A kind of degradable film with antibacterial function and preparation method thereof

A degradable film and function technology, applied in the field of fresh-keeping film materials, can solve problems such as affecting commercial value, loss of juice, surface stickiness, mildew and discoloration, and achieve the effect of inhibiting harmful microorganisms, maintaining quality and commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

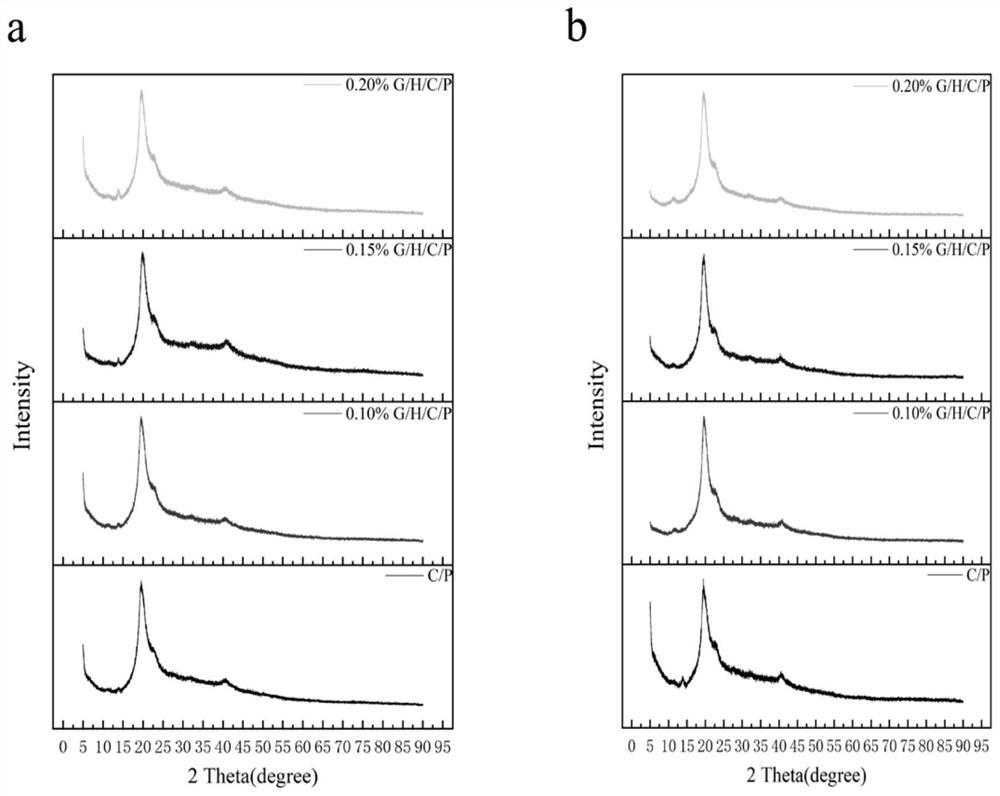

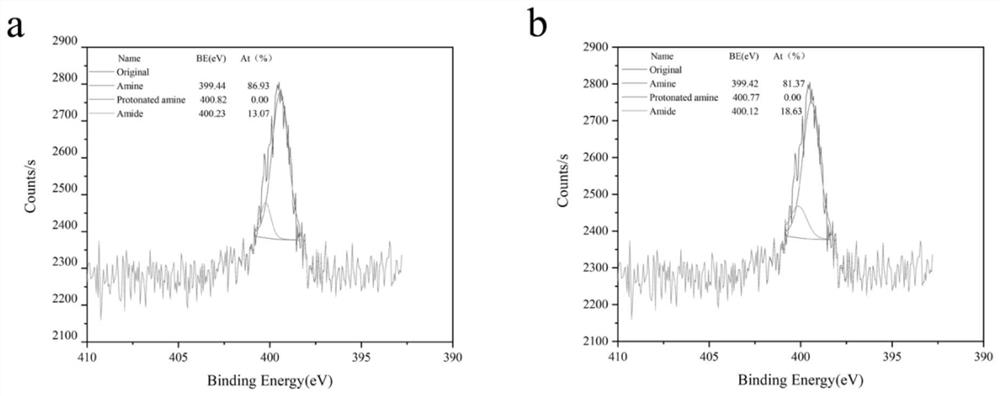

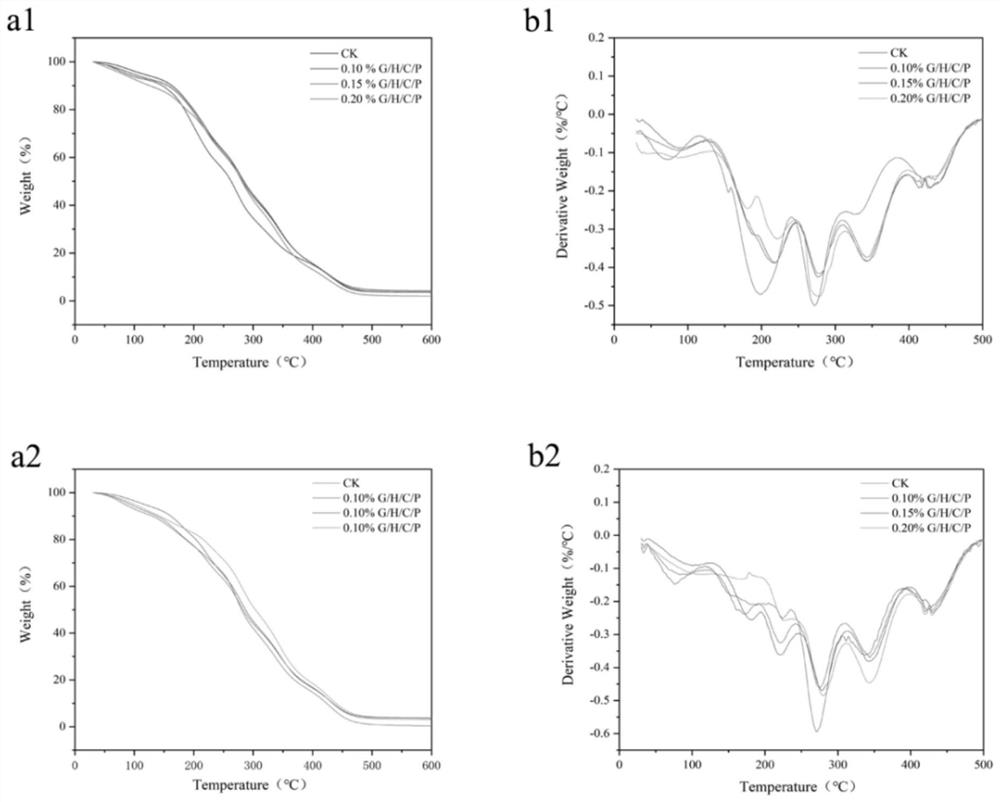

Embodiment 1

[0050] This example is used to illustrate the preparation method of the degradable film with antibacterial function according to the present invention.

[0051] Specific steps are as follows:

[0052] 1. Preparation of GML / HP-β-CD inclusion complex

[0053] S1: Dissolve 300mg of HP-β-CD in 30mL of distilled water and stir on a magnetic stirrer at 60°C and 400r / min until completely dissolved. Dissolve 57.75mg of GML in 8mL of ethanol, wait until it is completely dissolved, add it into HP-β-CD, then add 1mL of ethanol, the reaction temperature is 60°C, the stirring speed is 400r / min, and the inclusion time is 1h, until it becomes Completely transparent.

[0054] S2: Place the transparent sample liquid obtained in S1 on a rotary evaporator, depressurize, and evaporate the ethanol completely at 70-80°C. No foam will appear during the process, then raise the temperature to 80-90°C, and evaporate the sample completely. Dry and vacuum-dry to obtain the GML / / HP-β-CD inclusion compoun...

Embodiment 2

[0063] The difference between this example and Example 1 is that in the step of preparing the GML / HP-β-CD / CS / PVA film, the addition amount of the GML / HP-β-CD clathrate was changed to 0.15%.

Embodiment 3

[0065] The difference between this example and Example 1 is that in the step of preparing the GML / HP-β-CD / CS / PVA film, the addition amount of the GML / HP-β-CD clathrate was changed to 0.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com