Whole bin whole-base ventilation low-speed drying grain storage system

A slow-speed and drying technology, applied in the direction of drying and preserving seeds, drying gas arrangement, local agitation dryer, etc., can solve the problem of difficult storage of grain, achieve the goal of maintaining the original quality, improving utilization rate, and prolonging the drying season Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0063] Note that "upstream" and "downstream" in the present invention are defined according to the direction of air flow, and the direction of air flow is from upstream to downstream.

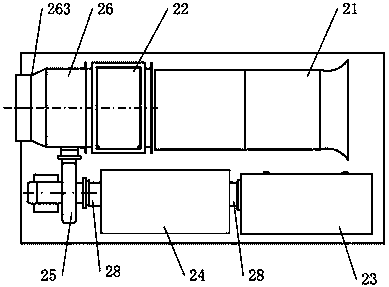

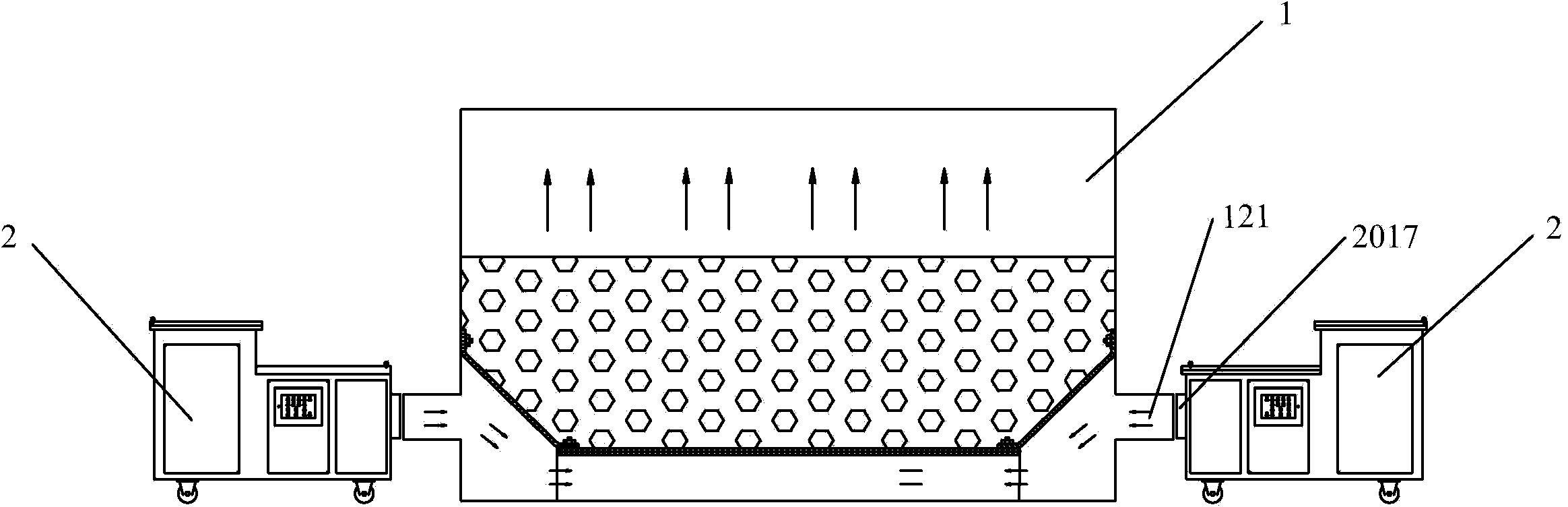

[0064] Such as figure 1 As shown, the full-bottom ventilated slow-speed drying grain storage system of the present invention includes a grain storehouse 1 and a grain storehouse processing equipment 2, and the grain storehouse 1 is a full-bottom ventilated grain storehouse. The air outlet 2017 of the grain storage processing equipment 2 is connected with the ventilation inlet 121 of the grain storage 1 .

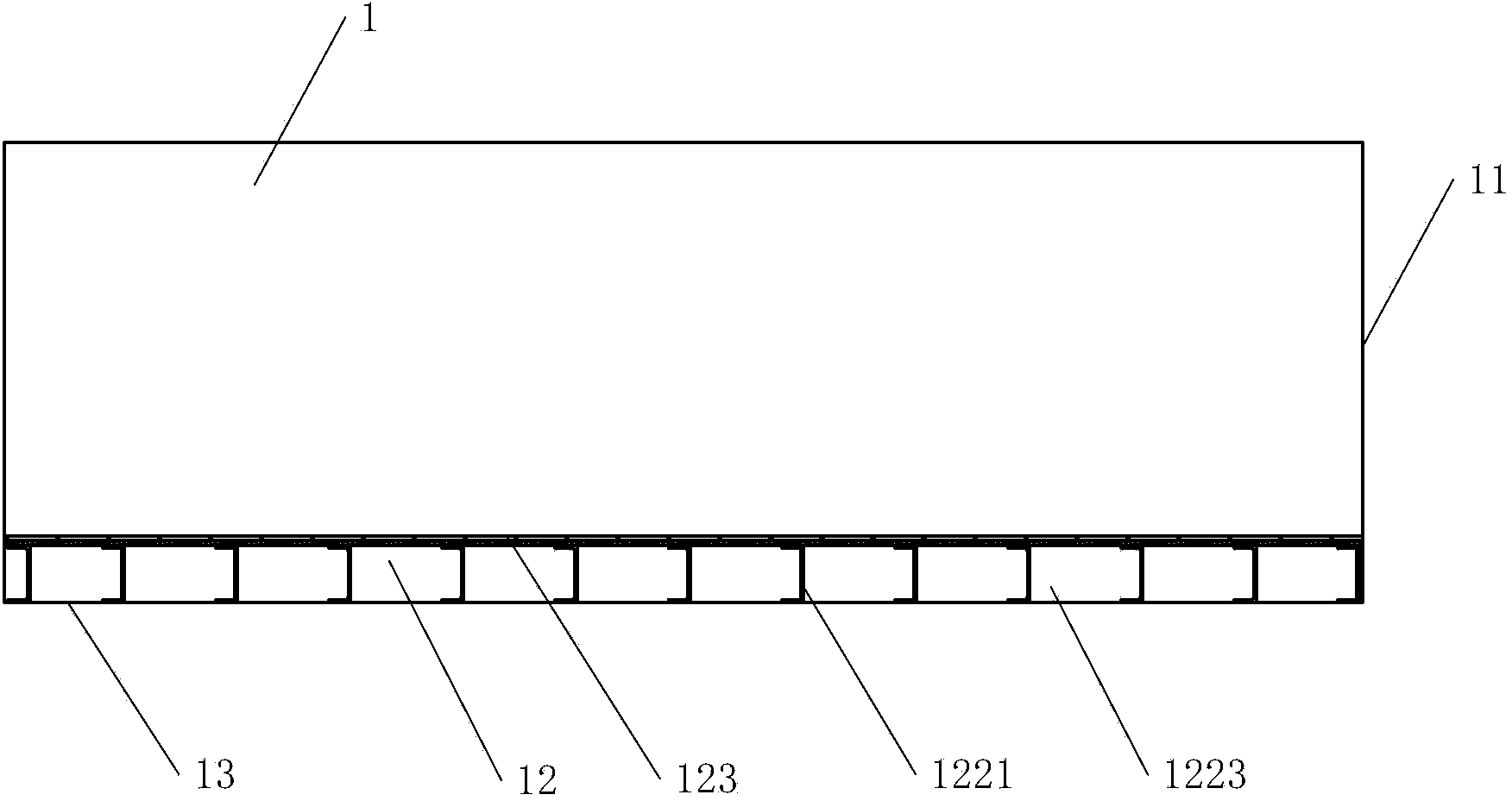

[0065] Such as Figure 2-Figure 6 As shown, the grain depot 1 includes an oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com