Packaging stage-type film bioreactor device for treating sewage or micro-polluted raw water

A membrane bioreactor and micro-pollution technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., to achieve the effect of saving floor space and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

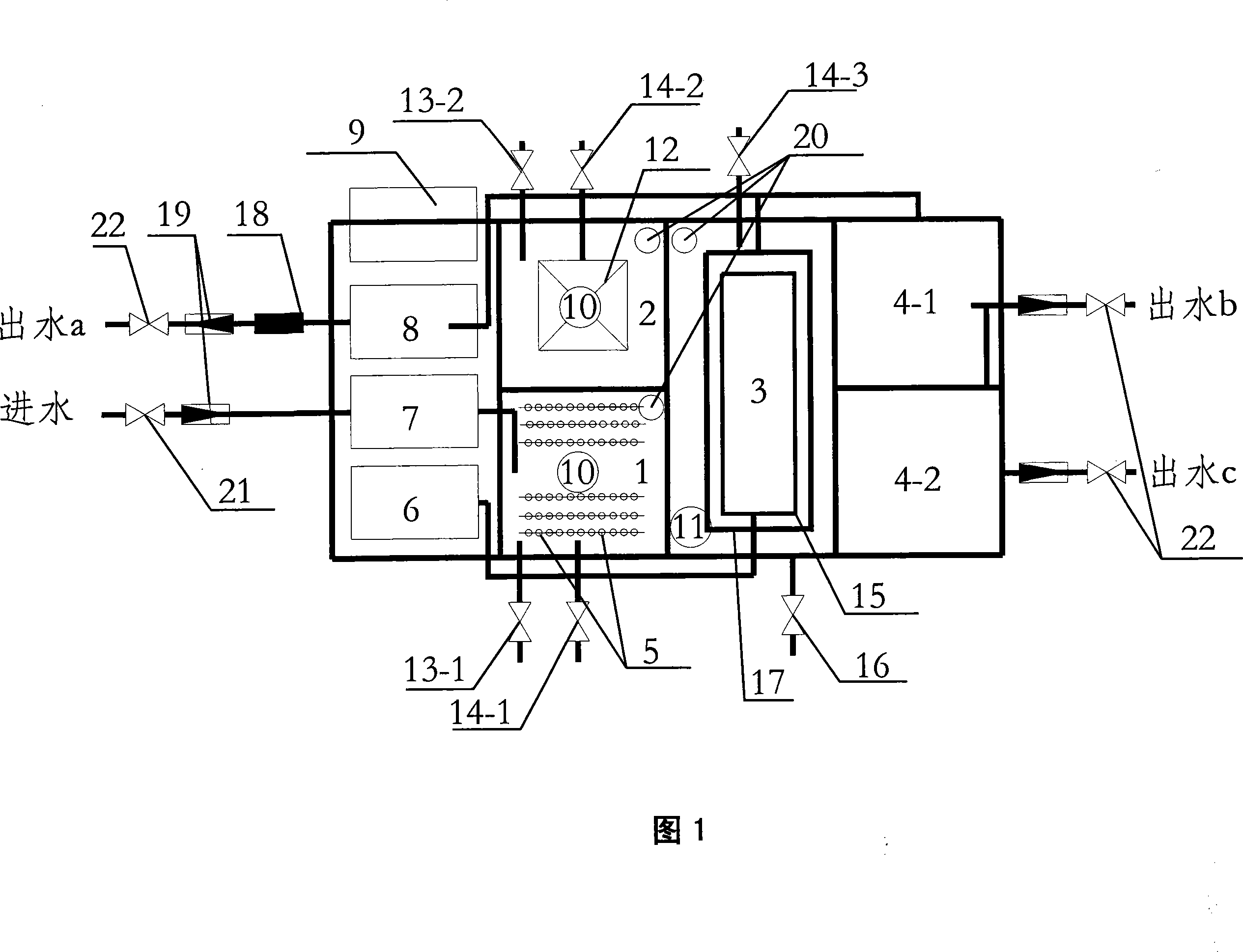

[0048] The container-type staged membrane bioreactor device is in the structure of a container body, which is sequentially composed of a semi-reaction zone 1, anaerobic reaction zone 2, aeration reaction zone 3, pure water zone 4-1, and pure water zone 4-2 (the other The structure is shown in Figure 1), except that the reaction zones are separated by partitions, and the pure water zone is not connected to the bottom of the anaerobic zone, but the semi-reaction zone is connected to the bottom of the aeration zone, which separates and defines each functional zone. effect.

[0049] The water inlet system is composed of filler 5, water inlet pump 7, mixer 10, vent valve 14-1, flow meter 19 and water inlet valve 21. The water inlet is sucked by the water inlet pump 7 located on the side of the half-reaction area to the half-reaction area 1; the water inlet valve 21 is connected to the water inlet pump 7 through the flow meter 19 to control the flow rate; the filler 5 is located in ...

Embodiment 2

[0058] The container-type staged membrane bioreactor device is in the structure of a container body, which is composed of a semi-reaction zone 1, anaerobic reaction zone 2, and aerated reaction zone 3 in sequence (the structure is shown in Figure 1). The separator is separated, and the half reaction zone is connected with the bottom of the aeration zone.

[0059] The water inlet system is composed of filler 5, water inlet pump 7, mixer 10, vent valve 14-1, flow meter 19 and water inlet valve 21. The water inlet is sucked by the water inlet pump 7 located on the side of the half-reaction area to the half-reaction area 1; the water inlet valve 21 is connected to the water inlet pump 7 through the flow meter 19 to control the flow rate; the filler 5 is located in the semi-reaction zone 1, with a ring arrangement as the main body, and is mainly used to strengthen the denitrification and hydrolysis functions of the semi-reaction zone The mixer 10 is located at the top of the semi-r...

Embodiment 3

[0068] The container-type staged membrane bioreactor device is a container body structure, which is composed of a flocculation tank 1, a sedimentation tank 2, a reaction tank 3, a pure water area 4-1, and a pure water area 4-2 (the structure is shown in Figure 1 Shown), each reaction area is separated by a partition, the pure water area is not connected to the bottom of other areas, and it has the function of separating and defining each functional area.

[0069] The water inlet system is composed of water inlet pump 7, mixer 10, dosing port 13-1, vent valve 14-1, flow meter 19 and water inlet valve 21. In the flocculation tank 1; the water inlet valve 21 is connected to the water inlet pump 7 through the flow meter 19 to control the flow rate; at the same time, the dosing port 13-1 is enabled to add the flocculation agent, and the mixer 10 is located at the top of the half reaction zone 1 to promote the flow of the agent. Dissolving and flocculation net capture; if maintenanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com