Antibacterial bacteriostatic polysulfone hollow fiber ultrafiltration membrane and preparation method thereof

A technology of ultrafiltration membrane and polysulfone, applied in the field of preparation of ultrafiltration membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

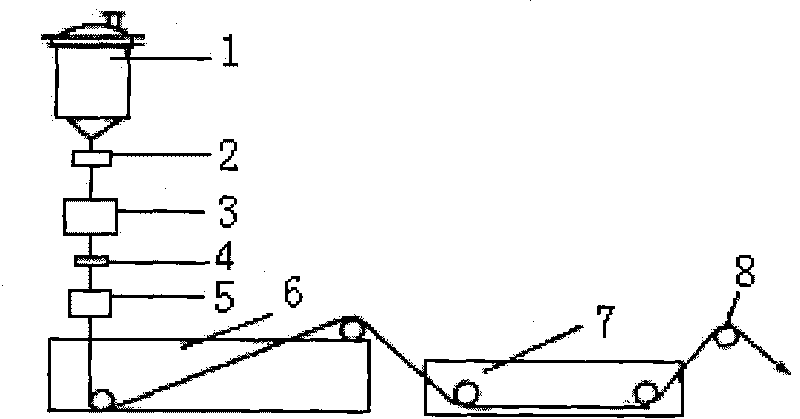

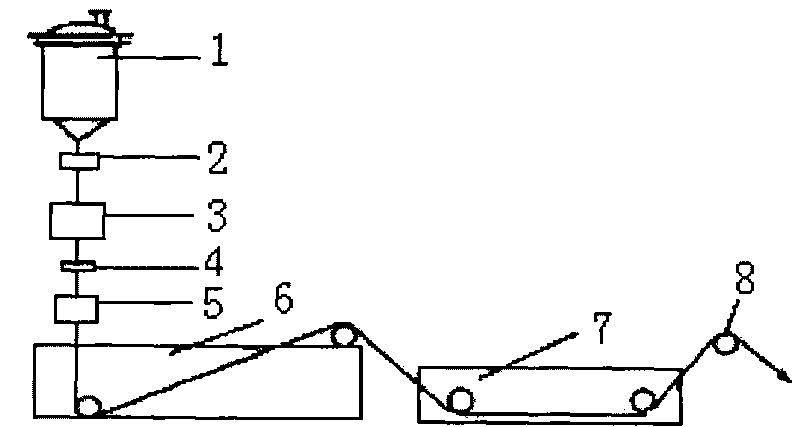

[0037] A preparation method of antibacterial and antibacterial polysulfone hollow fiber ultrafiltration membrane, such as figure 1 Shown, comprise the following steps (by weight):

[0038] (1) First select dry polysulfone (PS) material, if the material is not dry, dry it at 110°C for 2 hours, then dissolve 20 parts of dry polysulfone (PS) in spinning solution tank 1 Make a transparent polymer solution in 75 parts of dimethylacetamide (DMAC), add 0.2 parts of nanometer antibacterial material nano-silver and 5 parts of polyvinylpyrrolidone (PVP) and 5 parts of triethyl nitrate in the polymer solution, Stir at 45°C for 0.5h until it is evenly stirred to obtain a stable, uniform and transparent casting solution; the addition of nano-antibacterial material nano-silver increases the viscosity of the casting solution;

[0039] (2) Stand still for 24h in the spinning liquid material tank 1, defoaming, ripening;

[0040] (3) Extrude the above-mentioned matured material in the spinnin...

Embodiment 2

[0045] A preparation method of antibacterial and antibacterial polysulfone hollow fiber ultrafiltration membrane, such as figure 1 Shown, comprise the following steps (by weight):

[0046] (1) First select dry polysulfone (PS) material. If the material is not dry, it can be dried at 110-120°C for 2-4 hours, and then in spinning solution tank 1, 5-25 parts of dry polysulfone Polysulfone (PS) is dissolved in 65-90 parts of dimethylacetamide (DMAC) to make a transparent polymer solution, and 0.1 part of 1 titanium dioxide 1 and 110 parts of additive polyvinylpyrrolidone (PVP) are added to the polymer solution, Stir at 30°C for 0.5h until evenly stirred to obtain a stable, uniform and transparent casting solution; the addition of nano-antibacterial material titanium dioxide increases the viscosity of the casting solution;

[0047] (2) After the above-mentioned casting solution is stirred, it is left standing in the spinning solution tank 1 for 24h, defoaming and aging;

[0048] ...

Embodiment 3

[0053] A preparation method of antibacterial and antibacterial polysulfone hollow fiber ultrafiltration membrane, such as figure 1 Shown, comprise the following steps (by weight):

[0054] (1) First select dry polysulfone (PS) material. If the material is not dry, it can be dried at 120°C for 4 hours, and then in spinning solution tank 1, dissolve 25 parts of dry polysulfone (PS) Prepare a transparent polymer solution in 65 parts of dimethylacetamide (DMAC), add 5 parts of nano-zinc and 8 parts of triethyl nitrate to the polymer solution, and stir at 50°C for 1 hour until the stirring is uniform and stable , Uniform and transparent casting solution; the addition of nano-antibacterial material nano-zinc increases the viscosity of the casting solution;

[0055] (2) Stand still for 24h in the spinning liquid material tank 1, defoaming, ripening;

[0056] (3) Extrude the above-mentioned matured material in the spinning liquid material tank 1 at a pressure of 4 kg, filter through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com