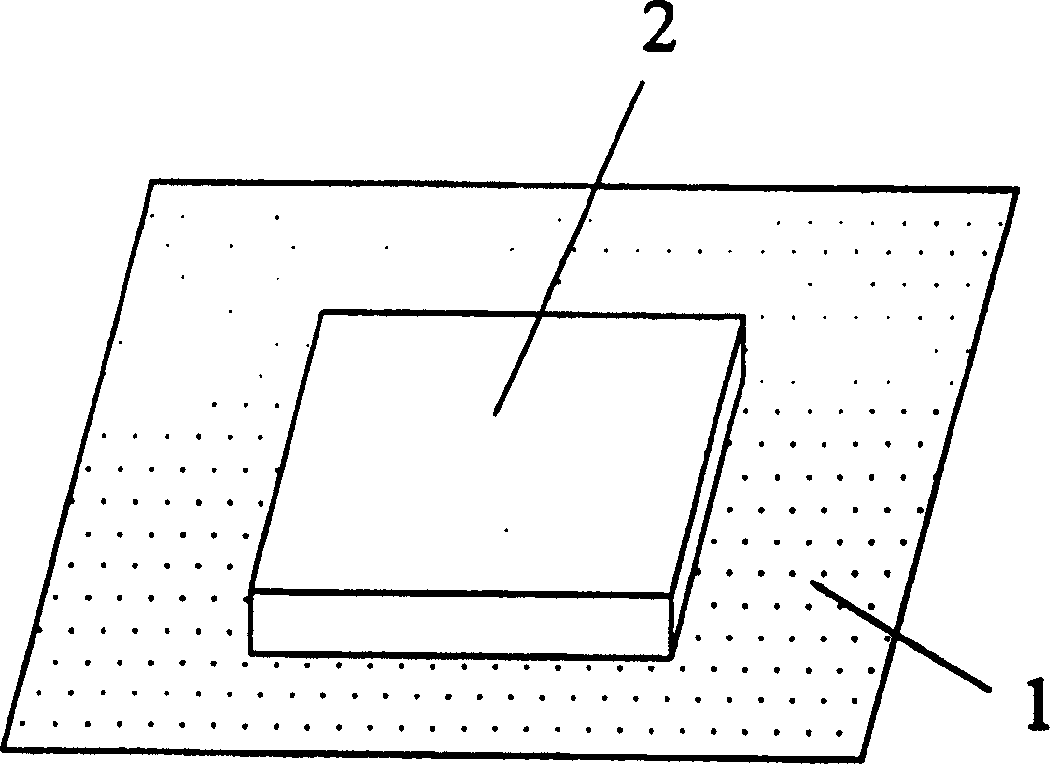

[0047] The structure of polyurethane wound dressing in the present embodiment is as figure 1 As shown, the outer layer 1 and the inner layer 2 are compounded by pressure-sensitive adhesive, the inner layer is polyurethane soft foam slices, and the outer layer is polyurethane film. The preparation method is as follows:

[0048] 1. Preparation of polyurethane soft foam slices

[0049] Raw material formula:

[0050] Polyethylene glycol (molecular weight 1000) 47.25%

[0051] Toluene diisocyanate (TDI-80) 29.04%

[0052] Glycerol 1.97%

[0053] Polyether N210 17.39%

[0054] Stannous octoate 0.87%

[0055] Triethylenediamine 1.16%

[0056] Styrene / acrylonitrile graft polyether alcohol 0.29%

[0057] L-580 Silicone 0.87%

[0058] Deionized water 1.16%

[0059] The above percentages are percentages by weight.

[0060] Technological process: Stir the polyethylene glycol, toluene diisocyanate (TDI-80) and glycerol evenly at room temperature, then heat up to 80°C and react for...

Embodiment 2

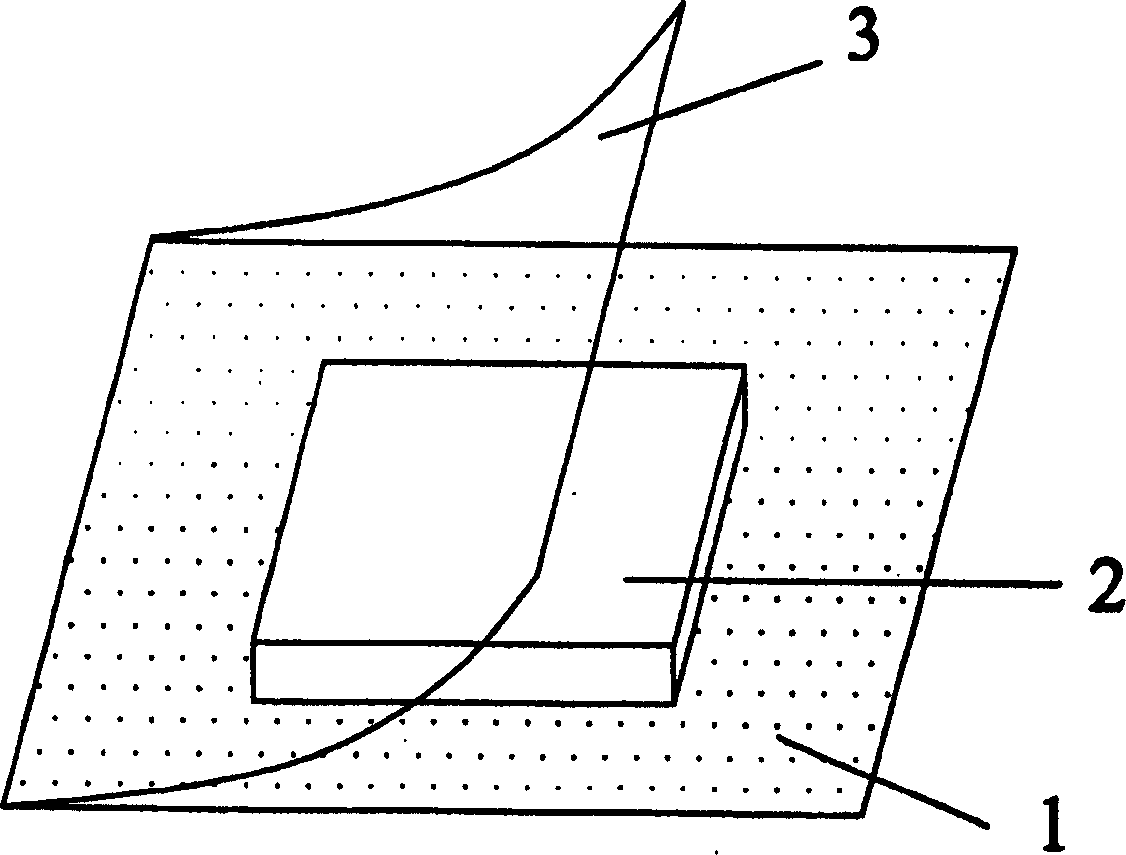

[0071] The structure of polyurethane wound dressing in the present embodiment is as figure 2 As shown, the outer layer 1, the inner layer 2, and the peeling paper 3 are compounded by pressure-sensitive adhesive, the inner layer is a polyurethane soft foam slice, and the outer layer is a polyurethane film. The preparation method is as follows:

[0072] 1. Preparation of polyurethane soft foam slices

[0073] Raw material formula:

[0074] Polyethylene glycol (molecular weight 2000) 49.85%

[0075] Toluene diisocyanate (TDI-80) 27.81%

[0076] Glycerol 2.71%

[0077] Polyether N3010 14.57%

[0078] Stannous octoate 1.19%

[0079] Triethylenediamine 1.19%

[0080] Polybutadiene diol 0.30%

[0081] L-580 Silicone 0.89%

[0082] Deionized water 1.49%

[0083] The above percentages are percentages by weight.

[0084] Process flow: Stir the above polyethylene glycol, toluene diisocyanate (TDI-80) and glycerol at room temperature, then raise the temperature to 85°C and rea...

Embodiment 3

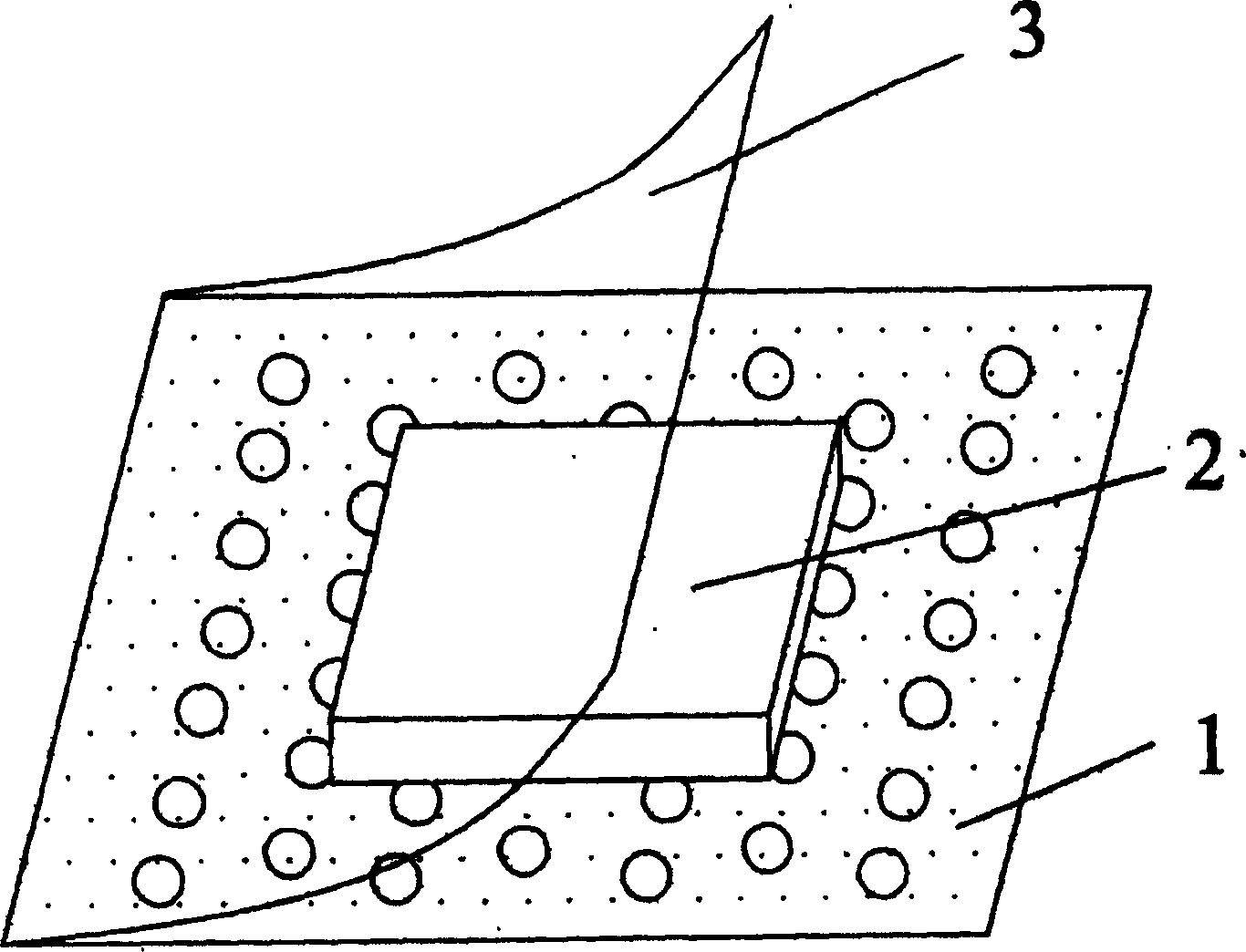

[0097] The structure of polyurethane wound dressing in the present embodiment is as image 3 As shown, the outer layer 1, the inner layer 2, and the release paper 3 are bonded and compounded. The inner layer is polyurethane soft foam slices, and the outer layer is medical adhesive tape or medical non-woven fabric with air holes. The preparation method is as follows:

[0098] 1. Preparation of polyurethane soft foam slices

[0099] Raw material formula:

[0100] Polyethylene glycol (molecular weight 1500) 45.44%

[0101] Toluene diisocyanate (TDI-80) 34.53%

[0102] Glycerol 2.10%

[0103] Polyether N210 12.16%

[0104] Stannous octoate 0.61%

[0105] Triethylenediamine 0.91%

[0106] Polybutadiene diol 0.91%

[0107] L-580 Silicone 1.52%

[0108] Deionized water 1.82%

[0109] The above percentages are percentages by weight.

[0110] Process flow: Stir the above polyethylene glycol, toluene diisocyanate (TDI-80) and glycerin at room temperature, then raise the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com