Patents

Literature

63results about How to "Small quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

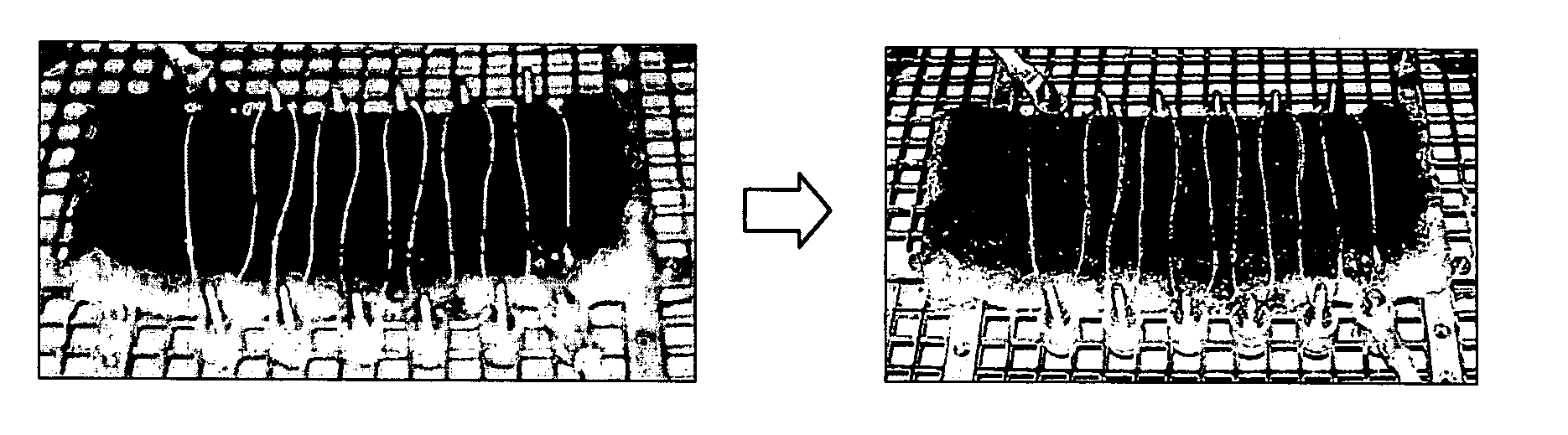

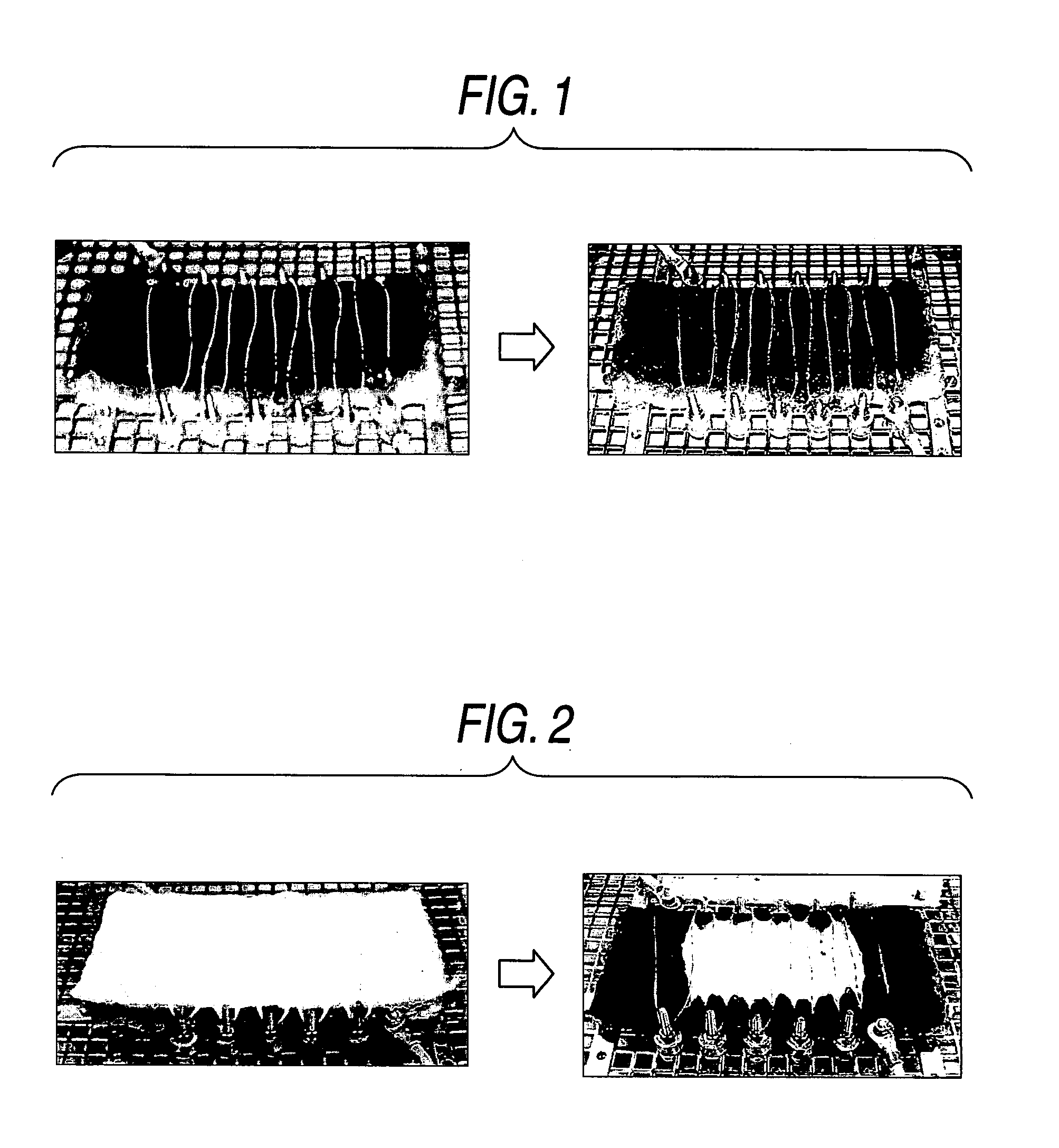

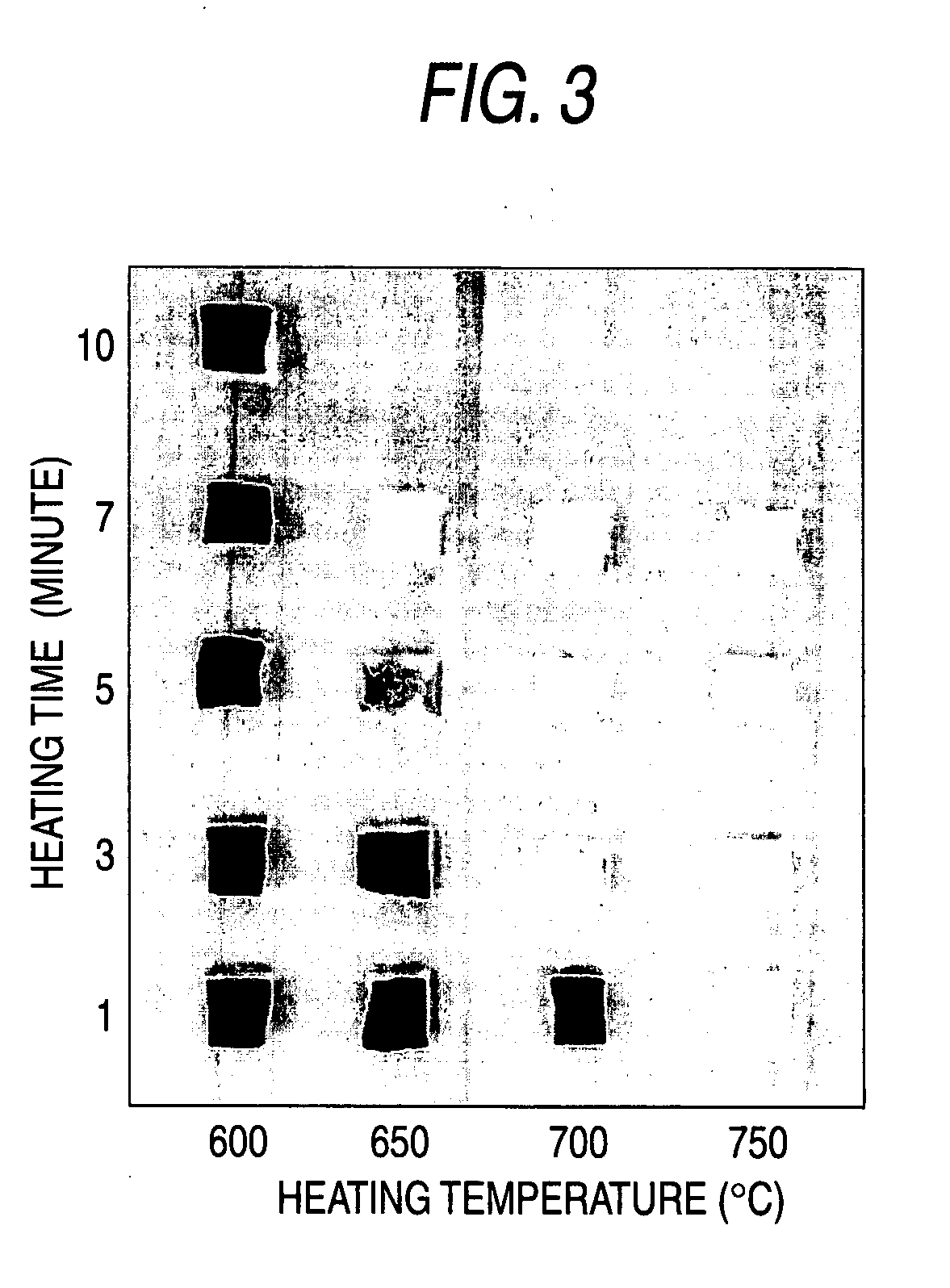

Particulate matter removal apparatus

InactiveUS20080066621A1Improve heating efficiencyRegenerate in small quantityCombination devicesAuxillary pretreatmentParticulatesThermal energy

A filter is made with heat-insulating ceramic fibers, and where the filter is increased in pressure loss due to particulate matter captured after filtration of exhaust gas, gas flow is blocked, a heating element is used to heat the surface of the filter, thereby burning and removing particulate matter. The filter is of heat insulating properties, by which a heat insulating material is arranged near the particulate matter capturing face of the filter, and the heating element is incorporated between the surface of the filter and the heat insulating material. The filter can be regenerated at a higher heating efficiency in a smaller quantity of thermal energy. The heat insulating material is also used as a filter, by which the apparatus can be made more compact. A charging element is arranged upstream of the filter material, by which the filter material is increased in particulate matter capturing performance, thereby suppressing the rate of increase in the pressure loss and improving heating efficiency of particulate matter.

Owner:NISSIN ELECTRIC CO LTD

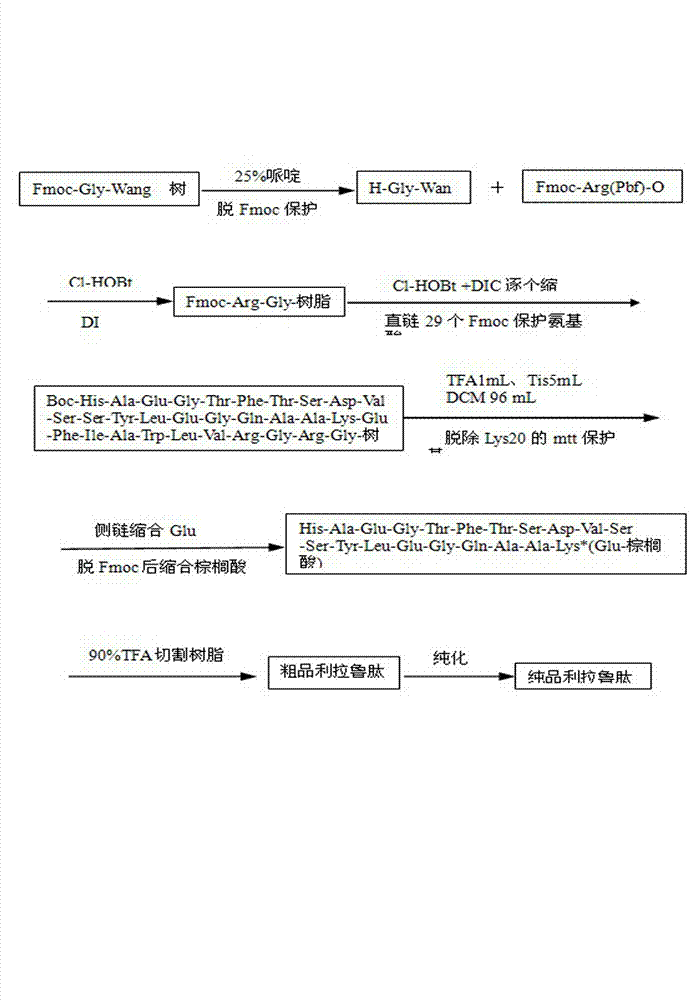

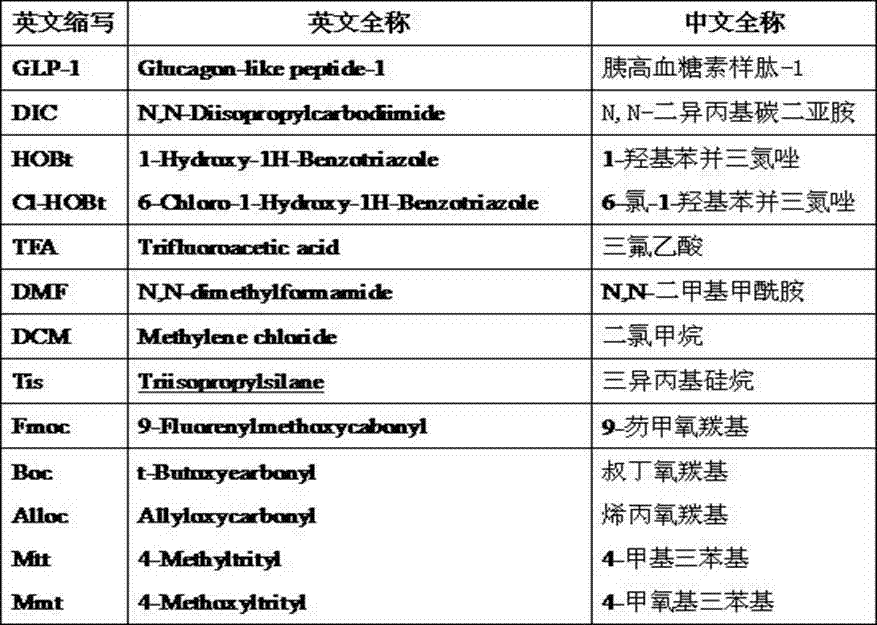

Solid-phase synthesis method of liraglutide

InactiveCN103087181ALess usableSmall quantityPeptide preparation methodsBulk chemical productionSide chainWang resin

The invention discloses a method for synthesizing liraglutide. The method comprises the following steps of: 1, selecting Fmoc-Gly-Wang resin and N terminal Fmoc protected and side chain protected amino acid as raw materials, wherein lysine on a 26th site adopts Fmoc-Lys(Mtt)-OH or Fmoc-Lys(Mmt)-OH, histidine on an N terminal adopts Boc-His(Trt)-OH or Boc-His(Boc)-OH; 2, selectively removing a Mtt or Mmt protecting group on the lysine by adopting 1 percent TFA (Trifluoroacetic Acid); 3, sequentially coupling one g-glutamic acid and palmitic acid on a side chain; and 4, cutting resin by the TFA to obtain a crude product of the liraglutide, and carrying out preparative liquid chromatography purification and lyophilization to obtain a pure product of the liraglutide. The method for synthesizing the liraglutide is simple in steps, saves time and labor, is less in difficult sequences in a coupling process, simple and easy to operate during side chain de-protection, less in byproducts and high in yield, and is suitable for industrialized production.

Owner:刘卫 +1

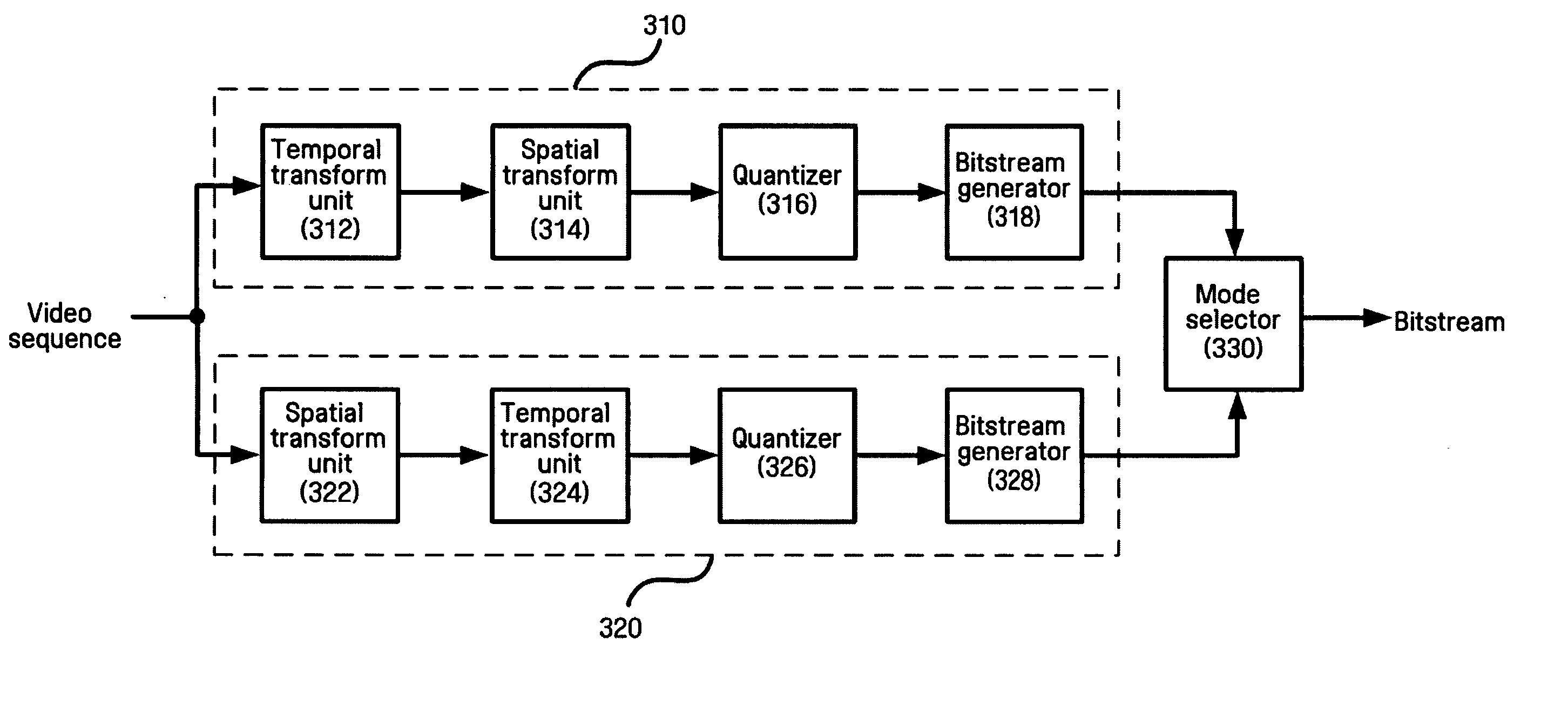

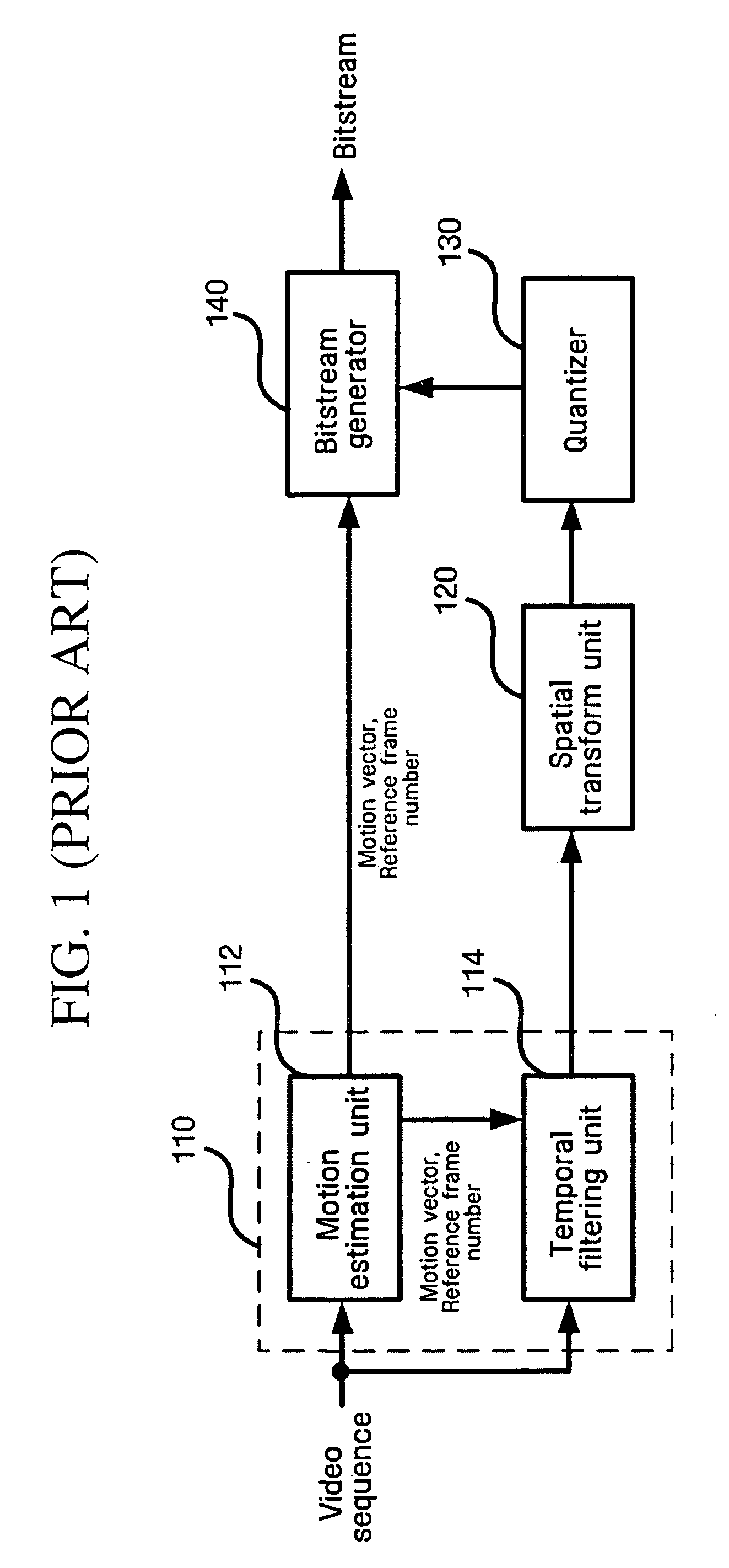

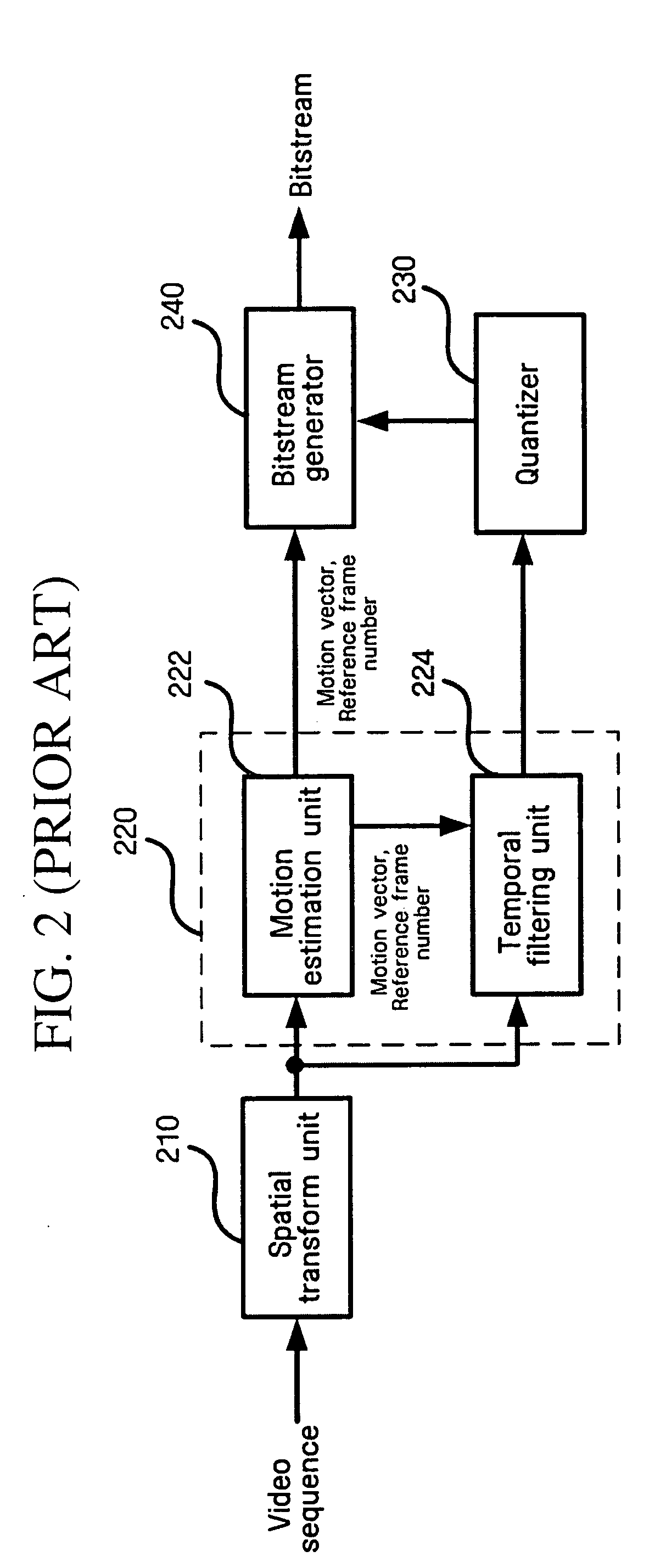

Method and apparatus for coding and decoding video bitstream

InactiveUS20050163217A1Small quantityRemoves temporal redundancyPulse modulation television signal transmissionConvertible garmentSelf adaptiveImage resolution

Provided are a video encoder, a video coding method, a video decoder, and a video decoding method for transmitting a compressed video signal based on a suitable compression method adaptively selected according to the environment. The video coder includes a first encoding portion that removes temporal and spatial redundancy of input video frames, quantizes transform coefficients generated by removing temporal and spatial redundancies from the input video frames, and generates a bitstream, a second encoding portion that removes spatial and temporal redundancy of input video frames, quantizes transform coefficients generated by removing spatial and temporal redundancies from the input video frames, and generates a bitstream, and a mode selector that compares the bitstreams input from the first encoding portion and the second encoding portion with each other, and outputs only the bitstream selected based on the comparison result. Therefore, video frames decoded with various resolution levels can be restored.

Owner:SAMSUNG ELECTRONICS CO LTD

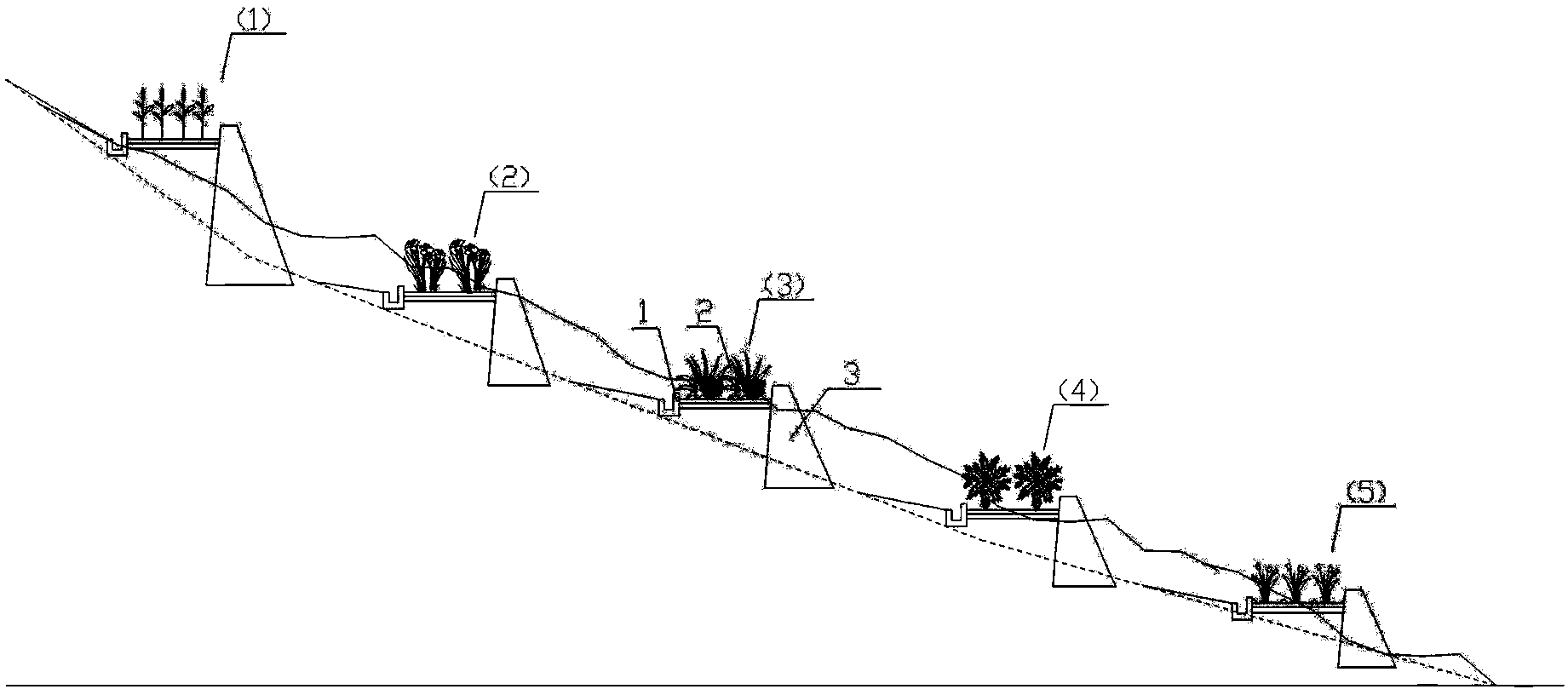

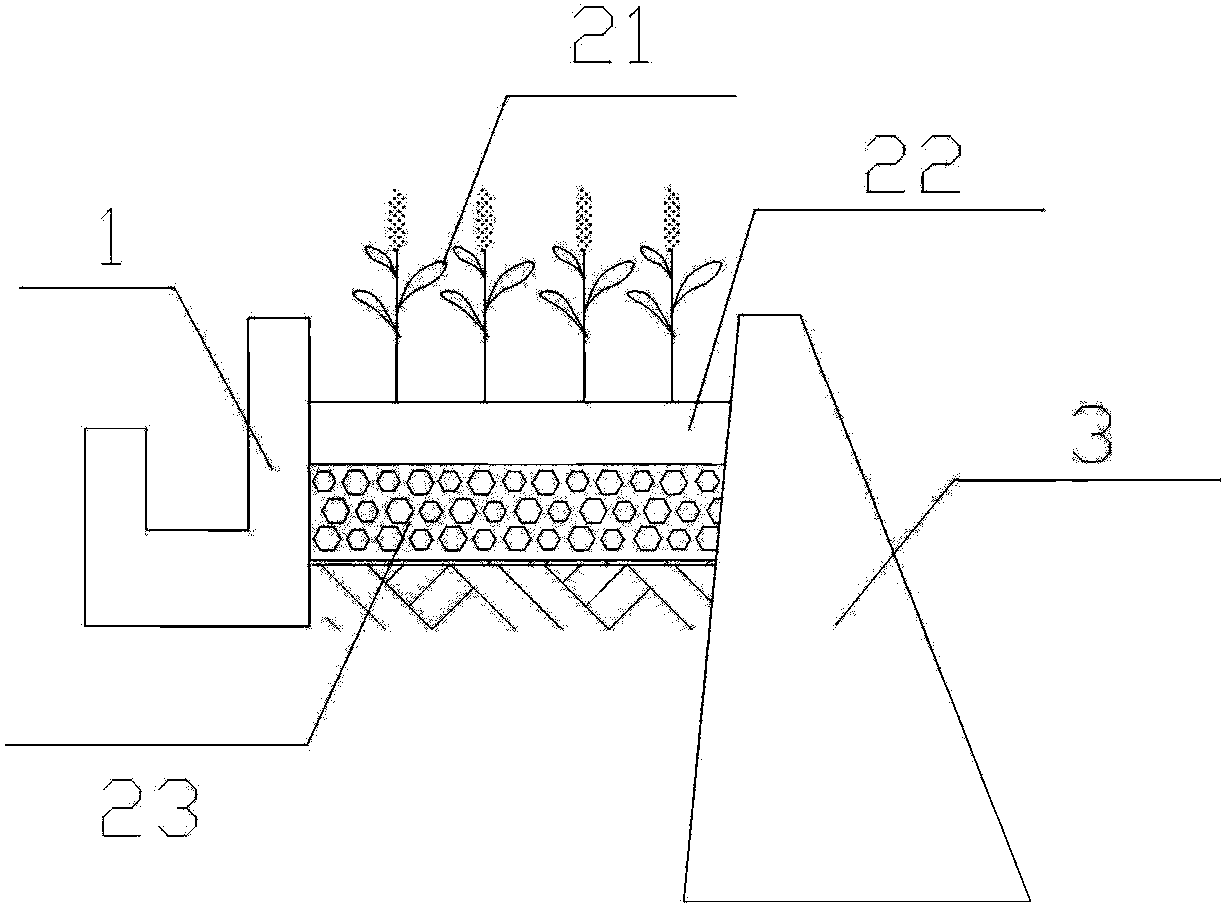

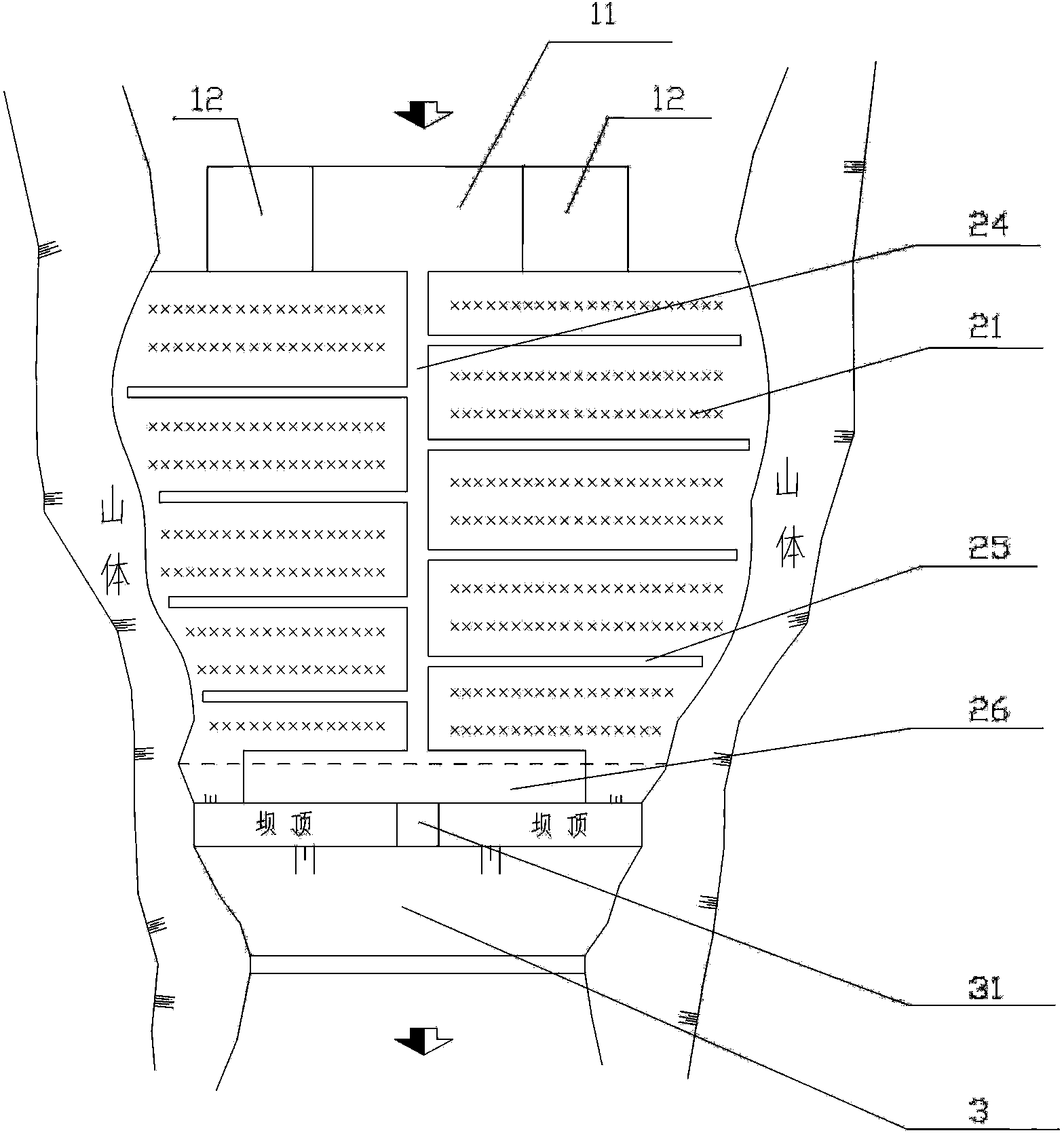

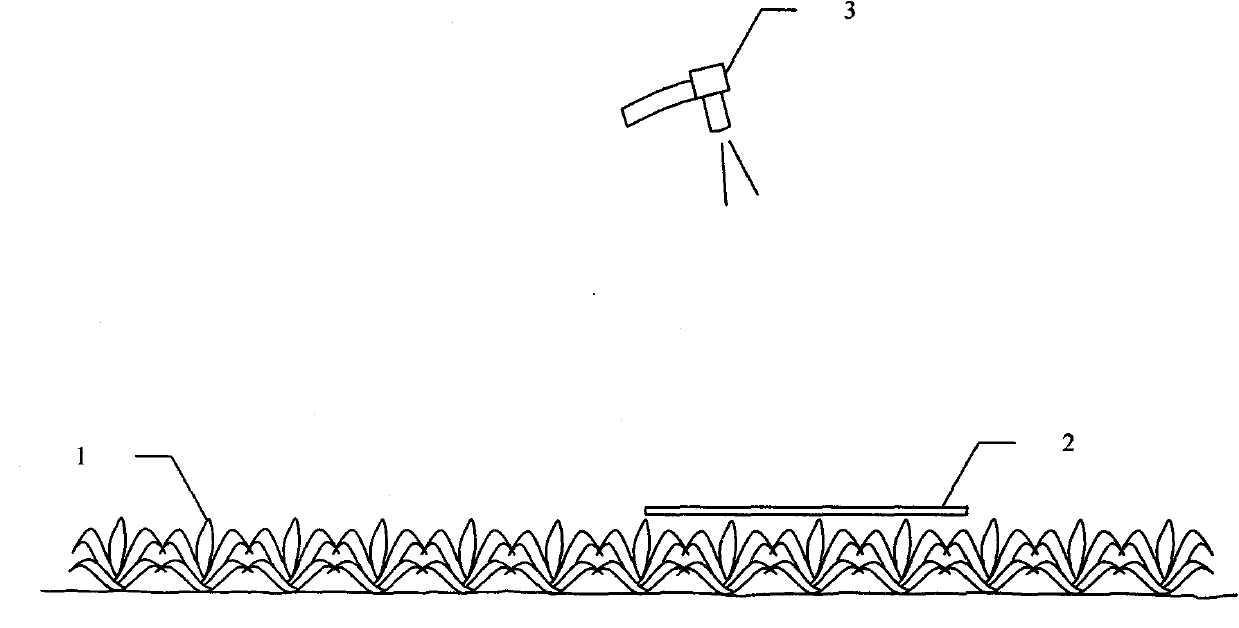

Ecological check dam prevention and control system for three gorges reservoir region hilly land ravine agricultural non-point source pollution

ActiveCN103588303ANo energy consumptionAvoid easy cloggingSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandEngineering

The invention relates to the fields of environmental engineering and ecological engineering. An ecological check dam prevention and control system for three gorges reservoir region hilly land ravine agricultural non-point source pollution is characterized in that multiple levels of ecological check dams are in trapezoidal distribution with natural fall from high to low along with the hilly land; each level of ecological check dam consists of a water storage regulating pond, a constructed wetland and a check dam main body, which are arranged sequentially according to the water flow direction; the water storage regulating pond is communicated with an overflow port in the previous level of the check dam main body. The system can effectively intercept and control the hilly land ravine agricultural non-point source pollution of the drainage basin, can reduce water and soil loss, can perform water-harvest irrigation, can reduce attenuation of channel nutrients before and after rainfall on sloping fields, and can realize ecological interception of agricultural non-point source pollutants.

Owner:WUHAN UNIV OF TECH

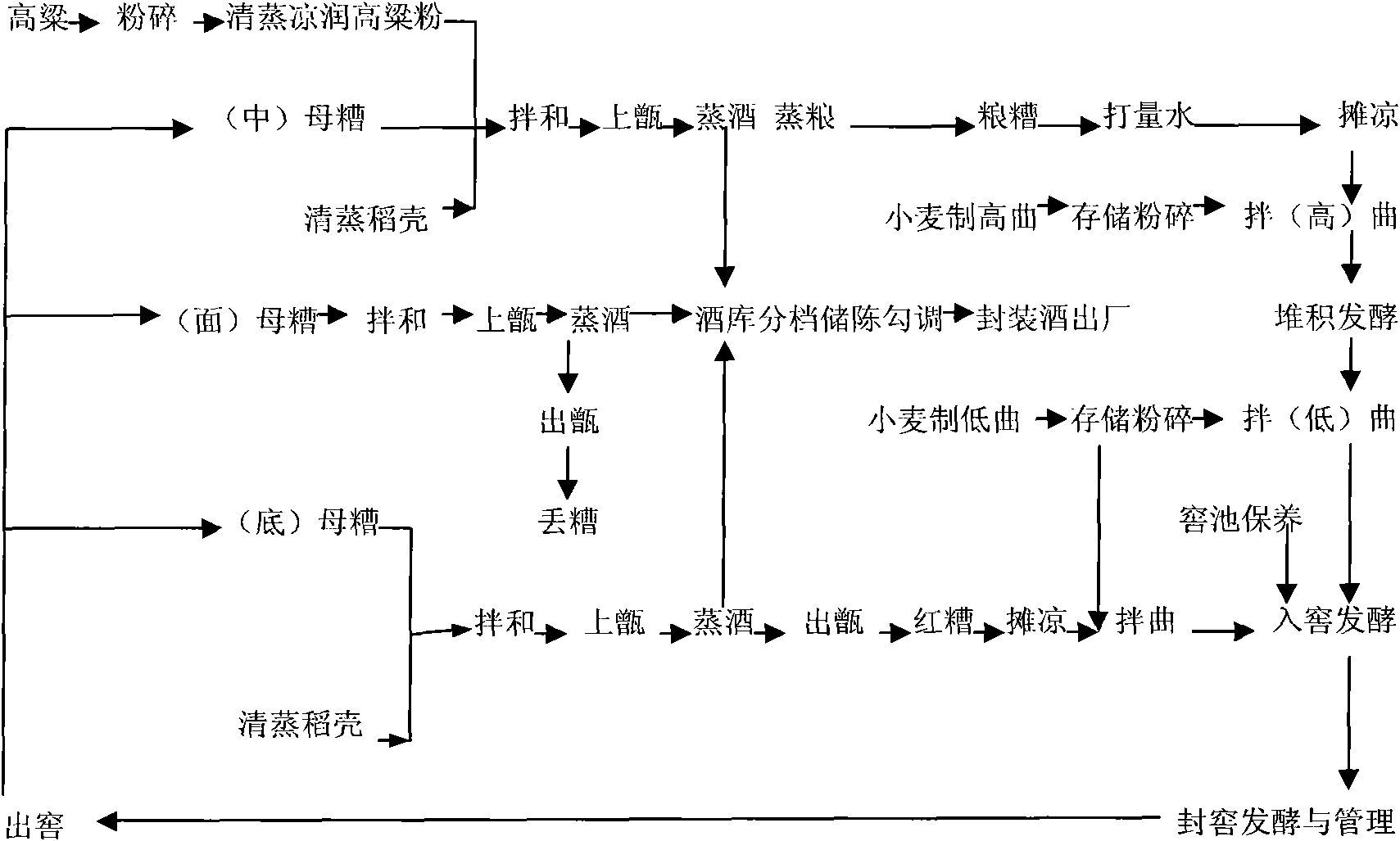

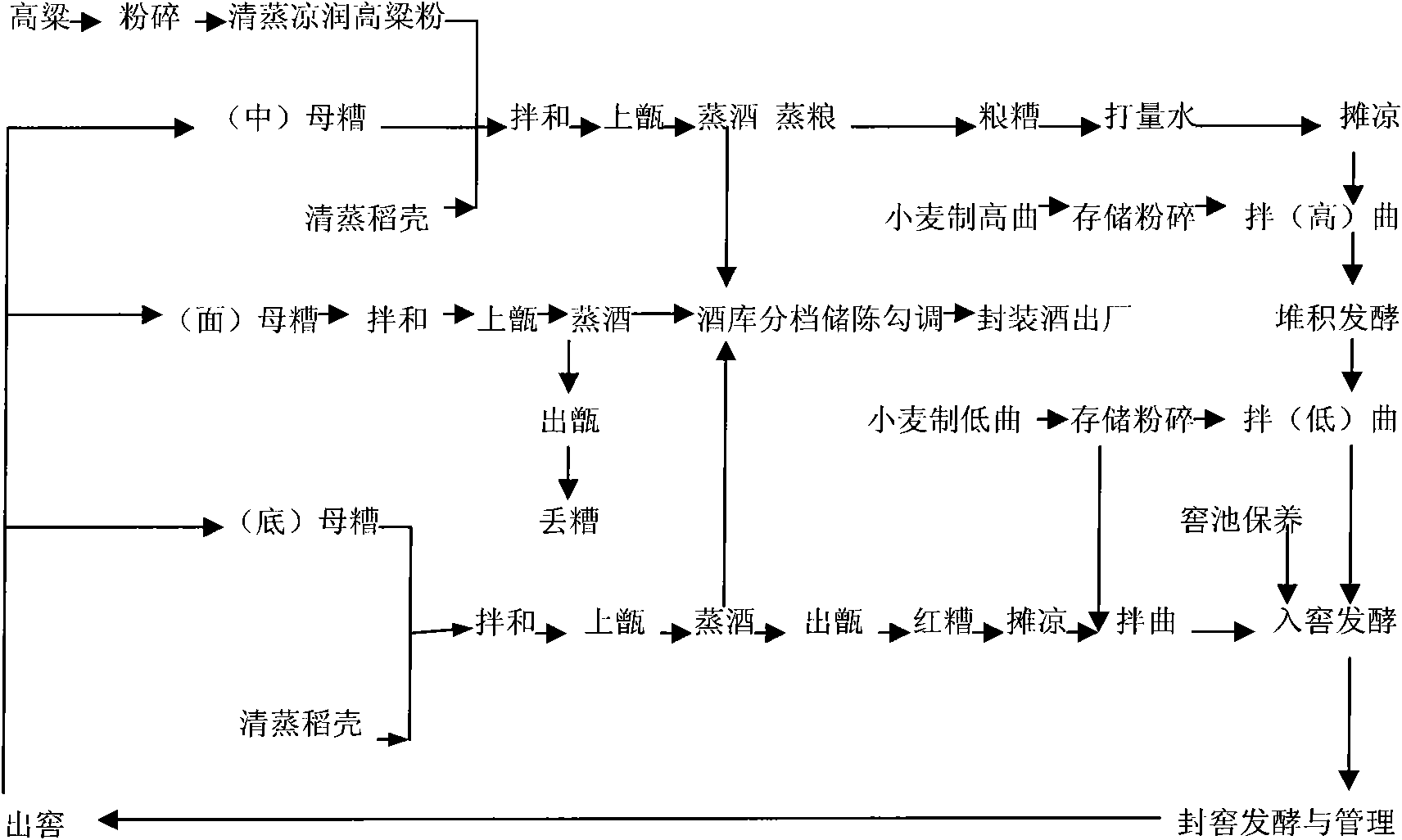

Method for producing white spirit

ActiveCN101792706AAuxiliary and personalityIncrease refreshing sweetnessAlcoholic beverage preparationDistillationVinasse

The invention discloses a method for producing white spirit. By adopting the method, the white spirit which is characterized by clearness and transparentness, full-bodied cellar vinasse, soft, sweet and mellow taste, harmonious flavors, and safety and health by green raw materials selection, steaming and impurity removal, mixed steaming and reaction in an aged pit mud, double aspergillus driving,high and low combination, high-temperature accumulation, polyxenie coexistence, same tank and different vinasse, thermophilic fermentation, laminated distillation, liquor storage according to quality, long air storage and aborative blending. The method has the advantages of simplicity and easily controlled condition and the produced white spirit is characterized by clearness and transparentness, full-bodied cellar aroma, secluded soya sauce, comfortable aroma, soft, sweet and full-bodied taste, harmonious favors, thick wine body, unique style and typical character.

Owner:安徽省金裕皖酒业有限公司

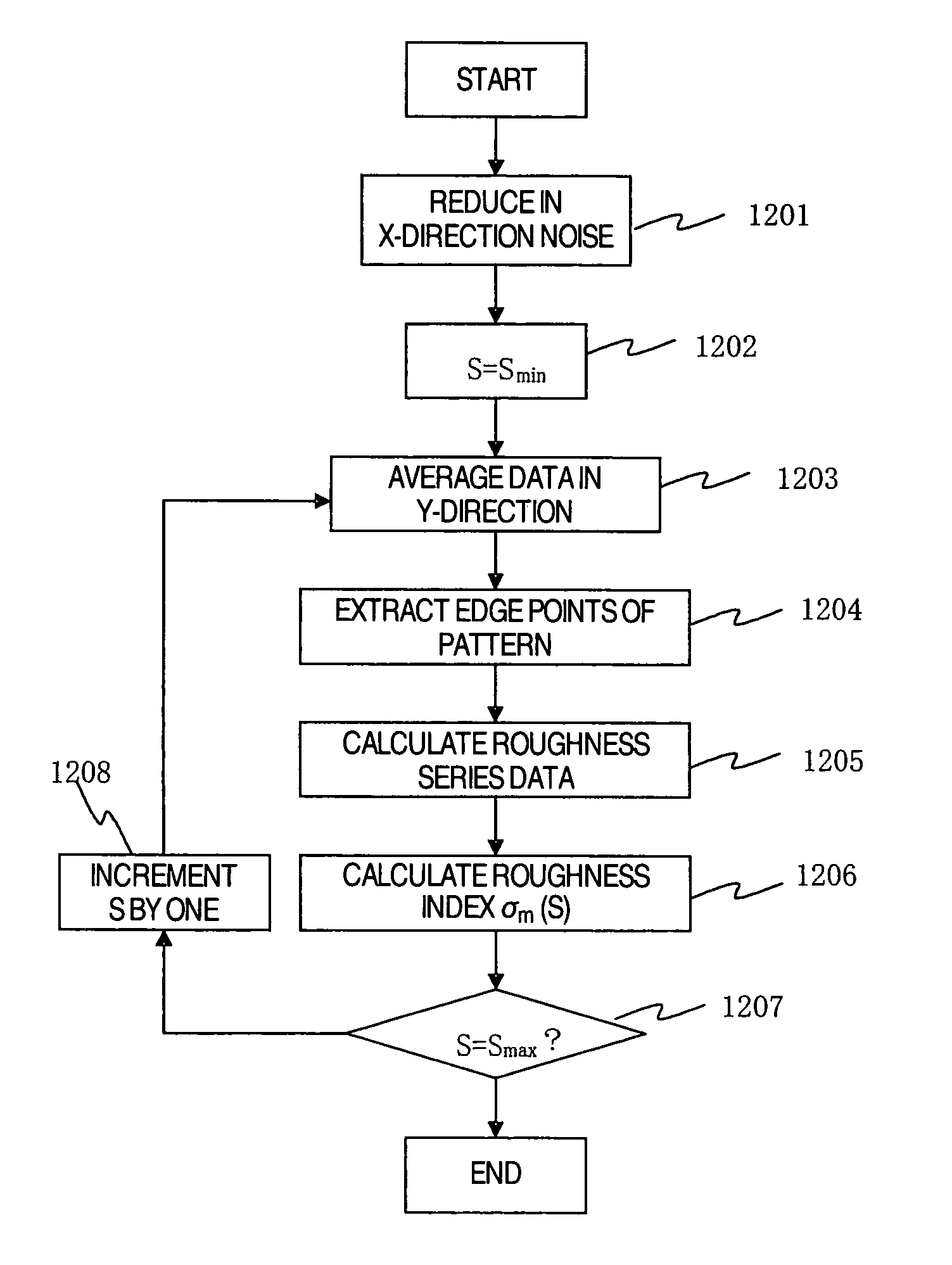

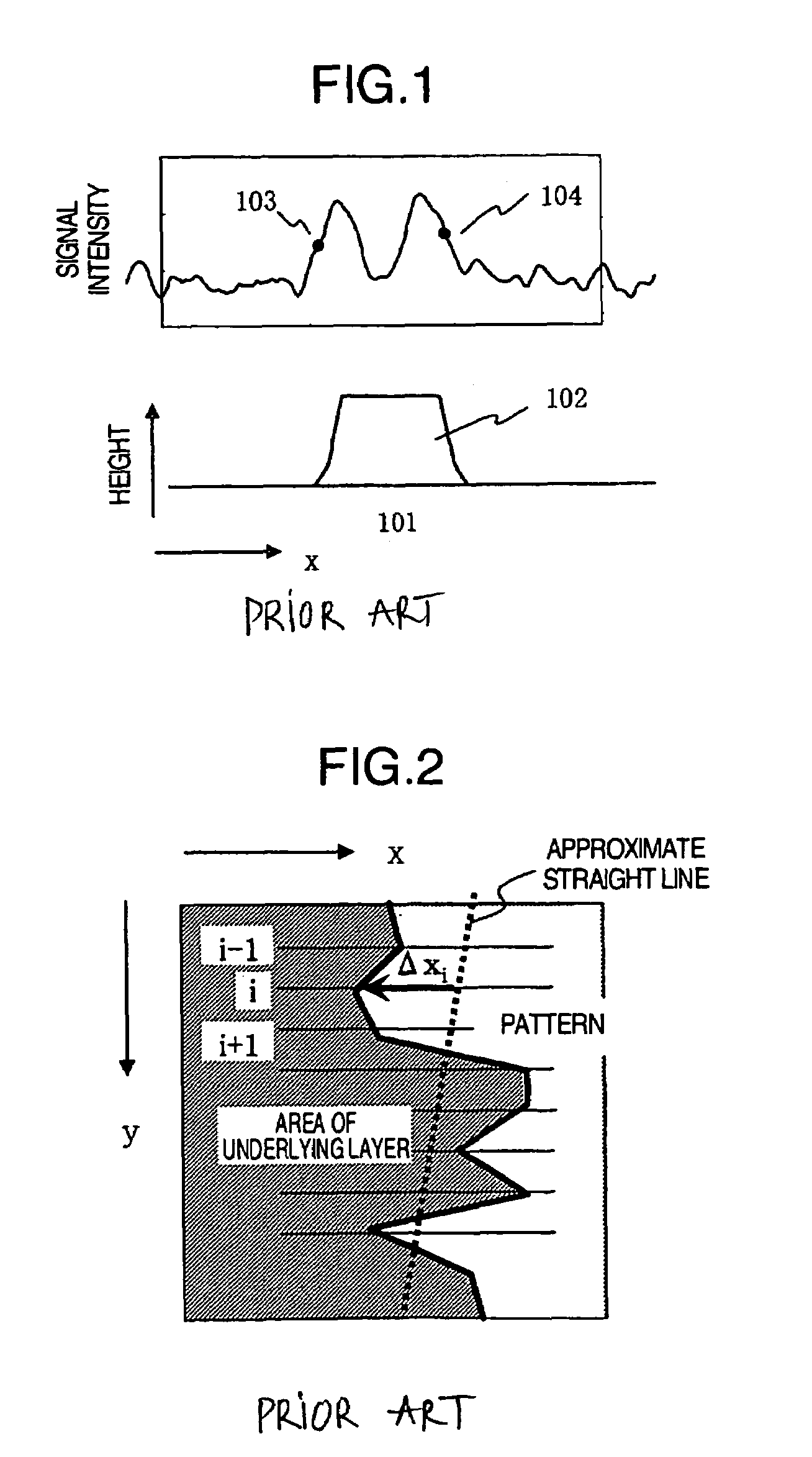

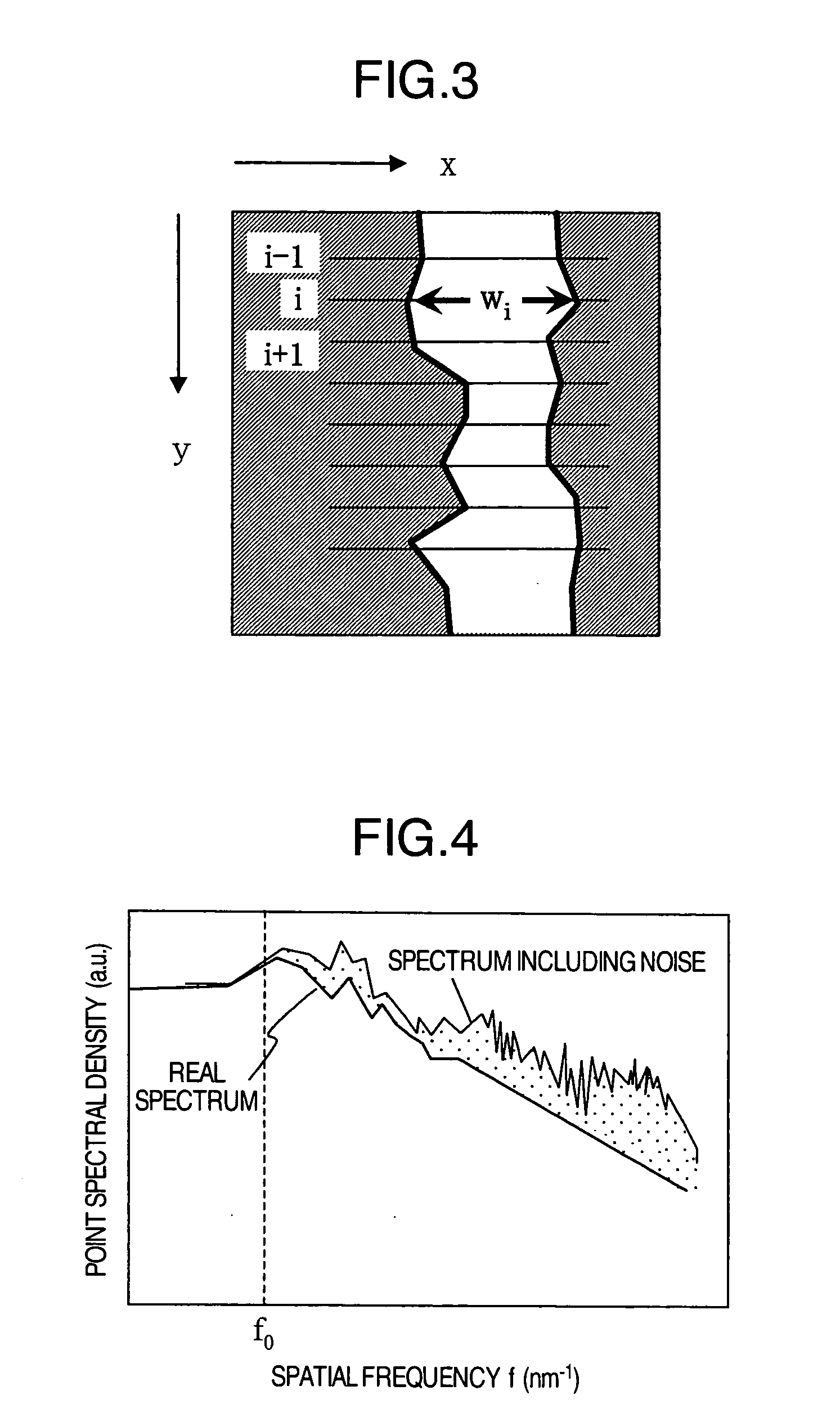

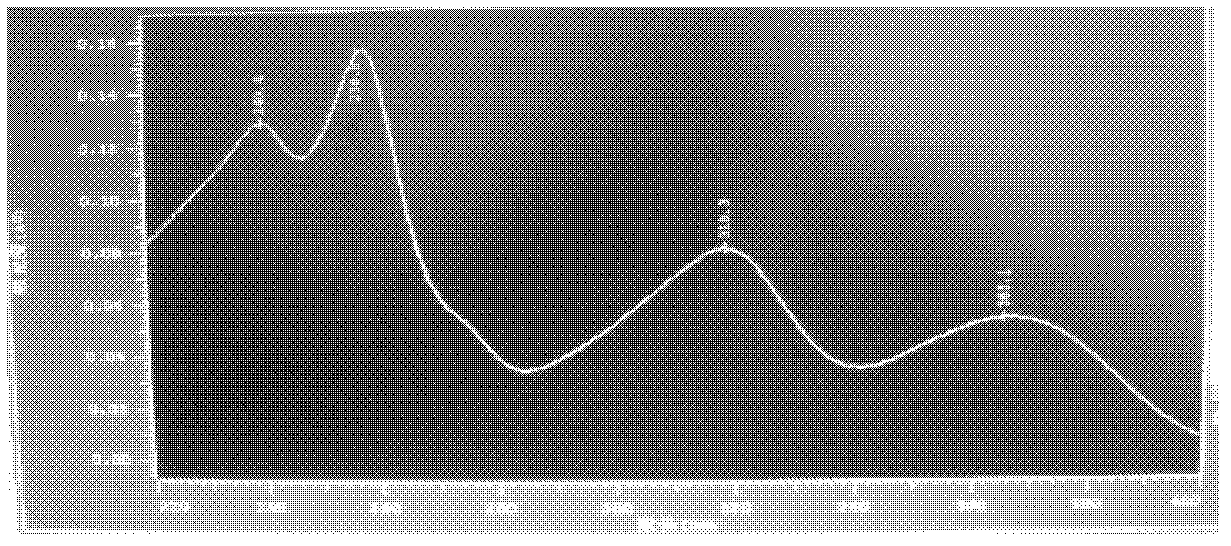

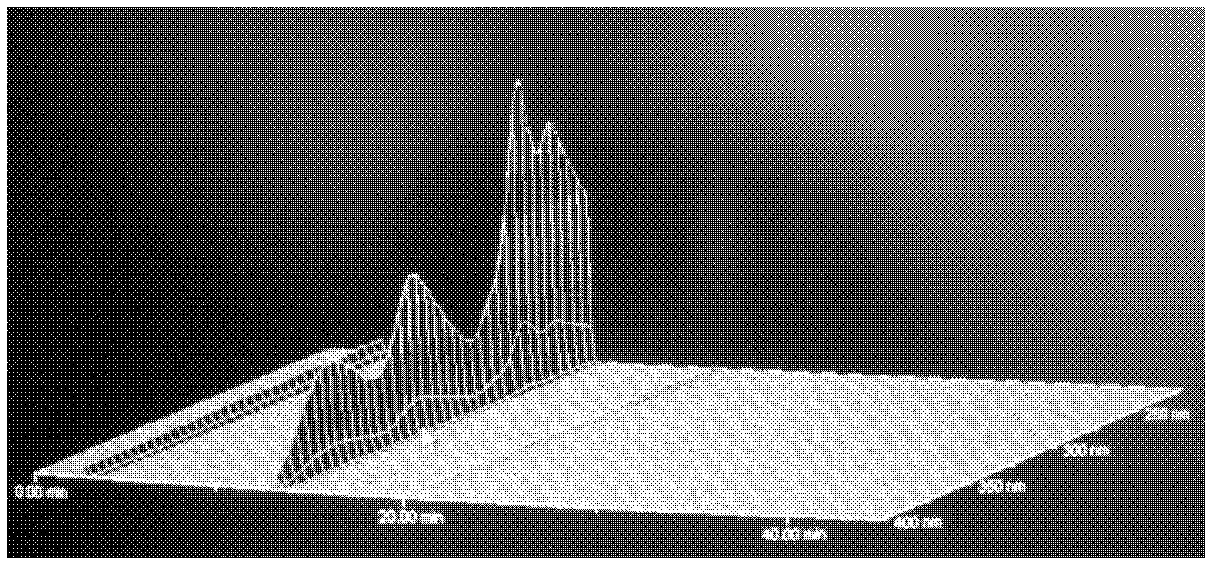

High-accuracy pattern shape evaluating method and apparatus

ActiveUS7230723B2Reduce total powerReduce the required powerMaterial analysis using wave/particle radiationMaterial analysis by optical meansAlgorithmRandom noise

A quantity (or dispersion value) of a distribution of edge position due to random noise is expected to be reduced statistically to 1 / N when N edge position data items are averaged. Using this property, the single page image is averaged in a vertical direction with various values of parameter S, and then the edge roughness index is calculated. The S-dependence of the edge roughness index is analyzed and a term of a dispersion value directly proportional to 1 / S is determined as being due to noise.

Owner:HITACHI HIGH-TECH CORP

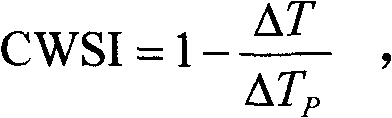

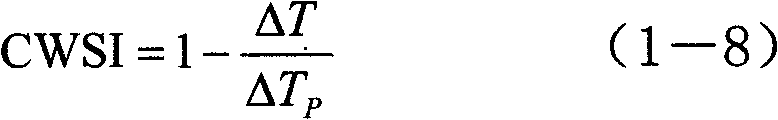

Index method for diagnosing degree of water shortage of crop

The invention relates to an index method for diagnosing the degree of the water shortage of a crop. The method comprises the following steps of: placing a reference crop which cannot generate transpiration at a place with the same environment as the detected crop, wherein delta T in the index formula for diagnosing the degree of the water shortage is temperature difference between a canopy of an actual reference crop and the canopy of the detected crop; delta TP is the temperature difference between a potential or maximum canopy of the reference crop and the canopy of the detected crop; meanwhile measuring the temperature of the canopies of the reference crop and the detected crop and substituting the temperature difference into the formula to calculate the CWSI; and quantizing and determining the degree of water shortage of the detected crop. The method has the advantages of few detection parameters, no complex calculation or multi-factor detection accumulative error, reliable data, capability of detecting in a non-contact way and economy and practicability.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

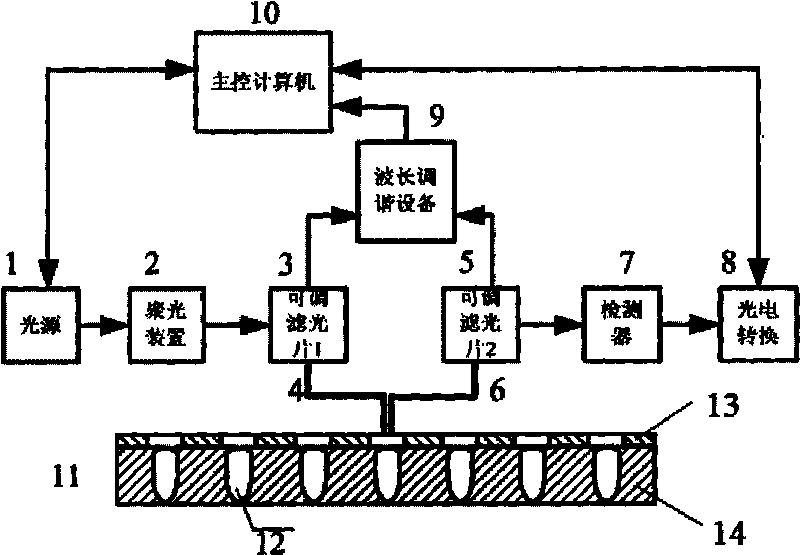

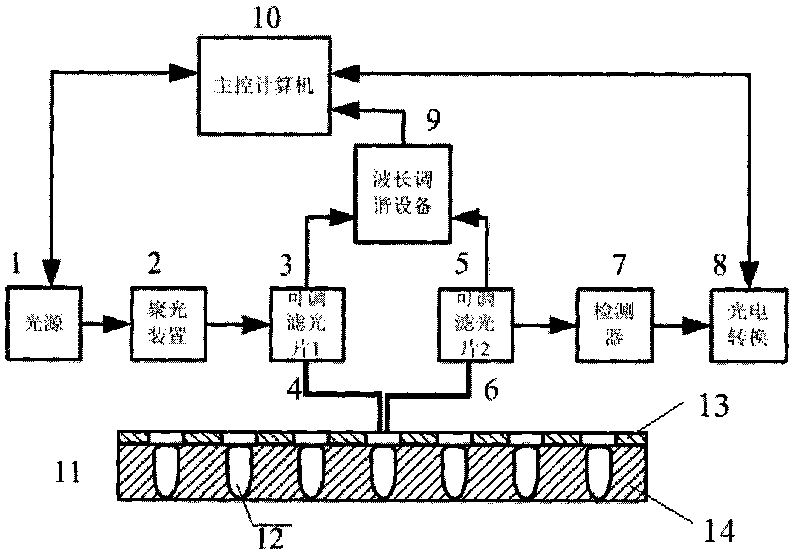

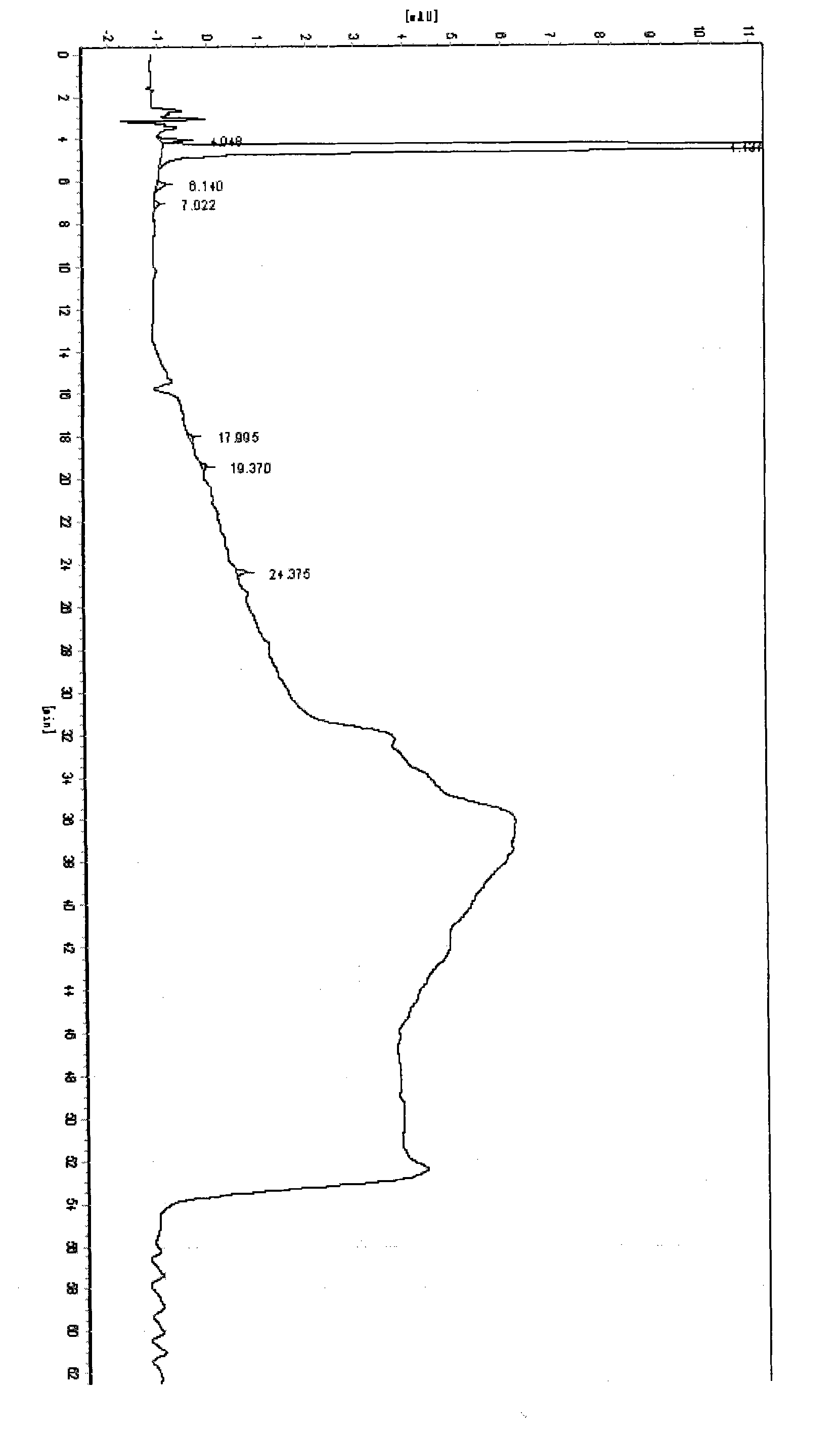

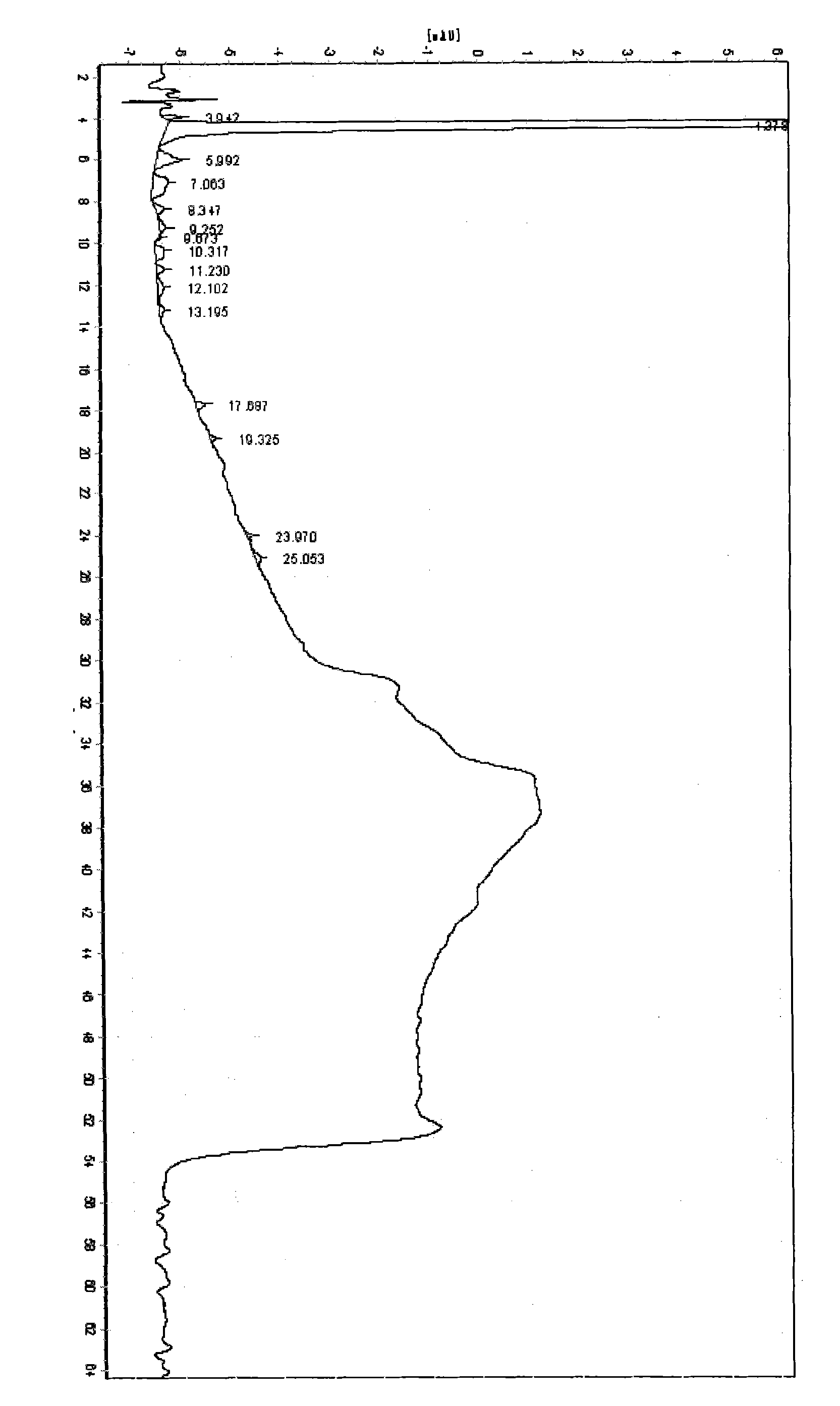

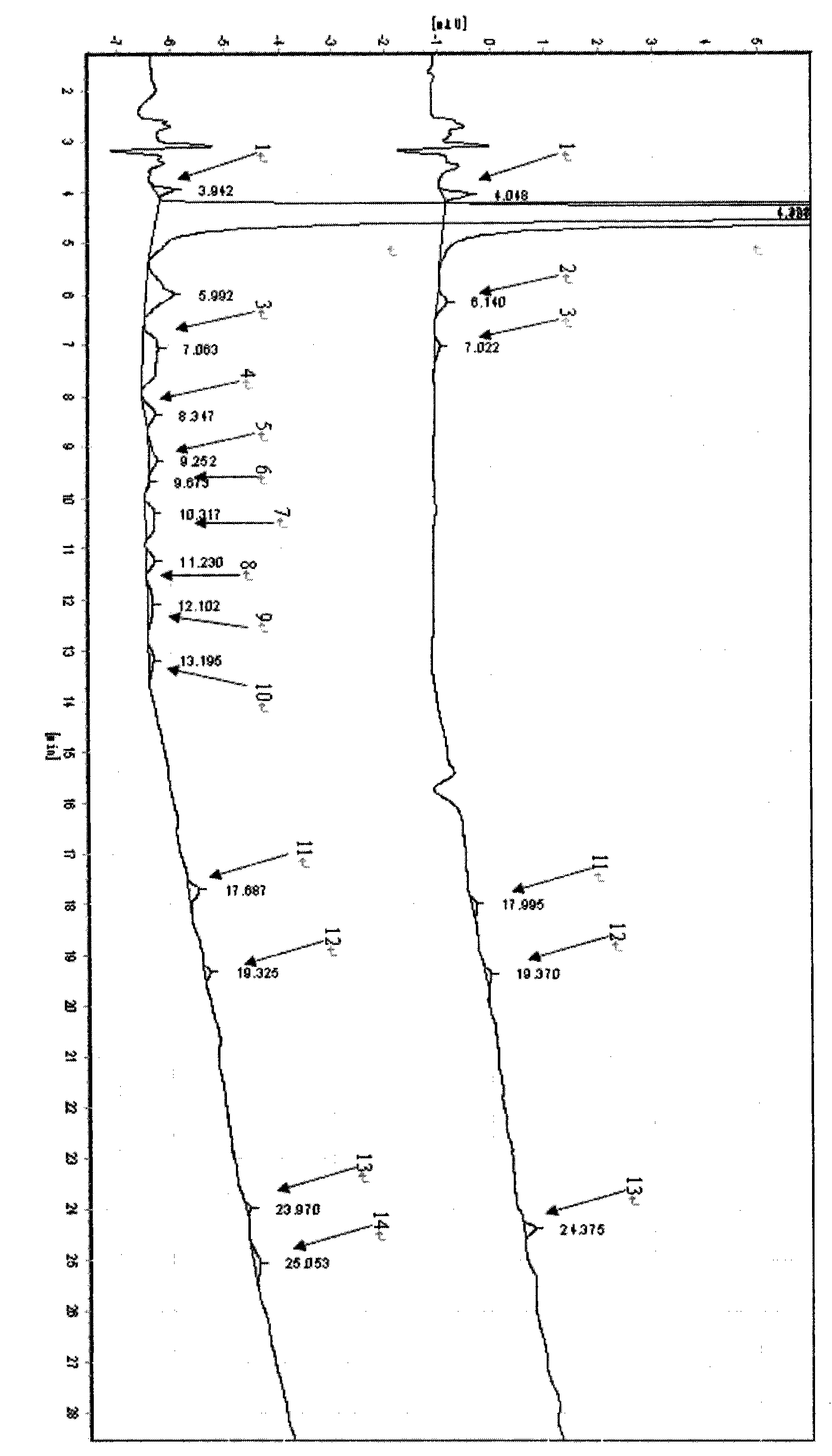

Real-time fluorescence quantitative PCR excitation detection system

InactiveCN101699271ANo moving partsEasy maintenanceBioreactor/fermenter combinationsBiological substance pretreatmentsFluorescenceComputer module

The invention provides a quantitative PCR detection system which is based on a tunable filter and can realize the full wavelength fluorescence excitation detection, and the quantitative PCR detection system comprises a fluorescence excitation module consisting of a light source, a light gathering device and a first adjustable filter, a fluorescence detection module consisting of a second adjustable filter, an optical detector and a photoelectric conversion device, a control unit consisting of a wavelength tuning device and a main control computer, and a heat circulation system consisting of a reaction test tube, a metal warm block and a constant temperature hot cover. The light gathering is carried out on excited light, then the wavelength section is carried out by the tunable filter, the excited fluorescence passes through the tunable filter, the components of the excited light and other interference signals are filtered, and then the optical detector and the photoelectric conversion device are used for delivering to the main control computer for carrying out data analysis.

Owner:XIAN TIANLONG SCI & TECH

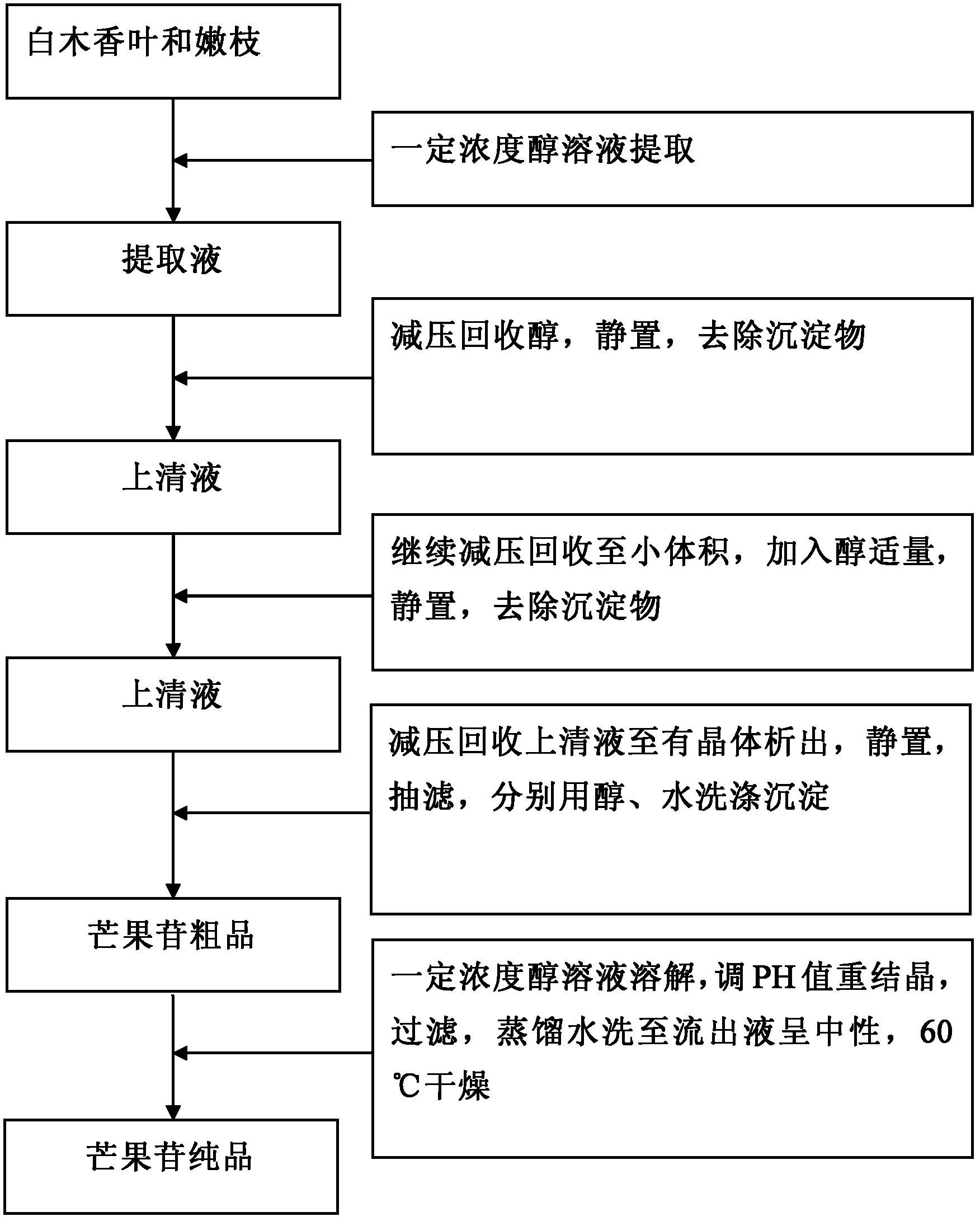

High-purity mangiferin prepared from leaves and twigs of aquilaria sinensis and preparation method thereof

The invention discloses high-purity mangiferin prepared from leaves and twigs of aquilaria sinensis and a preparation method thereof. The method comprises the following steps: on the basis of utilizing leaves and / or twigs of aquilaria sinensis as raw materials, extracting with an alcohol solution; after recovering alcohol at reduced pressure, carrying out water precipitation, alcohol precipitation, devitrification and the like so as to obtain a mangiferin crude product; and then recrystallizing to prepare the high-purity mangiferin. The method has the advantages that the leaves and twigs of aquilaria sinensis are used as the raw materials; the content of the mangiferin is high, and the variety and quantity of impurities are both low; the obtained high-purity mangiferin dose not contain allergic components, and the final product is high in quality and can be widely applied to the industries such as medicine, health care products and cosmetics; and the method has the advantages of simple, stable, practicable preparation process step, short production period, less labor consumption and low cost.

Owner:林励

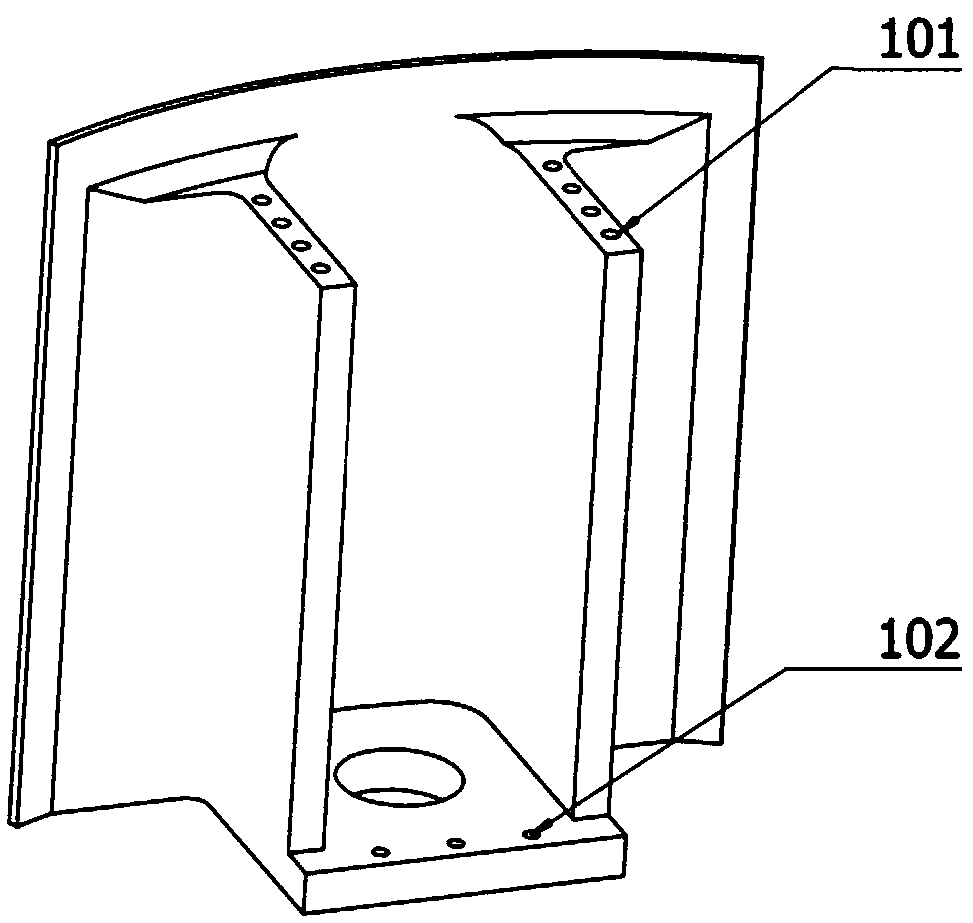

Method for installing and using cable-stayed bridge reinforced concrete cable tower prestressed system

ActiveCN102400441AReduce volumeSmall volumeCable-stayed bridgeBridge structural detailsReinforced concretePre stress

The invention belongs to the technical field of cable-stayed bridge construction, in particular relates to a method for installing and using a cable-stayed bridge reinforced concrete cable tower prestressed system, and solves the problem that a steel bar, a prestressed end and a prestressed steel bar at the prestressed end are subjected to cross interference due to the traditional anchor box with the prestressed end. The method comprises the following steps of: precasting a prestressed system, namely fixing a pier head anchor, an anchor box and a prestressed steel wire bundle; measuring and lofting the position of the anchor box; installing the anchor box; installing the prestressed system; performing prestressed tensioning and mud jacking; and performing water prevention and anchor sealing. The invention has the advantages that: the influence of the end on the common steel bar can be reduced, and the steel bar is prevented from being cut off; and a special template is not required to be installed during subsequent anchor sealing, the cubic amount of used concrete is small, workload is low, and the prestressed system is easy to construct.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

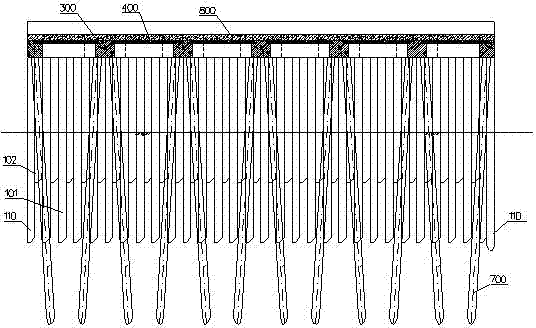

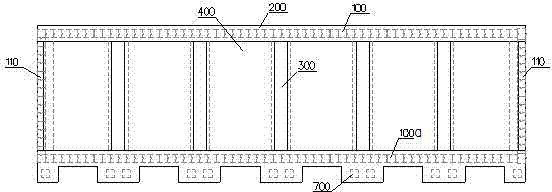

Reinforced Concrete Pile Embankment and Its Construction Method

The invention relates to a reinforced concrete pile type dyke. The reinforced concrete pile type dyke comprises two rows of reinforced concrete sheet piles, a dyke top, a filler and a beach-protecting structure, wherein the two rows of reinforced concrete sheet piles are arranged in parallel in a closed mode and inserted into the foundation; the dyke top is arranged between the two rows of reinforced concrete sheet piles and is connected with the pile tops of the reinforced concrete sheet piles; the filler is filled above a mud surface line between the two rows of reinforced concrete sheet piles; and the beach-protecting structure is arranged on the outer sides of the two rows of reinforced concrete sheet piles. The reinforced concrete pile type dyke has the advantages that: 1, volume is small, occupied area is little, and investment is saved; 2, the quantity of required earth work is small and the problem of shortage of diking sand and stone material is solved by utilizing earth worknear the project; 3, the reinforced concrete sheet piles are manufactured in an industrialized mode and constructed in situ and has high mechanized construction degree; 4, the reinforced concrete pile type dyke is applicable to soft soil foundation and the whole stability is high; and 5, the periphery of the structure is the reinforced concrete structure and the wave impact resistance is high. The reinforced concrete pile type dyke can be applied to the peripheral dyke of the reclamation project and is particularly applicable to diking on deep water soft soil foundation. The invention also discloses a construction method of the reinforced concrete pile type dyke.

Owner:SHANGHAI WATER ENG DESIGN & RES INST

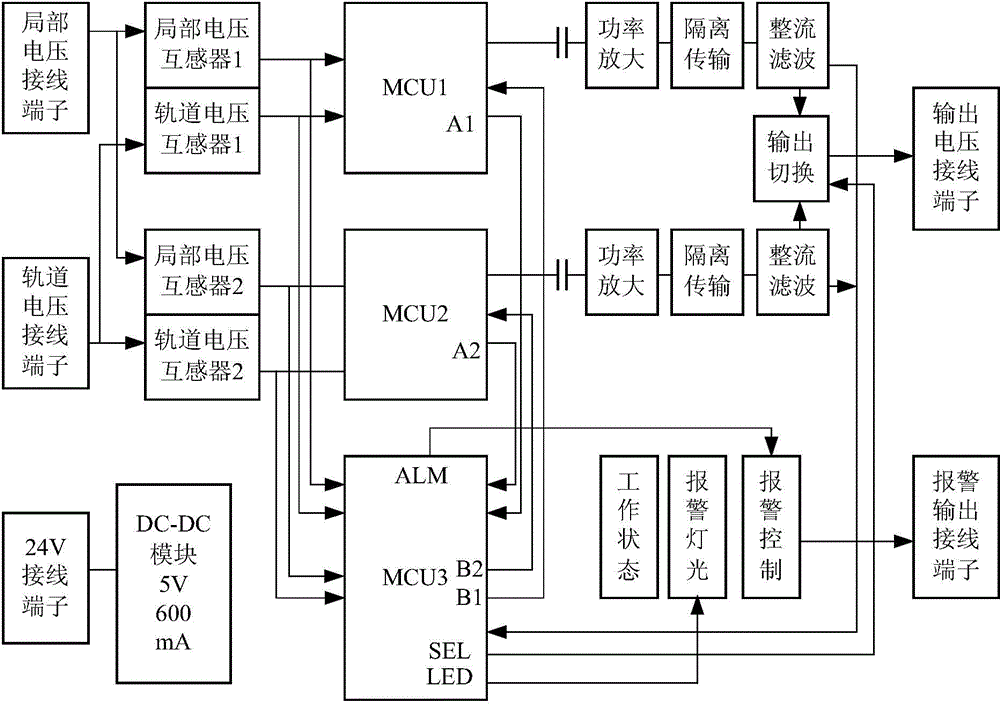

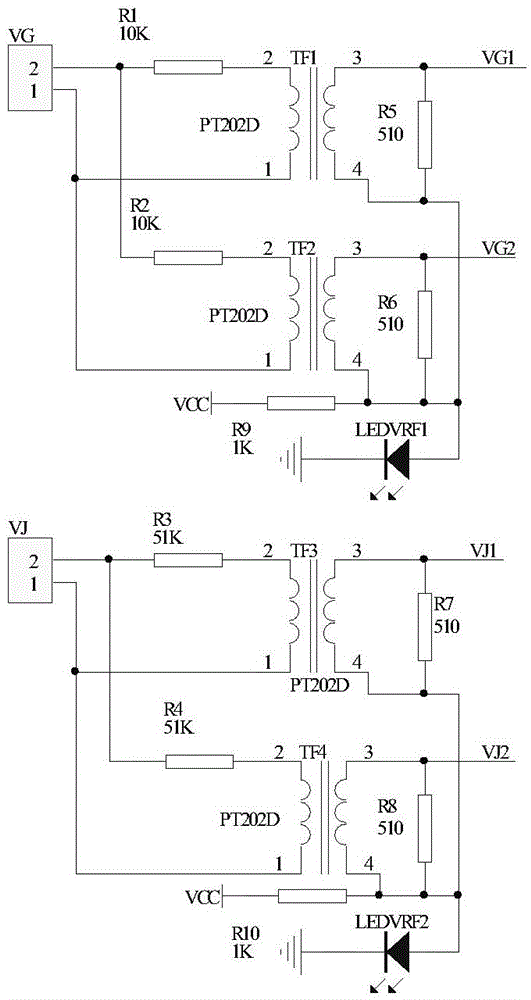

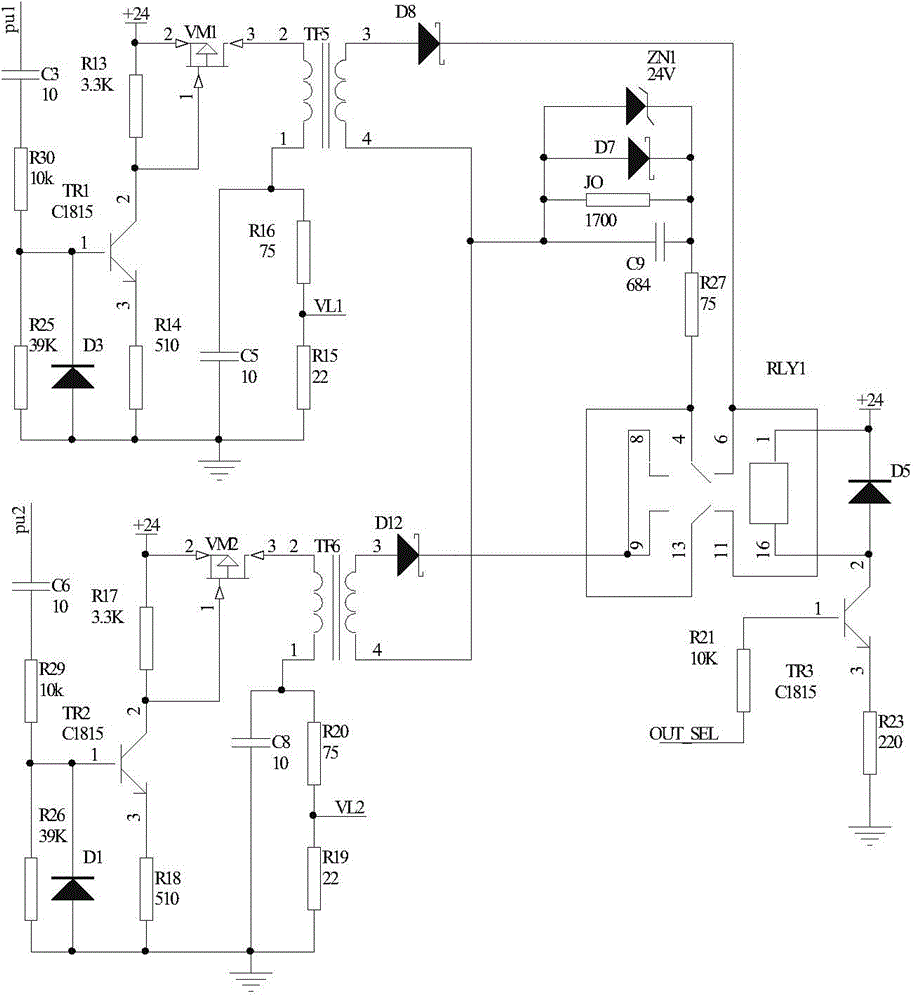

Microelectronic phase-sensitive receiver

ActiveCN104155910ASafe and reliable triggerSimple structureProgramme controlCurrent/voltage measurementPhase differenceLow voltage

The invention provides a microelectronic phase-sensitive receiver. The microelectronic phase-sensitive receiver is simple in structure, can accurately and reliably trigger a relay to work and achieves the abnormity alarm function and the like. According to the microelectronic phase-sensitive receiver, two measurement circuits with an MCU1 and an MCU2 as cores are the same in structure, local voltage and track voltage are connected to A / D input pins of the MCUs through miniature mutual inductors, the MCUs collect two paths of voltage waveforms of a period, the initial phase angles and the effective values of the two paths of signals are calculated through a Fourier transform algorithm, a phase difference is solved, logic judgment is carried out, square signals are output when the condition is met, amplification, isolation transmission and rectification filter are carried out on the square signals, and the square signals wait for selection and output. An MCU3 collects and calculates four paths of voltage, a result is compared with a processing result of the MCU1 and a processing result of the MCU2 respectively, whether the voltage is normal or not is judged, one path of voltage is selected according to a set strategy, an output voltage amphenol connector outputs direct current voltage to enable a 1700 relay to work, and an alarm signal is given out if necessary.

Owner:XIAN JIAXIN RAILWAY EQUIP CO LTD

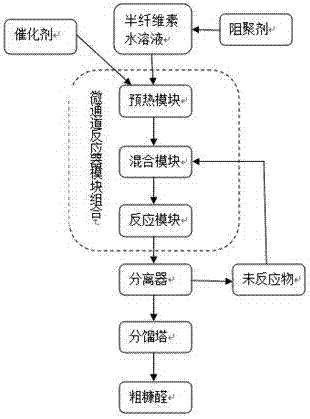

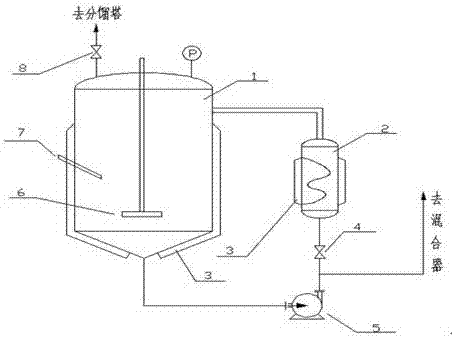

Method for preparing furfuraldehyde through hemicellulose by use of continuous flow microchannel reactor

ActiveCN106977473ASmall quantityContinuous processOrganic chemistryChemical recyclingFiberEcological environment

The invention belongs to the field of organic synthesis, and specifically a method for preparing furfuraldehyde through hemicellulose by use of a continuous flow microchannel reactor. The method comprises the following steps: controlling a mole ratio of the hemicellulose aqueous solution containing polymerization inhibitor to a catalyst through a metering pump; enabling the hemicellulose aqueous solution and the catalyst to enter the micro channel reactor to perform the mixing reaction; after the mixing reaction is finished, continuously passing through a series of enhanced mass transfer type micro-channel modules and a flow type micro-channel module, after the reaction process is finished, enabling the product to flow out from the outlet of the reactor and then enter a gas-liquid separator to perform the gas-liquid separation, wherein the furfuraldehyde and water vapor mixed gas enters a fractionating tower after being discharged from an upper gas-guiding tube through a throttling valve, and the liquid falls into the separator. By use of the method disclosed by the invention, the hemicellulose recycled by the waste lye in a chemical fiber industry is used as the raw material, the hemicellulose is directly converted into the furfuraldehyde by use of the continuous micro-channel reactor; by use of the way of separating and recycling the catalyst, the yield and the economic benefit are improved, the pollution is lowered, and the ecologic environment is greatly improved.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

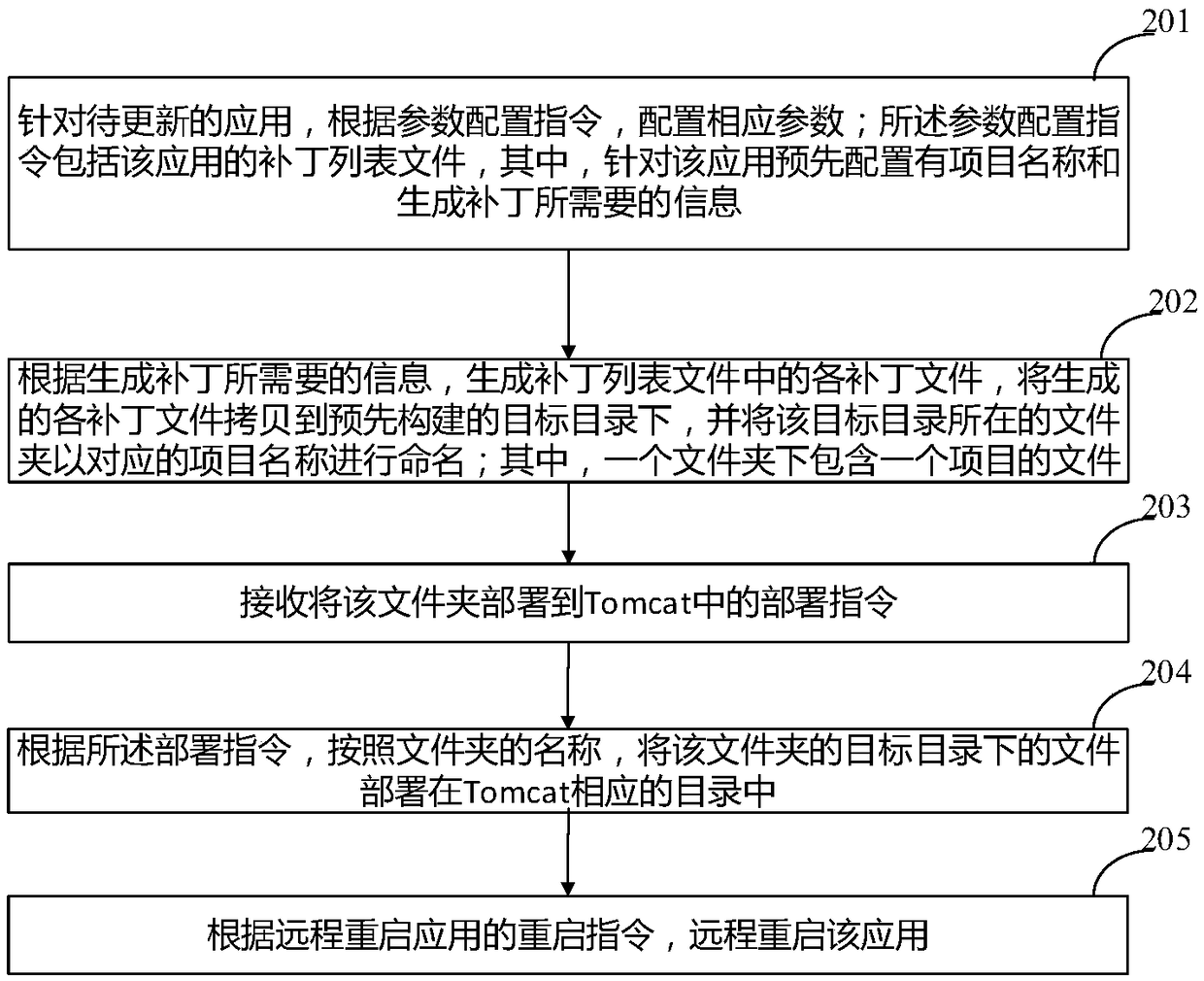

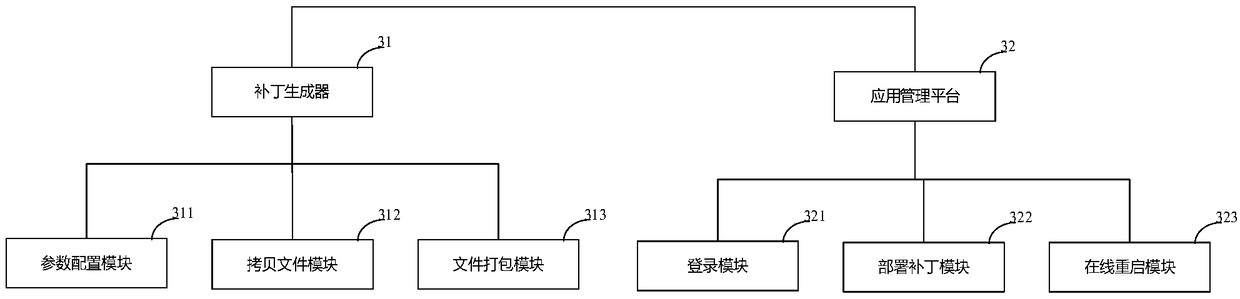

Java Web project updating method based on Eclipse and Tomcat and related devices

InactiveCN108829430ASmall quantityFast transferSoftware engineeringProgram loading/initiatingEclipseOperating system

The invention relates to a Java Web project updating method based on Eclipse and Tomcat and related devices. The method for updating an application by abandoning a mode of a traditional complete war package comprises the steps that firstly, patch files which need to be updated are generated according to configured parameters, and secondly, the patch files are packaged for deployment. An incremental updating mode is implemented. Compared with the traditional complete war package, the amount of updated data is much smaller, and transmission and deployment are facilitated. Moreover, the updatingmode does not need manual directory searching, and compared with manual deployment, the error of manual operation can be avoided.

Owner:XIAMEN HYMAKE TECH

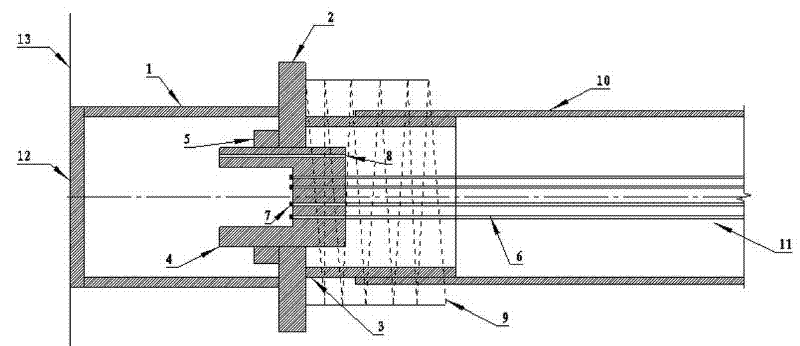

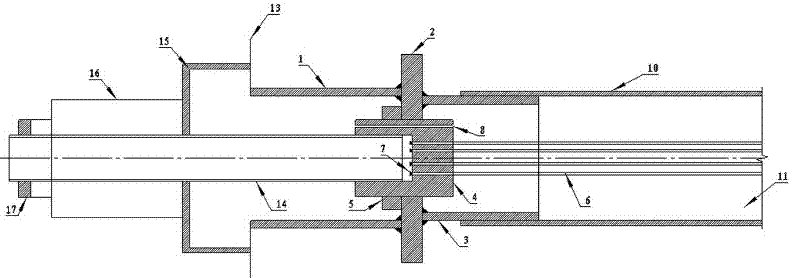

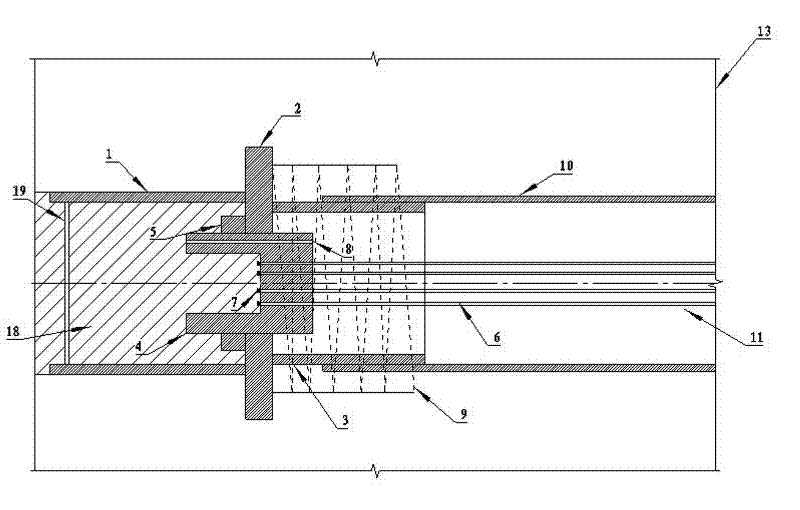

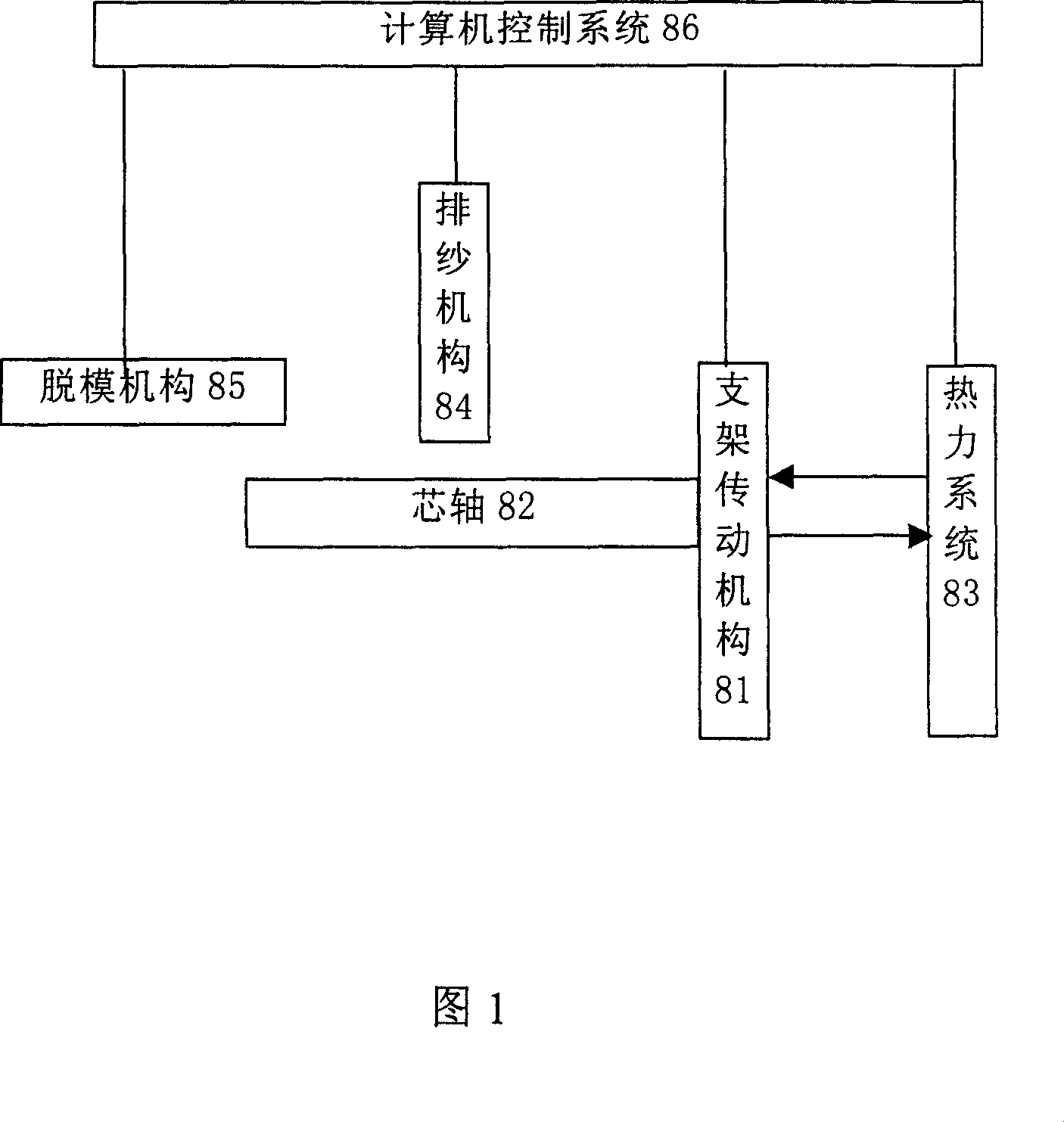

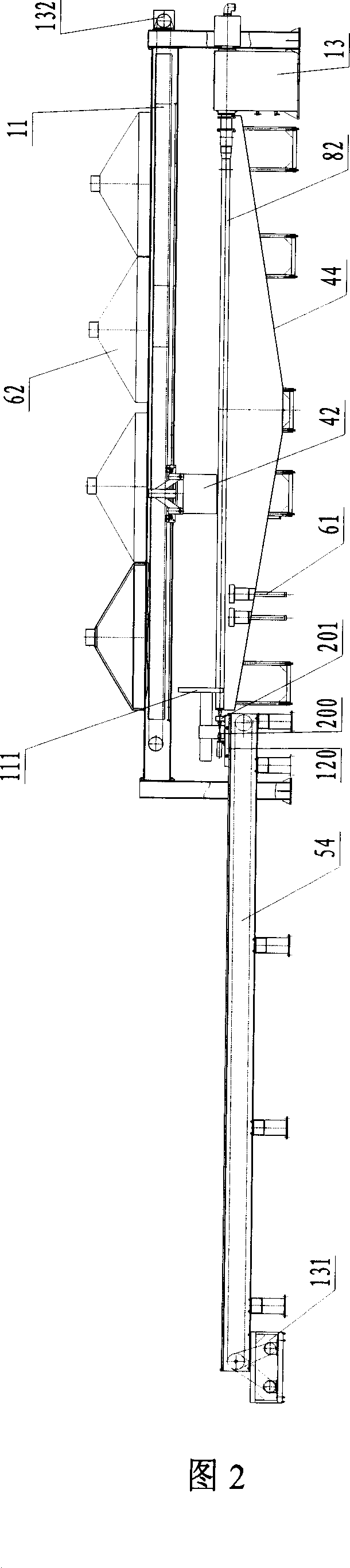

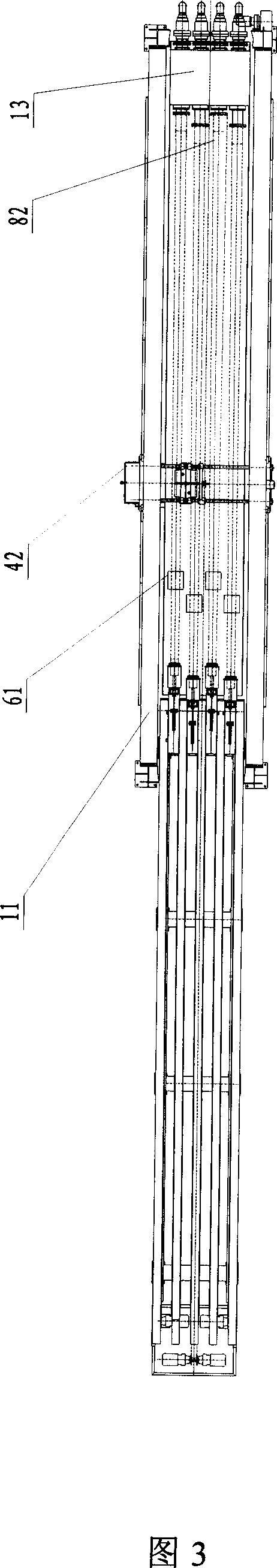

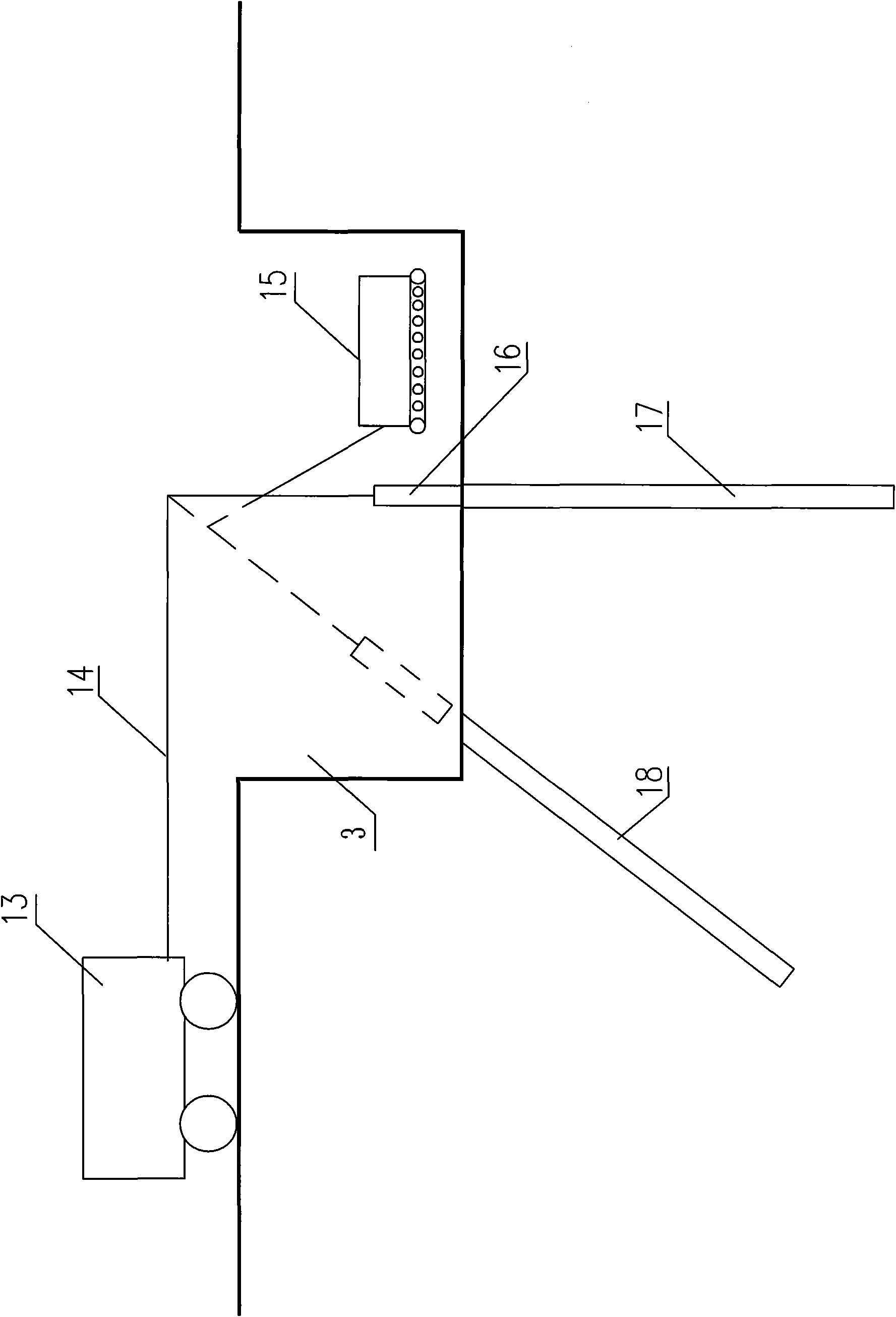

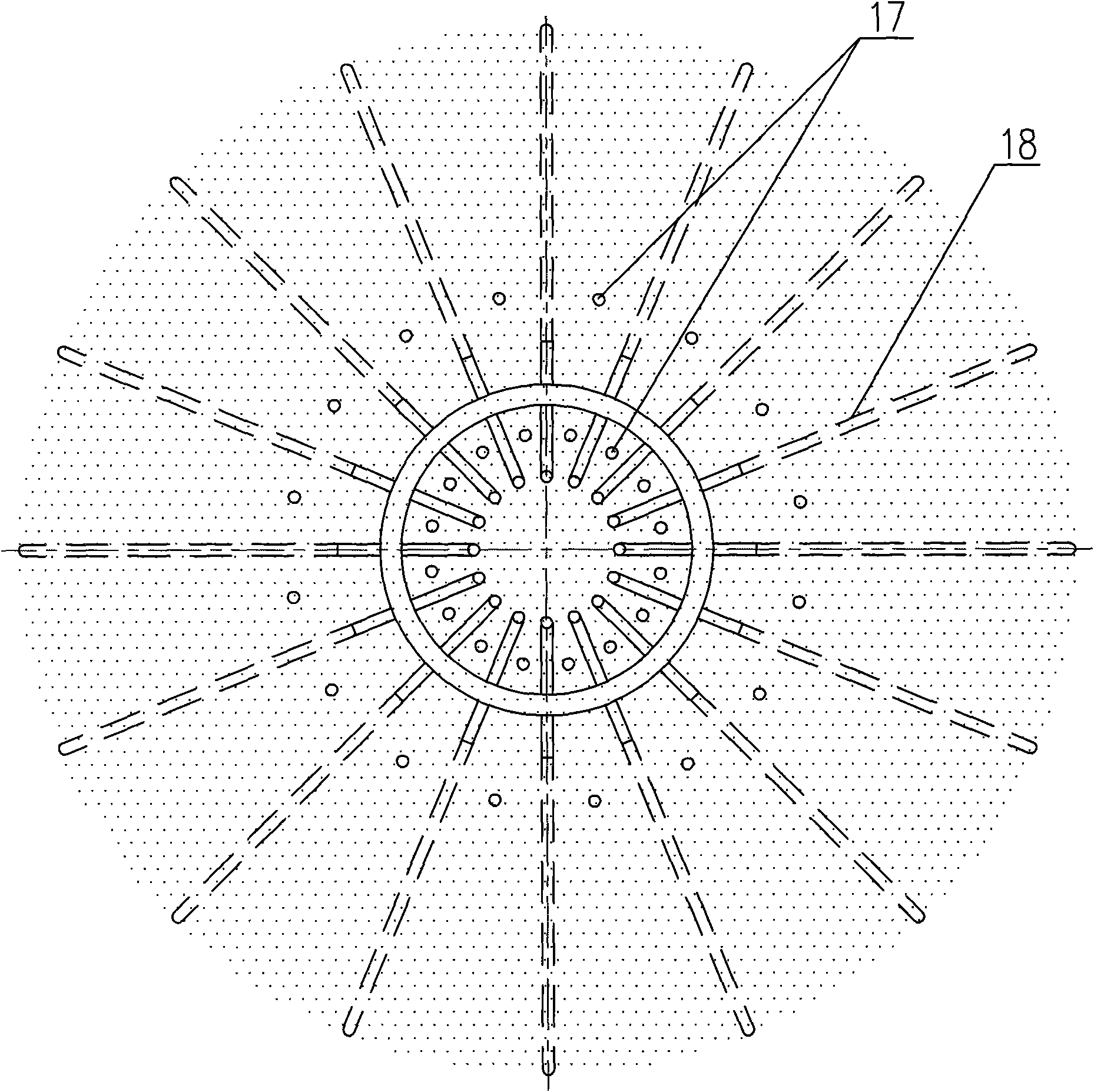

Producing system of internally-heating curing glass fibre reinforced plastic controlled by programm

InactiveCN1982037AImprove product qualityIncrease productivityProgramme controlComputer controlYarnGlass fiber

A program controlled system with internal heating and solidifying for preparing the glass fiber reinforced plastic pipe is composed of a supporting frame-drive mechanism, a dual-layer metallic mandrel for delivering high-temp steam, a steam system, a yarn arranging system, a demoulding unit and computer control system.

Owner:北京朗瑞达管道技术有限公司

Method for separating and purifying amoxicillin trihydrate

The invention discloses a method for separating and purifying amoxicillin trihydrate, which comprises the following steps: adding certain amount of organic solvent and quaternary ammonium salts in an aqueous amoxicillin acid salt solution, and adjusting the pH value of the solution with an alkaline solution under low temperature to the isoelectric point of amoxicillin; continuing to maintain the temperature of the solution at 2-8 DEG C and growing the grain for some time, and separating out the amoxicillin trihydrate; and allowing the sample to be sequentially washed by a water-containing organic solvent and a pure organic solvent to obtain an amoxicillin trihydrate crystal. The method of the invention has simple operation, the impurities of the obtained amoxicillin trihydrate have the fewest types and quantity, the obtained amoxicillin trihydrate has the best quality, and the used organic solvents have low prices, so the method has low cost and is easy for industrialization production.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

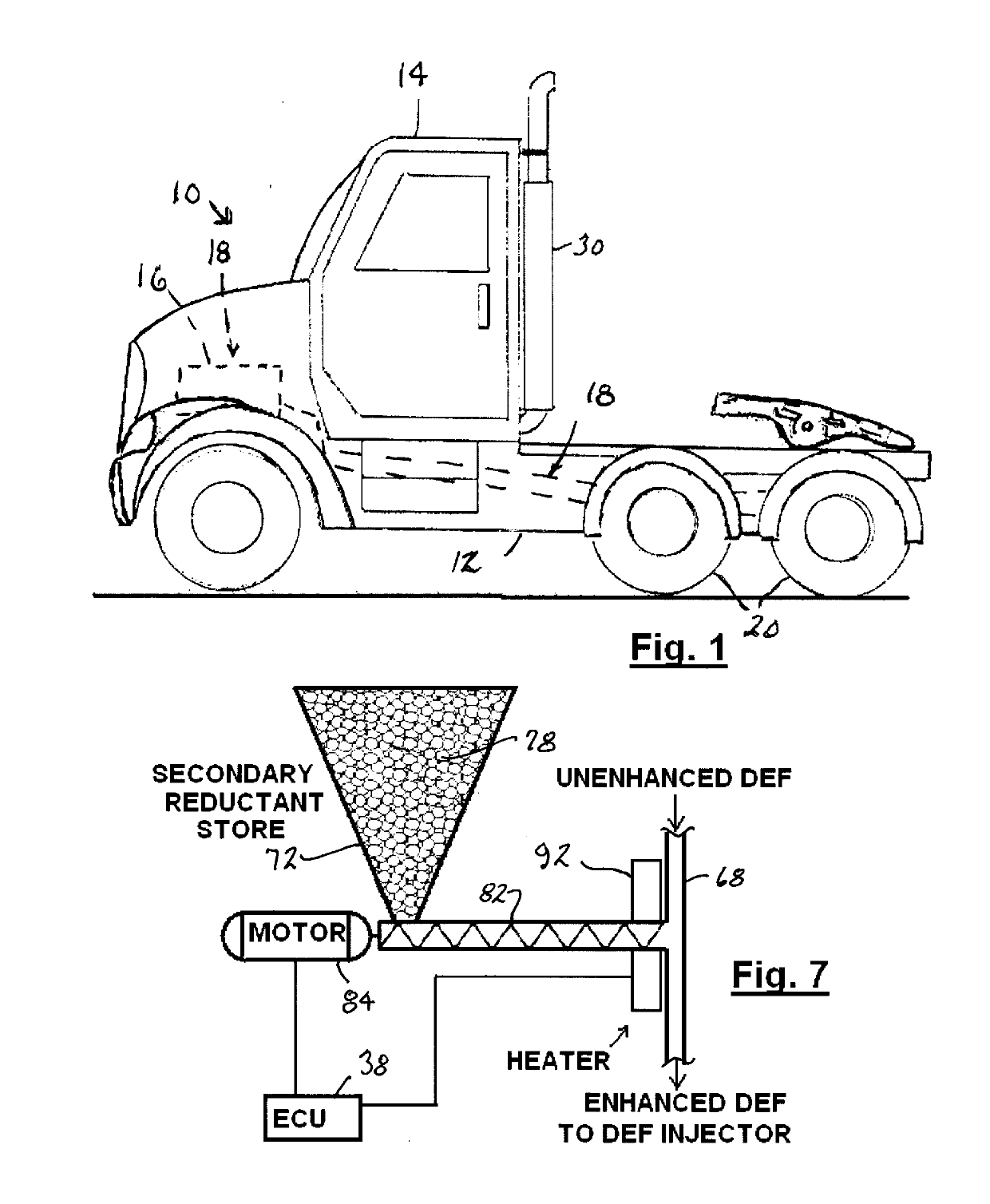

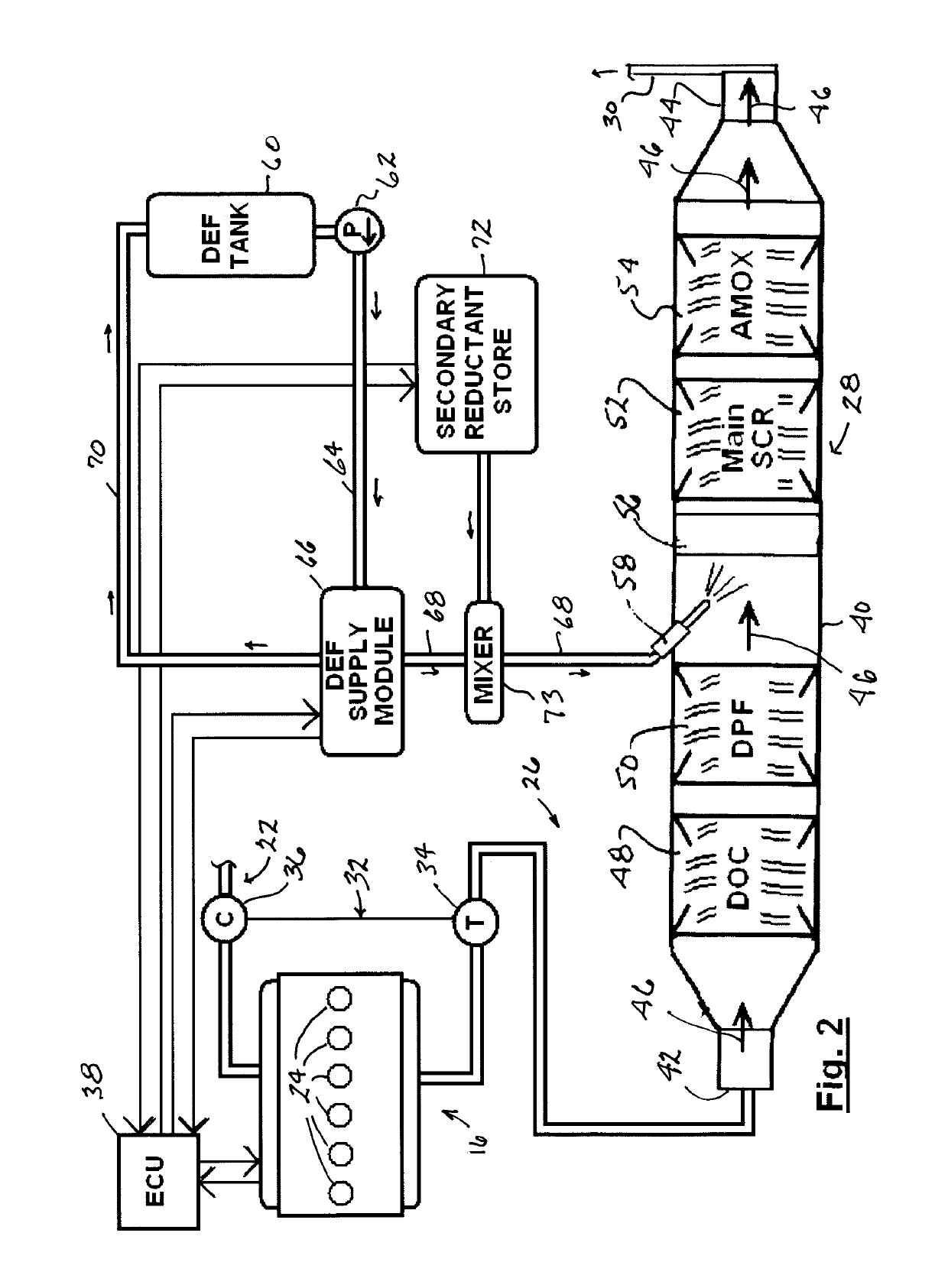

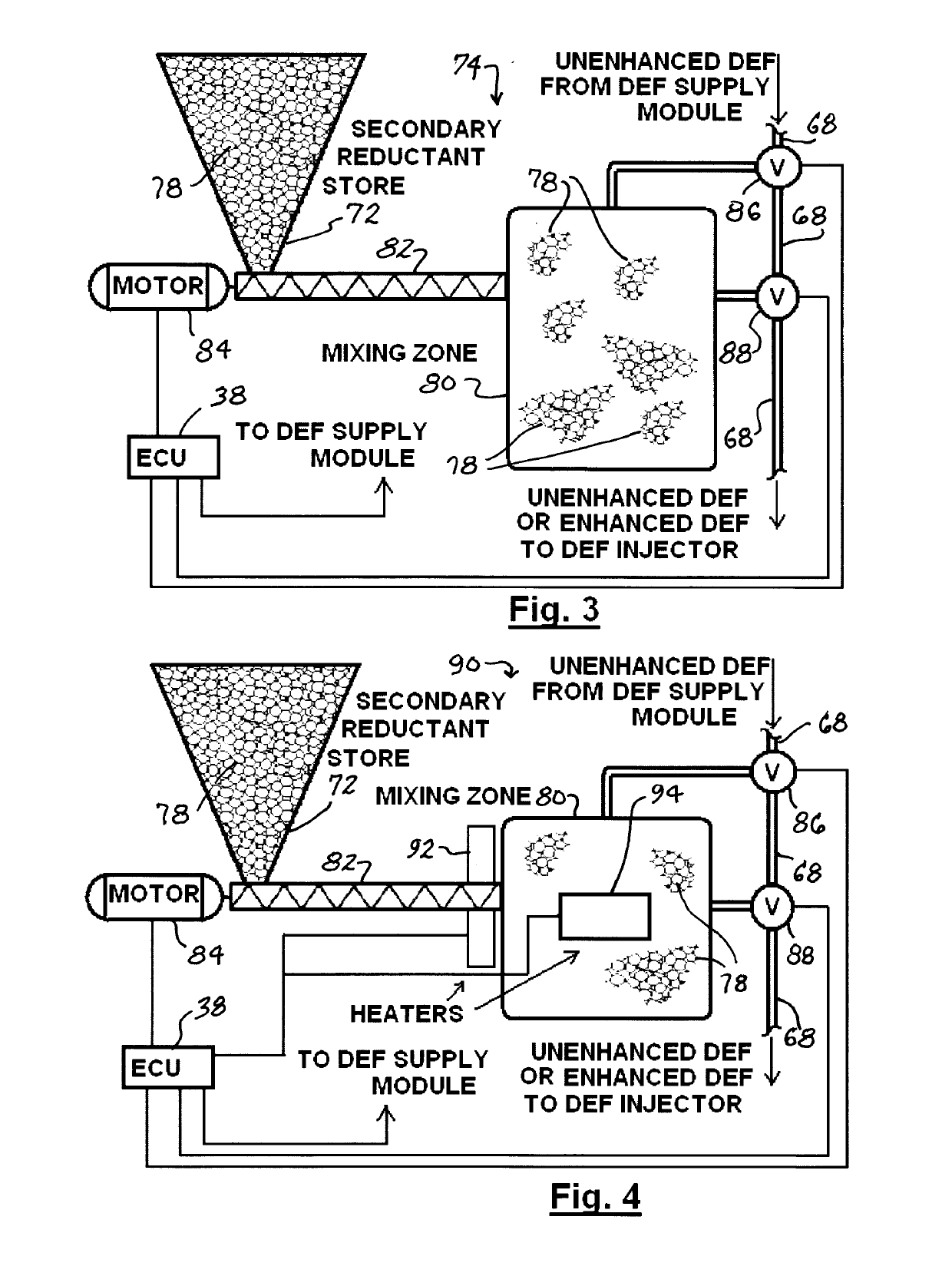

ENGINE OUT NOx REDUCTION USING ENHANCED DEF

InactiveUS20190234283A1Small quantityOperating efficiency greatGas treatmentInternal combustion piston enginesEngineeringSelective catalytic reduction

Unenhanced DEF and anhydrous solid reductant capable of forming ammonia are mixed to create enhanced DEF which is injected into an engine exhaust aftertreatment system which performs selective catalytic reduction (SCR) of engine-out exhaust.

Owner:INT ENGINE INTPROP CO LLC

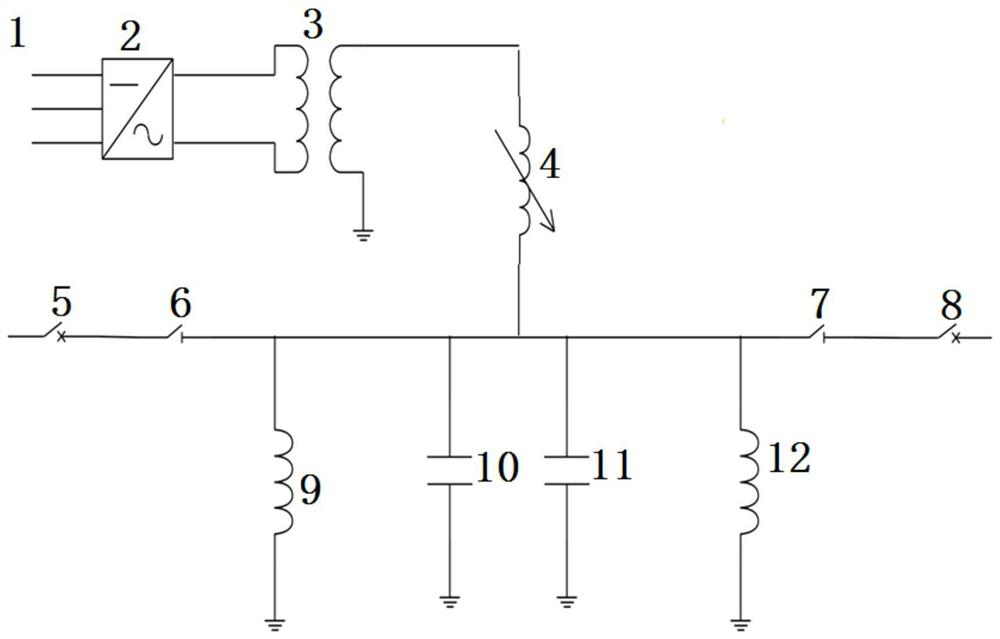

Method for carrying out long-distance submarine cable pressure test by using reactive compensation reactor

The invention discloses a method for carrying out a long-distance submarine cable pressure test by using a reactive power compensation reactor. The method comprises the following steps: calculating aparallel compensation inductance value L2 according to reactance values of a land station reactive power compensation reactor and a sea station reactive power compensation reactor; calculating an inductance value L1 of a test series adjustable reactor according to a series-parallel resonance calculation formula when series-parallel resonance is reached; adjusting the inductance value of the test series adjustable reactor according to the calculated inductance value of the test series adjustable reactor 4; setting the frequency of a variable frequency power supply, carrying out slow boost testing, when the reading of the test capacitive voltage divider reaches a test voltage, stopping boosting, keeping the station for preset time, disconnecting the variable frequency power supply to carry out discharging at the end of time so as to complete long-distance submarine cable pressure testing by a reactive compensation reactor. With the method, the alternating-current pressure test can be carried out on the submarine cable, the capacity and the number of field test equipment are relatively small, and the test difficulty and the test cost are relatively low.

Owner:XIAN THERMAL POWER RES INST CO LTD

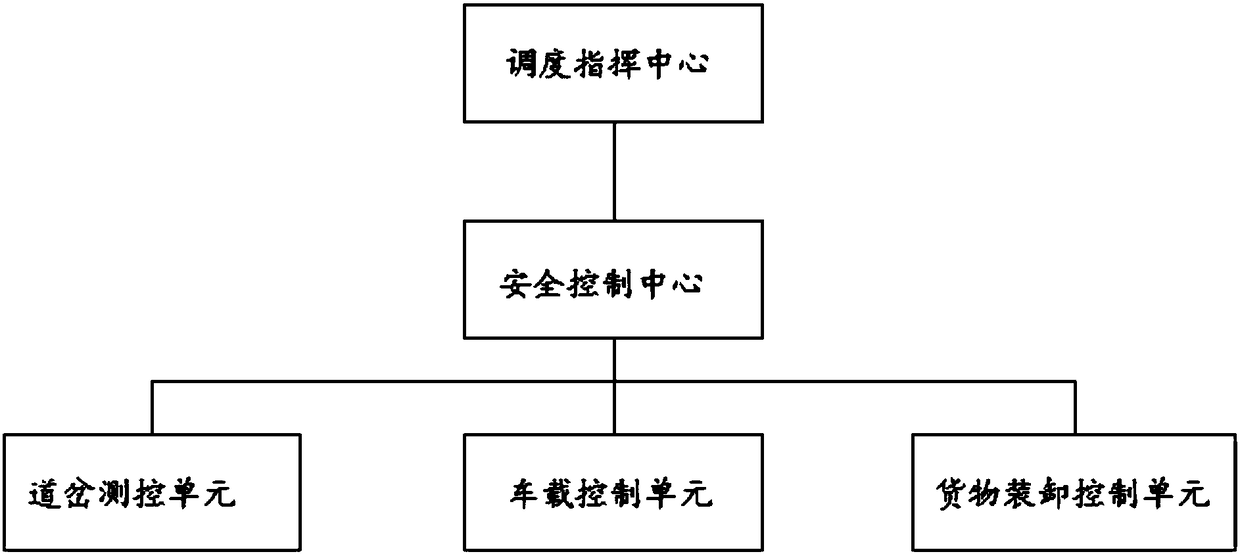

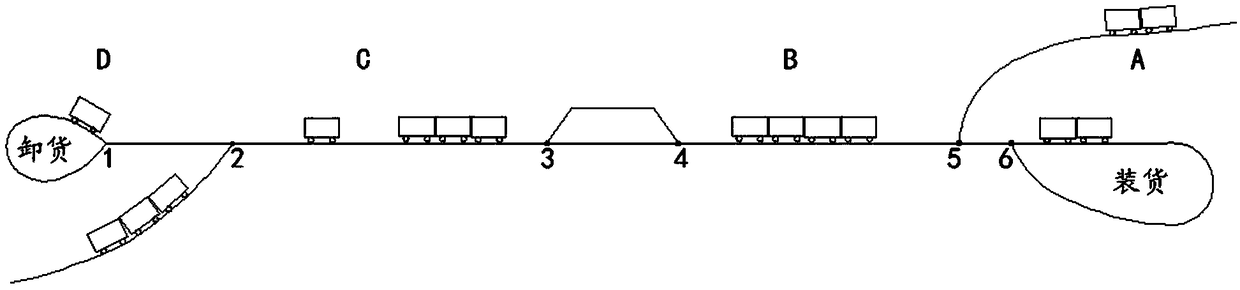

Tube rail train operation control system and control method of tube rail train operation control system

InactiveCN109334719ASimple structureImprove passabilityRailway traffic control systemsMode of transportCoupling

The invention belongs to the technical field of rail traffic operation control, and particularly relates to a tube rail train operation control system and a control method of the tube rail train operation control system. The tube rail train operation control system comprises a dispatch and command center, a safety control center and vehicle-mounted control units, wherein the dispatch and command center is responsible for whole line operation command, the safety control center is in communication with trains, turnouts and loading and unloading devices of the whole line and is responsible for the operation control of whole line equipment; instructions from the dispatch and command center are received, and the trains, the turnouts and the loading and unloading devices of the whole line are controlled and protected; each train is provided with the vehicle-mounted control unit, the vehicle-mounted control units among the trains are connected through wireless communication, and at least oneof the vehicle-mounted control units is connected with a safety control center through wireless communication; and the vehicle-mounted control units can realize in-transit coupling and in-transit disassembly of the trains through controlled mechanical interfaces between vehicles. The control method can optimize and adjust the transportation mode according to the actual operation route, and realizein-transit coupling and in-transit disassembly between the trains. The passage capacity of section lines and the utilization efficiency of line pipelines are greatly improved.

Owner:东沣管轨技术(北京)股份有限公司

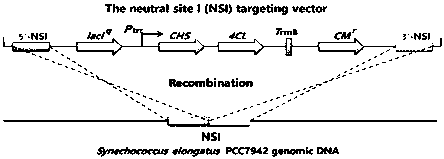

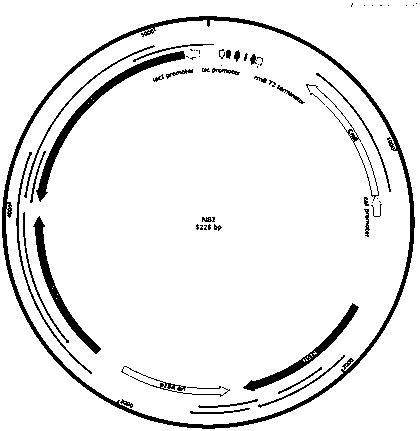

Method using blue algae to synthesize phloretin

PendingCN109913508AEasy to buildReduce manufacturing costBacteriaMicroorganism based processesPropanoic acidChalcone synthase

The invention provides a technical method using 'photosynthetic bacteria', namely blue algae as the substrate organism to synthesize phloretin. The method mainly includes: exogenously expressing 4 coumarate Coenzyme A Ligase (4CL) and Chalcone synthase (CHS) which are two key enzymes for phloretin synthesis in the blue algae so as to use p-hydroxybenzene propanoic acid (also called phloretic acid)as the substrate to catalytically synthesize the phloretin, the 4CL catalyzes single-molecule p-hydroxybenzene propanoic acid to generate p-hydroxybenzene propionyl coenzyme A, the CHS catalyzes three-molecule malonyl coA and the single-molecule p-hydroxybenzene propionyl coenzyme A to synthesize the single-molecule phloretin. The method has the advantages that the phloretin is produced by usingone microorganism which can perform photosynthesis, the phloretin biological synthesizing approach which is cheap in raw material, simple in equipment, low in environment pollution and high in yield is created, and the method conforms to the direction of green production.

Owner:嘉兴欣贝莱生物科技有限公司

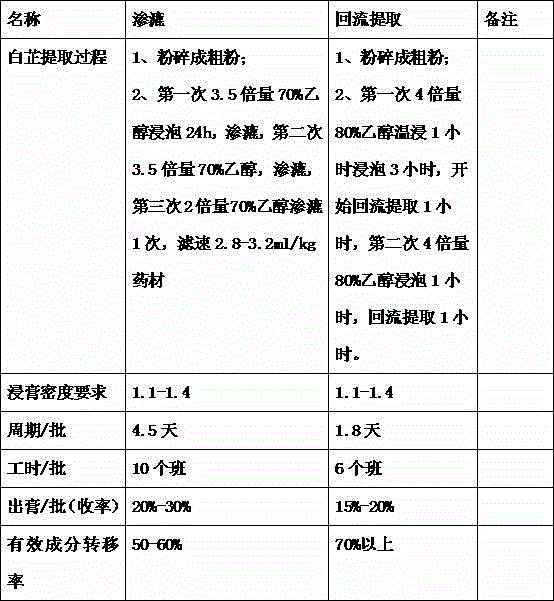

Extraction process for large-scale production of radix angelicae extract in medicinal radix angelicae material

ActiveCN104523783AReduce manufacturing costIncrease productivityPlant ingredientsSafety coefficientReflux extraction

The invention relates to an extraction process for large-scale production of a radix angelicae extract in a medicinal radix angelicae material. The extraction process is characterized by comprising the following steps: for primary refluxing, adding 10 parts by weight of coarse radix angelicae powder into an extraction tank; adding 40-50 parts by weight of 75% to 85% ethanol into the extraction tank; heating to the temperature of 60 DEG C; soaking for 1-1.5 hours and then stopping heating; soaking for 3 hours; heating again, controlling the temperature to be 75 to 78 DEG C and performing reflux extraction for 1 hour; for secondary refluxing, adding 40-50 parts by weight of 75% to 85% ethanol into the extraction tank, soaking for 1-1.5 hours at normal temperature, heating again, controlling the temperature to be 75 to 78 DEG C and performing reflux extraction for 1 hour; combining the two extraction solutions, decompressing and concentrating; discharging when the relative density of a radix angelicae extract is equal to 1.10 to 1.40. The extraction process is short in production period, high in production efficiency, low in production cost, complete in extraction, good in environmental protection property and high in safety coefficient. According to the process, reflux extraction is performed twice; the production period is 1.8 day / batch; the extraction rate is 15% to 20%; the extract yield is relatively smaller than that of a percolation process; the content of effective components in the extract is higher; the transfer rate of the effective components of the extract is above 70% based on imperatorin.

Owner:黑龙江仁合堂药业有限责任公司

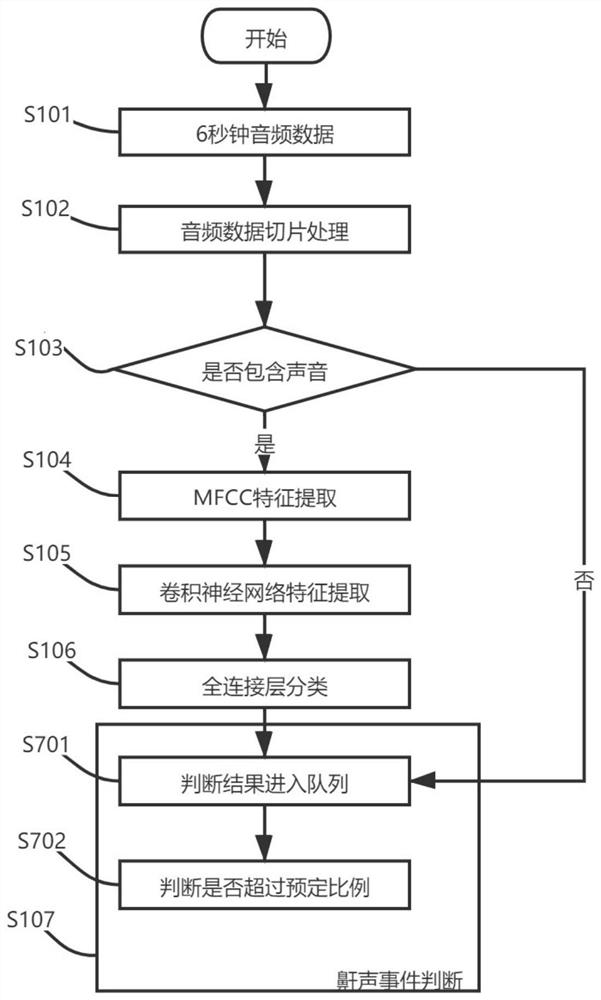

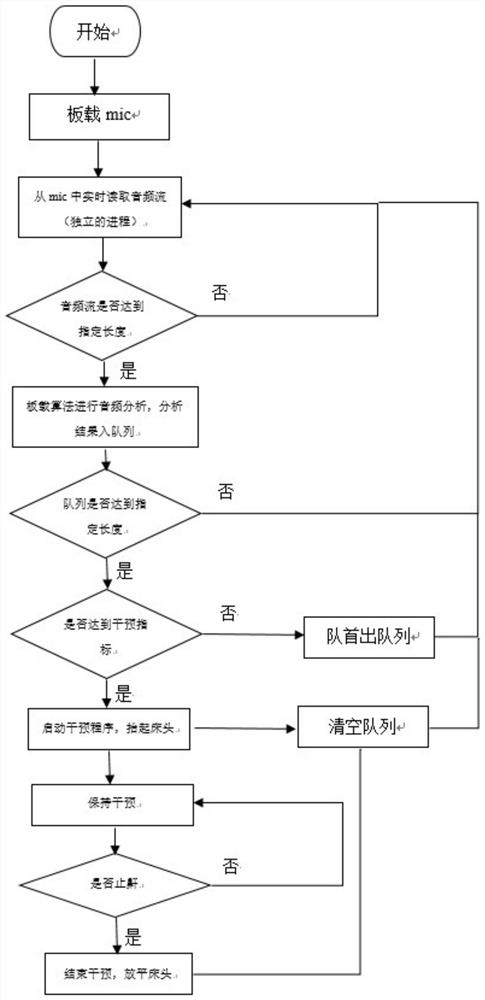

Snore monitoring method and system based on deep learning algorithm and corresponding electric bed control method and system

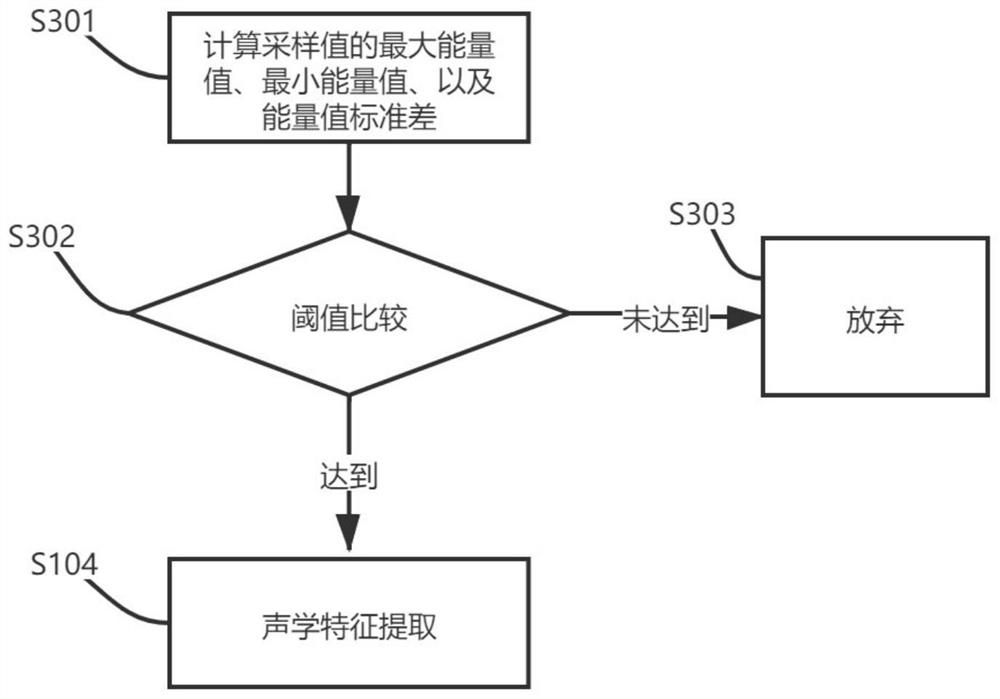

PendingCN113599052AImprove accuracyImprove experienceSofasSnoring preventionPattern recognitionFrequency spectrum

The invention discloses a snore monitoring method based on a deep learning algorithm. The snore monitoring method is based on deep learning and voice recognition technologies and comprises the steps of: acquiring an audio signal and slicing according to preset sample duration; judge whether a slice contains sound by using a silence detection algorithm; extracting acoustic spectrum features from the audio slice containing sound; inputting the generated spectrum features into a deep neural network to extract deep learning features; classifying the extracted deep learning features by using a fully connected layer; and carrying out snore event judgment and intervention according to preset duration. The invention also discloses a related system. Compared with a traditional method, the snore recognition method and system based on the deep learning algorithm, which are provided by the invention, have the advantages that the snore and non-snore judgment accuracy is greatly improved, and better user experience (Fig. 1) is brought.

Owner:KEESON TECH CORP LTD

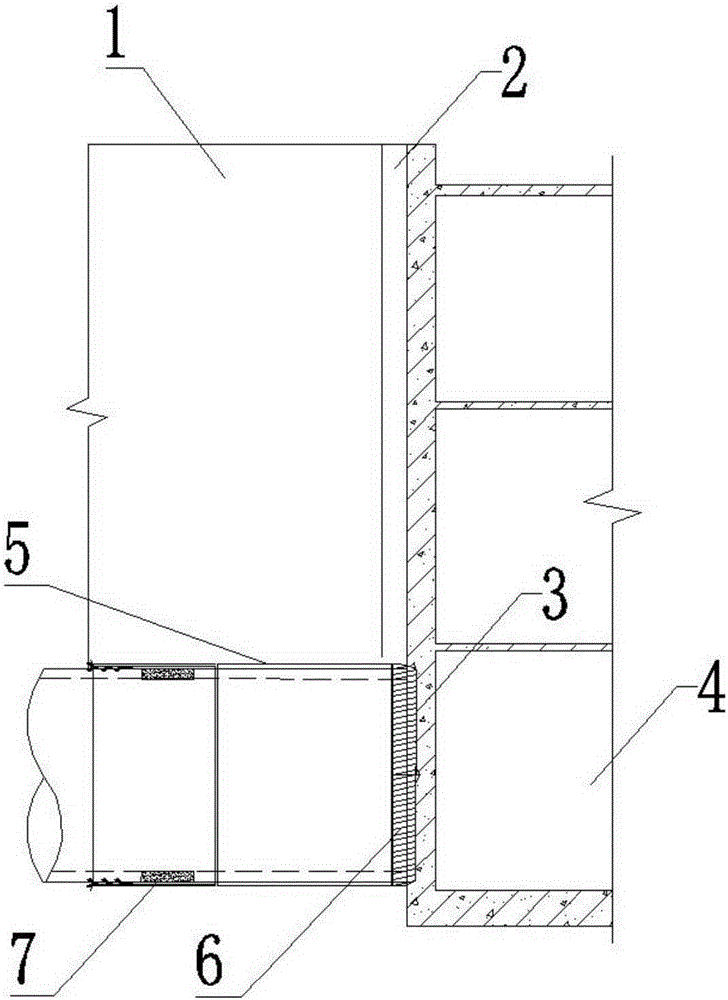

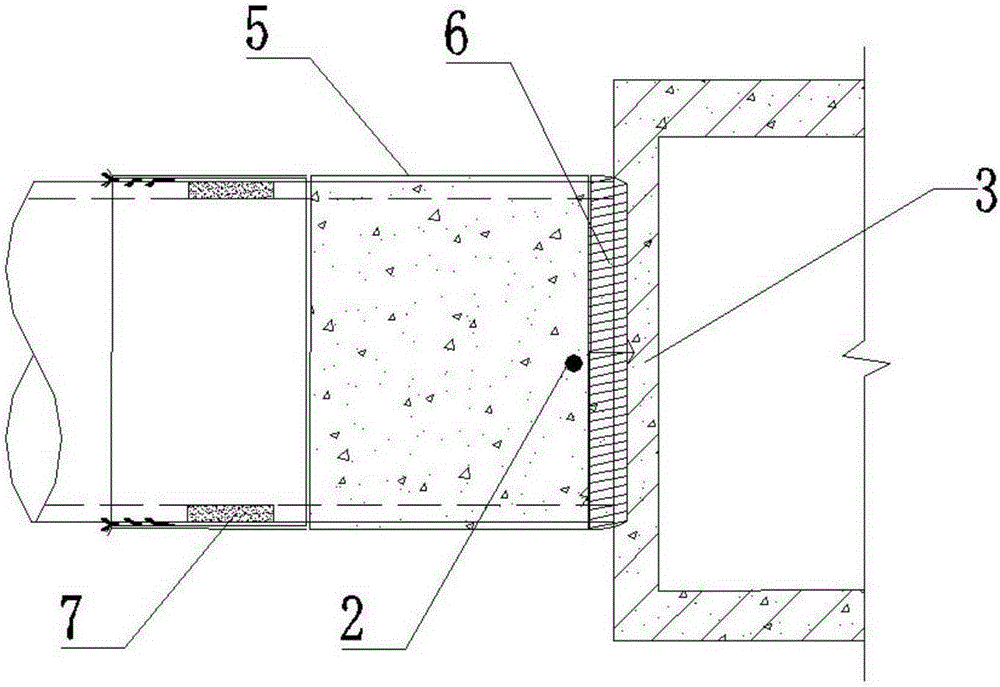

Construction method of shield departure and reception binary slurry injection

ActiveCN105221158AEnough propulsion and reactionQuality improvementUnderground chambersTunnel liningFilling materialsSlurry

The invention discloses a construction method of shield departure and reception binary slurry injection. The method comprises the following steps that construction preparation is performed; measurement and locating are carried out; drilling is performed; slurry is mixed; a shield tunneling machine is pushed; a binary slurry injection pump is used for injecting filling materials and additives into a slurry injection hole, and a cutter head of the shield tunneling machine rotates continuously in the slurry injection process; binary slurry is continuously injected, and the shield tunneling machine begins to be pushed forwards after friction force between a wrapped shield tunneling machine and surrounding soil is larger than a set value; the binary slurry is continuously injected when the shield tunneling machine is pushed; after the slurry is solidified, a tunnel portal continues to be broken till the cutter head of the shield tunneling machine is completely disengaged from a station maintenance structure. The construction method of shield departure and reception binary slurry injection is applicable to all stratums, long-time slurry grouting reinforcement is not needed, complement grouting is not needed during tunnel portal construction; enough pushing counter force can be provided when the slurry wraps the shield body, and the shield tunneling machine departure and reception section molding tunnel quality is effectively improved; the equipment is simple, conveying is easy and convenient, materials are efficiently utilized, and the material cost is saved.

Owner:国隧集团有限公司

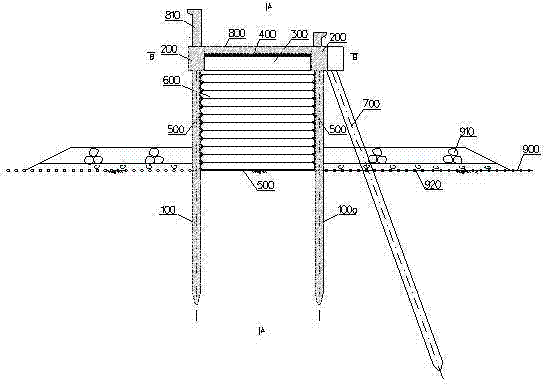

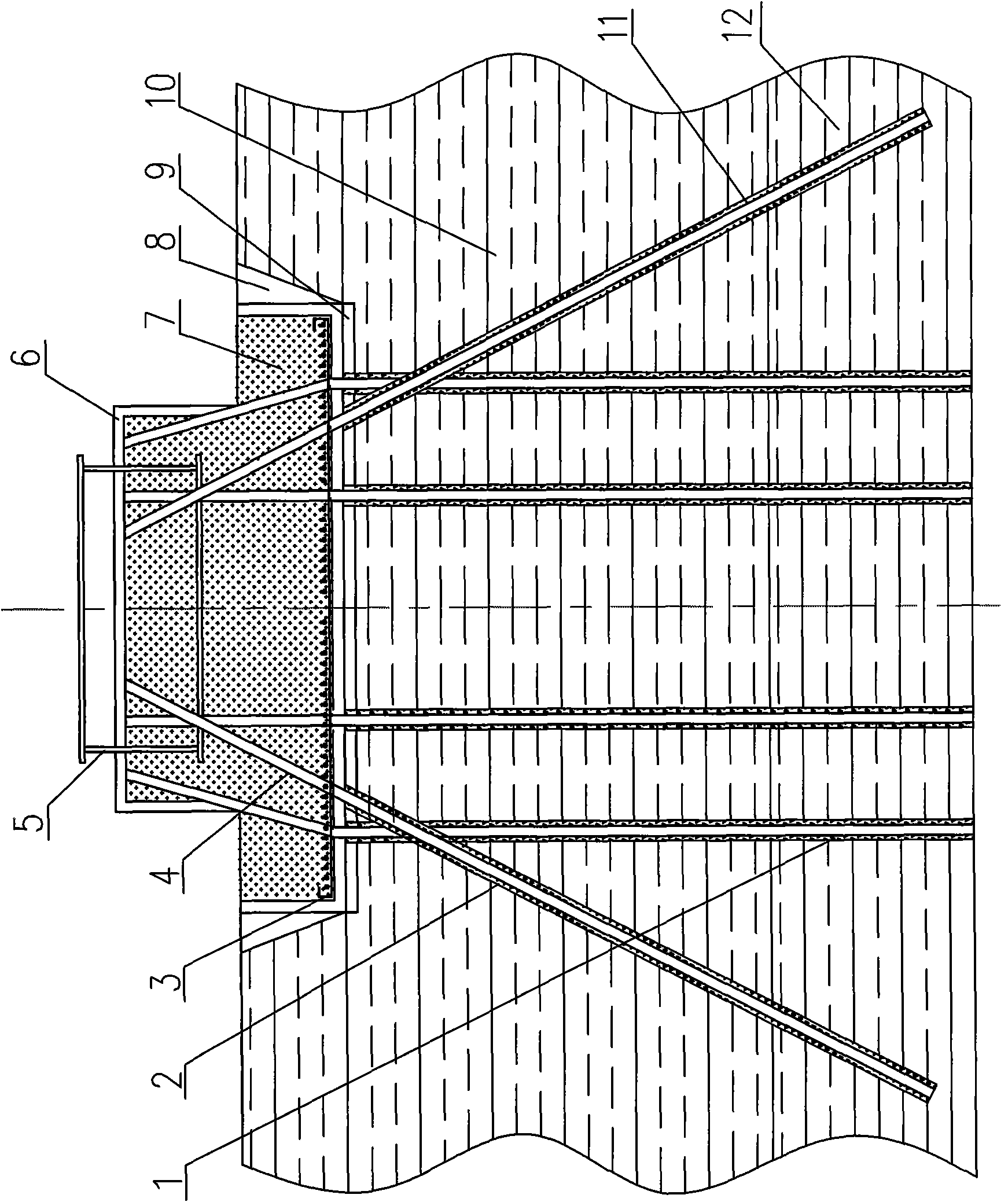

Wind driven generator base anchor pile construction technology taking rock as bearing stratum

A wind driven generator base anchor pile construction technology taking rock as a bearing stratum comprises the following steps: (1) excavating rock and soil volume in designed diameter, pouring concrete subslab after removing to the designed depth of excavation, and arranging anchor pile hole sites, (2) starting up an air compressor and downhole drill to drive an impacter to rotate and vibrate for punching, forming an anchor pile hole, (3) lifting a prefabricated reinforcing cage into the anchor pile hole, pouring concrete, and forming at least two circles of vertical pile and one circle of batter pile after the concrete strength reaches the standard, (4) putting a reinforcement mat rack into a base pit, fixedly connecting the reinforcing cage and the reinforcement mat rack and then pouring concrete, and (5) arranging a base embedded part above the concrete foundation and poring concrete. The invention has the advantages of less excavated rock and soil volume, no need of blasting operation, few amount of reinforcing steel bar and pouring concrete, no pollution to environment and soil, high construction efficiency and safety, small occupied area, low construction cost, high foundation strength, and strong pulling-out resistant and shearing resistant capacity.

Owner:高玉书

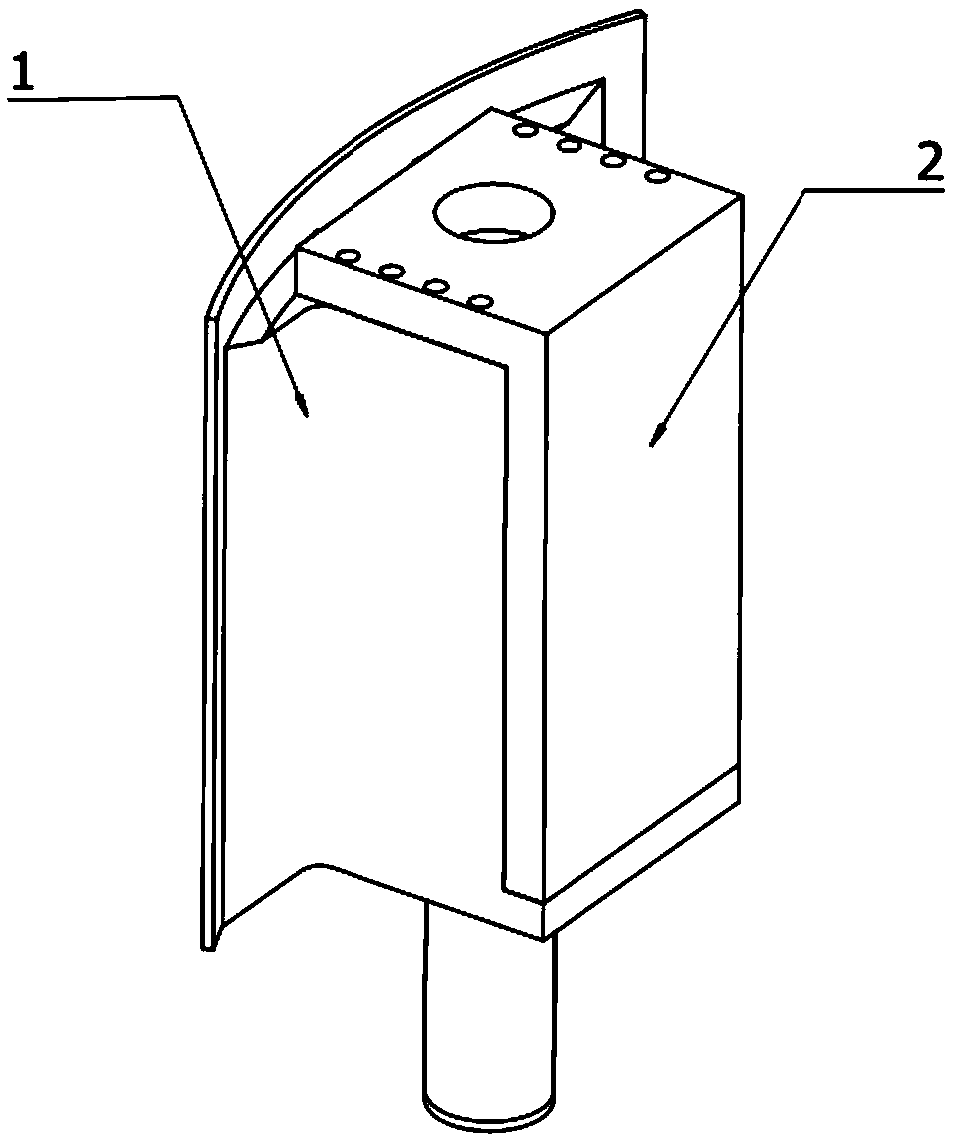

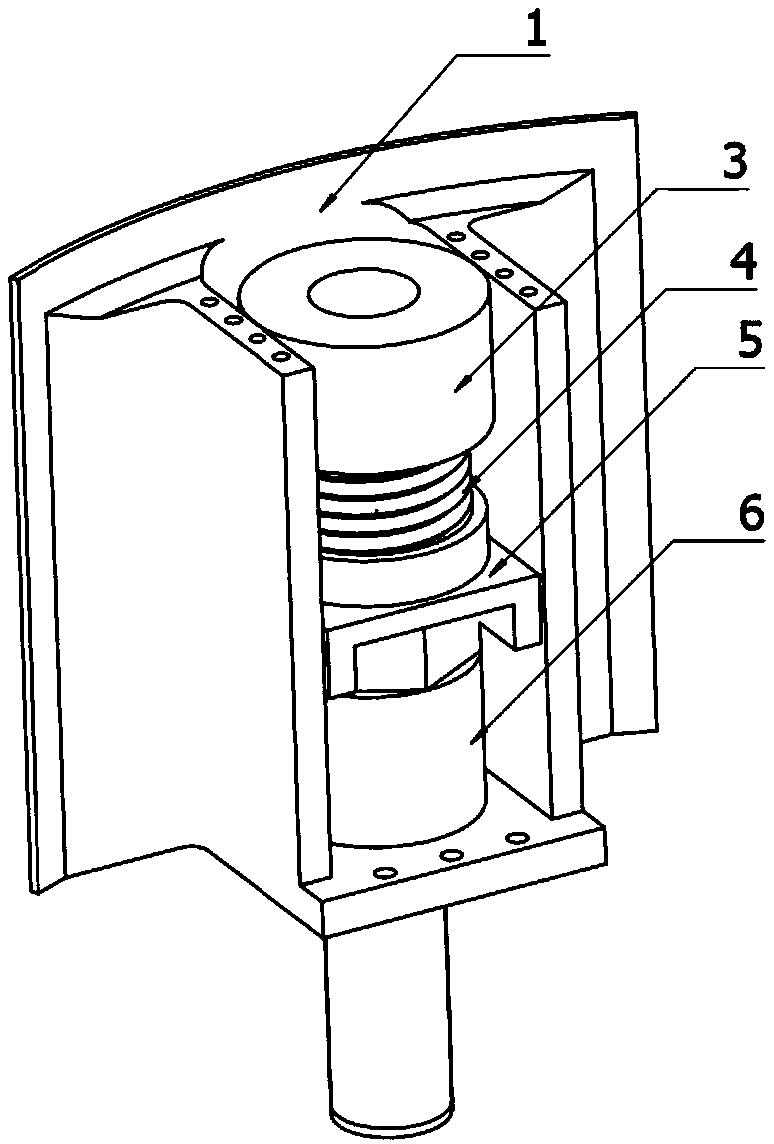

Explosive Bolt Buffer

ActiveCN108033038BSimple structureCompact structureCosmonautic vehiclesCosmonautic component separationEngineeringMachining process

The invention relates to the technical field of aerospace, in particular to an explosive bolt buffering device which comprises an installation base, a protection shell cover and an axial buffering device. An installation groove for installing an explosive bolt and the axial buffering device is formed in the installation base. A through hole for the explosive bolt to pass through is formed in the installation base. The protection shell cover is fixedly arranged on the installation base and can cover a groove opening of the installation groove, and the protection shell cover and the installationbase form a closed space together. The axial buffering device is arranged in the closed space. The effective buffering effect on instant large-impact loads is achieved, and the impact degree of the explosive bolt on an upper-stage cabin section in the stage separation test using process is remarkably reduced; the explosive bolt buffering device has the advantages of being small in part number, simple in structure, good in machining process, low in cost, convenient to install, compact in structure, light in weight, high in reliability, good in modularization compatibility and suitable for various aircrafts.

Owner:BEIHANG UNIV

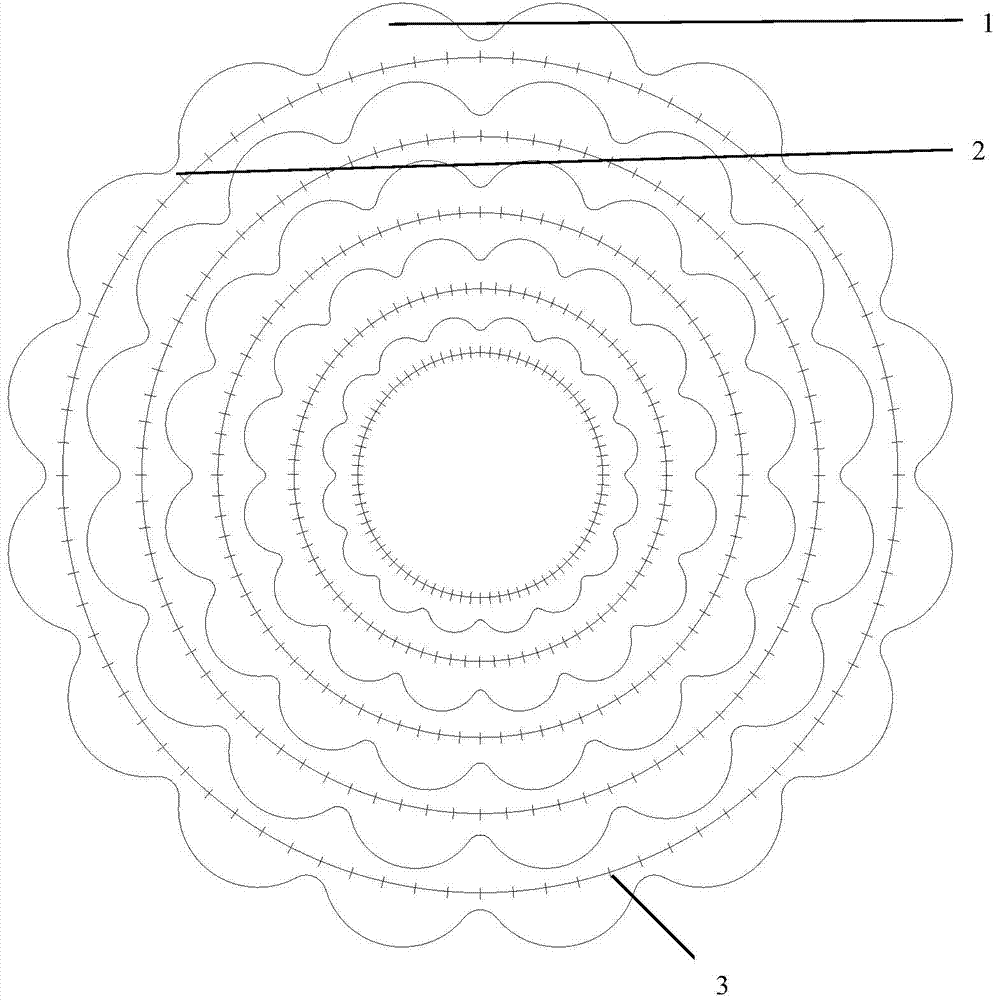

Corrugated wet-type electric dust remover anode

InactiveCN104722406AReduce voltageIncrease spacingElectrode constructionsTitanium alloyTitanium plate

The invention belongs to the field of environmental engineering and relates to a corrugated wet-type electric dust remover anode. The electric dust remover anode is a titanium plate or a titanium alloy plate. The thickness of the titanium plate or the titanium alloy plate is 2-4 mm; the titanium plate or the titanium alloy plate is pressed into a corrugated shape which is formed by up-down connection of a 30-degree arc and a semicircle with the diameter being 10-500mm. The corrugated wet-type electric dust remover anode has the advantages that due to adoption of a large-channel corrugated design, the dust depositing effect is effectively improved, the dust-depositing blind areas are solved, and the anode spacing is increased under the condition of not increasing the voltage, so that the occurrence of the short-circuit phenomenon is reduced, the quantity of anode plates is reduced and the expenditure is saved; and due to the corrugated design, the discharging and the dust deposition are divided into two areas, so that the problem that the power needs to be cut off when the existing wet-type electric dust remover is washed is effectively solved. Since the titanium plate or the titanium alloy plate is used as the dust remover anode, the problems that the existing anode is too heavy, the base frame cannot bear the weight and the anode is extremely easy to corrode are solved.

Owner:UNIV OF SCI & TECH BEIJING

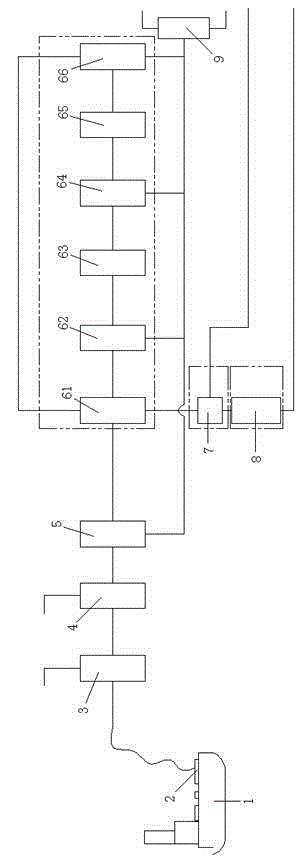

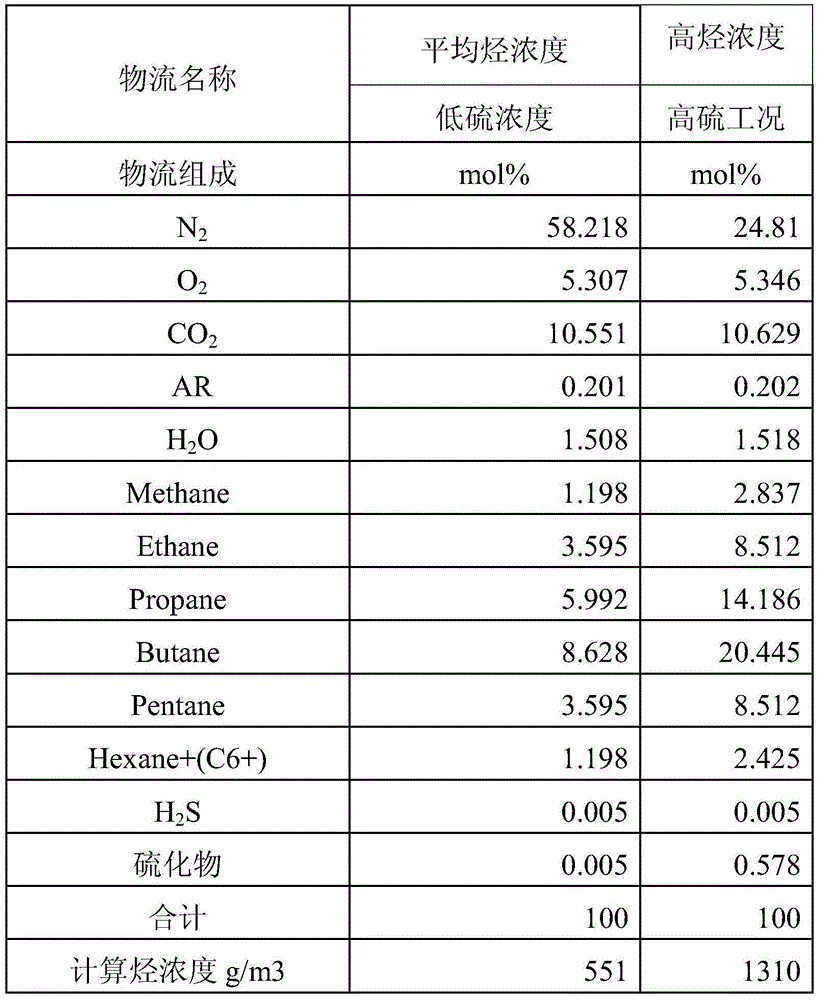

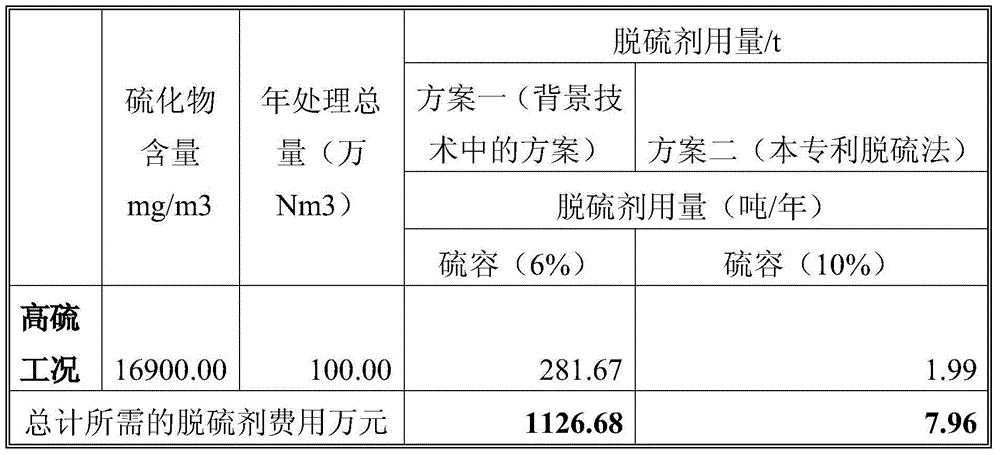

High sulfur crude oil oil-gas recovery technology and oil-gas recovery system

ActiveCN104830365AHigh breakthrough sulfur capacitySulfur content is easy to reach the standardLiquid hydrocarbon mixture recoveryActivated carbonDesorption

The present invention provides a high sulfur crude oil oil-gas recovery technology and oil-gas recovery system. The oil-gas recovery technology includes the following steps: a. high sulfur crude oil oil-gas is compressed, the compressed oil-gas is cooled, then gas and liquid separation is performed, and the separated liquid is collected; b, the separated oil-gas of the step a is condensed, then gas and liquid separation is performed, and the separated liquid is collected; c, the separated oil-gas of the step b is introduced into an activated carbon adsorption device, and is desulfurized, and desorption and collection of hydrocarbons in the activated carbon adsorption device are performed. According to the high sulfur crude oil oil-gas recovery technology, most of sulfides and hydrocarbons are condensed into liquid in the condensation processing process, species and quantity of sulfides entering into a desulfurization tower are less, and the composition is simple, so that breakthrough sulfur capacity of the desulfurization tower is high, the desulfurization effect is better, and when the sulfur content in the desulfurized oil-gas is very easy to meet.

Owner:上海森鑫新能源科技有限公司

Automatic high-yield purification method for preparing spherical graphite

The invention discloses an automatic high-yield purification method for preparing spherical graphite. The method comprises the following steps: dividing a fineness range value of a catalyst for preparing brominated polystyrene; weighing and taking materials; crushing; uniformly mixing; and completing the preparation of the catalyst. The method has the beneficial effects that the amount of the catalyst can be regulated and controlled according to the fineness ratio according to the preparation requirement, so the effect of preparing six different finenesses is achieved; the mode of crushing one by one and adding mixed powder is adopted, and various single materials can be fully mixed together in the same crushing equipment, so the consistency of the crushing fineness is ensured; and the crushing degree can be adjusted by reducing or increasing the number of the hammer heads of the crusher, so that the effect of adjusting the crushing fineness is achieved.

Owner:大同氢都驰拓新能源有限公司

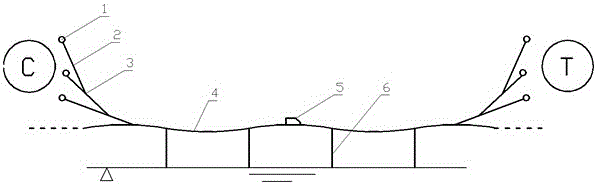

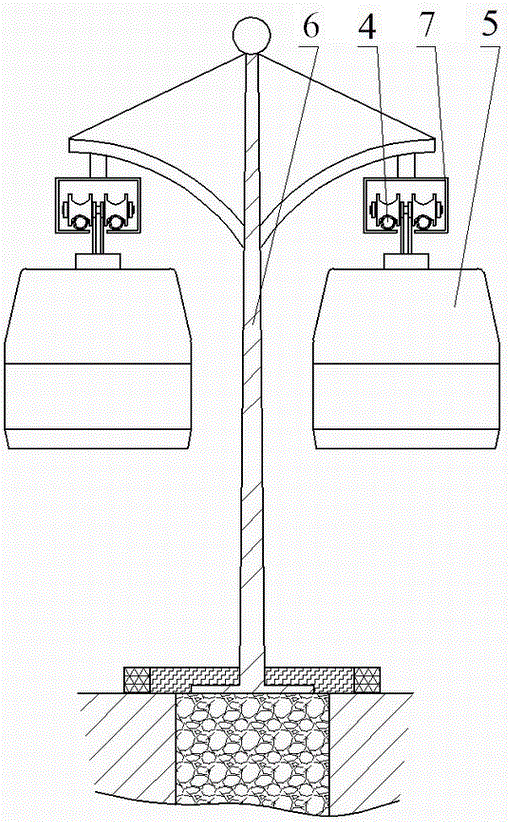

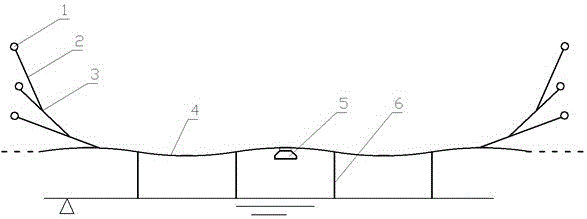

Low-altitude rail transportation network for fast physical distribution

InactiveCN106274915ASolve the problem of swelling and shrinkingTake advantage of the tensile strengthElevated railway without suspended vehicleRailway transportControl systemTraffic congestion

An inter-city or intra-city low-altitude rail transportation network for fast physical distribution comprises stations, supporting posts, a rail, turnouts, a rail vehicle, a power supply system and a control system, wherein the rail is erected in the air through the supporting posts; the stations are arranged at end points of the rail; the stations, the rail and the turnouts form a transportation network similar to the Internet; the rail vehicle runs along the rail under the actions of the power supply system and the control system. The inter-city or intra-city low-altitude rail transportation networks for fast physical distribution can be constructed at low cost, within a short time and in batches; the physical distribution efficiency can be greatly improved, the transportation cost can be greatly reduced, and traffic accidents are avoided; the problems of inter-city or intra-city traffic congestion and environment pollution are effectively solved.

Owner:戴长虹

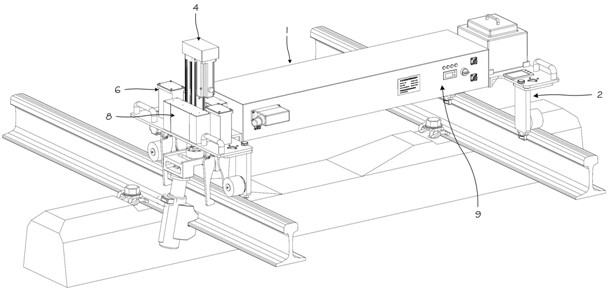

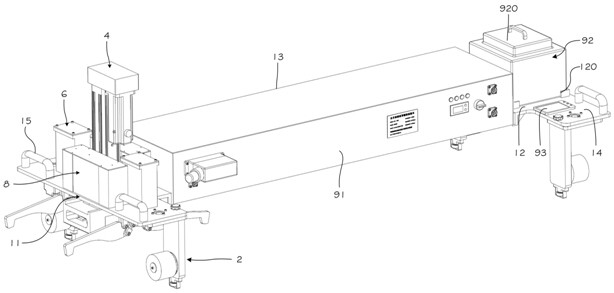

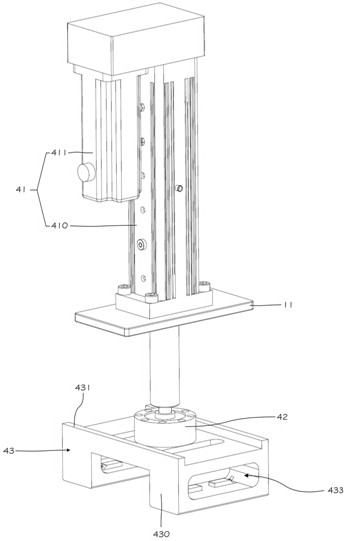

Fully automatic deceleration jack auxiliary inspection vehicle

ActiveCN112590834BEasy accessEasy to recordRailway inspection trolleysRailway auxillary equipmentWireless transmissionVehicle frame

The invention relates to the technical field of deceleration roof detection, and discloses a fully automatic deceleration roof auxiliary detection vehicle, which comprises: a vehicle frame; a plurality of running mechanisms installed at the bottom of the vehicle frame; A high pressure measuring mechanism; a rail gripping mechanism used to offset the oil and gas pressure of the deceleration roof and installed on the same side of the frame as the pressure measuring mechanism; installed on the same side of the frame as the pressure measuring mechanism and capable of detecting the installation gap of the deceleration roof The distance measuring mechanism; and a control system, which is used to control the running and automatic stop of the detection vehicle and complete the detection action. After the detection vehicle is started on the road, it can automatically identify the position of the deceleration roof, detect the relevant technical parameters of the deceleration roof, and transmit the detection data to the mobile terminal through the wireless transmission mode, so as to achieve the purpose of monitoring the status of the deceleration roof in real time.

Owner:中国铁路南昌局集团有限公司科学技术研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com