Method for preparing rice powder by adopting double-enzyme hydrolysis process and rice powder

A dual-enzyme hydrolysis and rice flour technology, which is applied in the food field, can solve the problems of caking, indigestion, poor brewing performance, etc., and achieve the effect of high quality and easy brewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

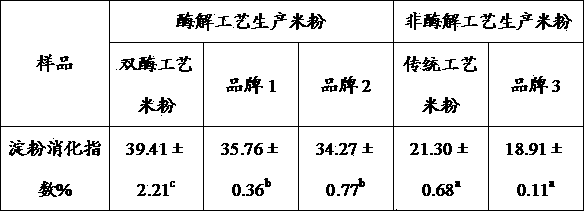

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Pour the finished rice into the rice washing tank and wash it once with tap water for 20 minutes;

[0047] (2) Drain the water after washing, and let the rice dry for 40 minutes. The moisture content of the rice should be controlled at 25% in terms of mass percentage;

[0048] (3) Use a pulverizer to grind rice flour so that at least 80% of the rice flour passes through an 80-mesh sieve, measured in mass percentage;

[0049] (4) Add 70°C water to adjust the rice flour to a rice starch milk with a mass concentration of 35%;

[0050] (5) Immediately add 0.04‰ (dry weight of rice starch milk) α-amylase and 1.0% (dry weight of rice starch milk) β-amylase, stir evenly and keep warm for 20 minutes for hydrolysis;

[0051] (6) Add auxiliary materials, among which the auxiliary materials are: 2% milk powder, 5% whey protein concentrate, 10% soybean protein isolate, all of which are calculated on the dry basis of rice starch milk, and the dry matter concentration in the mix...

Embodiment 2

[0060] (1) Pour the finished rice into the rice washing tank and wash it once with tap water for 20 minutes;

[0061] (2) Drain the water after washing, and let the rice dry for 30 minutes. The moisture content of the rice should be controlled at 25% in terms of mass percentage;

[0062] (3) Use a pulverizer to grind rice flour so that at least 80% of the rice flour passes through an 80-mesh sieve, measured in mass percentage;

[0063] (4) Add 65°C water to adjust the rice flour to a rice starch milk with a mass concentration of 40%;

[0064] (5) Immediately add 0.2‰ (dry weight of rice starch milk) α-amylase and 0.2% (dry weight of rice starch milk) β-amylase, stir evenly and keep warm for 20 minutes for hydrolysis;

[0065] (6) Add auxiliary materials, among which the auxiliary materials are: 15% milk powder, 1% whey protein concentrate, and 1% soybean protein isolate, all of which are calculated on the dry basis of rice starch milk, and the dry matter concentration in the ...

Embodiment 3

[0074] (1) Pour the finished rice into the rice washing tank and wash it twice with tap water for about 30 minutes;

[0075] (2) Drain the water after washing, and dry the rice for 50 minutes. The moisture content of the rice should be controlled at 28% in terms of mass percentage;

[0076] (3) Use a pulverizer to grind rice flour so that at least 80% of the rice flour passes through an 80-mesh sieve, measured in mass percentage;

[0077] (4) Add 75°C water to adjust the rice flour to a rice starch milk with a mass concentration of 38%;

[0078] (5) Immediately add 0.1‰ (dry weight of rice starch milk) α-amylase and 0.5% (dry weight of rice starch milk) β-amylase, stir evenly and keep warm for 15 minutes for hydrolysis;

[0079] (6) Add auxiliary materials, among which the auxiliary materials are: 5% milk powder, 10% whey protein concentrate, and 10% soybean protein isolate, all of which are calculated on a dry basis of rice starch milk, and the dry matter concentration in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com