Patents

Literature

47results about How to "High breakthrough sulfur capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for hydrolyzing carbonyl sulfur and preparation method thereof

InactiveCN101559379AWide concentration rangeHigh desulfurization precisionDispersed particle separationCatalyst activation/preparationMass ratioHydrolysis

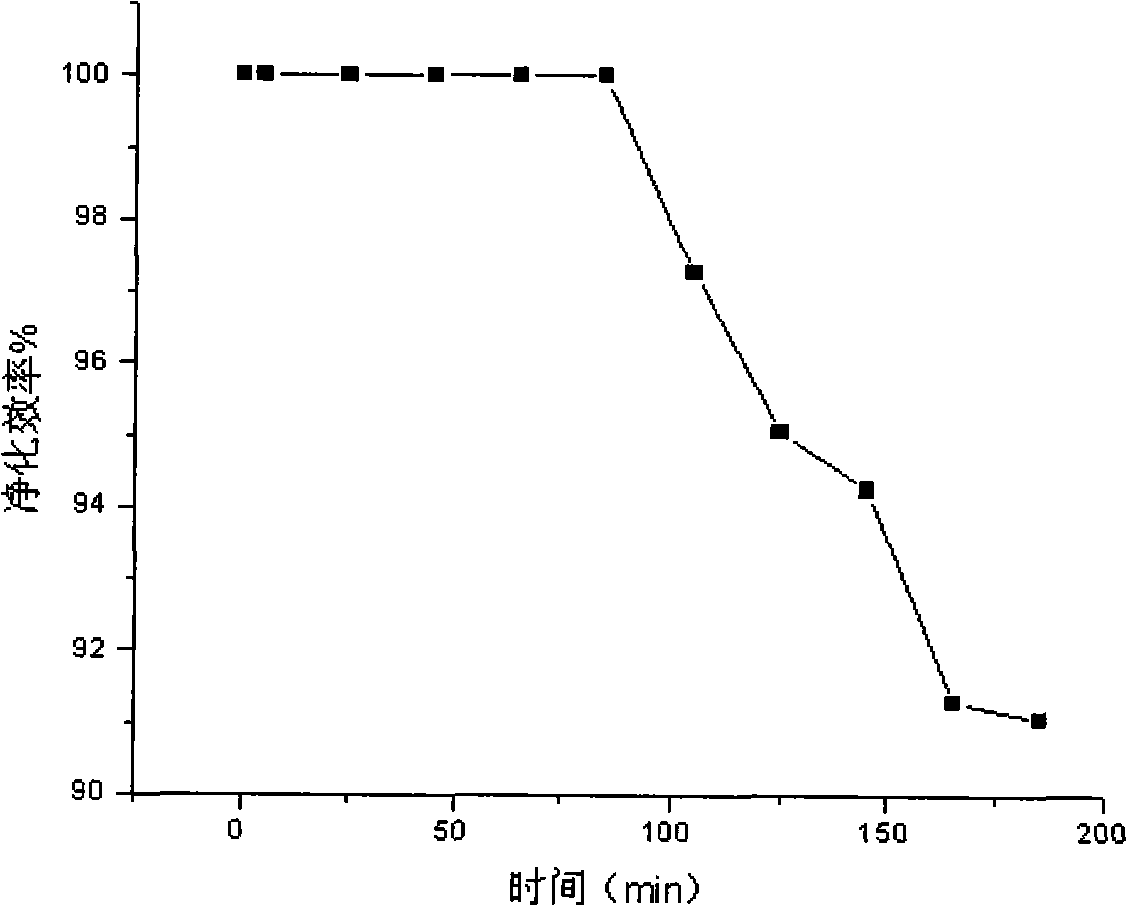

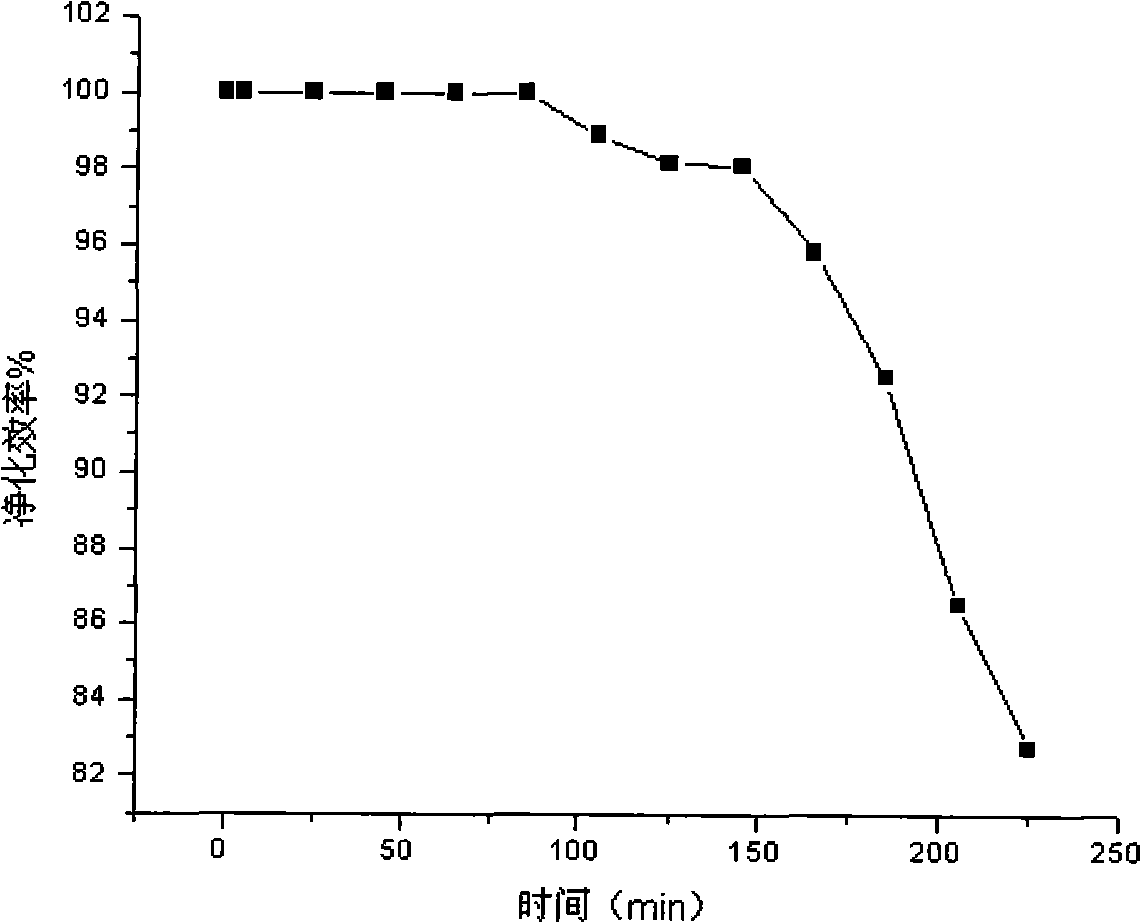

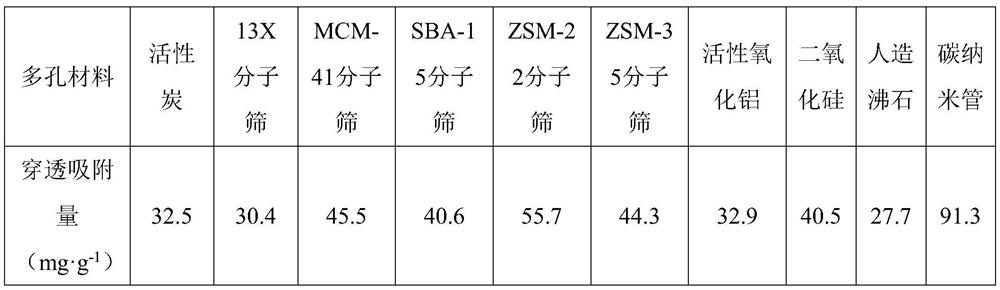

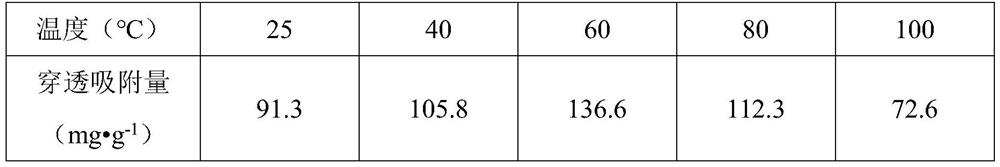

The invention discloses a catalyst for hydrolyzing active carbon-based COS under the condition of low temperature and a preparation method thereof, wherein a carrier of the catalyst is active carbon, and active compositions of the catalyst are alkali materials and metal oxide. The catalyst can remove COS in air at a low temperature (between 30 and 100 DEG C) and remove H2S generated by hydrolysis together. The preparation method comprises the following steps: firstly, using running water and distilled water to wash the active carbon, and drying the active carbon for 2 to 4 hours at a temperature of between 110 and 180 DEG C, wherein the active carbon can be coal and coconut husks; secondly, using a 1 mol / L KOH solution to boil the washed active carbon for 1.5 to 2 hours, performing modification treatment, and using distilled water to wash the solution until the pH value is approximately 6.0; thirdly, selecting one or more metallic salt solutions to soak the active carbon, performing modification treatment, and performing ultrasonic soakage for 0.5 to 1 hour, wherein the content of a soaking liquid is 10 to 90 percent of the mass ratio of the active carbon, and the volume of the soaking liquid is as follows: 20 milliliters of the soaking liquid is added into 10 grams of the catalyst; fourthly, drying the soaked active carbon for 2 to 6 hours in a 120 DEG C constant-temperature drying cabinet, and activating the catalyst for 2 to 4 hours under the protection of 300 to 600 DEG C N2; and fifthly, performing ultrasonic soakage on the activated catalyst in the fourth step in an alkali solution for 0.5 to 1 hour.

Owner:KUNMING UNIV OF SCI & TECH

Absorbent charcoal based catalyst for hydrolyzation and catalysis of carbonyl sulphur in low-temperature and preparation method thereof

InactiveCN101318130AWide concentration rangeHigh desulfurization precisionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationActivated carbonAlcohol

The invention provides an active carbon based catalyst for hydrolyzing and catalyzing carbonyl sulfur in low temperature, which is characterized in that the catalyst takes active carbon as a carrier and is prepared by the following method: washing the active carbon, drying the active carbon for 2-4 hours under 100-140 DEG C; impregnating the active carbon in the (A) step for 6-12 hours with the impregnation liquid of alkaline substances or metal oxides or organic alcohol amine, wherein, the mass content of the alkaline substances or the metal oxides or the organic alcohol amine accounts for 5-30 percent of that of the active carbon; drying the impregnated active carbon for 2-6 hours under the constant temperature of 100-140 DEG C and then activating the active carbon for 2-4 hours under the temperature of 300-500 DEG C and the protection of N2. The catalyst can be used for catalyzing and hydrolyzing COS and removing H2S; furthermore, the catalyst can remove the COS in the gas under the temperature of 30-100 DEG C, ensure the conversion rate of the COS to be larger than 90 percent and remove the H2S generated in hydrolysis at the same time. The COS concentration which is between 100-1500ppm has a wide adaptive range, high desulfurization accuracy and higher breakthrough sulfur capacity.

Owner:KUNMING UNIV OF SCI & TECH

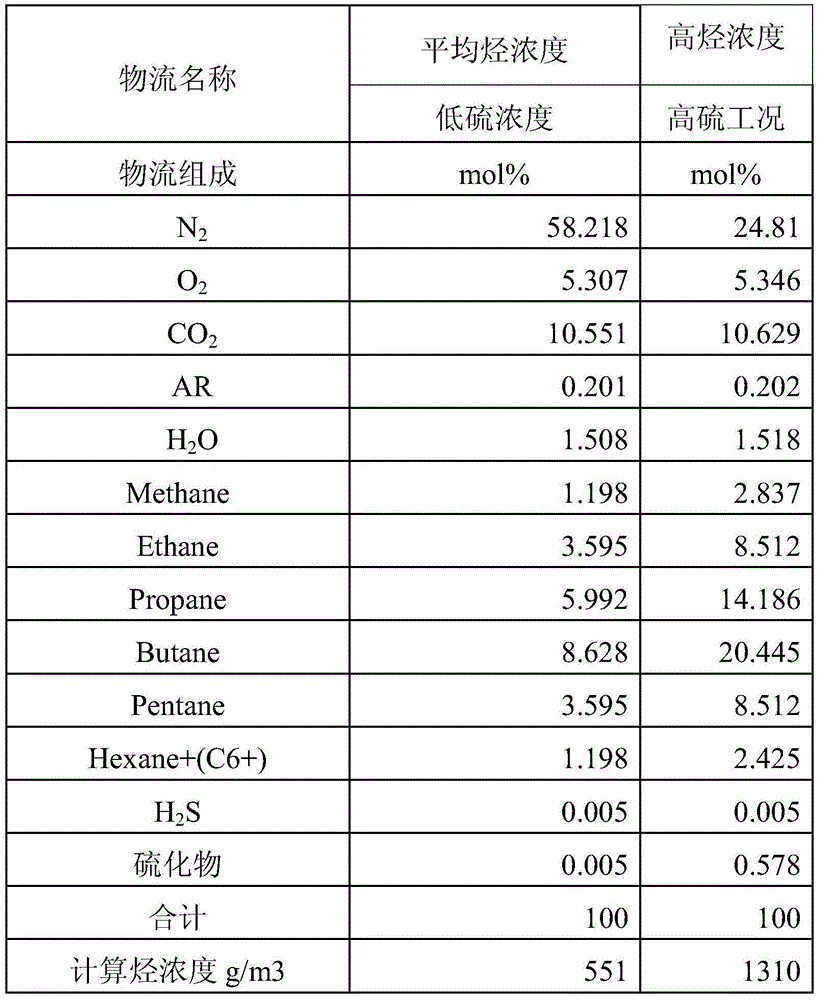

Method for refining catalytic liquefied petroleum gas

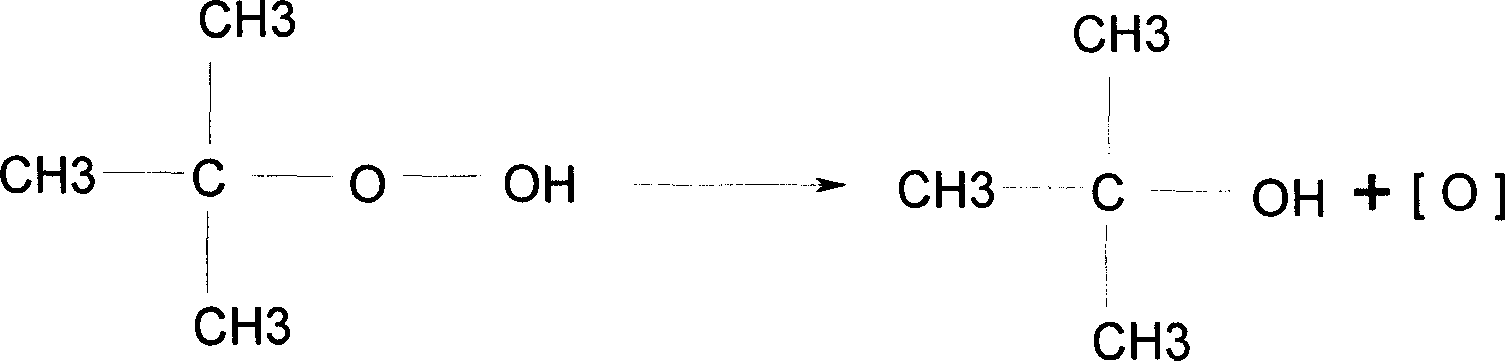

The present invention relates to a method for refining catalytic liquefied petroleum gas, in which catalyzed liquefied petroleum gas by alconol-amine method removing hydrogen sulfide process is operated by hydrolysis carbonyl sulfur process by passing through carbonyl sulfur hydrolysis activator bed layer, such that carbonyl sulfur hydrolysis generates sulfureted hydrogen and carbon dioxide; then it passes through the desulfurizer bed layer to operate hydrogen sulfide removing process, the preparation of reaction of the hydrogen sulfide and the desulfurizer is chemically absorbed on the desulfurizer; at last, liquid oxygen supplying agent having effective component of tert-butyl hydroperoxide is applied into the catalyzed liquefied petroleum gas, then it is processed by transformation mercaptan by passing through the double effects activator bed layer, under the effect of the double effects activator, the tert-butyl hydroperoxide is hydrogen peroxide decomposed to release fresh state oxygen, and the mercaptan is oxygenated to bisulfide; the activate component of the double effects activator is compound of manganic.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

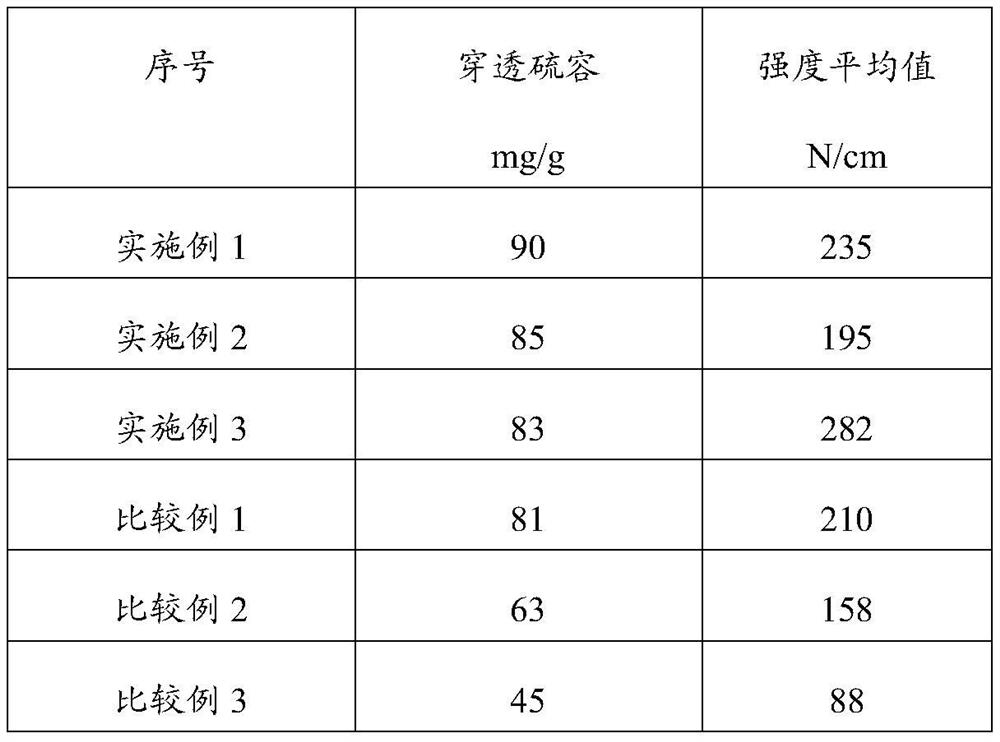

Medium temperature iron-manganese desulfurizing agent and preparation method thereof

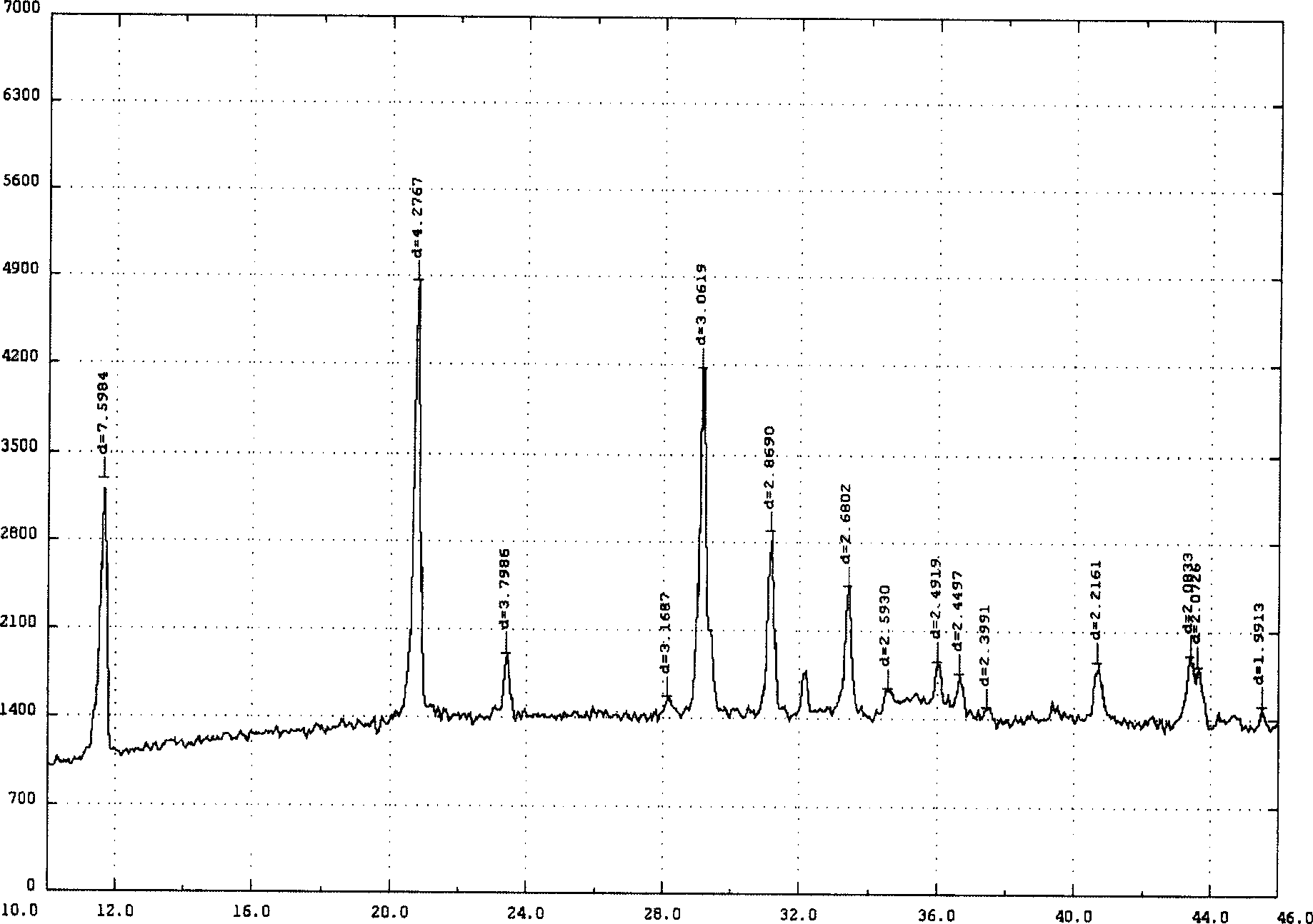

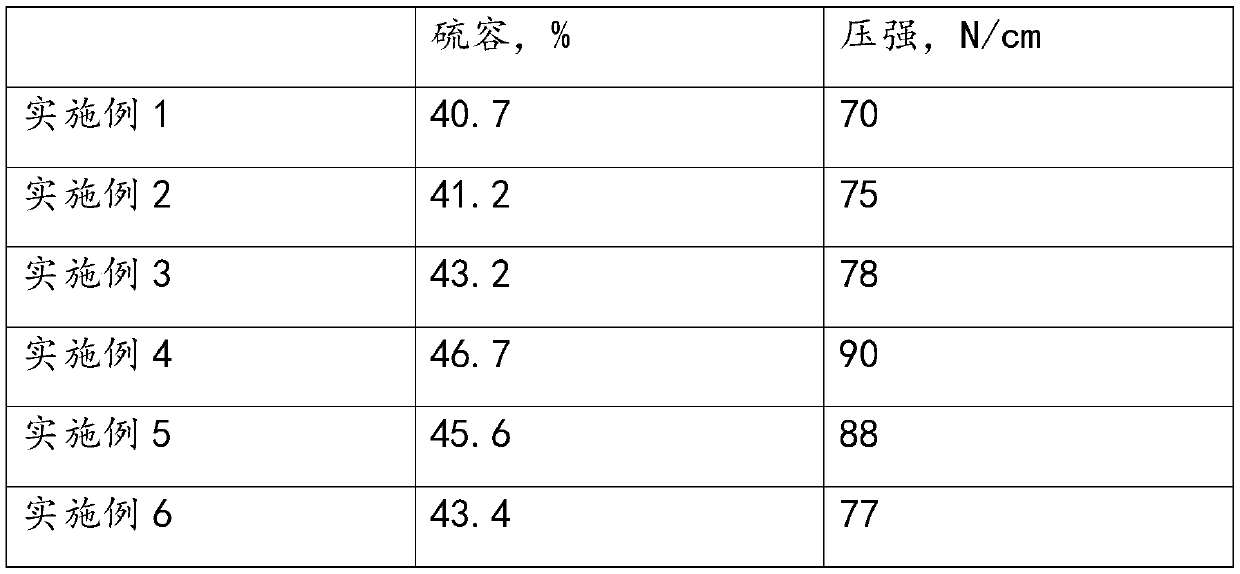

InactiveCN102039086AGood desulfurization effectHigh breakthrough sulfur capacityDispersed particle separationManganese oxideBrown iron oxide

The invention relates to an iron-manganese desulfurizing agent. The desulfurizing agent consists of 10 to 85 weight percent of iron oxide, 10 to 85 weight percent of manganese oxide and 5 to 20 weight percent of inorganic adhesive. The invention further discloses a preparation method for the iron-manganese desulfurizing agent. The iron-manganese desulfurizing agent is prepared by extruding and molding with a dry method and roasting at a specific temperature. The iron-manganese desulfurizing agent prepared by using the preparation method has optimal desulfurizing effect and high penetrating sulfur capacity. The test shows that the penetrating sulfur capacity of the desulfurizing agent can reach 25.1 percent. Moreover, the desulfurizing agent has high mechanical strength, can be widely applied in a chemical refining and desulfurizing process, and can be prevented from being broken to cause loss and affect the desulfurizing effect; and the test shows that the mechanical strength of the iron-manganese desulfurizing agent can reach 100N / cm.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

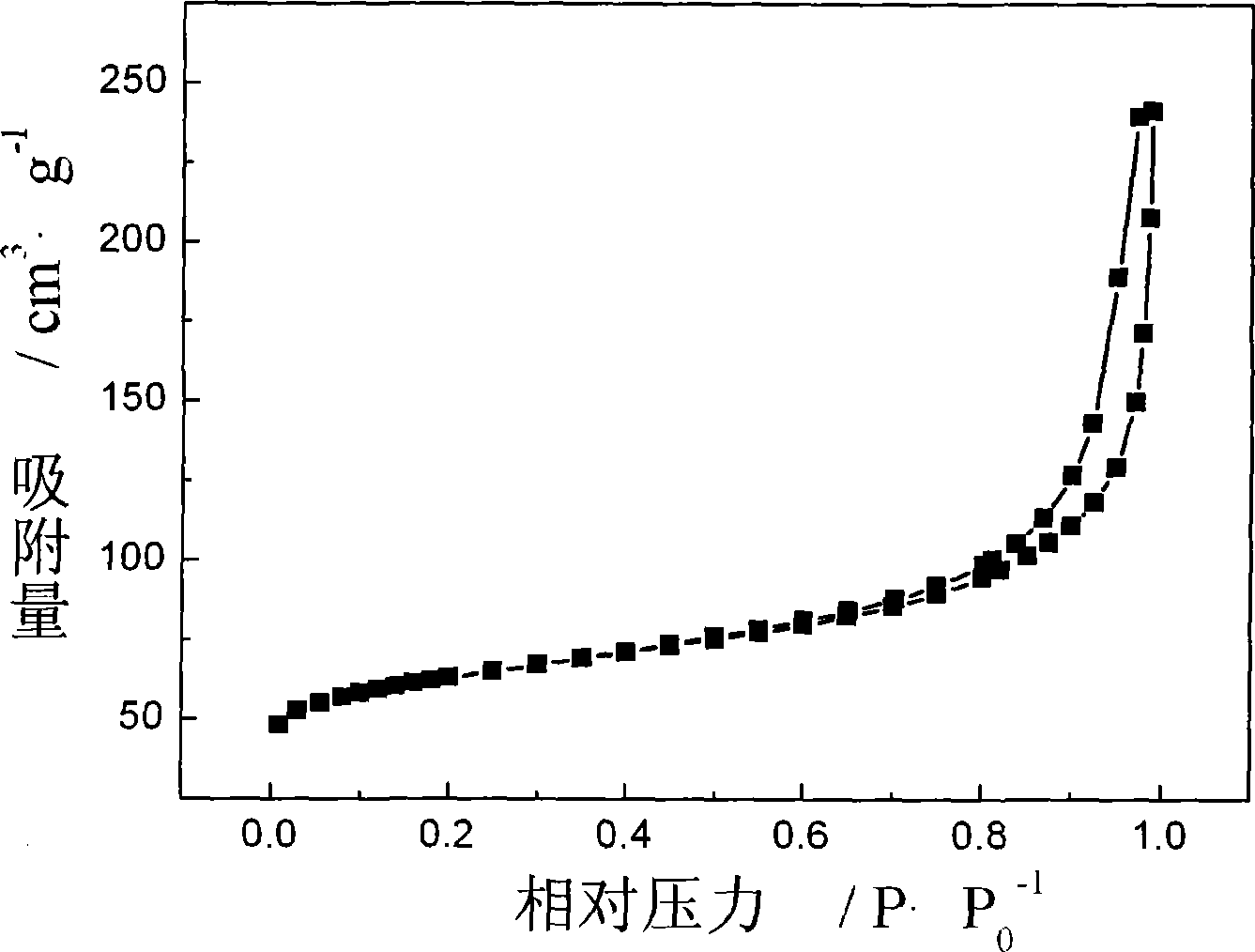

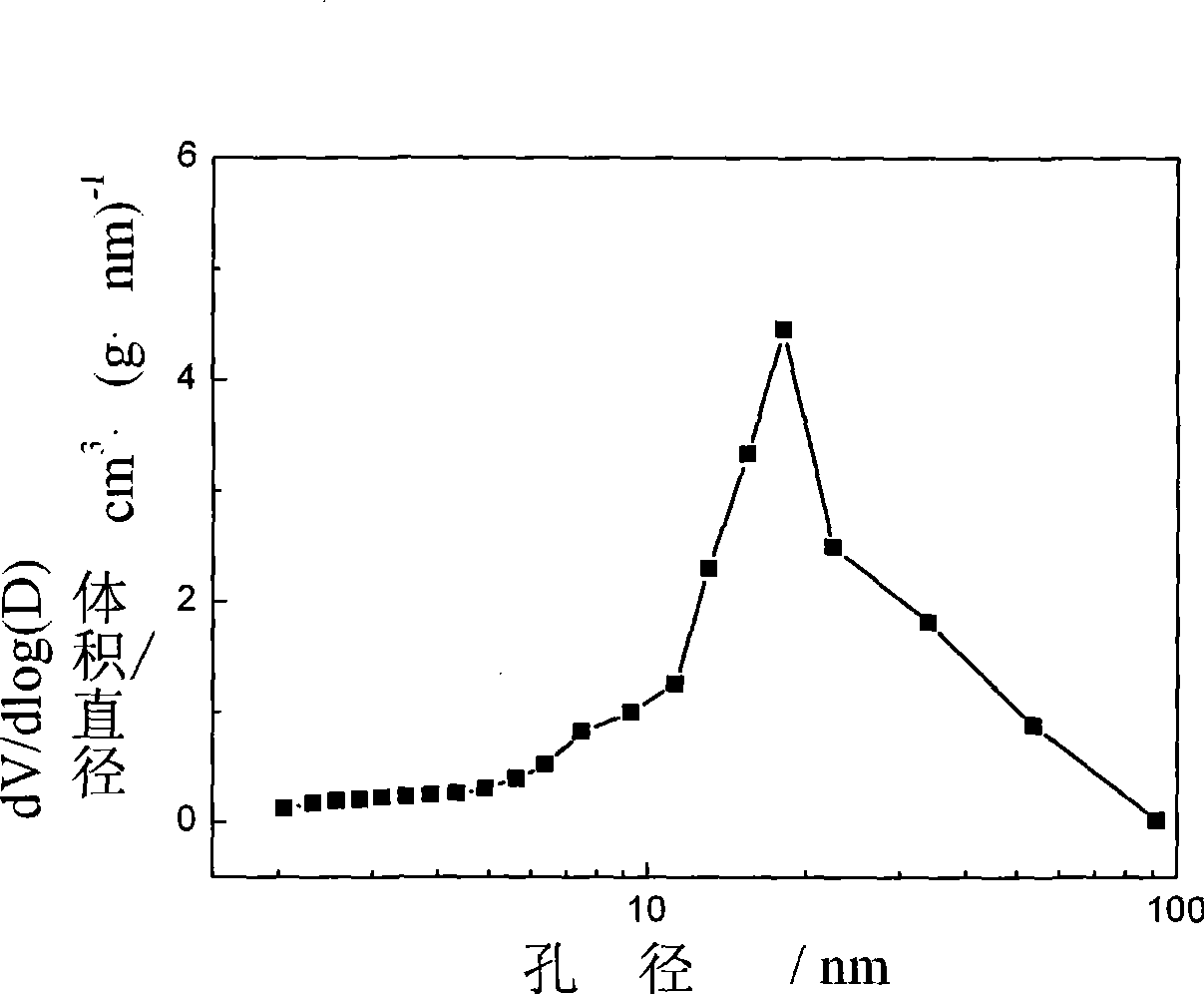

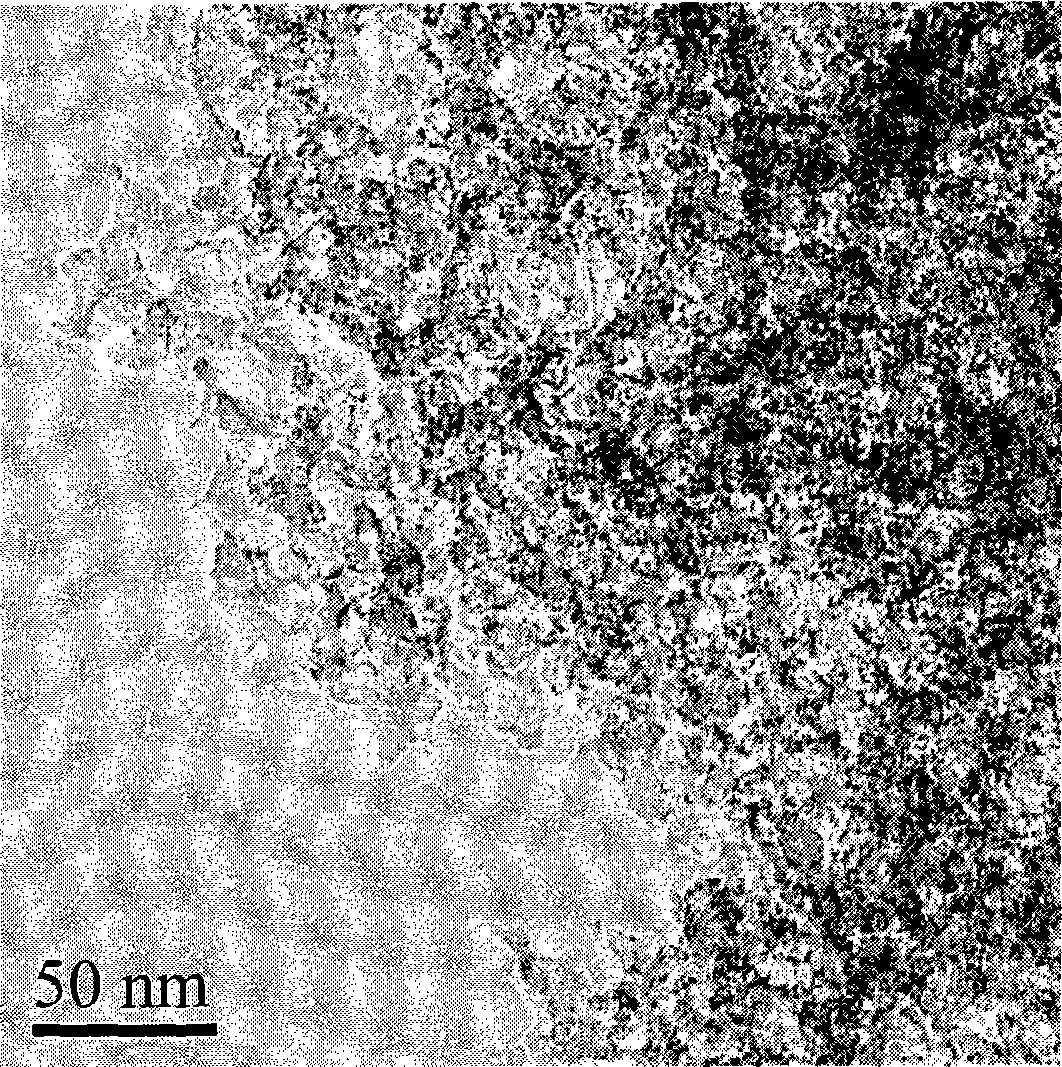

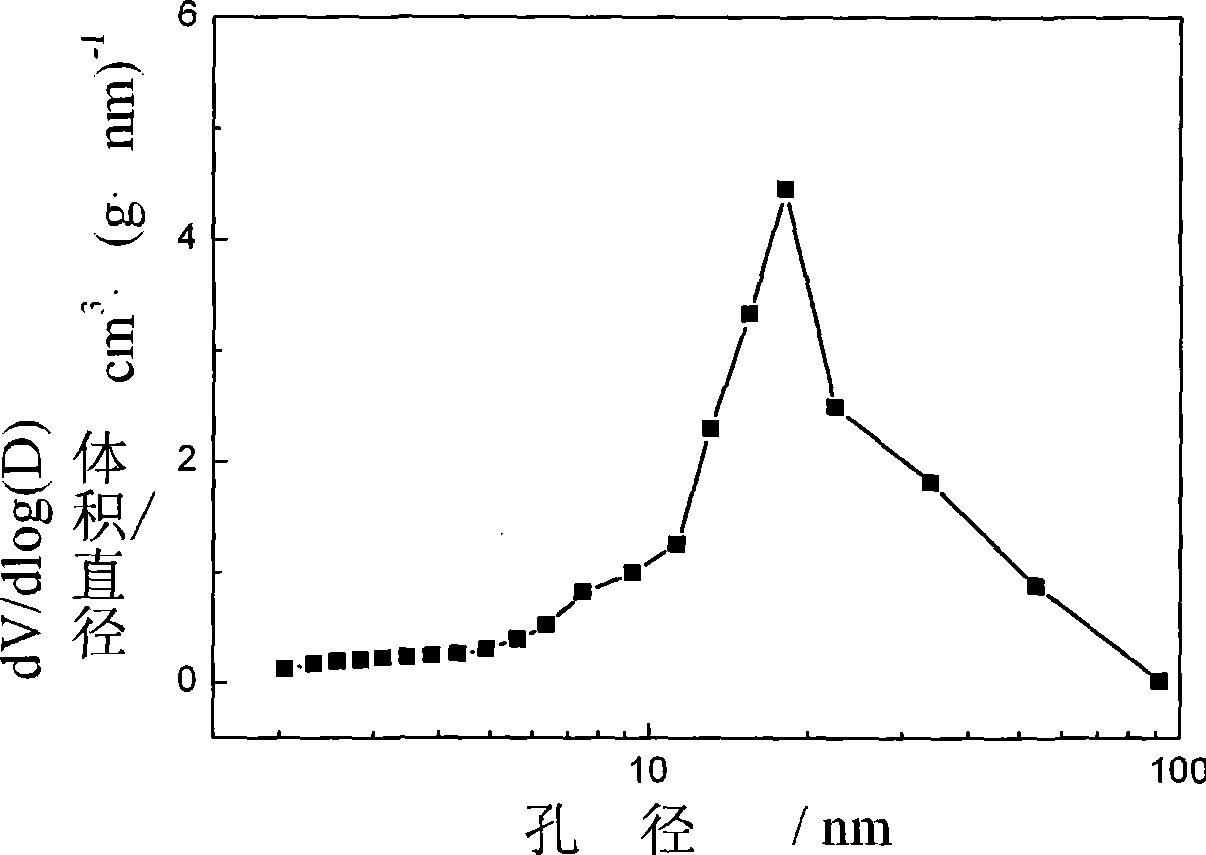

Method for preparing carbon aerogel desulfurizing agent

InactiveCN101376097APrevent collapseAvoid volumeOther chemical processesGas purification with selectively adsorptive solidsPotassiumPhenyl hydroxide

The invention provides a preparation method for a carbon aerogel desulfurization agent. The invention utilizes phenyl hydroxide, methanal and melamine as polymer precursors and utilizes nano-scale silica sol as an inorganic template. The precursors are mixed at a certain proportion and carry on sol-gel reaction; and pure carbon aerogel is produced after the processes of drying, high-temperature carbonizing and template removing. The invention has the advantages of mild preparation condition and conventional production device, and is suitable for large scale industrial production. The desulfurization agent produced by the method of the invention has large breakthrough sulfur capacity and saturated sulfur capacity, thereby being adopted in H2S removing process in oil and gas, synthesis gas, and the tail gas in sewage treatment plants.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst for removing H2S from gas by catalytic oxidation, preparation method and application

InactiveCN102500362AEasy to prepareHigh desulfurization activityGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonSulfur

A catalyst for removing H2S from gas by catalytic oxidation contains a metal oxide as active component, and active carbon as carrier, wherein the weight percentages of the two components are as follows: active carbon 95.0% to 99.9%, and metal oxide 0.1% to 5%; active carbon has a specific surface area of 850 to 900 m<2> / g, total pore volume of 0.45 cm<3> / g, and micro-pore volume of 0.154 cm<3> / g; and the metal oxide is oxide of Fe, V, Mn, Cu, Ce or Co. The catalyst provided by the invention has a simple preparation method, and can remarkably improve the desulfurization activity and selectivity of active carbon and greatly improve breakthrough sulfur capacity of desulfurizer.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

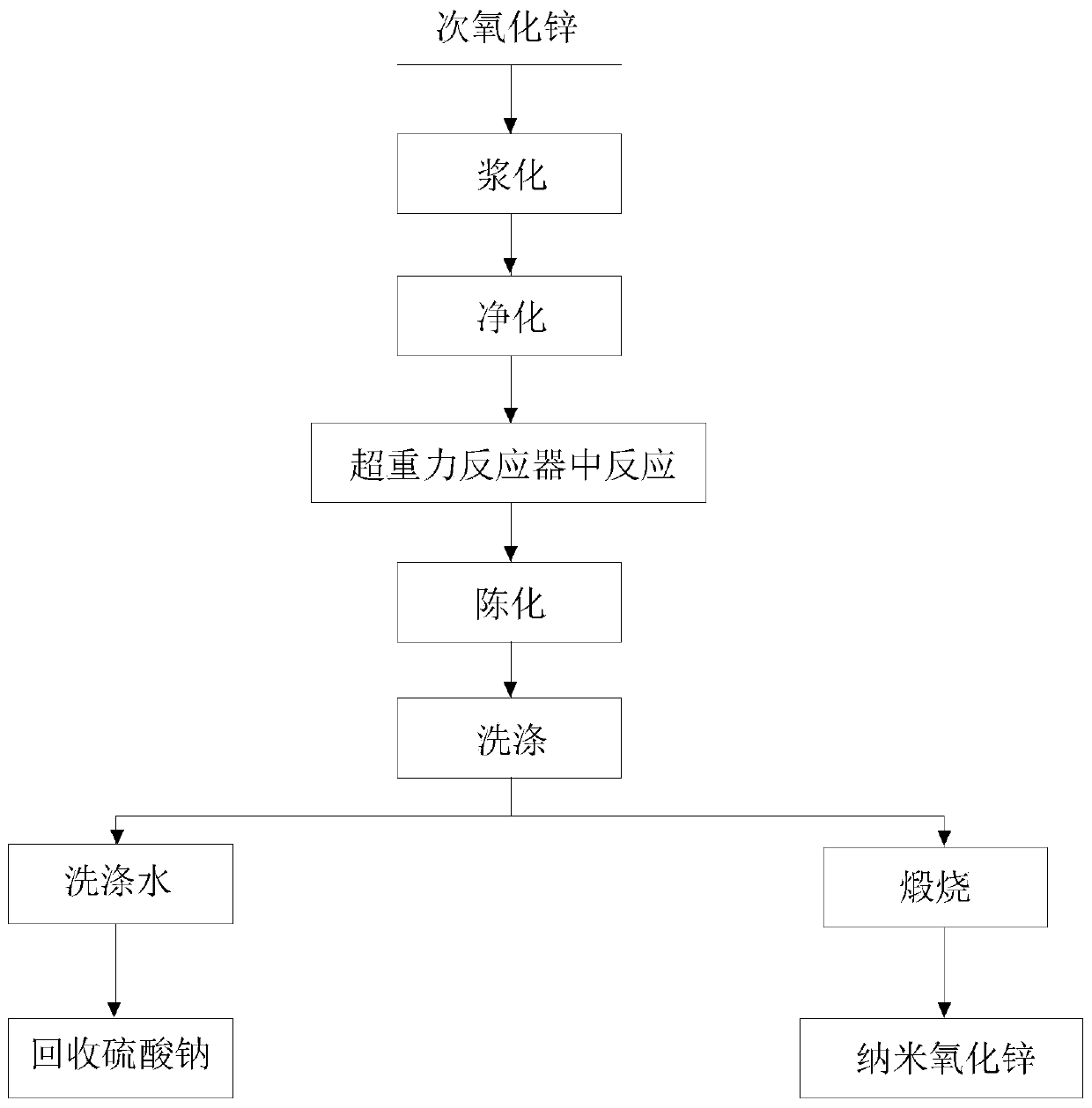

Nanometer zinc oxide, preparation method thereof and desulfurizing agent

PendingCN111333101AUniform particle sizeImprove purityZinc oxides/hydroxidesNanotechnologySulfate zincPhysical chemistry

The invention discloses nano-zinc oxide, a preparation method thereof and a desulfurizing agent, and relates to the field of nano-zinc oxide preparation. The preparation method of the nano-zinc oxidecomprises the following steps: carrying out neutralization reaction on a zinc sulfate solution and a sodium carbonate solution in a supergravity reactor to generate precursor slurry; adjusting the precursor slurry to be neutral, standing and aging for at least 2.5 hours, washing and carrying out filter pressing to obtain a precursor; calcining the precursor; carrying out direct precipitation reaction by adopting a supergravity reactor; the generated basic zinc carbonate precursor is quickly nucleated in a supergravity reactor; the method comprises the following steps: calcining nano-zinc oxide, then aging, nucleating uniformly and finely, mainly condensing and growing among nuclei, so that the particle size of the nano-zinc oxide after subsequent calcination is uniform and fine, the specific surface area of the nano-zinc oxide after calcination is effectively increased compared with that of a direct precipitation method, and the penetration sulfur capacity of the desulfurizing agent can be up to 25% when the prepared nano-zinc oxide is applied to the desulfurizing agent.

Owner:JIYUAN LUTAI NANO MATERIAL CO LTD

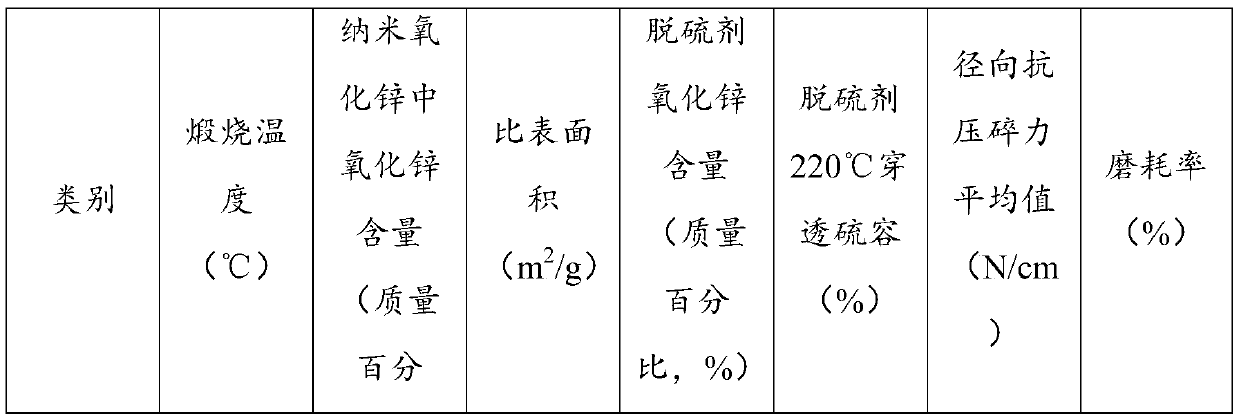

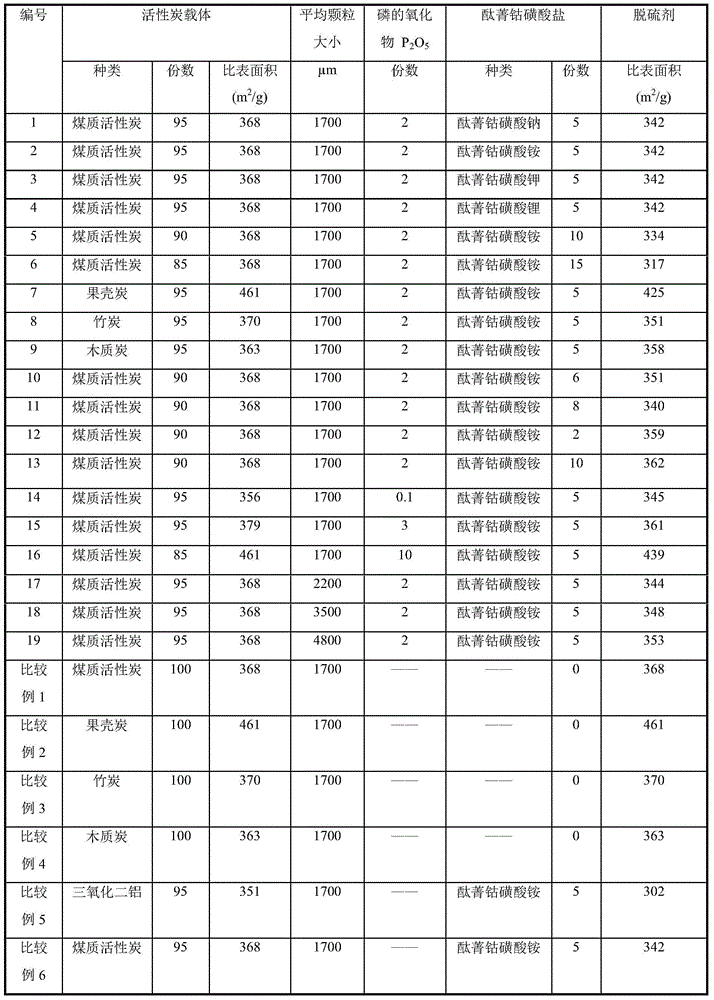

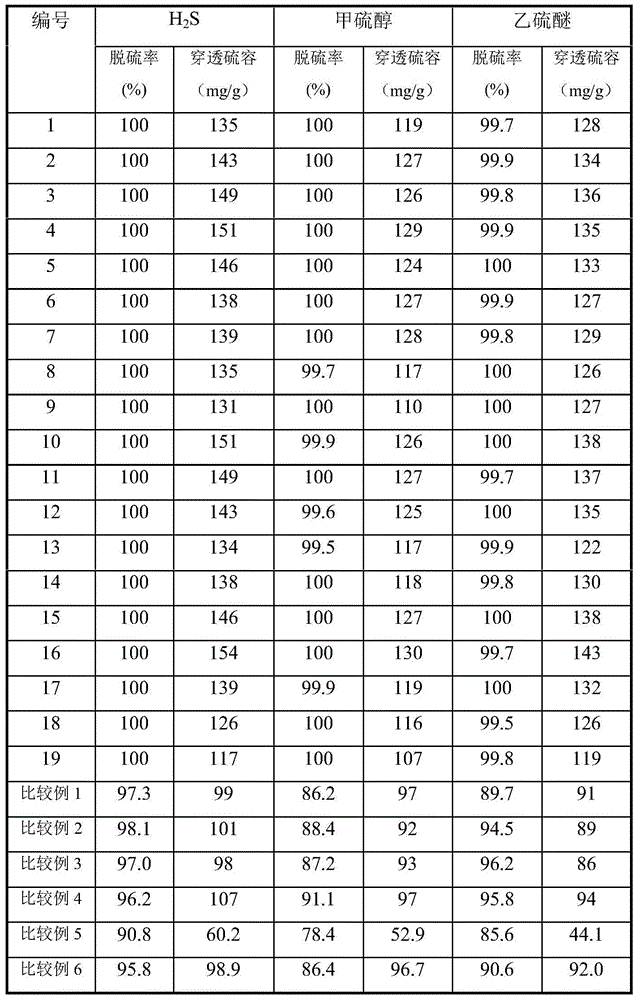

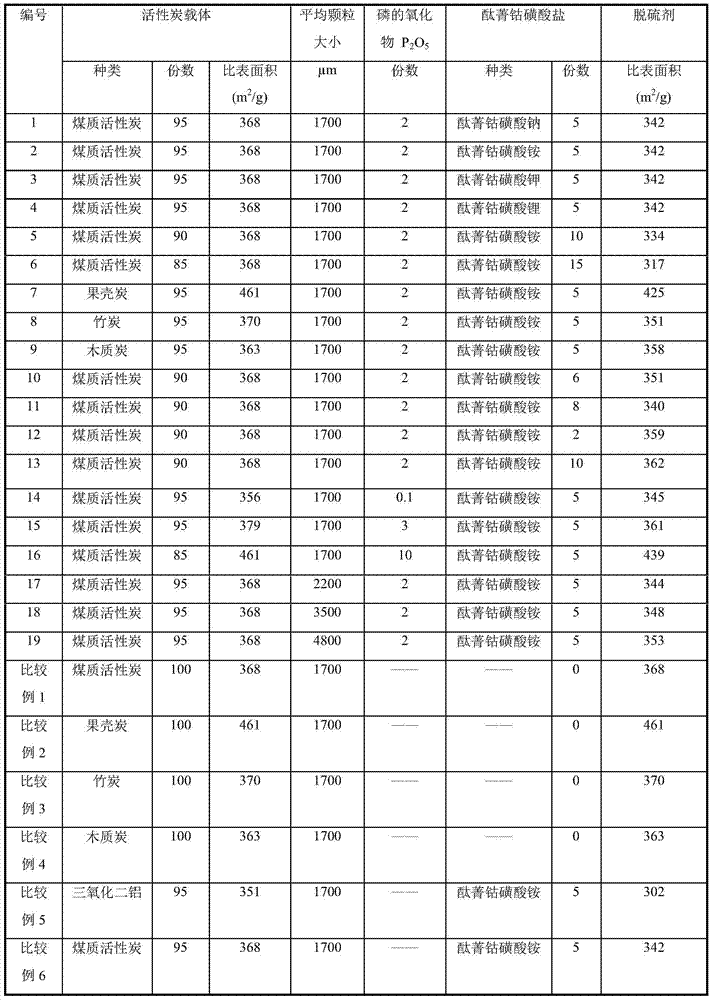

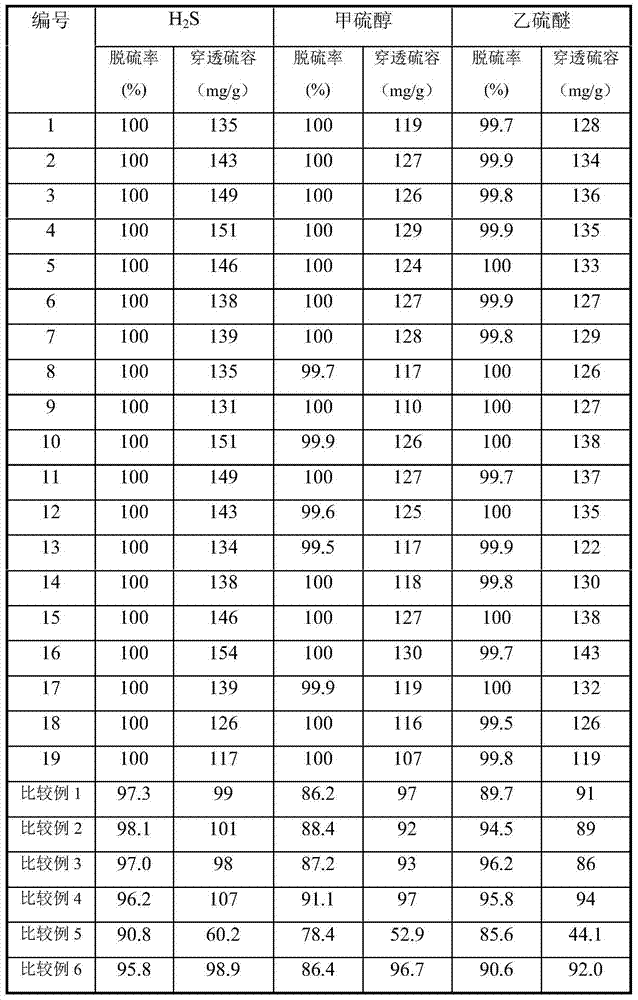

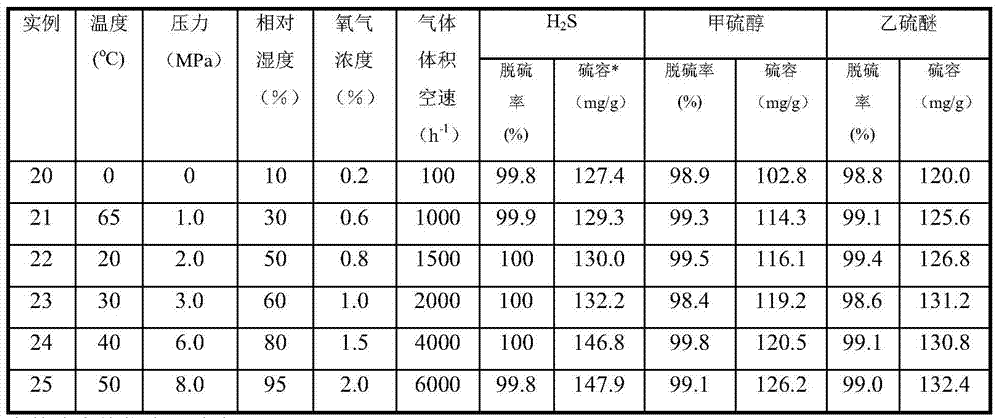

Active carbon desulphurization adsorbent loaded with cobalt phthalocyanine sulfonate and preparation method

ActiveCN105080488AHigh removal rateHigh breakthrough sulfur capacityIon-exchange process apparatusOther chemical processesActivated carbonSulfonate

The invention relates to a active carbon desulphurization adsorbent loaded with cobalt phthalocyanine sulfonate and a preparation method thereof, and mainly solves problems that sulfur removal rate is low, and breakthrough sulfur capacity of desulfurizer is low in existing gas adsorption, desulphurization and purification technology. In the invention cobalt phthalocyanine sulfonate is employed as active ingredient and a small amount of phosphor is added for modifying the active carbon. In this way, the solid adsorbent is obtained. The problems of low sulfur removal rate, etc. are solved. The desulphurization adsorbent of the invention can be used in adsorption and purification of gas materials for removal of sulfur-containing compound.

Owner:CHINA PETROLEUM & CHEM CORP +1

Potassium ion-containing molecular sieve desulfurizing agent, and preparation method thereof

InactiveCN103894146AReduce the number of regenerationsImprove adsorption capacityOther chemical processesHydrocarbon oils refiningMolecular sieveAbsorption capacity

The invention relates to a potassium ion-containing molecular sieve desulfurizing agent, and a preparation method thereof. According to the preparation method, metal cation K+ is used for modifying a molecular sieve, and potassium ion exchange degree is controlled to be 5 to 25%, so that electrostatic field intensity of local positions in hole passages of the molecular sieve is increased, and when the molecular sieve is used for desulphurization of hydrocarbon flow via physical adsorption, neutral sulfide and disulphide molecules in the hydrocarbon flow are polarized, and are absorbed easily, absorption capacity and absorption efficiency of the molecular sieve on the sulfides are increased. The potassium ion-containing molecular sieve desulfurizing agent with an ion exchange degree of 5 to 25% is excellent in absorption effect, is high in absorption capacity, and is capable of reducing generation times of the potassium ion-containing molecular sieve desulfurizing agent effectively.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

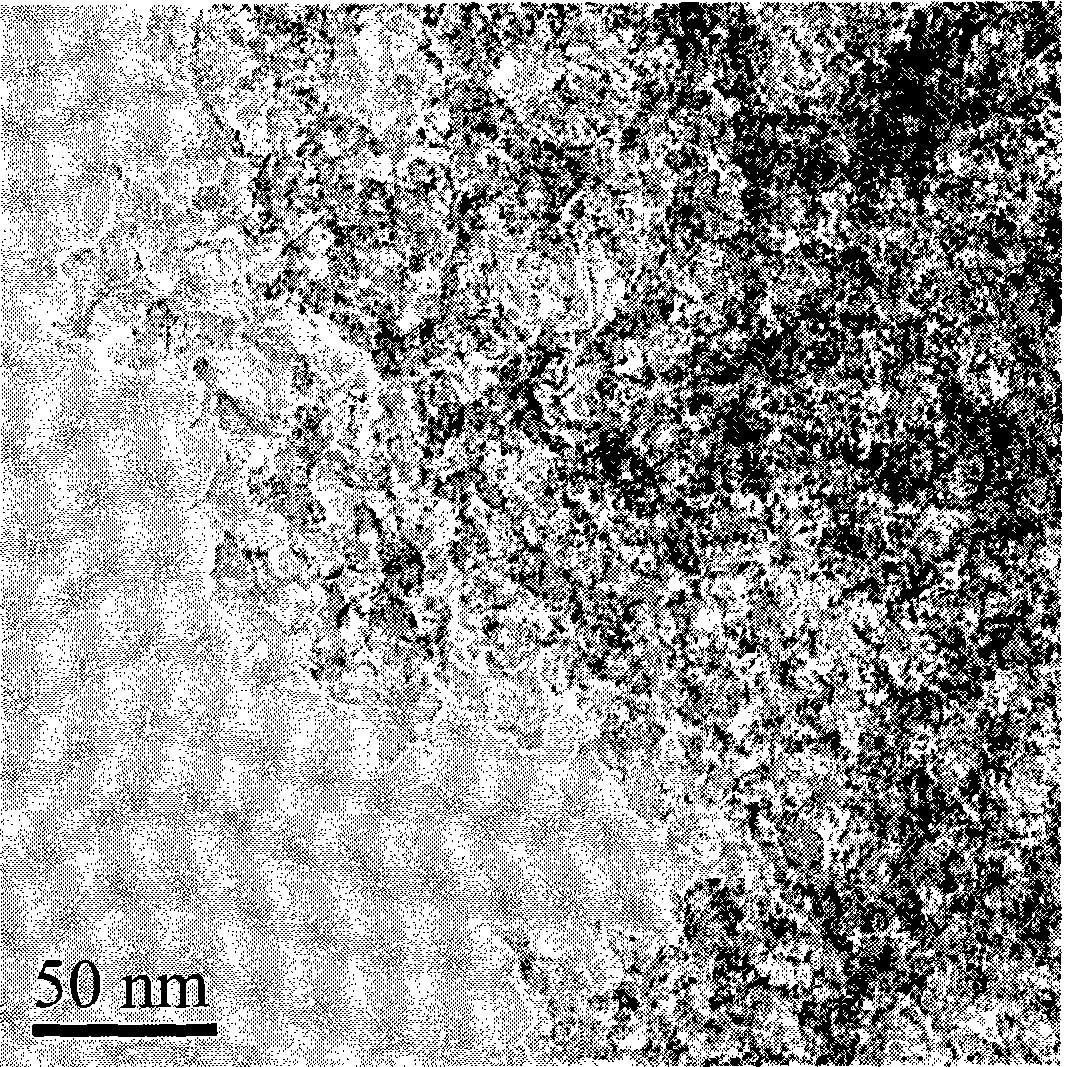

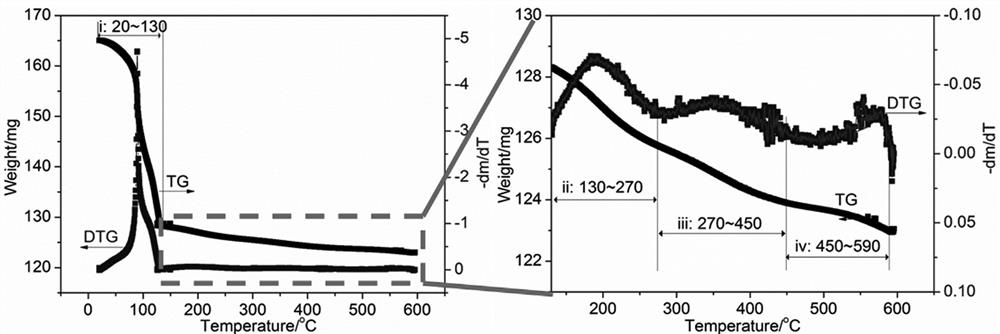

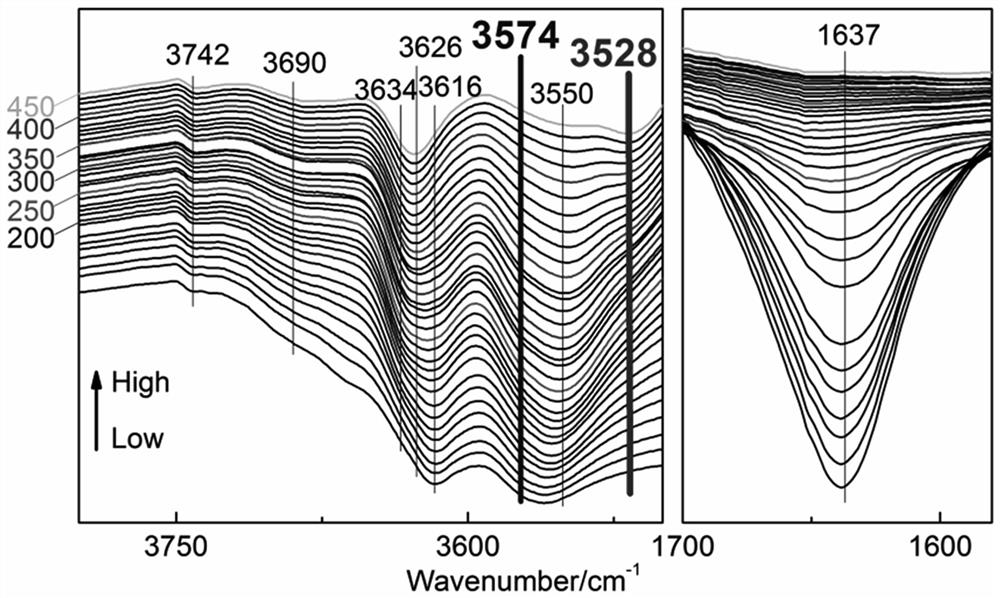

Iron-based composite desulfurizing agent and preparation method thereof and application of iron-based composite desulfurizing agent in removal of hydrogen sulfide in gas

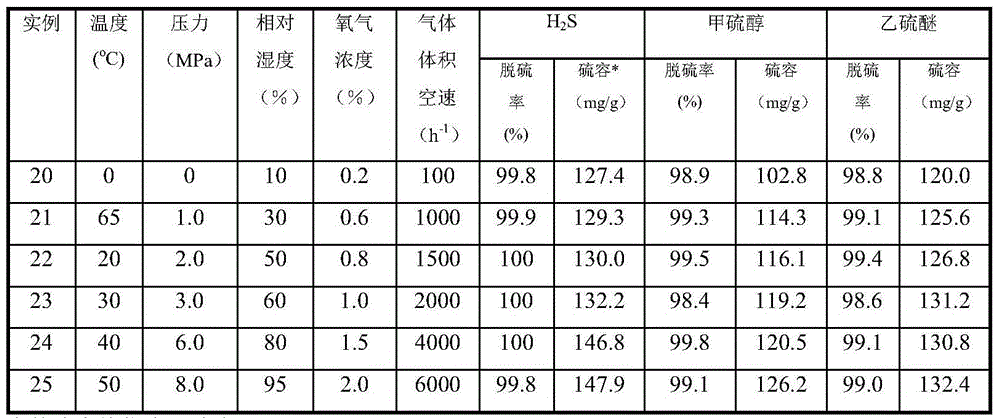

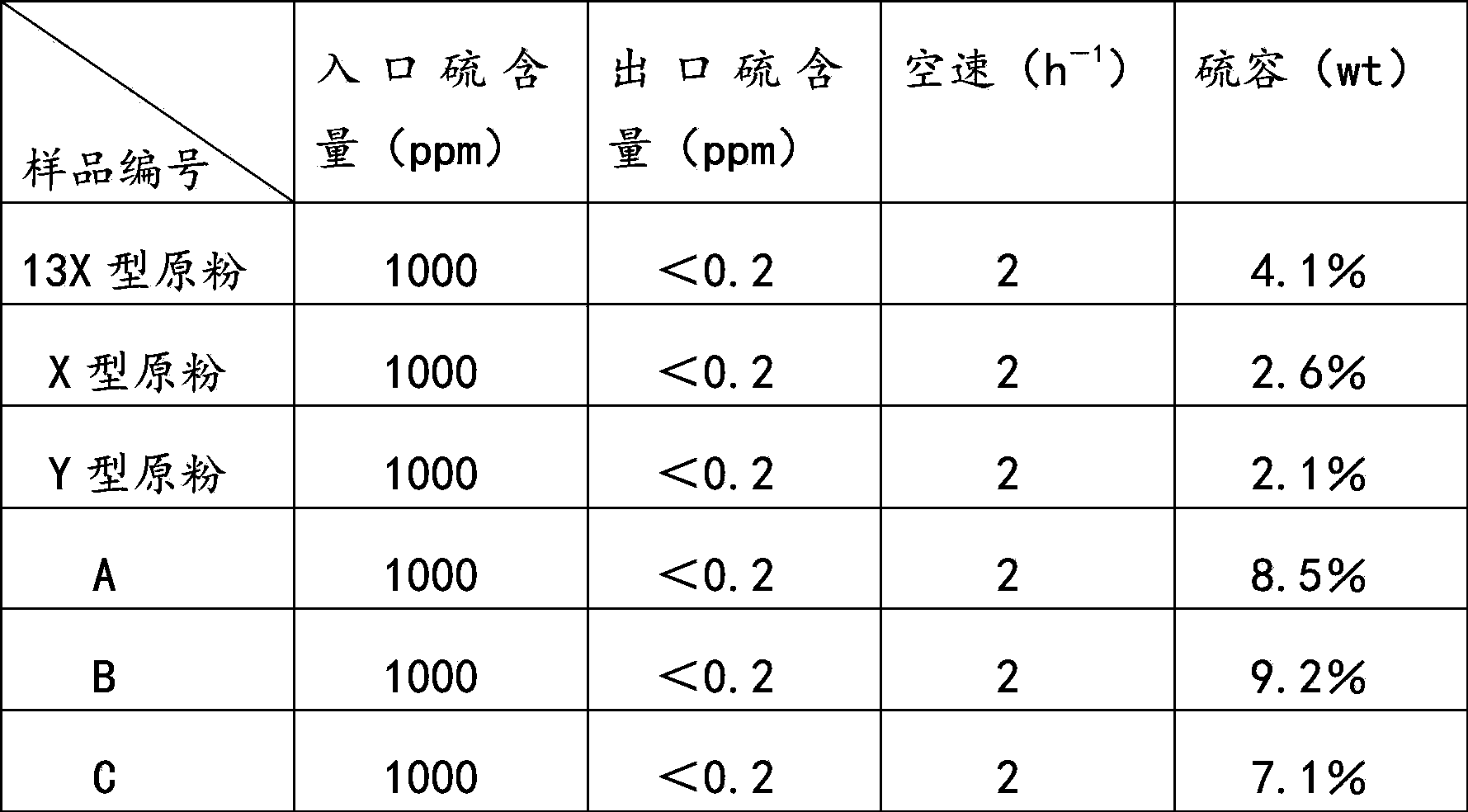

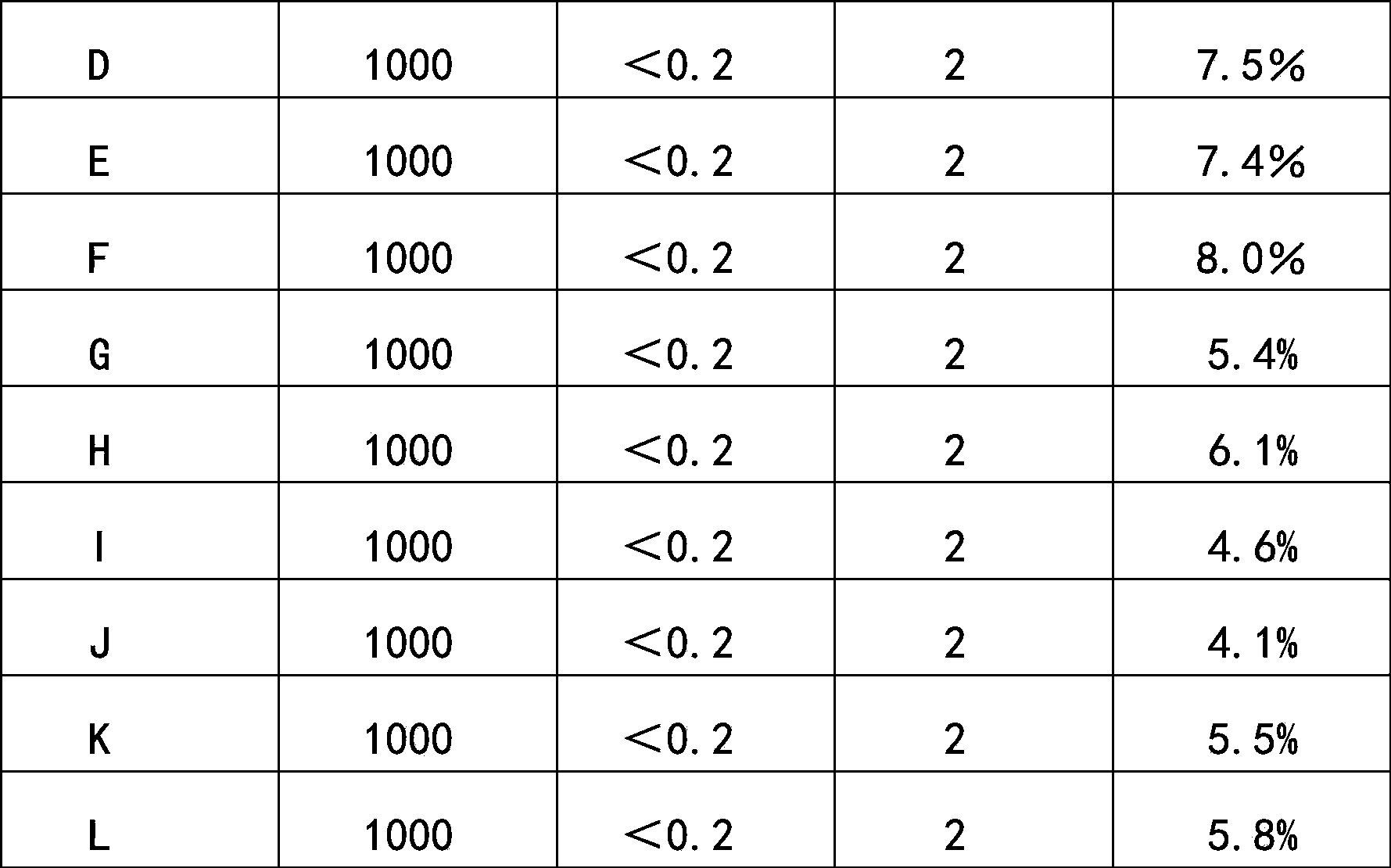

ActiveCN112717931AHigh desulfurization activityHigh breakthrough sulfur capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHydration reactionSulfur hydride

The invention provides an iron-based composite desulfurizing agent and a preparation method thereof and application of the iron-based composite desulfurizing agent in removal of hydrogen sulfide in gas, the iron-based composite desulfurizing agent comprises carbon nanotubes and ferric oxide hydrate loaded on the carbon nanotubes, and the mass percentage of ferric oxide hydrate in the desulfurizing agent is 50-90%. According to the method, the carbon nanotubes serving as a high-conductivity material are introduced into the desulfurizing agent for modification for the first time, and rich point defects and surface hydroxyl groups are formed on the surface of ferric oxide hydrate by utilizing strong interaction between the carbon nanotubes and the ferric oxide hydrate, so that the dispersity of the ferric oxide hydrate is improved, and the desulfurization activity and sulfur capacity of the ferric oxide hydrate are improved. Fe-O-C chemical bonds are formed between ferric oxide hydrate and the carbon nanotubes, so that the electron mobility during desulfurization reaction is promoted. The desulfurizing agent is mild in preparation condition, low in production cost and very suitable for industrial large-scale production. In addition, the desulfurizing agent has good low-temperature desulfurization performance, so that the desulfurizing agent can be used for removing trace hydrogen sulfide in high-concentration CO2 gas, and has the characteristic of wide universality.

Owner:中峰信和(大连)科技有限公司

Refinery waste gas desulfurizer, preparation method and applications thereof

ActiveCN105126597AIncrease alkalinityIncrease polarityDispersed particle separationCobalt phthalocyanineCerium

The invention provides a refinery waste gas desulfurizer, a preparation method and applications thereof. The desulfurizer is composed of the following components in percentage by weight: 1.6 to 6.4 wt% of CuO, 1 to 3 wt% of NiO, 0.2 to 0.8 wt% of CeO2, 0.1 to 0.5 wt% of cobalt phthalocyanine substance, and the balance being active carbon, which has been processed by nitrogen-containing compounds. The active carbon is modified by nitrogen-containing compounds, the alkali property and polarity of active carbon surface are both improved, and thus the absorbing performance of active carbon on acidic sulfides is enhanced. Then oxides of copper, nickel, and cerium are loaded on the modified active carbon so as to further improve the alkali property of the active carbon surface. Finally cobalt phthalocyanine is loaded on the active carbon and is capable of oxidizing mercaptan in the refinery waste gas into corresponding disulfides, which can be absorbed by active carbon. So the prepared desulfurizer can efficiently absorb and remove sulfides such as hydrogen sulfide, carbonyl sulfide, thioether, mercaptan, disulfides, and the like in the refinery waste gas in one time. The total sulfur concentration in the outlet is less than 2 mg / m3. The breakthrough sulfur capacity can reach 32% or more.

Owner:SHENYANG SANJUKAITE CATALYST

Solid desulfurizing agent and preparation method thereof

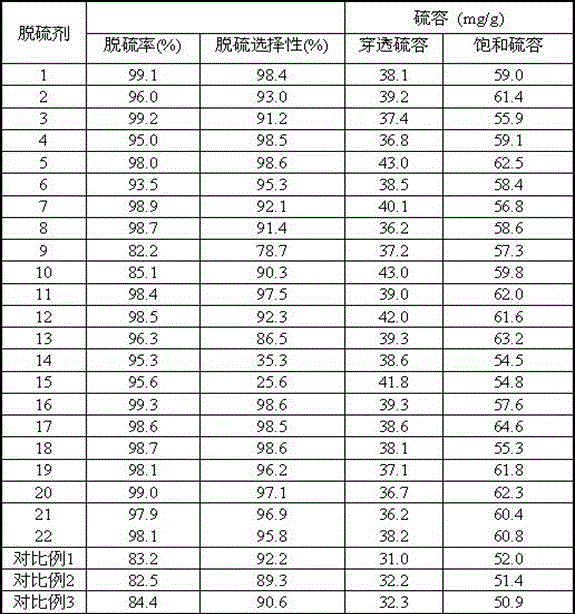

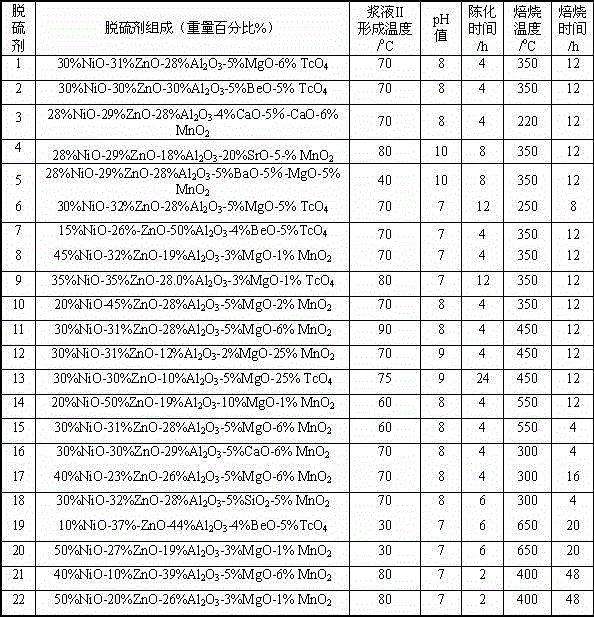

ActiveCN103933927AHigh breakthrough sulfur capacityHigh activityOther chemical processesSolid sorbent liquid separationCombinatorial chemistryAlkene

The invention relates to a one-step solid desulfurizing agent used for removal of low carbon olefins from sulfur-containing compounds and a preparation method thereof, and mainly solves the problems that desulfurization methods in the prior art are low in selectivity, low in breakthrough sulfur capacity, low in desulfurization rate and the like. The one-step solid desulfurizing agent is a high activity Ni based desulfurizing agent which comprises the following components by weight: a) 10.0-50.0% of NiO, b) 10.0-50.0% of ZnO, c) 1-25% of an oxide of at least one element selected from group IIVB in the periodic table of elements, d) 2.0-20.0% of an oxide of at least one element selected from group IIA in the periodic table of elements, and e) 10.0-50.0% of Al2O3. By adopting the technical scheme and the preparation method, the problems that desulfurization methods in the prior art are low in selectivity, low in breakthrough sulfur capacity, low in desulfurization rate and the like can be well solved, and the one-step solid desulfurizing agent can be used in the desulfurization process for propylene, butylenes and other low carbon olefin chemical raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Molecular sieve desulfurizer containing copper ion and potassium ion and preparation method thereof

InactiveCN103894147AReduce the number of regenerationsImprove adsorption capacityOther chemical processesHydrocarbon oils refiningMolecular sievePhysical chemistry

The invention relates to a molecular sieve desulfurizer containing copper ion and potassium ion and a preparation method thereof. According to the molecular sieve desulfurizer, metal cations K+ and Cu<2+> are adopted to modify a molecular sieve, and the whole exchange rate of the potassium ion and the copper ion is 10-40%, and therefore the electrostatic field intensity of local positions in pore channels in the molecular sieve is enhanced. When hydrocarbon flows are desulfurized by the molecular sieve through physical adsorption, mercaptan molecules and thioether molecules in the hydrocarbon flows are polarized, so that the mercaptan molecules and the thioether molecules are prone to adsorption, and the adsorption capability and the adsorption efficiency of the molecular sieve for sulfides are increased. The molecular sieve desulfurizer containing the copper ion and the potassium ion, the exchange rate of which is 10-40%, is good in adsorption effect and large in adsorption capability, thus effectively reducing the number of times of regeneration of the desulfurizer.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing absorbing agent for medium-temperature gas desulfurization

ActiveCN102764629AThe preparation process is simple to operateEasy to operateOther chemical processesGas purification with selectively adsorptive solidsChemistryIron oxide

The invention discloses a method for preparing an absorbing agent for medium-temperature gas desulfurization. The method comprises that an isometrical ferric nitrate solution is soaked in a Gamma-Al203 carrier isometrically, vacuum impregnation and ultrasonic wave impregnation are performed simultaneously, and the absorbing agent for medium-temperature gas desulfurization with an active componentof ferric oxide is obtained after vacuum drying and high-temperature roasting. During the preparation process of the absorbing agent for medium-temperature gas desulfurization, by the aid of ultrasonic and vacuum synergy effects, the specific surface area of the carrier is improved, the active component is loaded on the carrier uniformly simultaneously, a hole structure of the carrier is improved, component load and drying are completed under ultrasonic and vacuum action, the active component of the prepared absorbing agent is distributed uniformly on the surface of the carrier, the utilization rate of the active component is high, the breakthrough sulfur capacity is large, and the breakthrough time is long.

Owner:TAIYUAN UNIV OF TECH

Desulfurizer making method

InactiveCN105582791AHigh sulfur capacityHigh desulfurization precisionDispersed particle separationCombustible gas purificationCalcium hydroxideAmmonium carbonate

Belonging to the technical field of desulfurizer preparation, the invention provides a desulfurizer making method. The making method comprises the steps of: (1) mixing and rolling ferrous sulfate heptahydrate with ammonium hydrogen carbonate or ammonium carbonate uniformly, and drying the obtained material in the air; (2) adding calcium hydroxide into the dried material of step (1), further mixing and rolling the materials evenly, performing strip extrusion and drying, thus obtaining the material containing amorphous hydroxyl iron oxide. The amorphous hydroxyl iron oxide desulfurizer obtained by the method provided by the invention has a content of the active component amorphous hydroxyl iron oxide up to more than 95%, and one-time breakthrough sulfur capacity up to more than 40%, and has the advantages of high sulfur capacity and high desulfurization precision.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

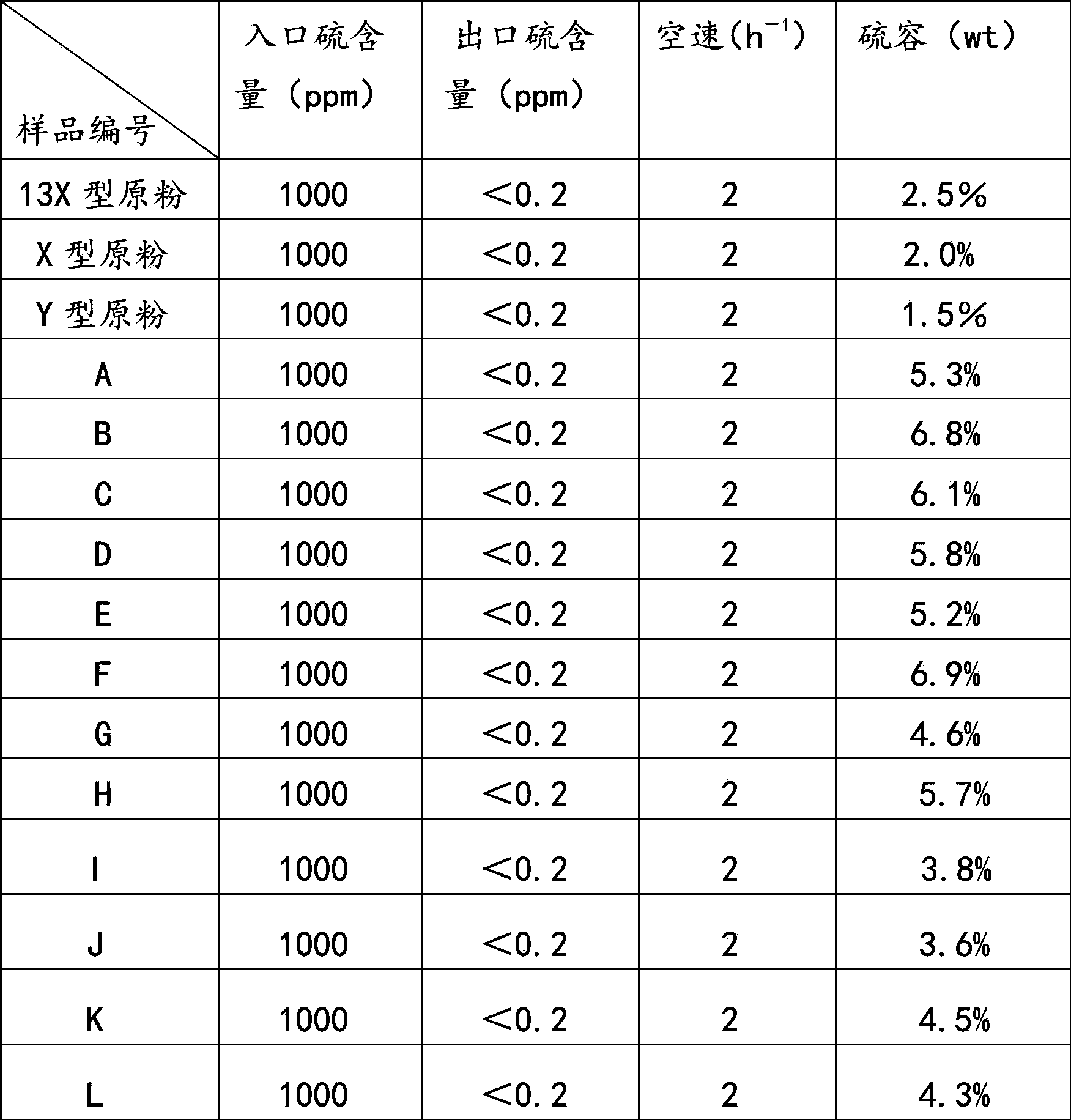

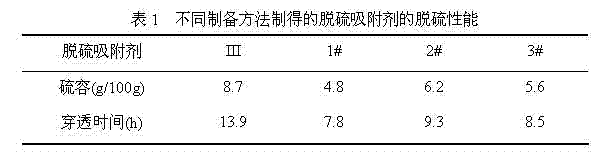

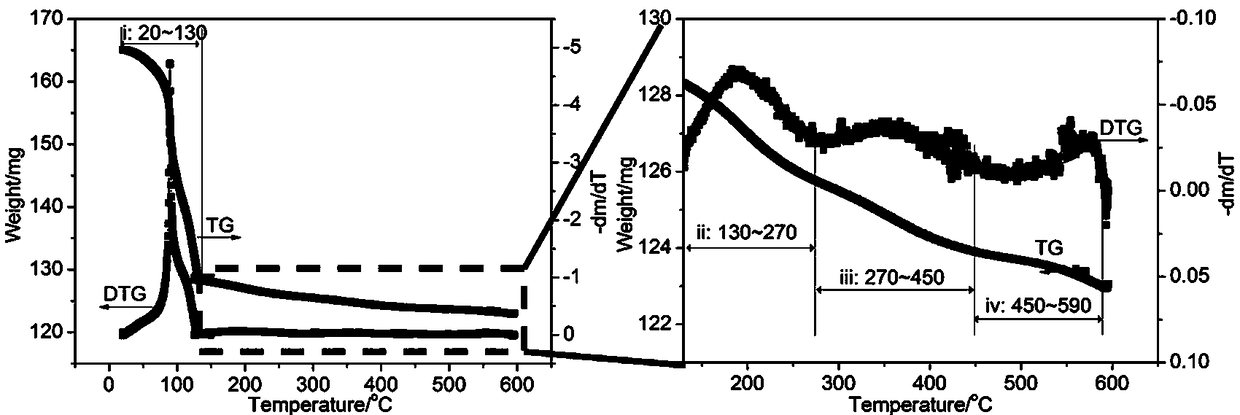

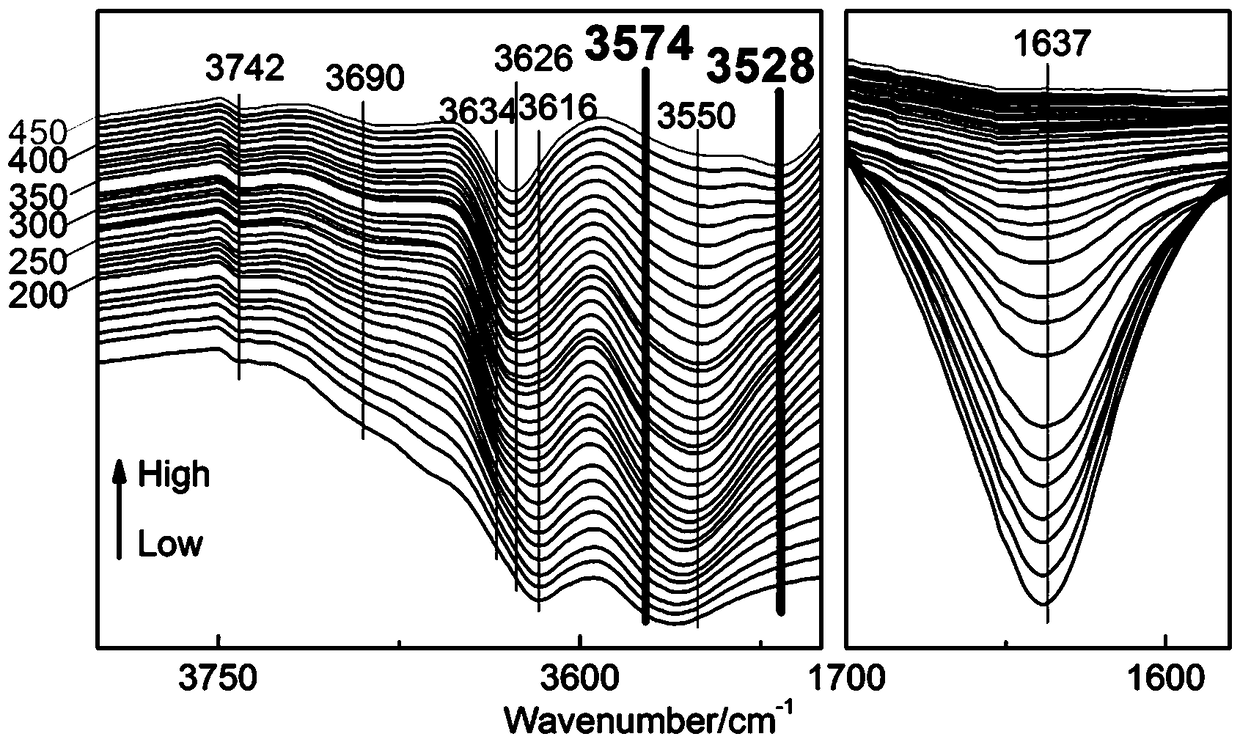

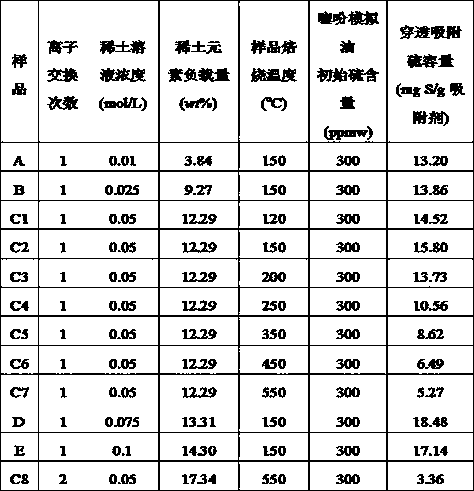

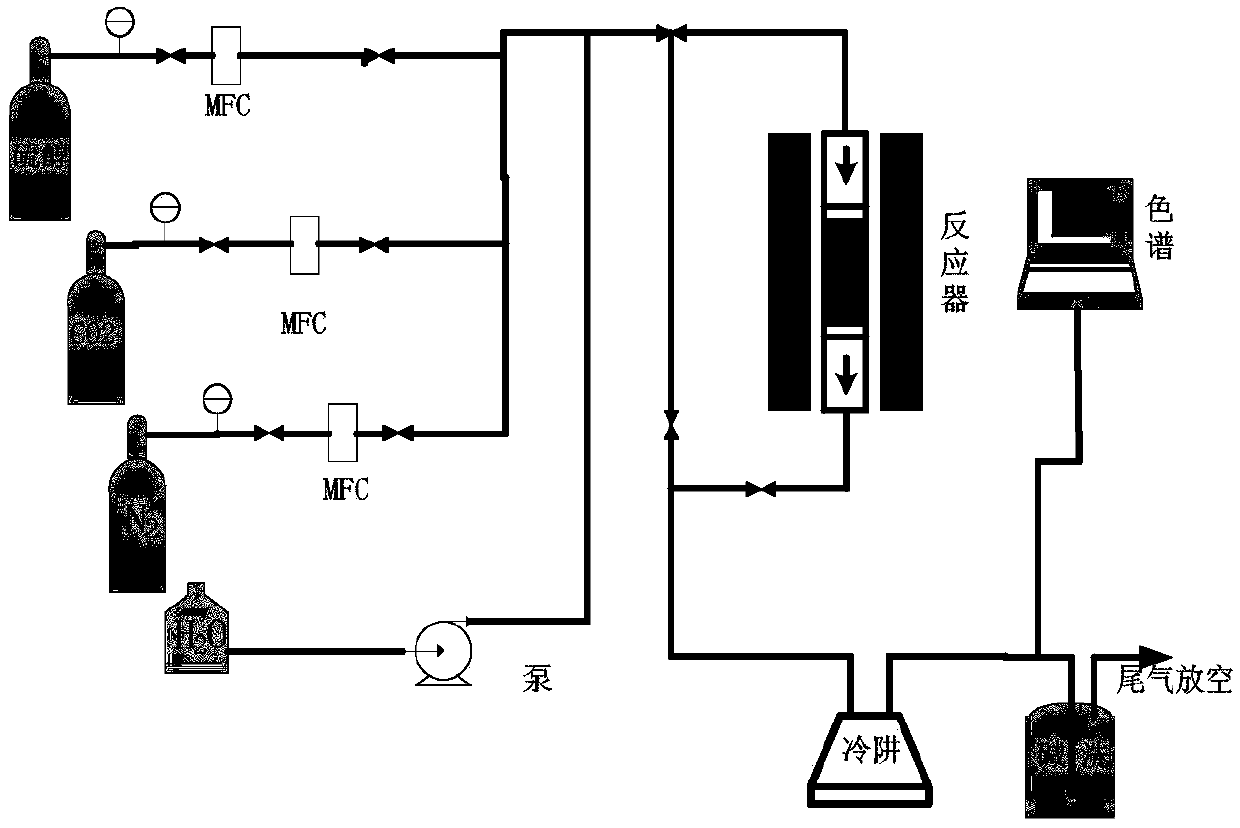

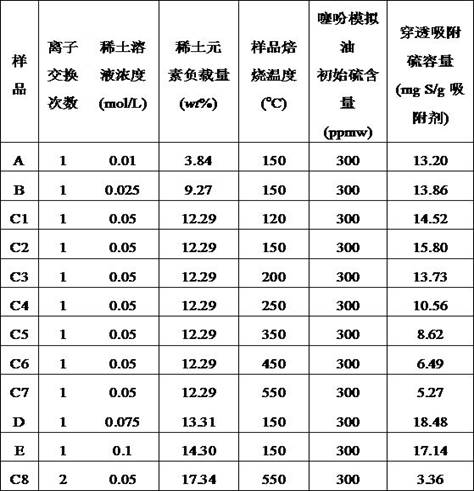

Preparation method and application of REY molecular sieve adsorbent for deeply removing thiophene type sulfide in gasoline

ActiveCN108543515ALow firing temperatureIncrease profitOther chemical processesCombustible gas purificationIon exchangeMolecular sieve

The invention belongs to the field of environmental pollution chemistry and gasoline desulfurization, and relates to a preparation method and application of a REY molecular sieve adsorbent with high penetrating sulfur adsorption capability on sulfur-containing compounds in gasoline. The preparation method comprises the following steps of a, selecting Y type molecular sieve raw powder with different silicon-aluminum mole ratios; b, preparing a rare earth salt solution; c, mixing the Y type molecular sieve raw powder in the step a and the rare earth salt solution in the step b according to a certain solid-liquid ratio; performing once or multiple ion exchange at certain temperature; washing, filtering and drying; d, roasting the product dried in the step c to obtain a target product of REY molecular sieve adsorbent. The preparation cost is low; the energy consumption is low; the penetrating sulfur adsorption capability is great; the desulfurization efficiency is high; the adsorbent can be regenerated for many times.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

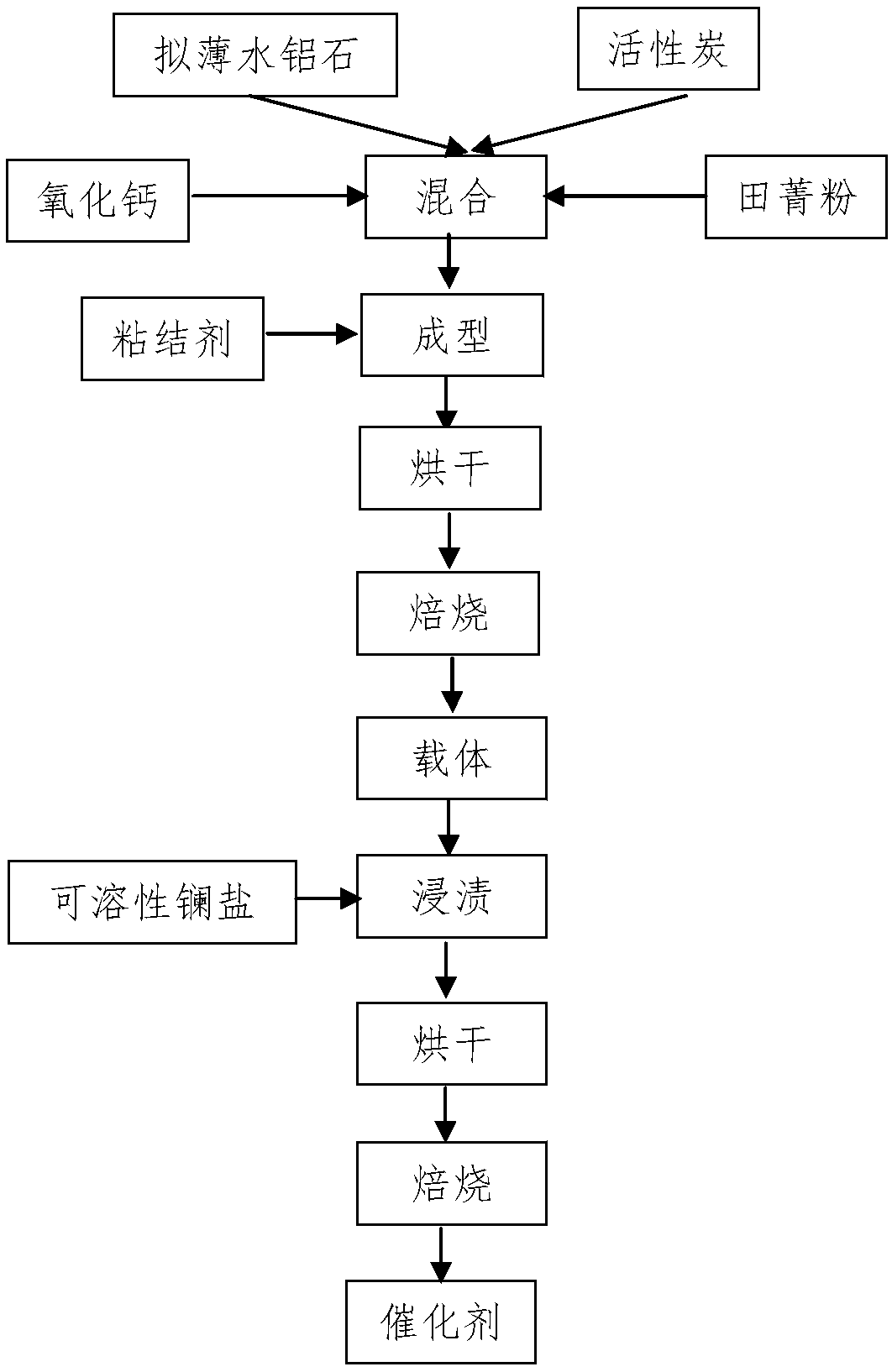

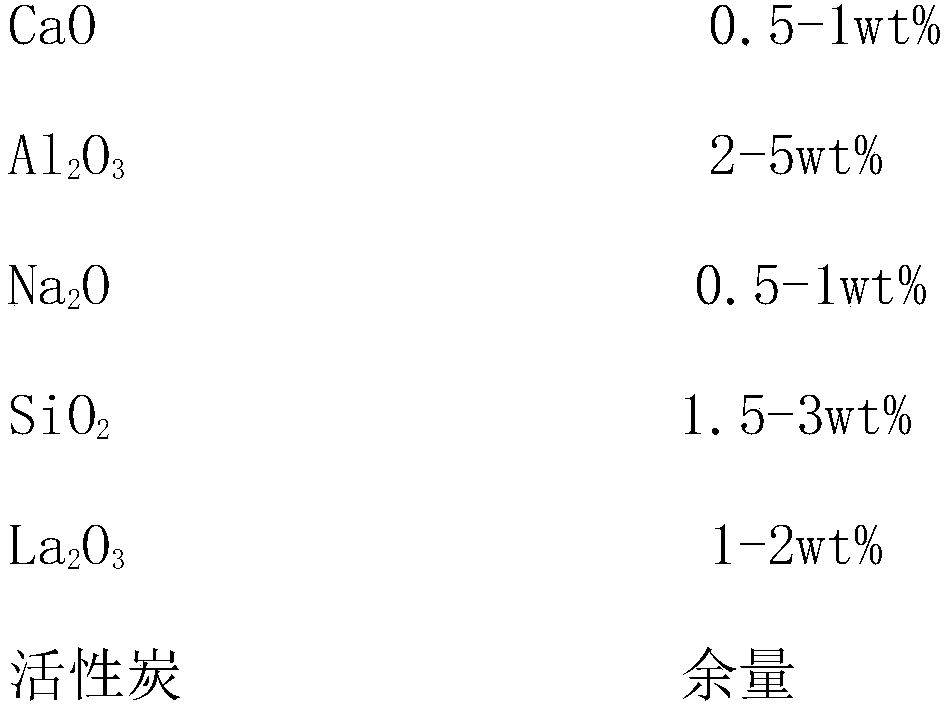

Catalyst for removing mercaptan in natural gas, and preparation method thereof

ActiveCN111068642AHigh breakthrough sulfur capacityHigh catalytic activityGas treatmentDispersed particle separationActivated carbonPtru catalyst

The invention relates to a catalyst for removing mercaptan from natural gas, and a preparation method of the catalyst, wherein active carbon is used as a catalyst carrier, lanthanum oxide is added asan active component, pseudo-boehmite with large specific surface area and calcium oxide are used as auxiliary agents, and the catalyst is prepared from the following components in percentage by weight: 0.5-1% of CaO, 2-5% of Al2O3, 0.5-1% of Na2O, 1.5-3% of SiO2 and 1-2% of La2O3. The method is simple in preparation process and free of secondary pollution in the preparation process. The catalyst prepared by the method has high mercaptan removal rate and penetration sulfur capacity, is low in reaction temperature, can react at normal temperature, has good regeneration performance, can be recycled multiple times, and can be used for a desulfurization purification device in the natural gas purification industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fine desulfurizer and preparation method thereof

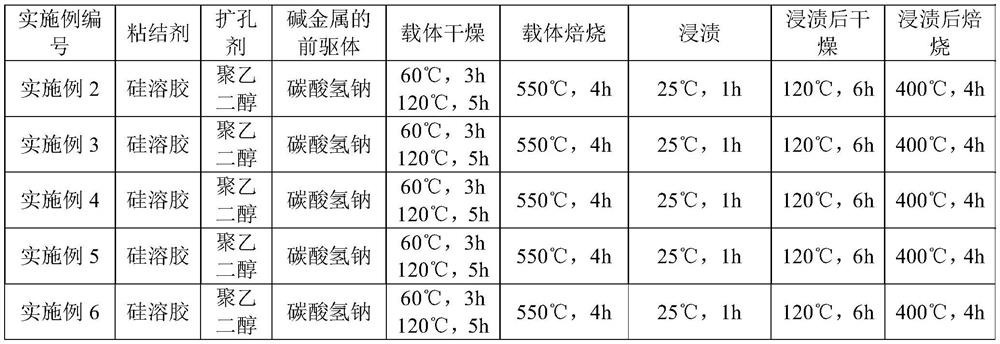

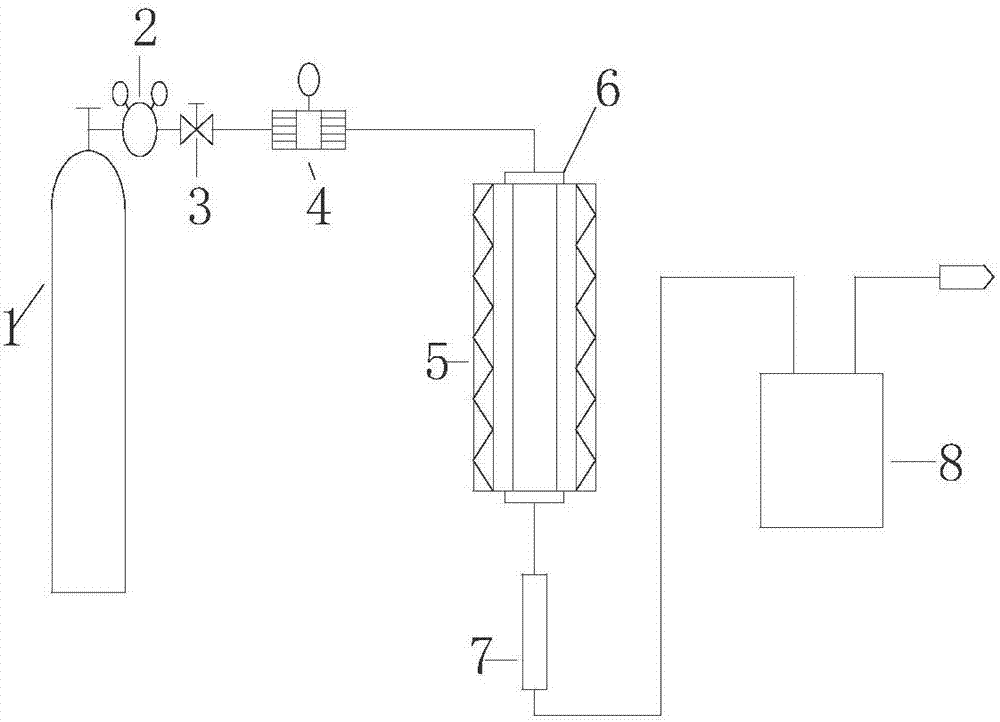

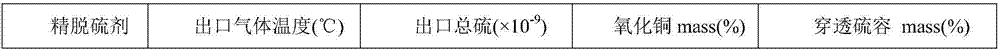

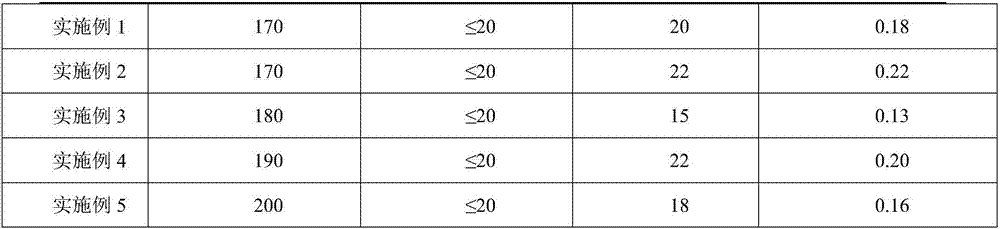

ActiveCN105038863ACarrier with rich pore sizeLarge specific surface areaCombustible gas purificationManganeseCopper nitrate

The invention discloses a fine desulfurizer and a preparation method thereof. The fine desulfurizer comprises a carrier and an active component, wherein the carrier is composite oxide formed through reacting one or two of zinc, manganese and magnesium with aluminum; the active component is cupric oxide; the preparation method of the fine desulfurizer includes the following steps: mixing one or two of zinc nitrate, manganous nitrate and magnesium nitrate with aluminium nitrate to prepare a mixed salt solution; carrying out coprecipitation through reacting aqueous alkali as a precipitant with the mixed salt solution; washing, drying and calcinating the precipitate obtained in the previous step to obtain a calcination sample; placing the calcination sample in acid liquor for acid dipping treatment to obtain the carrier; placing the carrier into a copper nitrate solution for dipping treatment, then drying and carrying out pyrolysis to obtain the fine desulfurizer. The fine desulfurizer can effectively eliminate thiofuran which is difficult to remove through conventional methods; the carrier of the fine desulfurizer is subjected to acid dipping treatment, so that the fine desulfurizer is large in specific surface, high in mechanical strength, good in stability and high in desulfuration effect and breakthrough sulfur capacity.

Owner:CNOOC GAS & POWER GRP +1

Modified activated carbon and composite material as well as preparation methods and application thereof

ActiveCN112642396AHigh breakthrough sulfur capacityGood breakthrough sulfur capacityGas treatmentOther chemical processesActivated carbonRare-earth element

The invention relates to the technical field of desulfurization, and discloses modified activated carbon and a composite material as well as preparation methods and application thereof. The modified activated carbon contains activated carbon, an oxide of an alkali metal and an oxide of silicon, and the weight ratio of the activated carbon to the oxide of the alkali metal to the oxide of the silicon is 100: (0.2-3): (0.8-5). The composite material contains activated carbon, an oxide of alkali metal, an oxide of silicon, an oxide of iron and an oxide of a rare earth element, and the weight ratio of the activated carbon to the oxide of alkali metal to the oxide of silicon to the oxide of iron to the oxide of the rare earth element is 100: (0.2-3): (0.8-5): (0.5-5): (1-10). The invention further discloses preparation methods of the modified activated carbon and the composite material and application of the modified activated carbon and the composite material in desulfurization. The composite material prepared from the modified activated carbon has high breakthrough sulfur capacity as an adsorbent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-temperature ultra-fine desulfurizing agent and preparation method thereof

InactiveCN107096359AReduce production processEasy to shapeGas treatmentGaseous fuelsCopper oxideUltra fine

The invention provides a low-temperature ultra-fine desulfurizing agent, and belongs to the technical field of desulfurizing agents. The desulfurizing agent comprises 50-90 parts by mass of a carrier, and 10-50 parts by mass of an active component, wherein the carrier is a porous composite comprising aluminum oxide and silicon oxide; the active component comprises one or a plurality of copper oxide, manganese oxide and zinc oxide. The desulfurizing agent is prepared by ultrasonically soaking the carrier in a saline solution of the active component after the carrier is treated by soaking and pickling through acid liquid and drying, and then drying and decomposing at high temperature. According to the low-temperature ultra-fine desulfurizing agent, the silicon-aluminum composite carrier is low in manufacturing cost, easy to form, high in stability, high in resistance to acid corrosion, developed in pore channel structure, and high in one-time soaking rate; the carrier is pickled, so that the specific surface area of the carrier can be further increased, and as a result, the dispersing performance of the active component on the carrier can be improved, the quantity of the active component loaded on the carrier is increased, and the desulfurizing effect of the desulfurizing agent is effectively improved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

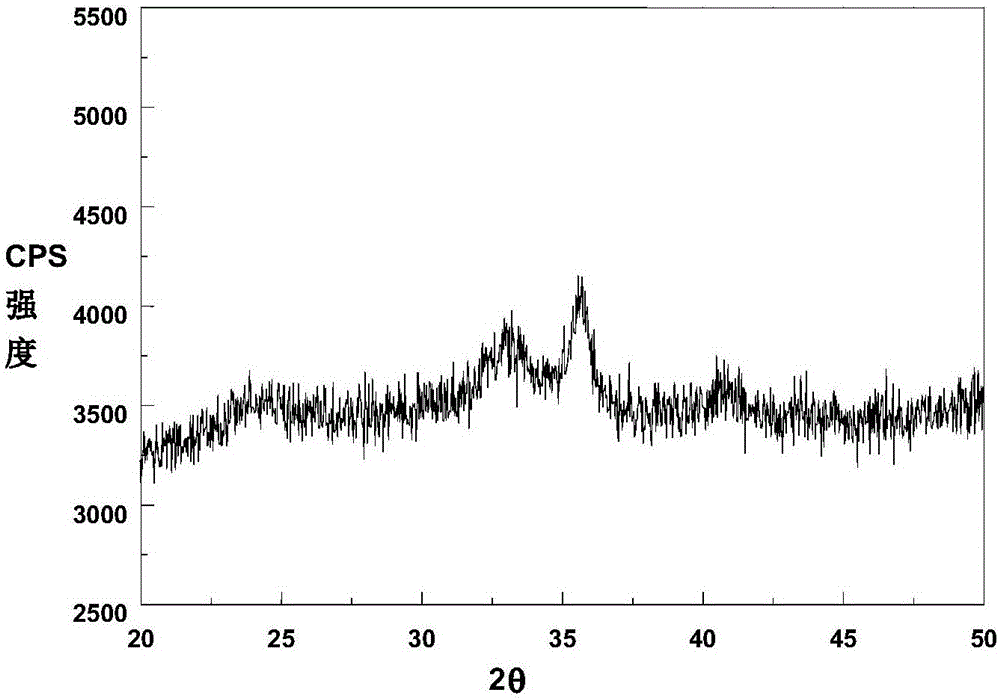

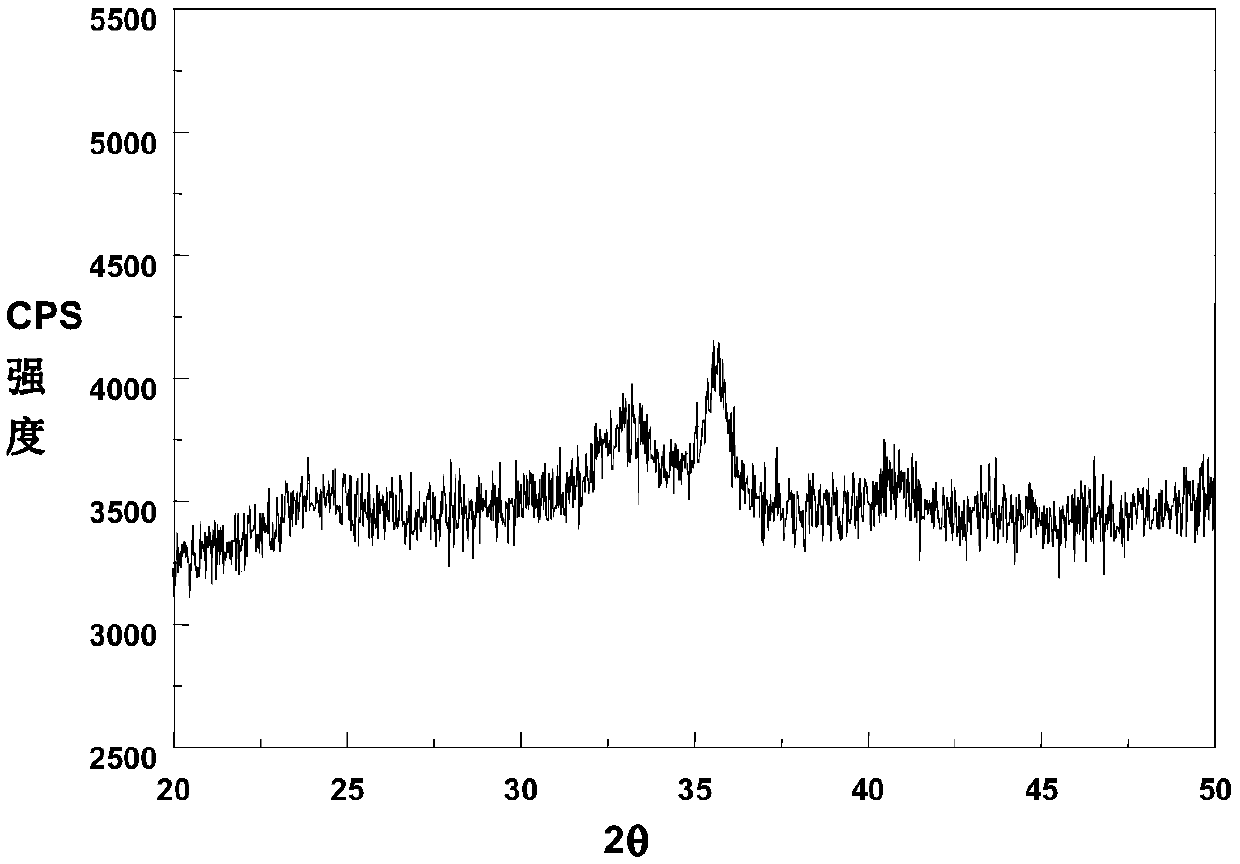

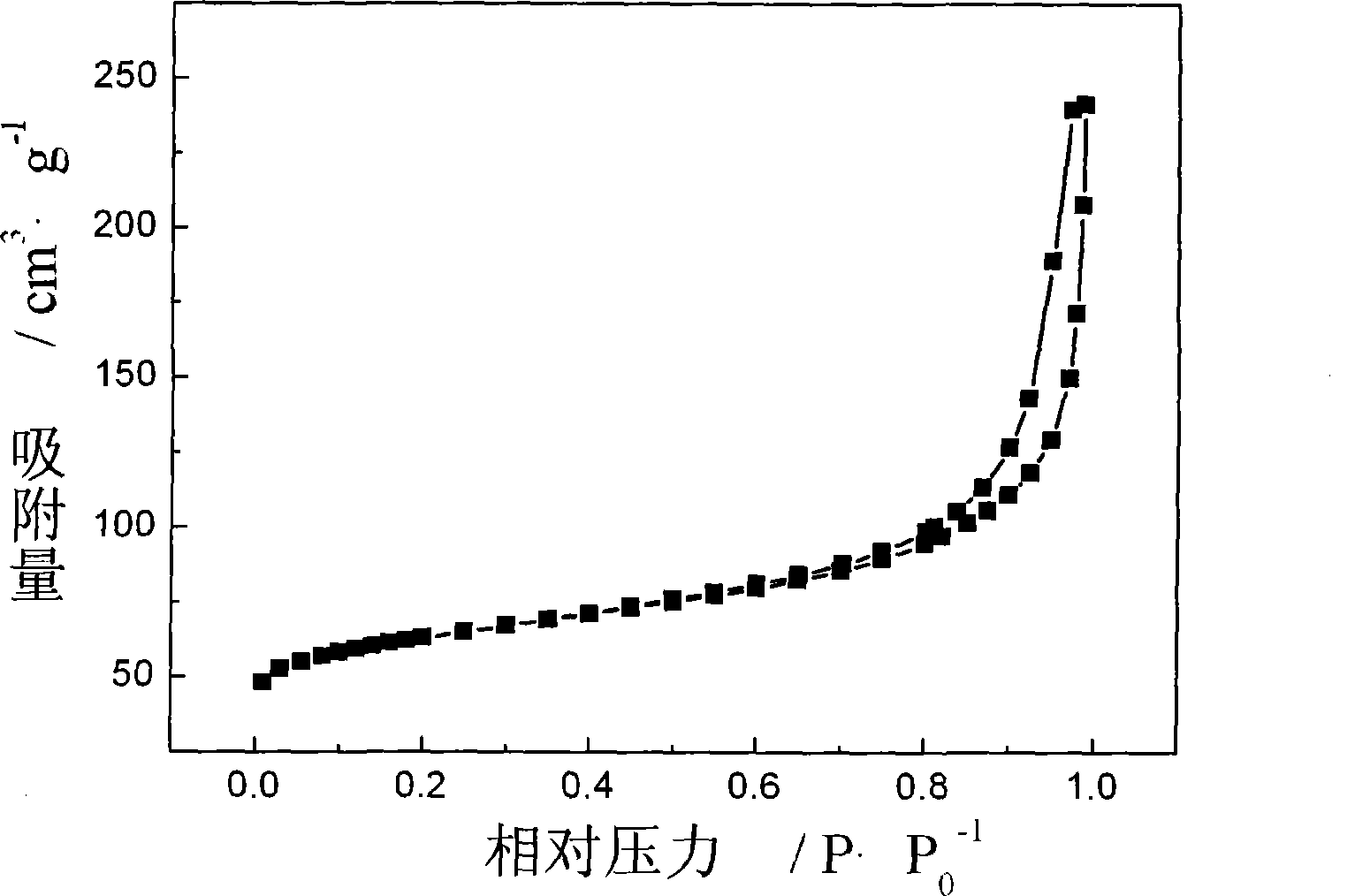

Preparation method of magnetic iron oxide

ActiveCN106430325AHigh breakthrough sulfur capacityAvoid generatingFerric oxidesAmmonium salt fertilisersSlurryDiammonium carbonate

The invention discloses a preparation method of a magnetic iron oxide. The preparation method comprises the following steps that 1, solid soluble ferrite and solid ammonium carbonate and / or solid ammonium bicarbonate are mixed and kneaded, water is added in the mixing and kneading process to form slurry, the pH value of the slurry in the mixing and kneading process is controlled to be 6.5-7, and the pH value of the slurry when the mixing and kneading process is finished is controlled to be 7-8; 2, the slurry obtained in the step 1 is subjected to first-time solid-liquid separation, and a first solid phase is collected; 3, water is adopted for being matched with the first solid phase to form a sizing, hydrogen peroxide is added into the sizing to perform an oxidation reaction, after the reaction is ended, second-time solid-liquid separation is performed, and a second solid phase is collected; 4, the second solid phase is dried and roasted in sequence, and the magnetic iron oxide is obtained. The magnetic iron oxide crystal has multiple defects, the magnetic iron oxide is large in specific surface area, and multiple bonding active sites combined with sulfur elements exist, so that the magnetic iron oxide has the high breakthrough sulfur capacity.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

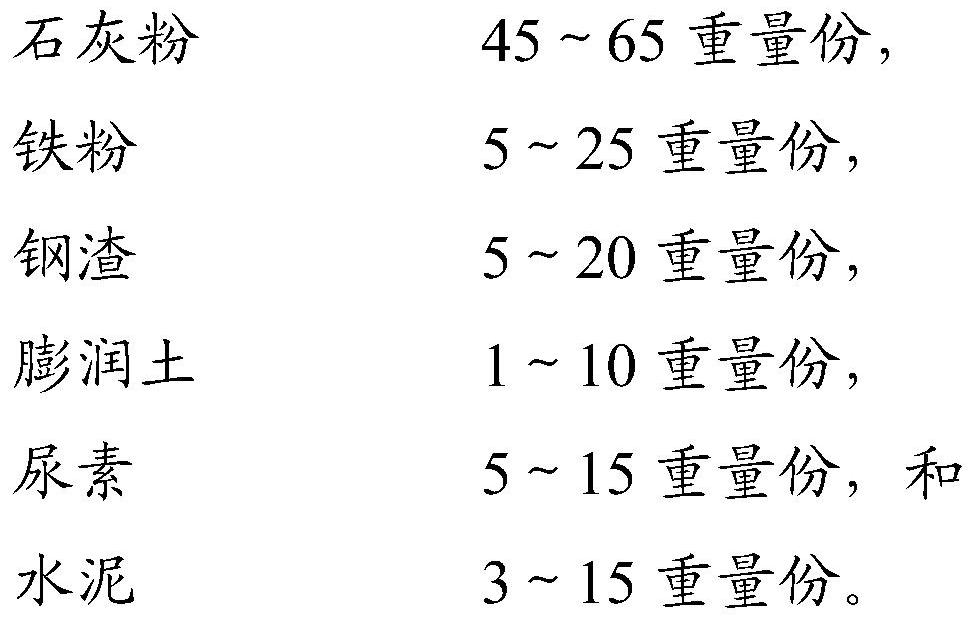

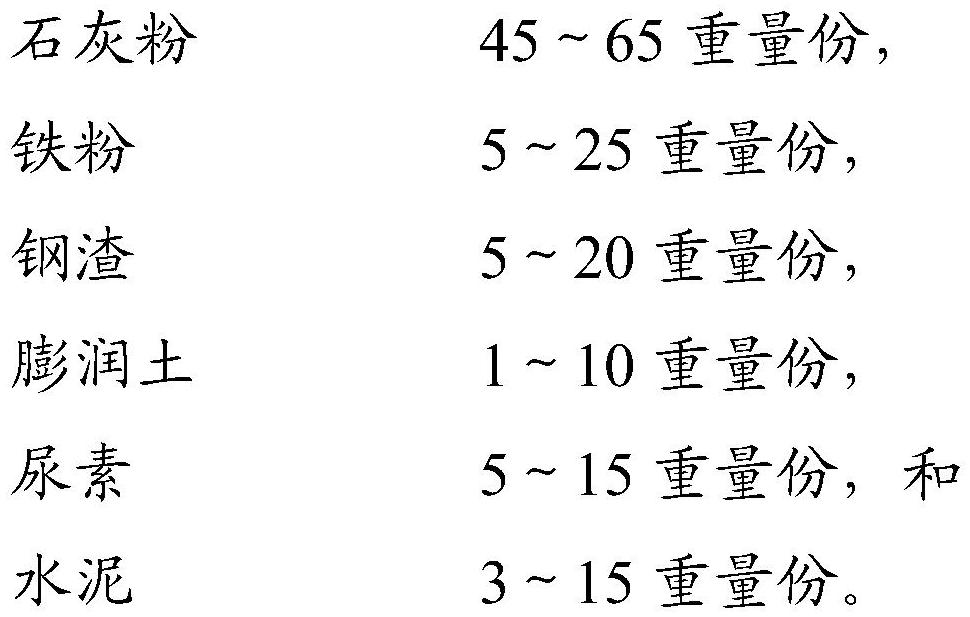

Absorbent for flue gas desulfurization and preparation method and application of composition of absorbent

ActiveCN113499674AAchieve reuseImprove desulfurization effectGas treatmentDispersed particle separationIron powderSlag

The invention discloses an absorbent for flue gas desulfurization and a preparation method thereof. The absorbent is prepared from the following raw materials in parts by weight: 45-65 parts of lime powder, 5-25 parts of iron powder, 5-20 parts of steel slag, 1-10 parts of bentonite, 5-15 parts of urea and 3-15 parts of cement. The absorbent is low in manufacturing cost, high in strength and relatively high in breakthrough sulfur capacity. The invention also discloses application of the composition.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Desulfurization and denitrification solid particles as well as preparation method and application thereof

PendingCN113663504AProper and uniform porosityGuaranteed StrengthDispersed particle separationAir quality improvementIron powderCerium

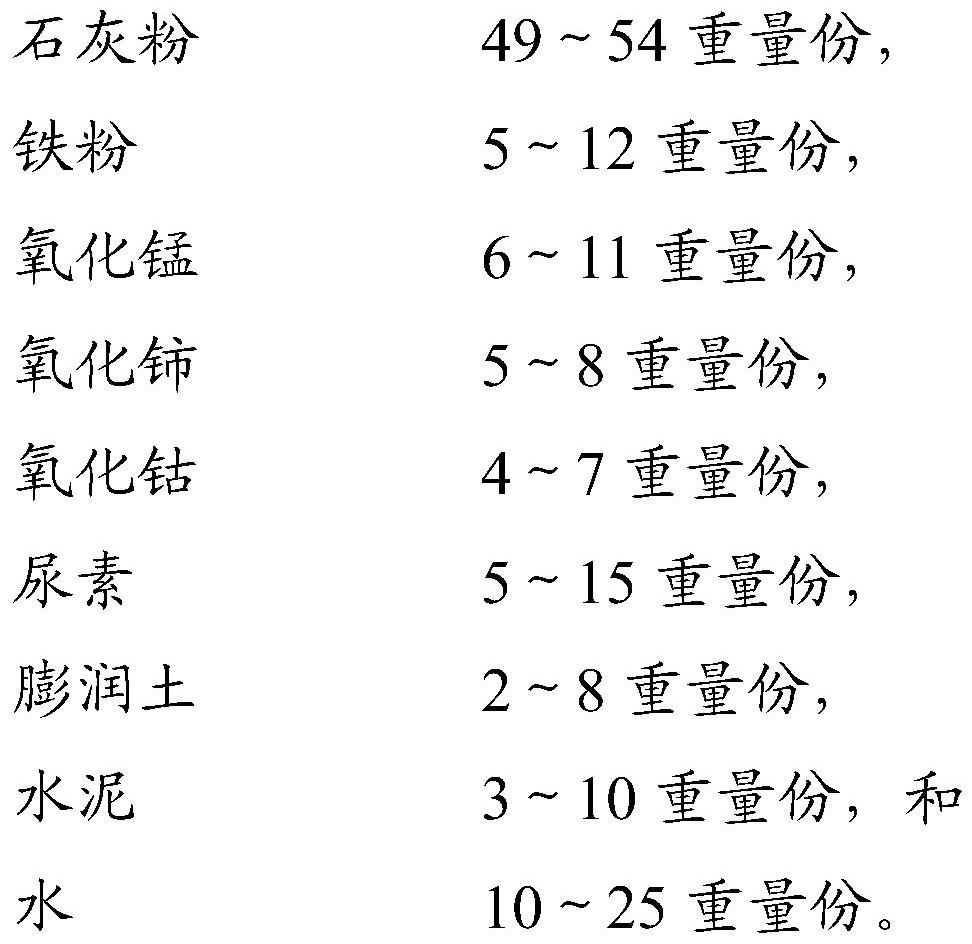

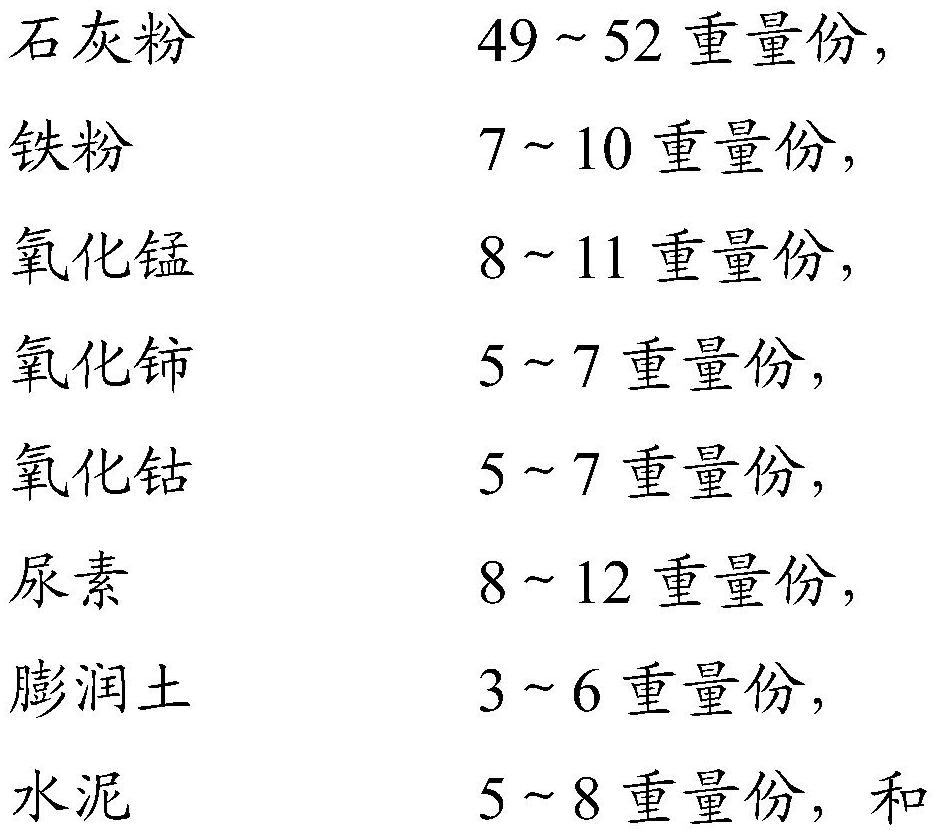

The invention discloses desulfurization and denitrification solid particles as well as a preparation method and application thereof. The desulfurization and denitrification solid particles are prepared from the following raw materials in parts by weight: 49-54 parts of lime powder, 5-12 parts of iron powder, 6-11 parts of manganese oxide, 5-8 parts of cerium oxide, 4-7 parts of cobalt oxide, 5-15 parts of urea, 2-8 parts of bentonite, 3-10 parts of cement and 10-25 parts of water. The desulfurization and denitrification solid particles disclosed by the invention have relatively high breakthrough sulfur capacity and breakthrough nitrate capacity, and are relatively high in strength.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

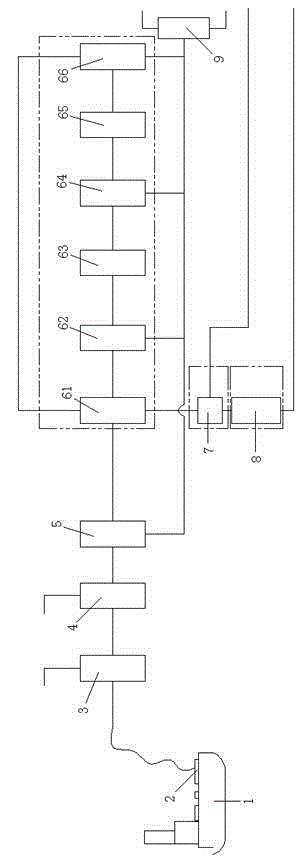

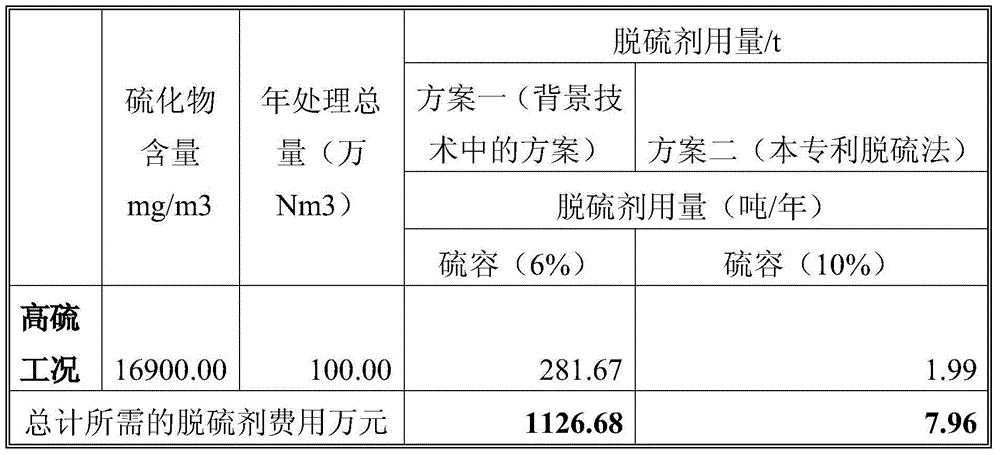

High sulfur crude oil oil-gas recovery technology and oil-gas recovery system

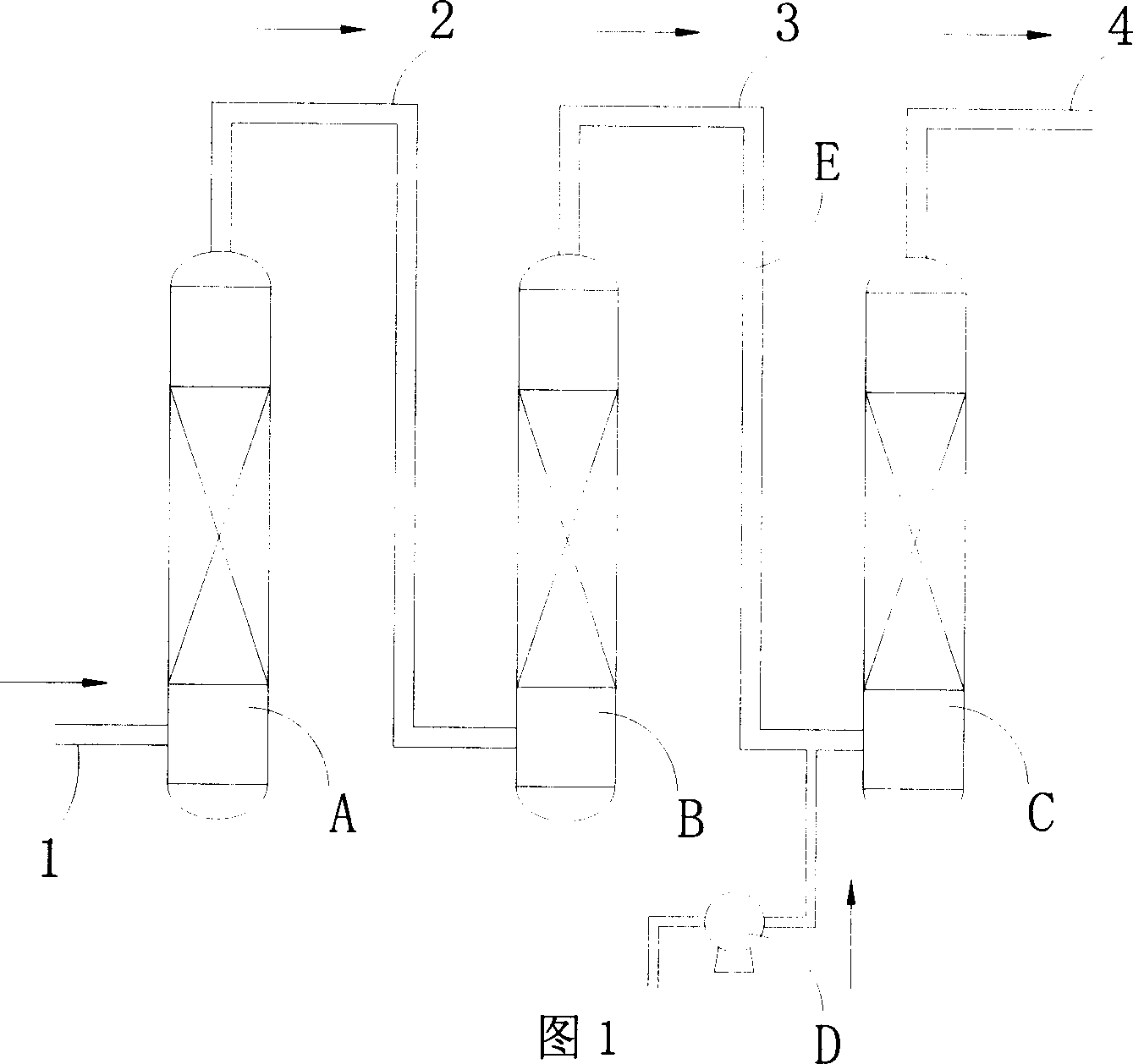

ActiveCN104830365AHigh breakthrough sulfur capacitySulfur content is easy to reach the standardLiquid hydrocarbon mixture recoveryActivated carbonDesorption

The present invention provides a high sulfur crude oil oil-gas recovery technology and oil-gas recovery system. The oil-gas recovery technology includes the following steps: a. high sulfur crude oil oil-gas is compressed, the compressed oil-gas is cooled, then gas and liquid separation is performed, and the separated liquid is collected; b, the separated oil-gas of the step a is condensed, then gas and liquid separation is performed, and the separated liquid is collected; c, the separated oil-gas of the step b is introduced into an activated carbon adsorption device, and is desulfurized, and desorption and collection of hydrocarbons in the activated carbon adsorption device are performed. According to the high sulfur crude oil oil-gas recovery technology, most of sulfides and hydrocarbons are condensed into liquid in the condensation processing process, species and quantity of sulfides entering into a desulfurization tower are less, and the composition is simple, so that breakthrough sulfur capacity of the desulfurization tower is high, the desulfurization effect is better, and when the sulfur content in the desulfurized oil-gas is very easy to meet.

Owner:上海森鑫新能源科技有限公司

A kind of refinery waste gas desulfurizer, its preparation method and application

ActiveCN105126597BIncrease alkalinityIncrease polarityDispersed particle separationBisulfideCobalt phthalocyanine

The invention provides a refinery exhaust gas desulfurizer, its preparation method and application. The desulfurizer is composed of the following components: 1.6-6.4wt% CuO, 1-3wt% NiO, 0.2-0.8wt% CeO2, 0.1-0.5wt% cobalt phthalocyanine substances, and the balance is activated carbon treated with nitrogen-containing compounds. The preparation method adopts nitrogen-containing compounds to modify the activated carbon, which improves the alkalinity and polarity of the surface of the activated carbon, and enhances the adsorption of acidic sulfides; then the oxides of copper, nickel, and cerium are loaded on the modified activated carbon On the surface, the alkalinity of the activated carbon surface is further improved; finally, the phthalocyanine cobalt is loaded, and the mercaptan in the refinery exhaust gas is oxidized to the corresponding disulfide by using its oxidation ability, which is adsorbed by the activated carbon. Thus, the refinery exhaust gas desulfurizer prepared by the present invention realizes the one-time and efficient removal of sulfides such as hydrogen sulfide, carbonyl sulfide, sulfide, mercaptan, and disulfide in the refinery exhaust gas through adsorption, and is exported The total sulfur concentration is less than 2mg / m3, and the breakthrough sulfur capacity is as high as 32%.

Owner:SHENYANG SANJUKAITE CATALYST

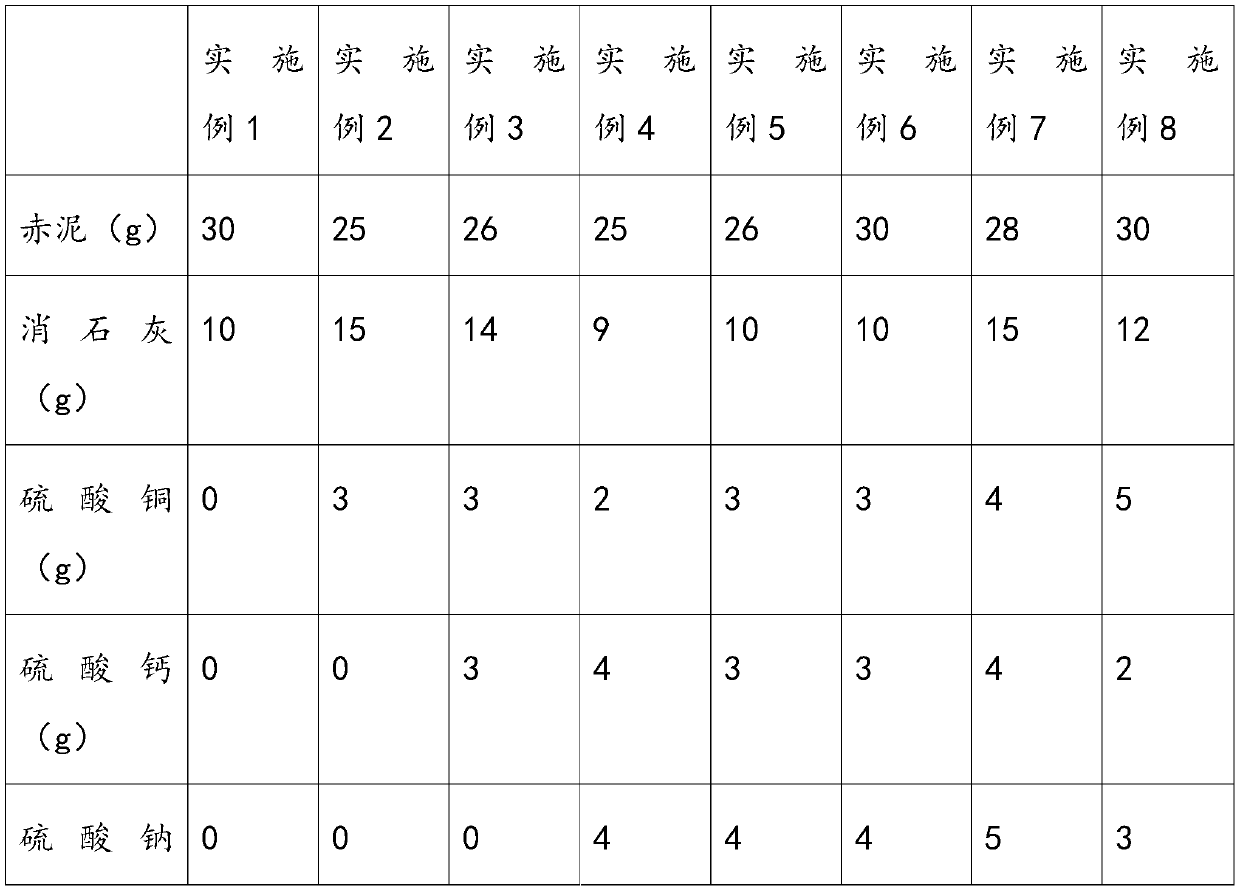

Iron desulfurizer and preparation method thereof

InactiveCN110115921AExtended service lifeImprove the accuracy of useDispersed particle separationPorosityDispersity

The invention relates to the field of desulfurizing agents, in particular to an iron desulfurizer which comprises iron oxyhydroxide and oil shale waste residue ceramsite. The iron oxyhydroxide has very strong stability in combination with sulfur atoms, so that the desulfurizing effect is good, the service life of the desulfurizing agent is prolonged and the use precision of the desulfurizing agentis improved by introducing oxygen-containing alkaline functional groups, and the oil shale waste residue ceramsite contains a large amount of silicon dioxide, aluminum oxide and a small amount of ferric oxide and iron oxide, adhesion can be provided, the iron desulfurizer also has higher strength, porosity and larger specific surface area, accordingly the dispersity of active components can be improved, and thus the sulfur capacity of the desulfurizer can be improved. In addition, a small amount ferric oxide and iron oxide contained in the oil shale waste residue ceramsite can also serve as the active components in the desulfuration process, and accordingly the desulfuration activity and desulfuration precision of the desulfurizer are further improved.

Owner:SHENYANG SANJUKAITE CATALYST

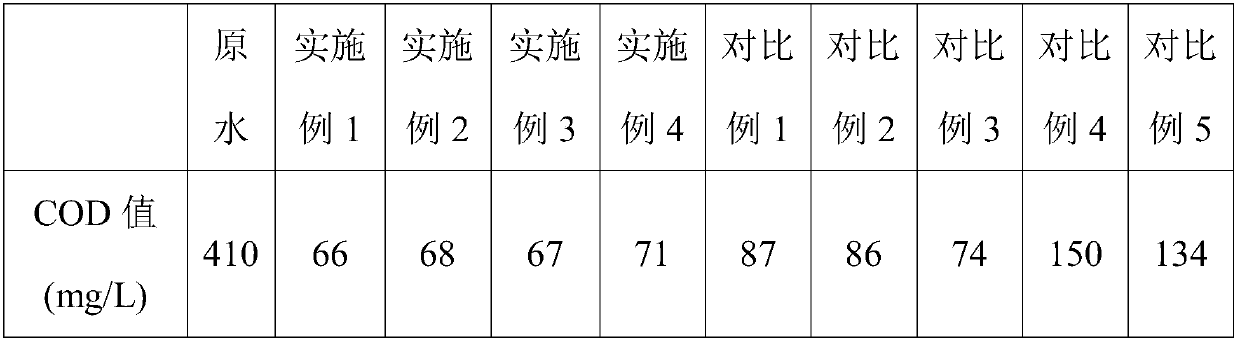

A kind of preparation method of magnetic iron oxide

ActiveCN106478084BHigh breakthrough sulfur capacityShort manufacturing cycleWater treatment parameter controlAmmonium sulfatesBinding siteSulfate

The invention discloses a magnetic iron oxide preparing method. The magnetic iron oxide preparing method includes: 1) acidizing ferrous sulfate by an acid; 2) mixing the acidized ferrous sulfate with hydrogen peroxide to enable reaction to prepare a hydroxyl-ferric oxide precursor; 3) subjecting the hydroxyl-ferric oxide precursor and ammonium bicarbonate or ammonium carbonate to neutralization reaction so as to obtain a reaction product; 4) subjecting the reaction product to solid-liquid separation and collecting solid phases; 5) drying and roasting the solid phases sequentially to prepare magnetic iron oxide. The magnetic iron oxide has a lot of lattice imperfections, a lot of active binding sites and a large specific surface area, thereby being high in adsorption capacity and widely applicable to the fields of sewage treatment and gas purification.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing carbon aerogel desulfurizing agent

InactiveCN101376097BPrevent collapseAvoid volumeOther chemical processesGas purification with selectively adsorptive solidsPotassiumPhenyl hydroxide

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method and application of rey molecular sieve adsorbent for ultra-deep removal of thiophene sulfides in gasoline

ActiveCN108543515BImprove desulfurization effectImprove desulfurization efficiencyOther chemical processesCombustible gas purificationMolecular sieveSorbent

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Loaded phthalocyanine cobalt sulfonate activated carbon desulfurization adsorbent and preparation method thereof

ActiveCN105080488BHigh removal rateHigh breakthrough sulfur capacityIon-exchange process apparatusOther chemical processesSulfonateActivated carbon

The invention relates to a active carbon desulphurization adsorbent loaded with cobalt phthalocyanine sulfonate and a preparation method thereof, and mainly solves problems that sulfur removal rate is low, and breakthrough sulfur capacity of desulfurizer is low in existing gas adsorption, desulphurization and purification technology. In the invention cobalt phthalocyanine sulfonate is employed as active ingredient and a small amount of phosphor is added for modifying the active carbon. In this way, the solid adsorbent is obtained. The problems of low sulfur removal rate, etc. are solved. The desulphurization adsorbent of the invention can be used in adsorption and purification of gas materials for removal of sulfur-containing compound.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com