Aging-resistant adhesive tape used for protecting edge of film photovoltaic module and preparation method of adhesive tape

A thin-film photovoltaic module and edge protection technology, which is applied in the direction of film/sheet adhesive, adhesive, adhesive type, etc., can solve the problem of hard base material on the surface of the tape and lack of elasticity, so as to achieve good sticking effect and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

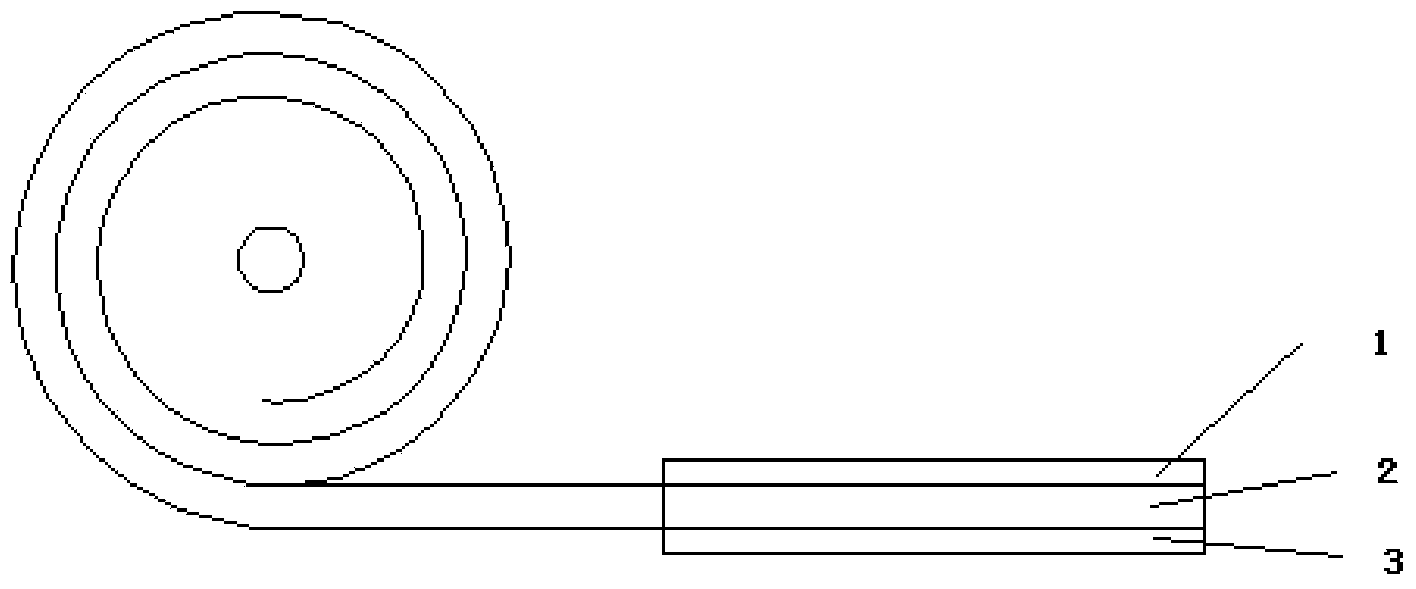

[0023] Such as figure 1 As shown, an aging-resistant tape for edge protection of thin film photovoltaic modules consists of a release layer 3, a pressure-sensitive adhesive layer 2 coated on the release layer 3 and a substrate 1 compounded on the pressure-sensitive adhesive layer 3 Composition, first prepare substrate 1, described substrate is polyether type thermoplastic polyurethane elastomer black film, thickness is 150 μ m, after corona electric field intensity is 32 kV / cm corona treatment, substrate 1 surface corona The value is 41 dynes;

[0024] Prepare single-sided release material release paper, apply acrylic acid-butyl acrylate polymer (commercially available from Changxing Chemical as a product of 7002E) on the release layer of the release paper, set the gap of the coating head scraper to make The thickness of the acrylic acid-butyl acrylate polymer is 60 μm, the drying temperature of the drying tunnel is set at 75-90 ° C, and the release paper coated with the acry...

Embodiment 2

[0028] Such as figure 1 As shown, an aging-resistant tape for edge protection of thin film photovoltaic modules consists of a release layer 3, a pressure-sensitive adhesive layer 2 coated on the release layer 3 and a substrate 1 compounded on the pressure-sensitive adhesive layer 3 Composition, first prepare substrate 1, described substrate is polyether type thermoplastic polyurethane elastomer black film, thickness is 160 μ m, after corona electric field intensity is 36 kV / cm corona treatment, substrate 1 surface corona The value is 44 dynes;

[0029] Prepare single-sided release material release paper, apply acrylic acid-butyl acrylate polymer (commercially available from Changxing Chemical as a product of 7002E) on the release layer of the release paper, set the gap of the coating head scraper to make The thickness of the acrylic acid-butyl acrylate polymer is 50 μm, the drying temperature of the drying tunnel is set at 80-90 ° C, and the release paper coated with the acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com