Low concentration acid gas low-sulfur emission sulphur recovery process

A technology of sulfur recovery and acid gas, which is applied in the direction of sulfur preparation/purification, energy input, etc., can solve the problems that waste sulfur can not be effectively used, more safety and environmental pollution, and affect the safety of operators, etc., to achieve scrap disposal Good conditions, good safe operation conditions, and good site environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

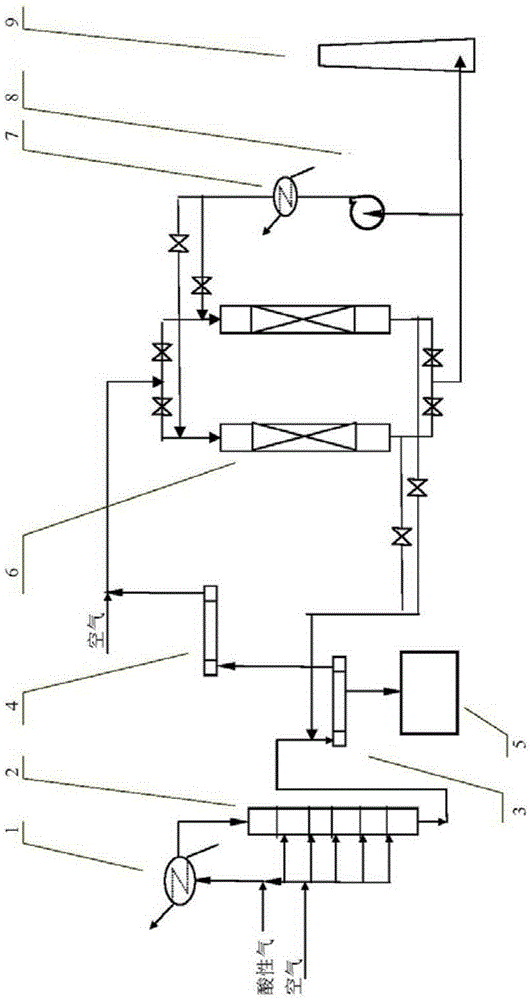

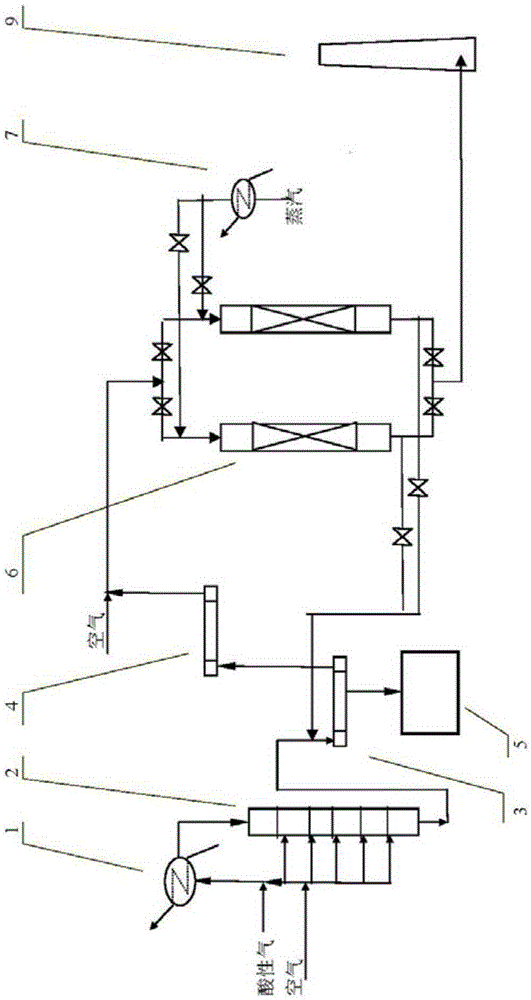

[0043] A set of 10,000 tons / year sulfur recovery unit, including selective oxidation reactor and two adsorption desulfurization towers that can be connected in series and parallel, the selective oxidation reactor is filled with Fe 2 o 3 / SiO 2 selective oxidation of H 2 S Catalyst 60m 3 , the catalyst is packed in 6 layers, and a cooling coil is installed between the layers to generate steam; two adsorption desulfurization towers are filled with Na 2 CO 3 / Activated carbon catalytic oxidation adsorption desulfurizer 150m 3 ; The basic operating conditions of the device are:

[0044] 1) Acid gas 28000m 3 / hr,H 2 S volume content 3.6%, the rest is mainly CO 2 , COS≤20mg / m 3 , SO 2 ≤100mg / m 3 , the difficult-to-handle CS 2 , with air 2400m 3 / hr or so, preheated to 200°C and enters the selective oxidation reactor, H 2 S is selectively oxidized to elemental sulfur. The process gas from the selective oxidation reactor enters the medium temperature condenser and is co...

Embodiment 2

[0054] A set of 10,000 tons / year sulfur recovery unit, including selective oxidation reactor and two adsorption desulfurization towers that can be connected in series and parallel, the selective oxidation reactor is filled with Fe 2 o 3 / SiO 2 selective oxidation of H 2 S Catalyst 60m 3 , the catalyst is packed in 6 layers, and a cooling coil is installed between the layers to generate steam; the two adsorption desulfurization towers are filled with Fe 2 o 3 / Activated carbon catalytic oxidation adsorption desulfurizer 140m 3 ; The basic operating conditions of the device are:

[0055] 1) Acid gas 20000m 3 / hr,H 2 S volume content 5%, the rest is mainly CO 2 , SO 2 ≤100mg / m 3 , excluding COS, CS 2 , mercaptan, sulfide and other organic sulfur; with air 2400m 3 / hr or so, preheated to 200°C and enters the selective oxidation reactor, H 2 S is selectively oxidized to elemental sulfur. The process gas from the selective oxidation reactor enters the medium temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com