High sulfur crude oil oil-gas recovery technology and oil-gas recovery system

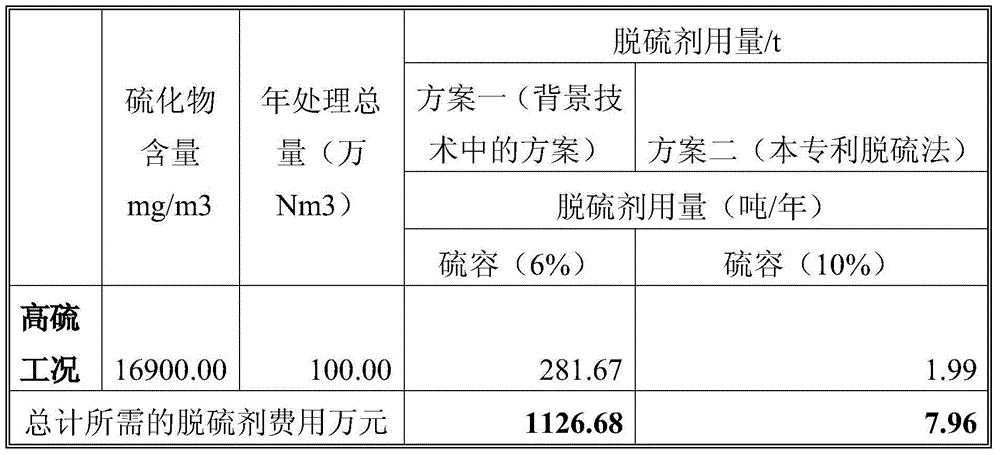

An oil and gas recovery system and high-sulfur crude oil technology, which is applied in the petroleum industry and the recovery of liquid hydrocarbon mixtures, etc., can solve the problems of difficult to reach the standard of sulfur content in oil and gas, low penetration of sulfur in the desulfurization tower, poor desulfurization effect, etc., and achieve low desulfurization cost , The effect of reducing the amount of engineering and the amount of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

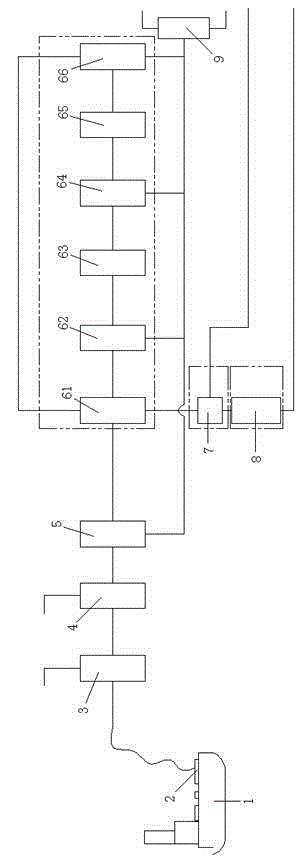

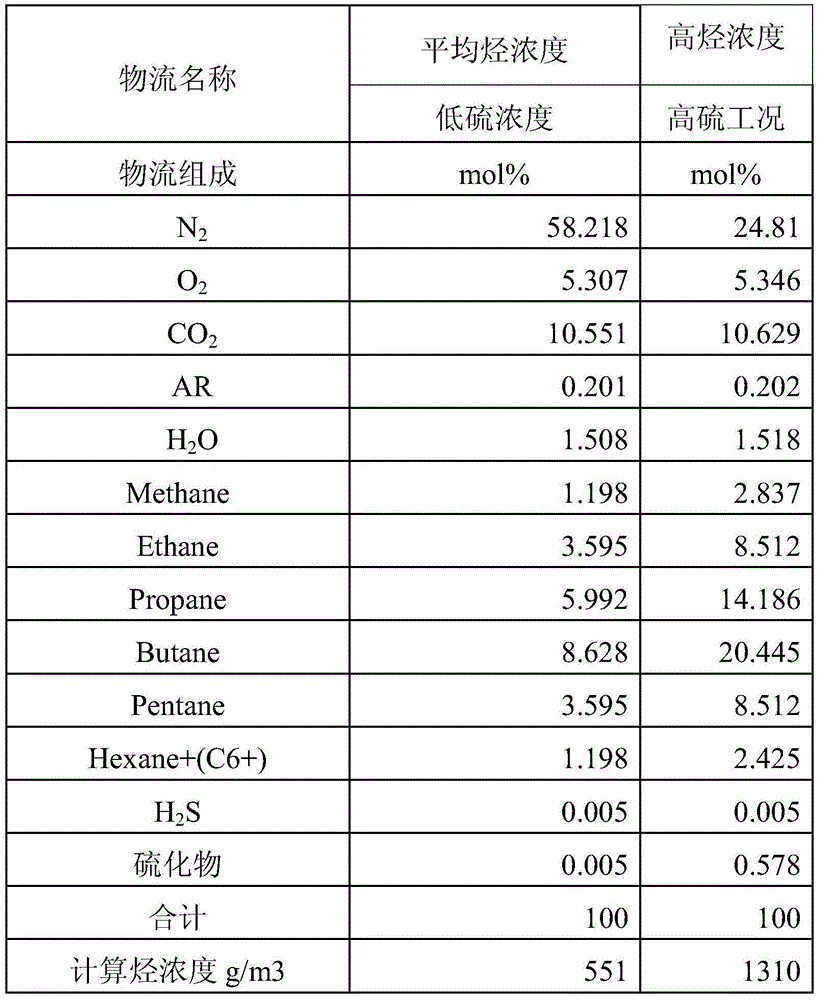

[0080] see figure 1 , an oil and gas recovery system for high-sulfur crude oil and gas recovery process, including a compression device 4, a cooling device (not shown in the figure), a separation device X5, a condensation separation subsystem, an activated carbon adsorption device 7 and a desulfurization device 8, the The compression device 4, the cooling device, the separation device X5, the condensation separation subsystem, the activated carbon adsorption device 7, and the desulfurization device 8 are connected in sequence. The oil and gas recovery system of the present invention condenses most of the sulfur-containing compounds and hydrocarbons into liquids through the condensation and separation subsystem, so that the types and quantities of sulfur-containing compounds entering the desulfurization device are less and the components are relatively simple, which can make the desulfurization device The penetration sulfur capacity is higher, and the desulfurization effect is ...

Embodiment 2

[0088] The difference between this embodiment and Embodiment 1 is that the condensation separation subsystem includes a condenser I and a separation device I, and the oil and gas recovery system also includes a dehydration device I, and the dehydration device I is connected to the gas outlet of the separation device X , the gas outlet of the dehydration device I is connected to the condenser I, the condenser I is connected to the separation device I, and the gas outlet of the separation device I is connected to the activated carbon adsorption device. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0089] In this embodiment, only one set of condensing devices is provided, the structure is simple, the energy consumption is small, and the cost of oil and gas recovery is lower.

Embodiment 3

[0091] The difference between this embodiment and Embodiment 1 is that the condensation separation subsystem includes condenser III, separation device III, condenser IV and separation device IV, the oil and gas recovery system also includes dehydration device II, and the separation device X The gas outlet of the dehydration device II is connected to the condenser III, the condenser III is connected to the separation device III, the dehydration device II is connected to the gas outlet of the separation device III, and the gas outlet of the dehydration device II is connected to the dehydration device II. The condenser IV is connected, the condenser IV is connected with the separation device IV, and the gas outlet of the separation device IV is connected with the activated carbon adsorption device. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0092] In this embodiment, two sets of condensing devices are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com