Indoor thick steel structure fireproof coating and preparation method thereof

A technology for fire-resistant coatings and steel structures, applied in fire-resistant coatings, alkali metal silicate coatings, coatings, etc., can solve problems such as loss of bearing capacity, aggravated smoke generation, and cracking of fire-resistant coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

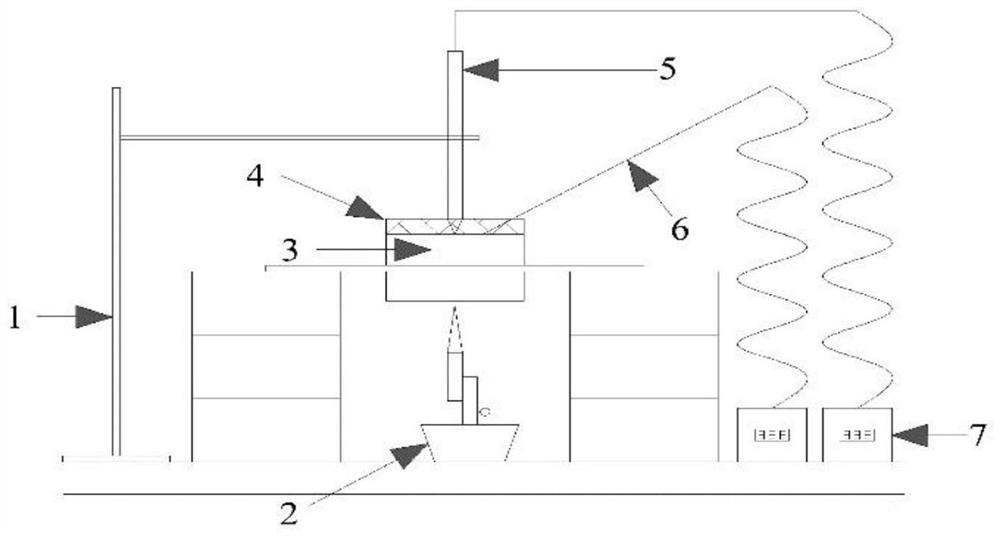

Image

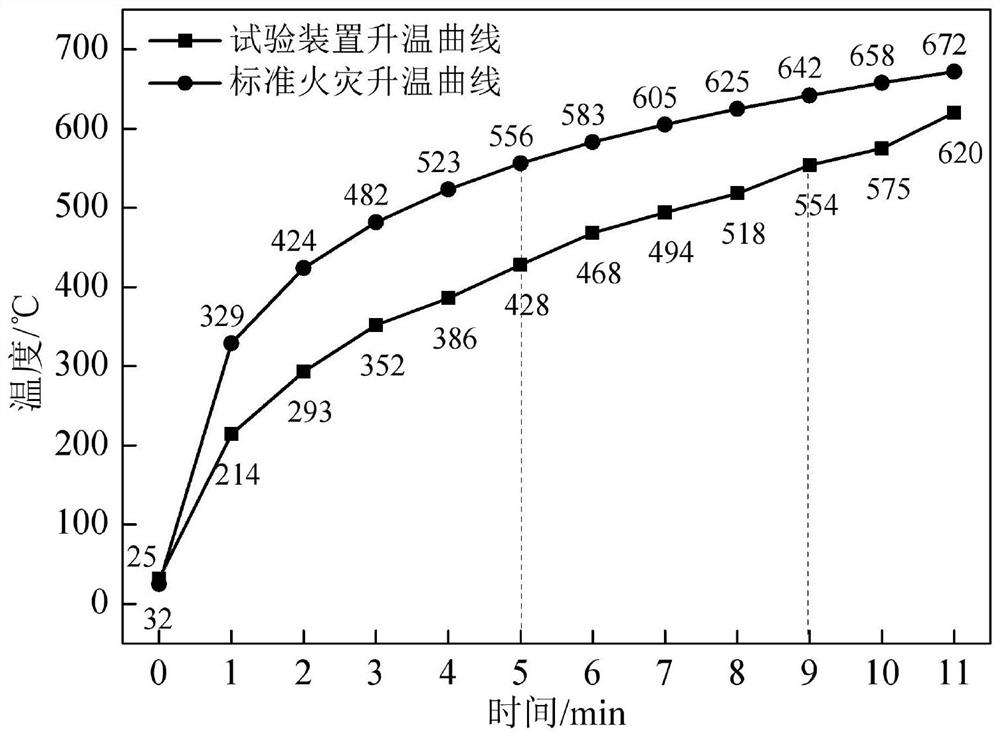

Examples

preparation example Construction

[0054] In the present invention, the acid leaching filtrate obtained in the preparation process of the sodium silicate solution is preferably taken, and the pH is adjusted to 11-13 to obtain an alkaline solution.

[0055] In the present invention, the pH adjustment is preferably by adding an alkaline solution, and the alkaline solution is preferably a sodium hydroxide solution; the mass concentration of the alkaline solution is 15-25%, more preferably 18-22%.

[0056] After the alkaline solution is obtained, the present invention preferably passes excess carbon dioxide into the alkaline solution to obtain a suspension and then remove the solvent to obtain aluminum hydroxide.

[0057] In the present invention, the rate and time of introducing carbon dioxide are not particularly limited, as long as the components in the alkaline solution can be fully reacted.

[0058] In the present invention, the method of removing the solvent after obtaining the suspension is preferably drying...

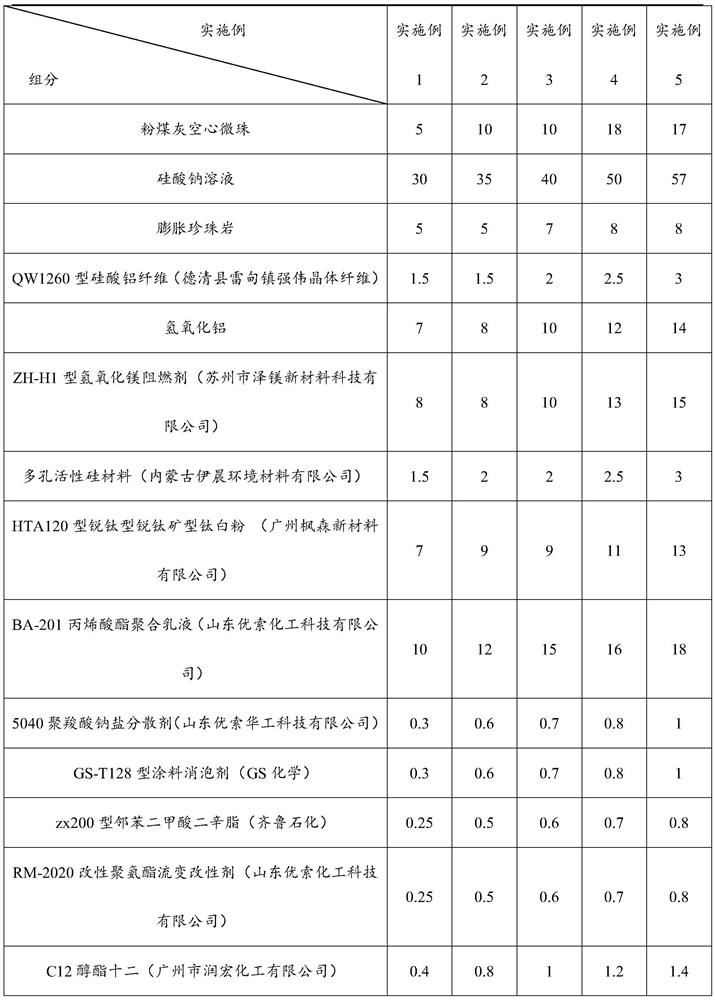

Embodiment 1

[0087] The specific preparation steps of the indoor thick steel structure fireproof coating prepared in this embodiment are as follows:

[0088] Pass the fly ash hollow microspheres through an 80-mesh standard sieve, and take the unsieved microspheres (particle size > 180 μm) for ball milling at a speed of 300 r / min for 4 hours until the particle size is about 19 μm.

[0089] After the above-mentioned ball-milled fly ash hollow microspheres and the compound alkali are ground and mixed uniformly according to the mass ratio of 0.5:1, they are roasted at 700° C. for 1 hour to obtain nepheline; the compound alkali is sodium carbonate and sodium hydroxide, The mass ratio is 0.5:1.

[0090] The nepheline obtained in the above steps was acid-leached with 8% hydrochloric acid at 95°C for 10 minutes to obtain acid residue and acid leaching filtrate, wherein the mass ratio of liquid to solid during acid leaching was 15:1.

[0091] The acid slag obtained in the above steps is added to s...

Embodiment 2

[0098] The specific preparation steps of the indoor thick steel structure fireproof coating prepared in this embodiment are as follows:

[0099] Pass the fly ash hollow microspheres through an 80-mesh standard sieve, and take the unsieved microspheres (particle size > 180 μm) for ball milling at a speed of 400 r / min for 5 hours until the particle size is about 17 μm.

[0100] After the above-mentioned ball-milled fly ash hollow microspheres and the compound alkali are ground and mixed uniformly according to a mass ratio of 1:1, they are roasted at 790° C. for 2 hours to obtain nepheline; the compound alkali is sodium carbonate and sodium hydroxide, Its mass ratio is 1:1.

[0101] The nepheline obtained in the above steps was pickled with hydrochloric acid with a mass concentration of 12% at 80°C for 15 minutes to obtain acid residue and acid leach filtrate, wherein the mass ratio of liquid to solid during acid leaching was 12:1.

[0102] The acid slag obtained in the above st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com