Patents

Literature

403results about How to "No lumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Normal-temperature drinking type yoghourt and preparation method thereof

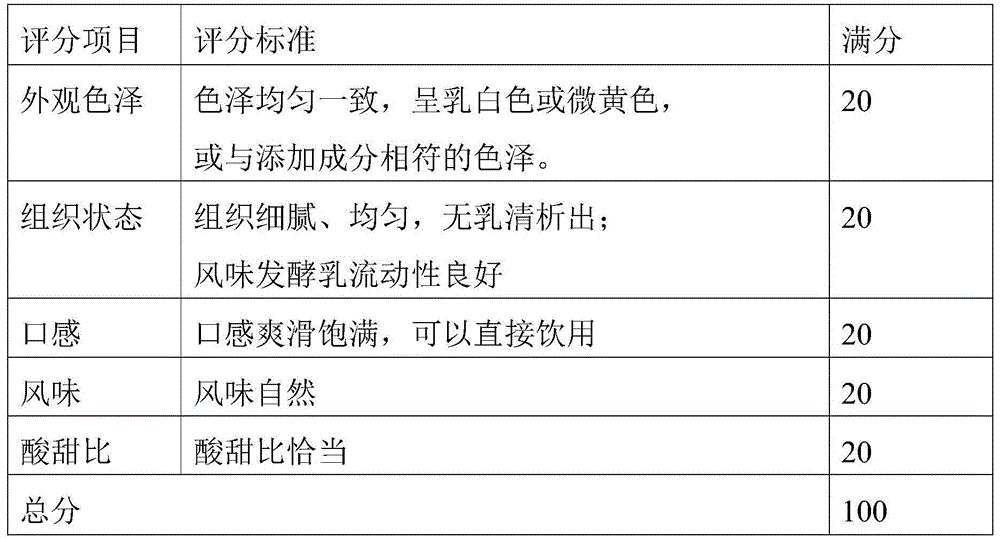

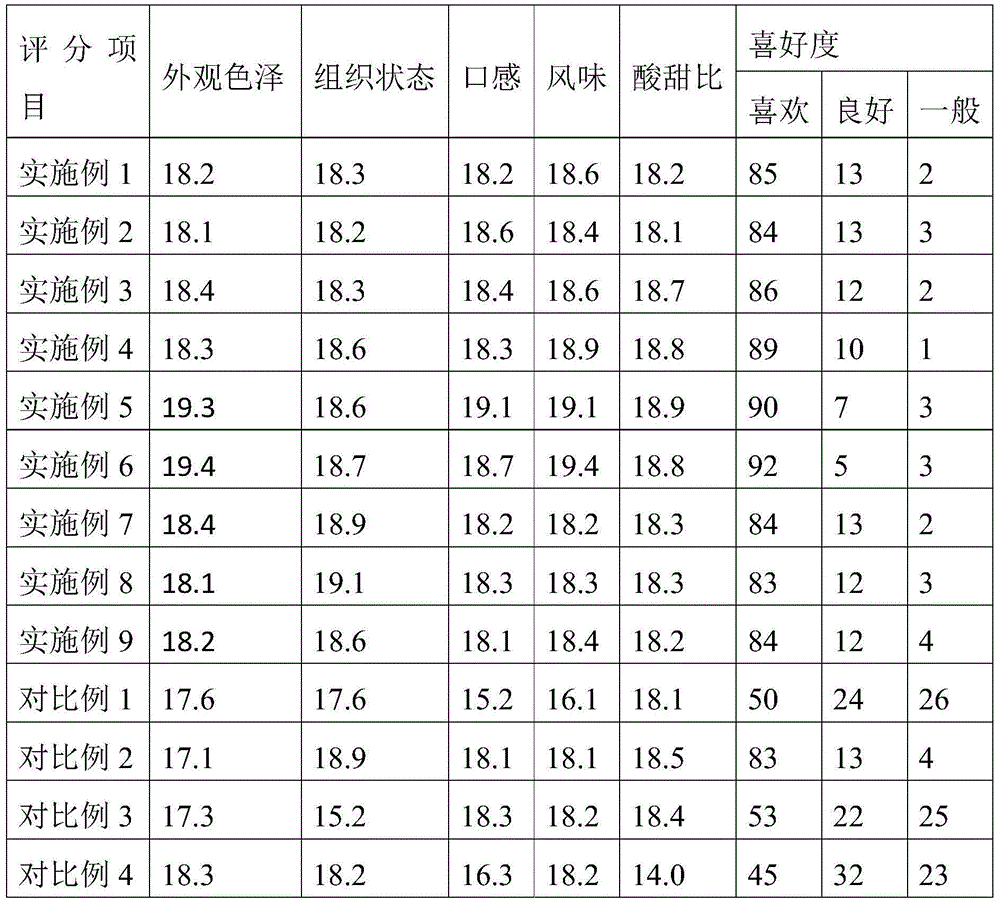

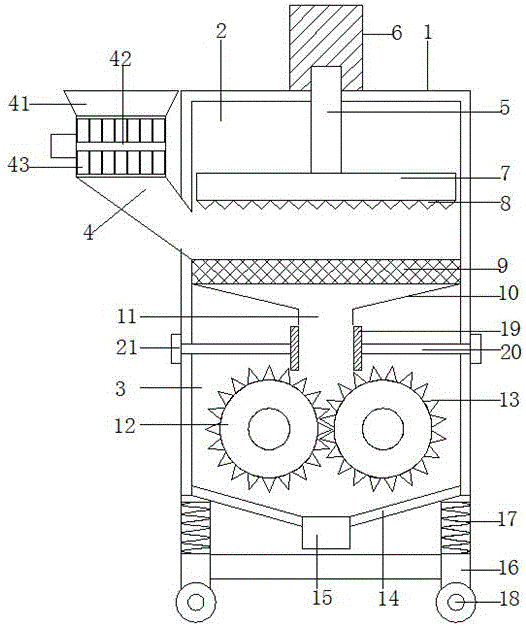

The invention discloses normal-temperature drinking type yoghourt and a preparation method thereof. The normal-temperature drinking type yoghourt comprises the following raw materials in percentage by weight: 56.6%-60% of concentrated raw milk, 1*10<6>-7*10<9>cfu / mL of a fermenting agent, 0.03-0.5% of a stabilizing agent, a proper amount of a sweetening agent and a proper amount of water, wherein the stabilizing agent is selected from one or multiple of pectin, soybean polysaccharide and gellan gum, and the percentage is the mass percent of the stabilizing agent, accounting for the total mass of the normal-temperature drinking type yoghourt. The preparation method comprises the following steps: (1) homogenizing the concentrated raw milk and milk powder and sterilizing to obtain a sterilized liquid mixture A; (2) cooling, adding the fermenting agent for fermentation, overturning a jar by back pressure, homogenizing and cooling again; (3) uniformly mixing with the sterilized liquid mixture A, adjusting the acidity, homogenizing so as to obtain a liquid mixture B, wherein the liquid mixture A comprises the stabilizing agent, the sweetening agent and the water; and (4) sterilizing the liquid mixture B. The normal-temperature drinking type yoghourt and the preparation method disclosed by the invention have the advantages that the requirements of heat treatment for the viscosity of the yoghourt and the adding amount of the stabilizing agent are effectively reduced, the obtained normal-temperature drinking type yoghourt is good in fluidity and smooth in taste and has no obvious layering condition after being stored for 6 months under the normal temperature.

Owner:BRIGHT DAIRY & FOOD

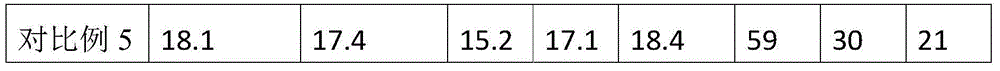

Crushing device for chemical industry production

InactiveCN106733113AQuality assuranceImprove work efficiencyGrain treatmentsChemical industryHydraulic cylinder

The invention discloses a crushing device for chemical industry production. The crushing device for chemical industry production comprises a crushing machine body. The crushing machine body is divided into a crushing cavity and a smashing cavity in an upper-lower mode. The bottom end of the left side of the crushing cavity is connected with a feeding pipe, a feeding hopper is arranged on the upper side of the feeding pipe, and an iron removing rotary shaft is horizontally arranged in the center in the feeding hopper. Permanent magnet sheets are arranged on the outer wall of the iron removing rotary shaft in a vertically symmetrical mode. A telescopic column is vertically arranged in the center in the crushing cavity, the top end of the telescopic column stretches out of the crushing cavity and is connected with a hydraulic cylinder fixed on the outer wall of the upper side of the crushing machine body, and the bottom end of the telescopic column is connected with a crushing hammer arranged horizontally. The crushing device for chemical industry production can conduct iron removing on materials twice, thereby being good in iron removing effect and sufficient in iron removing; two crushing mechanisms arranged up and down are adopted for sufficiently crushing materials, gears are engaged to conduct crushing, and thus the crushing effect is good, and crushing is sufficient; and besides, effective shock absorption can be achieved, and the service life of the machine body is prolonged.

Owner:GUANGXI UNIV

Method for preparing ginseng and coix seed mixture and ginseng and coix seed paste

ActiveCN102415525AHigh total extraction rateNo pollution in the processFood preparationDigestionAbsorption rate

The invention provides a method for preparing a ginseng and coix seed mixture and a ginseng and coix seed paste. Raw materials comprise 1 to 10 parts of ginseng, 10 to 30 parts of coix seed, 2 to 10 parts of lotus seed, 10 to 35 parts of glutinous rice, 5 to 20 parts of black rice, 10 to 30 parts of flour, 2 to 15 parts of black sesame, 1 to 6 parts of walnut kernel, 1 to 10 parts of peanut kernel, 3 to 10 parts of malto dextrin, 1 to 4 parts of black soya bean, 1 to 4 parts of small red bean, 1 to 10 parts of edible modified starch and 2 to 10 parts of white granulated sugar. The ginseng is subjected to supercritical CO2 extraction, the green production process is really realized, and the total extraction rate of active substances such as ginsenoside and the like is over 90 percent. The obtained product is fine powder without cakes, is easy to store and convenient to use, has characteristics of fine and smooth texture, delicious taste and tasty mouthfeel, cleanness and faint scent, and high digestion and absorption rate of natural nutrients, and maintains natural nutrient components of the raw materials, and improves the mouthfeel and the nutrient component absorption rate.

Owner:TIANJIN UNIV

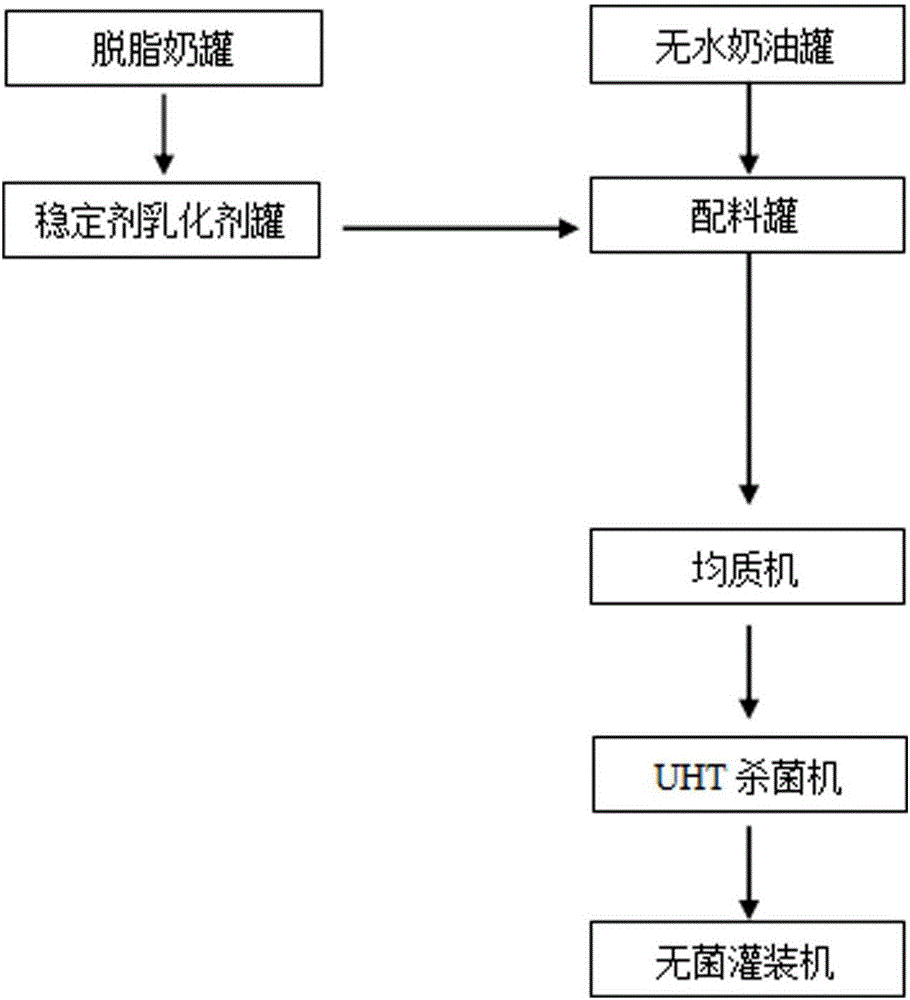

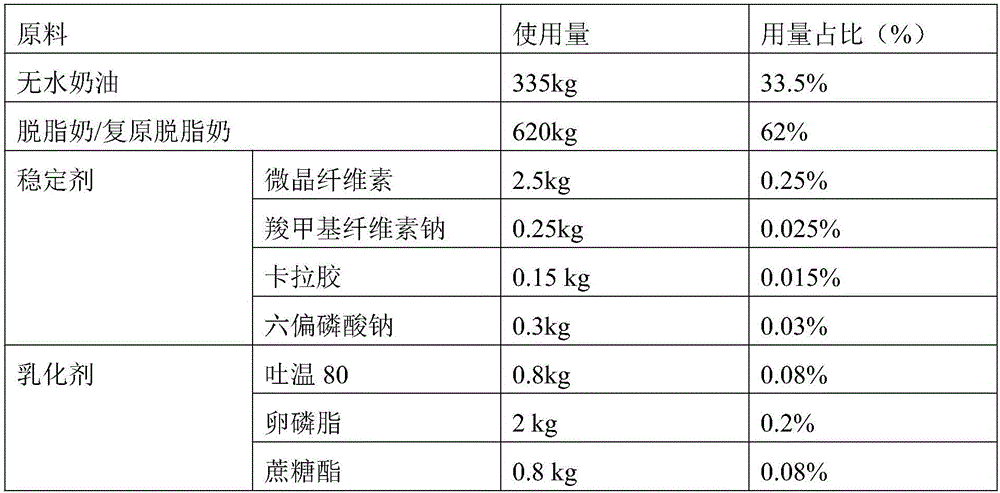

Light cream produced from anhydrous cream and production process of light cream

The invention relates to light cream produced from anhydrous cream and a production process of the light cream. The light cream is produced from the anhydrous cream, skimmed milk or skimmed powder, a certain amount of stabilizer and a certain amount of emulsifying agent, wherein the produced light cream contains the following components in percentage by mass (100% in total): 33%-37% of fat, 1.5%-2.0% of proteins, 0.3%-0.5% of the stabilizer, 0.5%-1.5% of the emulsifying agent and the balance of water. The produced light cream can be used for producing products such as ice cream, yoghourt and candies and has the advantages that the phenomena of agglomeration, water separation, fat floatation and protein settling are avoided after the light cream is preserved at room temperature for 6 months, and the mouthfeel is stable. The production process of the light cream has the beneficial effects that the technical process is reasonable, and the operation is simple and convenient; and the partial side product, namely skimmed milk separated from cow milk is comprehensively utilized, so that the wasting of the resource is avoided, and the production cost is lowered.

Owner:宁夏塞尚乳业有限公司

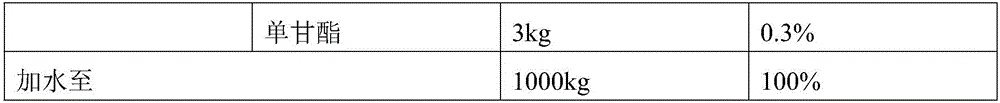

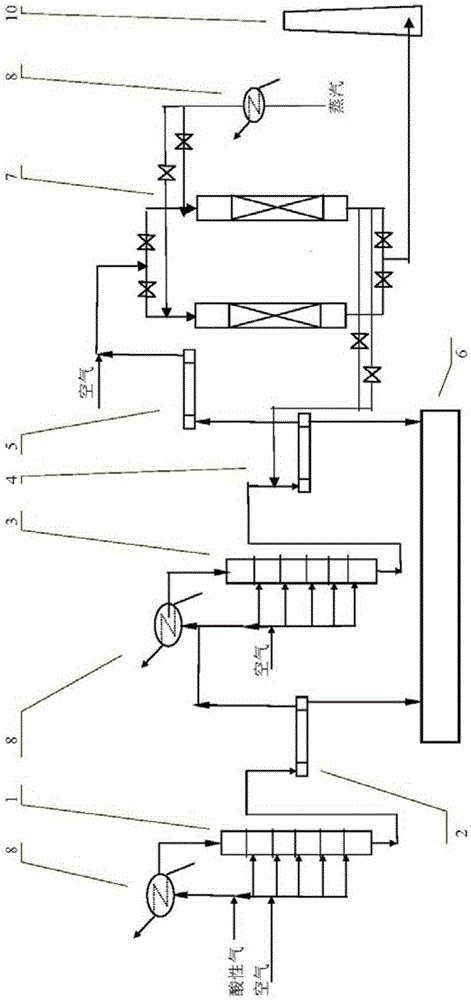

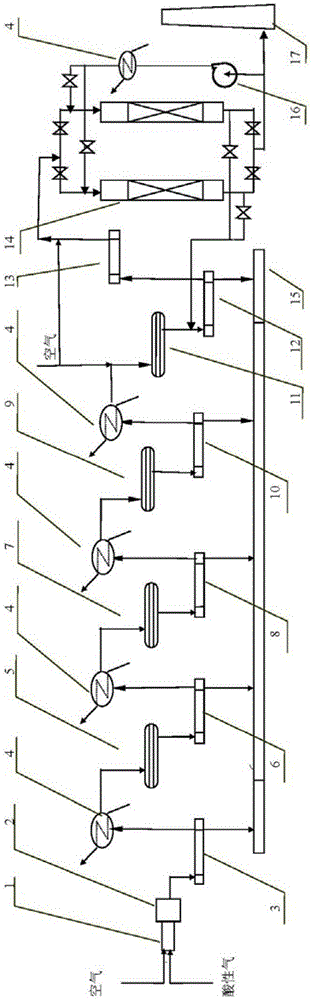

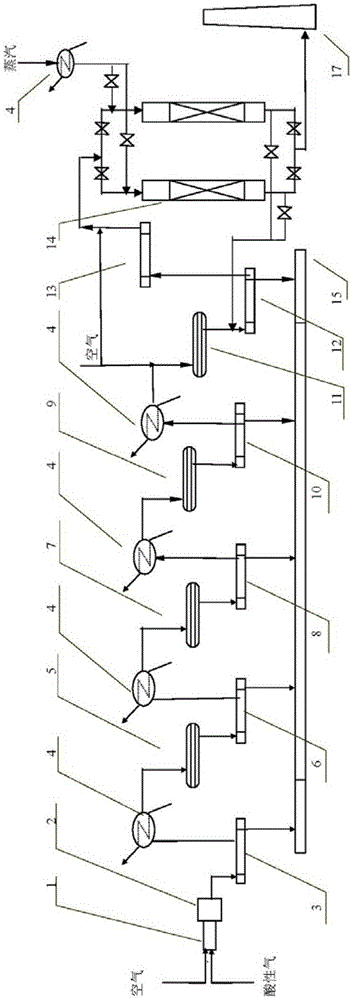

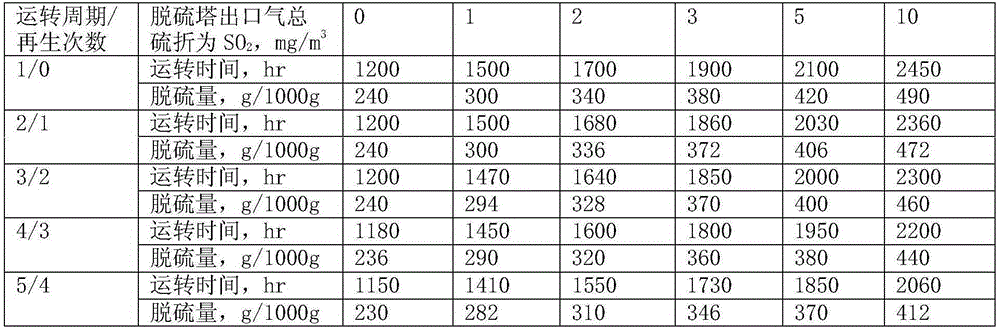

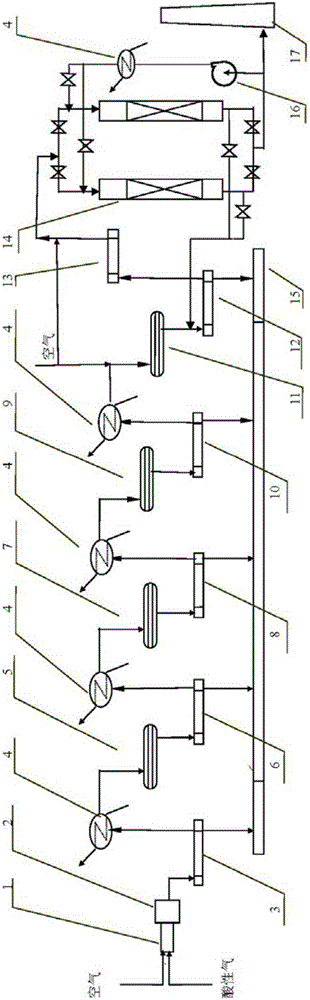

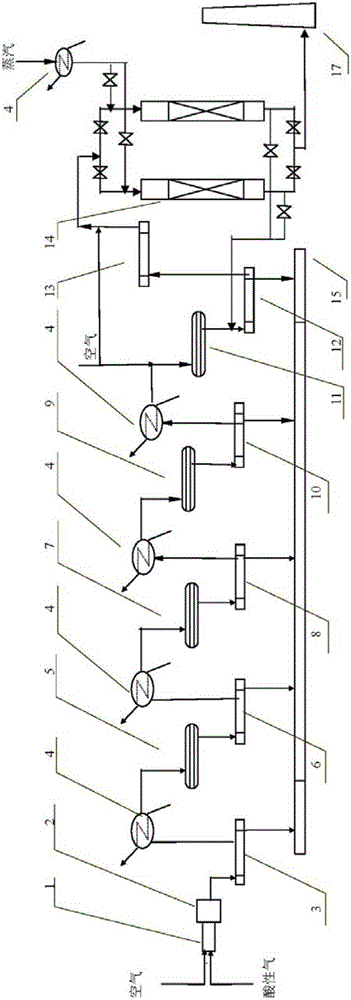

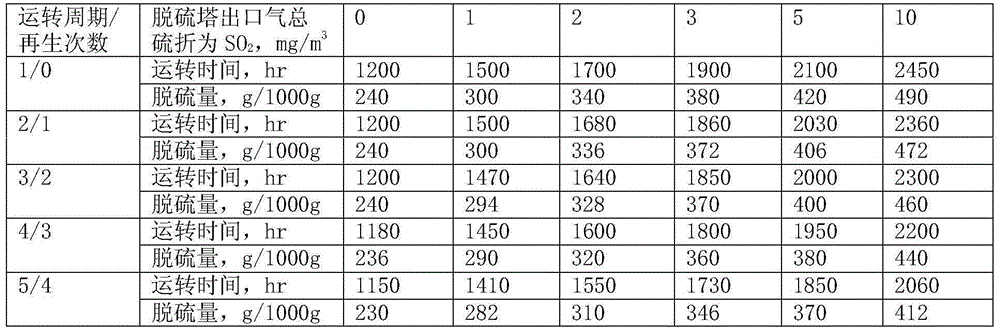

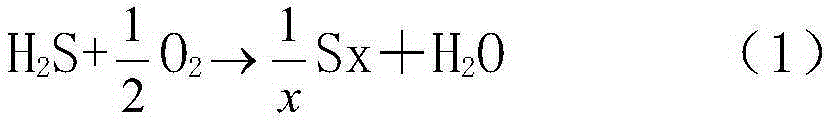

Low-sulfur discharging and sulfur recycling process of intermediate concentration acid gas

ActiveCN105314607ALow sulfur concentrationHigh desulfurization precisionEnergy inputSulfur preparation/purificationCatalytic oxidationCooling coil

The invention provides a low-sulfur discharging and sulfur recycling process of intermediate concentration acid gas. A purpose of desulphurizing low-concentration acid gas with H2S content of 5 to 20 percent can be achieved by treating the low-sulfur acid gas by virtue of a direct oxidation reactor, a selective oxidation reactor and two adsorption desulphurization towers which can be connected in series and parallel; the direct oxidation reactor is filled with a TiO2 sulfur recycling catalyst, the selective oxidation reactor is filled with a H2S selective oxidation catalyst, catalysts in the direct oxidation reactor and selective oxidation reactor are packed in multiple layers, an air inlet and a cooling coil pipe are respectively arranged between two layers, and the adsorption desulphurization tower is filled with a thermally-renewable catalytic oxidation adsorption desulphurization agent; by selecting the appropriate catalyst and desulphurization agent and precisely controlling the process condition of each step, the total sulfur contained in the process discharged gas is that SO2 content is less than or equal to 10mg / m<3>. By virtue of thermal regeneration, the service life of the catalytic oxidation adsorption desulphurization agent is greatly prolonged, and the desulphurization amount of the catalytic oxidation adsorption desulphurization agent is greatly increased. The process has the advantages of low sulfur emission, high sulfur recycling rate (approximate to 100 percent), long service life and large desulphurization amount of the desulphurization agent, fewer replacement times, less expense, good desulphurization agent removal and scrapping condition, safety and the like.

Owner:山东迅达化工集团有限公司

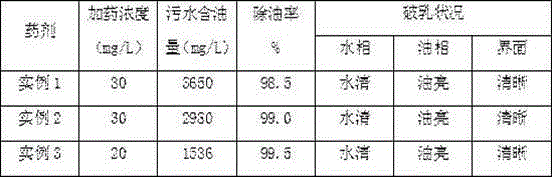

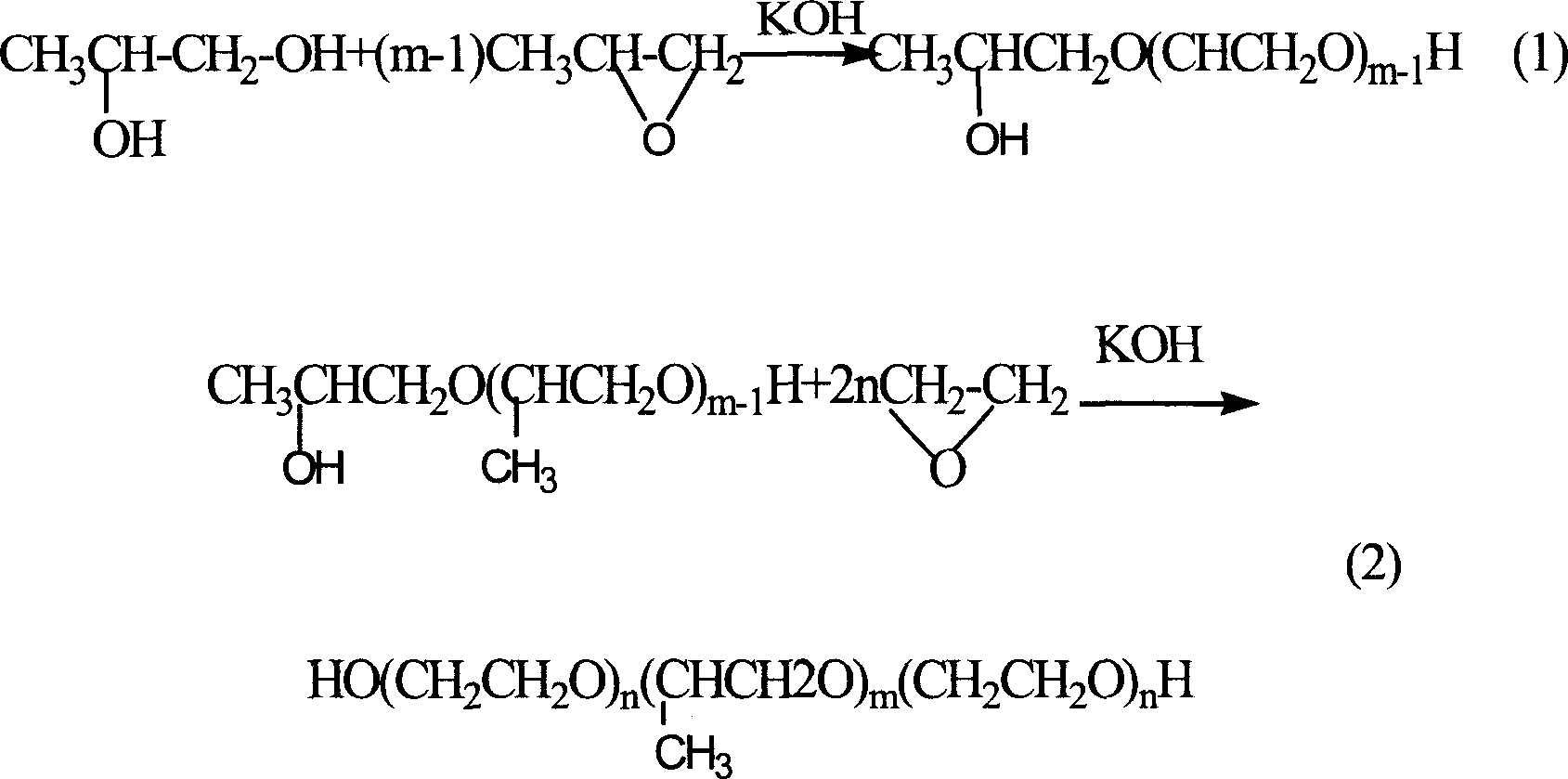

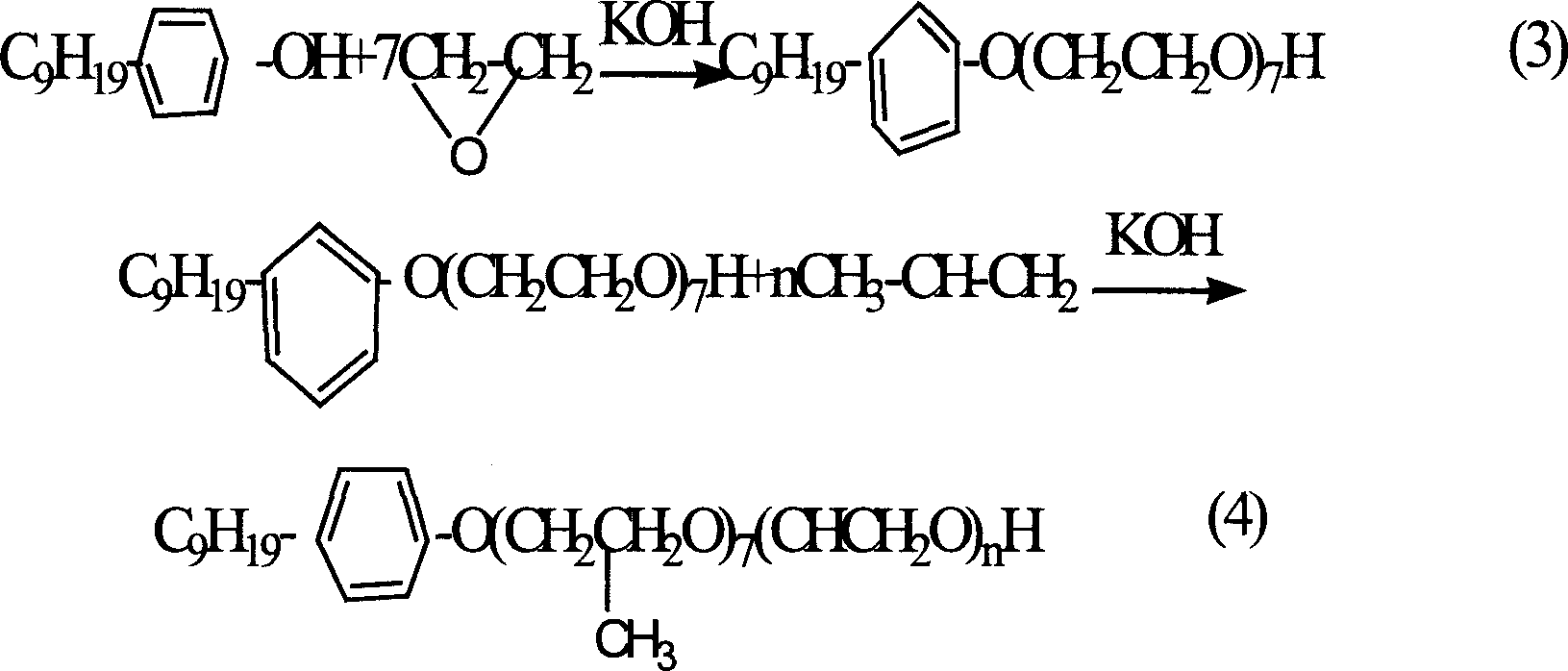

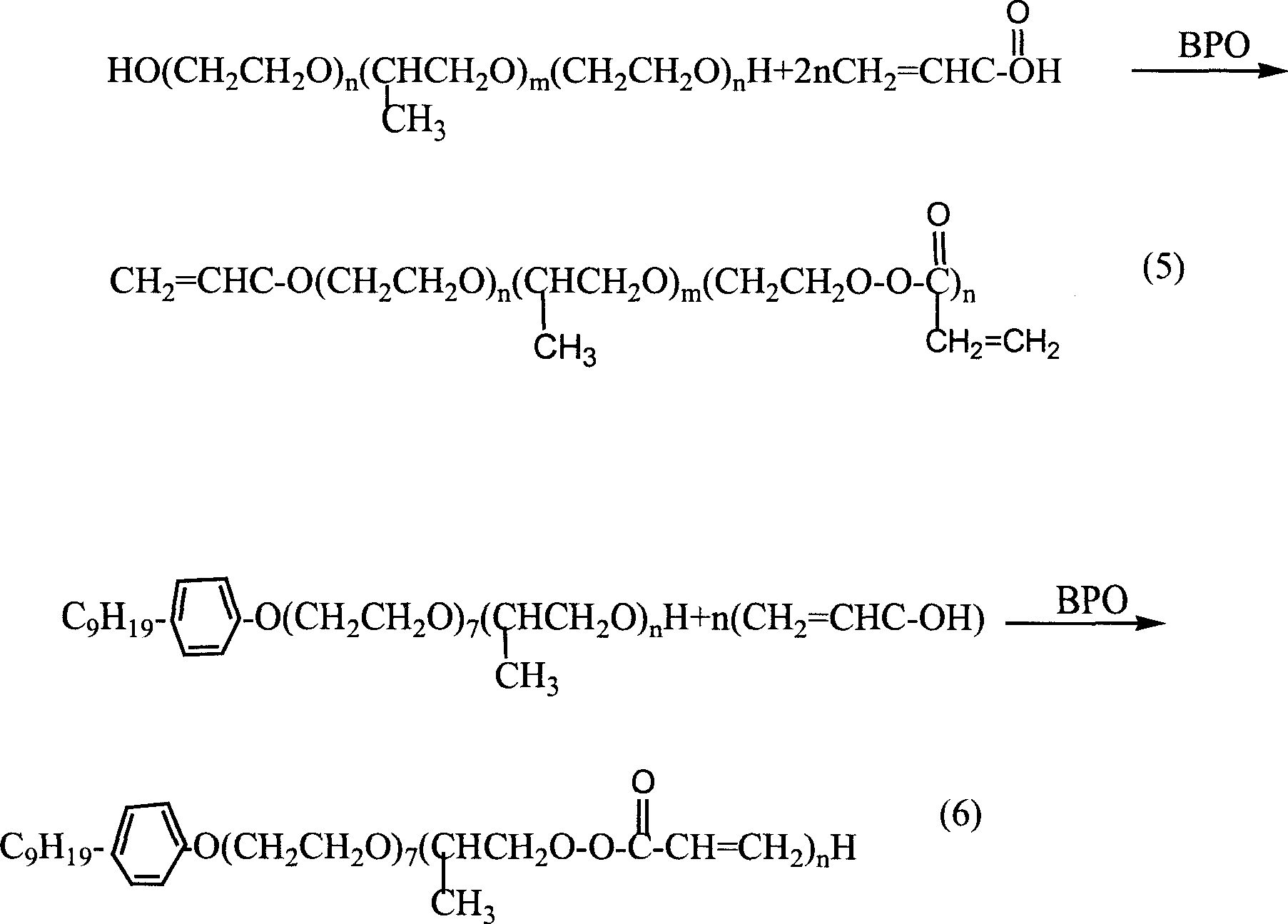

Oil-in-water type emulsion demulsifying agent and preparation method thereof

ActiveCN105384927ANo lumpsFast separationWaste water treatment from quariesFatty/oily/floating substances removal devicesDemulsifierWastewater

The present invention discloses an oil-in-water type emulsion demulsifying agent and a preparation method thereof. Firstly, bisamide is prepared, then chlorinated polyether is prepared, and finally cationic polyether is obtained, namely the oil-in-water emulsion demulsifying agent. The preparation method has readily available raw materials, is simple in operation, and has low equipment requirements. The prepared demulsifying agent is a cationic polymer with a network structure formed by the reaction of bisamide and epichlorohydrin, has a special network structure and a very strong surface activity, has a good demulsification function, is a reverse demulsifying agent suitable for chemical flooding produced liquid, can be used in oilfield produced wastewater treatment, can break the emulsion interfacial energy, and has an oil removal rate of more than 98% in a use amount of 20-30 mg / L. The prepared demulsifying agent is not layered, has no caking and no mechanical impurities, and has characteristics of being fast in oil and water separating speed and being low in oil content of water, and a good demulsifying effect for a three compound combination flooding O / W emulsion and high oil removal efficiency.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

Highly efficient anti-phase emulsion breaker for thick oil pollution water processing

InactiveCN1966138AFast separationReduce oil contentTransportation and packagingMixingWater processingPhenol

The invention relates to a dense oil sewage treatment reverse-phase demulsifying agent, wherein the invention is characterized in that: it uses methyl glycol as initial agent, via catalyst, to process oxypropylation reaction, and process aggregation with epoxyethane, to generate methyl glycol polyether; uses nonyl phenol as initial agent, via catalyst, to react with epoxyethane to generate nonyl phenol ethoxy compound, then to be aggregated with epoxypropane, to generate alkyl phenol polyvinyl ether; then mixing two products, to process esterification with acroleic acid under acid condition, via initiator to process free group aggregation, to generate esterified product, then uses maleic acid to seal end, to generate acroleic acid modified macromolecule demulsifying agent. The invention has simple process, warm reaction, and high efficiency.

Owner:YANGTZE UNIVERSITY

Preparation method of liquid plant dye

The invention discloses a preparation method of a liquid plant dye, comprising the following steps of: firstly selecting plant materials, crushing, then adding fermenting strain and alcohol solution for fermentation, extracting the obtained solution, reducing pressure, concentrating, distilling, preparing dye concentrated solution, adding an auxiliary agent in the dye concentrated solution and preparing liquid dye. The invention has rich resource of utilized plants and simple preparation method, and does not cause pollution of chemical synthetic dye to the environment in the preparation process; the prepared dye has natural and elegant color, does not have hazardous effect on human body, is applied to clean production in the textile industry and can be produced in large scale; and based on the traditional process, the invention adopts modern means and improves the extraction process so as to facilitate the storage and transportation.

Owner:WUYI UNIV

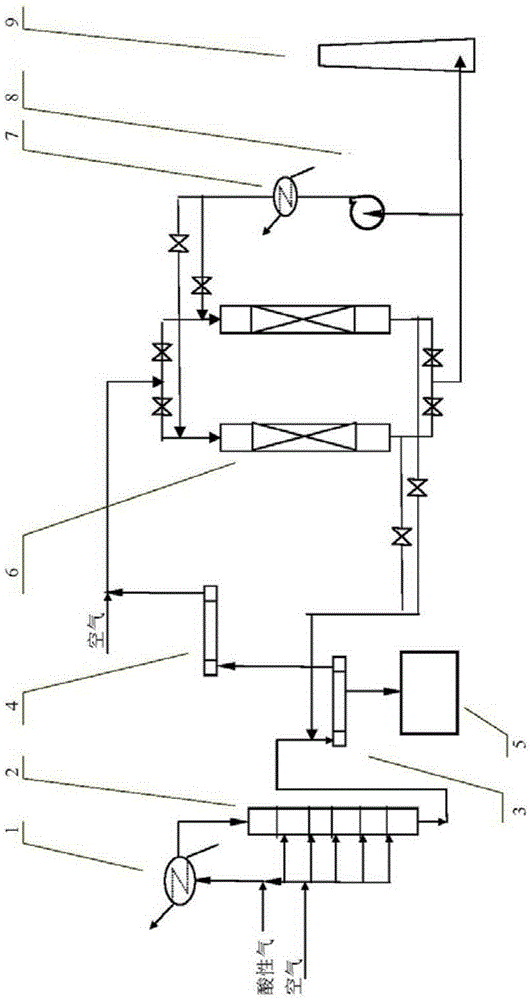

Sulfur recovery technology realizing low sulfur emission

ActiveCN105399057AHigh desulfurization precisionLow sulfur concentrationSulfur preparation/purificationCombustionConversion factor

The invention provides a sulfur recovery technology realizing low sulfur emission. The sulfur recovery technology comprises a combustion furnace, a first-stage Claus reactor, a second-stage Claus reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor and two adsorption desulfurization towers capable of being connected in series or parallel, and the devices are sequentially connected in series; the total sulfur conversion factor of process effluent gas is that SO2 is smaller than or equal to 10 mg / m<3> through proper selection of various catalysts and desulfurizers and accurate control of process conditions of steps. The desulfurizers after breakthrough are subjected to in-situ thermal regeneration by inert gas at the temperature of 250-300 DEG C, regenerated outlet gas returns to the combustion furnace, a condenser I behind the combustion furnace, a condenser II behind the first-stage Claus reactor, a condenser III behind the second-stage Claus reactor, a condenser IV behind the selective hydrogenation reduction reactor or a condenser V behind the selective oxidation reactor, sulfide such as elemental sulfur, H2S,SO2 and the like in the regenerated gas is recovered, and the total sulfur conversion factor of exhaust tail gas in the regeneration period of the desulfurization towers is that SO2 is smaller than or equal to 10 mg / m<3>. The sulfur recovery technology realizing low sulfur emission has the advantages of the low sulfur emission, the long-term operation of the desulfurizers, the high desulfurization capacity, the small number of replacement times, the low expenses and the like.

Owner:山东迅达化工集团有限公司

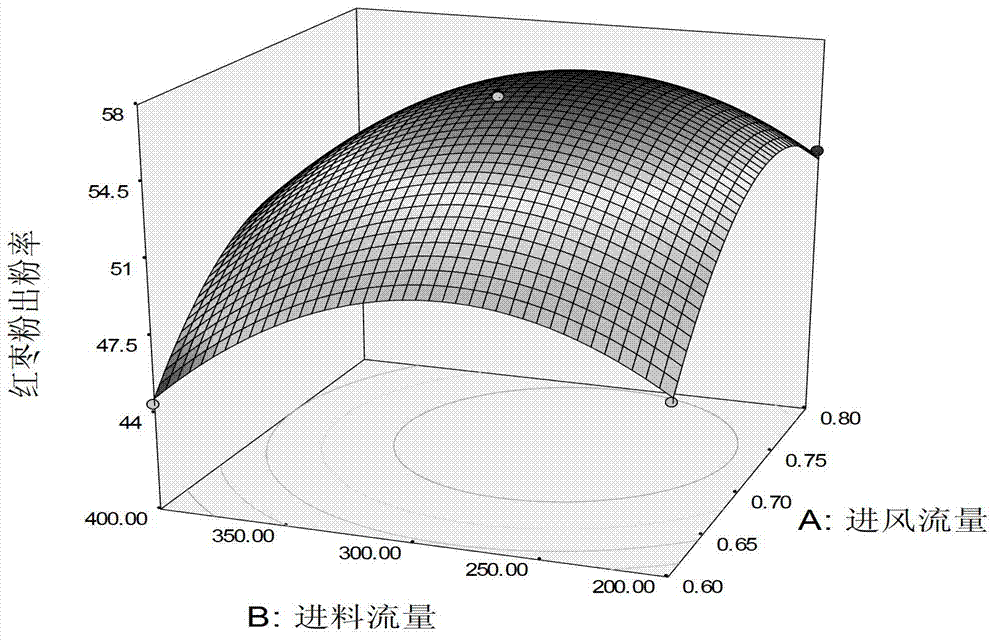

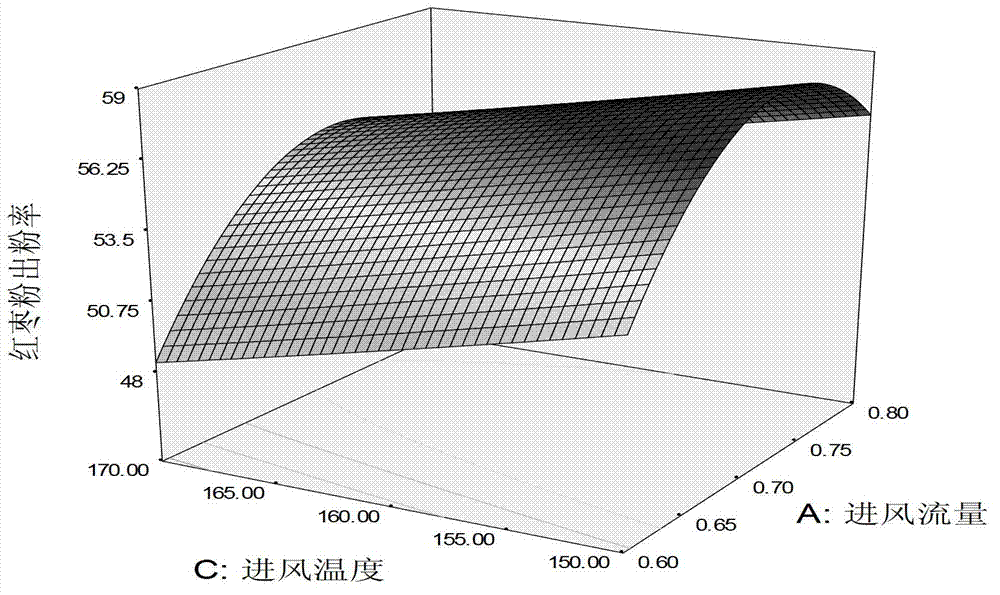

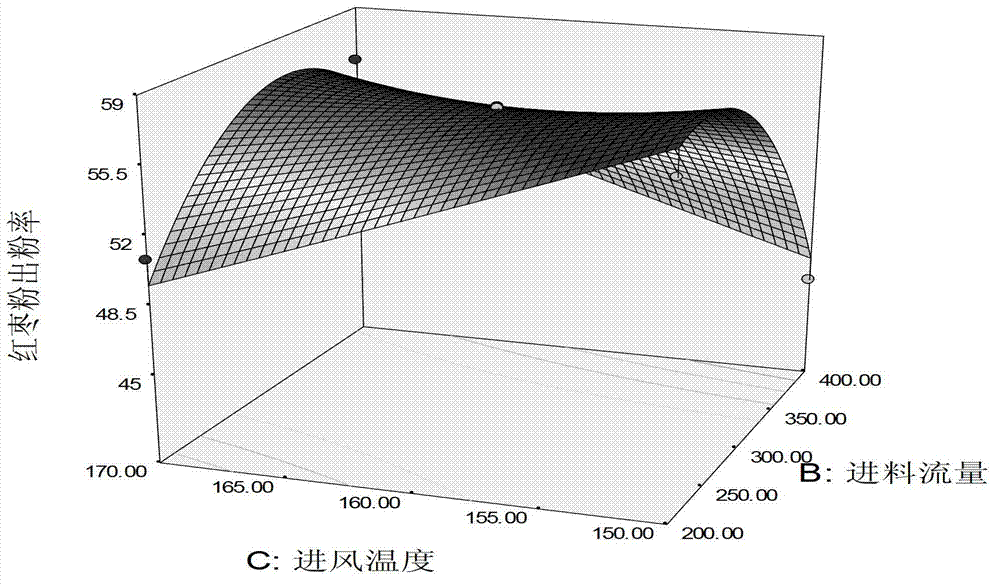

Making method of red date powder

The invention discloses a making method of red date powder. The making method includes the steps of selecting red dates, cleaning, pre-boiling, removing stones, adjusting acidity, protecting the color, allowing for enzymolysis, concentrating, adding anticaking agent, homogenizing, spray-drying, labeling, spraying the code, and boxing. The making method has the advantages that extraction rate of the method is 57.95%, the red date powder is 4.23% in water content and yellow, granules of the red date powder are even without caking, the red date powder has strong flavor of red date and the inherent taste of red date, and the red date powder which is fully dissolvable can be dissolved into solution in red of red date with no impurities visible to naked eyes.

Owner:SHIHEZI UNIVERSITY

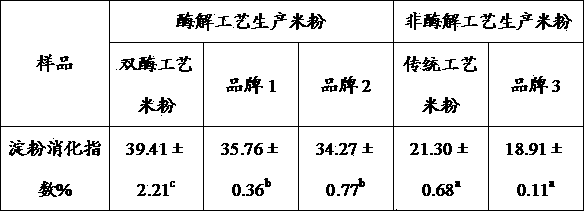

Method for preparing rice powder by adopting double-enzyme hydrolysis process and rice powder

ActiveCN103798623AEradicates the problem of reduced digestive performanceImprove digestibilityFood preparationBiotechnologyAmylase

The invention discloses a method for preparing rice powder by adopting a double-enzyme hydrolysis process and the rice powder. The method comprises the following steps: cleaning, draining and drying rice; grinding the rice and blending slurry to prepare rice starch milk; adding 0.002 to 0.05 percent of alpha-amylase and 0.2 to 5 percent of beta-amylase into the rice starch milk on the basis of dry rice starch milk to obtain a mixture, performing hydrolysis for 10 to 40 minutes after the mixture is stirred uniformly; adding auxiliary materials and continuing stirring to obtain a mixture I; performing refining, drying and the like after the mixture I is stirred uniformly to obtain the rice powder. According to the method, starch long-chain molecules are degraded into short-chain small molecules by the alpha-amylase, and side chains outside starch side chains are also cut by utilizing the beta-amylase so as to inhibit the regeneration, the problem that the digestive performance caused by the regeneration is eliminated, and the digestive performance of the produced rice powder is higher than that of the rice powder produced by adopting other hydrolysis processes through the collaborative enzymolysis of two kinds of enzymes; moreover, the rice powder is relatively easy to brew, does not have cakes, and has the relatively high quality.

Owner:广东每智健康科技有限公司

Walnut meal composite nutrition powder and preparation technology thereof

The invention discloses walnut meal composite nutrition powder and a preparation technology of the walnut meal composite nutrition powder. The preparation technology of the walnut meal composite nutrition powder comprises the steps that (1) pearl barley powder and walnut meal powder serve as main raw materials, extrusion processing is carried out on the raw materials through a bulking machine under the conditions that the extrusion temperature is 150DEG C-170DEG C, and the screw speed is 540-580r / min, and pearl barley and walnut powder extruded materials are obtained; (2) the extruded materials are smashed to form powdery materials with the specification of being larger than 100 meshes, the powdery materials are placed into a homogenizer, sucrose and water are added, high-pressure homogeneity processing is carried out under the conditions that the pressure is 20-25MPa, and the temperature is 70-80DEG C, then, composite probiotics inoculated fermentation processing is carried out on the materials to form walnut meal composite fermentation liquid, and spray drying processing is carried out on the walnut meal composite fermentation liquid to obtain the walnut meal composite nutrition powder. The walnut meal composite nutrition powder and the preparation technology of the walnut meal composite nutrition powder have the advantages of being simple in processing technology, low in manufacturing cost, capable of making full use of the nutrition complementary advantage of the raw materials, capable of achieving all nutritional functions of the walnut meal raw materials, good in quality of products, good in taste of the products, rich in nutrient of the products, stable in quality and performance of the products and the like.

Owner:GUIZHOU UNIV

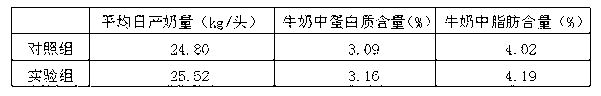

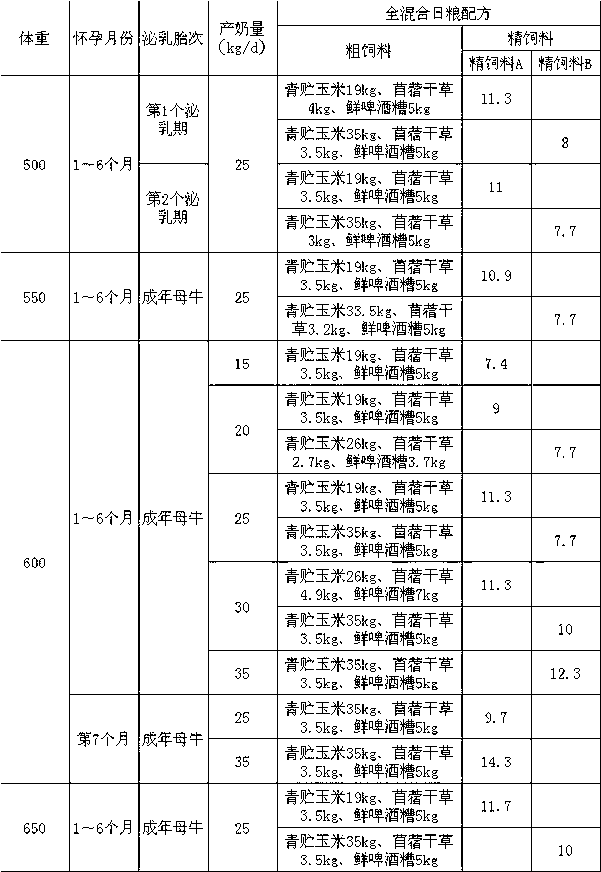

Cow total mixed ration and preparation method and application thereof

InactiveCN102696890AReduce incidenceIncrease proteinFood processingAnimal feeding stuffAlfalfa hayRapeseed

The invention relates to a cow total mixed ration which comprises roughage feed and concentrated feed, wherein the roughage feed comprises silage corn, alfalfa hay, and fresh brewer's grain, and the concentrated feed comprises corn, flax cake, rapeseed meal, cottonseed meal, vinasse protein feed, wheat bran, and composite premix. The invention also provides a preparation method of the cow total mixed ration, which comprises the following steps: firstly preparing the concentrated feed, orderly adding the alfalfa hay, concentrated feed, silage corn, and fresh brewer's grain into a total mixed ration mixer according to a ratio, uniformly stirring to prepare the cow total mixed ration. The invention also provides an application of the cow total mixed ration for cows with different body weights, milk yield, and pregnancy months; with the cow total mixed ration of the invention, the cow nutrition requirements can be met accurately.

Owner:宣城吉思知识产权运营有限公司

Low sulfur emission sulphur recovery process

ActiveCN105293445AHigh desulfurization precisionLow sulfur concentrationSulfur preparation/purificationTowerProcess conditions

The present invention provides a low sulfur emission sulphur recovery process, which comprises a burning furnace, a first stage Claus reactor, a second stage Claus reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor, and two adsorption desulfurization towers capable of being connected in a series parallel connection manner, wherein the burning furnace, the first stage Claus reactor and the second stage Claus reactor are sequentially connected in series. According to the present invention, with the appropriate selection of each catalyst, the appropriate selection of the desulfurization agent, and the accurate control of each step process condition, the total standard sulfur in the process emission gas is that SO2 is less than or equal to 10 mg / m<3>; after the desulfurization agent penetrates, 250-300 DEG C inert gas is used to perform in-situ thermal regeneration, the regeneration outlet gas returns to the burning furnace, the condenser after the burning furnace, the condenser after the first stage Claus reactor, the condenser after the second stage Claus reactor, the condenser after the selective hydrogenation reduction reactor, or the condenser after the selective oxidation reactor to recover elemental sulfur, H2S, SO2 and other sulfides in the regeneration gas, and the total standard sulfur in the evacuation tail gas during the desulfurization tower regeneration process is that SO2 is less than or equal to 10 mg / m<3>; and the low sulfur emission sulphur recovery process has advantages of low sulfur emission, long desulfurization agent operating, high desulfurization capacity, less replacement frequency, low cost and the like.

Owner:山东迅达化工集团有限公司

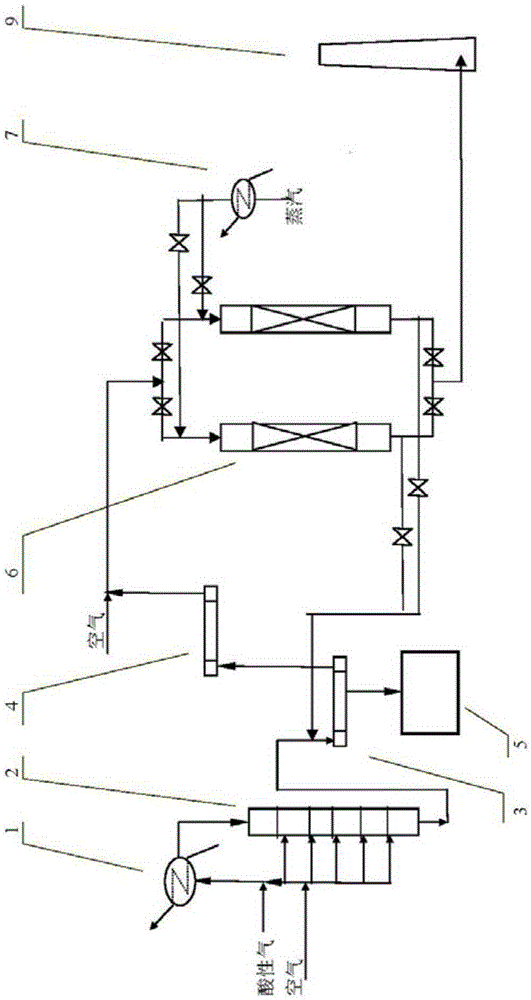

Low concentration acid gas low-sulfur emission sulphur recovery process

ActiveCN105293446AExtend your lifeLarge amount of desulfurizationEnergy inputSulfur preparation/purificationChemistryScrap

The present invention provides a low concentration acid gas low-sulfur emission sulphur recovery process. According to the present invention, low concentration acid gas having a H2S content of less than 5% is treated by a selective oxidation reactor and two adsorption desulfurization towers capable of being connected in a series parallel connection manner so as to achieve the desulfurization purpose; a H2S selective oxidation catalyst is filled in the selective oxidation reactor, and a thermal renewable catalytic oxidation adsorption desulfurization agent is filled in the adsorption desulfurization tower; with the appropriate selections of the catalyst and the desulfurization agent, and the accurate control of each step process condition, the total standard sulfur in the process emission gas is that SO2 is less than or equal to 10 mg / m<3>; with the thermal regeneration, the service life and the desulfurization capacity of the catalytic oxidation adsorption desulfurization agent are substantially improved; and the process has advantages of low-sulfur emission, sulphur recovery rate of close to 100%, long desulfurization agent service life, high desulfurization capacity, less replacement frequency, low cost, good desulfurization agent unloading and scrap treatment conditions, safety, and the like.

Owner:山东迅达化工集团有限公司

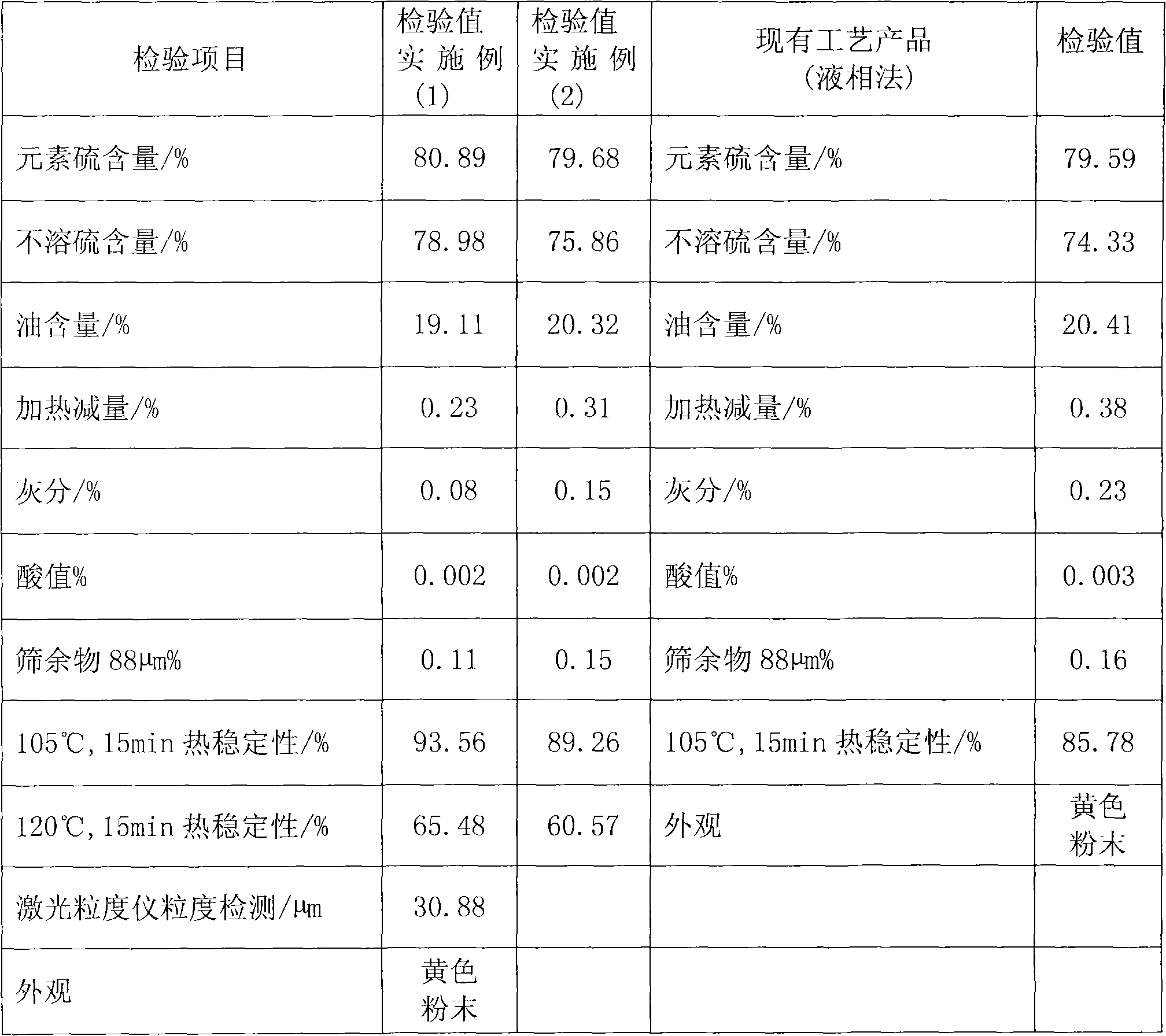

Method for producing insoluble sulfur by using liquid phase method

ActiveCN102020249AImprove thermal stabilityHigh insoluble sulfur contentSulfur preparation/purificationAcid waterSulfur

The invention discloses a method for producing insoluble sulfur by using a liquid phase method, which comprises the following steps of: adding sulfur into a melting kettle, keeping for 30-40 min at a temperature of 340-350 DEG C, then spraying FeCl3, HNO3 and H2O quenching liquid for quenching; extracting aged 60 strip with a CS2 solvent for 3-4 times to ensure that the content of insoluble sulphur is not less than 95 percent, wherein the aged 60 strip is extracted for 40-50min each time; stabilizing an extractant for 20-40min by using a composite stabilizing agent prepared from KCl, KClO3 and acid water solution; drying for 30-40 min at a temperature of 70-80 DEG C to ensure that the water content is controlled below 0.5 percent; charging oil for absorbing by respectively using naphthenic oil and liquid rubber after drying; and crushing oil charged adsorbate to 100-180mu to obtain the insoluble sulfur. The insoluble sulfur prepared by using the method of the invention has the characteristics of high thermal stability, high content of insoluble sulphur, high dispersibility and high thinness. The method has the advantages of simple operation, high efficiency, low cost and high safety, and is suitable for industrialized production.

Owner:朝阳明宇化工有限公司

Wood flour putty and preparation process thereof

InactiveCN1962769AImprove mildew resistanceImprove water resistanceFilling pastesPolymer scienceEmulsion

The invention discloses wood powder putty and preparing method, which comprises the following parts: 100% white emulsion, 15-40% wood powder, 1-3% anti-fungus agent, 1-3% curing agent, wherein the fineness of wood powder is 300-1000 order. The putty possesses excellent painting effect, which is superior to calcium carbonate putty. The invention also provides wooden wares and manufacturing method with the wood powder putty.

Owner:山东堡珍家居板材有限公司

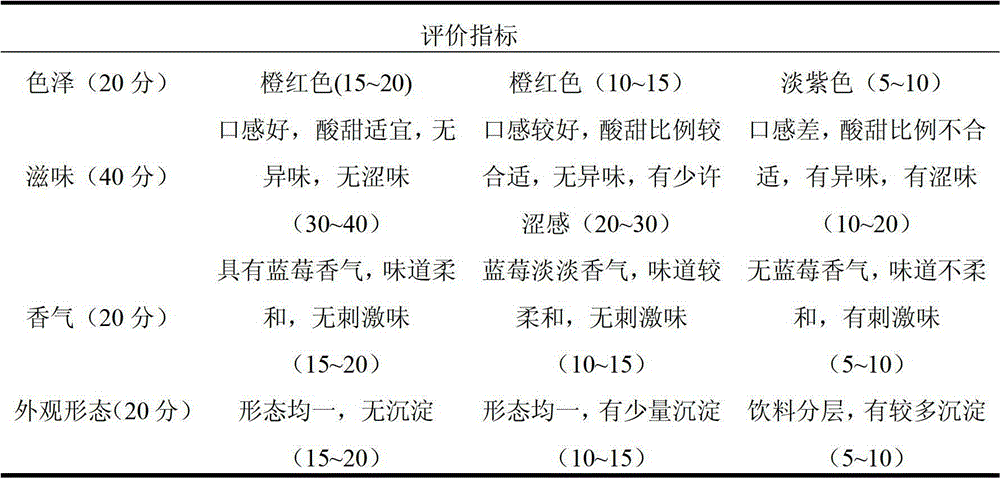

Blueberry eye-pupil-brightening composite granules and preparation method thereof

InactiveCN102742912AHomogeneous tissue stateLoose organizationFood preparationEyes pupilsSodium citrate

The invention provides blueberry eye-pupil-brightening composite granules and a preparation method thereof, relates to a health-care composite granules and a preparation method thereof and aims at solving the problems of visual fatigue and decreased vision of users facing computers for a long period time. The blueberry eye-pupil-brightening composite granules are prepared by blueberry anthocyanin, chrysanthemum yellow pigment, cassia seed extract, maltodextrin, xanthan gum, citric acid, white granulated sugar, honey and sodium citrate. The preparation method comprises the steps of 1 weighing the blueberry anthocyanin, the chrysanthemum yellow pigment, the cassia seed extract, the maltodextrin, the xanthan gum, the citric acid, the white granulated sugar, the honey and the sodium citrate by mass, 2 mixing, 3 performing sterilization, 4 performing homogeneity, 5 performing spray drying, 6 performing granulation and 7 performing drying. The preparation method is mainly used for preparing the blueberry eye-pupil-brightening composite granules.

Owner:大兴安岭兴安有机食品有限公司

Preparation method of molybdenum powder

The invention relates to a preparation method of molybdenum powder, in particular to a process method of the molybdenum powder with even particle size, good dispersibility and no aggregates. The method is characterized by comprising the following steps: taking molybdenum dioxide as a raw material, and firstly sieving and grading the molybdenum dioxide power; respectively reducing the sieved and graded molybdenum dioxide with two temperature regions to obtain the molybdenum powder by a high temperature-first and low temperature-last hydrogen reduction process; and then sieving the prepared molybdenum powder to obtain the molybdenum powder with even particle size, good dispersibility and no aggregates. The method has simple, safe and reliable operation, and is applicable to batch productionof the molybdenum powder; and compared with the conventional molybdenum powder, the molybdenum powder prepared by the method has even particle size, good dispersibility and no aggregates and agglomeration, and is mostly present in a single particle form. Fisher particle size of the finished molybdenum powder is 2.5-4.5 mu m, and yield rate thereof is more than 90% after being sieved with a 500-mesh sieve.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Ultramicro pulpy disperse dye for terylene dyeing

InactiveCN101831203AReduce dosageSmall particle sizeOrganic dyesDyeing processDisperse dyeChemical oxygen demand

The invention aims at providing an ultramicro pulpy disperse dye for terylene dyeing. The ultramicro pulpy disperse dye has the viscosity of more than 3000 cp (an NDJ-1 viscometer), is used for the terylene dyeing, has the advantages of no dust, no foam, no cohesion and sedimentation, no migration, pure color and luster, high color yield, greatly reduced dyeing usage amount and good color fastness without reduction clearing and soaping after the dyeing, multiply reduces the polluted water dyeing and the polluted water discharge, reduces the CODcr (Chemical Oxygen Demand) contained in polluted water and opens a new way for the clean production of printing and dyeing mills.

Owner:朱梁

Infant multi-grain rice flour and preparation method thereof

InactiveCN103535599AImprove immunityPromote gastrointestinal digestionSugar food ingredientsVitamin food ingredientsMultivitaminLactose

The invention discloses infant multi-grain rice flour and a preparation method thereof. The infant multi-grain rice flour is prepared from the following raw materials in parts by weight: 20-40 parts of rice, 15-20 parts of oat, 15-20 parts of corn, 0.5-1.5 parts of galactooligosaccharide and glucose, 0.4-2 parts of soybean protein, 6-10 parts of hawthorn powder and 0.3-0.8 part of compound vitamin and mineral substance. Grains and hawthorn powder are added into the rice flour, so that the nutritive materials are enriched, the immunity of infants can be obviously improved, the gastrointestinal digestion function of the infants is favorably improved, and the enzymatically decomposed rice flour can be more easily absorbed and digested by the infants, can reduce the situations such as inflammation, diarrhea and dyspepsia after being eaten and is safe and reliable.

Owner:SUZHOU WILDER IND & TRADE

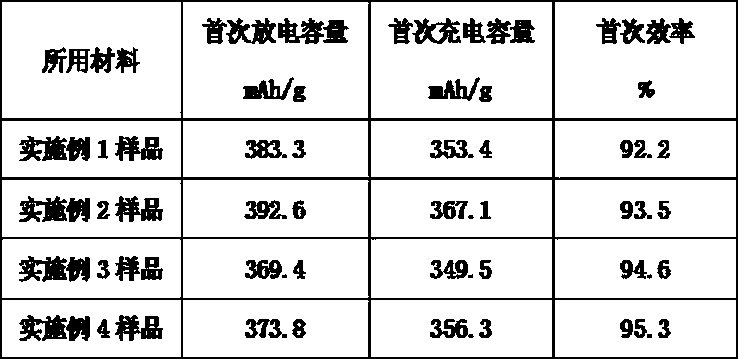

Preparation method for compound lithium ion battery cathode material and application of petroleum resin in preparation method

ActiveCN104201388AUniform and controllable particle sizeIncrease energy densityElectrode thermal treatmentSecondary cellsCarbon coatingHigh rate

The invention discloses a preparation method for a compound lithium ion battery cathode material with high energy density, high-rate-capability charge and discharge performance and good cycle performance, and application of petroleum resin in the preparation method. Petroleum resin is used as a coating material of a core material, particularly as a secondary coating and modifying material. The preparation method comprises steps of liquid preparation, material adding, drying for solidification, carbonization, modification, and high-temperature processing. The preparation technology is simple, and is easy to implement; a liquid phase system is adopted, coating is even and stable, and petroleum resin is adopted as a modifier, so that the modifier and a hard carbon coating layer have good compatibility and binding force, and the specific surface area of the hard carbon coating layer is reduced. The prepared cathode material has the tap density higher than 1.0g / cm<3> and the specific surface area of the prepared cathode material is controlled within 2m<2> / g-5m<2> / g. The prepared battery has the gram volume of 340mAh-370mAh, and supports continuous discharge lower than 40C, the momentary discharge can be higher than 60C, the charge and discharge capacity retention ratio is higher than 92% in 300 weeks, and the first charge and discharge efficiency is higher than 92%.

Owner:湖南宏翔新能源科技有限公司

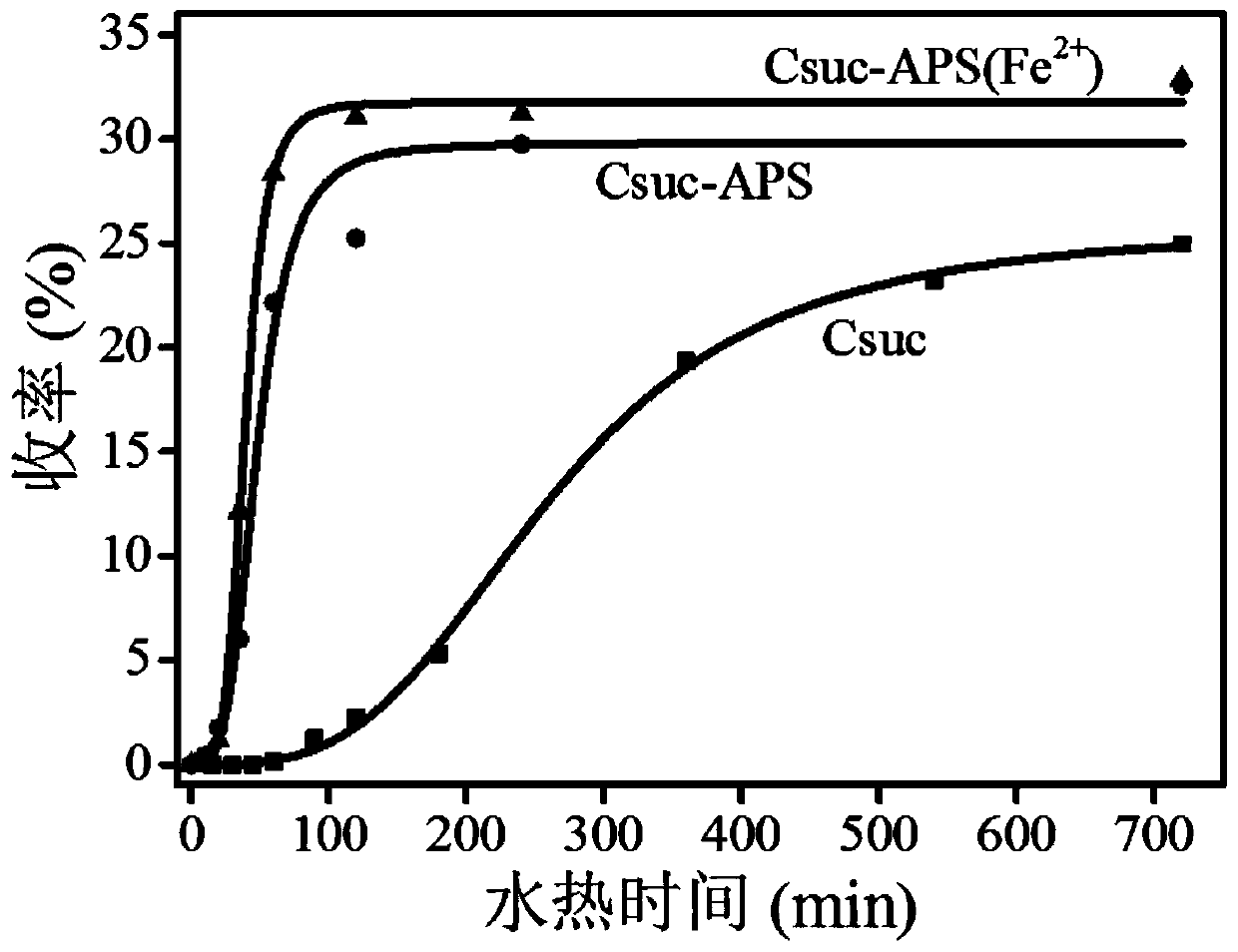

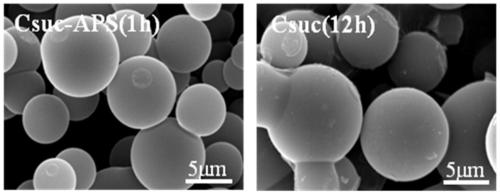

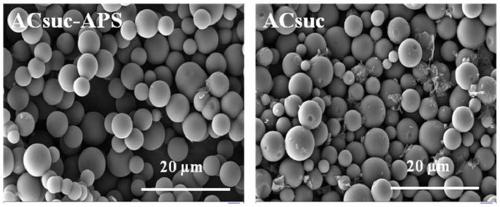

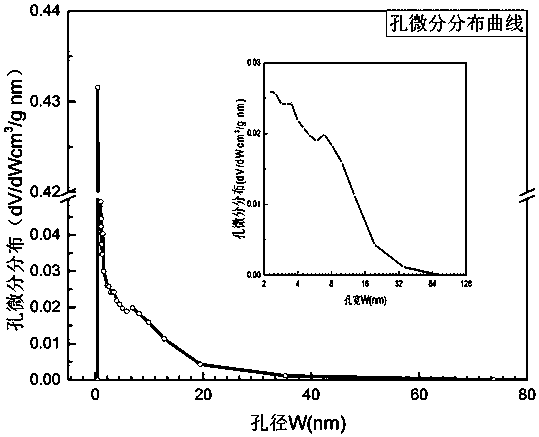

Method for rapidly preparing micron-sized carbon sphere with good dispersibility

ActiveCN109704337AGood dispersionIncrease oxygen contentProductsReagentsActivated carbonRoom temperature

The invention belongs to the technical field of adsorption materials and discloses a method for rapidly preparing a micron-sized carbon sphere with good dispersibility. The method disclosed by the invention comprises the following steps: (1) mixing 6 parts by mass of sugar and 0.2-5 parts by mass of strong oxidant and FeSO4 in water, carrying out heating for a reaction, and carrying out separationto obtain a hydrothermal carbon sphere; and (2) mixing 1 part by mass of hydrothermal carbon sphere obtain in step (1) with 1-5 parts by mass of potassium oxalate, and carrying out high-temperature roasting at an inert atmosphere and the temperature of 500-900 DEG C for 1-5 h to obtain the micron-sized carbon sphere. The method disclosed by the invention is high in reaction speed, the carbon sphere is started to be generated within 5 min since heating is started, and the reaction is to be completed within 1-4 h, so that the reaction time is greatly shortened, and the energy consumption is reduced; the prepared porous activated carbon sphere has abundant micropores and good dispersibility and has the specific surface area of 975-1430 m<2> / g; the adsorption quantity of CO2 at normal temperature and normal pressure is 3.43-3.74 mmol / g; and the method can be used for capturing CO2 at room temperature.

Owner:GUANGZHOU UNIVERSITY

Method for preparing hierarchical porous activated carbon from leaf as template

The invention relates to a method for preparing hierarchical porous activated carbon from a leaf as a template. According to the technical scheme of the method, hierarchical porous activated carbon isprepared from the leaf as the template and heavy duty bitumen as a carbon source with a template coupling method and a thermal decomposition control-partial steam activation method, so that an original structure of the leaf can be reserved in a carbonized decomposition process while bitumen in a melt flowing state can enter the microstructure of the leaf through imprinting and a trans-form structure of the microstructure of the leaf is formed. Activated carbon prepared with the method has obvious hierarchical pore characteristics, a pore diameter distribution curve shows obvious double peaks,micropore percentage is 14.9%-34.9%, and mesopore percentage is 65.0%-85.0%. According to the leaf template coupling technology for preparing hierarchical porous activated carbon, defects that an activating agent in a traditional activated carbon preparation technology is high in cost, corrodes equipment and pollutes environment, a product has chemical residues and the like can be overcome.

Owner:WUHAN UNIV OF SCI & TECH

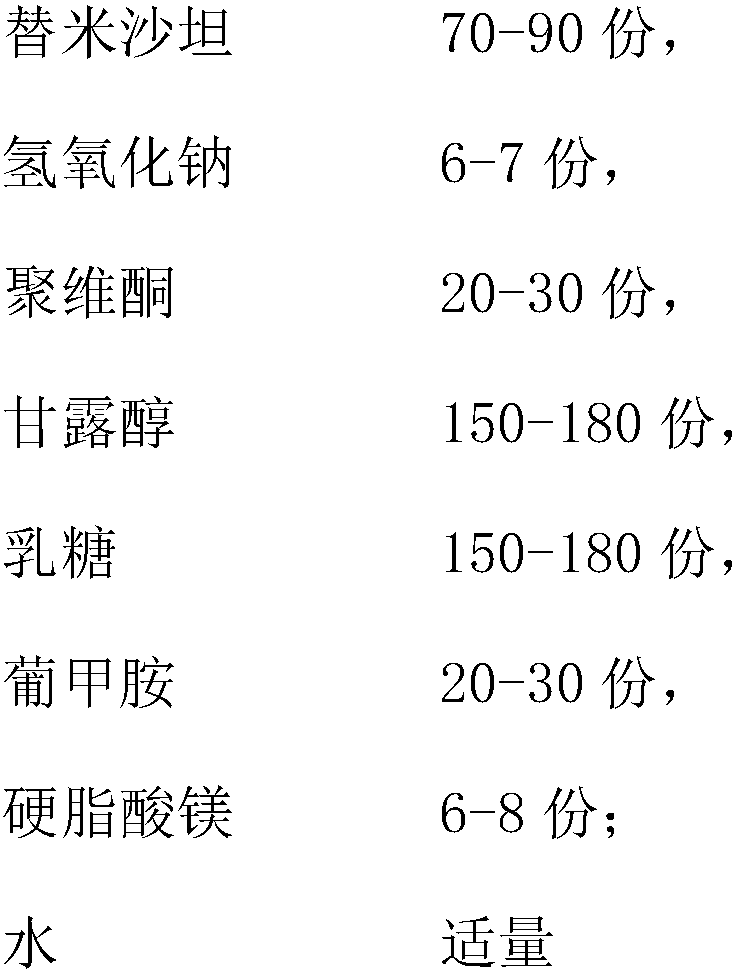

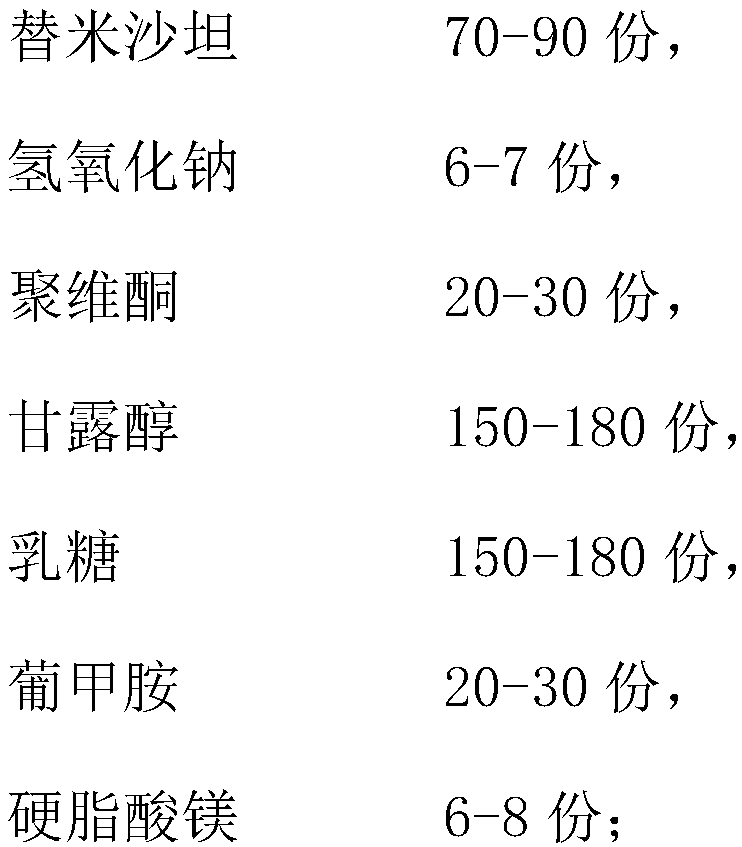

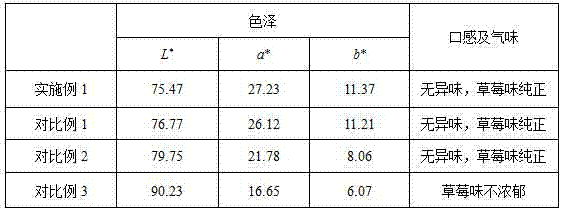

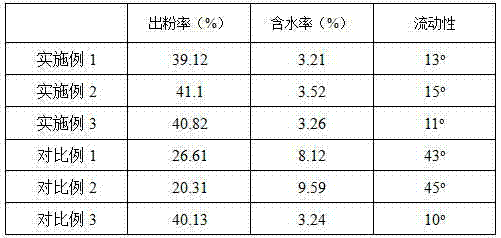

Preparation method of telmisartan tablets

InactiveCN107811984ANo lumpsNo bed collapseOrganic active ingredientsPill deliveryAir volumeAdhesive

The invention relates to a preparation method of telmisartan tablets. The preparation method comprises the following steps: dissolving telmisartan, sodium hydroxide and povidone in purified water forpulping, pelleting with mannitol in a fluidized bed to obtained dried particles, and adding lactose, meglumine and magnesium stearate tablets by adopting an addition method. Equipment conditions adopted according to the invention are as follows: the inlet temperature is 90-95 DEG C (the temperature does not exceed 105 DEG C), the fluidization air volume is 50m<3> / h, the atomizing air pressure is 45psi, and the flow rate of an adhesive is 3r / min.

Owner:南京双科医药开发有限公司

Preparation method of anti-adhering spray-drying fruit powder

The invention relates to a preparation method of fruit powder, in particular to a preparation method of anti-adhering spray-drying fruit powder, and belongs to the technical field of food processing. The method comprises the following steps: carrying out freezing-thawing treatment on fruits which are high in sugar content and easy to decay; preheating, adding glycerel monostearte and calsium lactate stearate, and stirring evenly; and adding a drying aid, carrying out homogenization treatment and then carrying out spray drying. According to the method provided by the invention, the usage amount of maltodextrin is greatly reduced; wall adhering is avoided to the greatest extent; and the prepared fruit powder is bright in color and luster and good in taste, is loose powder without progress, and is good in wettability and pure in flavor.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

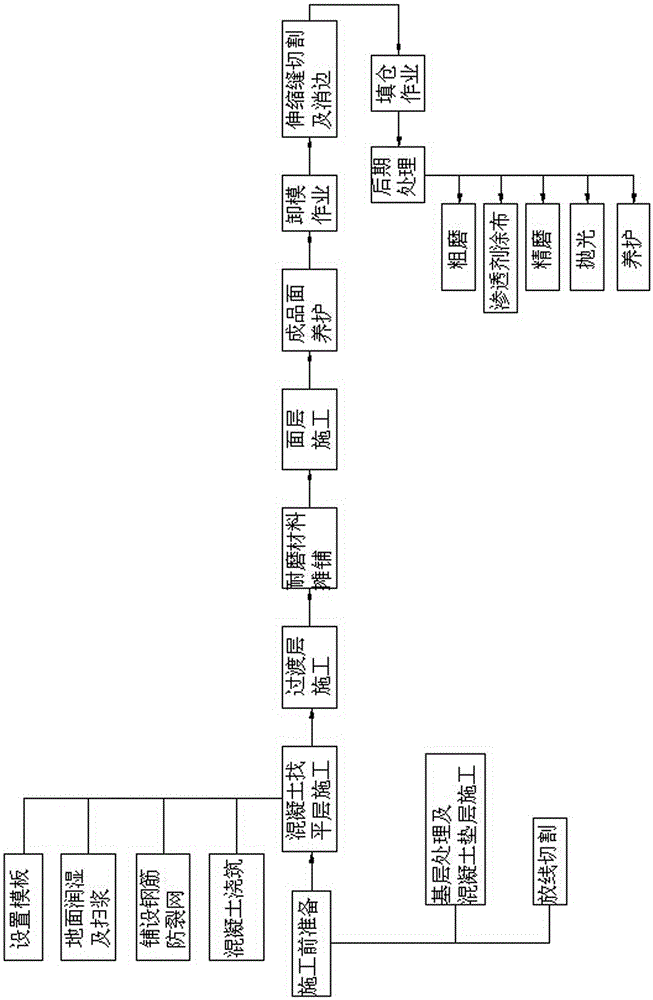

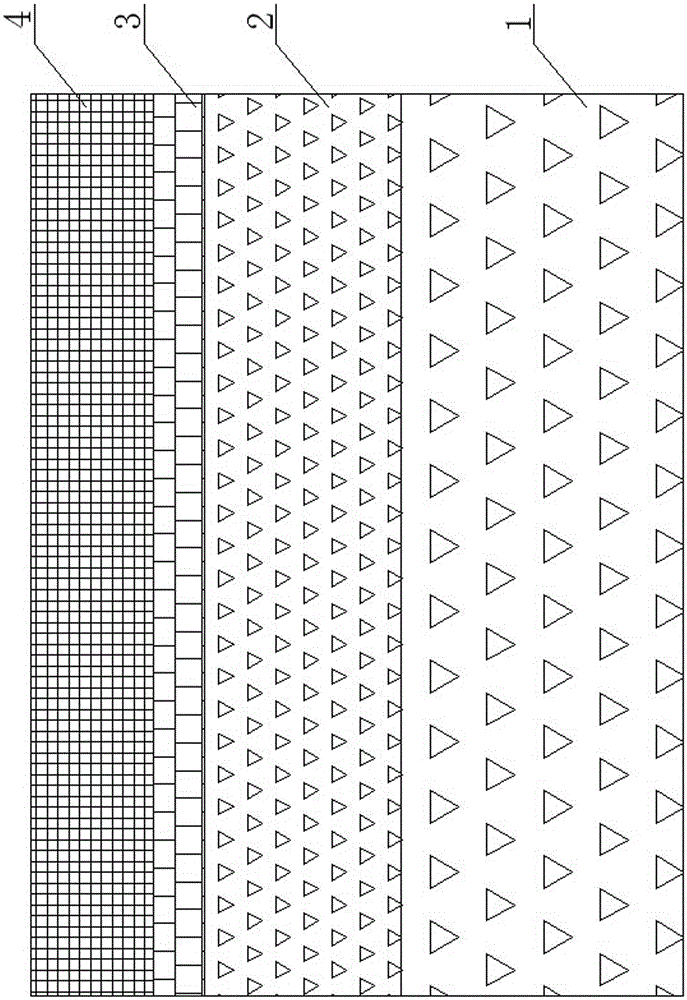

Construction method of wet-on-wet paving type high abrasion resistance terrace

ActiveCN105587102AImprove cleanlinessQuality assuranceBuilding material handlingFlooringSlurryEngineering

The invention discloses a construction method of a wet-on-wet paving type high abrasion resistance terrace, and relates to the technical field of terrace manufacturing. The terrace manufactured through the construction method is high in strength, good in abrasion resistance, consistent in overall color and good in appearance quality. The construction method comprises the steps of concrete cushion construction, paying-off cutting, template setting, concrete cushion slurry sweeping, pavement of a rebar anti-cracking net, concrete leveling layer construction, transition layer construction, abrasion resisting layer construction, finished terrace face construction, terrace maintenance, template removal, terrace expansion joint cutting, paying-off carried out on concrete on the two sides of the wide edge of the terrace, cutting of damaged and bent parts through a large cutting saw, bin filling operation after manual chiseling-off, and permeation polishing treatment carried out on the terrace after bin filling operation. According to the constructed terrace, the overall aesthetic extent and applicability are ensured, the effects of hardening, compaction, sealing and dust prevention are achieved, and the properties of high abrasion resistance, high scratch resistance, high impact resistance, high cleanliness degree and the like are achieved.

Owner:黑龙江泽林科技有限公司

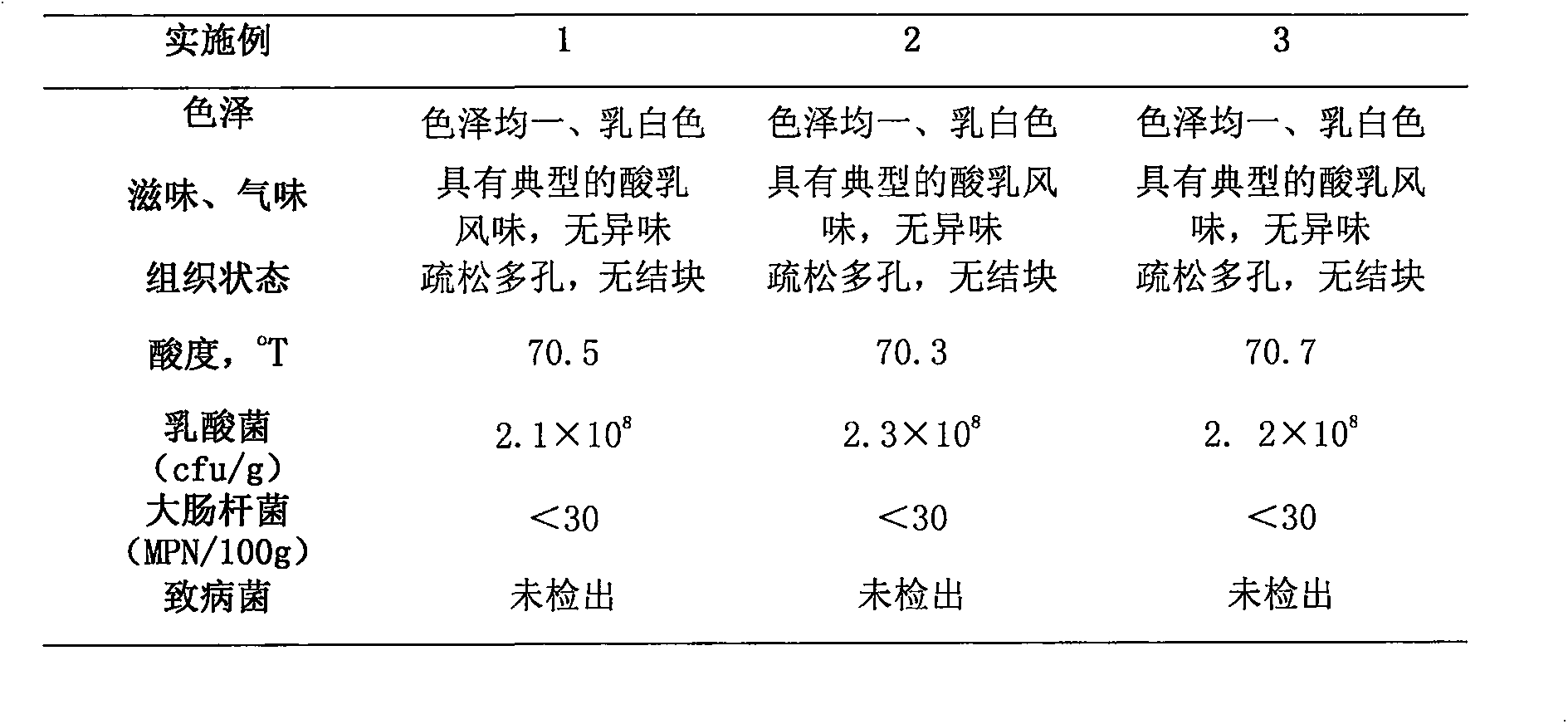

Method for preparing Tibetan spiritual mushroom yoghurt powder

The invention discloses a method for preparing Tibetan spiritual mushroom yoghurt powder. The method comprises the following steps of: pretreating and sterilizing raw material emulsion, performing starter propagation, performing incubation and fermentation, and finally freezing and drying. The method for preparing the Tibetan spiritual mushroom yoghurt powder has the advantages of simple process and easiness in operation. The Tibetan spiritual mushroom yoghurt powder is uniform in color, is milky or light-yellow powdered, loose and multihole and block-free, has typical yoghurt flavor, can sink quickly after being wetted; and after the Tibetan spiritual mushroom yoghurt powder is mixed with water, no block exits.

Owner:GANSU AGRI UNIV

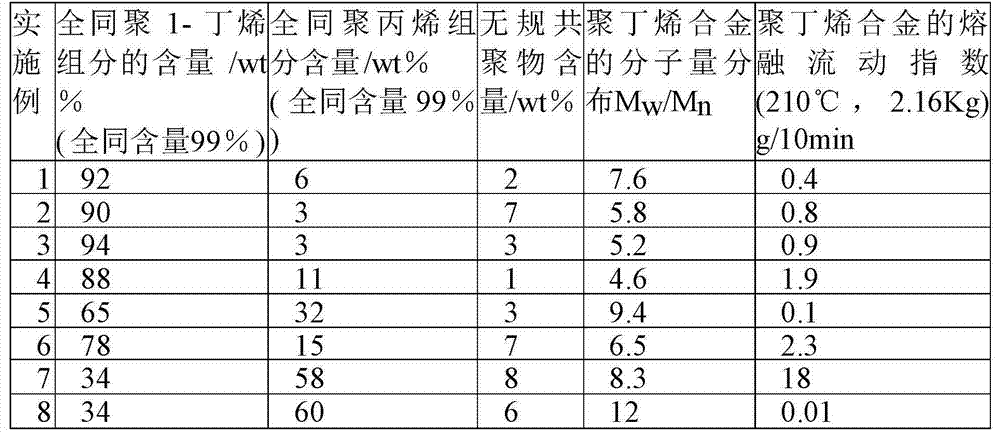

Preparation method of polyolefin alloy

The invention discloses a gas-phase bulk polymerization method of a polyolefin alloy, in particular a polybutene alloy material. The method is characterized by (1) adopting a continuous or batch polymerization process; (2) performing gas phase polymerization of the polybutene alloy material in a single gas phase reactor or two or more gas phase reactors which are connected in series; and (3) respectively implementing homopolymerization of two monomers in two stages. The method adopts a single heterogeneous Ziegler-Natta catalyst which has multiple active centers and good hydrogen sensitivity to catalyze stage-by-stage polymerization of butene-1 and propylene, so that the polybutene alloy material which is less in catalyst residue and good in particle shape, does not have agglomerates and has a core-shell structure can be obtained. The prepared polybutene alloy material comprises the following components in percentage by mass: 10-99% of polybutene-1, 1-80% of polypropylene and 0.01-10% of butene-1-propylene copolymer, and can be used for replacing part of polyethylene and polypropylene in use.

Owner:QINGDAO UNIV OF SCI & TECH +1

Graphene added anticorrosion latex paint for outer wall and preparation method thereof

InactiveCN104877504AImprove adhesionHigh adhesion, good strengthAnti-corrosive paintsEmulsion paintsCelluloseWater based

The invention discloses a graphene added anticorrosion latex paint for an outer wall. The graphene added anticorrosion latex paint is characterized by being prepared from the following raw materials in parts by weight: 38 to 35 parts of pure acrylic emulsion, 7 to 9 parts of water-based fluorine carbon emulsion, 2 to 3 parts of silicone oil, 20 to 23 parts of rutile titanium dioxide, 5 to 6 parts of graphene, 7 to 9 parts of zeolite, 7 to 9 parts of pearl wool leftovers, 105 to 107 parts of water, 1.5 to 2 parts of asolo-OT, 3 to 4 parts of carrageenan, 2 to 3 parts of ammonium bicarbonate, 0.8 to 1 part of lignocelluloses, and 0.5 to 0.7 part of 1, 2-benzisothiazolin-3-ketone. According to the graphene added anticorrosion latex paint, pure acrylic emulsion and water-based fluorine carbon emulsion are prepared into a filming base material which is outstanding in weather resistance and water resistance; surface activated fillers are added to improve the corrosion resistance and insulation performance of the coating; the prepared coating paint film is high in attaching force, high in strength, difficult to crack and high in corrosion resistance.

Owner:合肥启华环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com