Patents

Literature

105results about How to "High desulfurization precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for hydrolyzing carbonyl sulfur and preparation method thereof

InactiveCN101559379AWide concentration rangeHigh desulfurization precisionDispersed particle separationCatalyst activation/preparationMass ratioHydrolysis

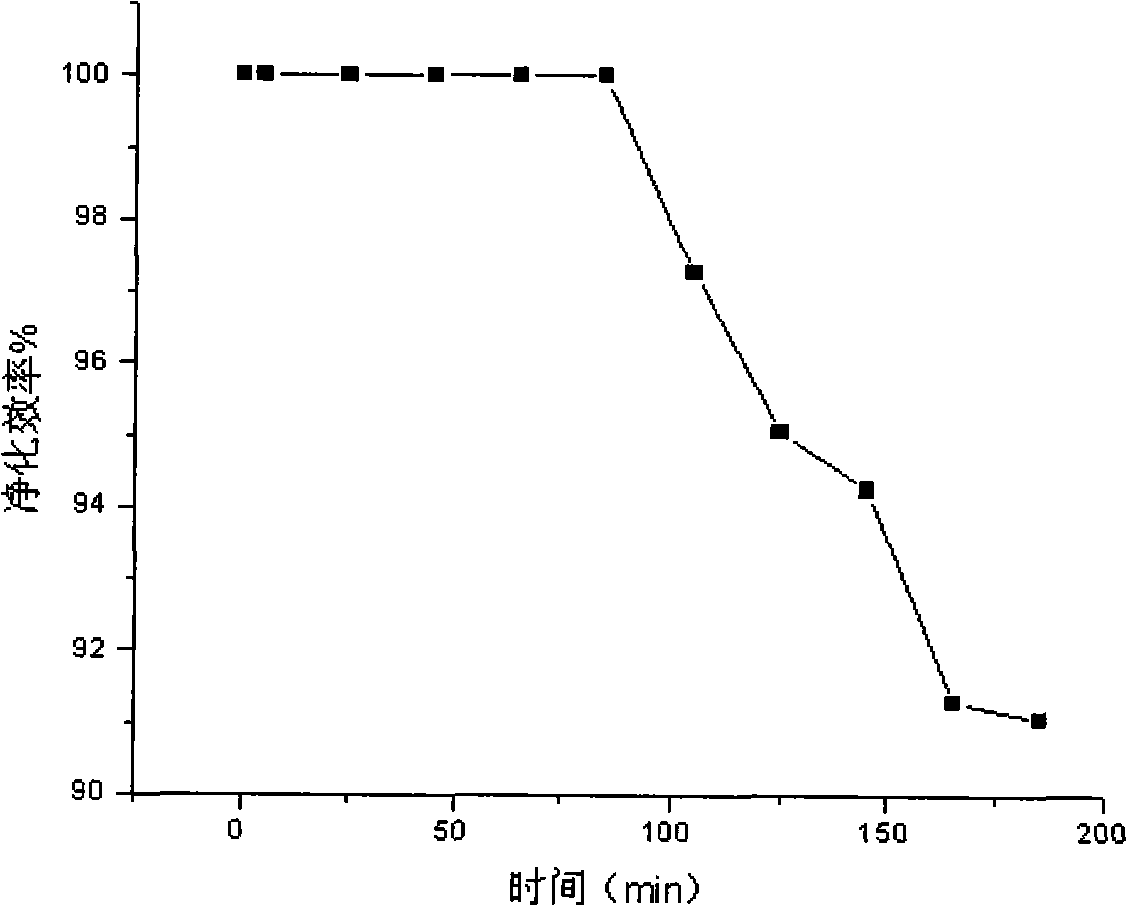

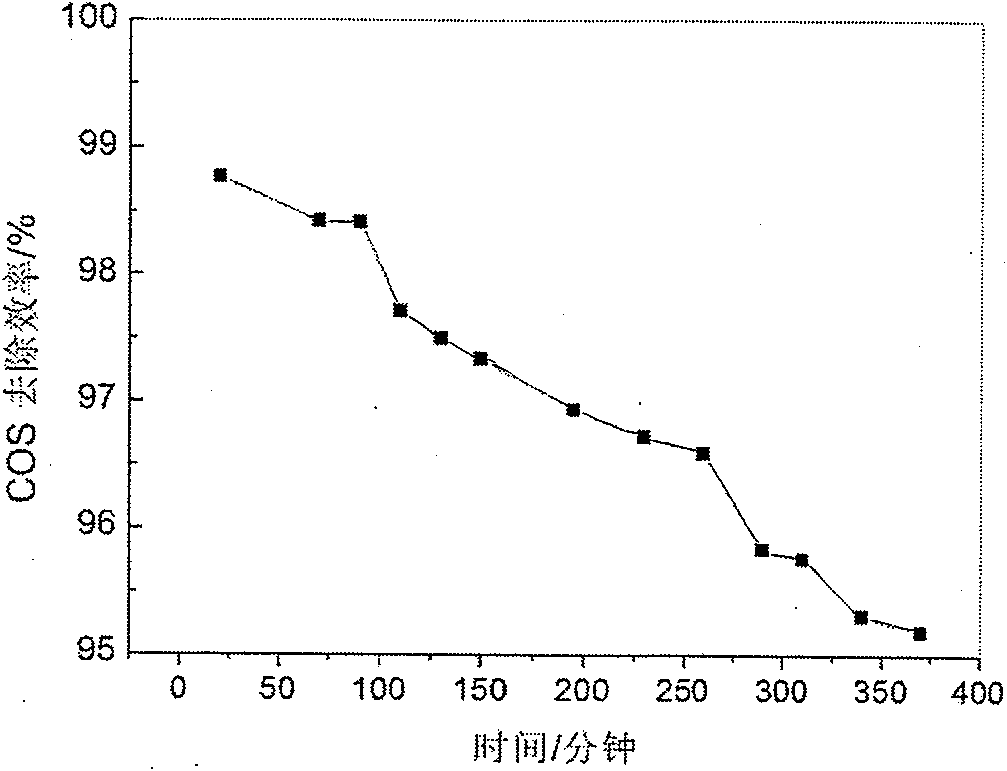

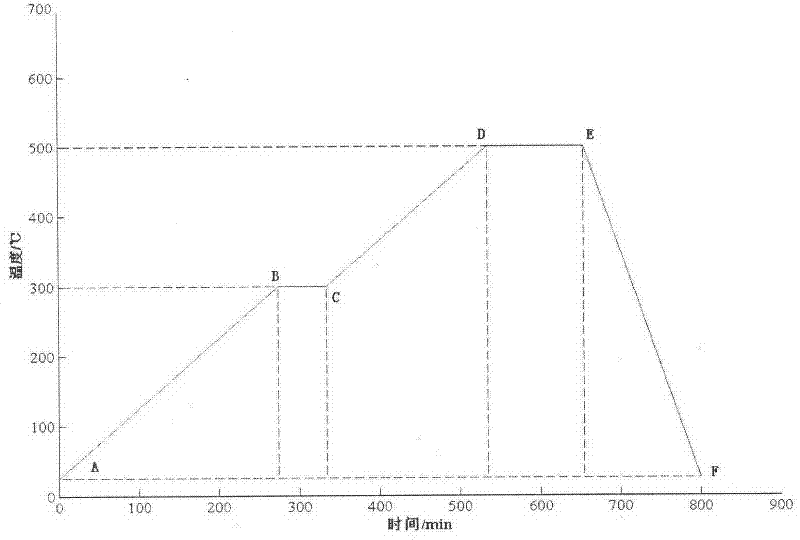

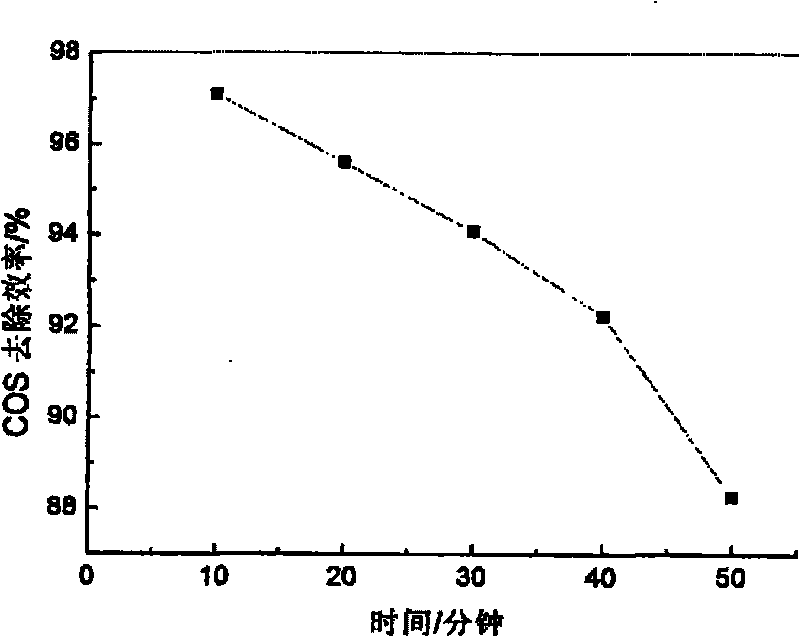

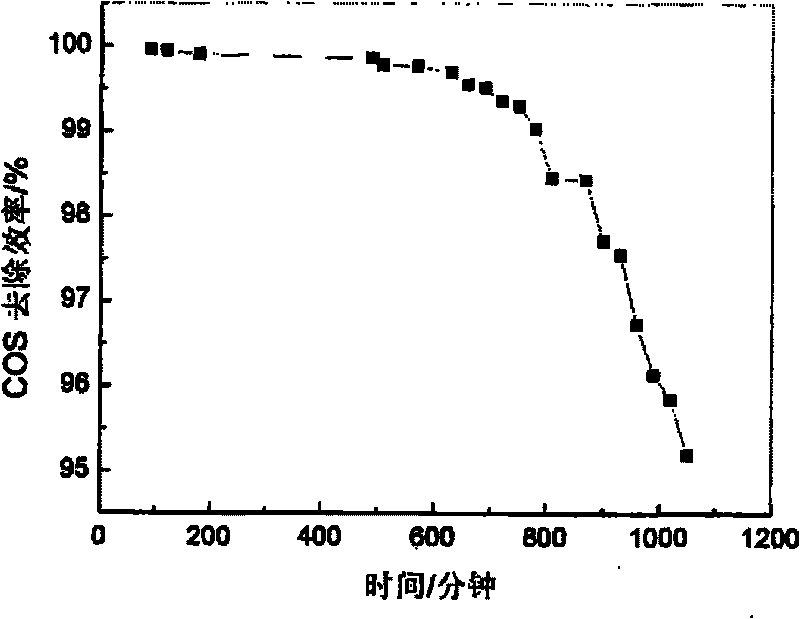

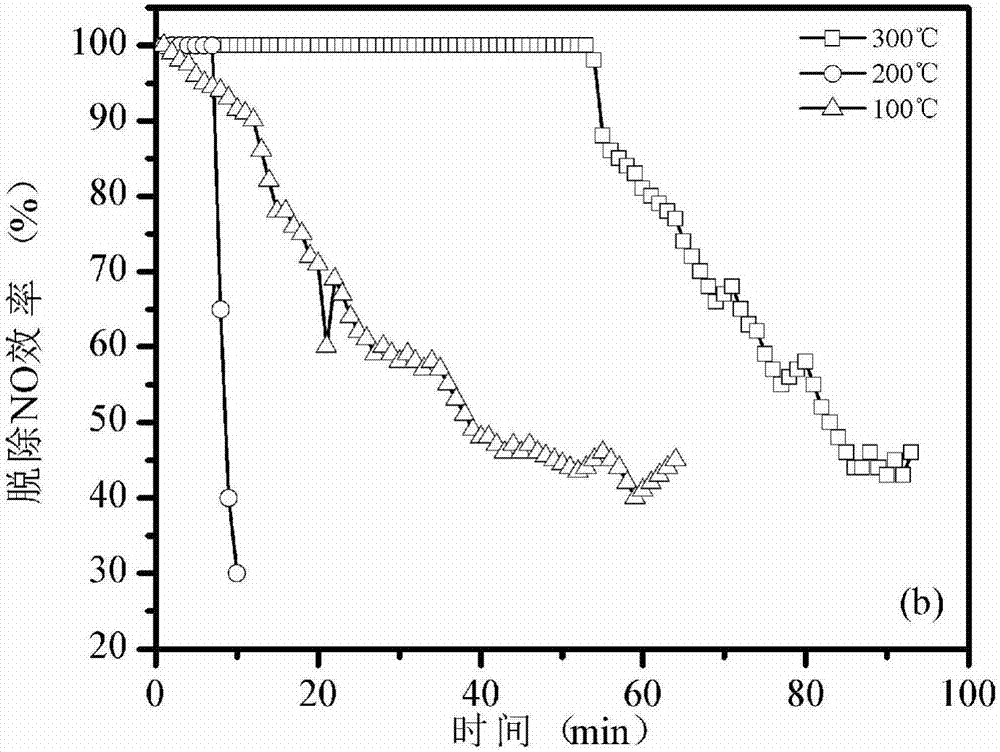

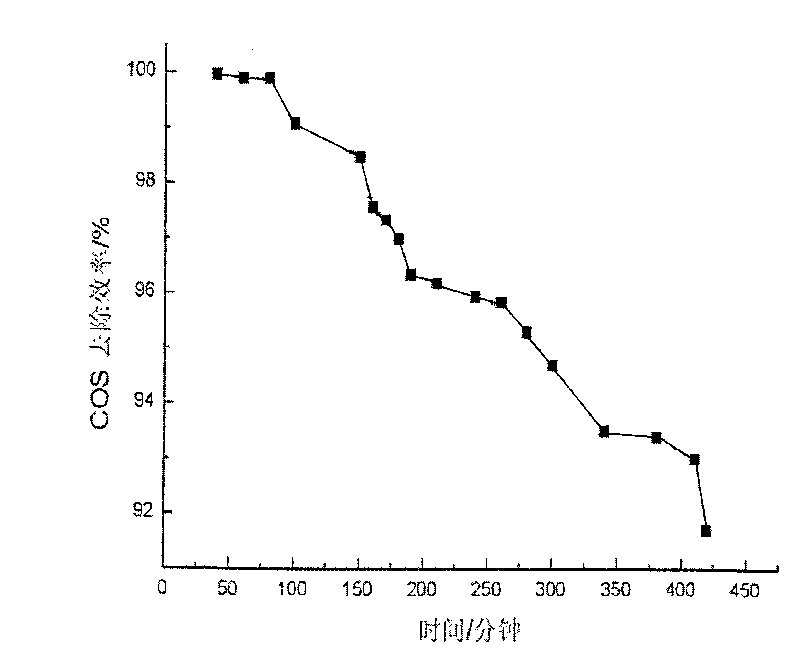

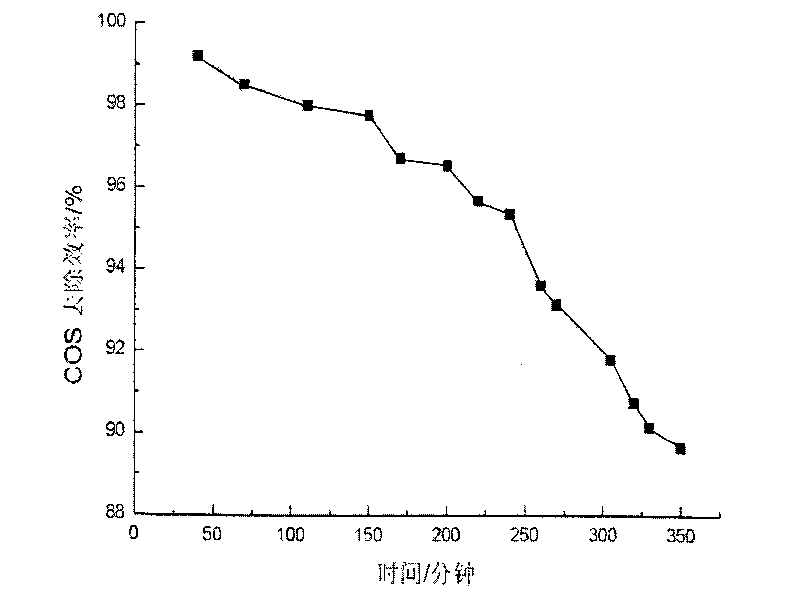

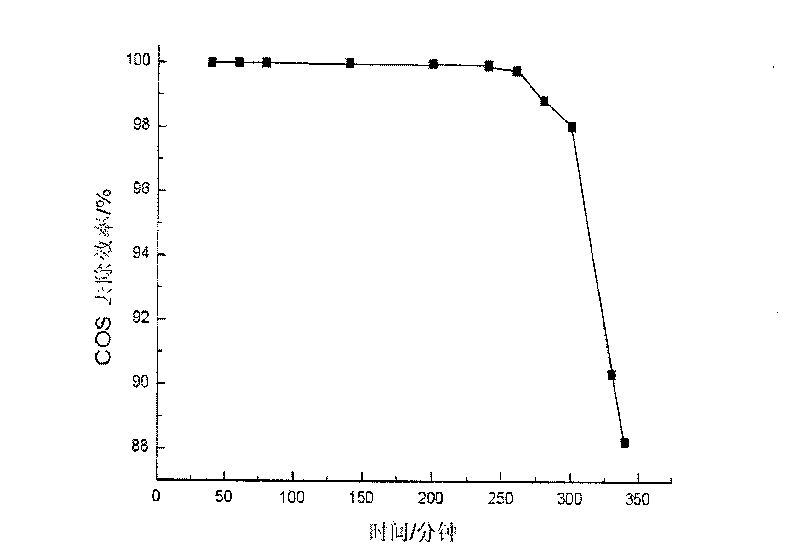

The invention discloses a catalyst for hydrolyzing active carbon-based COS under the condition of low temperature and a preparation method thereof, wherein a carrier of the catalyst is active carbon, and active compositions of the catalyst are alkali materials and metal oxide. The catalyst can remove COS in air at a low temperature (between 30 and 100 DEG C) and remove H2S generated by hydrolysis together. The preparation method comprises the following steps: firstly, using running water and distilled water to wash the active carbon, and drying the active carbon for 2 to 4 hours at a temperature of between 110 and 180 DEG C, wherein the active carbon can be coal and coconut husks; secondly, using a 1 mol / L KOH solution to boil the washed active carbon for 1.5 to 2 hours, performing modification treatment, and using distilled water to wash the solution until the pH value is approximately 6.0; thirdly, selecting one or more metallic salt solutions to soak the active carbon, performing modification treatment, and performing ultrasonic soakage for 0.5 to 1 hour, wherein the content of a soaking liquid is 10 to 90 percent of the mass ratio of the active carbon, and the volume of the soaking liquid is as follows: 20 milliliters of the soaking liquid is added into 10 grams of the catalyst; fourthly, drying the soaked active carbon for 2 to 6 hours in a 120 DEG C constant-temperature drying cabinet, and activating the catalyst for 2 to 4 hours under the protection of 300 to 600 DEG C N2; and fifthly, performing ultrasonic soakage on the activated catalyst in the fourth step in an alkali solution for 0.5 to 1 hour.

Owner:KUNMING UNIV OF SCI & TECH

Absorbent charcoal based catalyst for hydrolyzation and catalysis of carbonyl sulphur in low-temperature and preparation method thereof

InactiveCN101318130AWide concentration rangeHigh desulfurization precisionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationActivated carbonAlcohol

The invention provides an active carbon based catalyst for hydrolyzing and catalyzing carbonyl sulfur in low temperature, which is characterized in that the catalyst takes active carbon as a carrier and is prepared by the following method: washing the active carbon, drying the active carbon for 2-4 hours under 100-140 DEG C; impregnating the active carbon in the (A) step for 6-12 hours with the impregnation liquid of alkaline substances or metal oxides or organic alcohol amine, wherein, the mass content of the alkaline substances or the metal oxides or the organic alcohol amine accounts for 5-30 percent of that of the active carbon; drying the impregnated active carbon for 2-6 hours under the constant temperature of 100-140 DEG C and then activating the active carbon for 2-4 hours under the temperature of 300-500 DEG C and the protection of N2. The catalyst can be used for catalyzing and hydrolyzing COS and removing H2S; furthermore, the catalyst can remove the COS in the gas under the temperature of 30-100 DEG C, ensure the conversion rate of the COS to be larger than 90 percent and remove the H2S generated in hydrolysis at the same time. The COS concentration which is between 100-1500ppm has a wide adaptive range, high desulfurization accuracy and higher breakthrough sulfur capacity.

Owner:KUNMING UNIV OF SCI & TECH

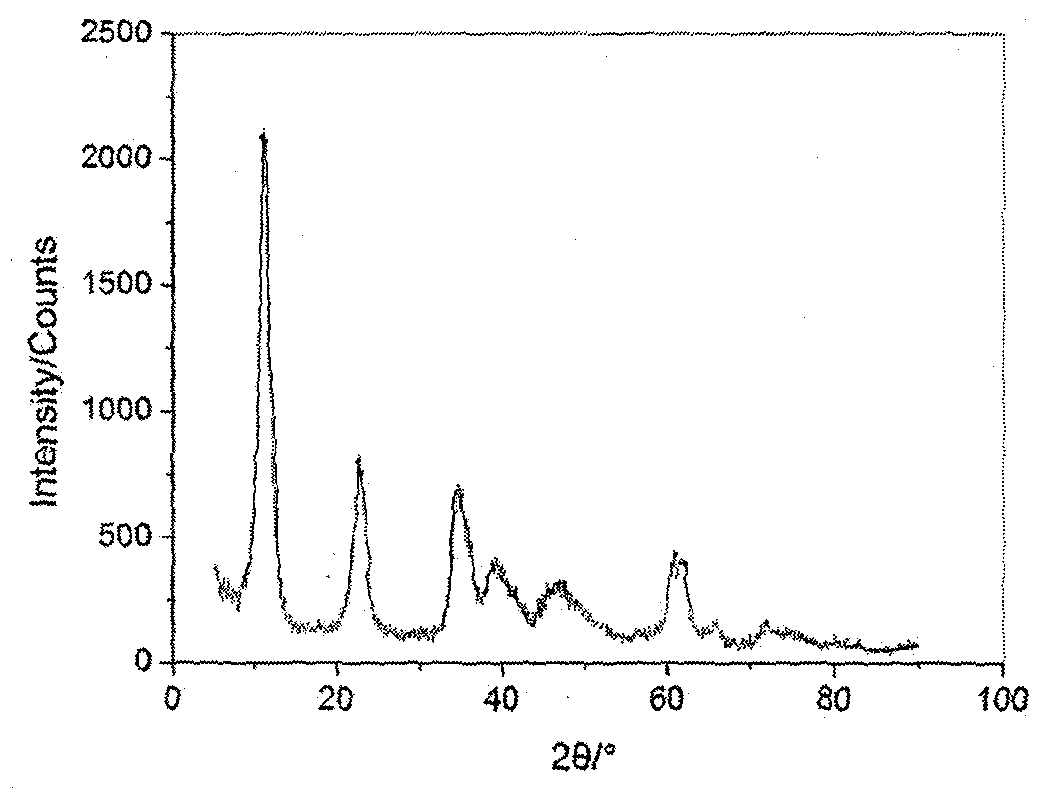

Application of nanometer copper oxide and the method of preparing the same

InactiveCN101041119AHigh desulfurization precisionSimple preparation processNanostructure manufactureDispersed particle separationLow demandSulfur

The invention relates to an application of nanometer copper oxide and the preparing method, belonging to an application of compound and the preparing method. Before the invention, there are not reports that single nanometer copper oxide is used as ambient temperature desulfurizer and the purity of nanometer copper oxide prepared by prior preparing method for nanometer copper oxide is low. In the invention, the nanometer copper oxide is used as the ambient temperature desulfurizer and the nanometer copper oxide is the only component of ambient temperature desulfuizer. The preparation of nanometer copper oxide is that sodium hydroxide is added in the copper nitrate solution and then it is filtered, dried and baked or the preparation of nanometer copper oxide is that sodium hydroxide is added in the copper nitrate solution and then it is filtered and dried. The desulfurization accuracy of nanometer copper oxide in the invention is high in ambient temperature condition and the sulfur capacity is high to 18.3%-28.7%. The purity of nanometer copper oxide prepared in the invention is higher than 99.9%. It is provided with simple preparing process, low demand for machining equipment, small energy consumption and low production cost. It is easy to be developed and implemented.

Owner:HARBIN INST OF TECH

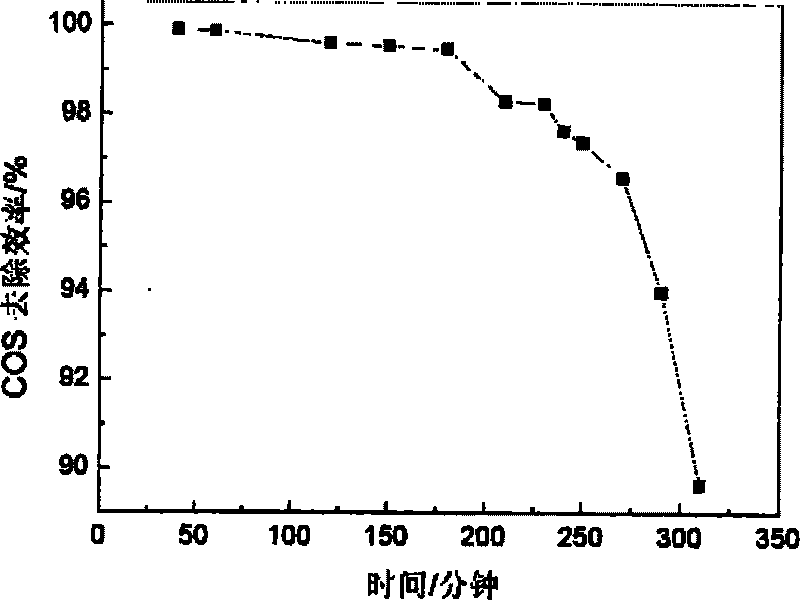

Carbonyl sulfide hydrolysis catalyst prepared by using cobalt(Co)-nickel(Ni)-aluminum(Al) hydrotalcites as precursor and preparation method thereof

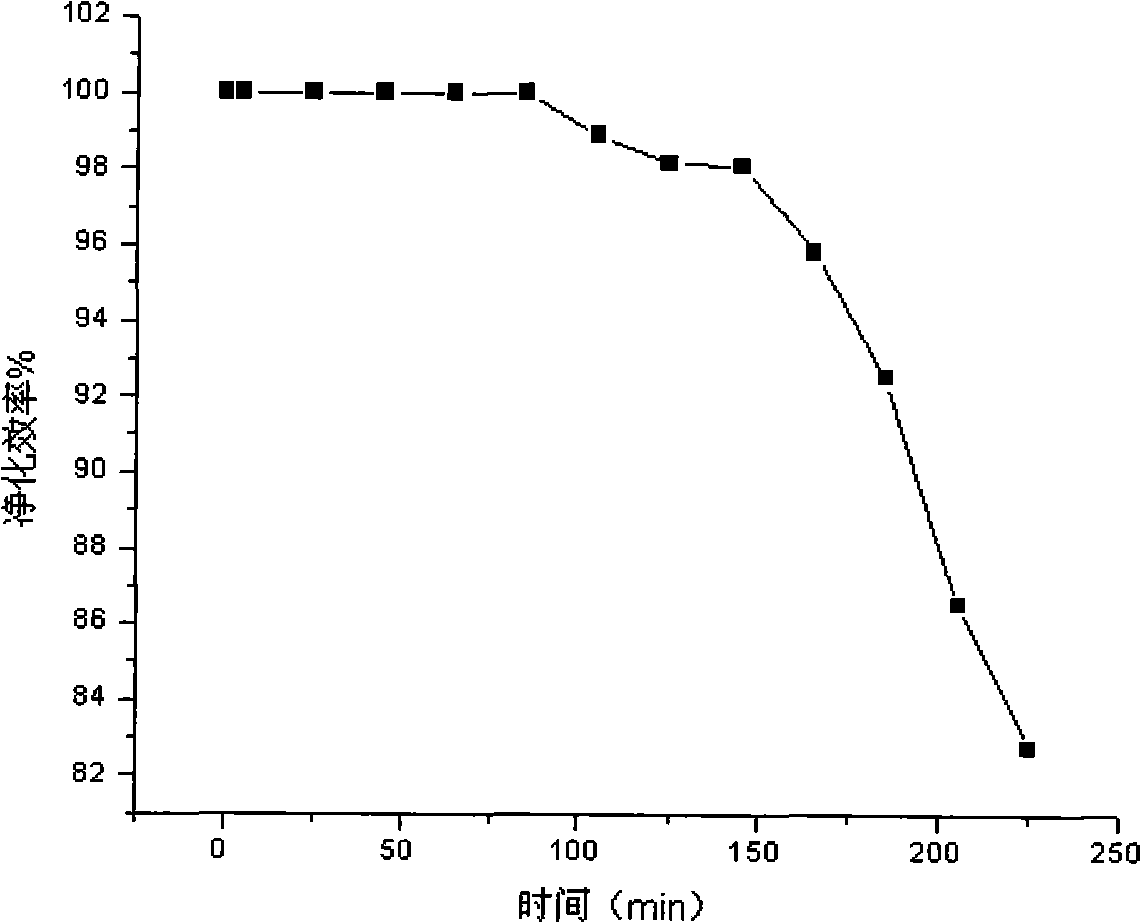

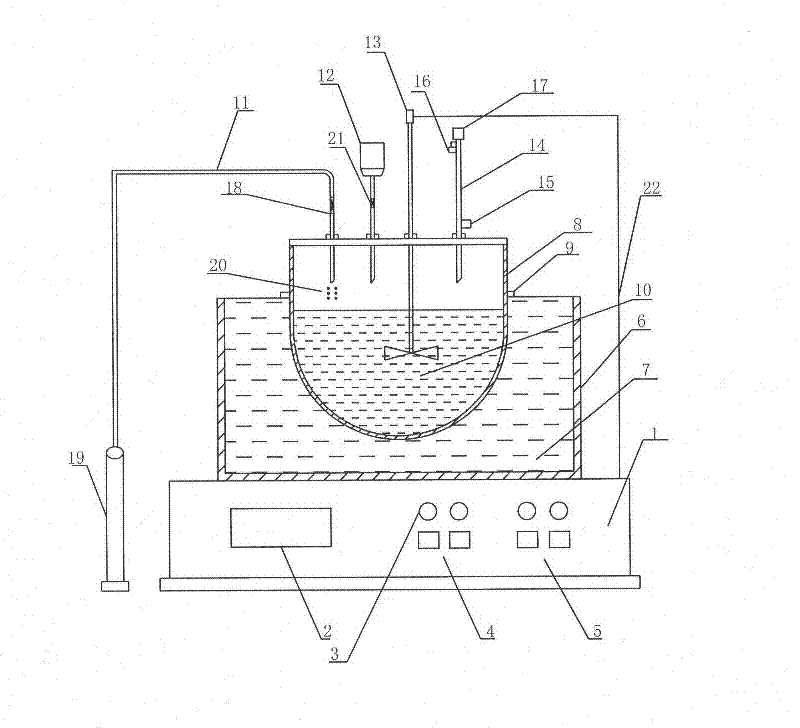

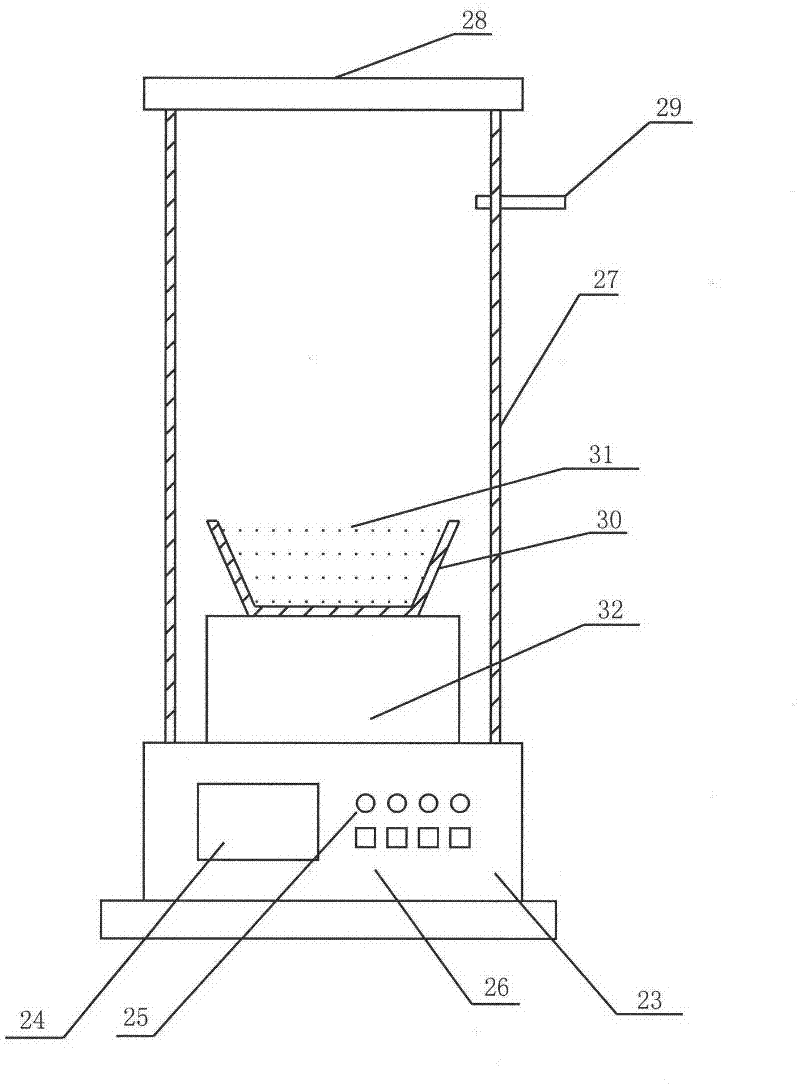

InactiveCN101811051AHigh desulfurization precisionReduce energy consumptionMetal/metal-oxides/metal-hydroxide catalystsWater bathsFiltration

The invention provides a carbonyl sulfide hydrolysis catalyst prepared by using Co-Ni-Al-like hydrotalcite as a precursor and a preparation method thereof. The preparation method comprises the following steps of: at room temperature, dissolving cobalt nitrate, nickel nitrate and aluminum nitrate in distilled water to prepare solution A, wherein the total metal molar number is 0.75mol, n(Co2+):n(Ni2+) is equal to 0.25 to 1, and n(Co2++Ni2+):n(Al3+) is equal to 1.5 to 4; by using NaOH and Na2CO3 as precipitators, dissolving 0.05 moles of the NaOH and the Na2CO3 in the distilled water to prepare solution B; adding the solution A into the solution B dropwise to obtain suspension; and crystallizing the suspension in water bath, and then performing vacuum filtration, washing the crystals by the distilled, drying the crystals, baking the crystals in air, milling the crystals, tabletting the powder and screening the powder to obtain the hydrotalcite derivational compound oxide catalyst. The hydrolysis catalyst prepared by the method can be remove COS in gases, and simultaneously remove H2S generated in hydrolysis, and the desulfurization precision is high; and the hydrolysis catalyst can be used at the low temperature, the operational temperature is between 30 and 80 DEG C, and the energy consumption is low.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of three-dimensional ordered macroporous ferric oxide desulfurizer

InactiveCN102260542AImprove desulfurization effectHigh purityGas purification with selectively adsorptive solidsNitratePore distribution

The invention relates to a preparation method of a three-dimensional ordered macroporous ferric oxide desulfurizer, which comprises the following steps: in view of the influence of the pore distribution of the desulfurizer on the desulfurization effect, preparing polystyrene microspheres by using ferric nitrate as the raw material, assembling an adhesive crystal template, and preparing the three-dimensional ordered macroporous ferric oxide desulfurizer. The preparation method has the advantages of short technological process, less equipment, full and accurate technological parameter data and high product purity (up to 96.9%). The pore size of the three-dimensional ordered macroporous ferric oxide desulfurizer is 90nm, the pores are orderly arranged, and the three-dimensional ordered macroporous ferric oxide desulfurizer has the advantages of favorable desulfurization effect and high desulfurization precision. The desulfurization effect of the three-dimensional ordered macroporous ferric oxide desulfurizer is enhanced by 91% as compared with the existing desulfurizer, thus, the preparation method is a very ideal method for preparing a ferric oxide desulfurizer.

Owner:TAIYUAN UNIV OF TECH

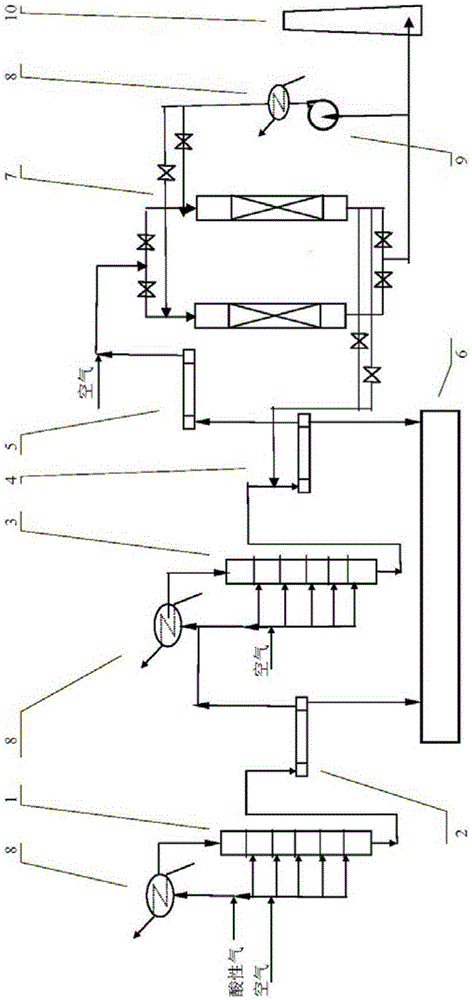

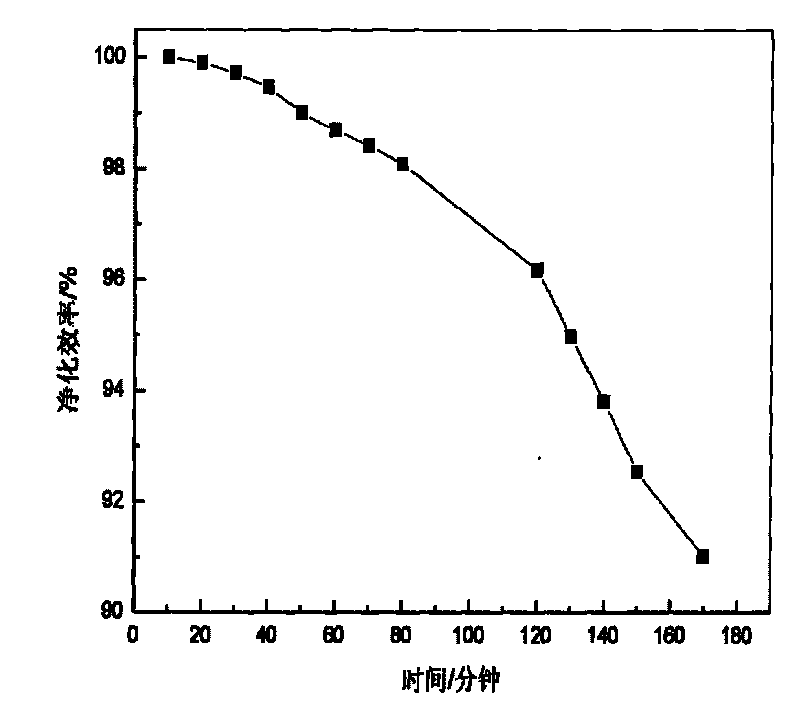

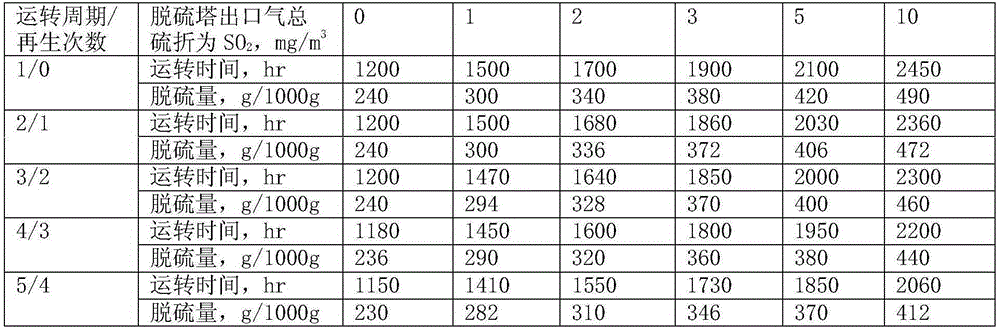

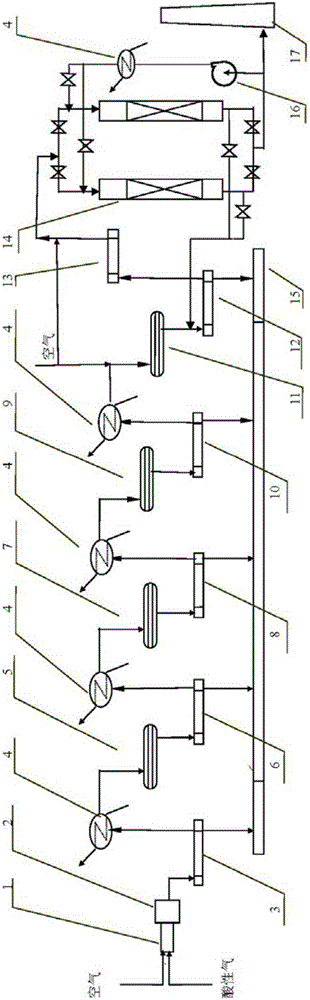

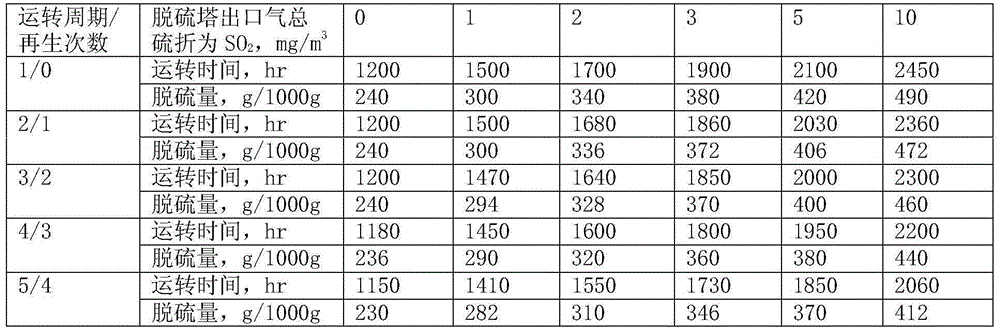

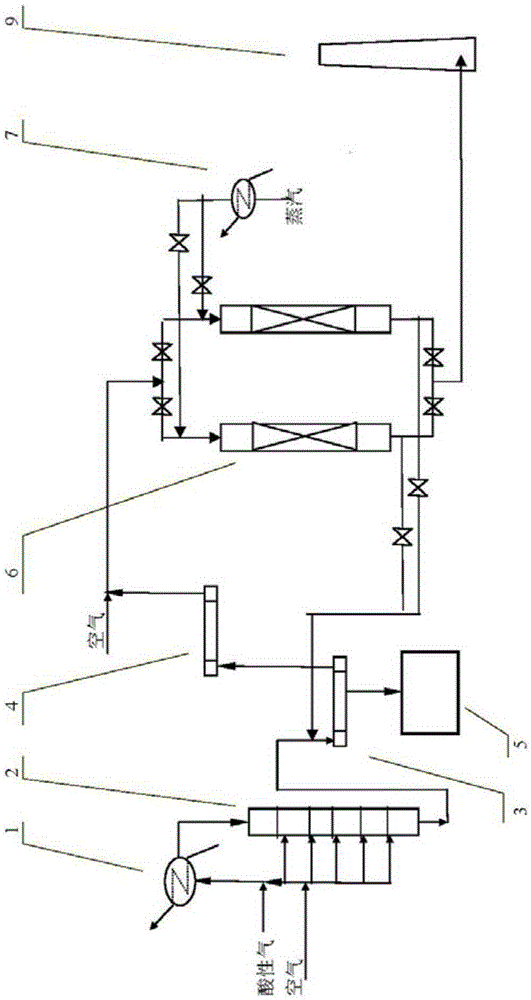

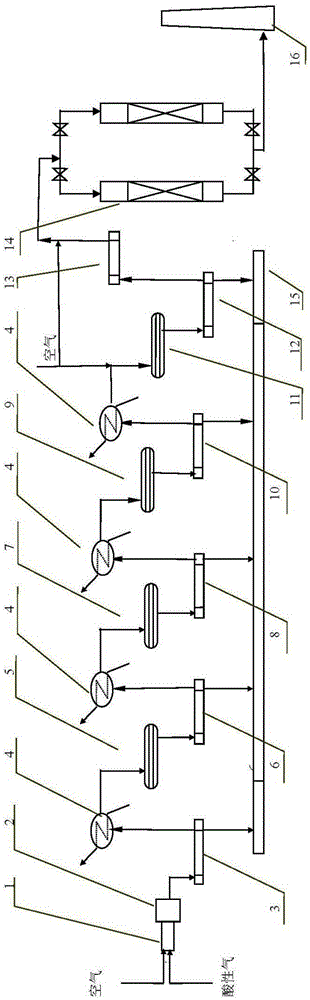

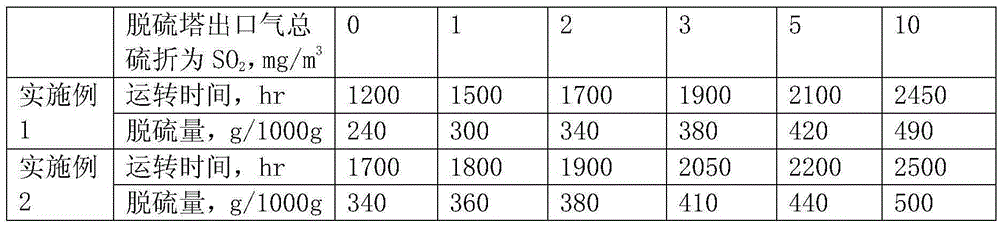

Low-sulfur discharging and sulfur recycling process of intermediate concentration acid gas

ActiveCN105314607ALow sulfur concentrationHigh desulfurization precisionEnergy inputSulfur preparation/purificationCatalytic oxidationCooling coil

The invention provides a low-sulfur discharging and sulfur recycling process of intermediate concentration acid gas. A purpose of desulphurizing low-concentration acid gas with H2S content of 5 to 20 percent can be achieved by treating the low-sulfur acid gas by virtue of a direct oxidation reactor, a selective oxidation reactor and two adsorption desulphurization towers which can be connected in series and parallel; the direct oxidation reactor is filled with a TiO2 sulfur recycling catalyst, the selective oxidation reactor is filled with a H2S selective oxidation catalyst, catalysts in the direct oxidation reactor and selective oxidation reactor are packed in multiple layers, an air inlet and a cooling coil pipe are respectively arranged between two layers, and the adsorption desulphurization tower is filled with a thermally-renewable catalytic oxidation adsorption desulphurization agent; by selecting the appropriate catalyst and desulphurization agent and precisely controlling the process condition of each step, the total sulfur contained in the process discharged gas is that SO2 content is less than or equal to 10mg / m<3>. By virtue of thermal regeneration, the service life of the catalytic oxidation adsorption desulphurization agent is greatly prolonged, and the desulphurization amount of the catalytic oxidation adsorption desulphurization agent is greatly increased. The process has the advantages of low sulfur emission, high sulfur recycling rate (approximate to 100 percent), long service life and large desulphurization amount of the desulphurization agent, fewer replacement times, less expense, good desulphurization agent removal and scrapping condition, safety and the like.

Owner:山东迅达化工集团有限公司

Low-temperature carbonyl sulfide hydrolysis activated carbon-supported catalyst and preparation method thereof

InactiveCN101703928ALow costHigh desulfurization precisionHydrogen sulfidesDispersed particle separationActivated carbonPtru catalyst

The invention relates to a preparation method of a low-temperature carbonyl sulfide hydrolysis activated carbon-supported catalyst. The method comprises the following steps: (1) grinding activated carbon, sieving the ground activated carbon to 40-60 meshes, washing for 3-4 times, then boiling for 1.5 h with l mol / L KOH solution, washing with distilled water until the pH value is constant, and then drying at the temperature of 120 DEG C for later use; (2) ultrasonic immersing the activated carbon in the step (1) with metal oxide immersion liquid with mass content accounting for 1-9 percent of that of the activated carbon for 30 min; (3) keeping the temperature of the activated carbon after immersing treatment in the step (2) constant for 3-6 h at the temperature of 120-170 DEG C, and then activating for 3 h at the temperature of 200-700 DEG C; and (4) ultrasonic immersing the activated carbon after activating in the step (3) with alkali solution with mass content accounting for 3-15 percent of that of the activated carbon for 30 min, and then keeping the temperature of the activated carbon constant for 3 h at the temperature of 110 DEG C to 160 DEG C to obtain the activated carbon-supported catalyst. The preparation method can remove the COS in the gas, simultaneously remove the H2S generated during the hydrolysis, has higher desulfurization precision, can obtain the low-cost raw material easily and also has the advantages of good activity at the normal and low temperature, low cost and the like.

Owner:KUNMING UNIV OF SCI & TECH

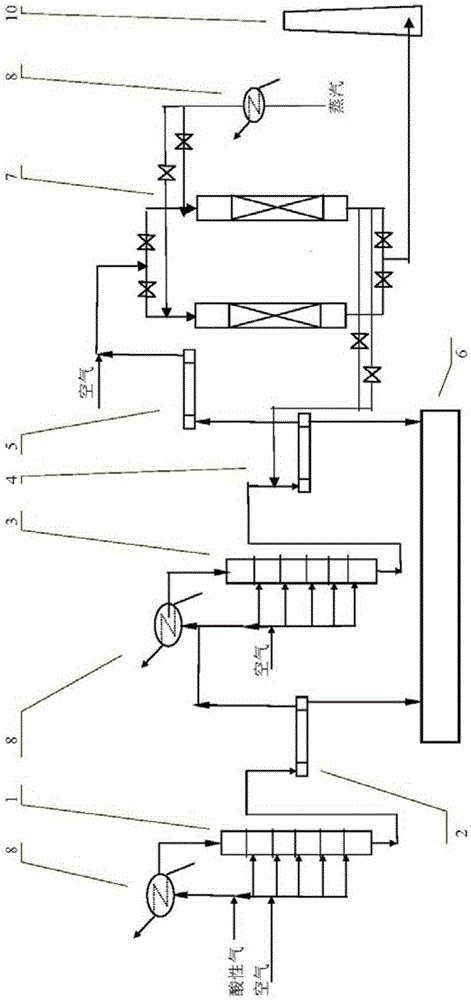

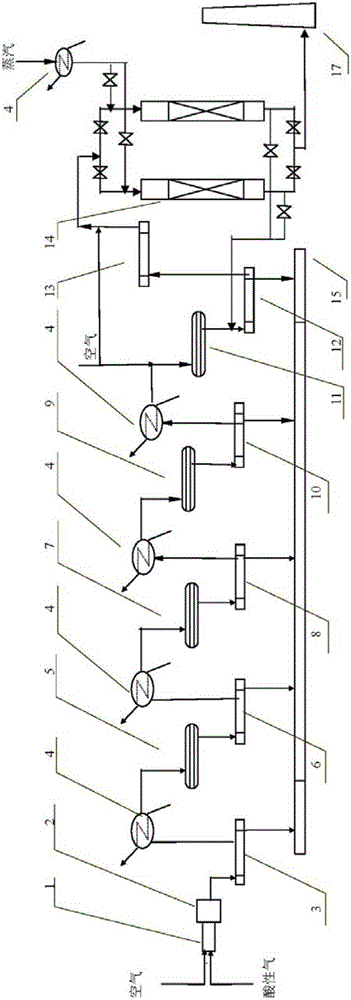

Sulfur recovery technology realizing low sulfur emission

ActiveCN105399057AHigh desulfurization precisionLow sulfur concentrationSulfur preparation/purificationCombustionConversion factor

The invention provides a sulfur recovery technology realizing low sulfur emission. The sulfur recovery technology comprises a combustion furnace, a first-stage Claus reactor, a second-stage Claus reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor and two adsorption desulfurization towers capable of being connected in series or parallel, and the devices are sequentially connected in series; the total sulfur conversion factor of process effluent gas is that SO2 is smaller than or equal to 10 mg / m<3> through proper selection of various catalysts and desulfurizers and accurate control of process conditions of steps. The desulfurizers after breakthrough are subjected to in-situ thermal regeneration by inert gas at the temperature of 250-300 DEG C, regenerated outlet gas returns to the combustion furnace, a condenser I behind the combustion furnace, a condenser II behind the first-stage Claus reactor, a condenser III behind the second-stage Claus reactor, a condenser IV behind the selective hydrogenation reduction reactor or a condenser V behind the selective oxidation reactor, sulfide such as elemental sulfur, H2S,SO2 and the like in the regenerated gas is recovered, and the total sulfur conversion factor of exhaust tail gas in the regeneration period of the desulfurization towers is that SO2 is smaller than or equal to 10 mg / m<3>. The sulfur recovery technology realizing low sulfur emission has the advantages of the low sulfur emission, the long-term operation of the desulfurizers, the high desulfurization capacity, the small number of replacement times, the low expenses and the like.

Owner:山东迅达化工集团有限公司

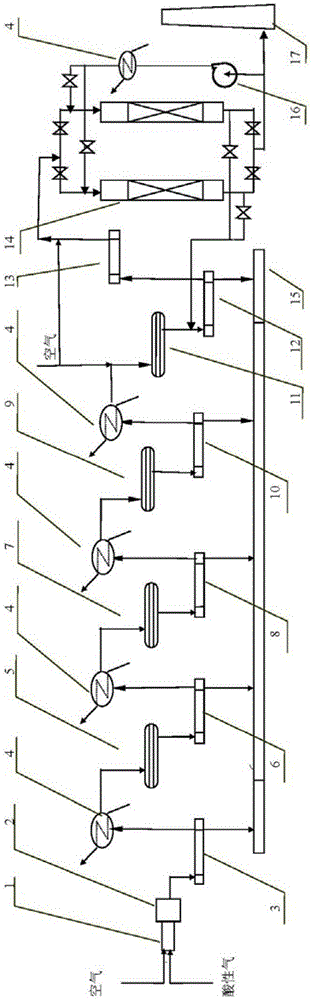

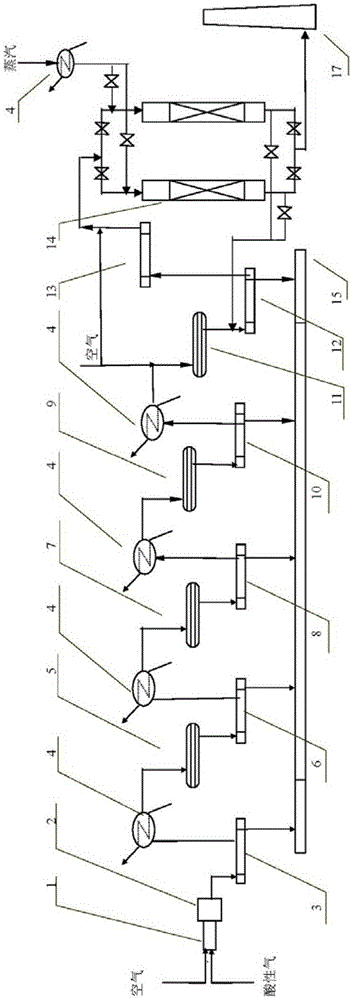

Fine desulfurization process by dry process for natural gas

ActiveCN101691512AEliminate adsorption and removal interferenceExtended regeneration cycleGaseous fuelsMolecular sieveSorbent

The invention relates to a fine desulfurization process by a dry process for natural gas. The process is three-stage normal-temperature fine desulfurization by the dry process for the natural gas: the first-stage desulfurization is crude removal of hydrogen sulfide, and uses a normal-temperature ferric oxide desulfurizer; the second-stage hydrogen sulfide fine removal reactors use a normal-temperature zinc oxide desulfurizer; and the third-stage organic sulfur fine removal reactors use a normal-temperature molecular sieve desulfurizer, wherein the normal-temperature ferric oxide desulfurizer and the normal-temperature molecular sieve desulfurizer can be regenerated for repeated use. The first-stage reactors, the second-stage reactors and the third-stage reactors must be one running reactor and one standby reactor which are mutually switched for use. The process prolongs the regeneration period of organic sulfur adsorbents, avoids the interference of inorganic sulfur on the absorption removal of the organic sulfur, reduces energy consumption and cost, and improves desulfurization accuracy.

Owner:长春惠工净化工业有限公司

Carbonyl sulfur hydrolyst prepared by using binary type hydrotalcite as precursor and method for preparing same

InactiveCN101733105AHigh desulfurization precisionLower operating temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater bathsFiltration

The invention provides a carbonyl sulfur hydrolyst prepared by using binary type hydrotalcite as a precursor and a method for preparing the same. The preparation method comprises the following steps of: at room temperature, dissolving a proper amount of nickel or magnesium and aluminum or iron in distilled water to prepare solution A, and making the mol number of the total metal reach 0.075mol, and n(M2+):n(M3+) equal to 2 to 3; dissolving 0.05mol of Na2CO3 and NaOH serving as precipitators completely reacted with binary metallic ions in the distilled water to prepare solution B; and adding the solution A into the solution B dropwise, controlling a pH value of the mixed solution to be 8 to 10 to obtain suspension liquid, crystallizing the suspension liquid in water bath at the temperature of 50 DEG C for 12 hours, and performing pumping filtration, washing by the distilled water, drying, roasting, grinding, tabletting and screening to obtain the hydrotalcite-typed derivation compound oxide catalyst. The hydrolyst prepared by the method of the invention has the advantages that: COS in the gas can be removed, simultaneously H2S generated in hydrolysis is also removed, and the sulfur removing accuracy is high; and the hydrolyst can be used at a low temperature, the operating temperature is low, and the energy consumption is saved.

Owner:KUNMING UNIV OF SCI & TECH

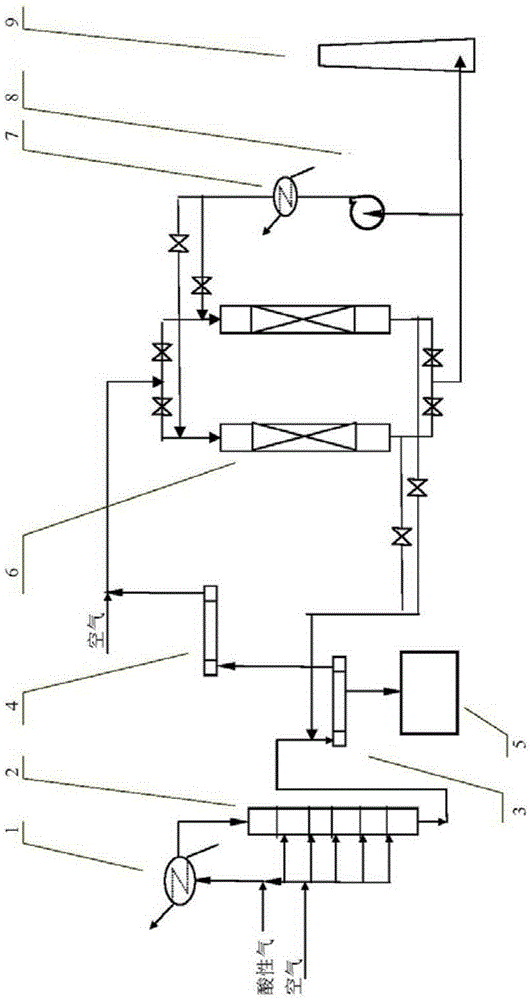

Low sulfur emission sulphur recovery process

ActiveCN105293445AHigh desulfurization precisionLow sulfur concentrationSulfur preparation/purificationTowerProcess conditions

The present invention provides a low sulfur emission sulphur recovery process, which comprises a burning furnace, a first stage Claus reactor, a second stage Claus reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor, and two adsorption desulfurization towers capable of being connected in a series parallel connection manner, wherein the burning furnace, the first stage Claus reactor and the second stage Claus reactor are sequentially connected in series. According to the present invention, with the appropriate selection of each catalyst, the appropriate selection of the desulfurization agent, and the accurate control of each step process condition, the total standard sulfur in the process emission gas is that SO2 is less than or equal to 10 mg / m<3>; after the desulfurization agent penetrates, 250-300 DEG C inert gas is used to perform in-situ thermal regeneration, the regeneration outlet gas returns to the burning furnace, the condenser after the burning furnace, the condenser after the first stage Claus reactor, the condenser after the second stage Claus reactor, the condenser after the selective hydrogenation reduction reactor, or the condenser after the selective oxidation reactor to recover elemental sulfur, H2S, SO2 and other sulfides in the regeneration gas, and the total standard sulfur in the evacuation tail gas during the desulfurization tower regeneration process is that SO2 is less than or equal to 10 mg / m<3>; and the low sulfur emission sulphur recovery process has advantages of low sulfur emission, long desulfurization agent operating, high desulfurization capacity, less replacement frequency, low cost and the like.

Owner:山东迅达化工集团有限公司

Low concentration acid gas low-sulfur emission sulphur recovery process

ActiveCN105293446AExtend your lifeLarge amount of desulfurizationEnergy inputSulfur preparation/purificationChemistryScrap

The present invention provides a low concentration acid gas low-sulfur emission sulphur recovery process. According to the present invention, low concentration acid gas having a H2S content of less than 5% is treated by a selective oxidation reactor and two adsorption desulfurization towers capable of being connected in a series parallel connection manner so as to achieve the desulfurization purpose; a H2S selective oxidation catalyst is filled in the selective oxidation reactor, and a thermal renewable catalytic oxidation adsorption desulfurization agent is filled in the adsorption desulfurization tower; with the appropriate selections of the catalyst and the desulfurization agent, and the accurate control of each step process condition, the total standard sulfur in the process emission gas is that SO2 is less than or equal to 10 mg / m<3>; with the thermal regeneration, the service life and the desulfurization capacity of the catalytic oxidation adsorption desulfurization agent are substantially improved; and the process has advantages of low-sulfur emission, sulphur recovery rate of close to 100%, long desulfurization agent service life, high desulfurization capacity, less replacement frequency, low cost, good desulfurization agent unloading and scrap treatment conditions, safety, and the like.

Owner:山东迅达化工集团有限公司

Iron-zinc-based composite lignin activated carbon desulfurizer and preparation method thereof

ActiveCN106925229ASave resourcesAchieve recyclingOther chemical processesDispersed particle separationActivated carbonIron salts

The invention discloses an iron-zinc-based composite lignin activated carbon desulfurizer and a preparation method thereof. Lignin extracted from masson pine papermaking black liquid is carbonized and activated to obtain lignin activated carbon, lignin activated carbon is dissolved in a zinc salt solution, an iron salt solution and a surfactant are added for reacting for 0.5-2 hours, then an alkaline solution with certain concentration is used for a titration mixed ultrasonic reaction for 2-4 h, a high-pressure reaction still is used for controlling the temperature to range from 100-200 DEG C for reacting for 8-24 h, and the iron-zinc-based composite lignin activated carbon desulfurizer is prepared. The desulfurizer is simple in preparation technological process and good in desulfurization effect, the precision of activated carbon desulfurization is improved through iron-zinc-based composite lignin activated carbon, and high temperature can be resisted. By the adoption of the lignin extracted from the papermaking black liquid, it is truly achieved that waste is turned into wealth, and practical use value and social value are achieved.

Owner:FUZHOU UNIV

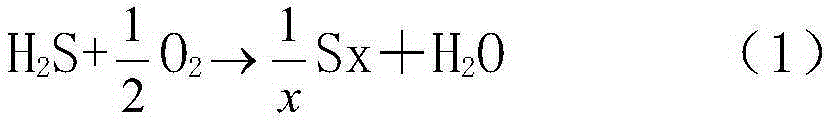

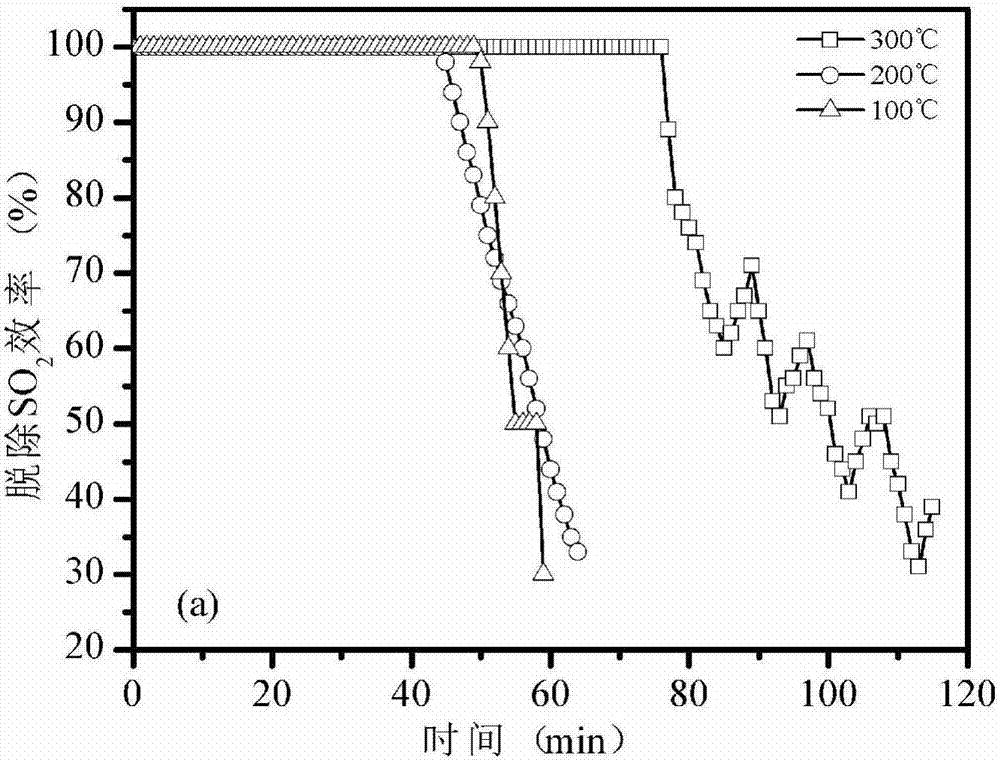

Method for preparing semicoke supported multi-element nano metal oxide desulfurization and denitrification adsorbing agent

InactiveCN107138132AWide variety of sourcesReduce manufacturing costGas treatmentOther chemical processesWater vaporMetal salts

The invention provides a method for preparing a semicoke supported multi-element nano metal oxide desulfurization and denitrification adsorbing agent. The method is characterized in that brown coal is used as the raw material, and pyrolysis and steam gasification are performed on the brown coal under N2 atmosphere by performing ultrasonic-assisted impregnation on metal salts serving as active component precursors to prepare a semicoke supporter and redistribute active components so as to directly obtain semicoke supported multi-element nano metal oxide. The method has the advantages that the low-metamorphic-grade brown coal relatively rich in reserves and the cheap metal nitrate are used as the raw materials prepare the desulfurization agent, and the method is wide in raw material source and low in production cost; compared with impregnation supporting using the semicoke supporter, the method simplifies the operation flow of early coke-making, reduces energy consumption, avoids supporting capacity reduction caused by pore structure changes caused by the fact that pore passages are blocked by tar and the like, is beneficial to the sufficient and even distribution of the active components on the surface of the supporter, increases the desulfurization precision of the desulfurization agent and increases the effective desulfurization time of the desulfurization agent.

Owner:UNIV OF SCI & TECH LIAONING

Carbonyl sulfide hydrolysis and preparation method thereof

InactiveCN101690893AHigh desulfurization precisionDispersed particle separationCatalyst activation/preparationFiltrationCarbonyl sulfide

The invention relates to a carbonyl sulfide (COS) hydrolysis and a preparation method thereof; the hydrolysis is prepared by taking hydrotalcite like compound as a precursor and is used for low-temperature carbonyl sulfide hydrolysis; the invention is characterized in that: divalent metal saline solution and trivalent metal saline solution are mixed according to mole ratio, the mixed solution of sodium hydroxide and sodium carbonate is added by adopting a coprecipitation method, the crystallization temperature is 40-80 DEG C, the solution flow rate is controlled to be 3.6mL / min under being stirred, the sediment pH is controlled, and then filtration, washing, drying and baking are carried out to obtain derive composite oxide catalyst of the hydrotalcite like compound. The catalyst prepared by taking the hydrotalcite like compound as the precursor in the invention has obvious catalytic activity and high selectivity.

Owner:KUNMING UNIV OF SCI & TECH

Low sulfur emission sulphur recovery process

ActiveCN105293444ASolution to short lifeLarge amount of desulfurizationSulfur preparation/purificationSulfurTower

The present invention provides a low sulfur emission sulphur recovery process, which comprises a burning furnace, a first stage Claus reactor, a second stage Claus reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor, and two adsorption desulfurization towers capable of being connected in a series parallel connection manner, wherein the burning furnace, the first stage Claus reactor and the second stage Claus reactor are sequentially connected in series. According to the present invention, with the appropriate selection of each catalyst, the appropriate selection of the desulfurization agent, and the accurate control of each step process condition, the total standard sulfur in the process emission gas is that SO2 is less than or equal to 10 mg / m<3>; and the low sulfur emission sulphur recovery process has advantages of low sulfur emission, long desulfurization agent service life, high desulfurization capacity, less replacement frequency, low cost and the like.

Owner:山东迅达化工集团有限公司

Activated carbon diatomite particles capable of rapid purification of flue gas and preparation method thereof

InactiveCN104475050AHigh desulfurization precisionQuick purificationOther chemical processesDispersed particle separationPorositySilicon dioxide

The invention discloses activated carbon diatomite particles capable of rapid purification of flue gas, and is characterized in that the activated carbon diatomite particles are prepared from the following raw materials in parts by weight: 105-110 parts of wooden activated carbon, 35-40 parts of diatomite, 1-2 parts of tripotassium citrate, 4-6 parts of expanded perlite, 3-5 parts of ammonium chloride, 2-3 parts of zirconium silicate, 6-9 parts of nano kaolin, 4-6 parts of nano silica, 3-5 parts of copper sulfate, 1-2 parts of rosin-polythylene oxide ester, 3-5 parts of methyldiethanolamine, 4-6 parts of an adsorption auxiliary agent, and a proper amount of water. The formula is reasonable; with addition of nano kaolin and expanded perlite, much surface pores exist, and the porosity is high; with addition of methyldiethanolamine, the activated carbon diatomite particles have a flue gas rapid purifying effect; with addition of the adsorption auxiliary agent, the activated carbon diatomite particles have special porousness, and prolong the contact time with gas; and activated carbon can quickly adsorb various solutes and free gases, and is high in activity, high in desulfurization precision, and suitable for industrial dry desulfurization, automobile tail gas desulfurization, daily air purification and the like.

Owner:ANHUI PHOENIX INT CO LTD

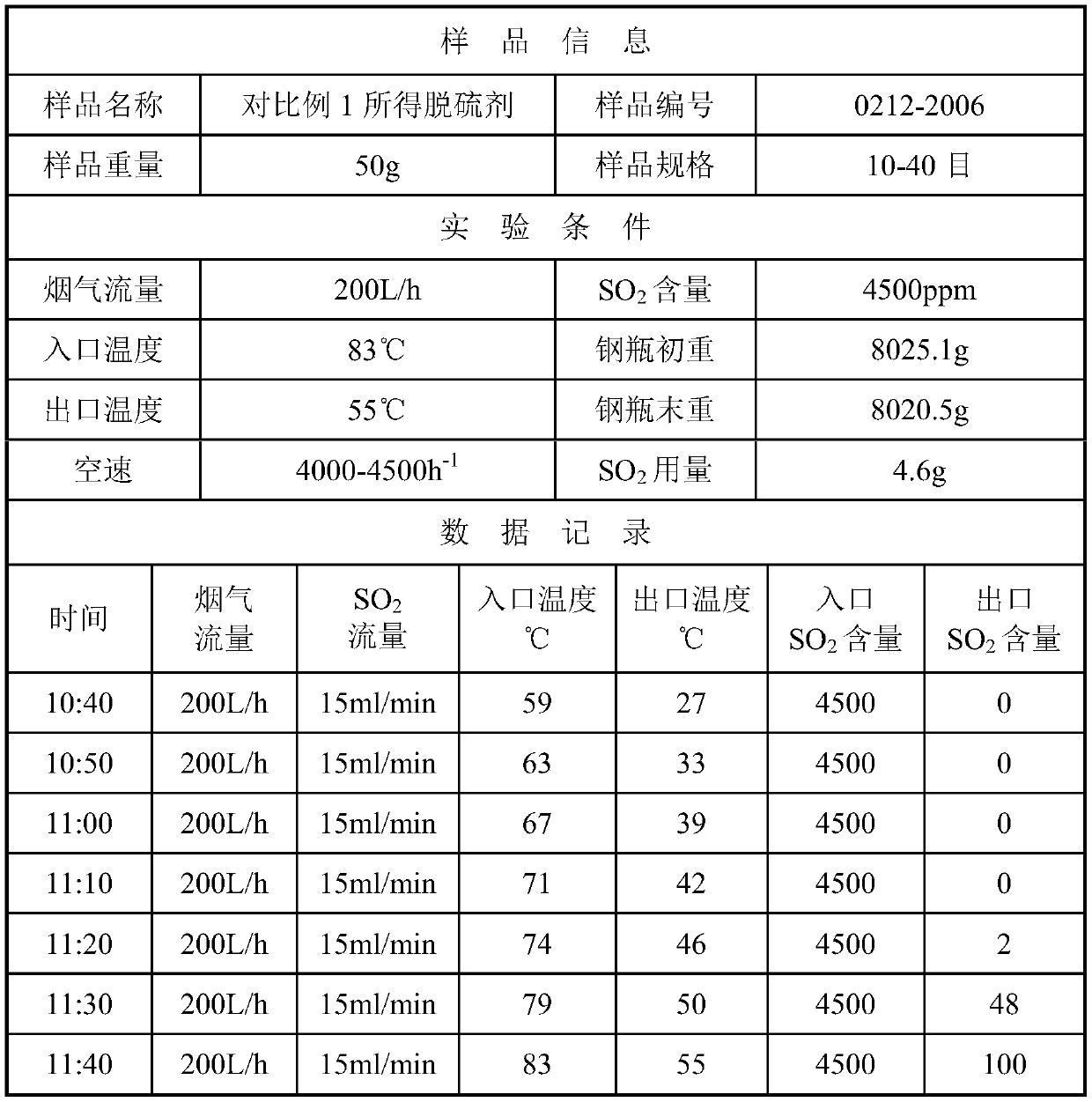

Blast furnace gas desulfurization catalyst as well as preparation method and application thereof

InactiveCN112058273AHigh sulfur capacityHigh desulfurization precisionMetal/metal-oxides/metal-hydroxide catalystsGas contaminants removalManganese oxideActivated carbon

The invention discloses a blast furnace gas desulfurization catalyst as well as a preparation method and application thereof. The desulfurization catalyst is composed of an activated carbon carrier, an active component and a cocatalyst; the active component is one or a combination of zinc oxide, iron oxide, manganese oxide and copper oxide; and the cocatalyst is an alkali metal or alkaline earth metal oxide. The preparation method comprises the following steps of: (1) carrying out functional group and surface acid-base modification treatment on the activated carbon carrier; (2) preparing an active component solution, loading an active component on the modified activated carbon carrier by adopting an impregnation method, and performing drying and roasting; and (3) preparing a cocatalyst component solution, loading a cocatalyst component on the modified activated carbon carrier by adopting an impregnation method, performing drying and roasting to obtain the desulfurization catalyst. Thecatalyst is used for removing sulfides in blast furnace gas; the concentration of the sulfides is reduced to 20 mg / Nm <3> or below, the saturated sulfur capacity is larger than 20%; high activity is still achieved after multiple times of regeneration, and the gas desulfurization cost can be greatly reduced.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Normal temperature iron oxide desulfurizing agent, preparation method and application thereof

InactiveCN101143290AImprove desulfurization efficiencyHigh sulfur capacityDispersed particle separationCombustible gas purificationMethanationFixed bed

The invention provides a normal temperature ferric oxide desulfurizer which consists of ferric oxide, binding agent, hole making agent and chips. The invention also provides the preparation method of the desulfurizer and method of removing hydrogen sulphide in the raw gas by using the desulfurizer. The normal temperature ferric oxide desulfurizer provided by the invention is applicable to the rough, fine desulfurization in the production processes of synthetic ammonia, methanol, combined methanol, low-carbon alcohol, synthetic fuel methanation and so on, and is also applicable to the removal of hydrogen sulphide by using various gas sources like semi-water gas, water gas, town gas, coke oven gas, natural gas, liquefied gas, chemical raw gas, marsh gas, carbon dioxide and so on, and using various reactors like fixed bed, moving bed and so on.

Owner:BAOSHAN IRON & STEEL CO LTD +1

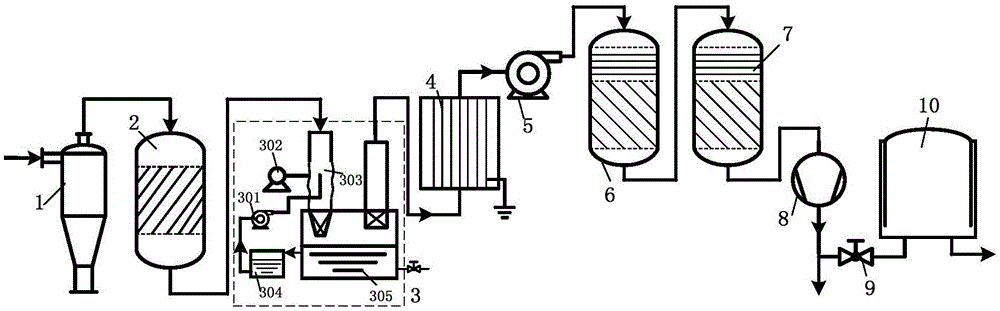

Recovery system and recovery method of low-order coal pyrolysis oil gas

InactiveCN105647592AHigh desulfurization precisionSimple processGas purification with selectively adsorptive solidsGas purification by non-gaseous materials condensationScrubberMolecular sieve

The invention provides a recovery system of low-order coal pyrolysis oil gas. The recovery system comprises a cyclone dust collector, a filter dust collector, washing equipment, an electrical tar precipitator, adsorption equipment and a desulfurizing tower, wherein the washing equipment comprises an ammonia water storage tank, a tar washing tank and a gas-liquid contact vertical pipe which is positioned above the tar washing tank; the adsorption equipment is internally filled with one or more of pyrolytic semi-cokes, cokes, sawdust, granular activated carbon, activated carbon fiber, silica gel, activated aluminum oxide and molecular sieve. According to the recovery system provided by the invention, a dynamic wave washer is adopted, the structure is simple, the manufacturing cost is low, the energy consumption is low, the operation flexibility is large, and the gas-liquid mass transfer effect is good; due to the additional arrangement of a soft connecting pipe wall and a vibrator / an oscillator, the situation that a pipeline is blocked as tar is condensed on the pipe wall can be effectively avoided; through an oil gas product recovery technology adopted by the invention, and by arranging a hydrogen sulfide adsorption device and a dewatering device, hydrogen sulfide and water vapor in pyrolysis gas can be adsorbed, and the problems that due to the condensation of tar mist, VOCs (Volatile Organic Compouns) and the water vapor in the pyrolysis gas, pipeline equipment is corroded, and long-distance transportation requirements are difficult to meet are effectively solved.

Owner:SHENWU TECH GRP CO LTD

Novel efficient desulfurizing agent and preparation method thereof

InactiveCN110893312AImprove desulfurization efficiencyHigh desulfurization precisionGas treatmentDispersed particle separationActivated carbonFlue gas

The invention relates to a novel high-efficiency desulfurizing agent and a preparation method thereof. The novel high-efficiency desulfurizing agent mainly comprises the following raw materials: Mg, Ca or Na oxide and / or hydroxide, activated carbon, red mud, a binder and a pore forming agent, and the novel high-efficiency desulfurizing agent is prepared from the raw materials through a special process. The novel high-efficiency desulfurizing agent disclosed by the invention can overcome the defects of an existing desulfurizing process, has the advantages of high desulfurization efficiency, high desulfurization precision, low power consumption, low investment and the like, can effectively reduce the desulfurization cost and reduce the economic pressure for desulfurization of enterprises, can perform deep desulfurization, can remove SO2 to be less than or equal to 1mg / m < 3 >, and obviously enhance the desulfurization efficiency; the novel high-efficiency desulfurizing agent can be usedfor secondary fine desulfurization of power plant flue gas, can also be used for tail gas SO2 treatment in the industries of fine chemical engineering, pharmacy, metal smelting and the like, and has huge market value.

Owner:山东庚辰环保新材料有限公司

Method for preparing normal temperature oil desulfurizer

ActiveCN106268619APromote generationRealize positioning loadOther chemical processesHydrocarbon oils refiningSulfideCopper

The invention relates to a method for preparing a normal temperature oil desulfurizer. The preparation method comprises the steps of preparing a zinc oxide mixture, preparing a ferric nitrate solution, preparing mixed liquid of silver and copper, squeezing, drying and baking. The normal temperature oil desulfurizer prepared from the method provided by the invention can not only remove hydrogen sulfide and a part of mercaptan sulfur in oils, but also has a good removal effect on elemental sulfur that is difficult to remove, the range of applicable oil raw materials is wide, and the oil corrosion problem caused by a variety of sulfides can be solved.

Owner:XIAN ORIGIN CHEM TECH

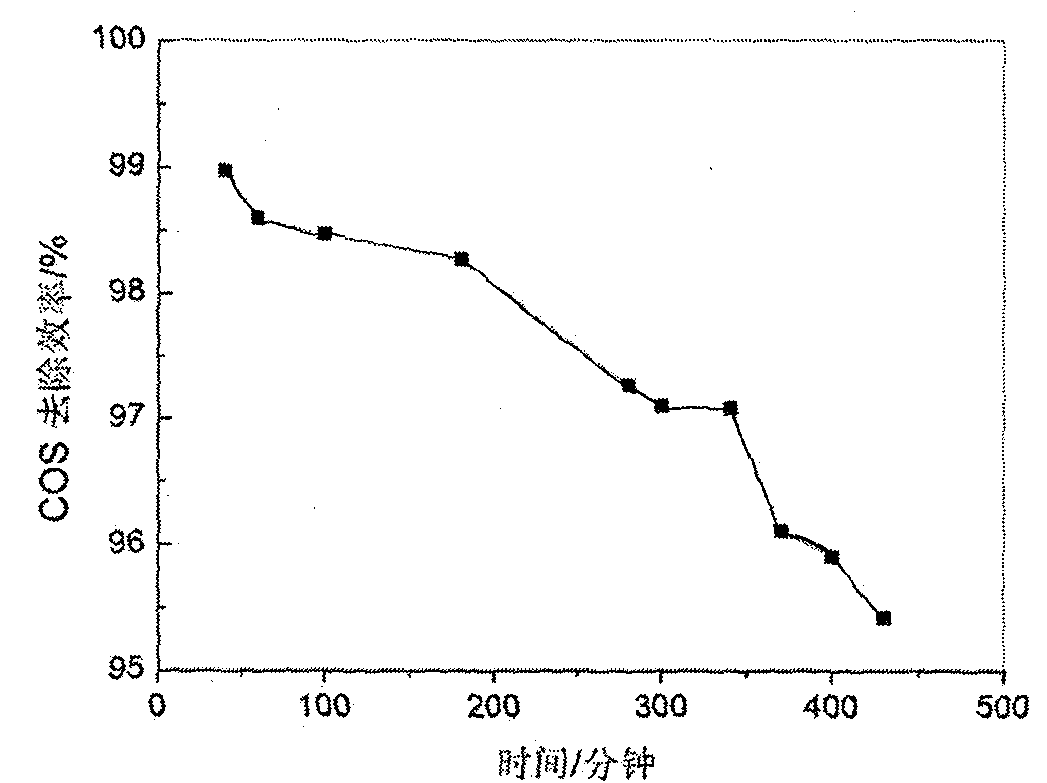

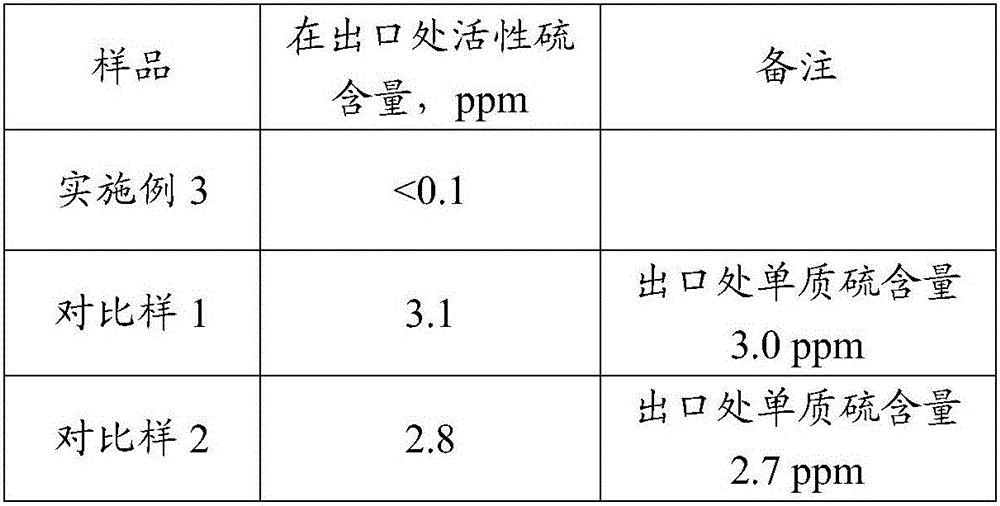

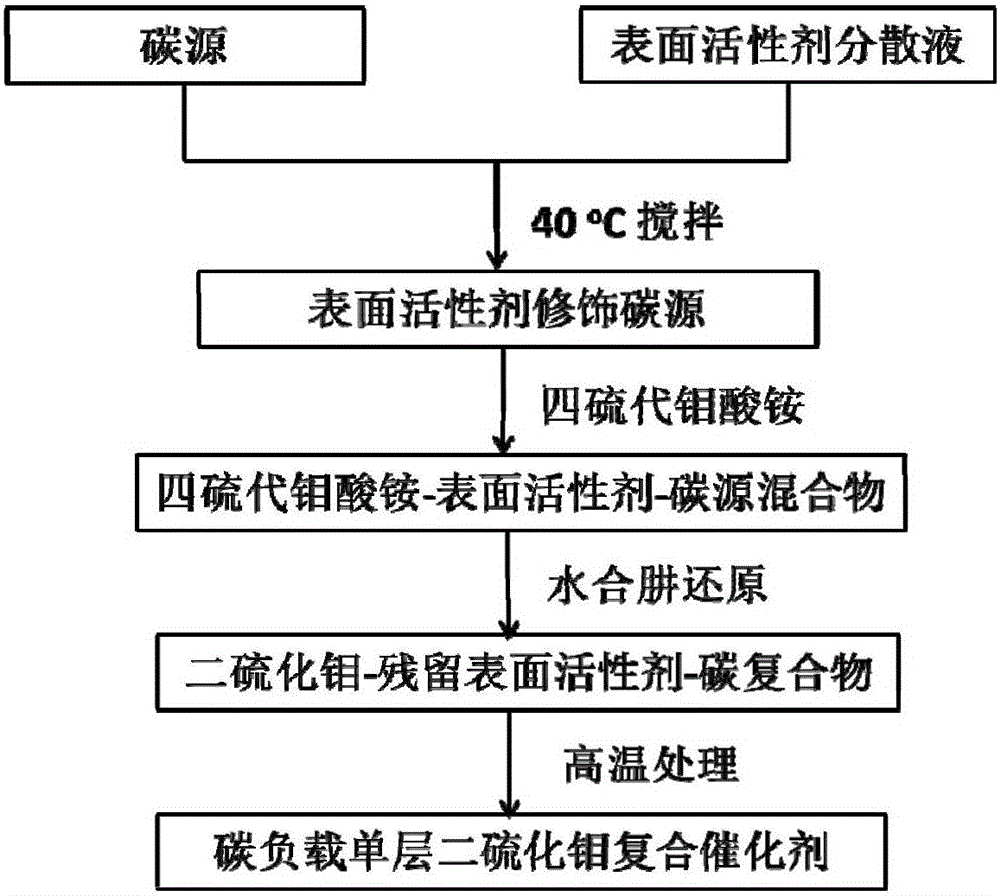

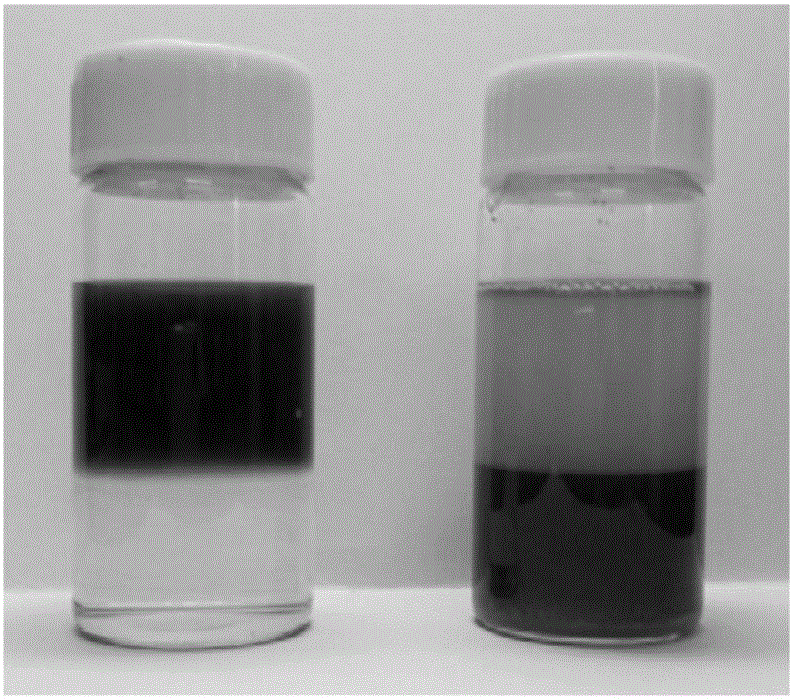

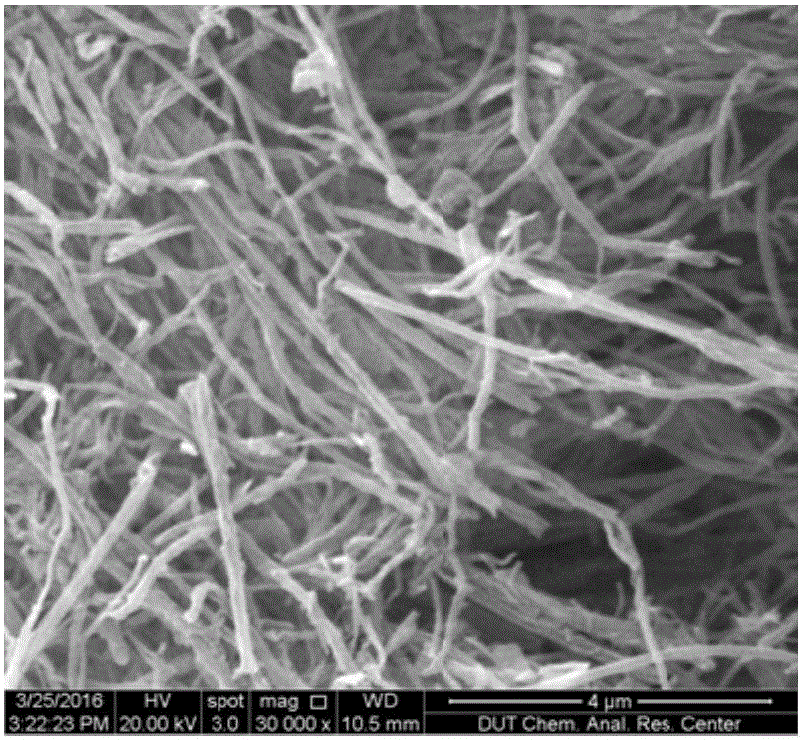

Preparation method for carbon-supported monolayer molybdenum disulfide composite catalyst for low-temperature hydro-conversion of carbonyl sulfide

InactiveCN105772036ASimple preparation processRaw materials are easy to getPhysical/chemical process catalystsHydrazine compoundCarbonyl sulfide

The invention provides a preparation method for carbon-supported monolayer molybdenum disulfide composite catalyst for low-temperature hydro-conversion of carbonyl sulfide, which belongs to the technical field of functional catalytic material preparation and environment-friendly catalytic application. Ammonium tetrathiomolybdate is uniformly dispersed on a surfactant-modified appropriate carbon source, and hydrazine hydrate liquid-phase reduction and high-temperature treatment are then performed, so that the carbon-supported monolayer molybdenum disulfide composite material is obtained. In the material, monolayer molybdenum disulfide uniformly grows on the surface of carbon support, the material shows property rich in defective and active sites, and shows excellent activity in catalytic conversion of carbonyl sulfide by hydrogenation, and the catalytic performance is stable. The preparation method is easy to operate, the cost is low, the temperature of catalysis is low, the accuracy of catalysis is high, the stability is good, and the invention has good economic benefit and industrial application prospect.

Owner:DALIAN UNIV OF TECH

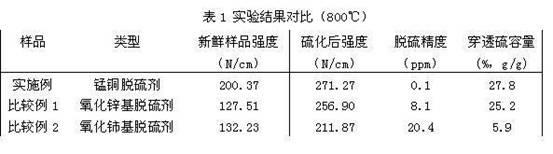

Manganin high-temperature gas desulfurizer and preparation method thereof

InactiveCN102021046AHigh sulfur capacityHigh precisionCombustible gas purificationHydration reactionManganese(II) carbonate

The invention relates to a manganin high-temperature gas desulfurizer and a preparation method thereof. The desulfurizer comprises the following components by weight percent: 80-95% of MnCO3, 5-20% of CuO, 5-15% of aluminum sol and 5% of pore-forming agent, wherein the pore-forming agent is one of starch or carbon black; and the aluminum sol and the pore-forming agent are added on the basis of the weight percent 100% of the MnCO3 and CuO. The preparation method comprises the following steps: adding a proper amount of ammonia water in nine hydrated aluminum nitrate used as raw material, and controlling the pH value of solution to 8.8-9.7 to obtain flocculent; filtering precipitate, adding a proper amount of water, and stirring the solution to turbid liquid; heating the turbid liquid to 40 DEG C-60 DEG C, adding a proper amount of nitric acid to control the ratio of acid to aluminum to 0.2-0.3; and heating to 80 DEG C-95 DEG C to obtain aluminum sol; based on the above weight percent, evenly ball-milling MnCO3, CuO and the pore-forming agent by a ball mill, adding the aluminum sol which is 5-15% of mixture, and drying for 4-6 hours at the temperature of 100 DEG C; extruding powder and molding; drying for 6 hours at the temperature of 100 DEG C; and roasting for 13-17 hours at the temperature of 850 DEG C-1000 DEG C, and obtaining the manganin high-temperature gas desulfurizer. The manganin high-temperature gas desulfurizer prepared by the preparation method has the characteristics of good high temperature desulfuration property, high breakthrough sulphur capacity and the like, and the preparation process is simple.

Owner:SHANGHAI UNIV

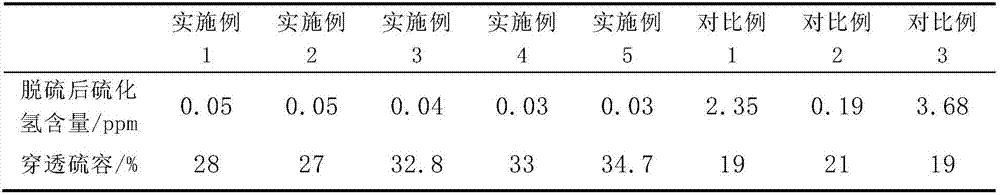

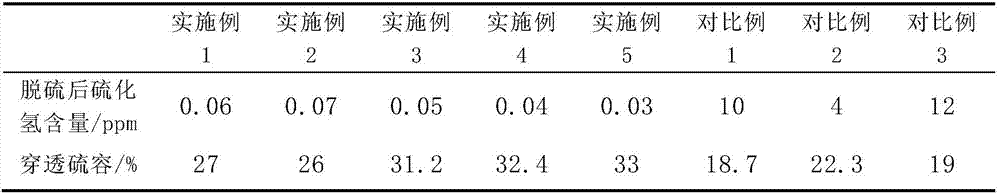

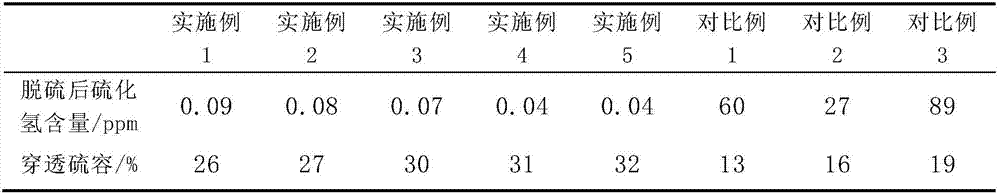

High airspeed iron desulfurizing agent, preparation method and application of desulfurizing agent

ActiveCN107497283AImprove unit throughputFully exposedDispersed particle separationMicroparticleHydroxy compound

The invention belongs to the technical field of desulfurization and particularly relates to a high airspeed iron desulfurizing agent, a preparation method and application of the desulfurizing agent. The desulfurizing agent provided by the invention takes activated zinc oxide with nanoparticle small size effect as an additive; the additive is fully utilized; when hydrogen sulfide molecules escape under the condition that a hydroxyl ferric oxide component is combined with hydrogen sulfide till reaching a saturated state, the activated zinc oxide can react with the escaping hydrogen sulfide; a compound active center is formed under the interaction of the hydroxyl ferric oxide and the activated zinc oxide, and the desulfurizing precision is effectively improved; meanwhile, the compound active center also can effectively accelerate the combining of the desulfurizing agent and the hydrogen sulfide molecules and the unit handling capacity of the desulfurizing agent can be increased. The desulfurizing agent provided by the invention can meet the high airspeed desulfurizing requirement; the desulfurizing precision is high; the hydrogen sulfide content in the desulfurized gas is smaller than 0.1ppm; the penetrating sulfur capacity under the airspeed of 6000h-1 under room temperature can reach up to 33%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Zinc oxide desulfurizer and preparation method thereof

InactiveCN101798521AHigh pore volumeHigh surface areaRefining with metal oxidesPorositySodium Bentonite

The invention relates to zinc oxide desulfurizer and a preparation method thereof. The zinc oxide desulfurizer is prepared by using ZnO, ZnCO3, TiO2 and NiO as a desulfuration active component, crosslinking bentonite as a porosity auxiliary agent, cement as agglomerant and methylcellulose as an extrusion aiding agent and by the steps of band extrusion forming, drying and roasting. The crosslinking bentonite is used as the porosity auxiliary agent of the zinc oxide desulfurizer, so that the pore volume and specific surface of the zinc oxide desulfurizer are increased effectively, and simultaneously, in order to ensure the strength of the zinc oxide desulfurizer, in the preparation method, aluminate cement is used as the agglomerant to increase the activity of desulfurization and sulfur capacity, wherein the pore volume is between 0.4 and 0.5 mL / g, the specific surface is between 60 and 80 m<2> / g, and the side pressure strength is between 80 and 100 N / cm. A small amount of NiO and TiO2 are added into the zinc oxide desulfurizer, so that the zinc oxide desulfurizer has high carbonyl sulfide and micromolecule mercaptan removing capacity, improves the desulfuration accuracy, is particularly suitable to be used as middle and low temperature desulfurizer, and has the advantages of cheap raw materials and simple preparation process. Due to the large pore volume and specific surface, the zinc oxide desulfurizer is high in desulfuration activity, high in desulfuration accuracy and large in sulfur capacity.

Owner:长春惠工净化工业有限公司

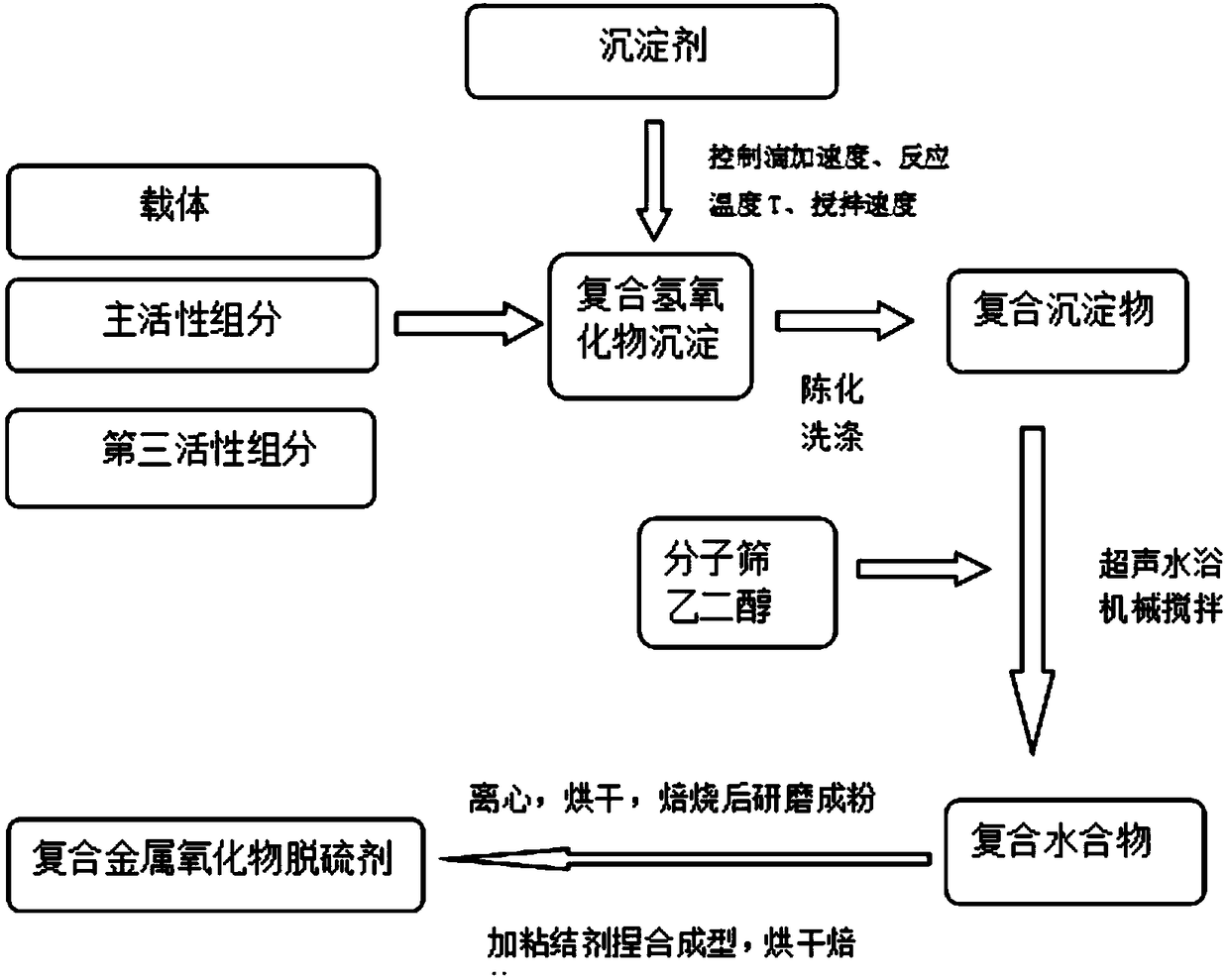

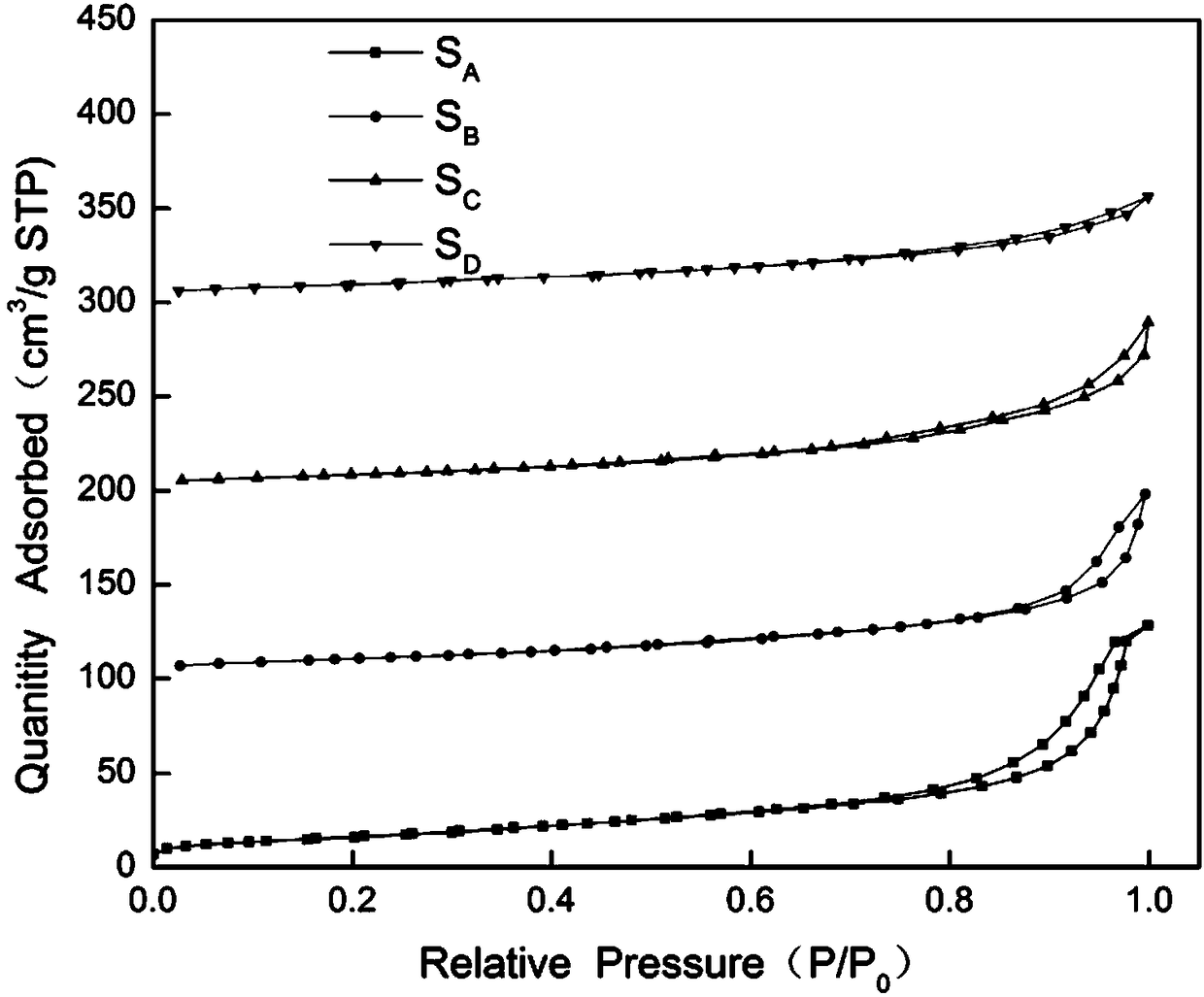

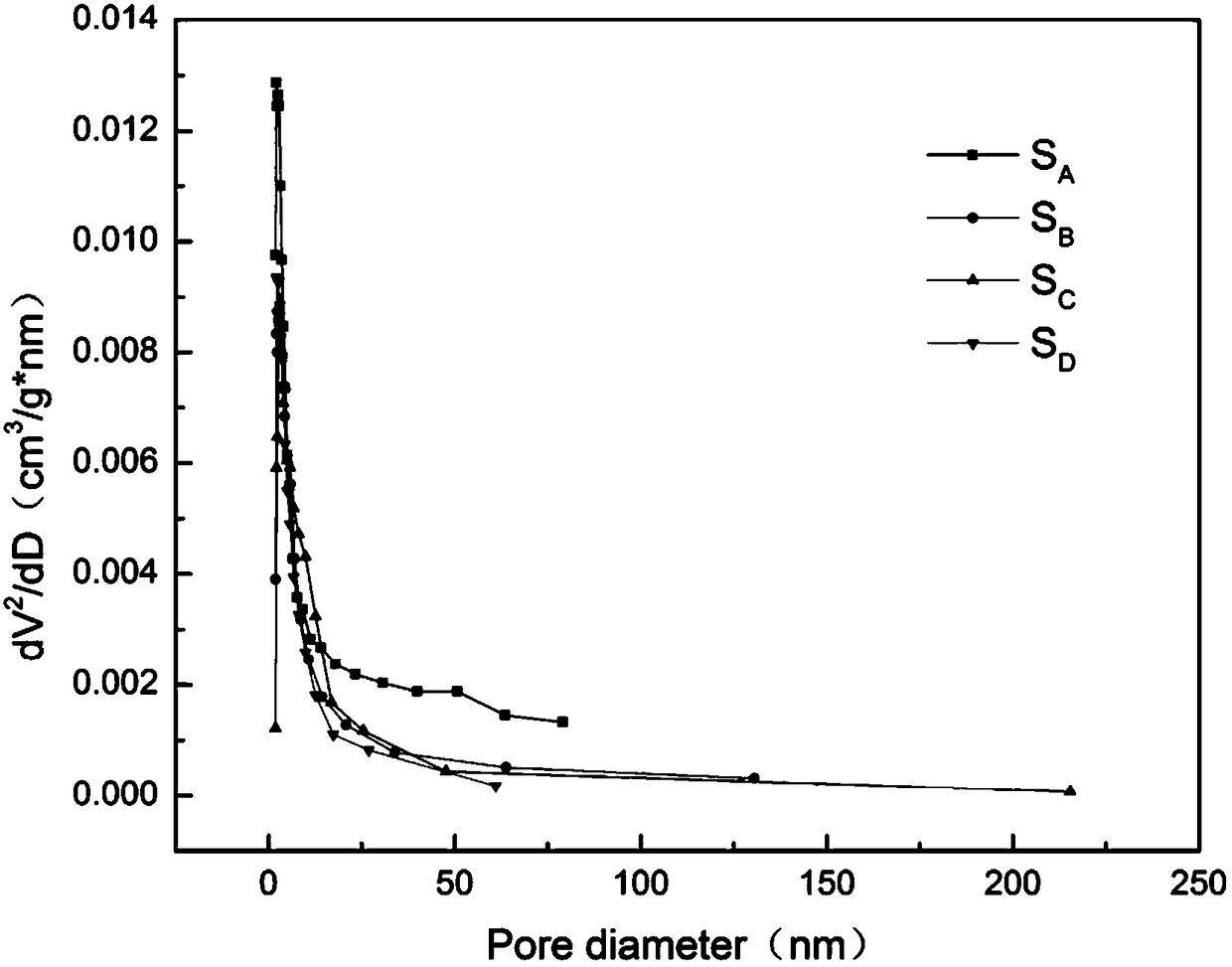

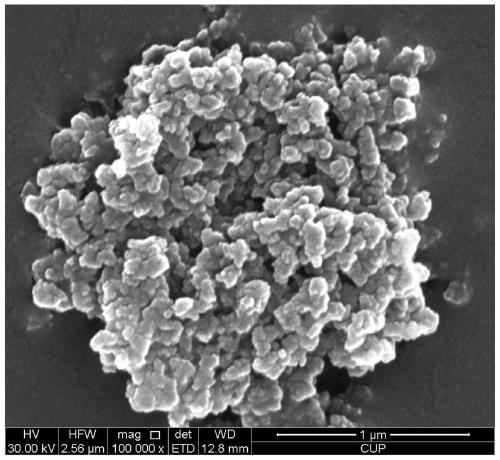

Composite metal oxide desulphurization agent and preparation method thereof

InactiveCN109107374AHigh removal accuracyImprove solubilityGas treatmentDispersed particle separationChemical industryActive component

The invention discloses a composite metal oxide desulphurization agent and a preparation method thereof, which belongs to the technical field of environmental protection and chemical industry. The desulphurization agent is prepared by precipitating an active component and a carrier by virtue of a precipitating agent in a kneading method, wherein the active component is classified into a main active component and a third active component, the main active component is Cu<2+>, the third active component is Mn<2+>, Zn<2+>, Ca<2+>, Fe<3+>, the carrier is Al<3+>, and the precipitating agent is organic amine. By mixing the multi-component metal, the utilization rate is maximized, the active components are sufficiently dispersed in pores of the carrier with a given specific surface area and a porous structure by adopting a co-precipitation method, so that the active components can be sufficiently mixed with sulfide, the utilization rate is greatly improved, and the desulphurization precision can be improved by utilizing the doping of different metal oxides.

Owner:WUHAN TEXTILE UNIV

Composite molecular sieve, desulfurization adsorbent and preparation method and application thereof

ActiveCN111420632AImprove removal efficiencyUnblockOther chemical processesFaujasite aluminosilicate zeoliteMolecular sieveSorbent

The invention provides a composite molecular sieve, a desulfurization adsorbent as well as a preparation method and application thereof. The preparation method of the composite molecular sieve comprises the following steps: adding a template agent for preparing a mesoporous molecular sieve into an alkaline solution, and stirring to obtain a clear solution; adding a metal zinc in-situ modified silicon-aluminum molecular sieve into the clear solution, and stirring to obtain a turbid liquid; adding a silicon source into the turbid liquid for stirring reaction, and filtering, drying and roasting after reaction to obtain the composite molecular sieve. The desulfurization adsorbent is prepared from the following raw materials in parts by weight: 30-70 parts of a composite molecular sieve, 1-10 parts of an IA group and / or IIA group metal oxygen-containing compound precursor and 30-60 parts of a binder. The desulfurization adsorbent disclosed by the invention is high in adsorption capacity, good in selectivity, high in desulfurization precision, capable of being recycled and long in service life; and C5 oil desulfurized by the desulfurization adsorbent can be directly used as a raw material for high-value utilization.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Middle and low temperature coal gas fine desulfurizing agent and preparation method thereof

InactiveCN102559291AGood dispersionIncrease profitCombustible gas purificationSulfurRoom temperature

The invention relates to a ZnO-MnO2 / gama-Al2O3 middle and low temperature coal gas fine desulfurizing agent and a preparation method thereof. The ZnO-MnO2 / gama-Al2O3 middle and low temperature coal gas fine desulfurizing agent comprises the following active elements in percentage by mass: 15-20% of active element MnO2 and ZnO, and 80-85% of gamma-Al2O3; and the mole ratio of the MnO2 to the ZnO is 1:(7.5-8.5). The masses of precursor Zn(NO3)2*6H2O and Mn(NO3)2 required to prepare a solution are calculated by the mass percent and the mole ratio of the active elements, and the volume of the solution is approximately equal to the volume of the carrier gamma-Al2O3. The preparation method of the ZnO-MnO2 / gama-Al2O3 middle and low temperature coal gas fine desulfurizing agent comprises the following steps of: adding the carrier gamma-Al2O3 to the solution for dipping at room temperature for 12h, putting a mixture to a 110 DEG C drying oven for drying, stirring once at each 3min during drying, transferring a sample to a Muffle furnace for roasting at 400-500 DEG C for 3h after water is totally evaporated so as to obtain the ZnO-MnO2 / gamma-Al2O3 load-type desulfurizing agent. The desulfurizing agent prepared by the method disclosed by the invention is 150-170m<2> / g in specific surface area, 0.50-0.55cm<3> / g in pore volume and 10-14nm in average aperture, and has the characteristics of high middle and low temperature desulfurization precision and sulfur breakthrough volume, simple preparation process and the like.

Owner:SHANGHAI UNIV

Fine desulfurization process by dry process for natural gas

ActiveCN101691512BEliminate adsorption and removal interferenceExtended regeneration cycleGaseous fuelsMolecular sieveThree stage

Owner:长春惠工净化工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com