Construction method of wet-on-wet paving type high abrasion resistance terrace

A construction method and high wear-resistant technology, applied in the processing of building materials, floors, buildings, etc., can solve the problems of uneven color, affecting the appearance quality, insufficient density of footprint areas, etc., and achieve the effect of enhanced stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

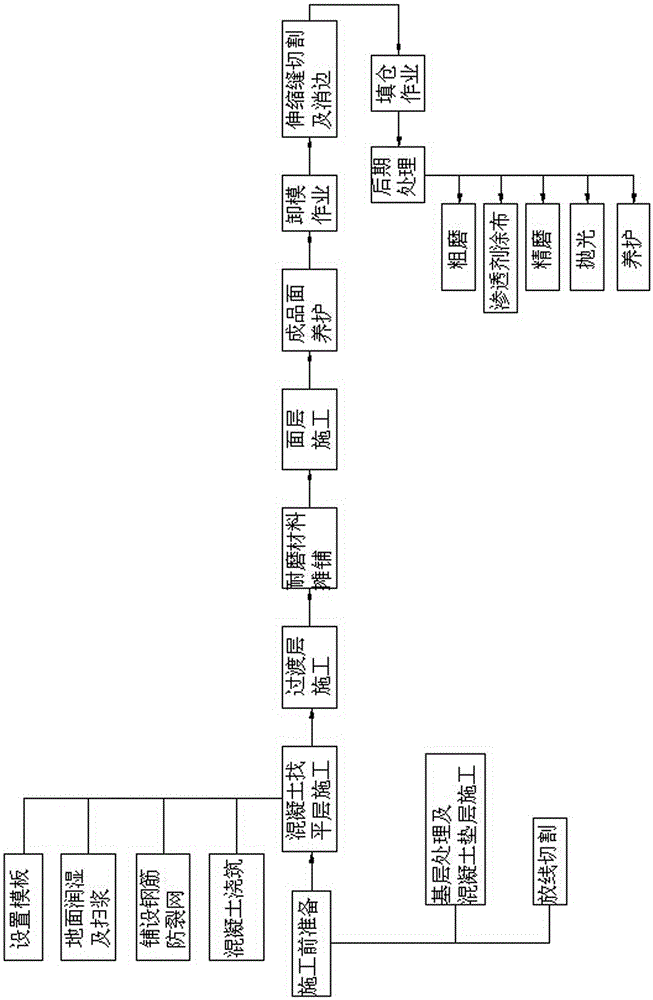

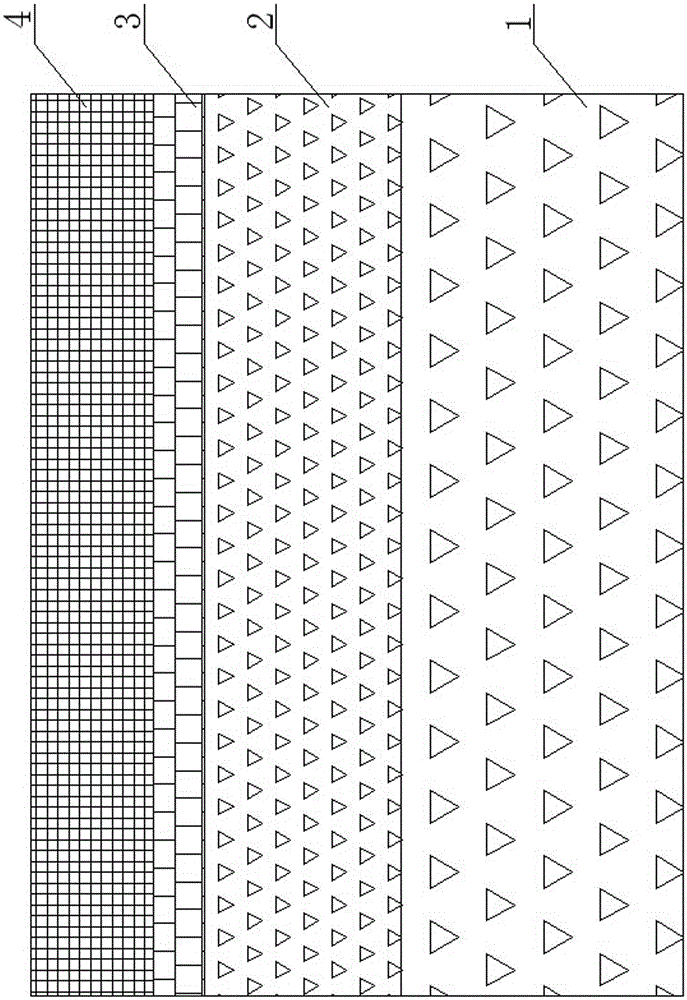

[0027] Specific implementation mode one: as figure 1 with figure 2 As shown, this embodiment discloses a construction method of a wet-to-wet paving type high wear-resistant floor, and the steps of the construction method are as follows:

[0028] Step 1: base treatment and concrete cushion construction; first, sprinkle water to wet the base, then use a compactor to roll the base, use a tamping machine to tamp the corners, and finally pour the concrete cushion 1, and perform grinding, leveling;

[0029] Step 2: setting-out cutting; on the concrete cushion 1, the north-south setting-out degree is 4~6m, and the east-west setting-out cutting is carried out according to the distance between the supporting columns (the garbage generated by cutting the expansion joints shall be cleaned up in time), mark the side

[0030] Step 3: Set up the formwork; set up the formwork according to the design elevation of the ground and apply the formwork oil, set the formwork according to the dir...

specific Embodiment approach 2

[0046] Embodiment 2: The construction method of the wet-to-wet paving type high wear-resistant and wear-resistant floor described in Embodiment 1. In step 7, the transition material is 20-30 parts by weight of special cement, bone 50-60 parts of raw materials, 20-30 parts of anti-cracking materials, 5-10 parts of functional additives, and mixed. Since the paving material is a cement-based material with extremely high strength and density, its strength is several grades higher than that of the base concrete. To make the paving material and the base concrete well combined without shrinkage and hollowing, excessive material must be used. In addition, because the base concrete is still in the reaction process of cement during the construction process, its water heating has not been completely released, and the transition material can accelerate the release of the water heating of the base concrete.

[0047] The special cement is preferably p.o52.5 cement; the aggregate is preferab...

specific Embodiment approach 3

[0048] Specific embodiment 3: The construction method of wet-to-wet paving type high wear-resistant wear-resistant floor described in specific embodiment 1, in step 8 and step 9, the wear-resistant materials used are the same, and the weight ratio is special cement 20-30 parts, 60-70 parts of aggregate, 10-20 parts of anti-cracking material, 5-10 parts of functional additives, 5-10 parts of pigments and fillers, mixed together. Paving construction is the most critical part of this design. The physical properties of the entire system are mainly realized by paving materials. Due to the chemical properties and physical properties of various materials used, the finished product can achieve high strength, high Density, good toughness, and little impact energy absorption, can finally realize the physical properties of this system product. In order to meet the different requirements of different customers and different pursuits of appearance effects, the use of the above wear-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com