Corrugated wet-type electric dust remover anode

A wet electrostatic precipitator and electrostatic precipitator technology, which is applied in the field of environmental engineering, can solve the problems of blind spots for dust accumulation, power outages for flushing, heavy anode weight, etc., and achieves easy installation and replacement, increased anode plate spacing, and dust removal. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the examples, the purpose of which is to better understand the content of the present invention, but the embodiments of the present invention are not limited thereto.

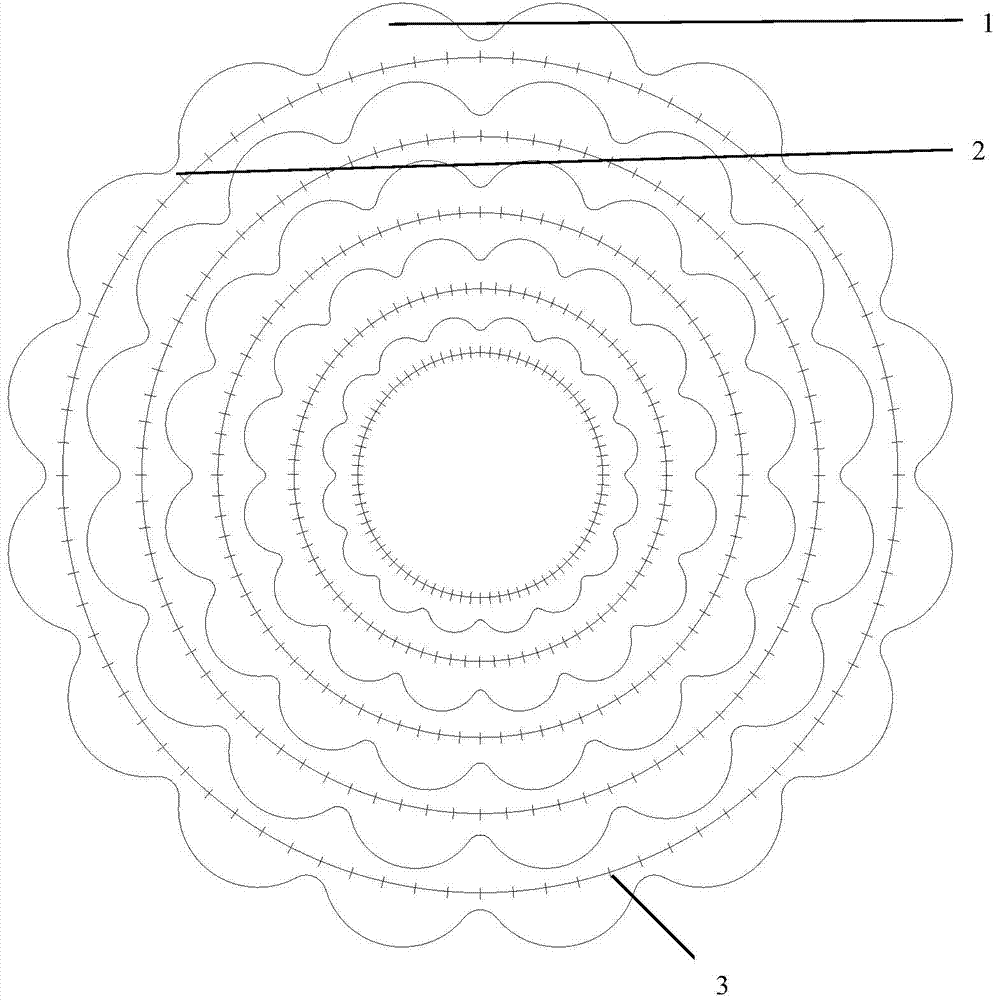

[0016] This embodiment adopts 5 layers of corrugated titanium plates, including dust accumulation area 1 and discharge area 2. The 5 layers of corrugated titanium plates are concentrically distributed, the thickness of the titanium plates is 2mm, and the innermost semicircle size: height is 2m, inner diameter is 100mm, The outer diameter is 102mm and the wall thickness is 2mm. Arc size: the angle is 30 degrees, the height is 2m, and the wall thickness is 2mm. Anode plate spacing is 600mm. The central position of the annular channel formed by the adjacent corrugated plates of the anode of the electrostatic precipitator is provided with a thorn-shaped cathode line 3, which surrounds a circle along the channel between each anode plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com