Patents

Literature

502results about How to "No dead ends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

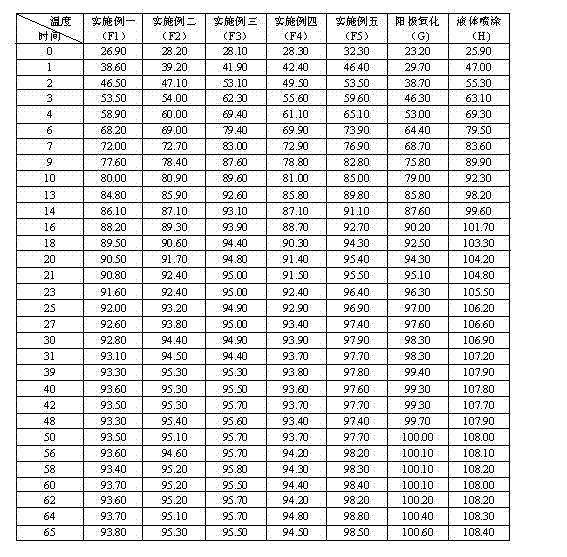

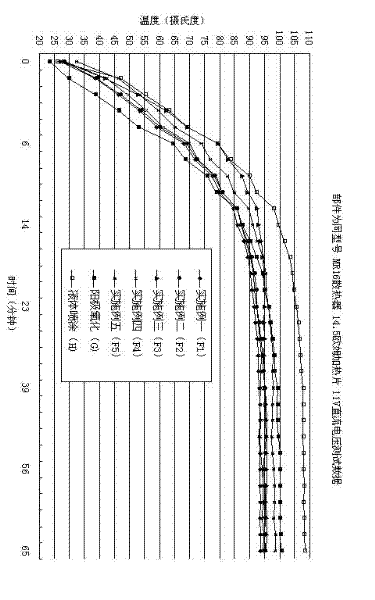

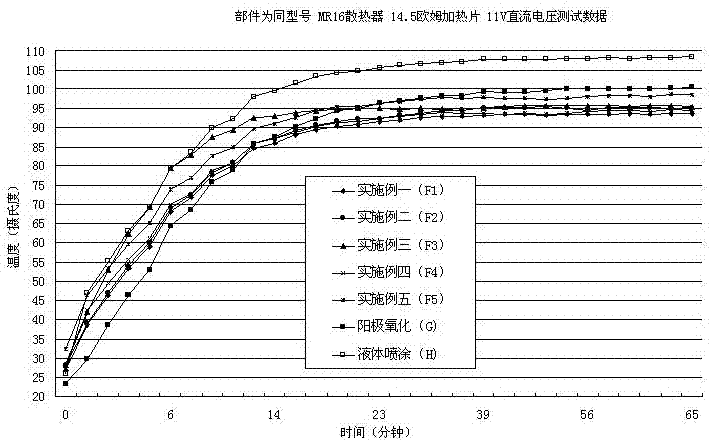

Radiating material and preparation method of radiating material

InactiveCN102181212AImprove cooling effectNo dead endsElectrophoretic coatingsPolyurea/polyurethane coatingsThermal insulationMixed materials

The invention discloses a radiating material and a preparation method of the radiating material. The radiating material comprises a component A and a component B, wherein the component A is an ionic modified resin, or a mixture of more than one ionic modified resin, or a composite of more than one ionic modified resin; and the component B is one or more mixed material with the far infrared emission rate greater than 0.80 or thermal conduction coefficient greater than 5W / m.K, and grain size smaller than 30mu. In use, the radiating material can not only improve the radiating performance of metal parts, but also achieve certain other special functions (for example, self-cleaning, infrared stealth, thermal insulation, corrosion resistance, thermostability, self-lubricating, insulation and other properties), and can be prepared into most needed color according to requirement.

Owner:东莞市中科智恒新材料有限公司

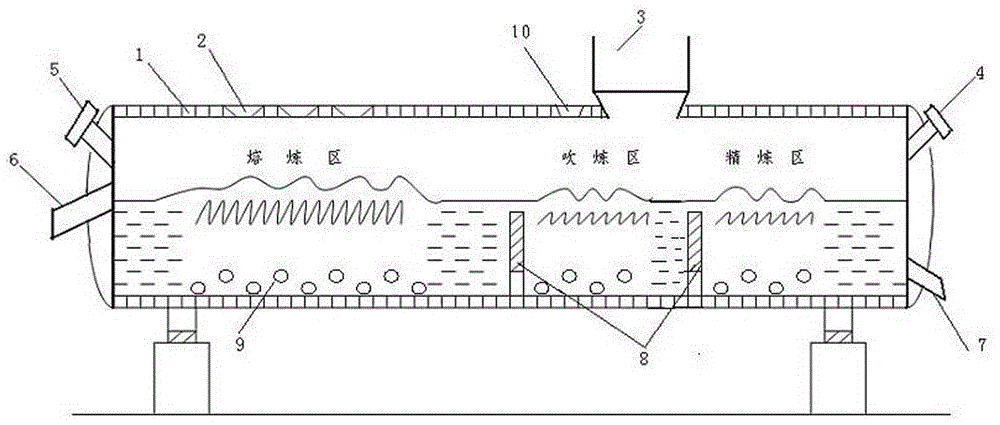

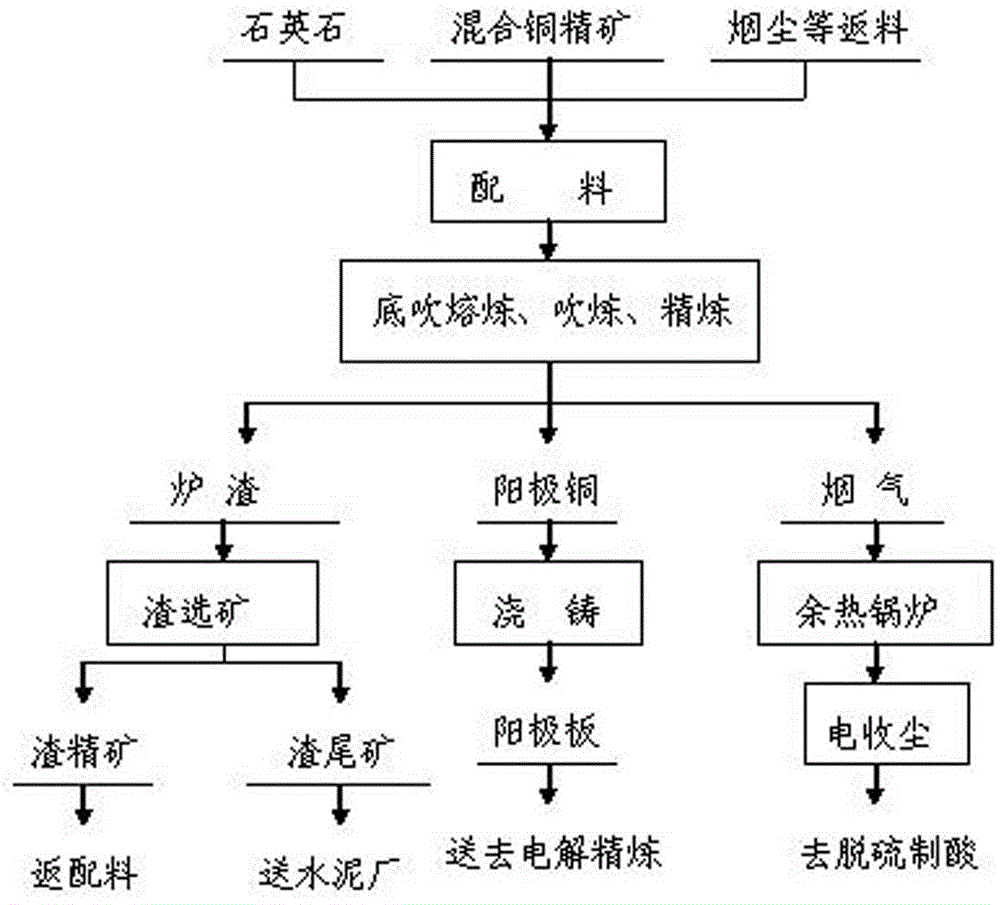

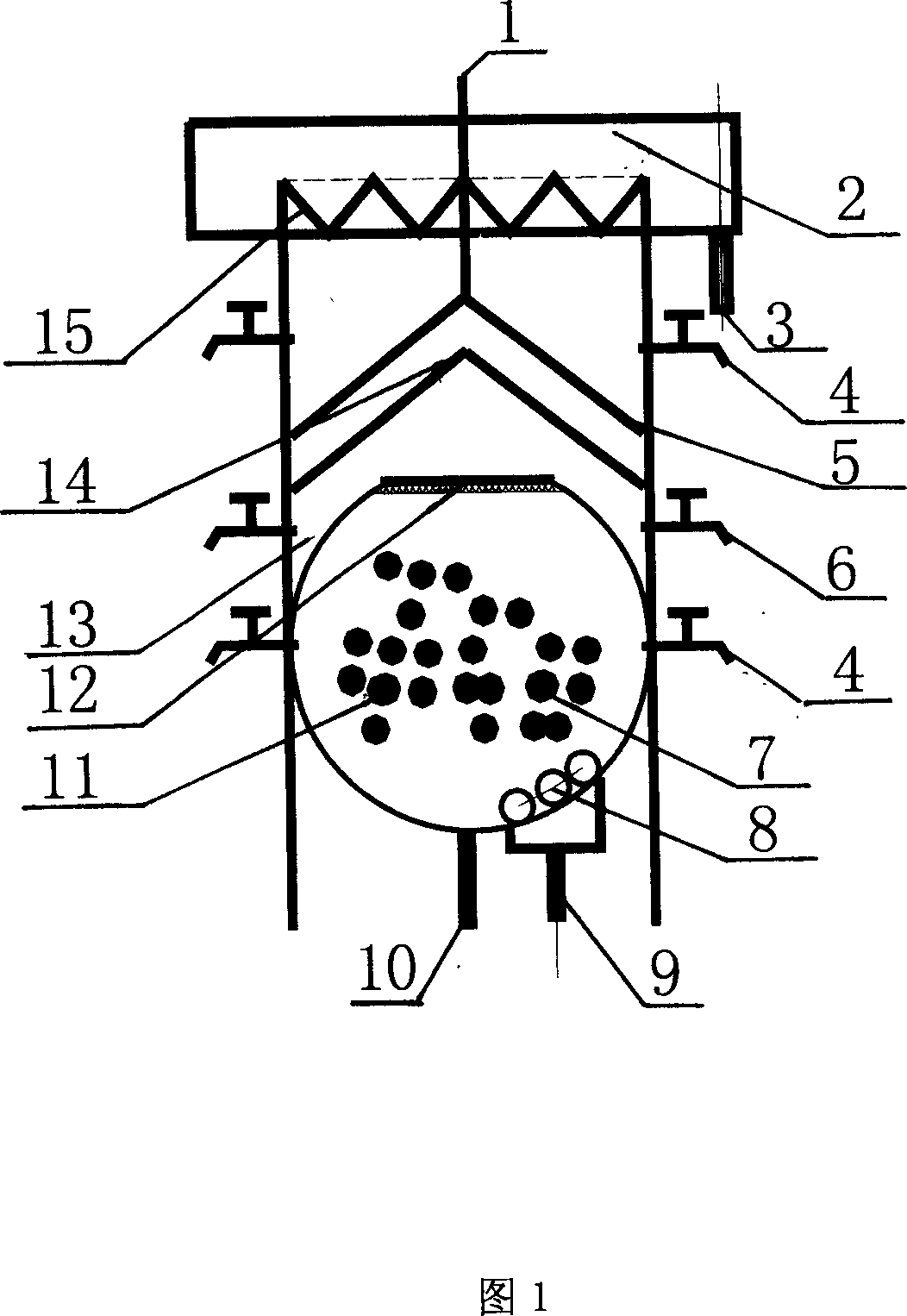

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

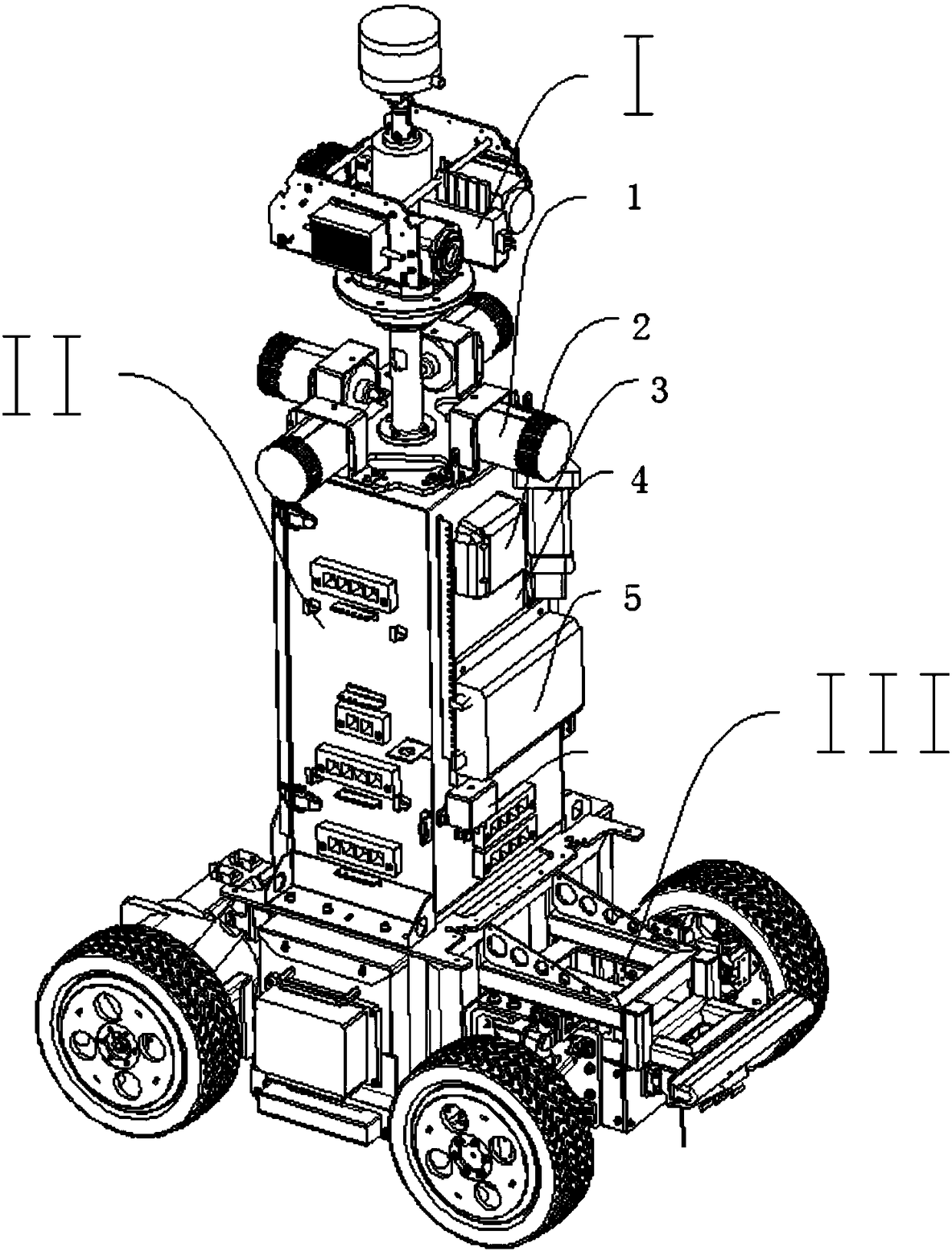

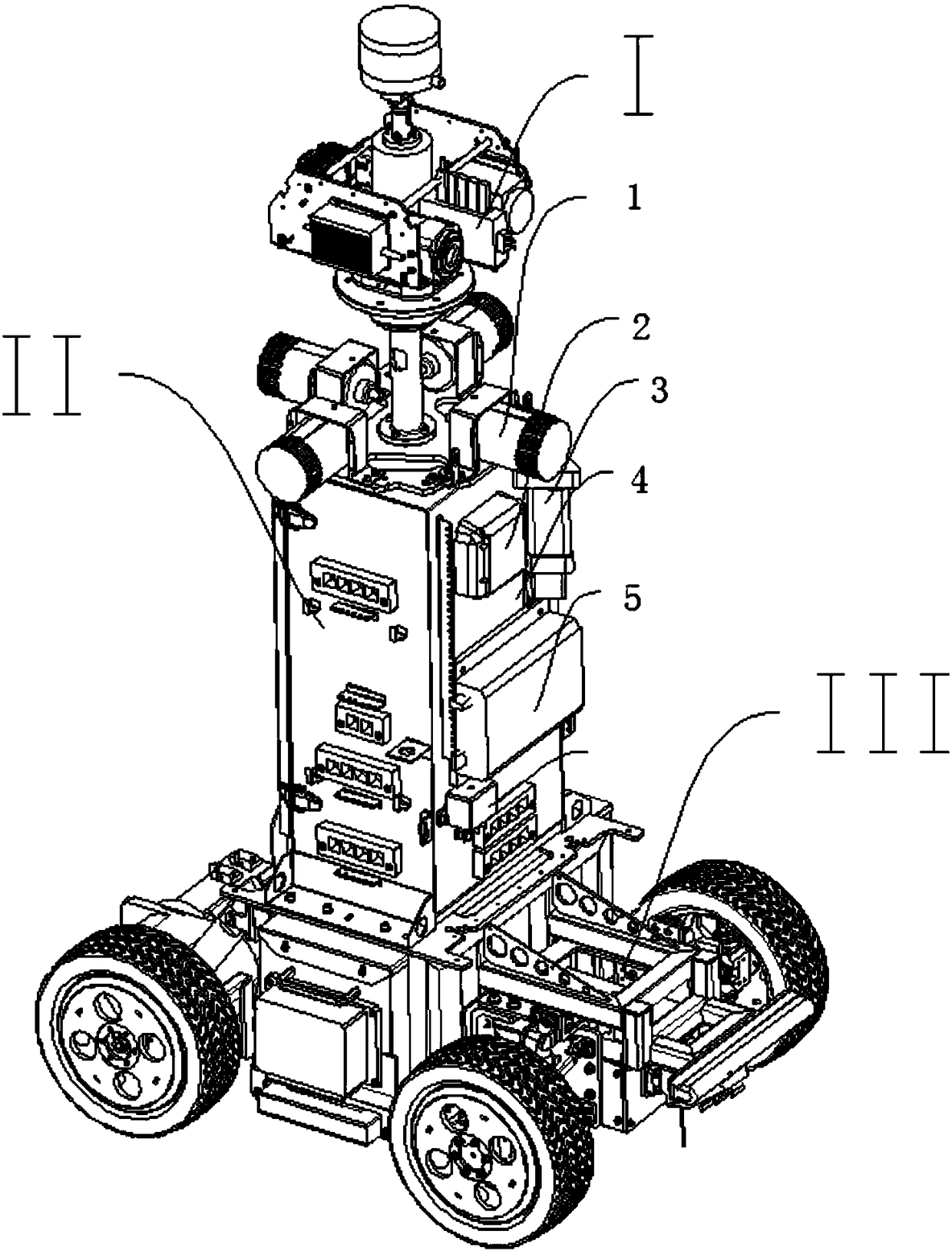

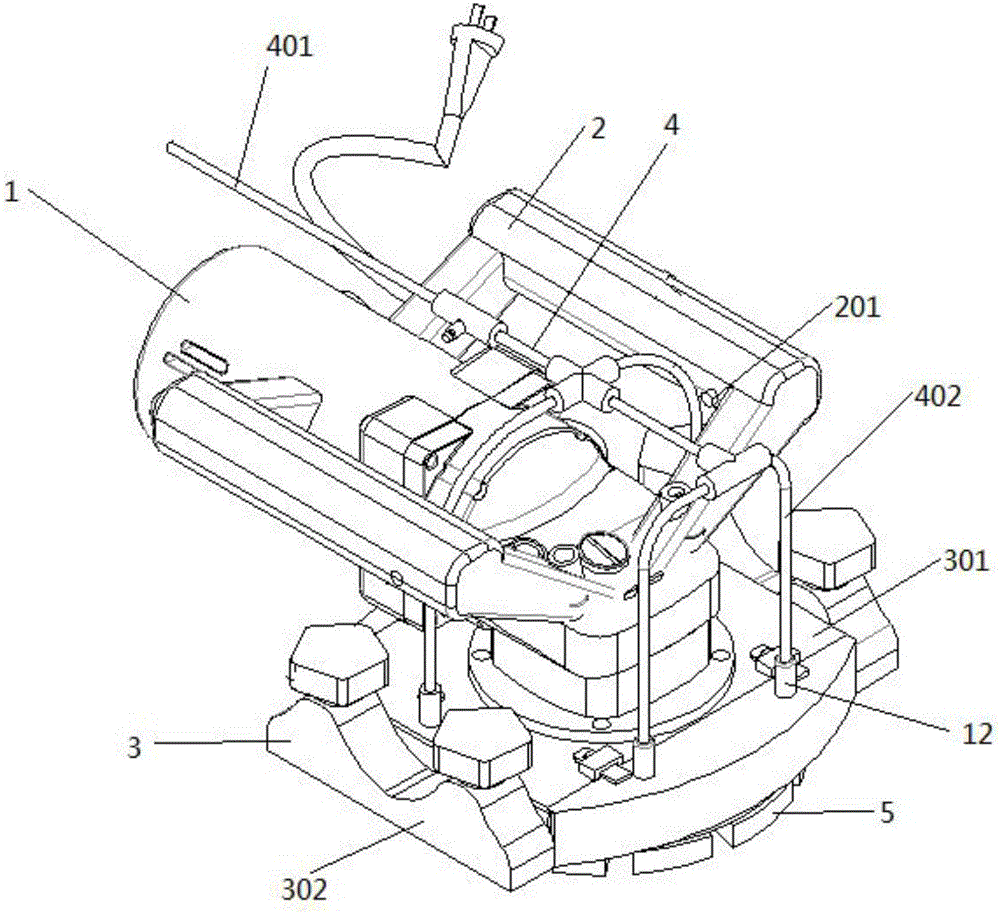

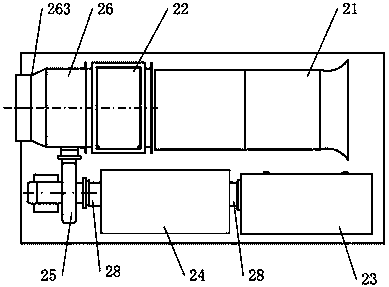

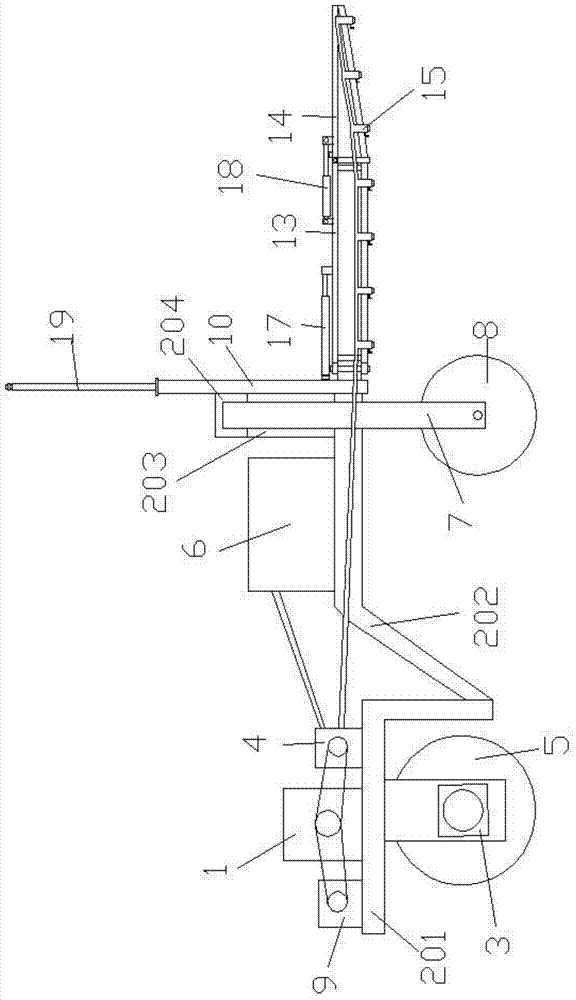

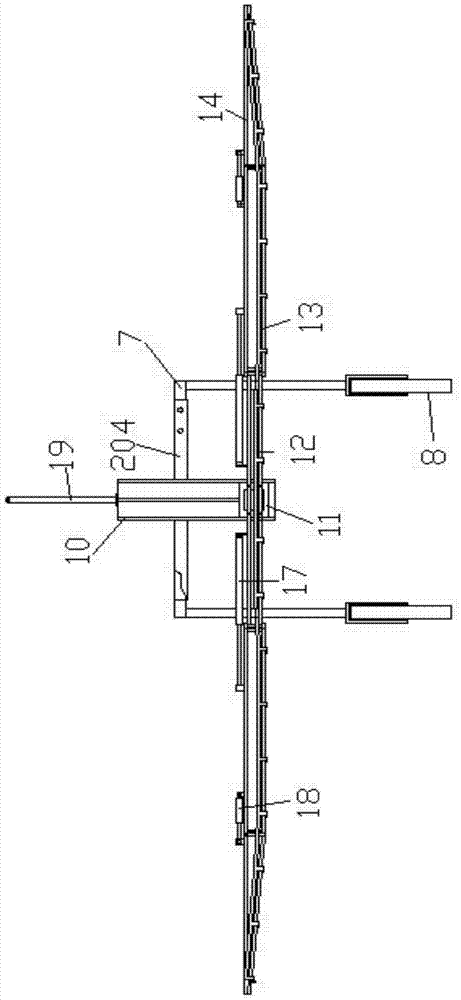

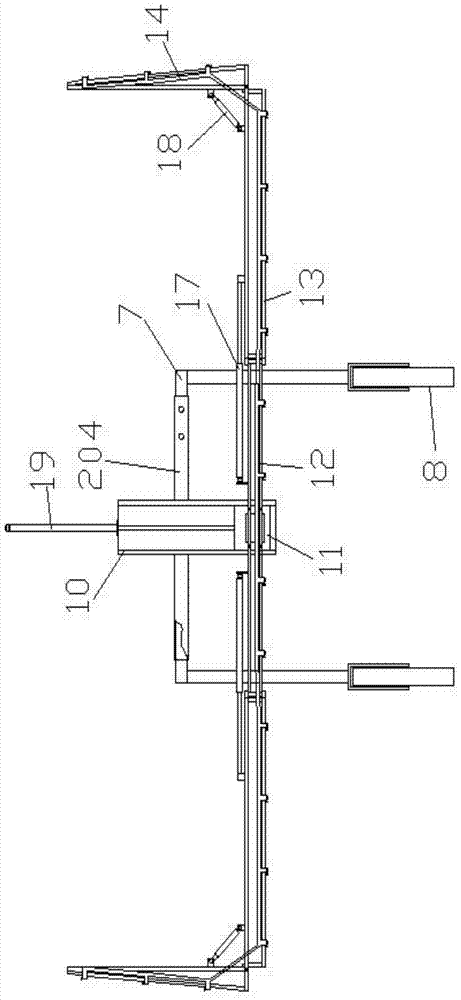

Novel intelligent security and protection robot and automatic routing inspection method thereof

ActiveCN108297059AHigh precisionRealize self-positioningProgramme-controlled manipulatorPosition/course control in two dimensionsVehicle frameDrive wheel

The invention relates to a novel intelligent security and protection robot solving the problems in the prior art. According to the technical scheme of the novel intelligent security and protection robot, the key points of the novel intelligent security and protection robot lies in that the novel intelligent security and protection robot is in communication connection with a client; the client is connected with a server of the novel intelligent security and protection robot through a network; and the working place position of the novel intelligent security and protection robot is provided withan underground charging point which is matched with an automatic charging interface. The novel intelligent security and protection robot is characterized by comprising a mobile platform, a trolley body and a pan-tilt; the mobile platform comprises a trolley frame, a turning module, a driving module, a driving wheel, a differential mechanism, the automatic charging interface and a charging socket;an electronic control processing module and a battery are arranged in the trolley body; the turning module is arranged on the front portion of the trolley frame; the driving module is fixed to the trolley frame; the differential mechanism is fixed to the rear portion of the trolley frame; and the driving module is connected with the driving wheel through the differential mechanism.

Owner:ZHEJIANG GUOZI ROBOT TECH

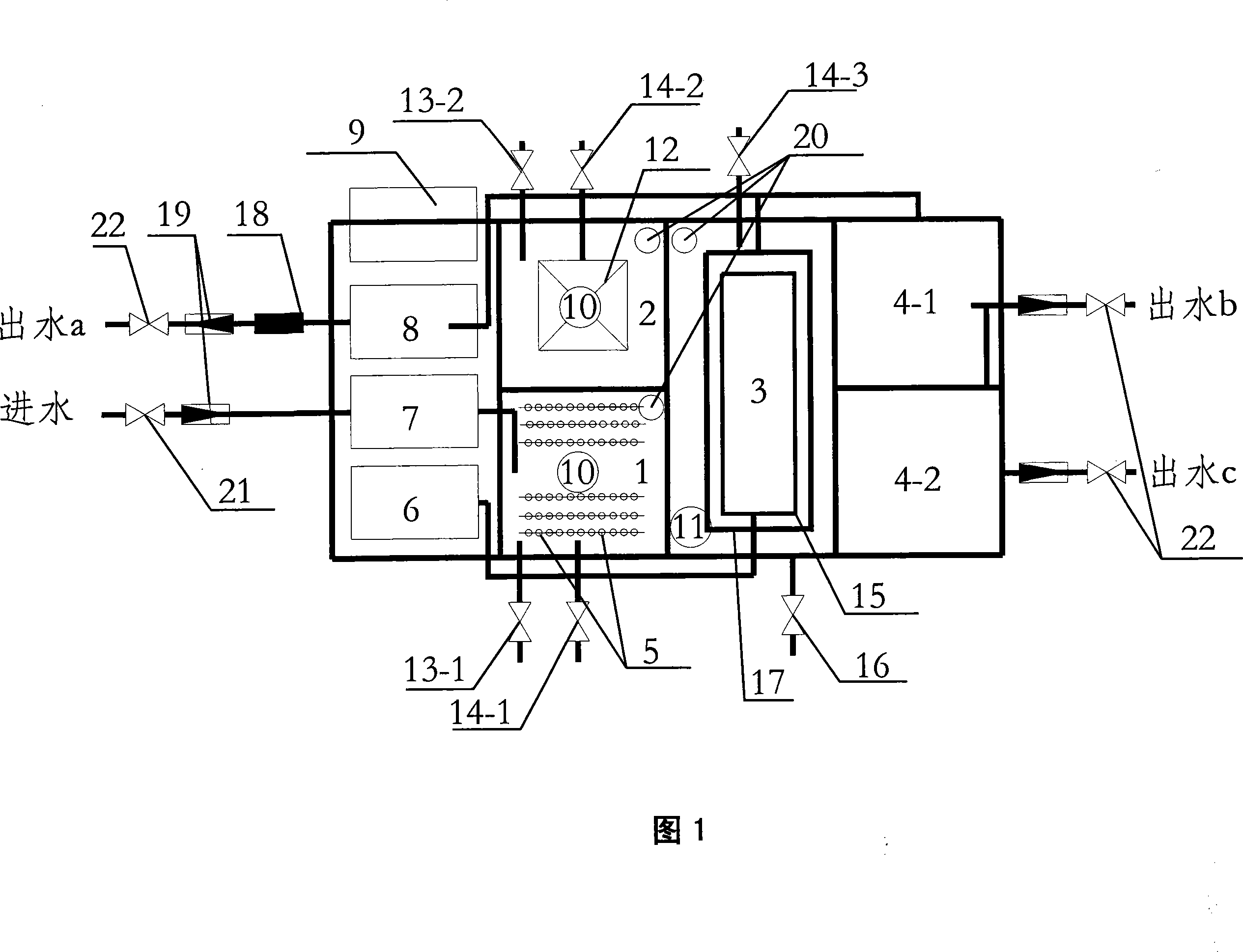

Packaging stage-type film bioreactor device for treating sewage or micro-polluted raw water

InactiveCN101186416ARealize quality water supplyFlexible and simple multi-functional areaTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater qualitySmall footprint

The invention relates to a staged membrane bioreactor device, for treating sewage or micro-polluted source water, with a water container, pertaining to the environmental protection technology field. The device consists of a half-reaction zone, an anaerobic reaction zone, an aeration reaction zone and a pure water zone. The half-reaction is communicated with the bottom of the aeration zone, the bottom of the half-reaction is provided with an empty valve, one side of the half-reaction zone has a water inlet pump, the inside of the half-reaction has an internal ring filled with stuff, and the top of the half-reaction is provided with a stirrer, and the effluent of the half-reaction automatically flows into the anaerobic reaction zone. The top of the anaerobic reaction zone is provided with a stirrer, the bottom thereof is provided with a sludge empty valve, and a sludge empty device is shaped like a horn mouth and positioned in the anaerobic reaction zone, and the top of the anaerobic reaction zone is provided with a drug feeding mouth. The bottom of the aeration reaction zone has an internal return pump, the lower part of the aeration reaction zone is provided with an aeration pipe with an air inlet positioned at one side of the aeration reaction zone, and a fan is connected to the aeration pipe through the air inlet; the top of the aeration reaction zone is provided with an overflow pipe, the bottom of the aeration reaction zone is provided with an empty valve, while the middle is provided with a membrane component. The pure water zone is divided into two units, and the inside of each unit is provided with an effluent valve. The invention has the advantages of good effluent quality, multi purposes, small land occupancy, flexible and convenient using method, and is applied to the treatment of domestic sewage and micro-polluted source water, and can widen and facilitate the application of membrane bioreactor water treatment and water resource reutilization technique.

Owner:TONGJI UNIV

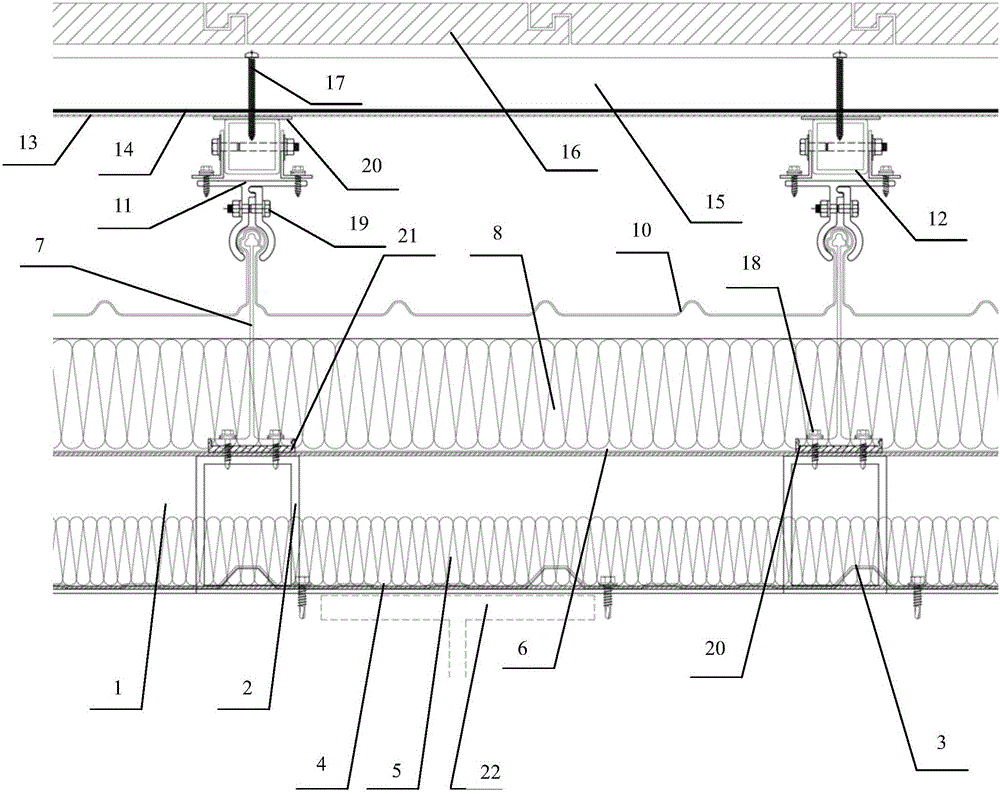

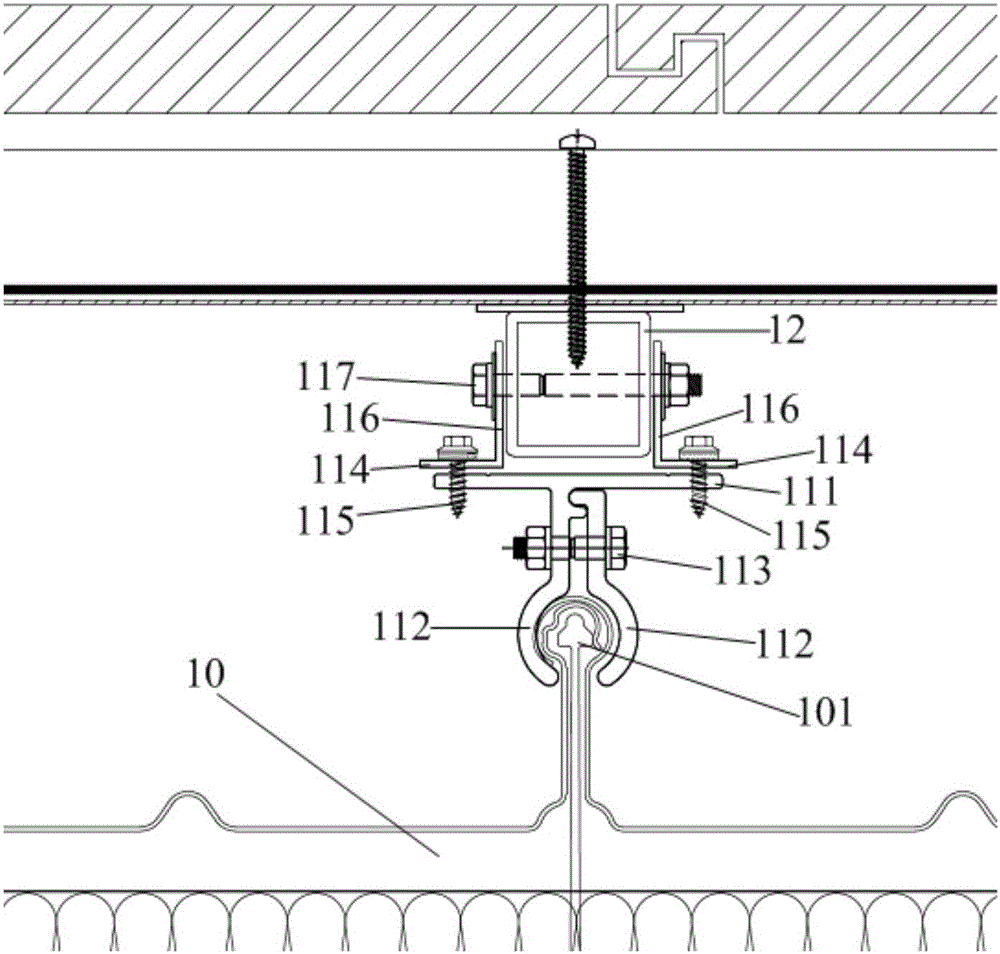

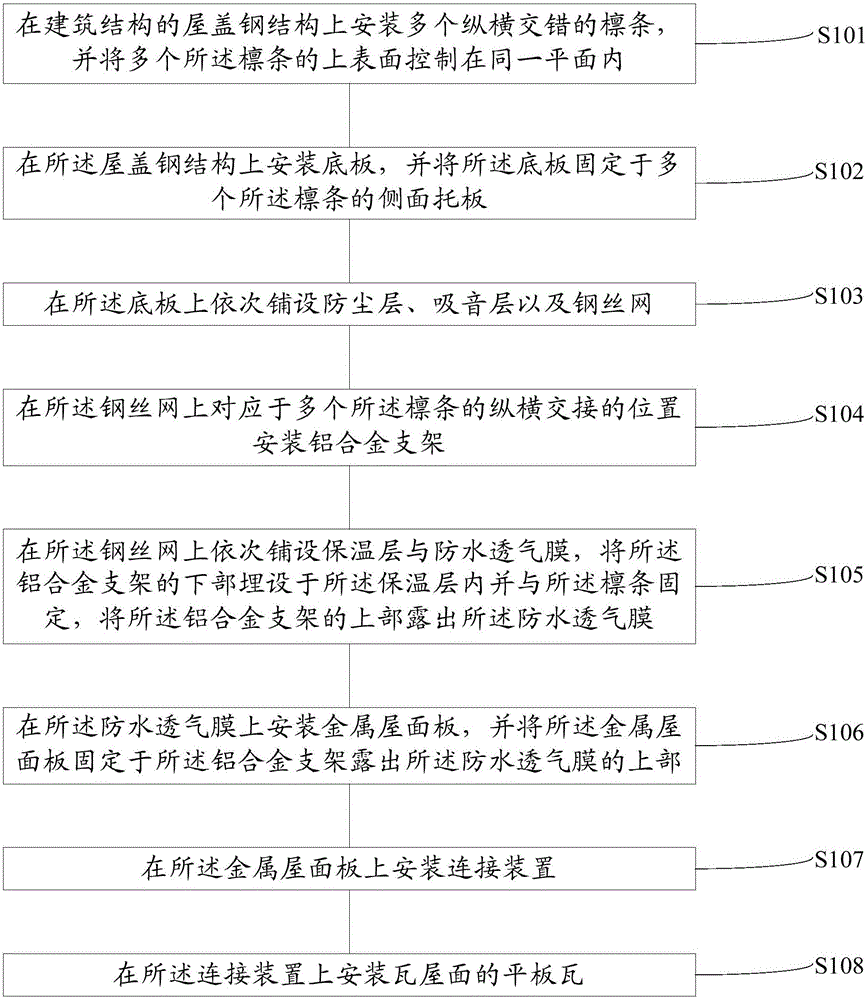

Metal roof plate and plane tile combined roof system and construction method thereof

ActiveCN105908910ASolve the problem of whether the connection is reliableSolve hidden dangers of waterproofingRoof covering insulationsInsulation layerAlloy

The invention discloses a metal roof plate and plane tile combined roof system and a construction method thereof. The method comprises the following steps that a plurality of longitudinally and transversely staggered purlines are arranged on a roof steel structure of a building structure, and the upper surfaces of the plurality of purlines are controlled in the same plane; a bottom plate is arranged on the roof steel structure, and is fixed on a side surface support plate of the plurality of purlines; a dustproof layer, a sound absorbing layer and a steel wire net are sequentially paved on the bottom plate; an aluminum alloy support frame is arranged in a position, corresponding to the longitudinally and transversely connected position, on the steel wire net; a heat insulation layer and a waterproof ventilated membrane are sequentially laid on the steel wire net; the lower part of the aluminum alloy support frame is embedded in the heat insulation layer and is fixed with the purlines; the upper part of the aluminum alloy support frame is exposed out of the waterproof ventilated membrane; a metal roof plate is arranged on the waterproof ventilated membrane, and is fixed at the upper part, exposed out of the waterproof ventilated membrane, of the aluminum alloy support frame; a connecting device is arranged on the metal roof plate; and plane tiles of a tiled roof are arranged on the connecting device.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

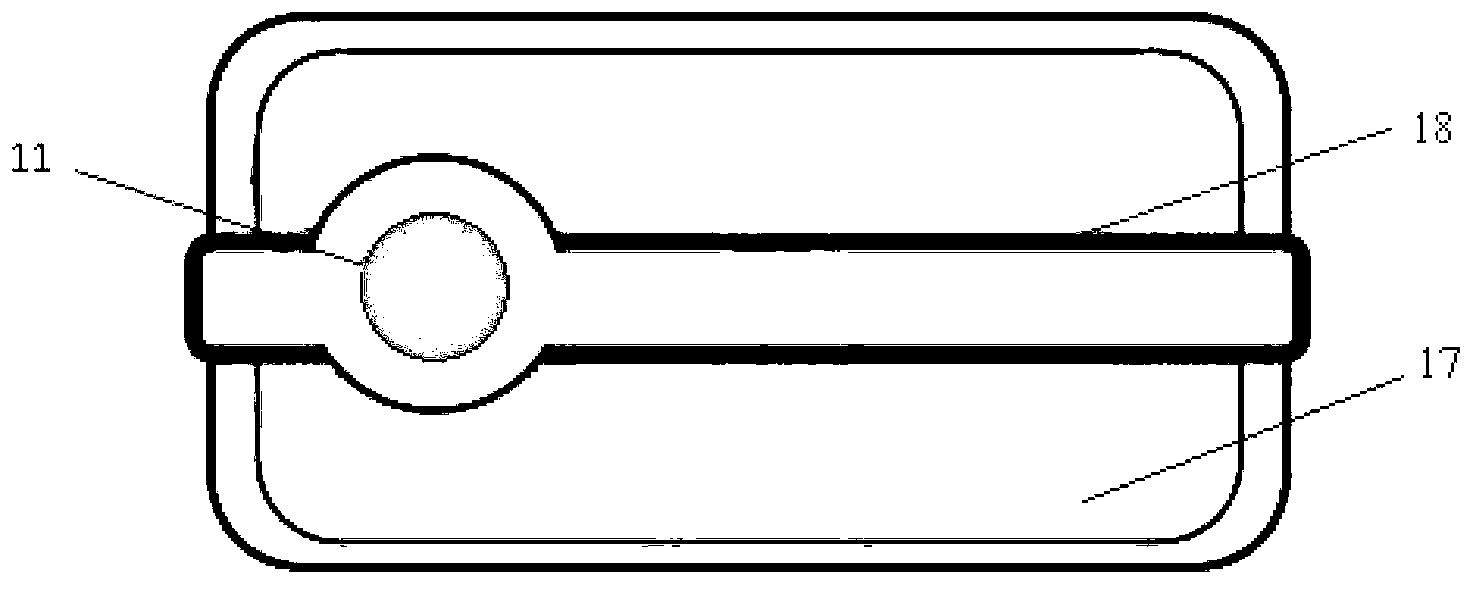

Integrated machine of washing vegetables, washing bowl, and disinfecting

InactiveCN101427891ASave electricityShorten washing timeKitchen equipmentTableware washing/rinsing machinesWater flowKitchen utensils

An integrative machine with functions of vegetable washing, dish washing and disinfection solves the problems of repeated expenditure and large occupied area of the prior separated vegetable washing machine and dish washing machine. The integrative machine is characterized in that two buckles are arranged on the left side of the upper end of a moving basket bracket; two pins are respectively arranged on the front and the rear sides of the left end of the moving basket bracket; an exhaust fan is fixed on the upper part of a housing and is communicated with a sealed chamber; the air inlet of a one-way air discharge door is fixed on the air outlet of the exhaust fan; and the air outlet of the one-way air discharge door is connected with an exhaust pipe. The fruits and vegetables can be washed by swaying and rotating the basket for the first time and then by swaying and sprinkling the basket for the second time. Water droplets on the washed dishes can be blown off by the fan, and the dished can be dried by a FIR drying device. No dead corners are present for the UV rays and the ejected water flow due to the swaying of the dish washing basket.

Owner:宋大伟

Dendrobium candidum ganoderma lucidum capsule

ActiveCN102772672ANo pollution in the processNarrow particle size distributionMetabolism disorderAntinoxious agentsDendrobium candidumHigh absorption

The invention discloses a dendrobium candidum ganoderma lucidum capsule, and relates to a traditional Chinese medicine capsule, in particular to a dendrobium candidum ganoderma lucidum capsule free from influence of air humidity and having high absorption and high bioavailability and a preparation method thereof. The dendrobium candidum ganoderma lucidum capsule disclosed by the invention is characterized by being prepared by the four steps of processing of dendrobium candidum, ultrafine grinding of dendrobium candidum, ultrafine grinding of ganoderma lucidum and mixing and capsule filling. In the dendrobium candidum ganoderma lucidum capsule disclosed by the invention, the ultrafine powder of dendrobium candidum and the ultrafine powder of ganoderma lucidum are mixed and packed in a capsule form, the influence of air humidity can be avoided, and the human body absorption and the bioavailability are high; and moreover, the dendrobium candidum ganoderma lucidum capsule has the functions of dendrobium candidum and ganoderma lucidum, and has a better taking effect.

Owner:XISHUANGBANNA ZENGLIANG BIOTECH

Security robot and automatic inspection method thereof

The invention relates to a security robot to solve existing technical problems. According to the technical scheme, the security robot is connected with a client in a communicating mode, the client isconnected with a server of the security robot through network, a buried charging point is arranged on the working place of the security robot, and the charging point is matched with an automatic charging interface. The security robot is characterized in that the security robot comprises a mobile platform, a vehicle body and a cradle head; the mobile platform comprises a vehicle frame, a steering module, a driving module, driving wheels, a differential mechanism, the automatic charging interface and a charging socket; an electric control processing module and a battery are arranged in the vehicle body, the steering module is arranged at the front portion of the vehicle frame, the driving module is fixed to the vehicle frame, the differential mechanism is fixed to the rear portion of the vehicle frame, and the driving module is connected with the driving wheels through the differential mechanism.

Owner:ZHEJIANG GUOZI ROBOT TECH

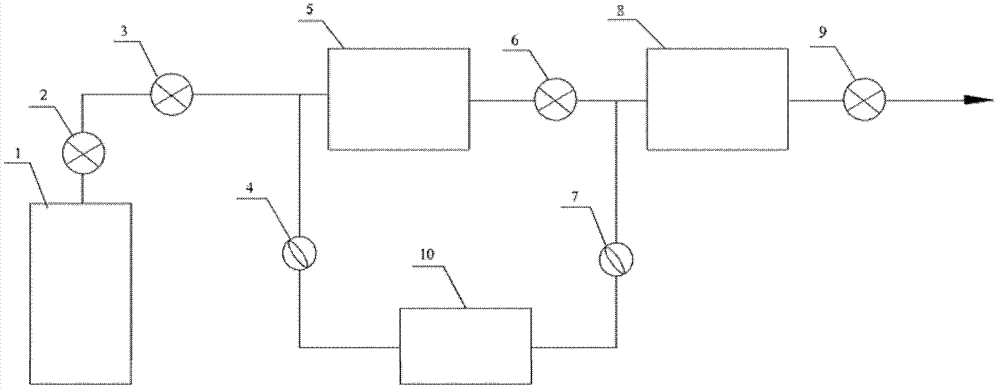

Rock sample porosity determination method

InactiveCN102901695ANo dead endsSimple and efficient operationPermeability/surface area analysisPetrologyInstrumentation

Owner:CHINA PETROLEUM & CHEM CORP +1

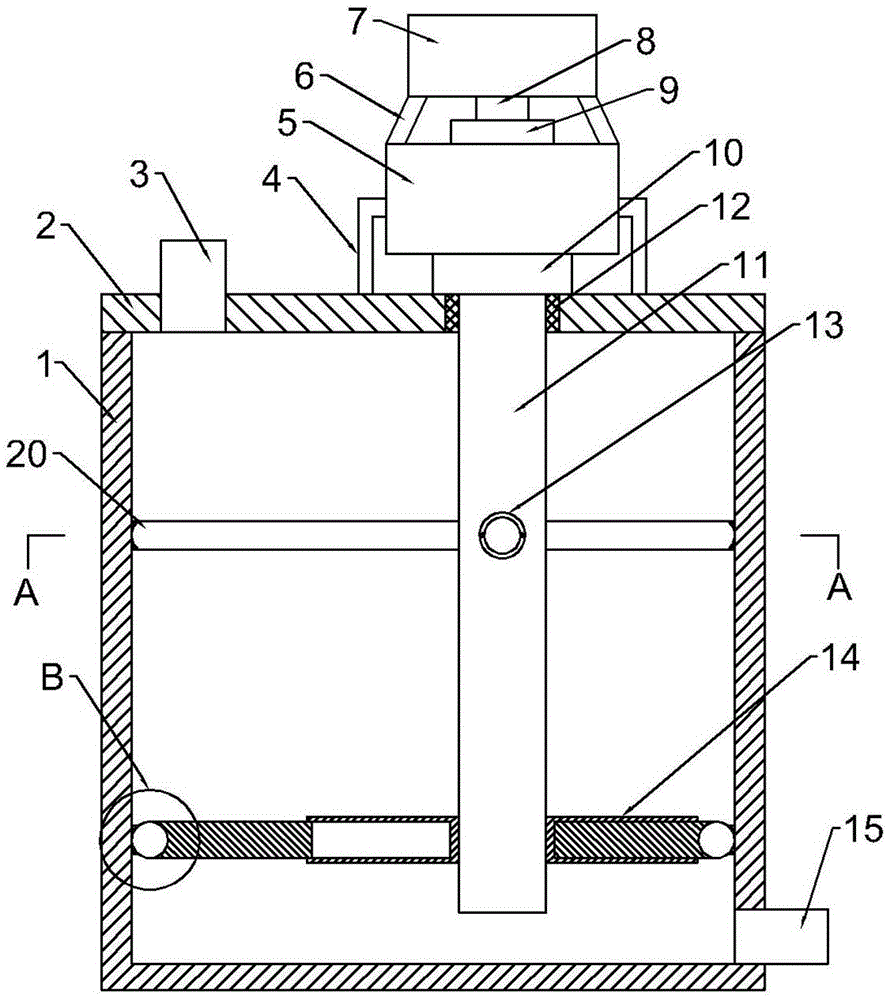

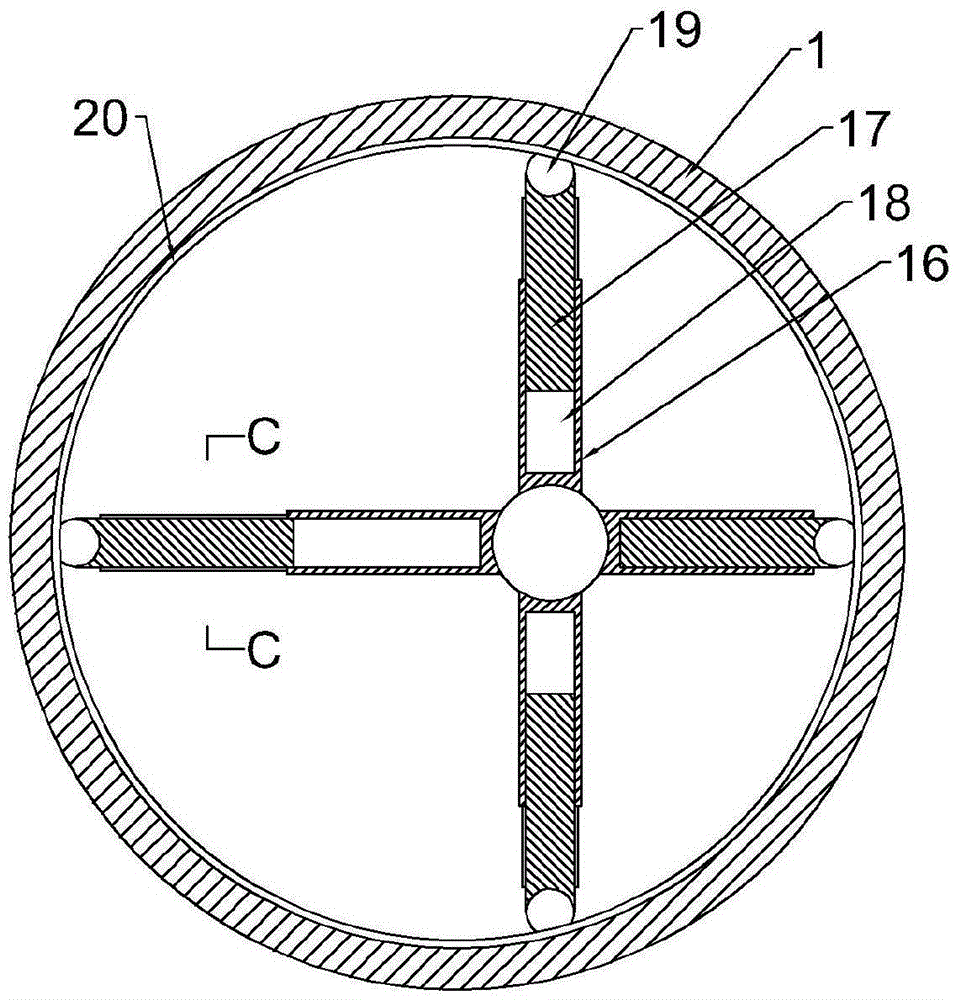

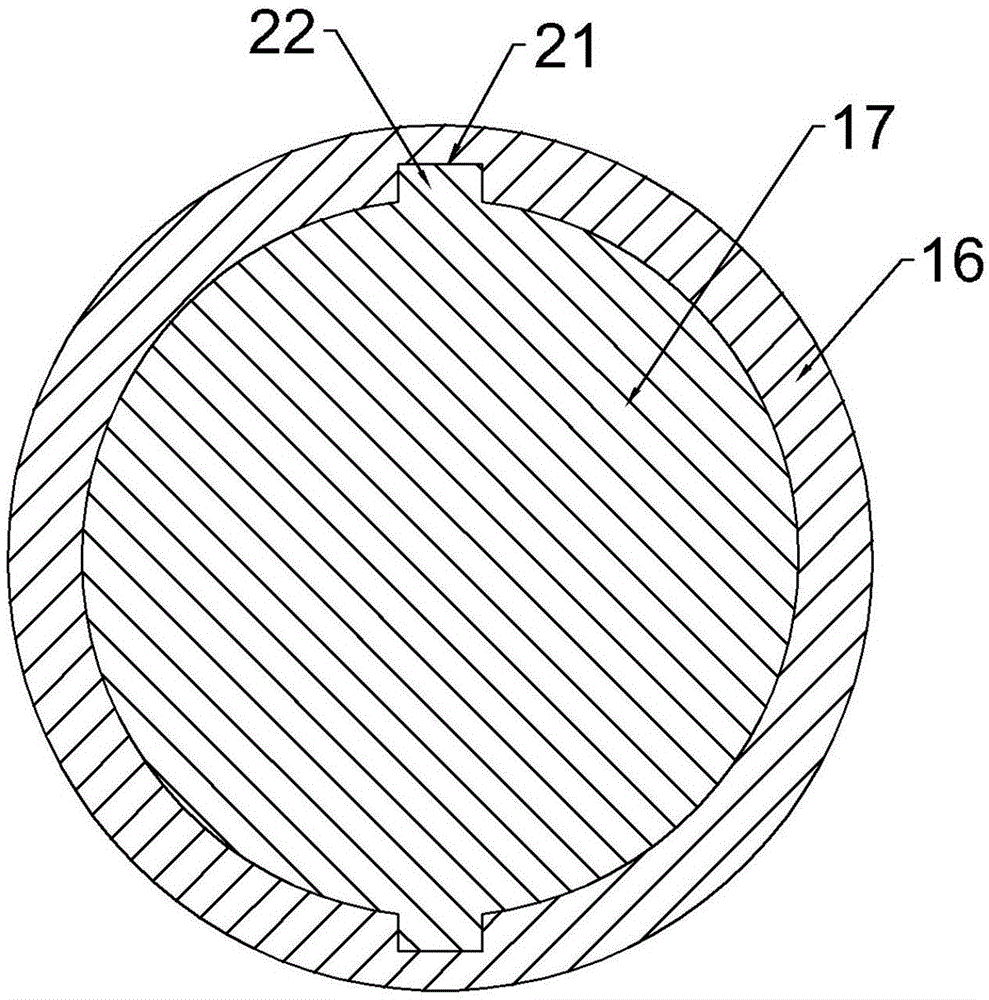

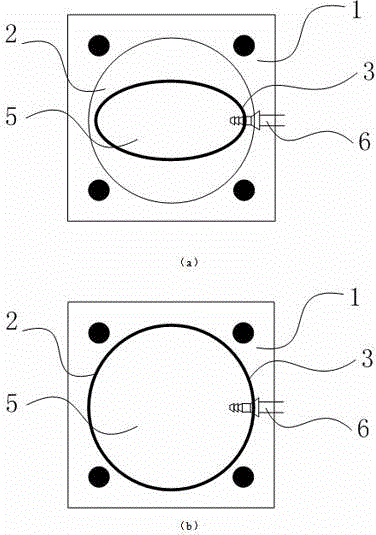

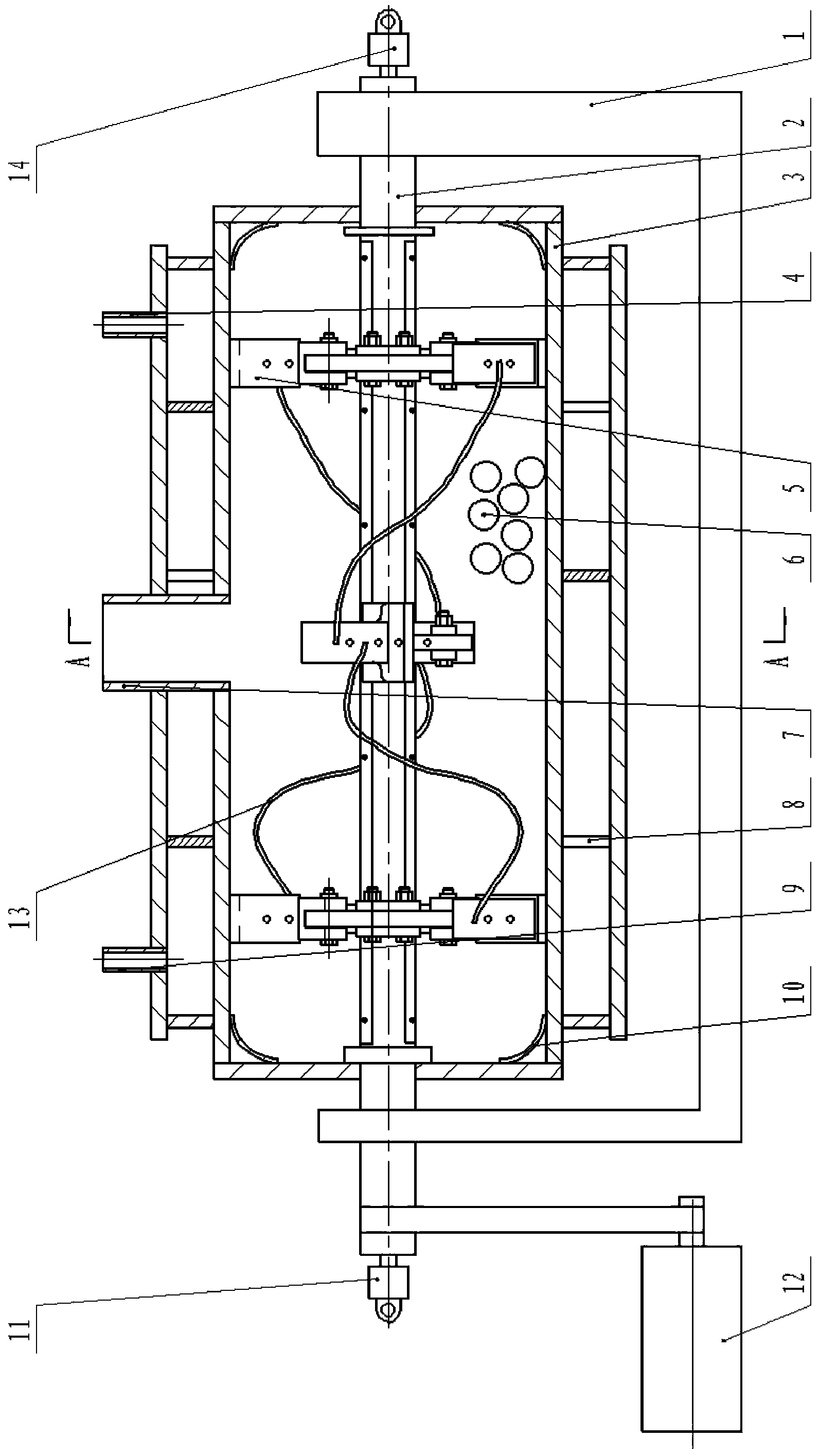

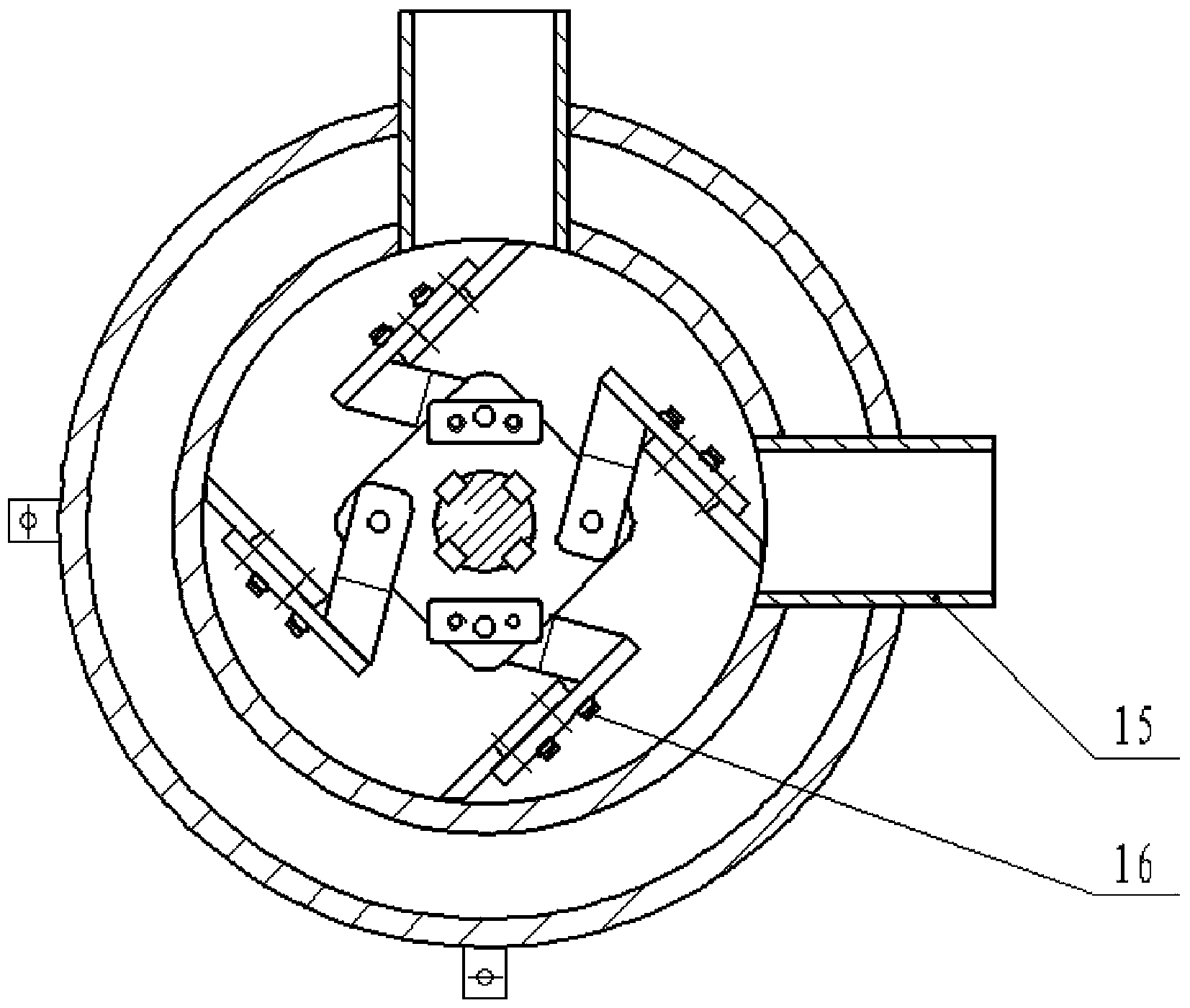

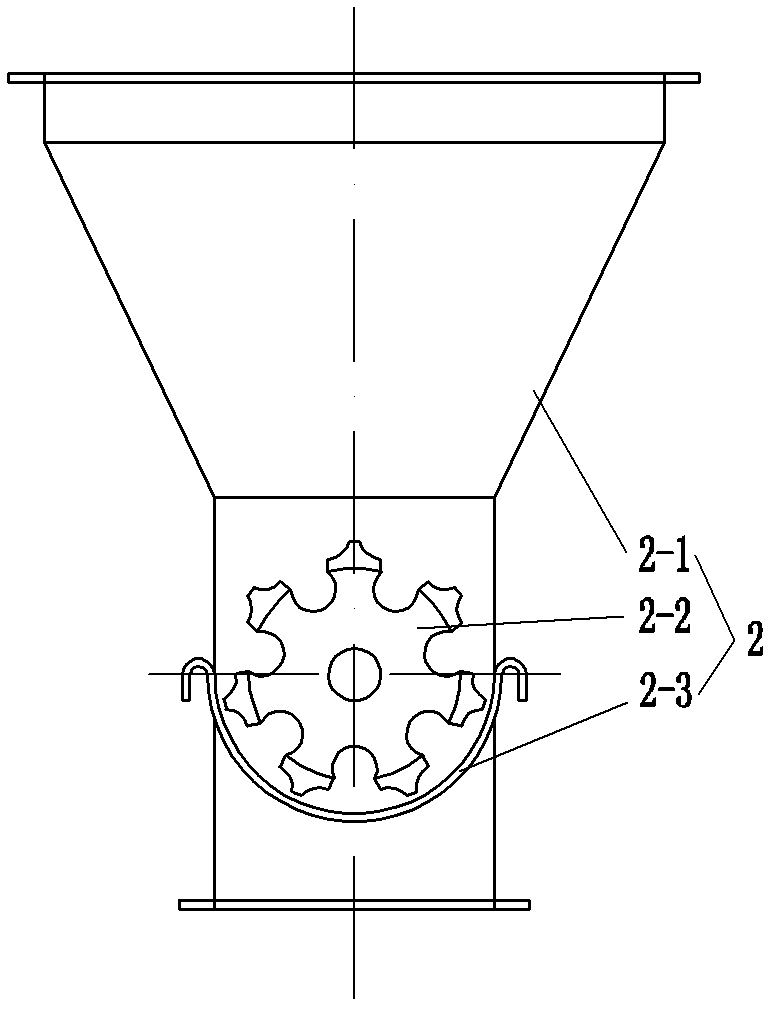

Dead-corner-free eccentric variable-blade-length stirring device

ActiveCN105642160AGood effectRotation diversificationTransportation and packagingRotary stirring mixersEngineeringScrew thread

The invention discloses a dead-corner-free eccentric variable-blade-length stirring device which comprises a barrel. A stirring shaft is arranged in the barrel, the stirring shaft and the center axis of the barrel are eccentrically arranged, an upper stirring mechanism and a lower stirring mechanism which are perpendicular to each other are fixed to the stirring shaft, and the upper stirring mechanism and the lower stirring mechanism are identical in structure. The upper stirring mechanism and the lower stirring mechanism both comprise a sleeve and a telescopic rod. The closed ends of the sleeves are installed on the stirring shaft through threads, the other ends of the sleeves are open, cavities are formed in the sleeves, and the telescopic rods are disposed in the cavities in a sliding mode. The ends, far away from the sleeves, of the telescopic rods are provided with grooves, and sliding assemblies are installed at the open ends of the grooves. A sliding rail matched with the sliding assemblies is installed on the inner wall of the barrel. The lengths of the upper stirring mechanism and the lower stirring mechanism are changed all the time along with stirring. The center of relative stirring of the upper stirring mechanism and the lower stirring mechanism is not the center axis of the barrel any more, the maximum stirring radius can be larger than the radius of the barrel, and the effect of liquid is better.

Owner:YANCHENG YONGYUE NEW MATERIAL CO LTD

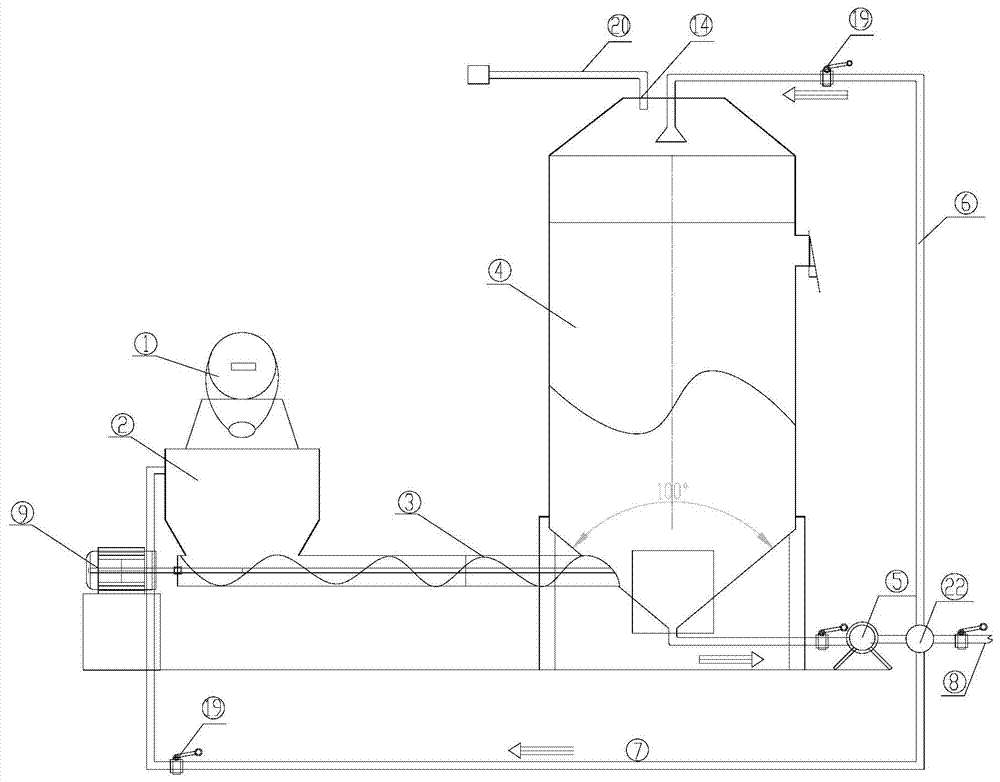

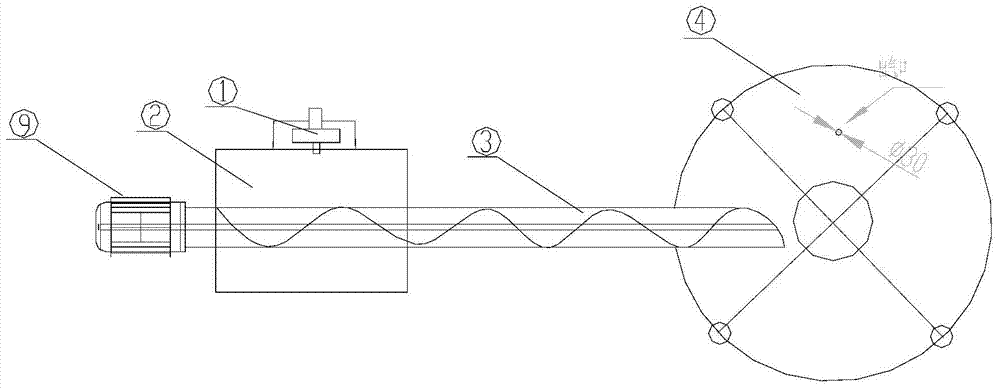

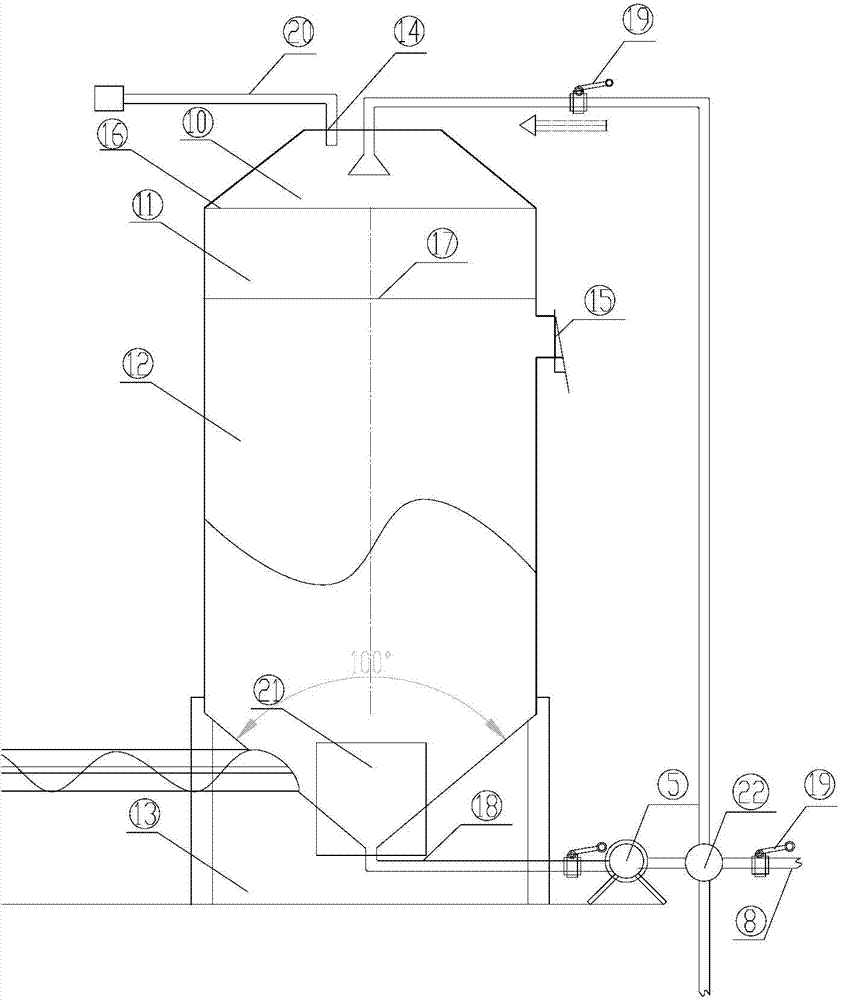

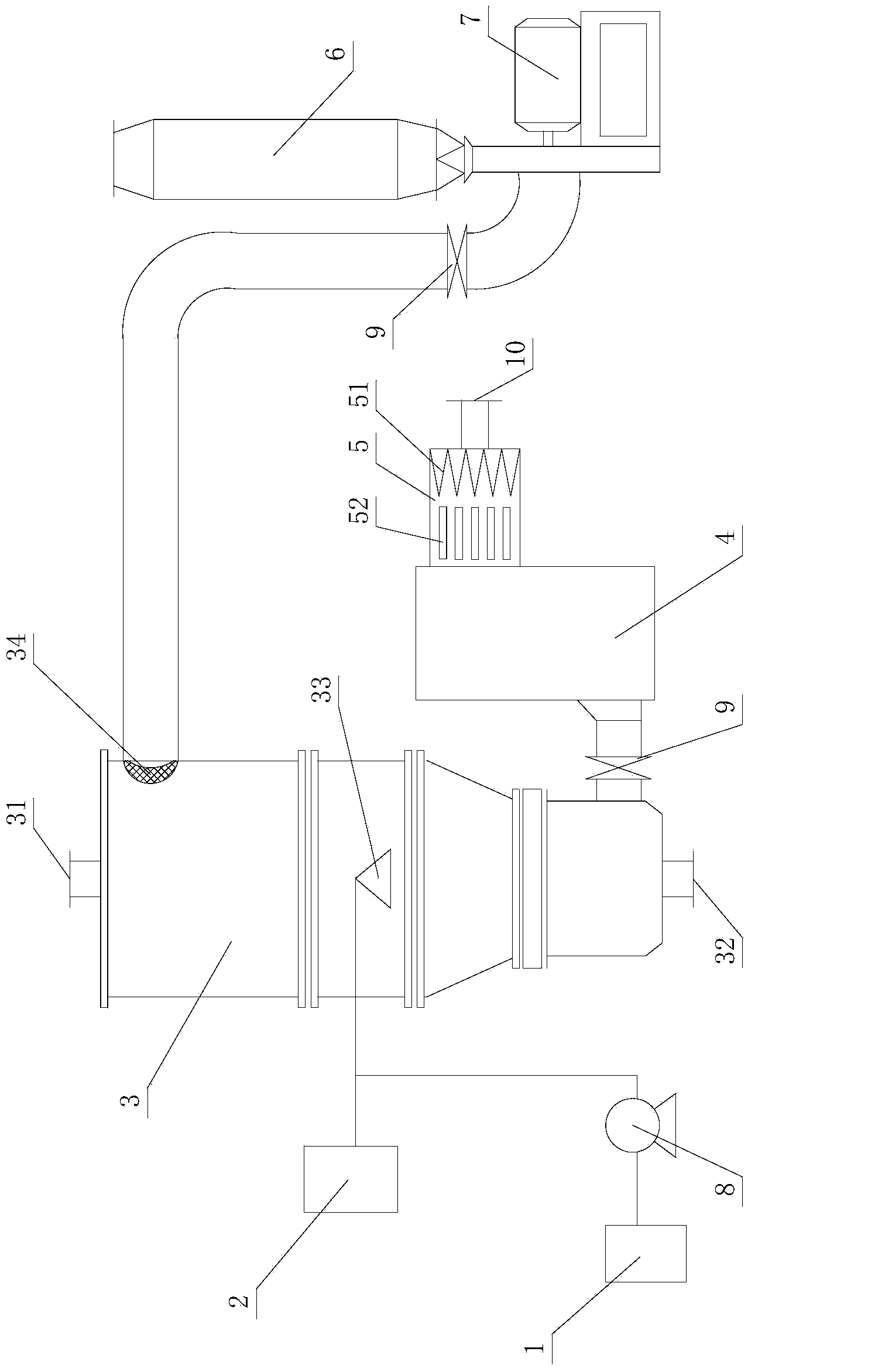

High-solid anaerobic reaction device and method for organic garbage

ActiveCN103614288AImprove processing efficiencyGuaranteed uptimeBiological substance pretreatmentsGas production bioreactorsPipe fittingSmall footprint

The invention relates to a high-solid anaerobic reaction device and method for organic garbage. The device comprises a pulverizer, a pretreatment pond and an anaerobic fermentation tank, wherein the pulverizer is arranged above the pretreatment pond; a spiral conveying device is arranged below the material outlet of the pretreatment pond and connected with the anaerobic fermentation tank; a liquid-collecting pipe is connected to the bottom of the anaerobic fermentation tank and connected to a four-way pipe fitting; the other three ports of the four-way pipe fitting are connected with a water draining pipe, a pretreatment pond backflow pipe and a biogas slurry spraying return pipe respectively; the anaerobic fermentation tank is internally sequentially provided with a spraying perforated plate and a sieve plate from top to bottom. According to the anaerobic reaction device for the organic garbage with the high solid content, the material pulverization, pretreatment and fermentation are integrated, the material uniformity is guaranteed, an anaerobic fermentation process is facilitated, the solid concentration and uniformity of a material are regulated through fermentation liquor backflow, and the stable fermentation of organic garbage is realized; the anaerobic reaction device has the characteristics of wide adaptability, high treatment efficiency, compact layout, stable operation, small land occupation area and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Wall and floor shoveling machine

The invention discloses a wall and floor shoveling machine. The wall and floor shoveling machine comprises a shell, two handles, a dust-free depth regulating cover, a water spraying device and a tool. The two handles are arranged on the upper portion of the shell and provided with control switches respectively, the water spraying device is arranged on the outer side of the dust-free depth regulating cover, and the dust-free depth regulating cover is mounted at the bottom of the shell and comprises a cover body and two symmetrical depth regulating devices. The tool is mounted in the middle of the cover and comprises a disc tool seat, and tool bits are uniformly distributed on an outer arc surface of the disc tool seat. The wall and floor shoveling machine is functionally versatile, stable in operation and free of dust raising, grinding depth can be regulated according to construction requirements, and water can be directly sprayed to wet walls and floors to soften putty, so that dust reduction can be realized. In addition, the wall and floor shoveling machine is simple, convenient and quick in operation and clean, flat and smooth in ground surfaces.

Owner:唐浩

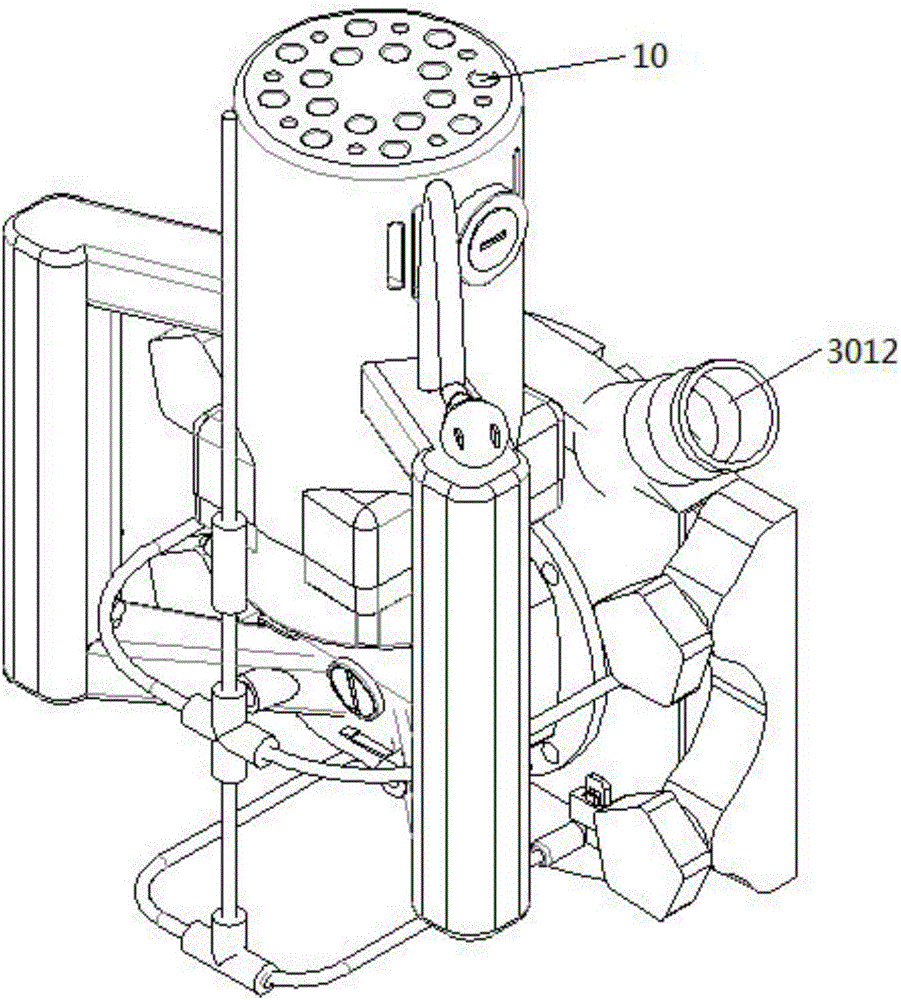

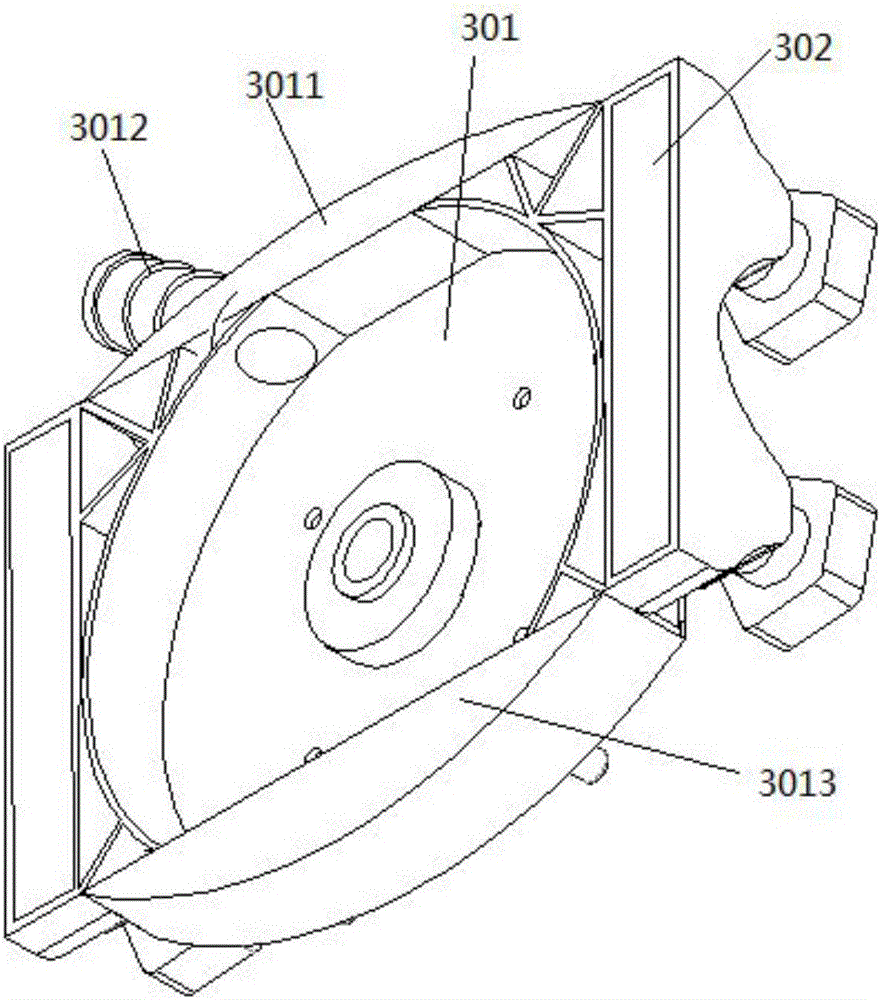

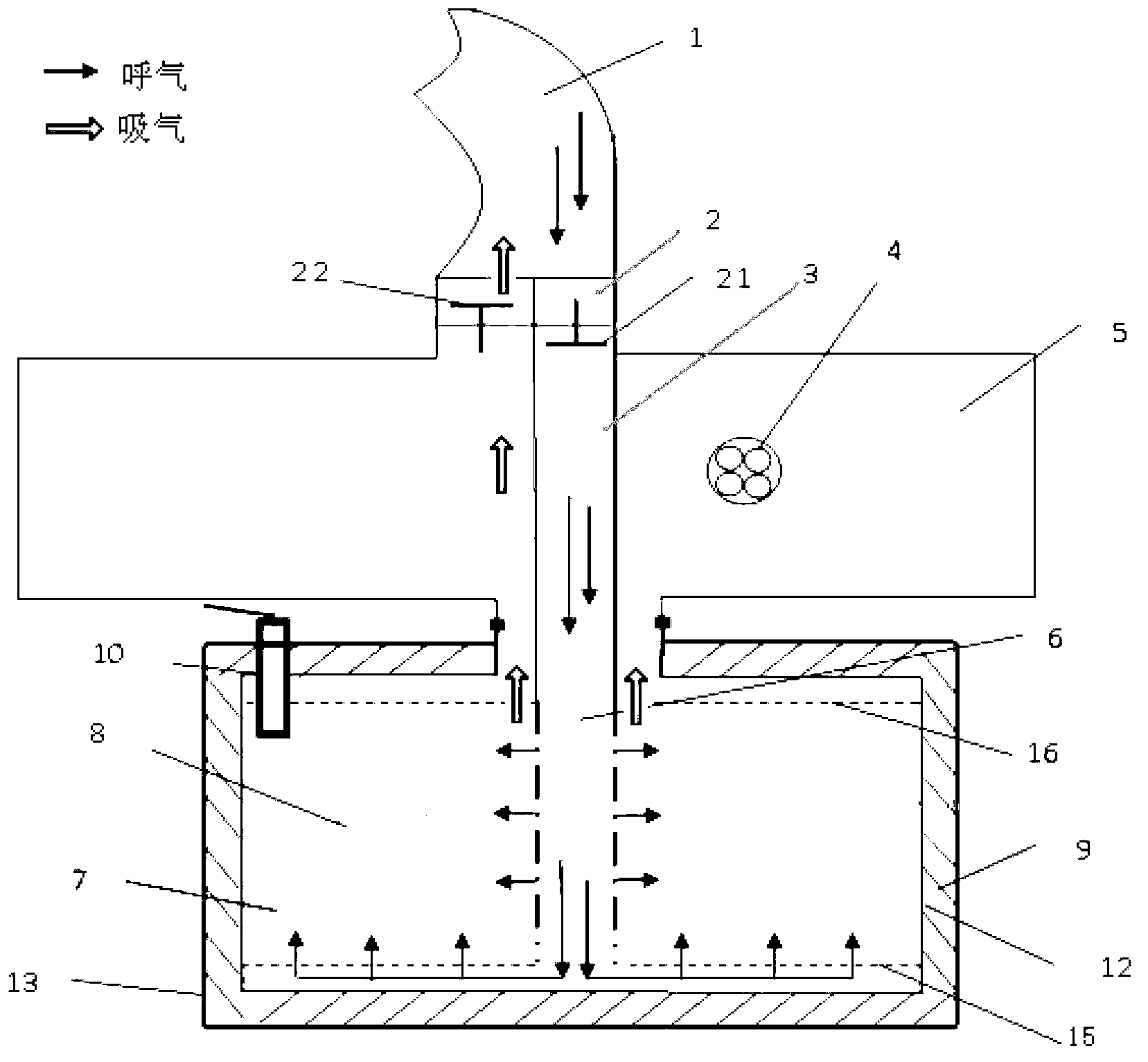

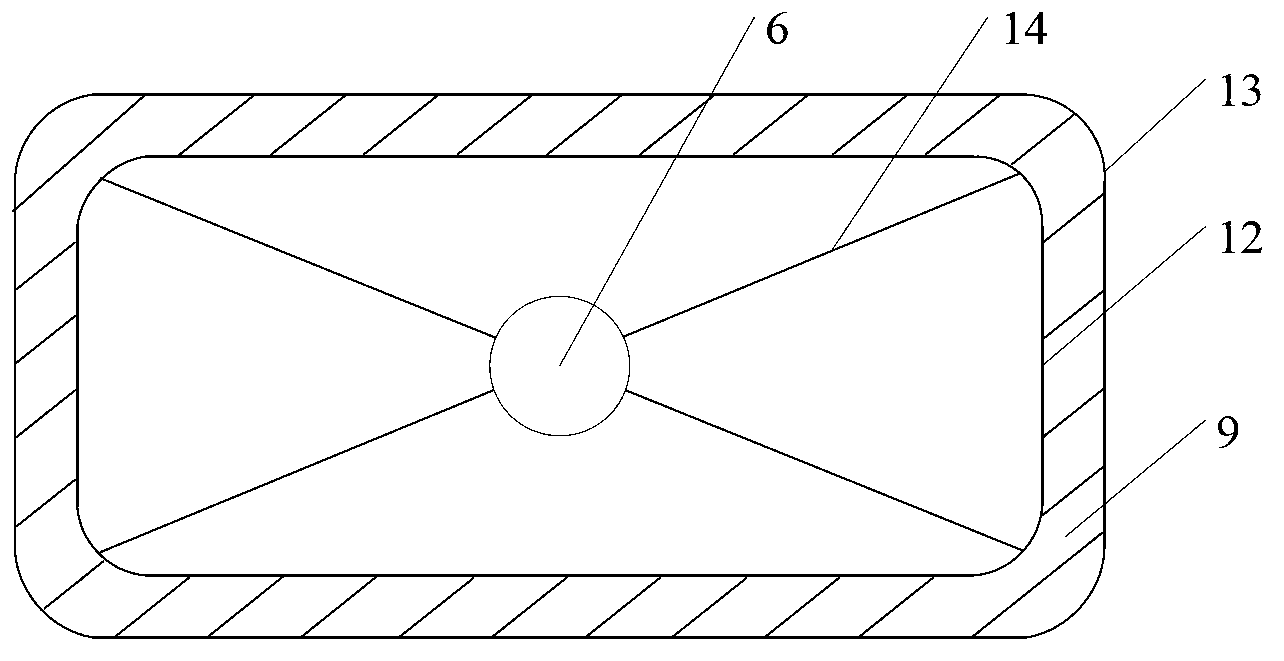

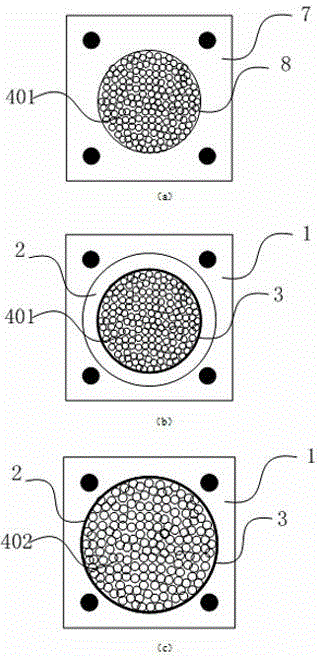

Chemical oxygen self-rescuer with diversion enhancement heat-transfer and cooling performances

InactiveCN103301584AIncrease profitIncrease contactFire rescueRespiratory apparatusChemical oxygen demandHeat conducting

The invention provides a chemical oxygen self-rescuer with diversion enhancement heat-transfer and cooling performances. The chemical oxygen self-rescuer comprises a breathing hose, an air bag, an oxygen generator, an upper shell and a lower shell and is characterized in that the oxygen generator is arranged in the lower shell, and a phase-change cooling-material cooling layer is arranged between the outer wall of the oxygen generator and the lower shell; a porous exhaling catheter is arranged on a vertical center shaft of the oxygen generator, and an upper-layer filtering baffle plate and a lower-layer filtering baffle plate are respectively arranged on the planes on which the upper catheter mouth and the lower catheter mouth of the porous exhaling catheter; the porous exhaling catheter is connected with the outer wall of the oxygen generator through a vertical support shunt heat-conducting plate. The oxygen generator with a diversion enhancement heat-transfer technology and the phase-change material melting decalescence cooling layer are adopted. The chemical oxygen self-rescuer has the advantages that the suction temperature and the temperature of the handheld surface of a product are low, the oxygen generating efficiency is high, and meanwhile the air tightness is conveniently inspected.

Owner:BEIJING ANYANGTE TECH

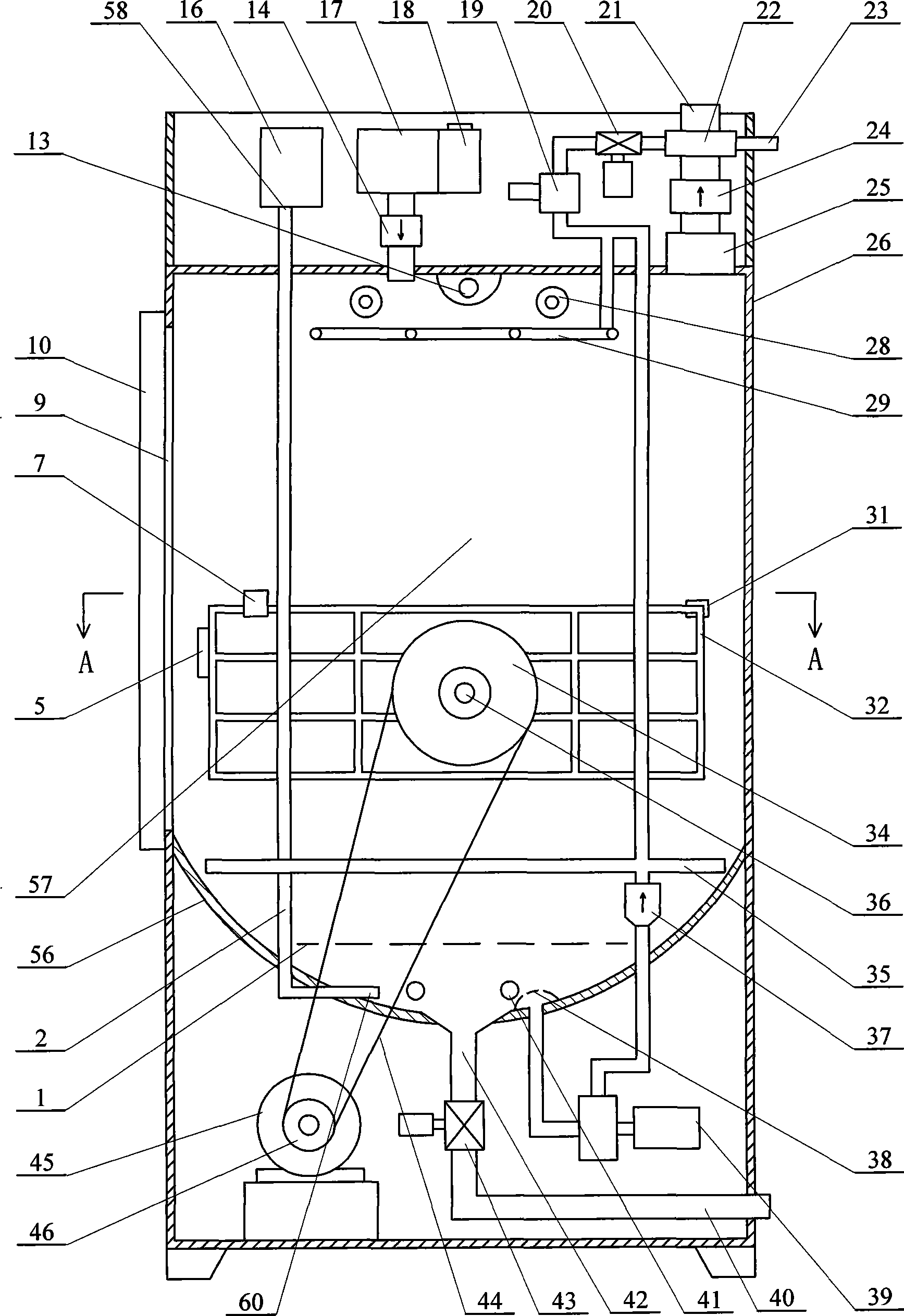

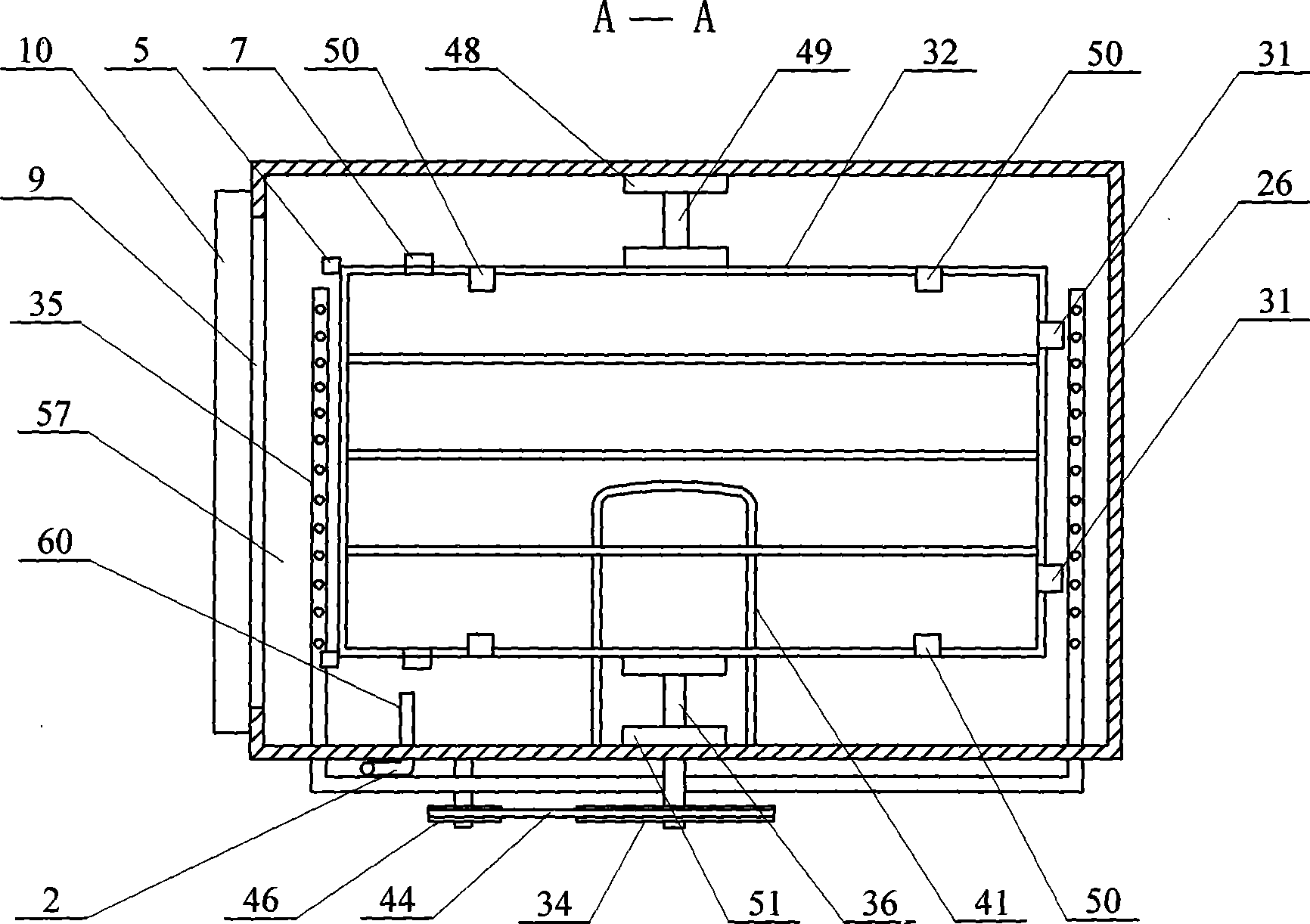

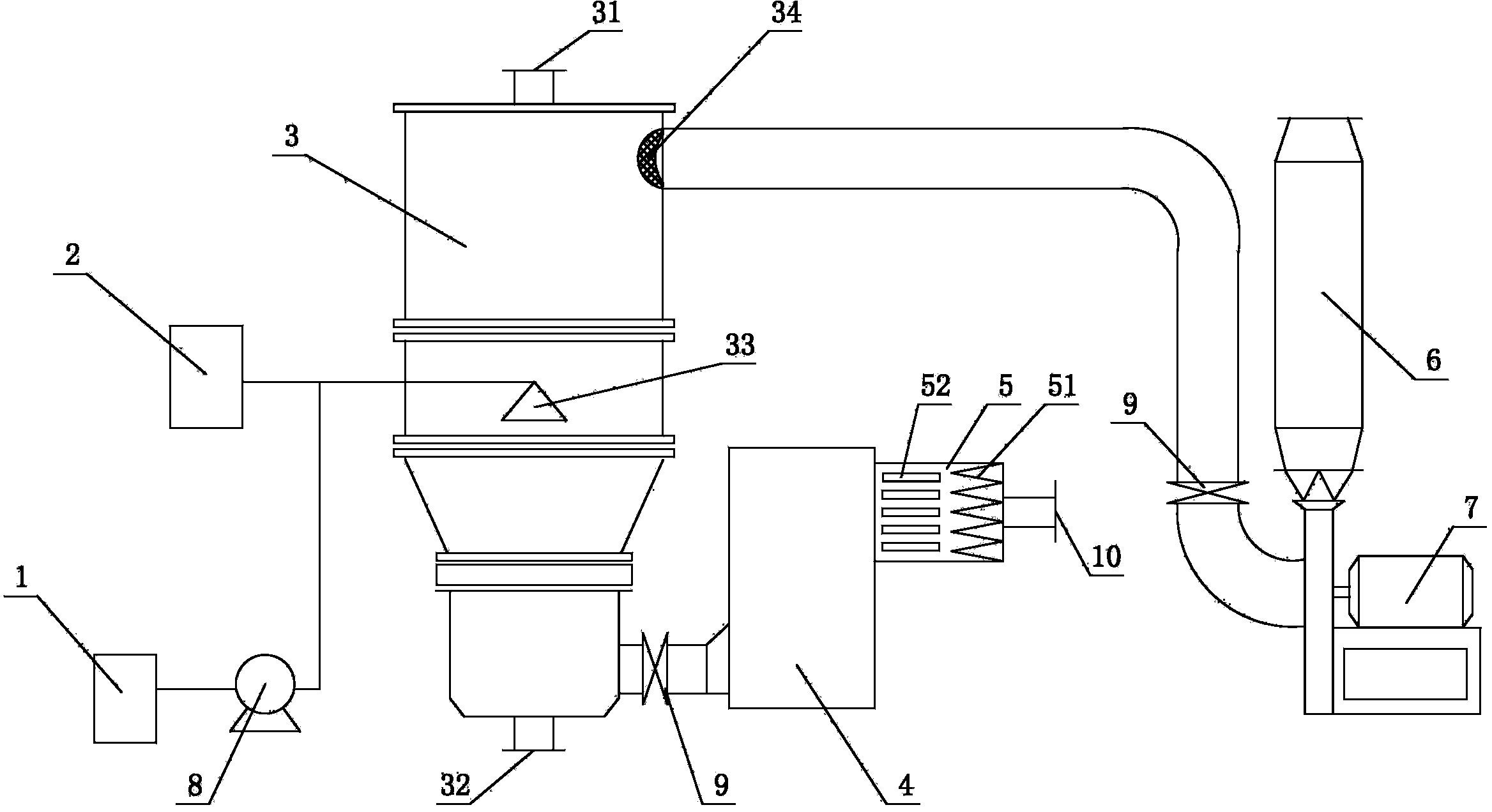

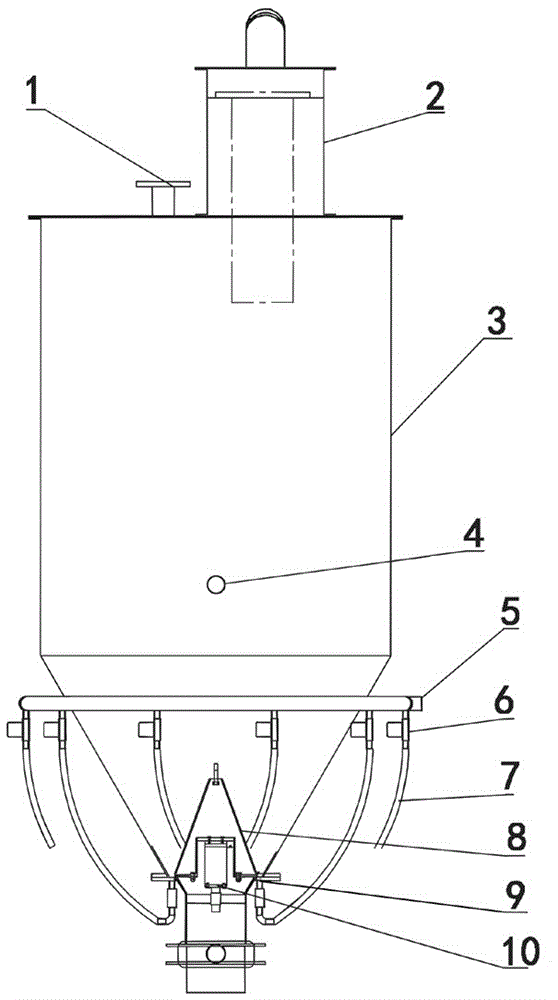

Fluid bed granulating drier and drying process thereof

InactiveCN104014278ANo flyingSimple structureDrying solid materials with heatChemical industryChemical industryGas compressor

The invention discloses a fluid bed granulating drier applied in various fields such as pharmacy, food, feeds, pigments and chemical industry and a drying process thereof. The fluid bed granulating drier comprises an adhesive tank, an air compressor and a fluid bed, wherein a hot air inlet is formed in the lower half part of the fluid bed and is connected with a heater; an air outlet of the fluid bed is connected with an exhaust fan via a pipeline; a filter is connected with the upper half part of the heater and is provided with an air inlet; filter cloth and a muffler are arranged at the air outlet of the fluid bed. The drier has a simple structure, is reasonable in design, completes the processes of mixing, granulating and drying in the same equipment, is quick in mass heat transfer, is operated at closed negative pressure, thus avoiding dust flying, is uniform in granules, does not have dead angles, is cleaned thoroughly, is free from cross pollution and is energy-saving and environment-friendly.

Owner:张家港市进润彩印包装有限公司

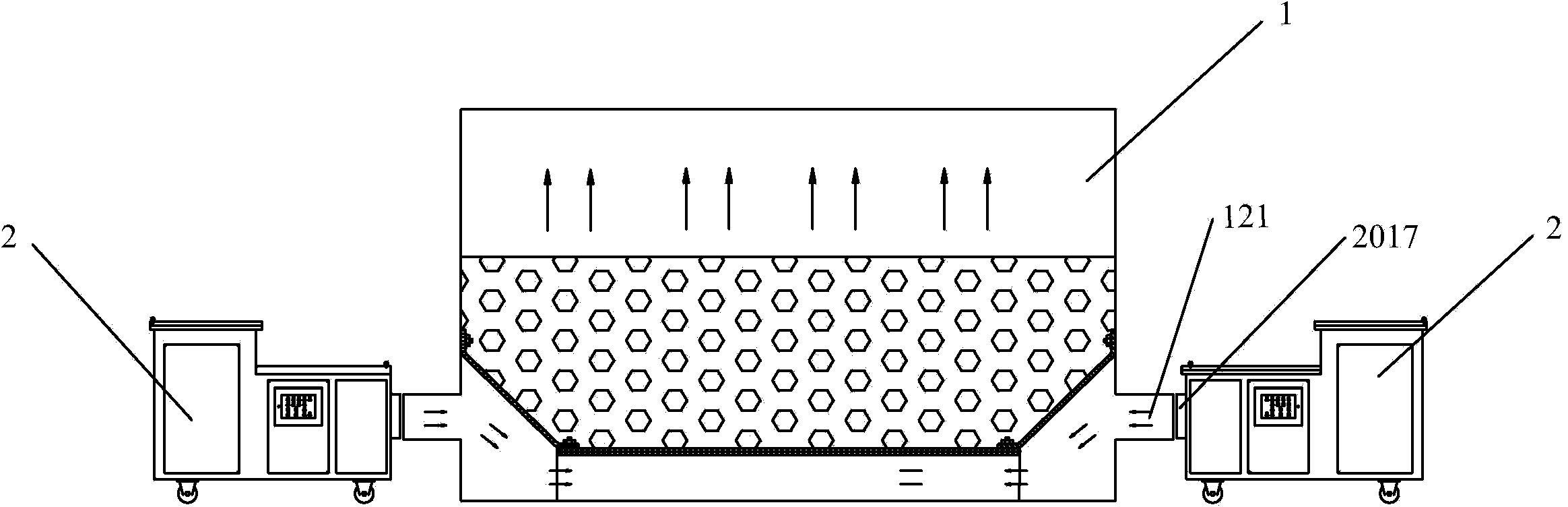

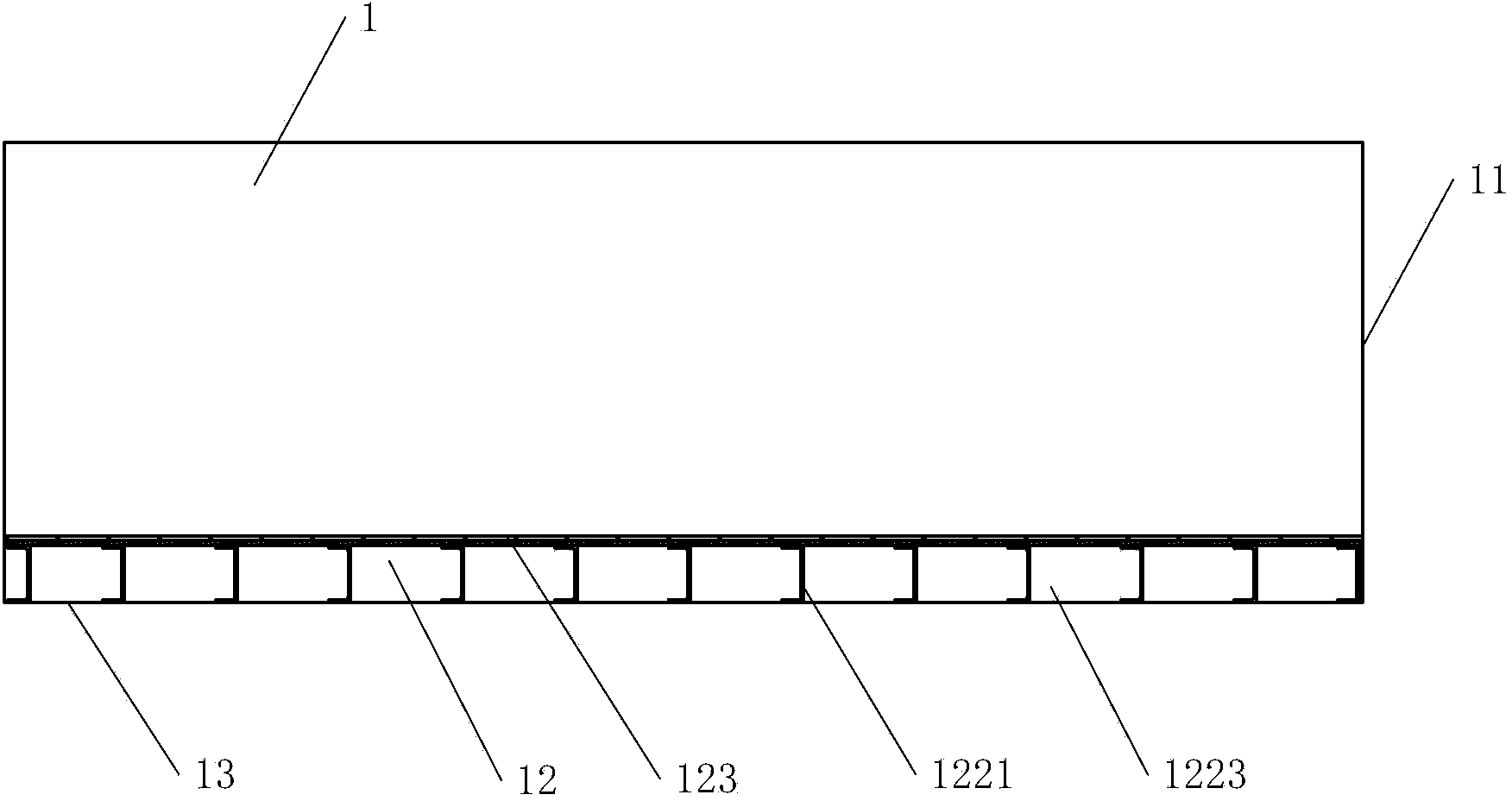

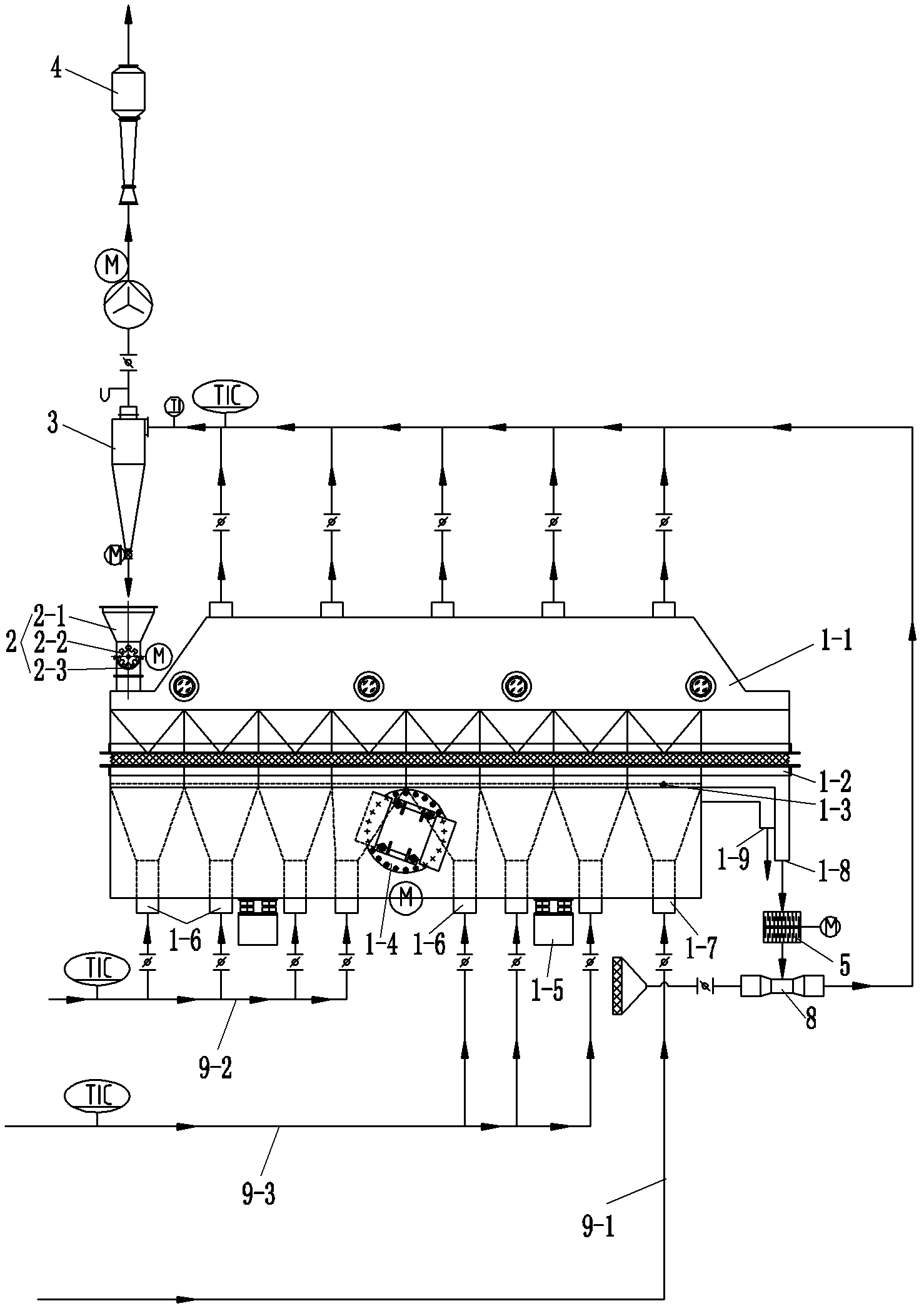

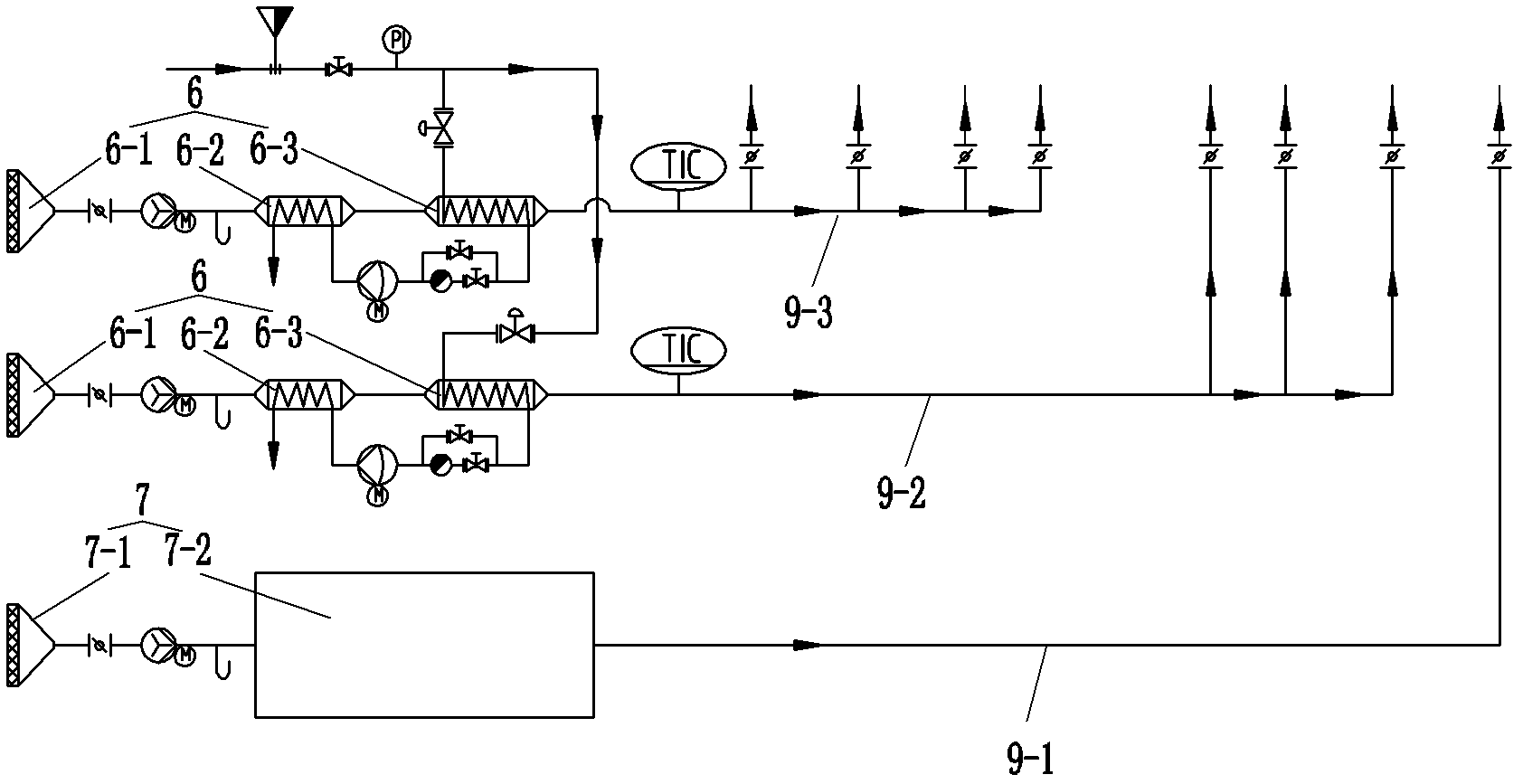

Whole bin whole-base ventilation low-speed drying grain storage system

InactiveCN104034130AMaintain commodity valueNo mildew lossDrying gas arrangementsSeed preservation by dryingLow speedPesticide residue

The invention relates to a whole bin whole-base ventilation low-speed drying grain storage system which comprises a grain bin and a grain bin treatment device. The system is characterized in that the grain bin is a whole-base ventilation grain bin, a ventilation structure is arranged on a base plate of the grain bin, the ventilation structure is connected with a ventilation inlet formed in the grain bin, and the ventilation structure is communicated with an inner cavity of the grain bin. The grain bin treatment device comprises a shell, and an air inlet and an air outlet are formed in the shell. The air outlet of the grain bin treatment device is connected with the ventilation inlet of the grain bin. According to the whole bin whole-base ventilation low-speed drying grain storage system, no drying pipelines exist in the grain bin, drying efficiency and the drying effect are greatly improved, the system can adapt to unprocessed grain conditions and climatic features in different areas, and the commodity value of the grain is ensured through low-temperature low-speed drying. In addition, by the adoption of technology application of ozone mould prevention and sterilization and pesticide residue degradation, it is ensured that no mould loss is produced in the treatment process, and meanwhile the drying season can be prolonged.

Owner:中机天安(北京)粮储安全技术研究院

Nitration denitrification integral type sewage denitrification biomembrane reactor

InactiveCN1962487AFast updatePromote growth and reproductionTreatment with aerobic and anaerobic processesDraining tubeMulti pollutant

The invention discloses a column-shaped denitrifying reactor through integrated nitrated and denitrificated biological film method in the environmental protective technique domain, which comprises the following parts: water collecting system, aerating reacting region, anaerobic region and sediment region, wherein the aerating reacting region is full of suspension fill with aerating pipe on the bottom; the gas inlet and water outlet are opened on the bottom; the gas inlet connects aerating pipe with top opening interconnecting hole; the peole-shaped mud baffle board is set in the sediment region with hole on the top, which connects one end of gas collecting pipe; the other end of gas collecting pipe pierces the water collecting system; the mud drainage valve lies on one side of sediment region under the mud baffle board; the bottom of water collecting system possesses overflow dam with water drainage pipe on one side; the sampling valve is set around aerating reacting region and sediment region.

Owner:TONGJI UNIV

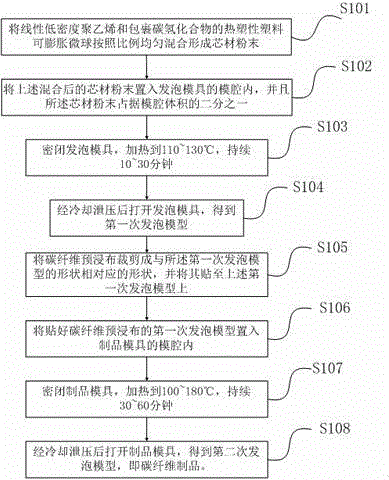

Preparation method of carbon fiber product

The invention discloses a preparation method of a carbon fiber product. The preparation method comprises the following steps: uniformly mixing linear low density polyethylene with thermoplastic plastic swellable microspheres packaging hydrocarbon in proportion to form core material powder; adding the mixed core material powder into a mold cavity of a foaming mold; sealing the foaming mold, heating the foaming mold to be 110-130 DEG C, and maintaining the temperature for 10-30 minutes; after carrying out cooling and decompression, opening the foaming mold to obtain a primary foaming model; gluing cut carbon fiber presoaked cloth to the primary foaming model; putting the primary foaming model glued with the carbon fiber presoaked cloth into a mold cavity of a product mold; sealing the product mold, heating the product mold to be 100-180 DEG C, and maintaining the temperature for 30-60 minutes; after carrying out cooling and decompression, opening the product mold, so as to obtain a secondary foaming model, namely the carbon fiber product. The carbon fiber product prepared by virtue of the preparation method is firm in structure, low in density and preparation cost and high in production efficiency, and dead corner is avoided by virtue of internal force.

Owner:WEIHAI YUNYANG CARBON TECH CO LTD

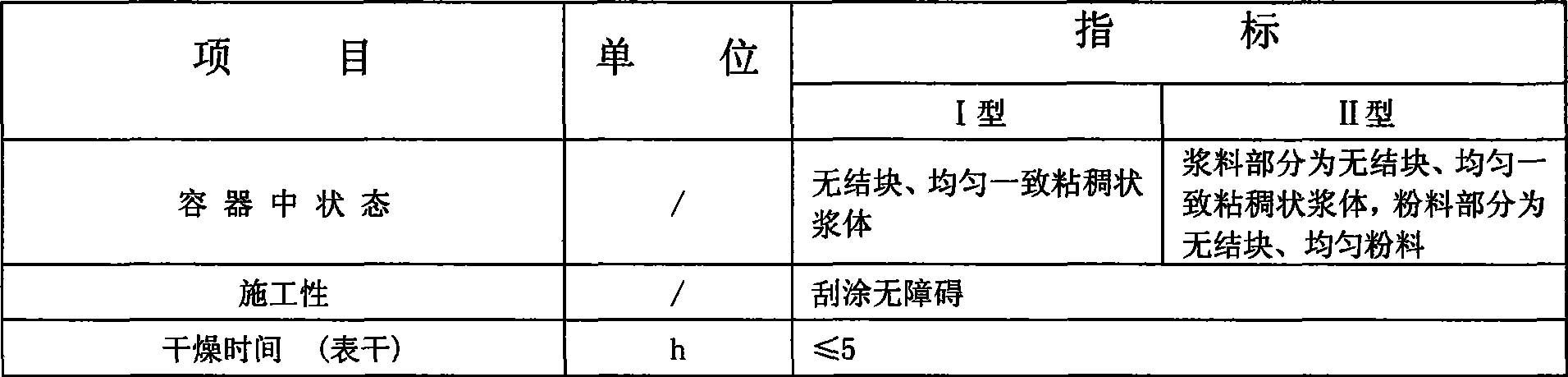

Microhollow super-fibre heat insulation coatings for building insulation and method of use thereof

InactiveCN101381546ACreate pollutionHealth hazardFireproof paintsCovering/liningsNoise removalThermal coefficient

The invention provides a micro hollow fiber thermal insulating coating for buildings and an application method thereof. The micro hollow fiber thermal insulating coating for buildings is divided into a I-type single-component micro hollow fiber thermal insulating coating for buildings and a II-type double-component micro hollow fiber thermal insulating coating for buildings, and is used as an exterior wall thermal insulating coating or used to pipes and other various places needing coating the thermal insulating coating. The coating is added with super hollow fibers and aramid fibers with high-temperature resistance, acid and alkali resistance and light weight, so that the coating has the advantages of low thermal coefficient and heat storage coefficient, obvious heat retaining effect, nontoxic formula, environmental protection, excellent fire resistance, super-strong chemical stability, high cohesional strength, noise removal, high cost performance, long service life, wide application, simple and easy construction, good effect, labor and physical resource conservation, and obvious economic and environment-friendly benefits.

Owner:FUJIAN OUNUO PAINT TECH

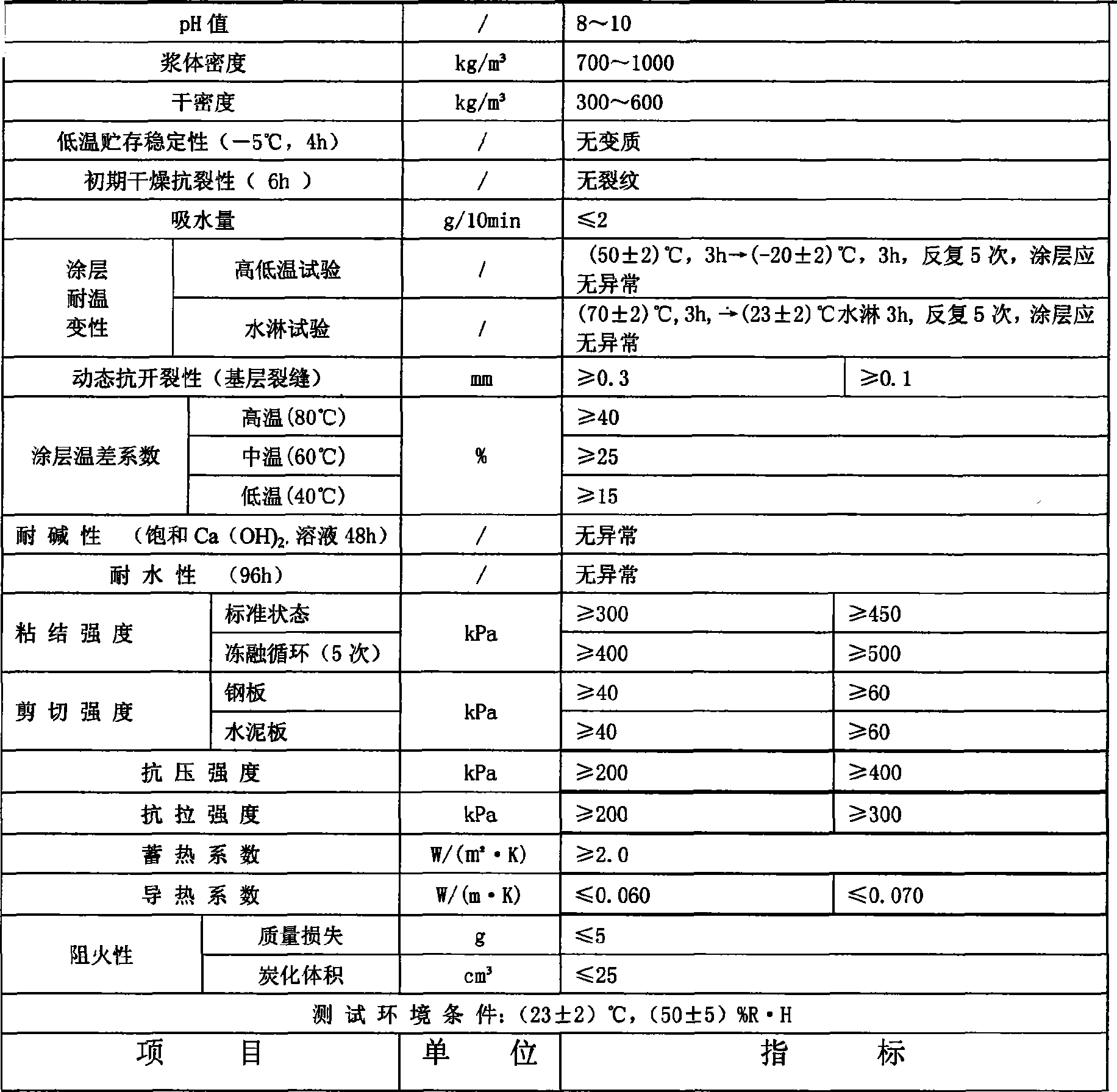

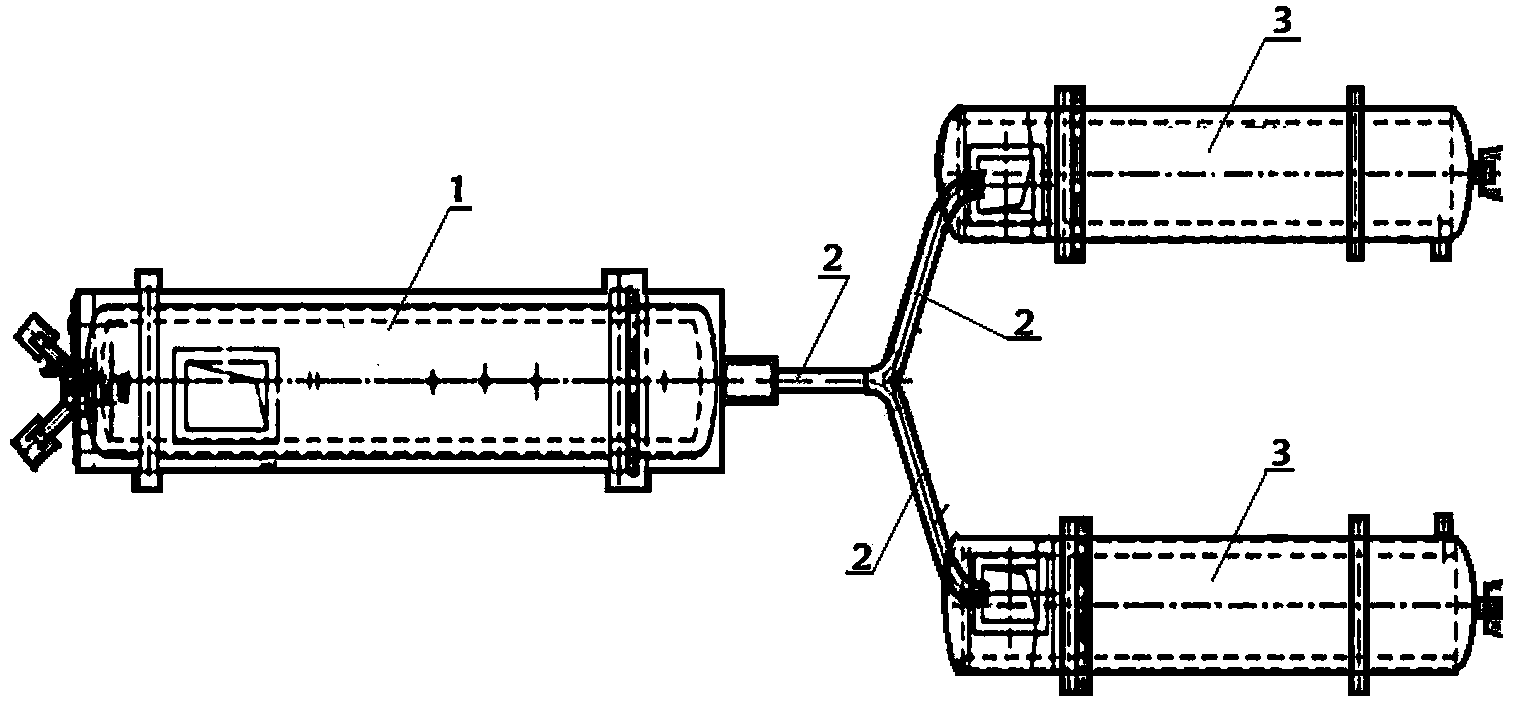

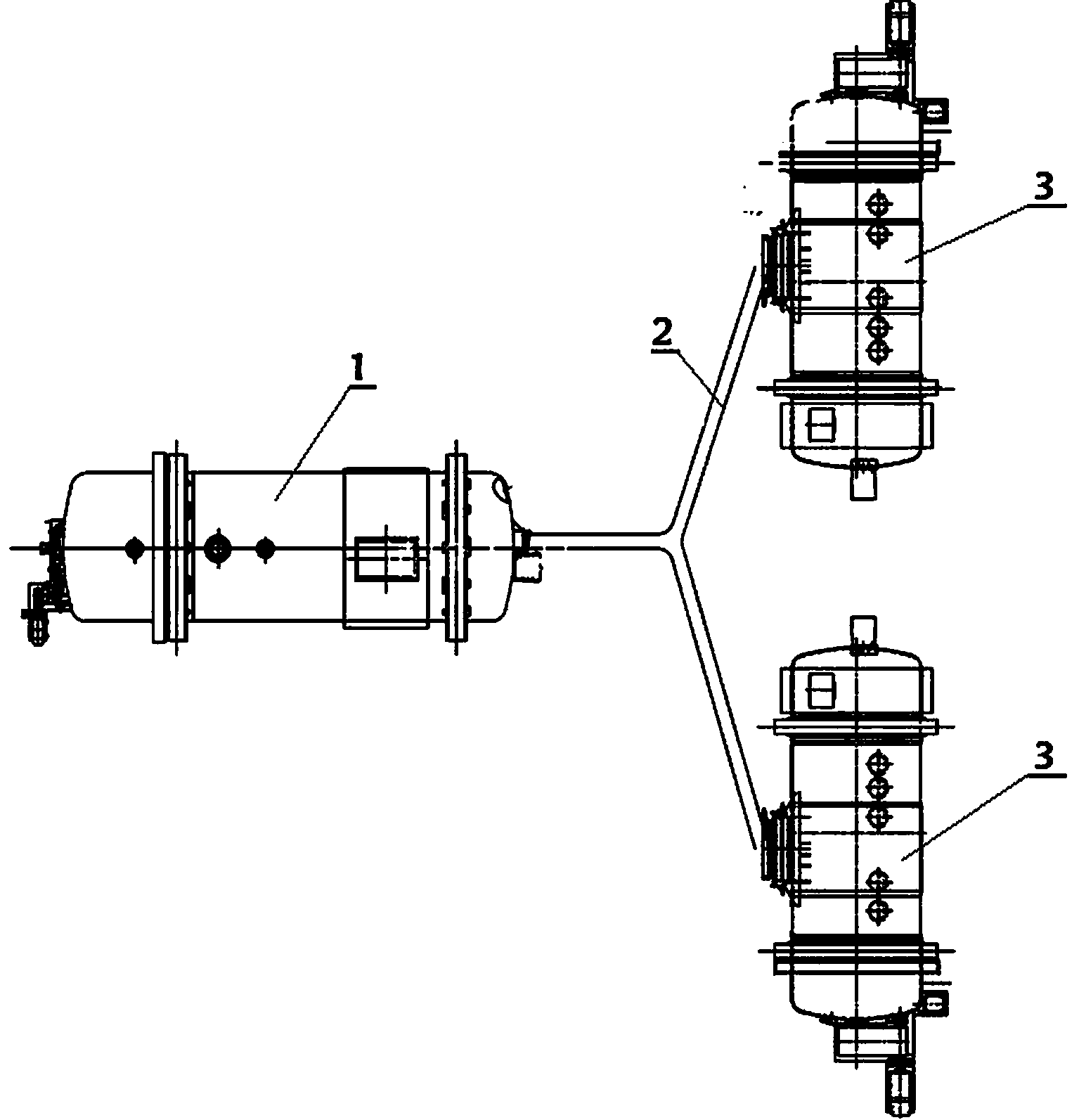

Reclaimed copper smelting process and device

ActiveCN103382529AIncrease production intensityImprove efficiencyProcess efficiency improvementShort cycleSmelting process

The invention provides a reclaimed copper smelting process and a device. The process device is composed of a smelting furnace and two parallelly arranged redox furnaces, which are in connection with two branch chutes through a main chute. The three furnaces are arranged in the shape of the Chinese character ''pin''. A furnace body consists of a feed inlet, a flue gas outlet, a copper matte outlet, a slag notch, a side wall jack on a furnace body lateral part and a spray gun jack at the furnace body bottom. The slag notch is located at the furnace body end face, the copper outlet is located on the furnace body end face at the slag notch end or the lower part of the furnace body. The furnace body is cylindrical and rotatable. The furnace body has a round cross section and its radial dimension is consistent in the axial direction of the furnace body. The spray gun is in a casing pipe form, and is inserted into the spray gun jack so as to spray oxygen and natural gas into the furnace at the same time. The included angle alpha between the opening direction of the spray gun and the vertical direction is greater than or equal to -65 degrees and smaller than or equal to +65 degrees. The process and the device involved in the invention have the advantages of high production intensity, high efficiency, short cycle, energy saving and environmental protection, and good economic benefits.

Owner:DONGYING FANGYUAN NONFERROUS METALS +1

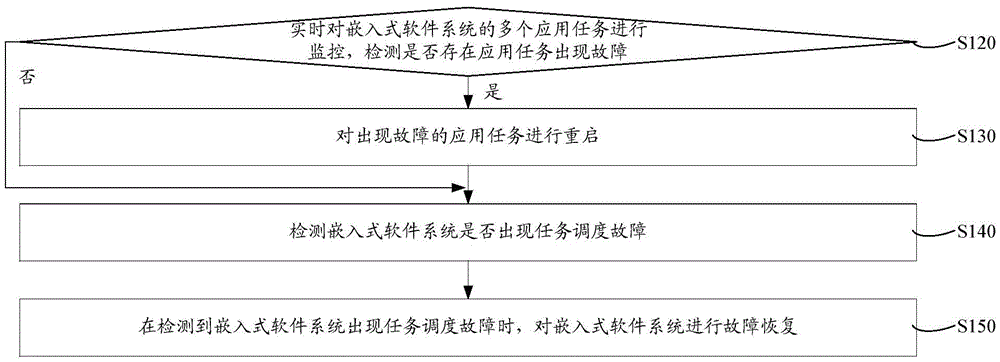

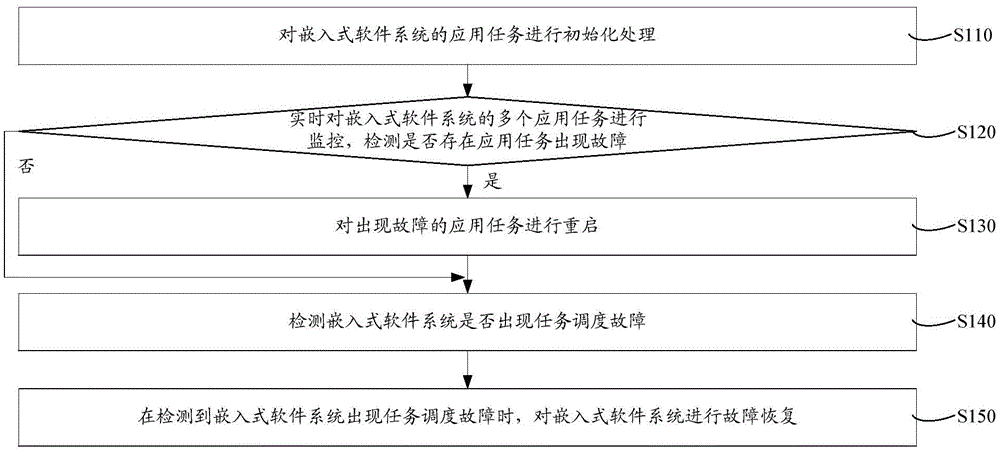

Embedded software system fault detecting and recovering method and system

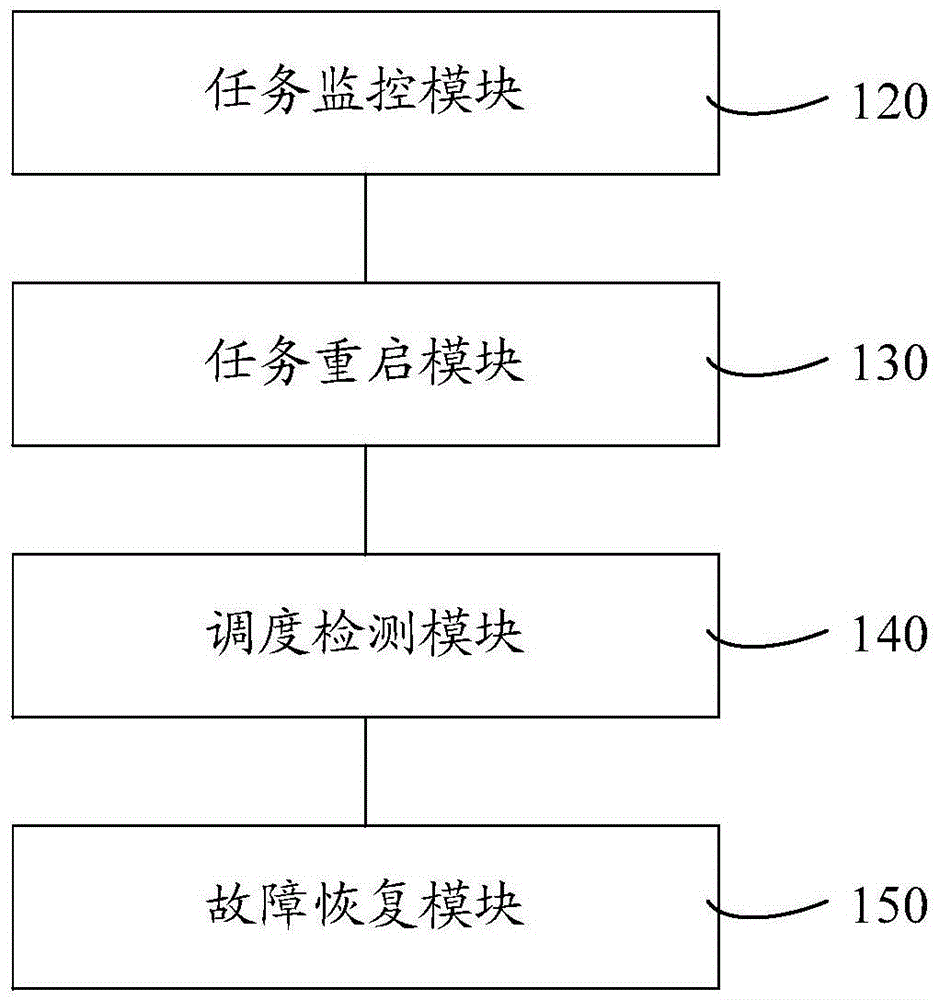

The invention relates to an embedded software system fault detecting and recovering method and system. Multiple application tasks of the embedded software system are monitored in real time; whether the application tasks generate faults is detected; the application tasks generating the faults are restarted. Whether the embedded software system generates a task scheduling fault is detected; when detecting that the embedded software system generates the task scheduling fault, fault recovery is carried out to the embedded software system. In adoption of the method and the system, the partial software faults and integrated software system faults in the multi-task system can be detected in real time; the software system is automatically recovered to the normal operation state when the software system generates the faults; selective software fault detection and recovery is realized; and the detection range is more comprehensive without a dead angle; and the detection is simple and reliable.

Owner:HNAC TECH

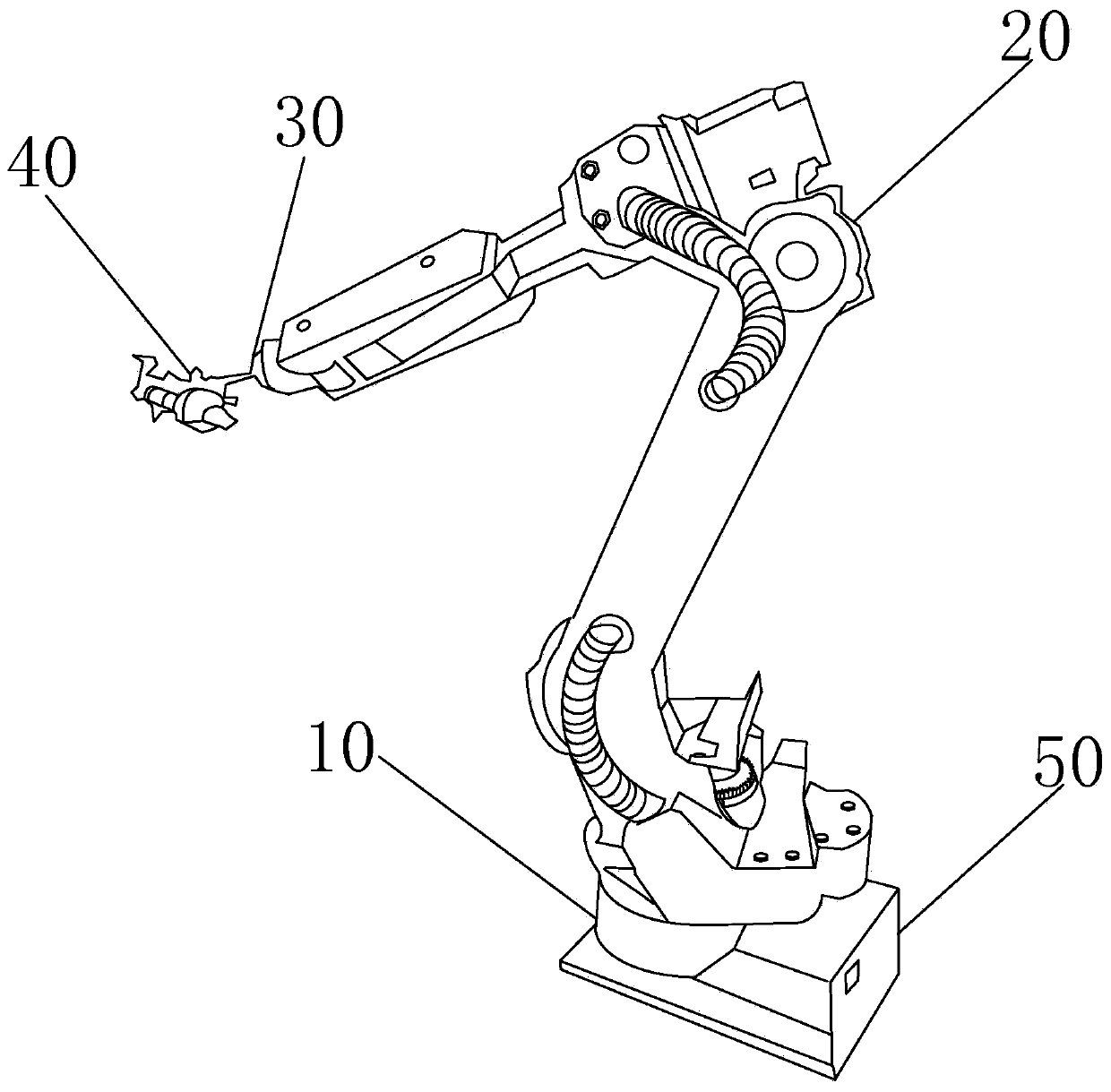

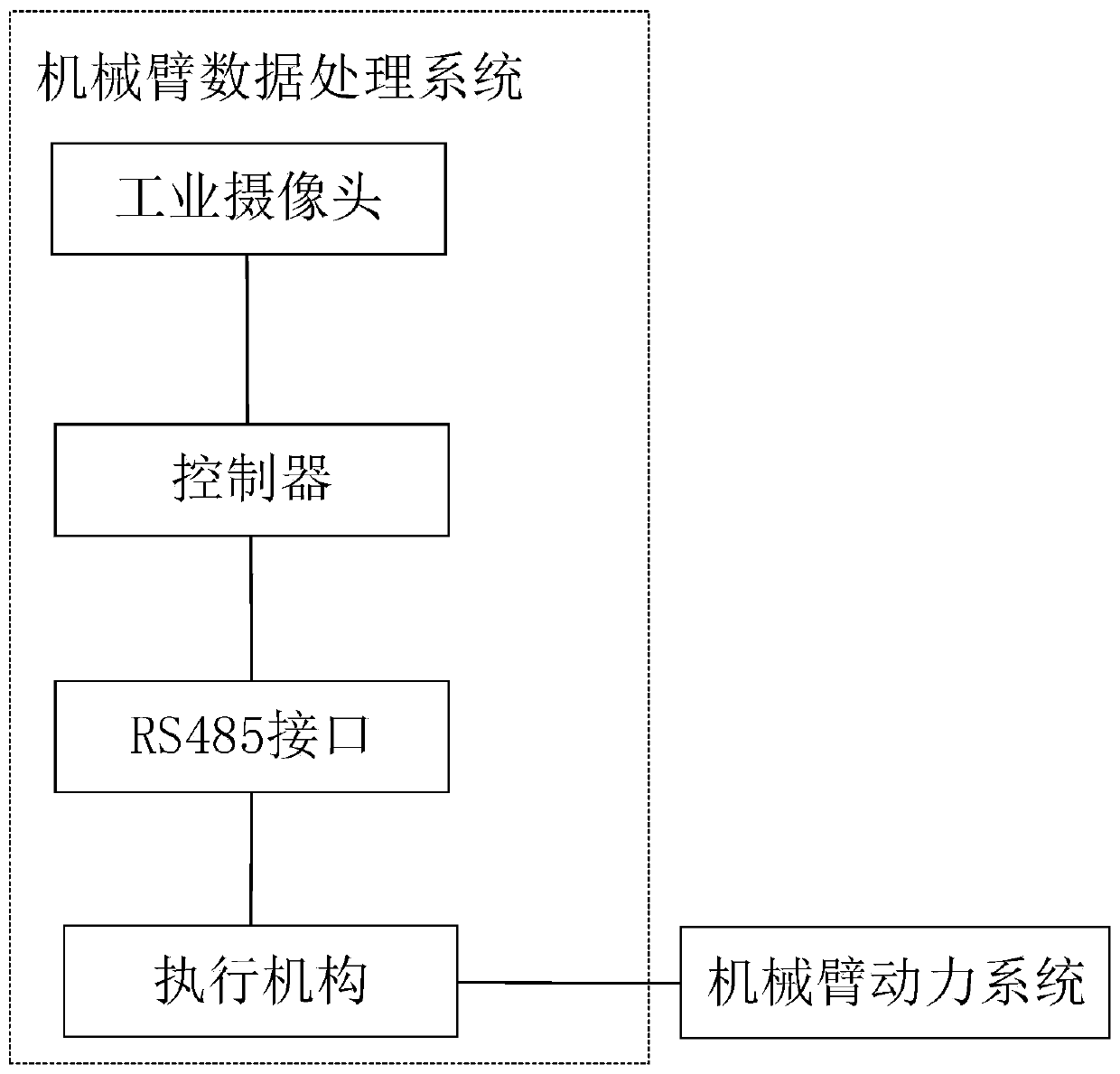

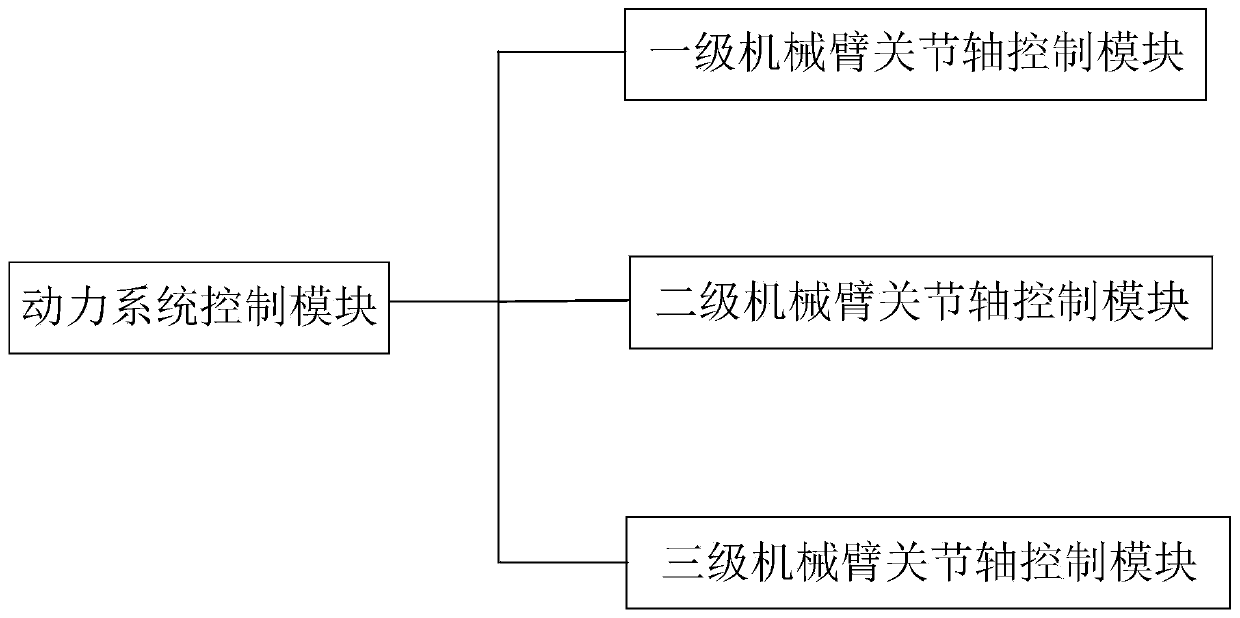

Mechanical arm control system achieving positioning through vision

PendingCN111360818ASolve the problem of targetingImprove interactivityProgramme-controlled manipulatorData processing systemControl signal

A mechanical arm control system achieving positioning through vision comprises a mechanical arm data processing system and a mechanical arm power system. An industrial camera generates an image by capturing work environment video, and an executing mechanism recognizes data in the image for a processing module. According to the processing module, the distance measuring algorithm and the four-element algorithm are adopted for positioning a bearing of a target control mechanical arm, the mechanical arm is controlled to achieve the high-precision operation task, and control signals are generated to control the mechanical arm to move. Through the above manner, traditional mechanical arm single operation and poor work environment interaction are avoided, and the problem about difficult mechanical arm positioning is solved.

Owner:上海锵玫人工智能科技有限公司

Multi-angle spraying cart

InactiveCN104285932ADirection adjustableThe spraying angle is variableInsect catchers and killersAgricultural engineeringPower unit

The invention discloses a multi-angle spraying cart. The multi-angle spraying cart comprises a frame, a power unit, a walking device and a spraying device. The frame comprises a front end installing frame, a main beam and a rear end installing frame, the rear end installing frame comprises frame vertical beams, sliding grooves and a frame beam, the lower ends of the frame vertical beams are connected to the rear end of the main beam, the frame beam is connected to the upper ends of the frame vertical beams, and the sliding grooves are formed in the rear sides of the frame vertical beams; the power unit is arranged above the front end installing frame, the walking device is arranged below the frame, and the spraying device is arranged at the rear end of the rear end installing frame. The position of a spraying frame can be adjusted according to needs, the spraying angle is varied, a spraying rod can be retracted and convenient to move, each nozzle is a fan-shaped five-opening nozzle, the spraying range is wide, the direction of the nozzles can be adjusted, mist spray is even, no dead angle exists, the multi-angle spraying cart is driven to walk in a hydraulically driving mode, walking speed is easy to control, and therefore the spray amount can be controlled more effectively.

Owner:ANHUI JIULI MACHINERY EQUIP

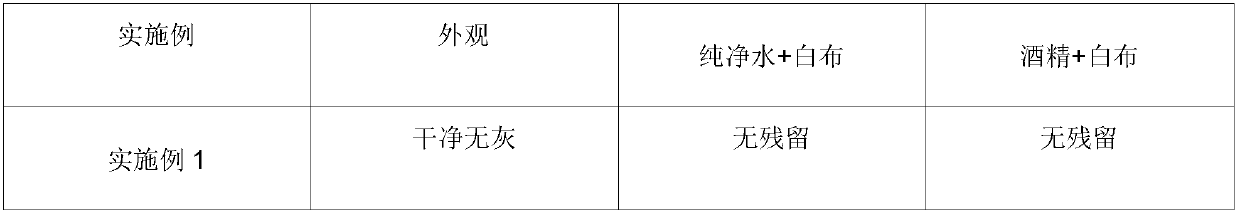

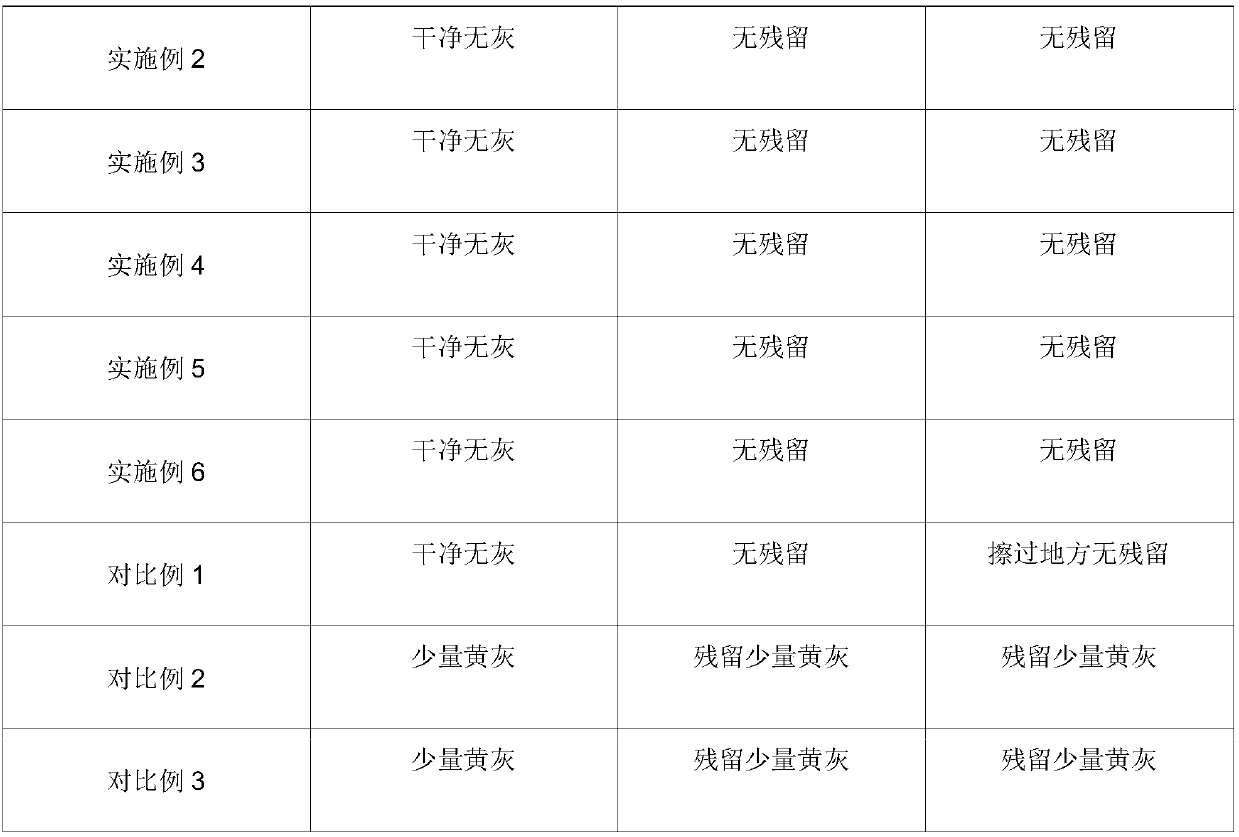

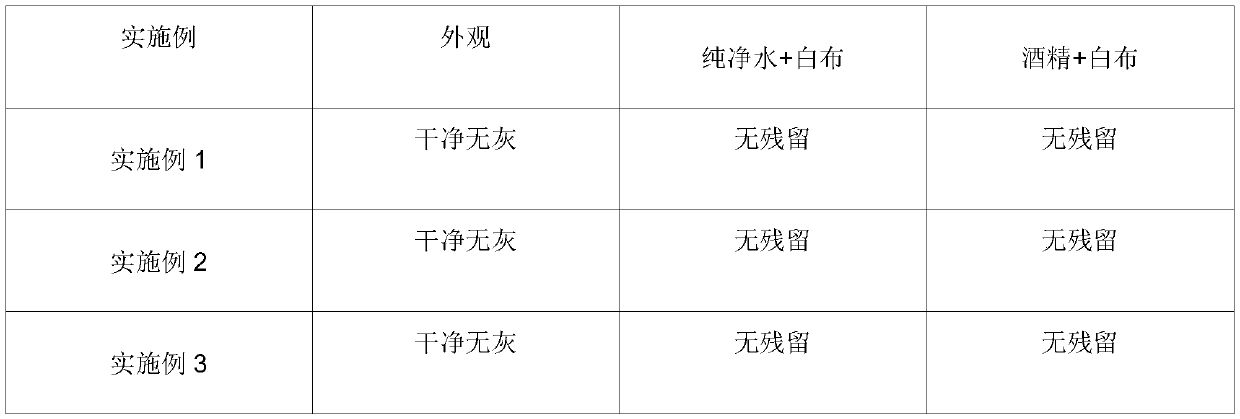

Ash removing agent for neutralization treatment of aluminum alloy and preparation method thereof

The invention relates to an ash removing agent for neutralization treatment of aluminum alloy and a preparation method thereof. The ash removing agent is applied to the neutralization treatment afterthe pretreatment of the aluminum alloy and comprises the following components according to parts by weight: 50-200 parts of sulfuric acid, 2-100 parts of hexavalent iron salt, 5-50 parts of ferric iron salt, 10-50 parts of hydrogen peroxide and 5-50 parts of corrosion inhibitor. The ash removing agent for the neutralization treatment of the aluminum alloy is used for removing ash in the neutralization treatment process after the pretreatment of the aluminum alloy, has little corrosion to the aluminum alloy, does not affect the glossiness of an aluminum alloy substrate, has a good ash removal treatment effect and fast ash removal speed, and is low in cost and environmentally-friendly without dead angles and residues; the ash removing agent does not generate toxic and harmful gases in the ash removal process, is environmentally-friendly, has no threat to the health of operators, and solves the problems that as ash cannot be removed completely by a traditional process, the ash can only bewiped by a wet towel after the follow-up anodic oxidation sealing and is difficult to completely wipe. The preparation technology of the ash removing agent is simple, high-efficiency, energy-saving and environmentally-friendly.

Owner:广东双成金属表面科技有限公司

Horizontal type stirring ball-milling reactor for intensifying bentonite modification

The invention discloses a horizontal type stirring ball-milling reactor for intensifying bentonite modification, and provides a ball mill which is uniform in material blending, has no stirring dead angle and controllable ball-milling temperature, can add materials at any time, and is high in ball-milling efficiency and used for intensifying bentonite modification. According to the invention, the main body structurally comprises a bracket, a stirring shaft mounted on the bracket, a stirring device mounted on the stirring shaft and composed of plough disc stirring blades and S-shaped stirring blades, and a ball-milling cylinder; the S-shaped stirring blades are mounted on the adjacent two groups of plough disc stirring blades; the stirring shaft is connected with a motor through a belt; the ball-milling cylinder comprises two layers of an outer cylinder and an inner cylinder; a cooling liquid flow leading channel is formed between the outer cylinder and the inner cylinder; the outer cylinder is provided with a coolant inlet pipe, a feed opening, a discharge opening and a coolant return pipe; the coolant inlet pipe and the coolant return pipe are respectively connected with a coolant inlet pipeline and a coolant return pipeline of a cooling system; milling balls are arranged in the ball-milling cylinder. The reactor can be used for polysaccharide superpolymer modification.

Owner:中国科技开发院广西分院 +2

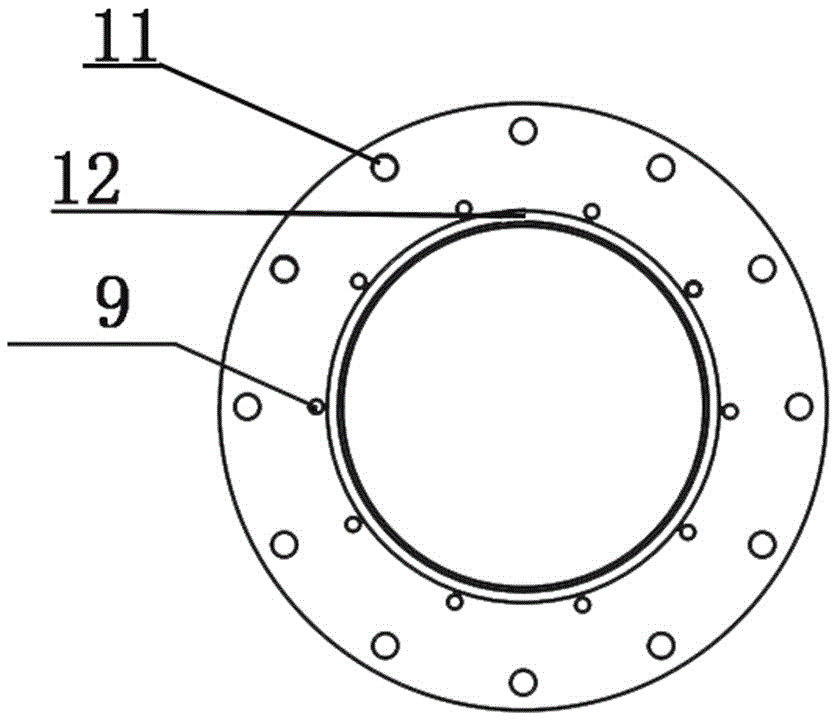

Fluid bed granulating drier

InactiveCN104014279ANo flyingSimple structureChemical industryGranulation by powder suspensionChemical industryGas compressor

The invention discloses a fluid bed granulating drier applied in various fields such as pharmacy, food, feeds, pigments and chemical industry. The fluid bed granulating drier comprises an adhesive tank, an air compressor and a fluid bed, wherein a hot air inlet is formed in the lower half part of the fluid bed and is connected with a heater; an air outlet of the fluid bed is connected with an exhaust fan via a pipeline; a filter is connected with the upper half part of the heater and is provided with an air inlet; filter cloth and a muffler are arranged at the air outlet of the fluid bed. The drier has a simple structure, is reasonable in design, completes the processes of mixing, granulating and drying in the same equipment, is quick in mass heat transfer, is operated at closed negative pressure, thus avoiding dust flying, is uniform in granules, does not have dead angles, is cleaned thoroughly, is free from cross pollution and is energy-saving and environment-friendly.

Owner:张家港市进润彩印包装有限公司

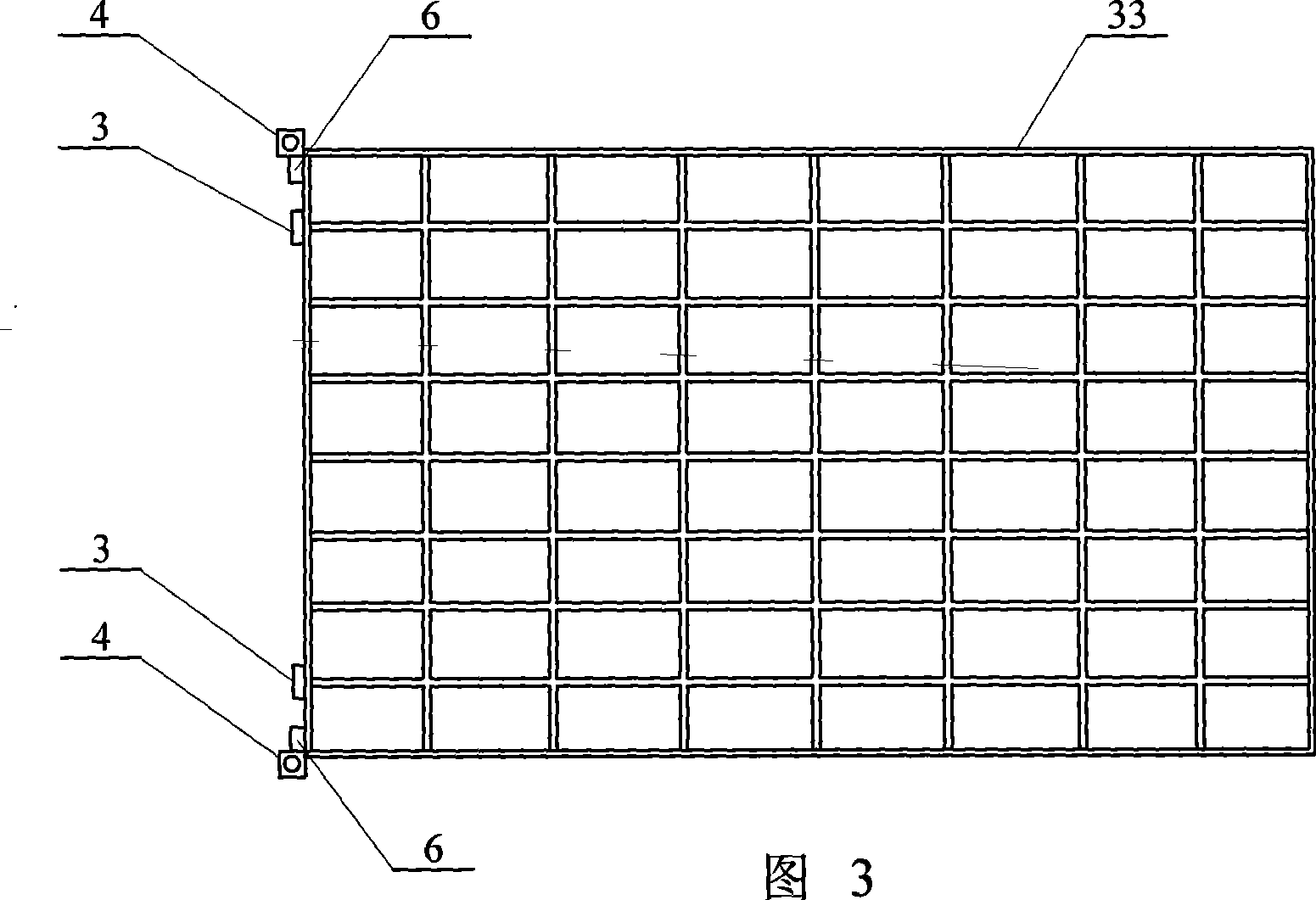

Granulating, fluidizing and drying system

InactiveCN102645088AImprove protectionStable fluidizationDrying solid materials with heatMaterial granulationEngineeringCrusher

A granulating, fluidizing and drying system is provided with a vibration fluidizing machine, a granulating machine, a cyclone separator, a water film dust remover, a crusher, a heating device and a cooling device. A ventilation area on a bed plate of the vibration fluidizing machine is formed by connecting round unit ventilation areas which are arranged in a line. A screening device is arranged at the tail end of the bed plate, air holes at the middle square positions of the unit ventilation areas on the bed plate are straight holes, and air holes on four bow-shaped parts of the unit ventilation areas on the bed plate are scale holes. The air outlet direction of the scale holes on two bow-shaped parts on the front part in each unit ventilation area is towards a box wall, and the air outlet direction of the scale holes on two bow-shaped parts on the rear part in each unit ventilation area is towards the connection position of two unit ventilation areas. Air inlet tubes corresponding to the unit ventilation areas one by one are arranged in an air chamber. The granulating, fluidizing and drying system can integrally achieve granulation, drying, cooling and screening, has high efficiency, treats exhausted tail gas, and is favorable for environment protection. By means of a special shape of the bed plate and the distribution of the air holes, fluidization of the vibration fluidizing machine is stable and free of dead corners.

Owner:CHANGZHOU LEMAR DRYING ENG

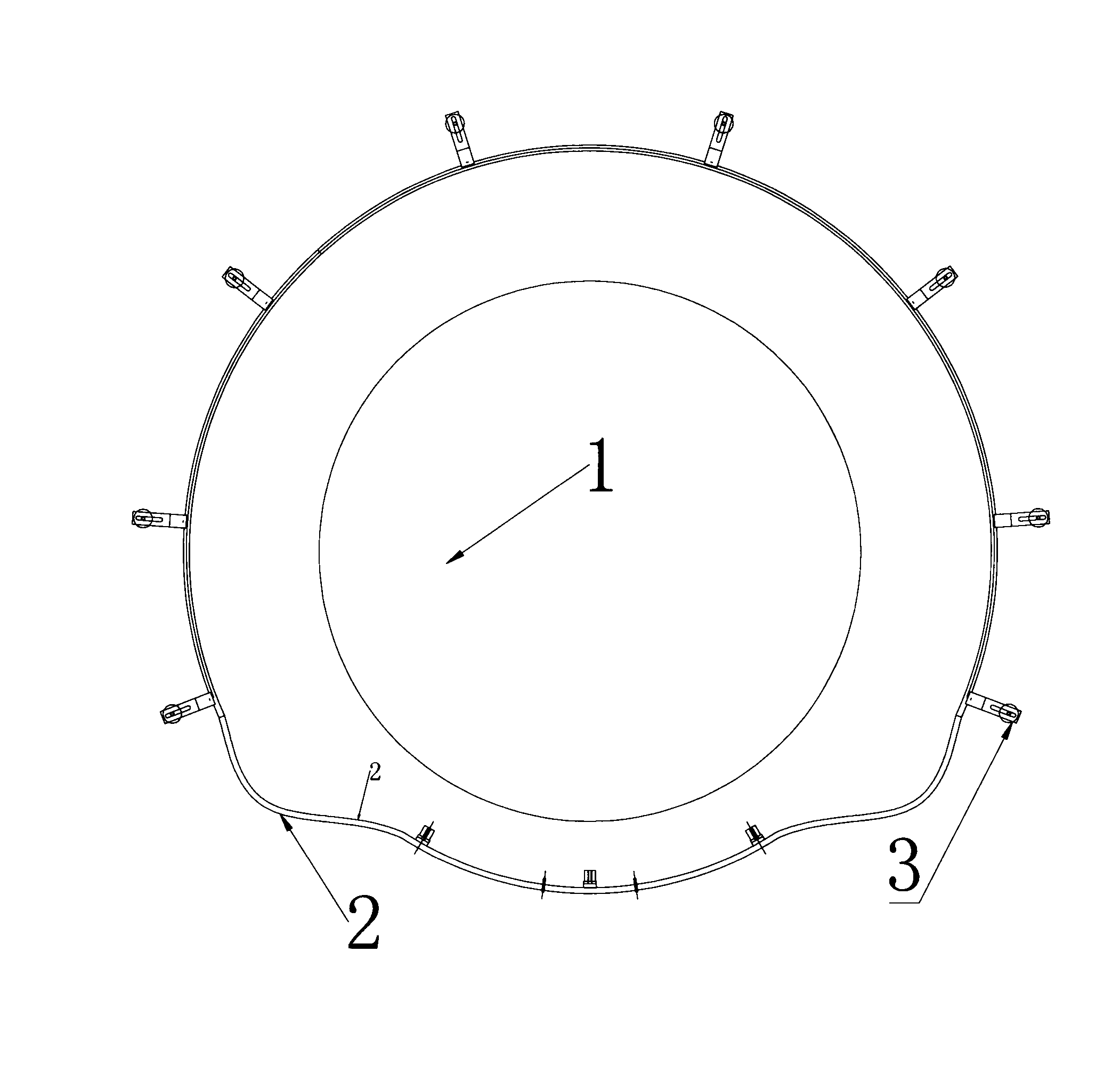

Bottle washing device capable of shaking bottle body

The invention discloses a bottle washing device capable of shaking a bottle body. The bottle washing device comprises a bottle washing water distributing device. A bottle rotating guide track is arranged on the periphery of the bottle washing water distributing device and is fixed through a plurality of columns. The bottle washing water distributing device comprises a movable rotary plate, a bottle clamping device and a nozzle are arranged at the end of the movable rotary plate, the bottle clamping device is hinged to the movable rotary plate, a guide rod is arranged on the bottle clamping device, and the guide rod clamps the bottle rotating guide track. The bottle rotating guide track is provided with a wave-shaped track. The bottle washing device capable of shaking the bottle body can wash the inside of the bottle body in all the directions, and dead spaces do not exist.

Owner:常熟市喆宏机械科技有限公司

Pulse type airflow mixer

InactiveCN105879763AFast mixing and homogenizationImprove fill factorTransportation and packagingMixersEngineeringButterfly valve

The invention relates to a pulse type airflow mixer. The pulse type airflow mixer comprises a powder particle feed port, a pulse bin top dust remover and a mixture bin. The powder particle feed port is formed in the top of the mixture bin, the pulse bin top dust remover is arranged beside the powder particle feed port, the bottom of the mixture bin is set in a conical shape, airflow mixing head nozzles are connected to the bottom of the mixture bin in a circle and connected with high-pressure air pipes, the high-pressure air pipes are communicated with an annular air bag through electromagnetic valves, and a butterfly valve is arranged at the bottom of the mixture bin. The mixing and homogenizing speed is high, products are not broken, high efficiency and energy saving are achieved, and the mixing and homogenizing value is high.

Owner:刘毅

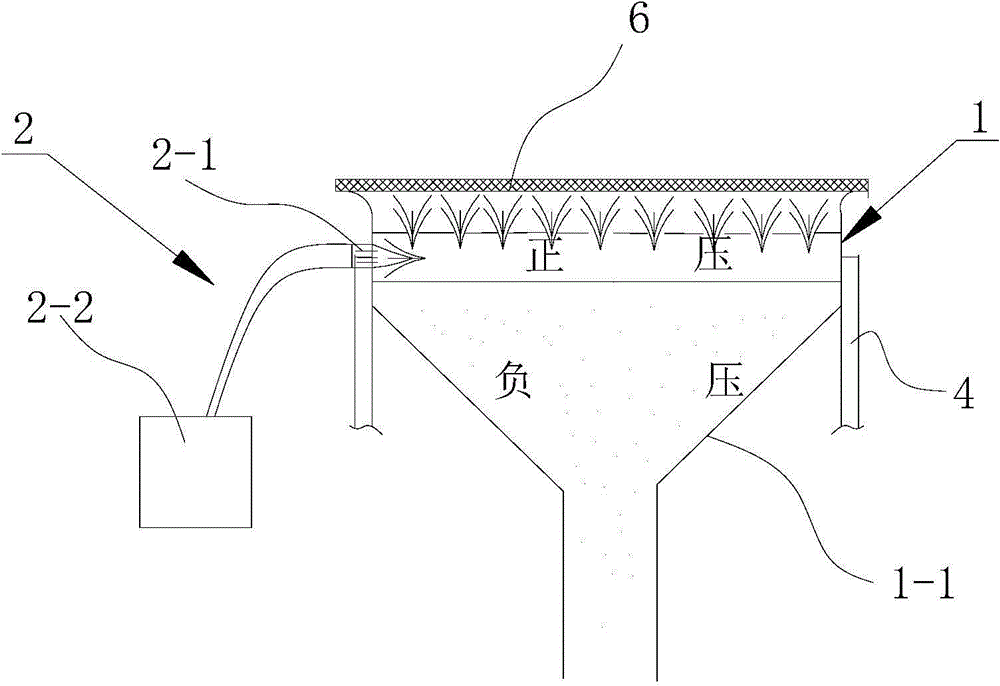

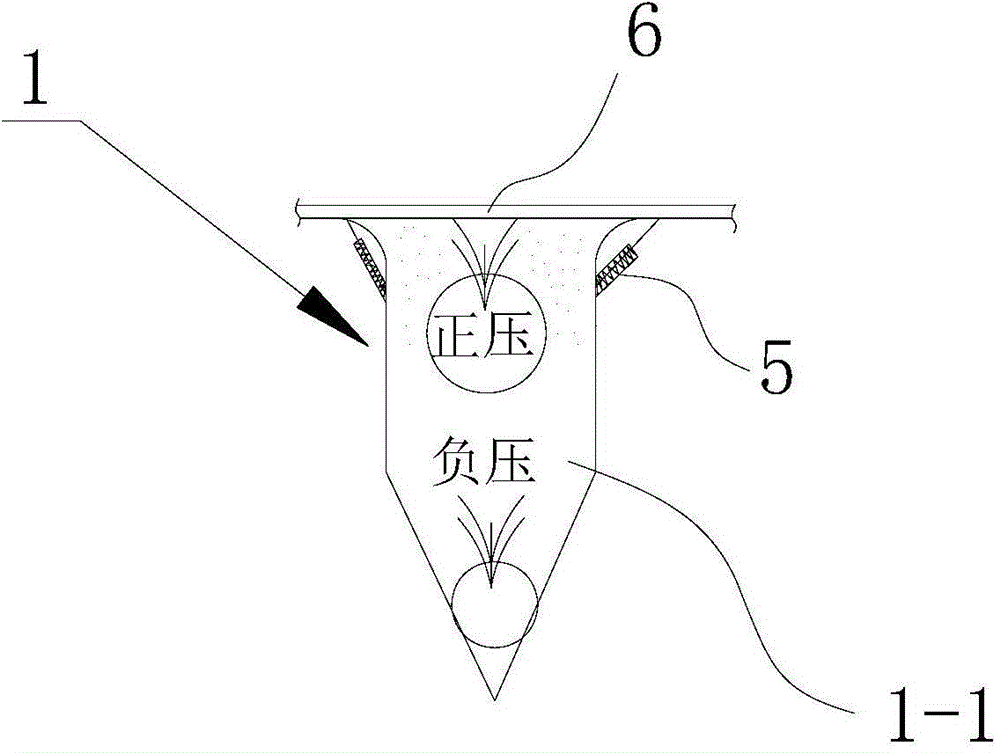

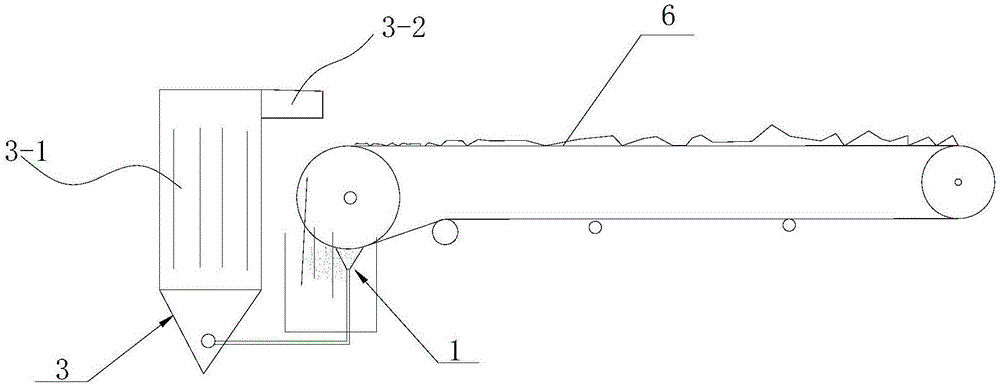

Dust cleaning device for belt conveyor belt surface

The invention relates to a dust cleaning device for a belt conveyor belt surface. The dust cleaning device is characterized by mainly comprising a dust collection hood, a dust blowing device and a negative pressure dust collection device, wherein the dust collection hood is installed below a conveyor belt at the discharge end of a belt conveyor, spring telescopic rods are installed between the dust collection hood and a supporting part, the upper end of the dust collection hood is connected with the dust blowing device in the direction of the cross section of the belt, a conical dust collection chamber is arranged at the lower end of the dust collection hood, the dust collection chamber is connected with the negative pressure dust collection device, and the amount of negative pressure of the negative pressure dust collection device is larger than the discharge of compressed air of the dust blowing device. Positive pressure is provided by the compressed air to blow off dust adhering to the belt or a part in a belt crack, dust is then absorbed through the negative pressure, accordingly, air under positive pressure and negative pressure is adopted as power to blow the dust away from the belt, the dust is blown off more thoroughly, and no dead angle is left during dust blowing; meanwhile, the spring telescopic rods can maintain good sealing performance between the dust collection hood and the belt, so that the dust collection effect is guaranteed.

Owner:TIANJIN ZHENXING CEMENT

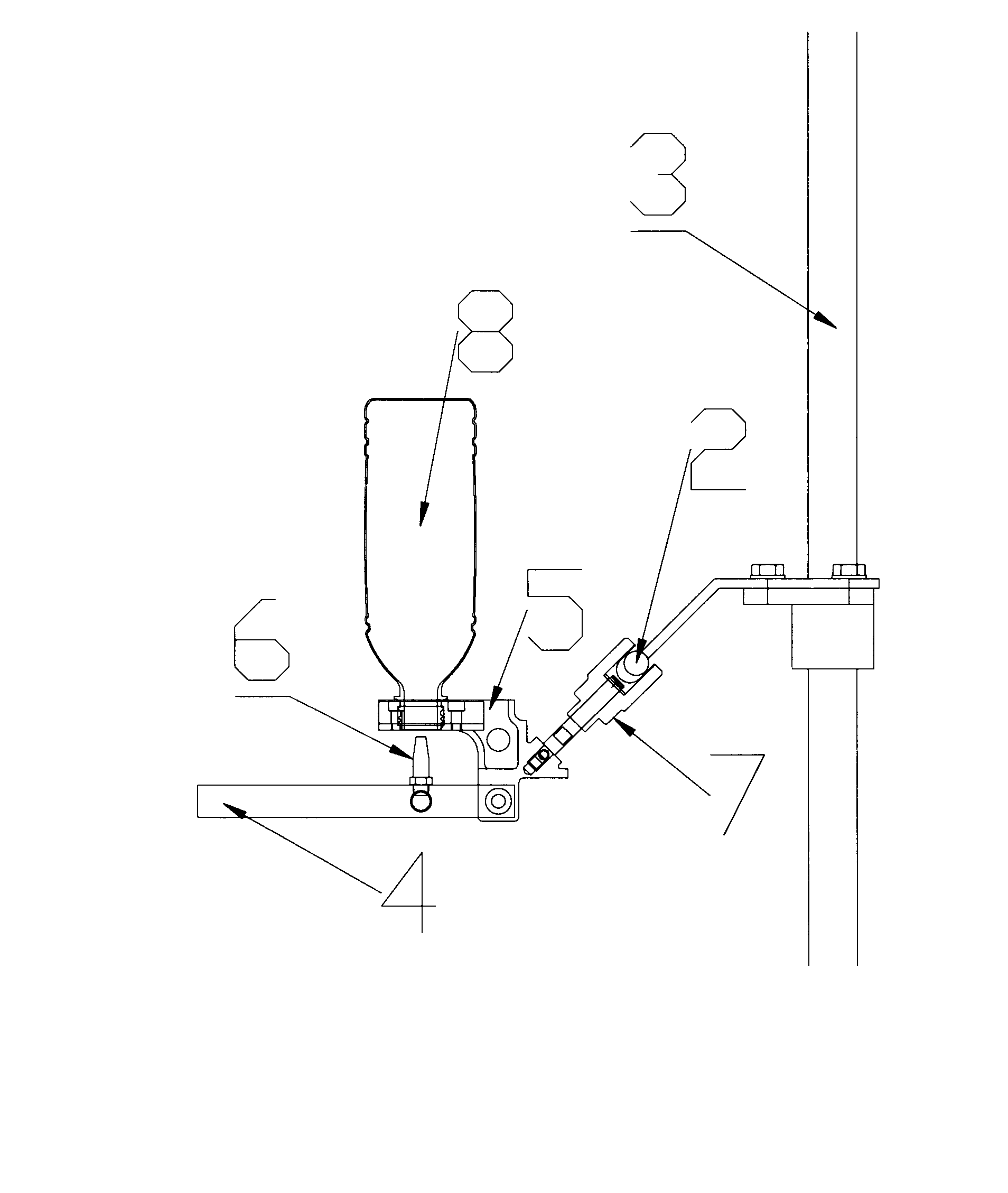

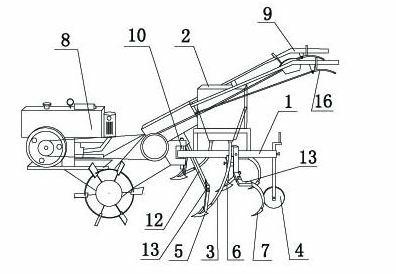

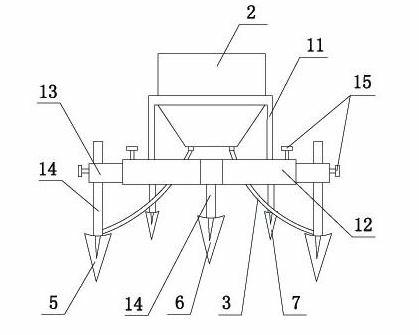

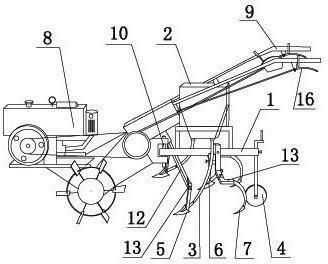

Small intertillage fertilizer applicator

InactiveCN102612879ACompact structureSimple structureSpadesPloughsAgricultural engineeringAgricultural machinery

The invention relates to a small intertillage fertilizer applicator, belonging to the technical field of agricultural machinery. The small intertillage fertilizer applicator comprises a cultivator and an intertillage fertilizer applicator at the back end, wherein the intertillage fertilizer applicator comprises a frame, a fertilizer hopper, a depth roller, fertilizer application coulters, a ditching knife and intertillage coulters, wherein the frame is provided with the fertilizer hopper through a hopper seat, a beam at the front end of the frame is symmetrically provided with the fertilizer application coulters through a transverse sleeve and a vertical sleeve, the depth roller is arranged on the back end of the frame, the ditching knife is arranged between the fertilizer application coulter and the depth roller, and the intertillage coulters are arranged on the both sides of the ditching knife through the transverse sleeve. The small intertillage fertilizer applicator has the advantages of being compact in structure and high in working efficiency, relieving the labor intensity of the operating personnel, and avoiding the problems of large labor intensity and low working efficiency caused by manual work because the conventional large and medium-type intertillage fertilizer applicators are unsuitable for the intertillage fertilizer application work of the farmland with the smaller area. According to the small intertillage fertilizer applicator, dead angles cannot be generated in the farmland at work so as to provide convenience for users.

Owner:HUBEI HONGFA AGRI MACHINERY MFGCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com