Iron desulfurizer and preparation method thereof

A technology for iron-based desulfurization and desulfurization agent, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of low desulfurization accuracy, influence industrial application, and poor strength of iron oxide desulfurizer, and achieve high strength , Improve the service life and use accuracy, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036]This embodiment also relates to a method for preparing an iron-based desulfurizer, comprising the following steps:

[0037] Ferric oxyhydroxide is mixed with soluble salt of additives, impregnated on oil shale waste slag ceramsite, and then dried and roasted.

[0038] Among them, iron oxyhydroxide is commercially available or prepared according to the following method: react red mud and slaked lime in water to generate iron oxyhydroxide, the mixing ratio of red mud and slaked lime is (2.5-3):1, and the reaction time is 1-2h , the reaction only needs to ensure that the red mud and slaked lime react completely, and the specific reaction time can be adjusted according to the actual situation. Since red mud is actually industrial waste, choosing red mud and slaked lime as raw materials to prepare iron oxyhydroxide has cheap and easy-to-obtain raw materials, and can It has the advantages of reducing the production cost of desulfurizer, and at the same time it can turn industr...

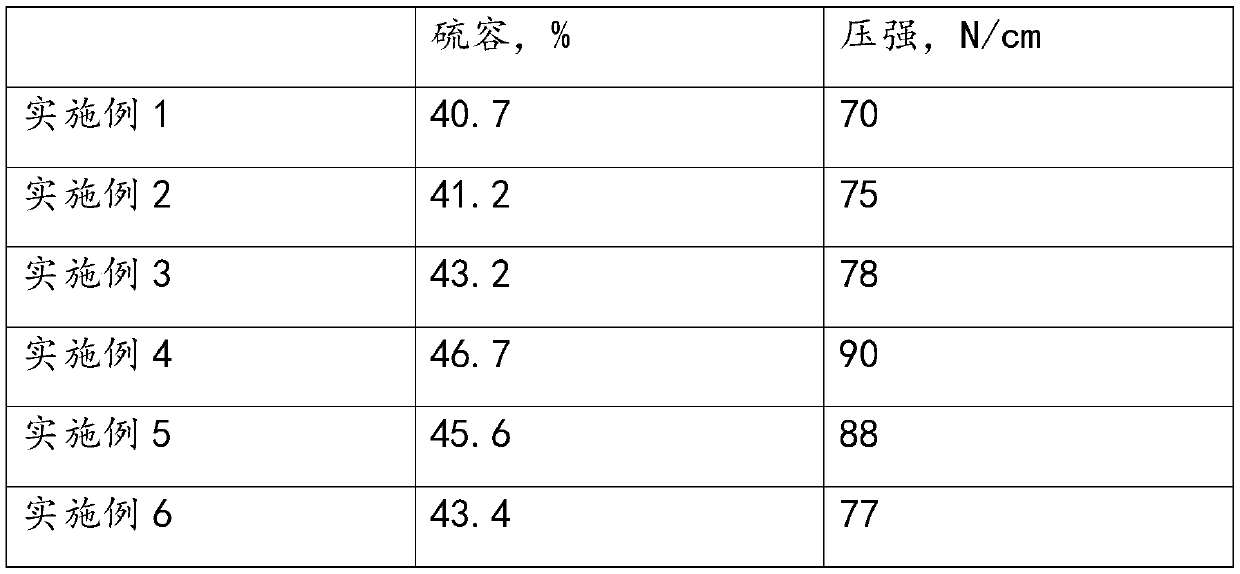

Embodiment 1-6

[0043] Embodiment 1-6 relates to an iron-based desulfurizer, which is prepared according to the following method:

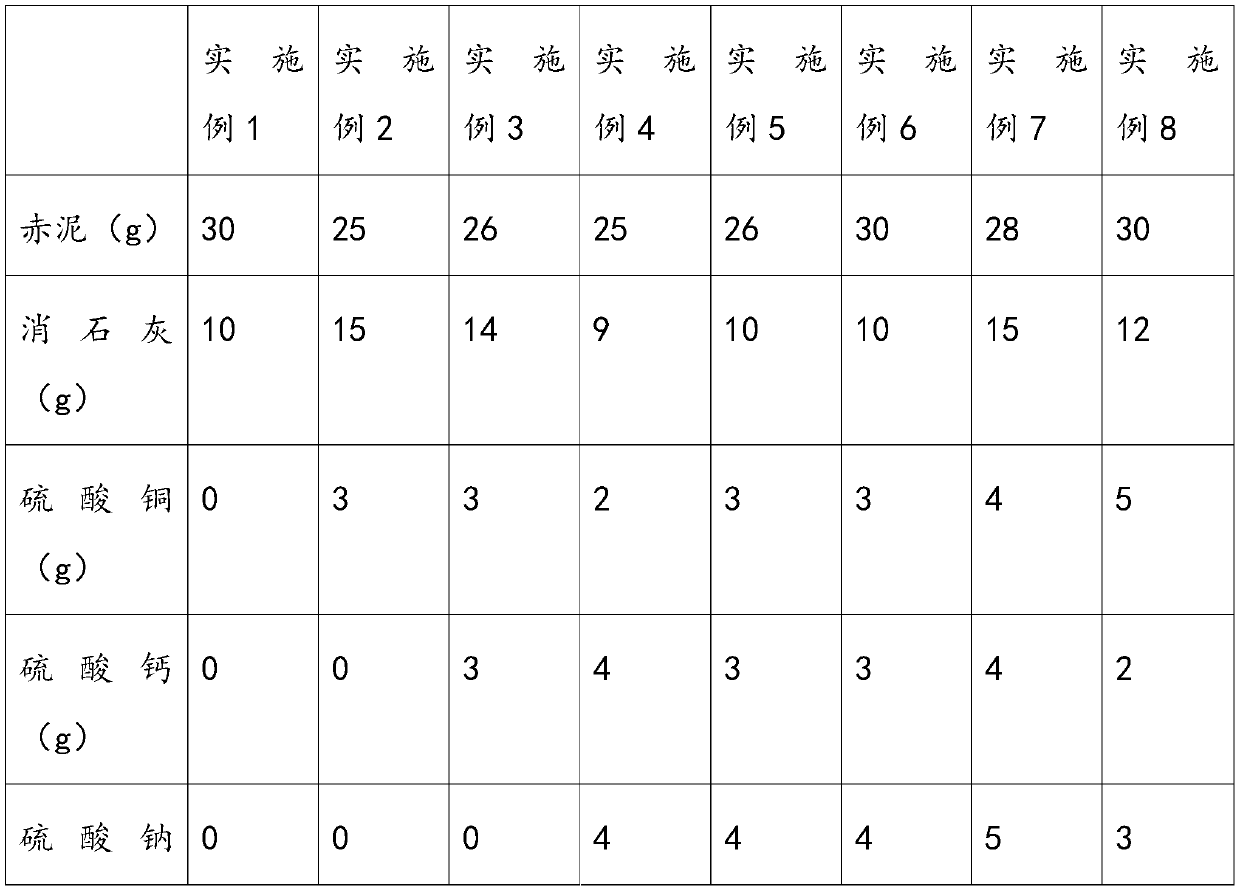

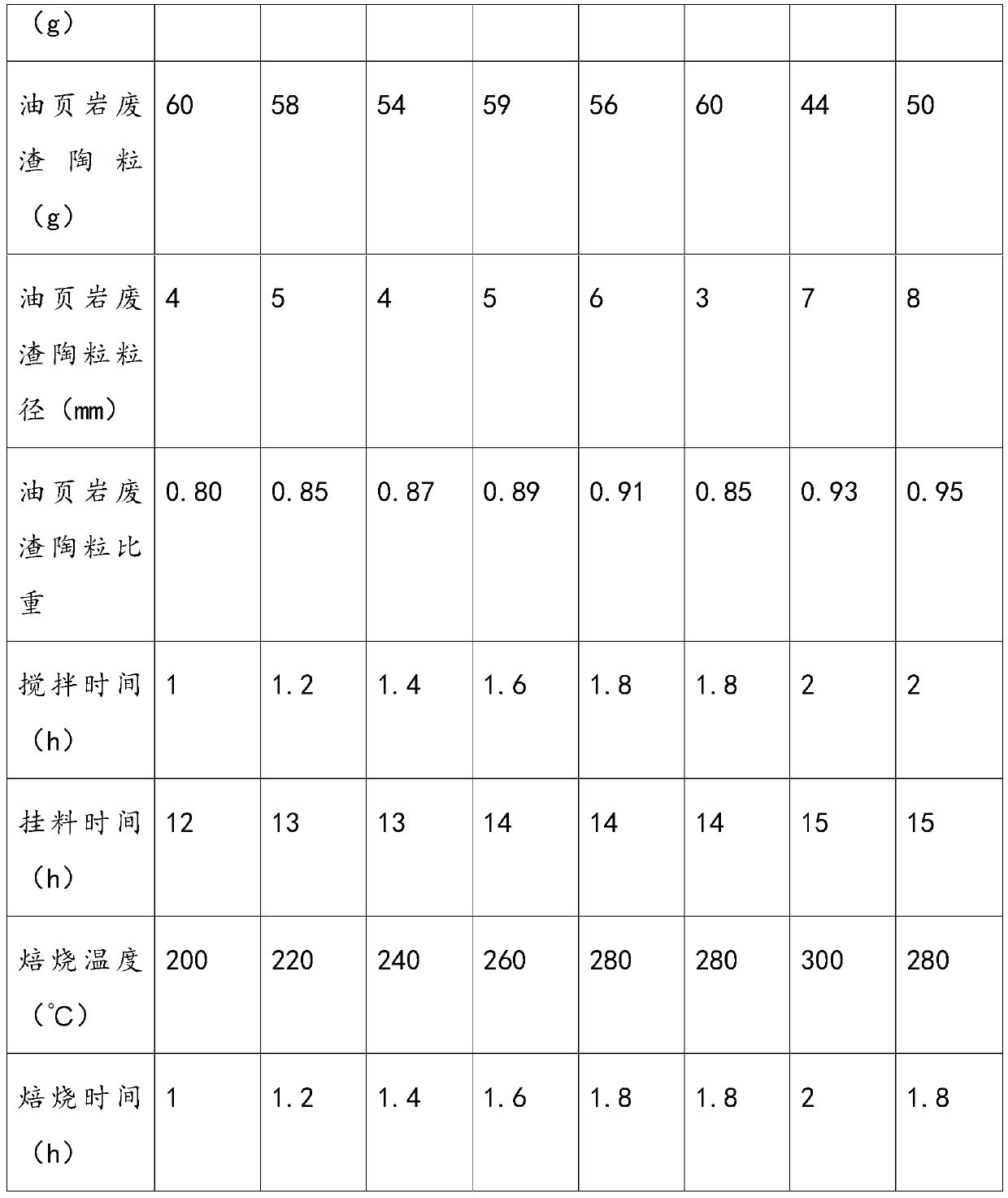

[0044] Add red mud and slaked lime to the kneading pot for dry mixing, then add water and stir to form a paste, the stirring time is 2 hours, then add soluble salt of additives for mixing, and then add oil shale waste slag ceramsite for hanging. The hanging material is uniform and turns yellow-red, then it is dried naturally, and the finished product is obtained after roasting. The amount of red mud and slaked lime used in each embodiment, the type and amount of soluble salts of additives, the amount of oil shale waste residue ceramsite, the particle size and specific gravity of oil shale waste residue ceramsite, material hanging time, roasting temperature and roasting See Table 1 for the time.

[0045] Table 1. The processing parameters of each embodiment

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com