Patents

Literature

79results about How to "Porosity change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

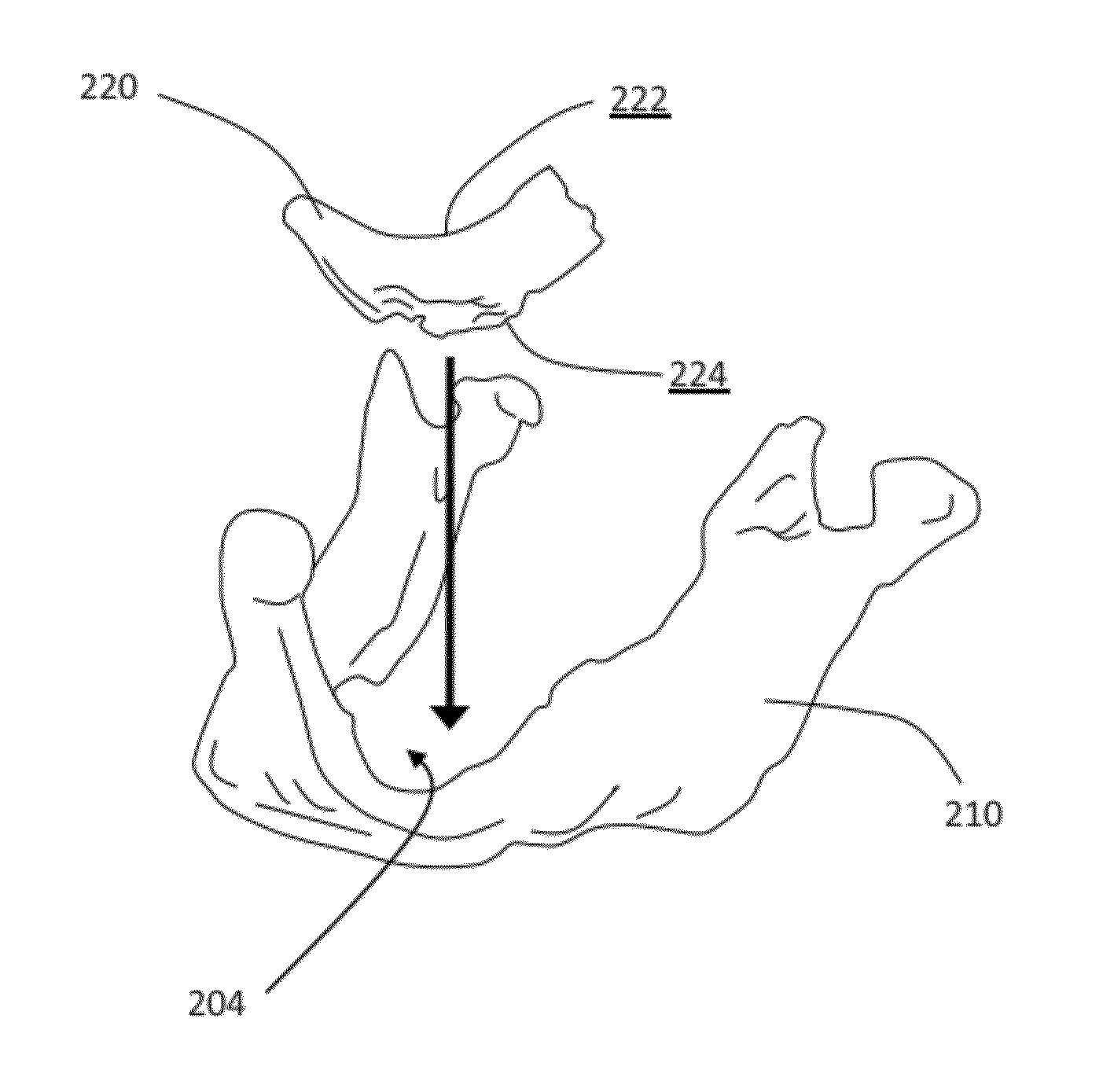

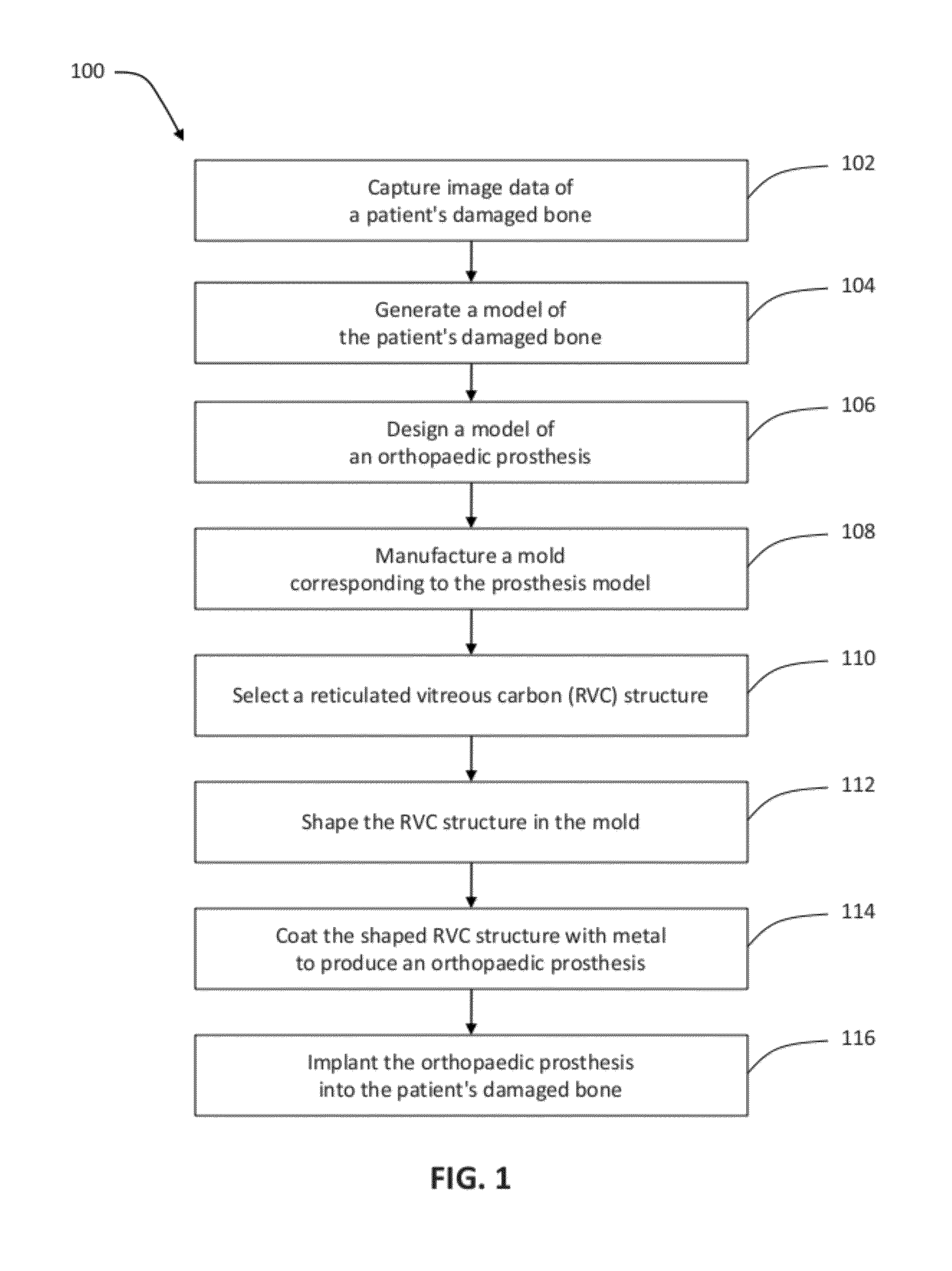

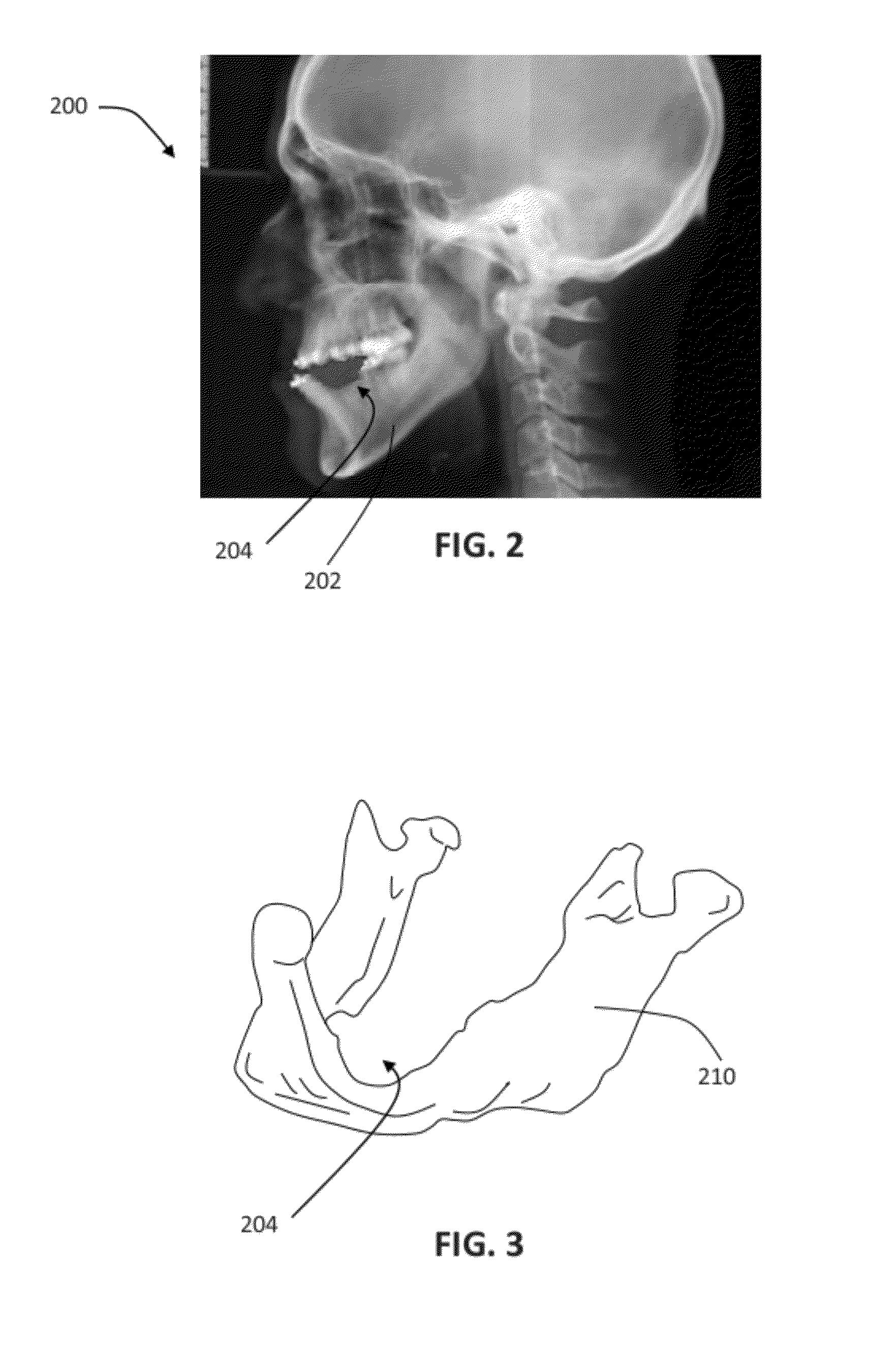

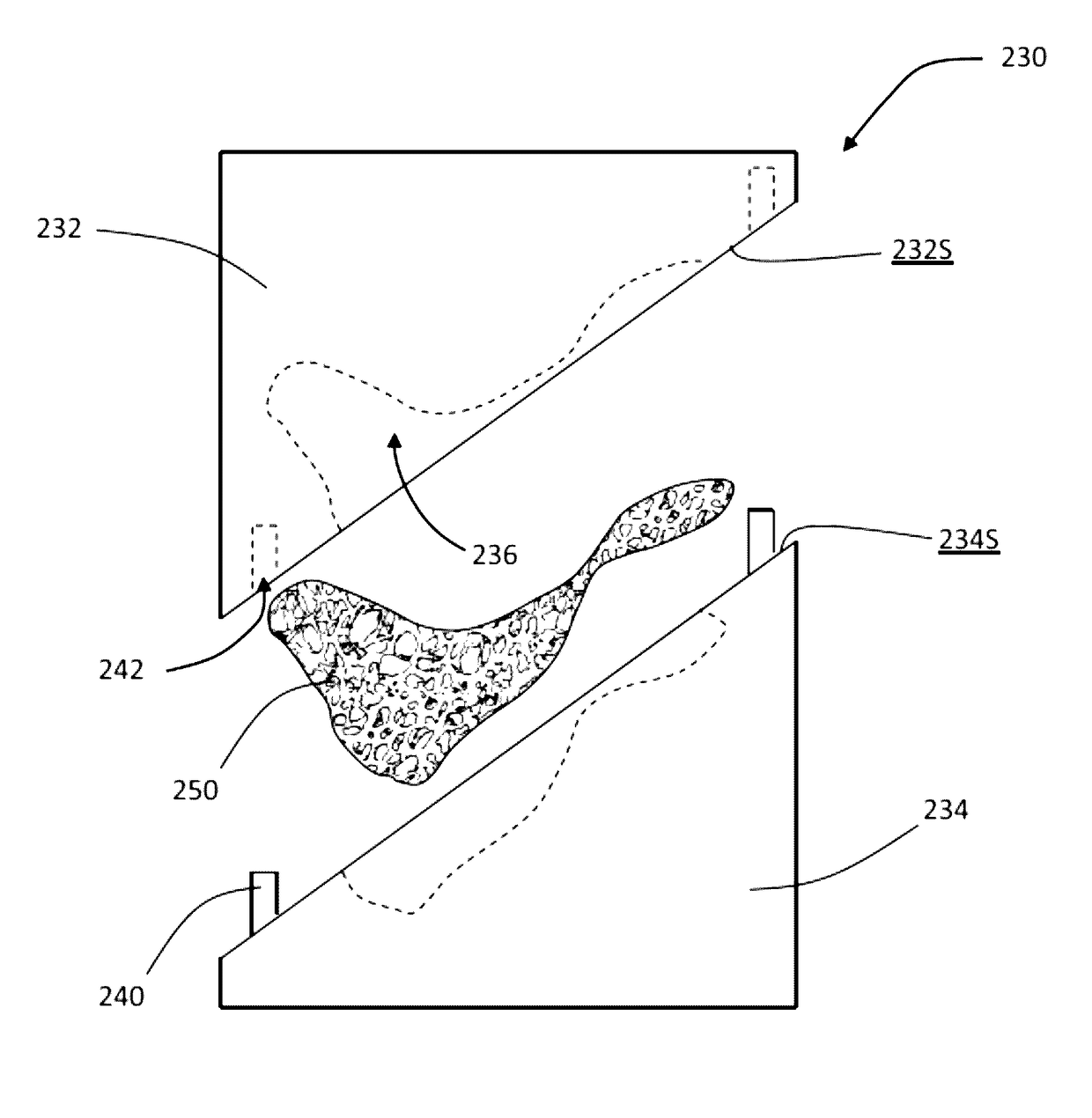

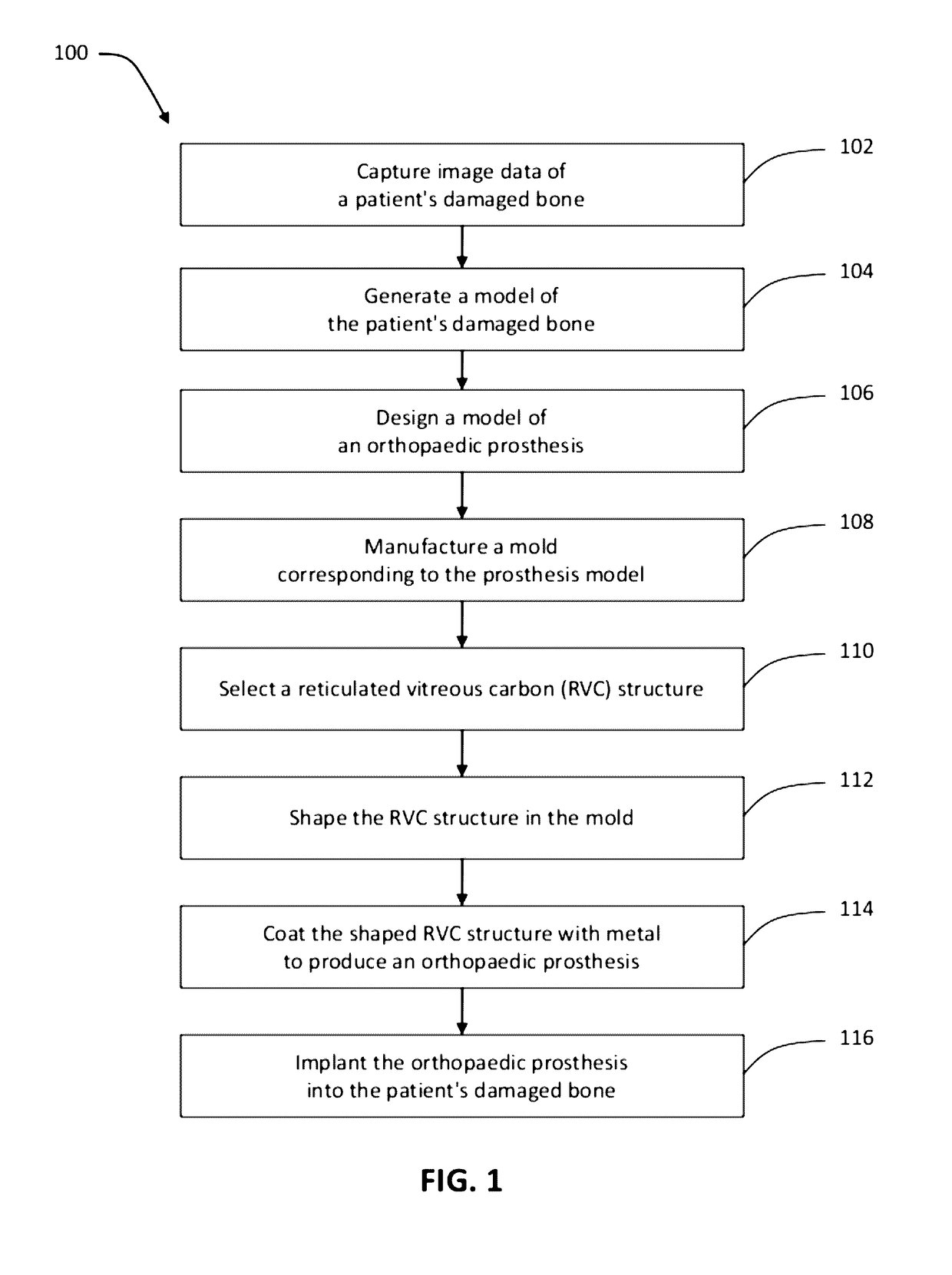

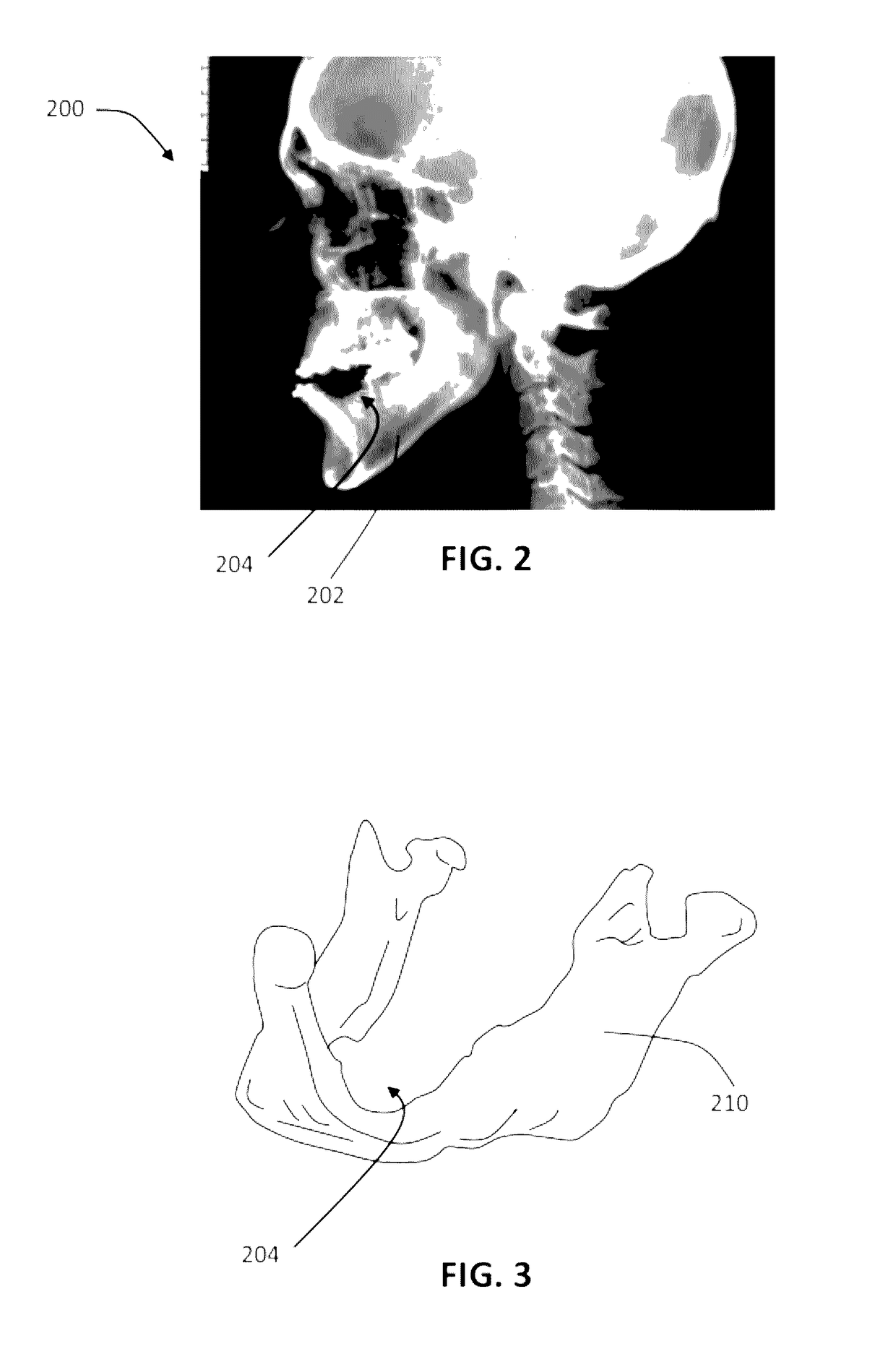

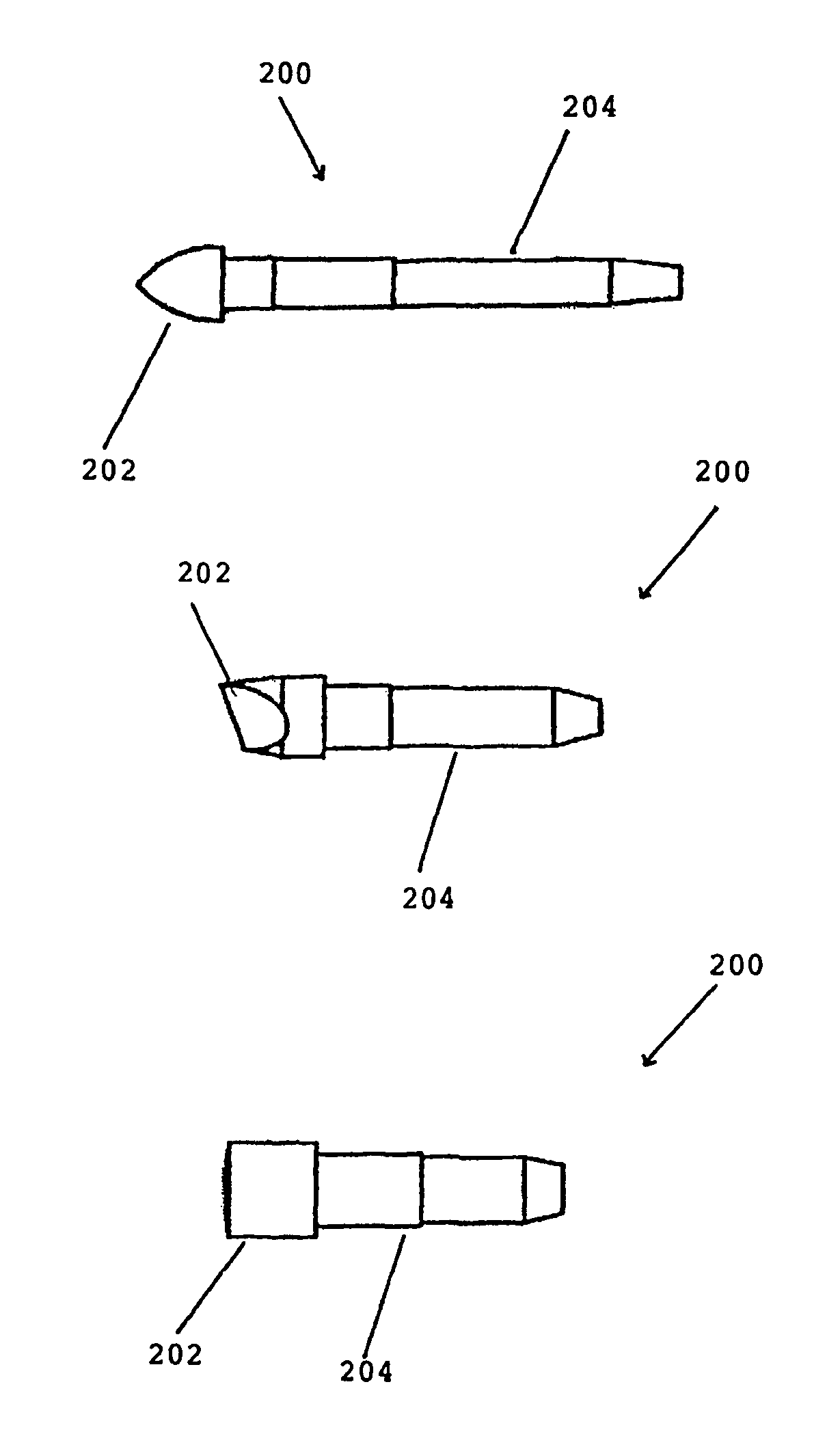

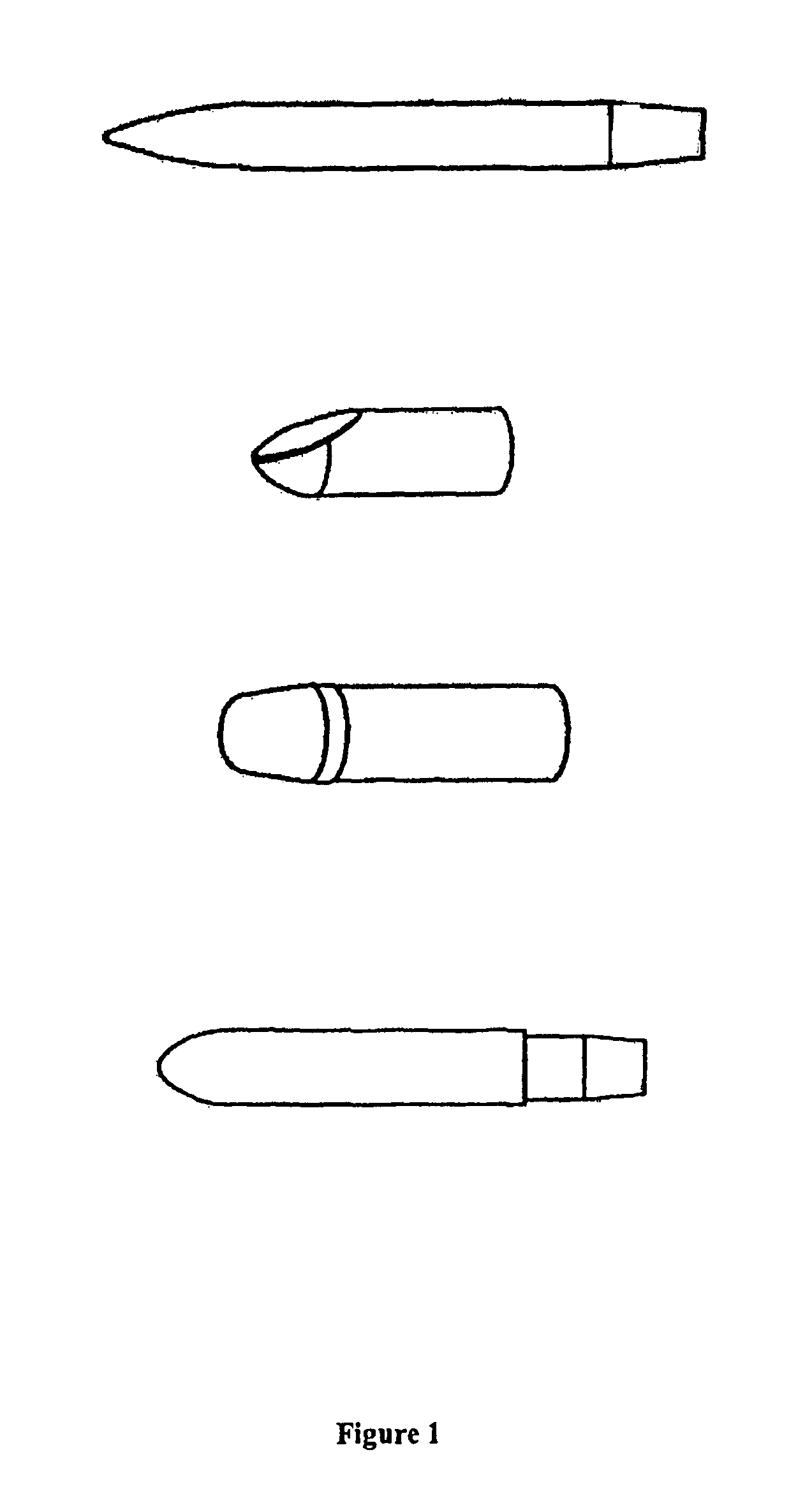

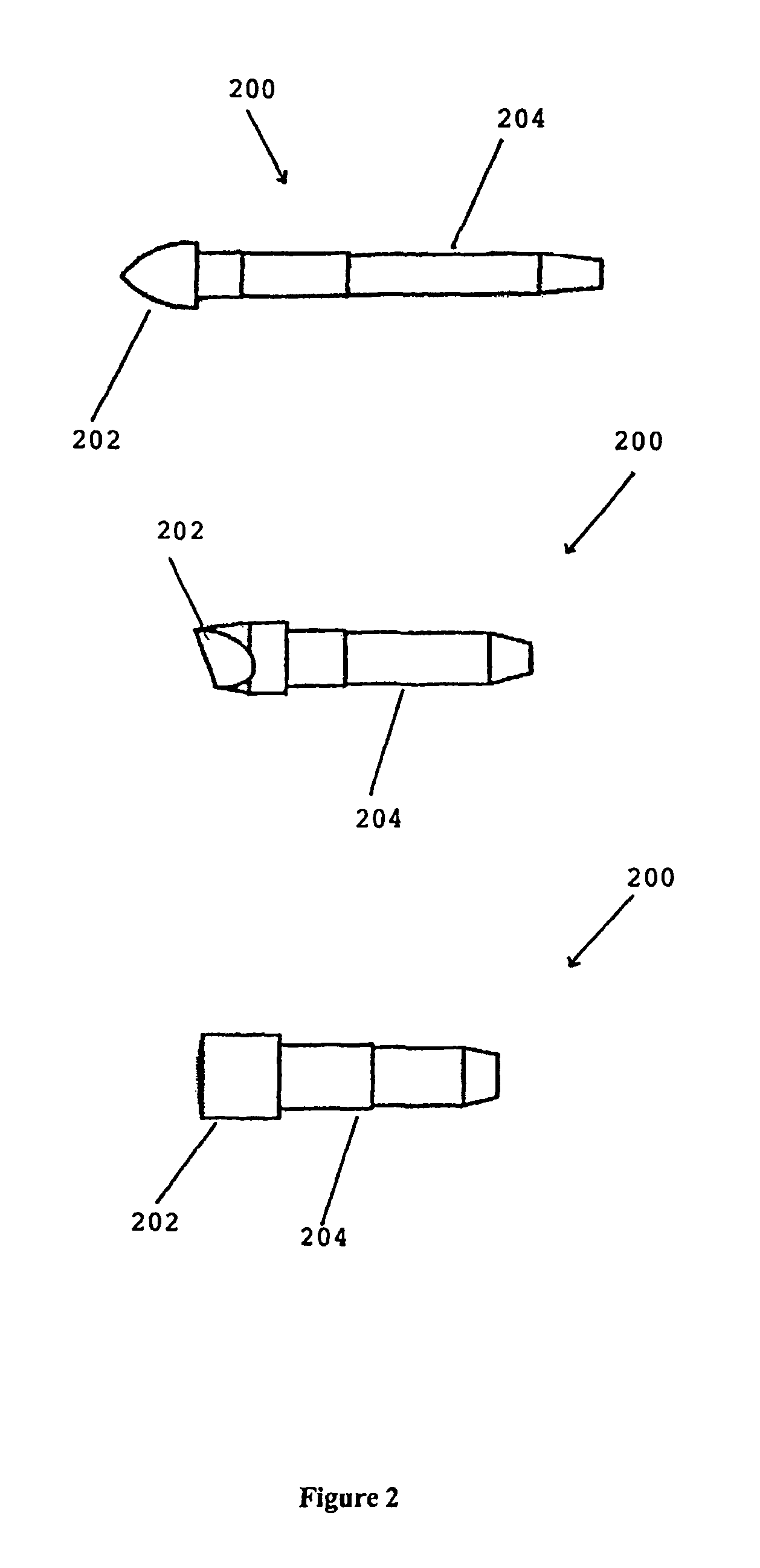

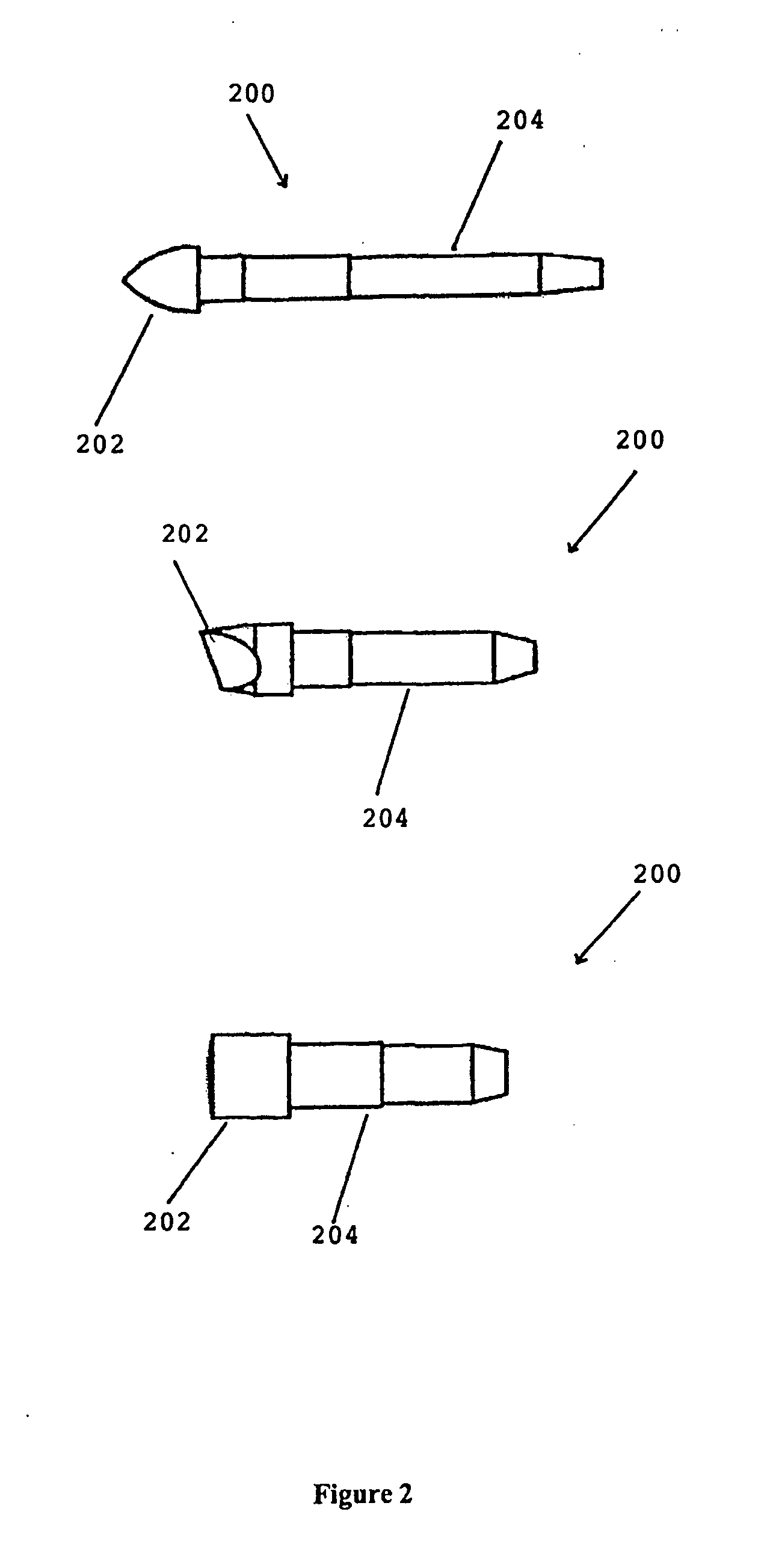

Patient-specific manufacturing of porous metal prostheses

ActiveUS20120310364A1Low efficiencyAvoid substantially changing porosityImpression capsPretreated surfacesProsthesisPlastic surgery

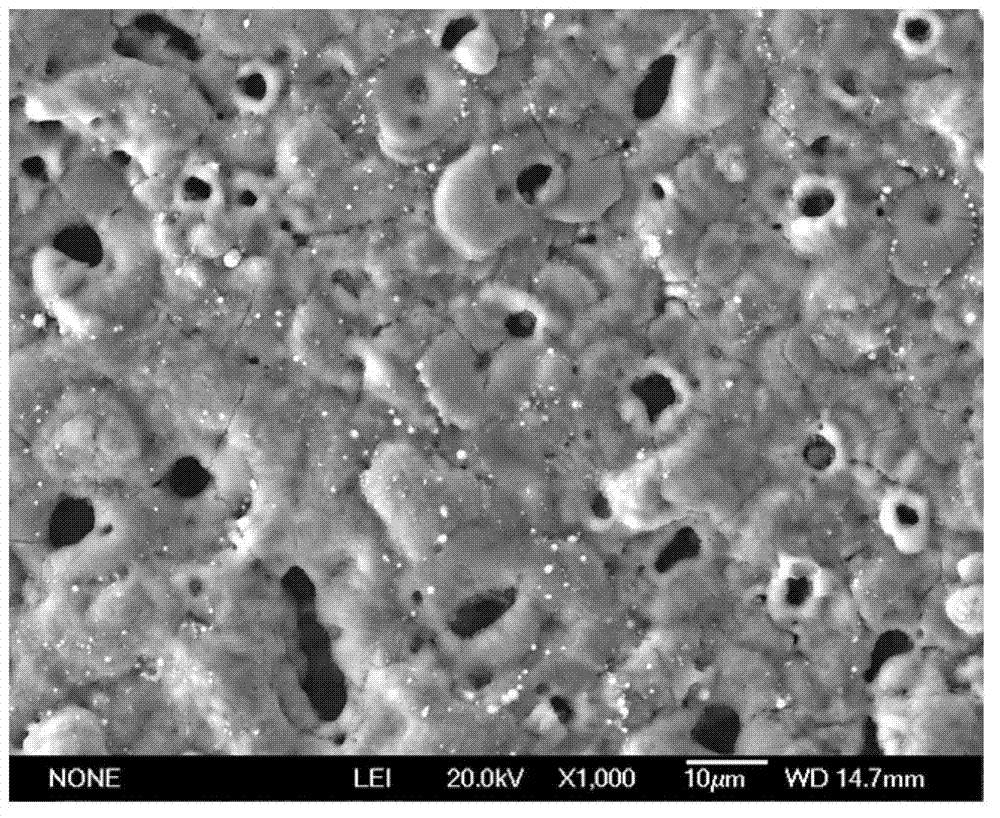

A patient-specific porous metal prosthesis and a method for manufacturing the same are provided. The orthopaedic prosthesis may be metallic to provide adequate strength and stability. Also, the orthopaedic prosthesis may be porous to promote bone ingrowth.

Owner:ZIMMER INC

Patient-specific manufacturing of porous metal prostheses

ActiveUS9662214B2Porosity changeLow efficiencyImpression capsPretreated surfacesProsthesisBone ingrowth

A patient-specific porous metal prosthesis and a method for manufacturing the same are provided. The orthopedic prosthesis may be metallic to provide adequate strength and stability. Also, the orthopedic prosthesis may be porous to promote bone ingrowth.

Owner:ZIMMER INC

Sintered polymeric materials and applications thereof

ActiveUS8141717B2Advantageous chemical and mechanical propertyIncrease flexibilitySemi-permeable membranesLaboratory glasswaresElastomerPolymer science

The present invention provides sintered polymeric materials and methods of making the same which are useful in a variety of applications. In one embodiment, the present invention provides a sintered polymeric material comprising at least one plastic and at least one elastomer.

Owner:POREX CORP

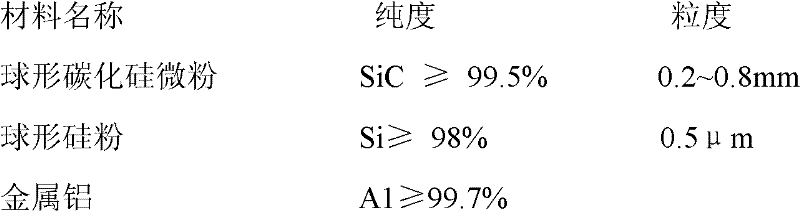

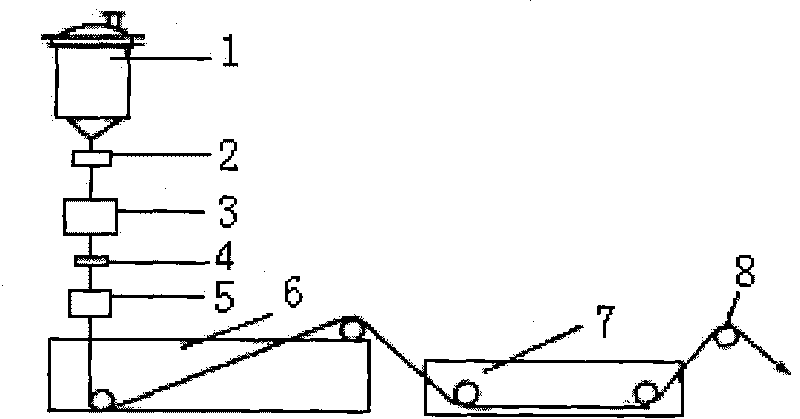

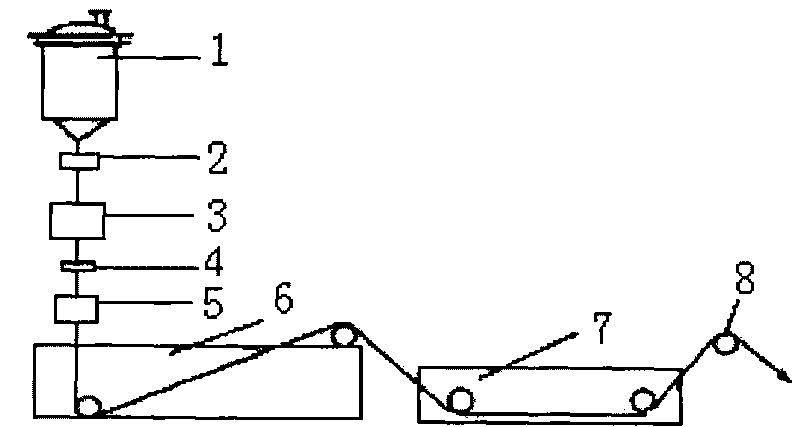

Method for preparing aluminum silicon carbide composite material

The invention discloses a method for preparing an aluminum silicon carbide composite material. Liquid metal aluminum is filled in a porous silicon carbide substrate which is prepared from spherical silicon carbide powder and spherical silicon powder which serve as raw materials and has a three-dimensional through hole structure through an injection molding process so as to form a bicontinuous phase, the density of the aluminum silicon carbide composite material and the product uniformity are improved, and a high-strength AlSiC substrate is obtained by changing molding pressure, adjusting ingredients of the spherical powder with different particle sizes, adding a pore-forming agent, and sintering at the temperature of between 1,400 and 2,400 DEG C. The porous substrate is fixed in a cavityof an injection machine, and the liquid metal aluminum enters the cavity from an injection port and is filled in through holes of the AlSiC substrate through a gas-liquid mixed injection process so as to form the aluminum silicon carbide composite material with a silicon carbide and metal aluminum bicontinuous phase structure. The aluminum silicon carbide composite material prepared by the process has the heat conductivity of 190 to 280 W / mK and the thermal expansion coefficient of 5.5 to 11.5*10(-6)K at room temperature of 200 DEG C, and has high rigidity, low density, high weldability and low machining amount.

Owner:CENT SOUTH UNIV

Antibacterial bacteriostatic polysulfone hollow fiber ultrafiltration membrane and preparation method thereof

InactiveCN101703892AImprove hydrophilicitySlow down the gelSemi-permeable membranesFiberUltrafiltration

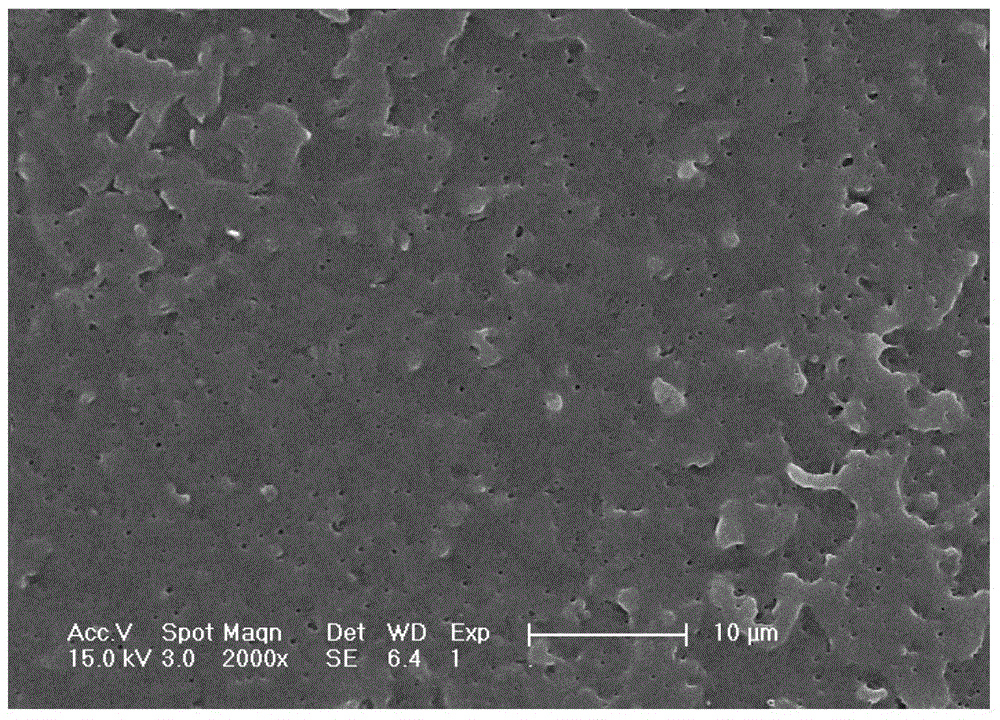

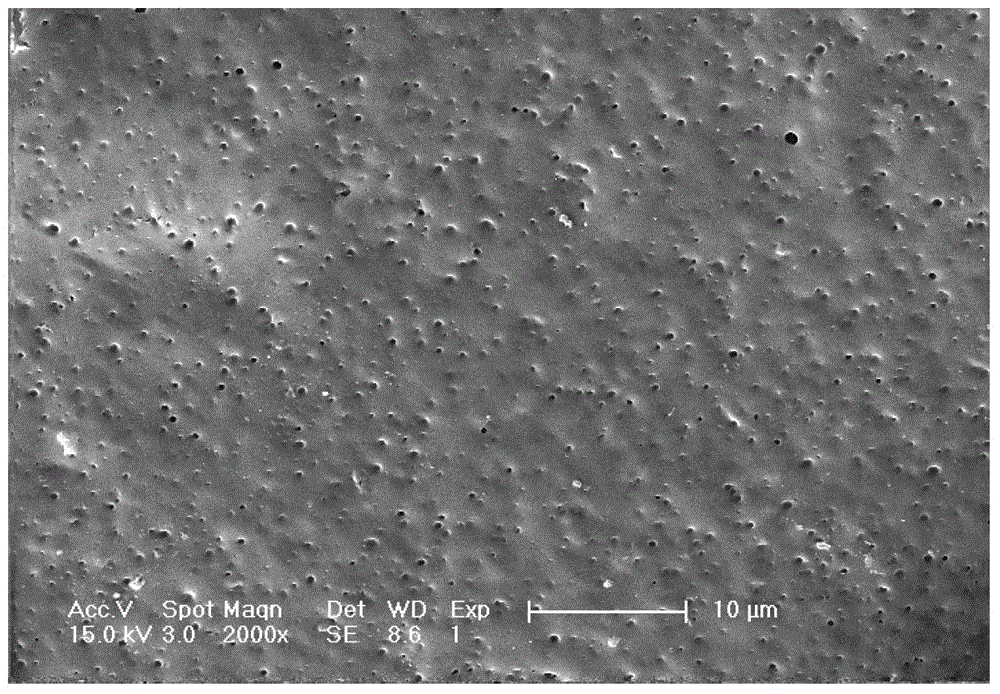

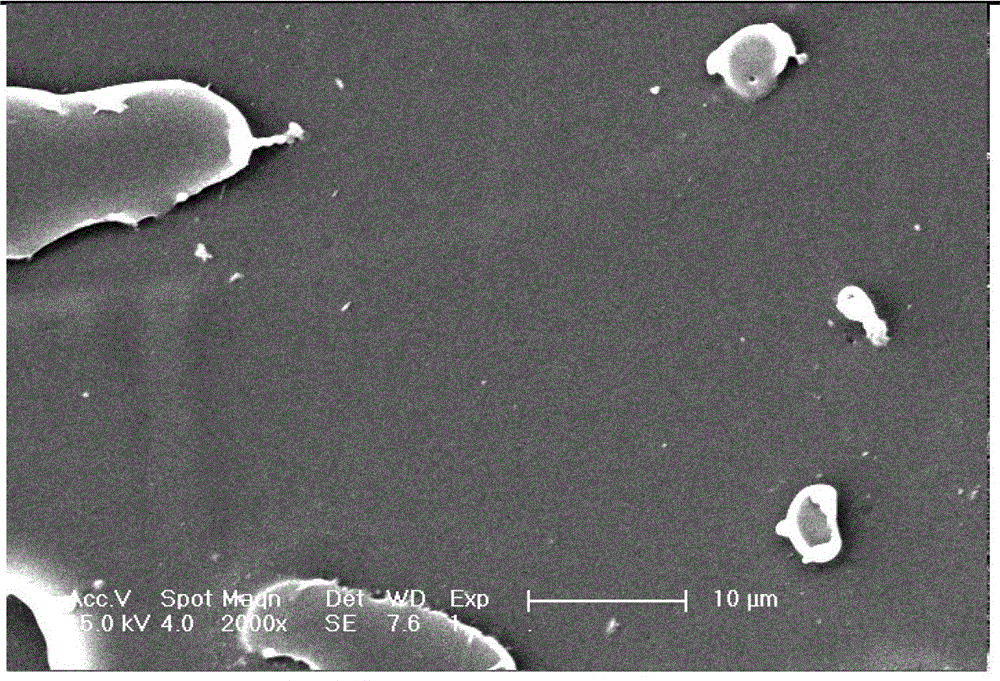

The invention provides an antibacterial bacteriostatic polysulfone hollow fiber ultrafiltration membrane, which is a mixture consisting of polysulfone (PS) dissolved in solvent and nanometer antibacterial material. Based on parts by weight, the ultrafiltration membrane comprises 5 to 25 parts of polysulfone, 0.05 to 5 parts of nanometer antibacterial material, 2 to 10 parts of additives, 65 to 90 parts of solvent. The invention simultaneously discloses a preparation method, which comprises: (1) dissolving the polysulfone in the solvent in a spinning liquid tank, adding the nanometer antibacterial material and the additives, mixing well and obtaining membrane casting liquid; (2) standing and curing the obtained product; (3) extruding the cured material in the spinning liquid tank, filtering the cured material through a filter so as to remove impurities, metering the obtained product through a metering pump and filtering the obtained product through the filter so as to remove the impurities; (4) spurting membrane silk through a silk-spurting plate; (5) forming the membrane silk into a membrane in coagulating bath; and (6) soaking the formed membrane in pure water in washing bath, washing the solvent and the additives away, winding and outputting the polysulfone hollow fiber ultrafiltration membrane. The membrane has a good bacteriostatic effect.

Owner:SHANGHAI AQUA PURIFICATION EQUIP

Sintered polymeric materials and applications thereof

ActiveUS20080197065A1Advantageous chemicalImprove mechanical propertiesIon-exchanger regenerationLaboratory glasswaresPolymerElastomer

The present invention provides sintered polymeric materials and methods of making the same which are useful in a variety of applications. In one embodiment, the present invention provides a sintered polymeric material comprising at least one plastic and at least one elastomer.

Owner:POREX CORP

Hydrophilic polyethene microporous membrane and preparation method thereof

The invention provides a hydrophilic polyethene microporous membrane and a preparation method thereof, belonging to a polyethene microporous membrane containing blending compatilizer with a polar group, calcium carbonate and thinner and a preparation method thereof. In the preparation method of the microporous membrane, polyethene, blending compatilizer, calcium carbonate and thinner are taken as raw materials; and hydrophilic polyethene microporous membrane is finally prepared by blending processing, membrane pressing by a flat bed presser, quenching by water bath in constant temperature, extracting by extracting agent, acid cleaning, washing and drying. The invention is characterized in that the blended compatilizer with a polar group is selected to react with the calcium carbonate particles, calcium carbonate particles are evenly filled into polyurethane base body through blending processing; and porous structures are formed by the thermal induced phase separation method and the method for removing fillings by acid cleaning. As for the hydrophilic polyethene microporous membrane prepared by the method, the range of the internal average aperture is 0.1-10mu m, the aperture rate is greater than 50% and the contact angle is less than 80 degrees.

Owner:PETROCHINA CO LTD

Anodic oxidation dyeing process for multi-blind hole aluminum extruded section product

The invention relates to an anode oxidating dyeing technique of aluminium extruded section product with a plurality of blind holes which has steps as follows: loading, removing oil, washing with clean water, washing and spraying, corrupting with alkali, washing with clean water, washing and spraying, cleaning with ultrasonic, washing with pure water, anode oxidating, cleaning, cleaning and spraying, washing with pure water, processing before dyeing, washing with pure water, dyeing, washing with pure water, closing with nickel salt, cleaning and spraying, washing with pure water, drying in vacuum. The technique changes oxidating film hole by using increase of oxidating temperature and electrolyte concentration for enhancing the film absorption ability to dye; a processing agent before dyeing can avoid poor dyeing effect caused by acid sewage flow in hole, screw hole of the anode oxidating product efficiently, and control poor dyeing effect, white point, color mistiness with flow hanging shape caused by residual medicinal liquor flow in dyeing by increasing dyeing ability of dye; replacement of dyeing agent can greatly increase stability of dyeing and prolong working life of dye, and increase absorption ability of the oxidating film to dye.

Owner:SHANGHAI REAL INDAL

Method for preparing hydrophilic polypropylene microporous film

The invention relates to a method for preparing hydrophilic polypropylene microporous film. The method includes subjecting low-melting-index polypropylene and diluents in a weight ratio of (20:80) to (80:20), a blending compatilizer containing polar groups and accounting for 0.5% to 20% of the total weight of the polypropylene and the diluents, and a material which is composed of nucleating agents and accounting for 0.05% to 10% of the total weight of the polypropylene and the diluents to solution blending or melt blending at a temperature ranging from 180 DEG C to 210 DEG C to obtain mixed materials; forming film by using a film scraping method or a hot-press method at a temperature of 170 DEG C to 190 DEG C; quenching the film in thermostatic waterbath at a temperature between 0 DEG C and 50 DEG C; extracting the film in an extracting agent to remove the diluents; dipping the film in a hydrochloric acid aqueous solution, and washing the film through distilled water and drying the film to obtain the hydrophilic polypropylene microporous film. According to the hydrophilic polypropylene microporous film prepared by the method, the average bore diameter range is between 0.1 micron and 10.0 microns, poriness is larger than or equal to 40%, and the water contact angle is smaller than or equal to 95 degrees.

Owner:PETROCHINA CO LTD

Porous ceramic and manufacturing process thereof

The invention discloses porous ceramic with good drainage performance and a manufacturing process. The porous ceramic employs silicon carbide, pottery clay, mullite, and iolite as aggregates; wollastonite and spodumene are used as auxiliary materials, and low temperature ceramic glaze powder is used as a fluxing agent; bamboo charcoal and wood chip are used as pore forming agents; the raw materials are prepared according to a certain proportion, paraffin is used as a binder for preparing a slurry, a hot pressure casting and forming machine is used for preparing green compacts, and one-time wax discharging and sintering are carried out by a kiln in order to obtain finished products. Compared with prior art, the product has the functions of common porous ceramics, such as filtering, heat insulation, noise abatement and the like, and the product is characterized in that the product has liquid drainage, penetration, adsorption and fine filtering and other excellent functions, and at the same time, the product has high temperature resistance, quenching and quick heating resistance, and good thermal conductivity; in addition, the common ceramic raw materials are selected, and the porous ceramic has the advantages of low energy consumption, environmental protection without secondary pollution, low cost, and simple technology, and the ceramic is suitable for large scale production. The porous ceramic has wide applications and extremely good development prospects.

Owner:李安成

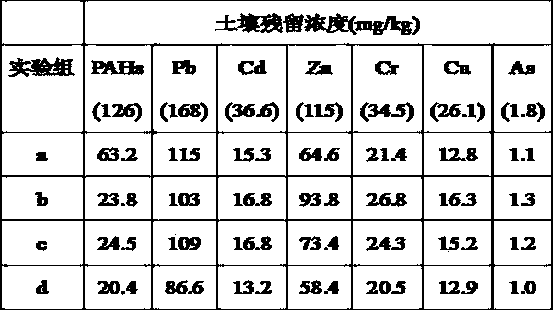

Method for repairing contaminated soil in coal-to-gas plant by adopting microbe-plant combined way

InactiveCN104226679AHigh porosityPromote degradationContaminated soil reclamationPolycyclic aromatic hydrocarbonSedum alfredii

The invention discloses a method for repairing contaminated soil in a coal-to-gas plant by adopting a microbe-plant combined way. The method comprises the following steps: adding an electronic receptor preparation in the contaminated soil so as to promote anaerobic degradation of polycyclic aromatic hydrocarbons and analysis of heavy metals; mixing and composting the contaminated soil with pig manure and a conditioning agent for several days; eluting partial heavy metals from the soil by using clear water; planting sedum alfredii hance and festuca arundinacea in the soil in a mixed way so as to extract the heavy metals from the soil and promote microbial degradation of the polycyclic aromatic hydrocarbons in the soil, wherein in the growth stage of plants, additives are sprayed periodically to enhance the repairing effect. Through the adoption of the method, the environment friendliness is very high, the repairing cost is low, and the ecological environment of the contaminated soil can be effectively restored, so that the method has a broad market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

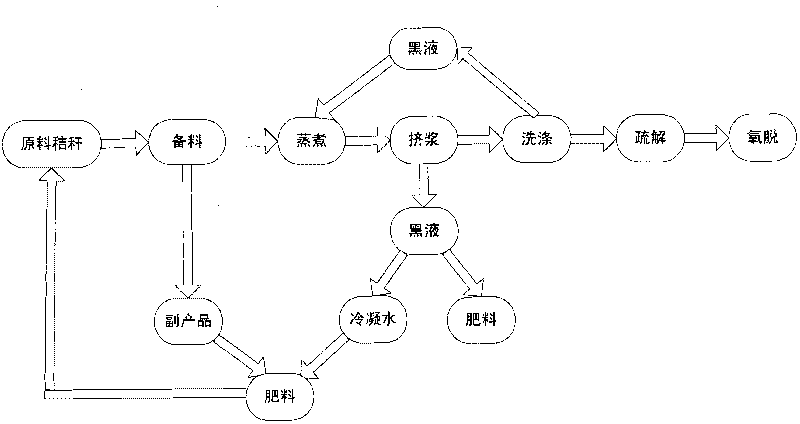

Circle application of waste condensate water during pulping with ammonium sulfite method

ActiveCN101759450AReduce moisture contentReduce porosityBio-organic fraction processingWater/sewage treatmentPotassiumCompost

The invention provides organic compost, which comprises 10-50 parts by weight of organic matter, 5-20 parts by weight of humic acid, 0.5-2.0 parts by weight of full nitrogen, 1.0-2.0 parts by weight of full potassium and 0.1-0.5 parts by weight of full phosphorus. The organic compost is prepared by mixing and fermenting heavily-polluted condensate water, crop straws, various plants or byproducts generated by preparing materials during making papers with ammonium sulfite method. The whole preparation technology is simple, wherein the heavily-polluted condensate water generated during making the papers and the crop straws are used for preparing organic fertilizer, the organic fertilizer is reused for the growth of crops, and the straws can be used for the paper-making industry, therefore, the technology is a positive cycle for the sustainable development of the industrial production. The organic compost can reduce the phenomenon of the hardening of soil, improves the structure of soil grains, effectively promote the roots to grow, obviously increase the amount and the thickness of the roots, stimulate the growing development of the crops, enhance the stress resistance performance of the corps, and improve the quality of farm produces, etc.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Abrasion-resistant gear and preparation method

The invention discloses an abrasion-resistant gear and a preparation method. A gear material comprises, by mass, 65%-85% of ferrum, 0.3%-1.2% of manganese dioxide, 0.5%-1.6% of molybdenum disulfide, 0.1%-0.9% of nickel oxide, 0.3%-1.2% of cobalt carbide, 1%-3% of silicon carbide, 1%-3% of silicon dioxide, 0.2%-0.8% of chromium, 1.5%-3.5% of tin, 3%-15% of copper, 0.1%-0.3% of phosphorus, 0.1%-0.5% of zirconium, 0.3%-2% of graphite, 0.5%-2% of lanthanum-cerium alloy, 0.2%-0.8% of auxiliaries and the balance inevitable microelements and impurities. The preparation method mainly comprises the steps of weighing of raw materials, pretreatment, component mixing, preforming, high-temperature sintering and aftertreatment. The produced gear material has high strength and hardness and also has good abrasion resistance and impact resistance.

Owner:WUHU SANDAO MATERIAL TECH CO LTD

A method for prepare a lithium-rich manganese-based cathode material for lithium ion battery

InactiveCN109148879APromote contractionPorosity changeSecondary cellsPositive electrodesLiquid oxygenCell system

The invention provides a preparation method of a lithium-rich manganese-based cathode material for a lithium ion battery, which comprises the following steps of: uniformly mixing carbonates of Mn, Niand Co, lithium sources and auxiliaries according to a certain proportion to obtain mixed powder; Sintering the mixed powder at 500 DEG C for 5 to 10 minutes, and then sintering at 700 to 1000 DEG C for 20 to 40 minutes; At that end of sinter, the powder is transfer into liquid nitrogen, liquid argon or liquid oxygen to be quenched, cooled, taken out and dried, and sieve to obtain a lithium-rich manganese-based cathode material for lithium ion batteries. As that quench after sinter of the invention can promote the shrinkage of the particles, so that that pore of the particles become small, More compact stacking, the vibrating density of the material particles is increased, The increase of vibrating density improves the machinability of the material, effectively enhances the energy densityof the cell system, at the same time, it can refine the grain size, increase the specific surface area of the material, improve the contact between the material and the electrolyte, and effectively enhance the comprehensive electrochemical properties of the material--in addition, it greatly improves the utilization rate of the equipment and the production efficiency.

Owner:桑顿新能源科技(长沙)有限公司

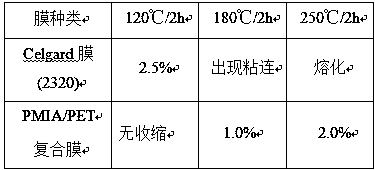

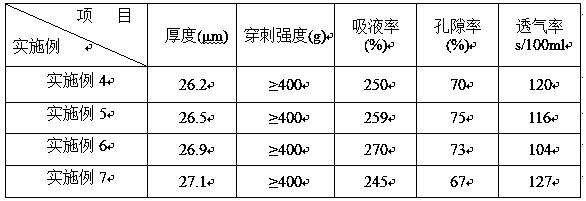

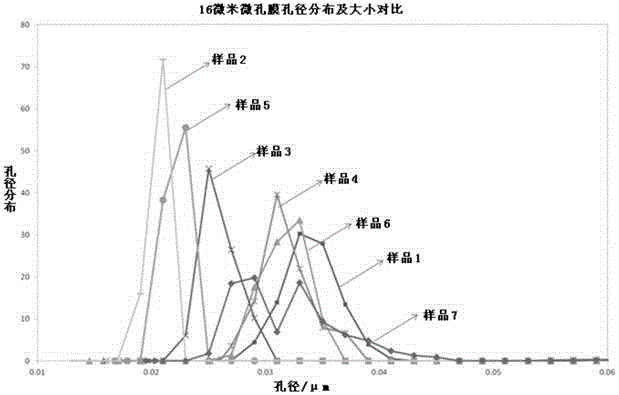

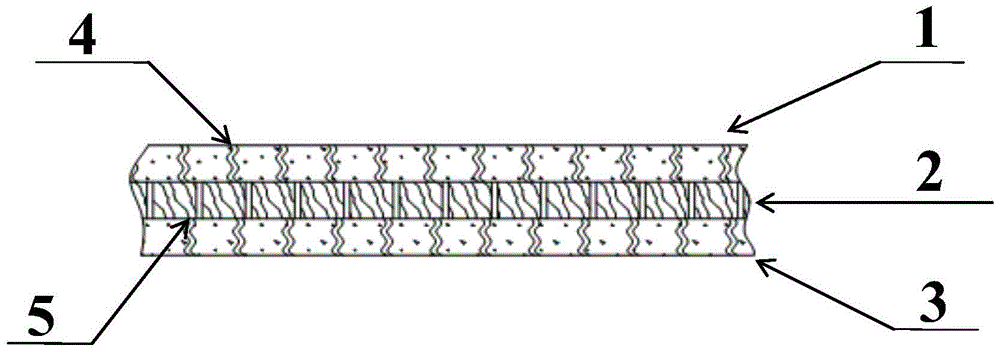

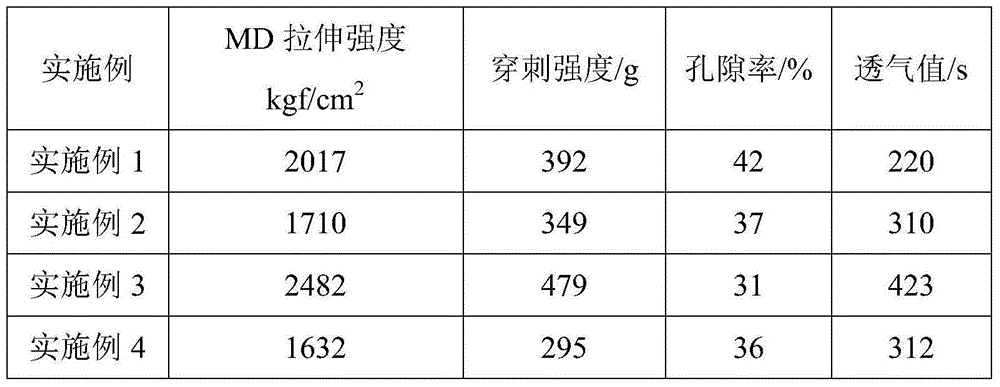

A preparation method of aramid lithium battery composite separator

InactiveCN109004155APorosity changeHigh porosityFibre typesElectro-spinningLithium chlorideNonwoven fabric

The invention discloses a preparation method of aramid lithium battery composite separator, comprising the following steps: (1) adding lithium chloride powder to N, N-Dimethylacetamide to form N, N-Dimethylacetamide / lithium chloride mixed solvent; (2) adding dried PMIA to N, N-Dimethylacetamide / lithium chloride mixed solvent with 15-25 wt% of a PMIA spinning solution in which the concentration oflithium chloride in the solution is 1-3wt%; (3) electrospinning the prepared PMIA spinning solution, and receiving the PET nonwoven fabric substrate treated with the treatment solution; (4) immersingthe fiber membrane obtained after spinning in ethanol solution at 40 DEG C and standing at 1-3 min, dry, and mechanically rolling to obtain PMIA / PET composite diaphragm. The invention can convenientlyadjust the electrospinning process parameters and effectively change the important characteristics of the membrane such as the porosity, the fiber diameter, the pore diameter, the thickness and the like so as to meet the actual needs in the application, thereby obtaining a lithium ion battery separator with high porosity and high liquid absorption capacity.

Owner:JIANGXI TONRY NEW ENERGY TECH DEV CO LTD

Preparation method of multi-layer lithium battery diaphragm with high security

ActiveCN105047843AUniform pore size distributionPore size distribution is easy to adjustLi-accumulatorsCell component detailsPolyolefinThermal treatment

The invention provides a preparation method of a multi-layer lithium battery diaphragm with high security. A microporous diaphragm is prepared by multi-layer coextrusion and unilateral stretching methods. The equipment and process technology of the method are perfect. A functional layer added with an inorganic filler or other pore-forming fillers and a polyolefin microporous membrane are subjected to composite strip casting in a multi-layer coextrusion manner; a multi-layer composite microporous membrane precursor is molded once; and then the composite membrane precursor is subjected to thermal treatment, multi-layer recombination and uniaxial stretching to obtain a high-performance microporous membrane. The microporous membrane obtained by the preparation method is uniform in pore size distribution, high in production efficiency, free of pollution, low in cost and beneficial to large-scale production; and in addition, according to the method, the pore size and distribution are easy to adjust.

Owner:SHENZHEN SENIOR TECH MATERIAL

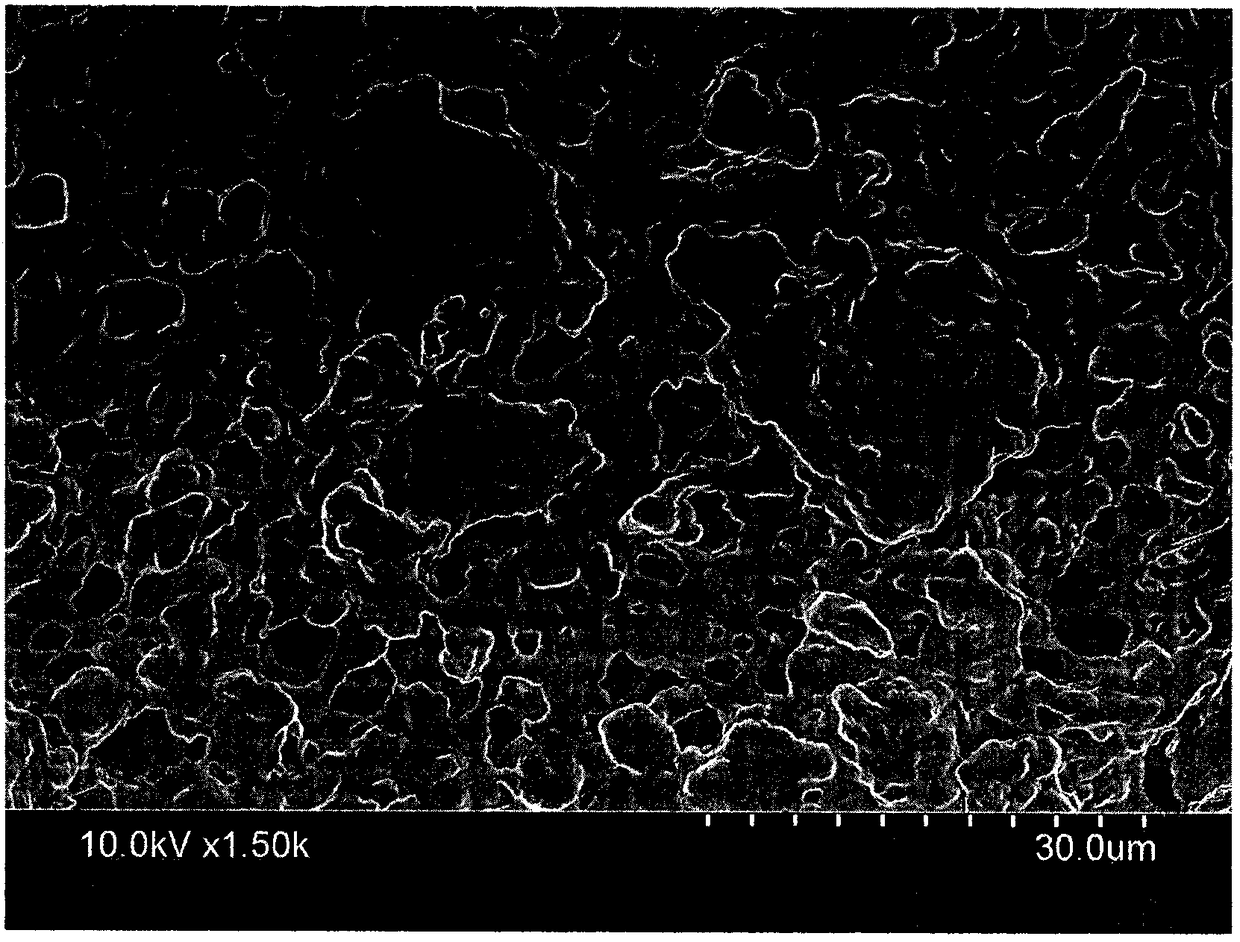

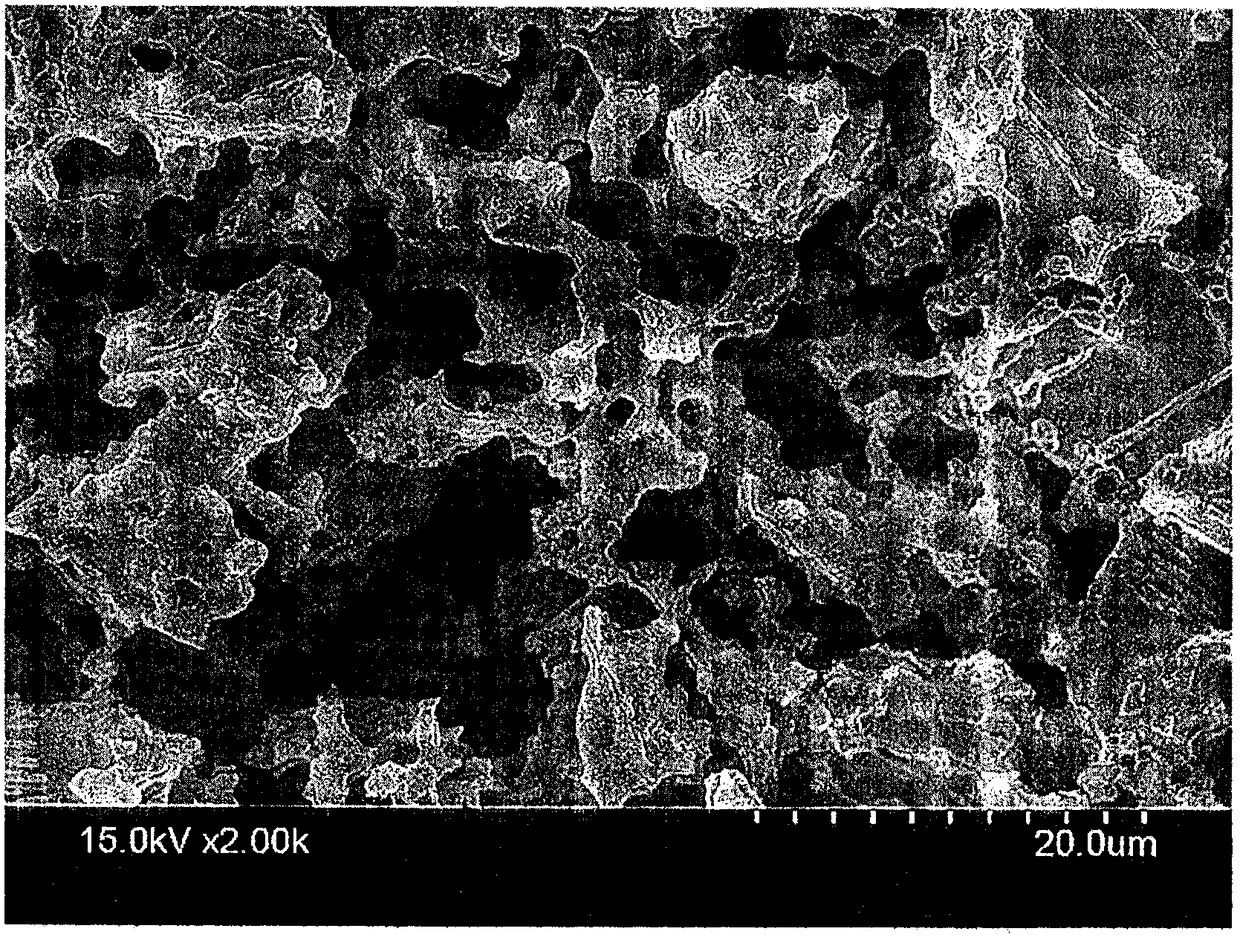

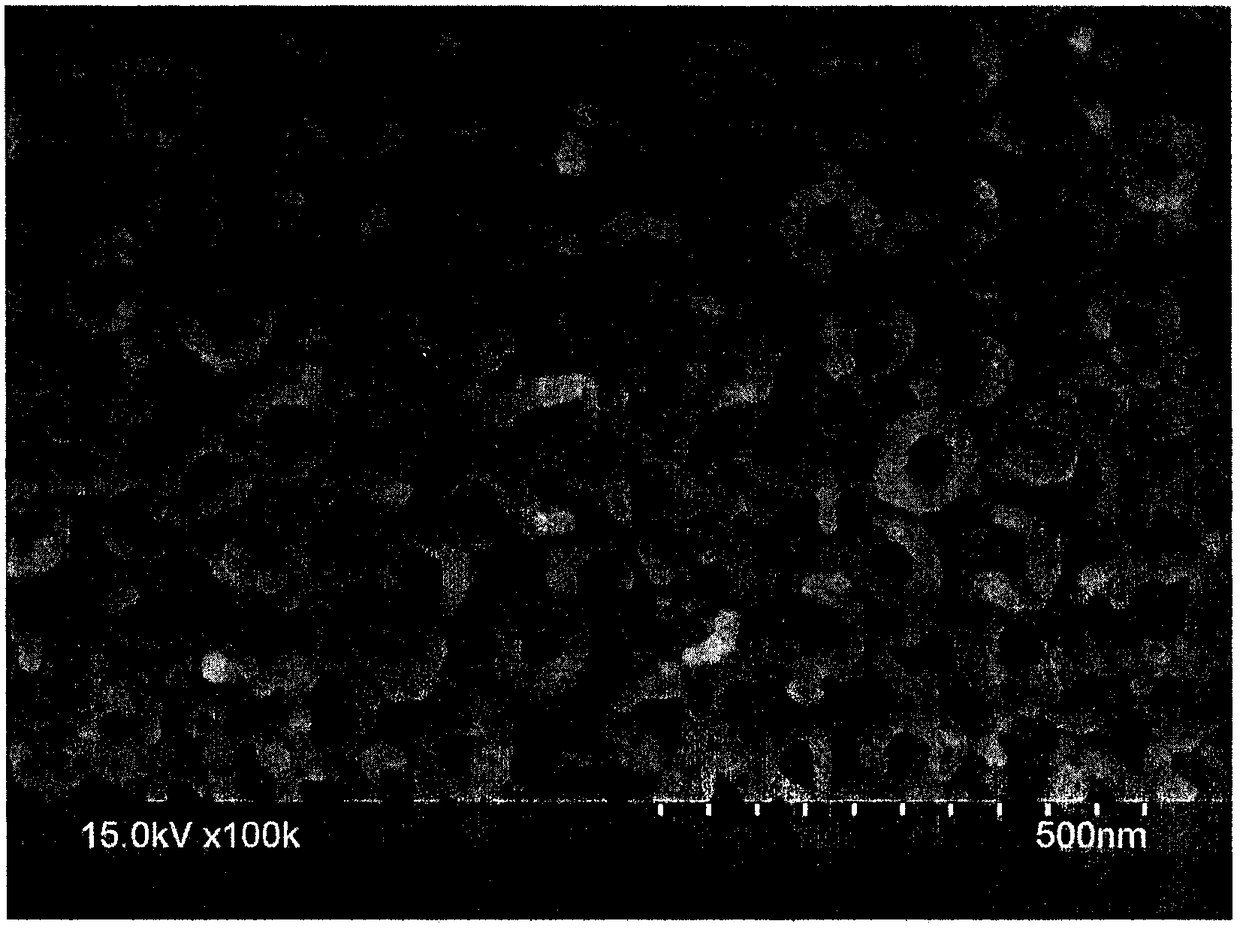

Large-size double-continuous porous foam bismuth and preparation method thereof

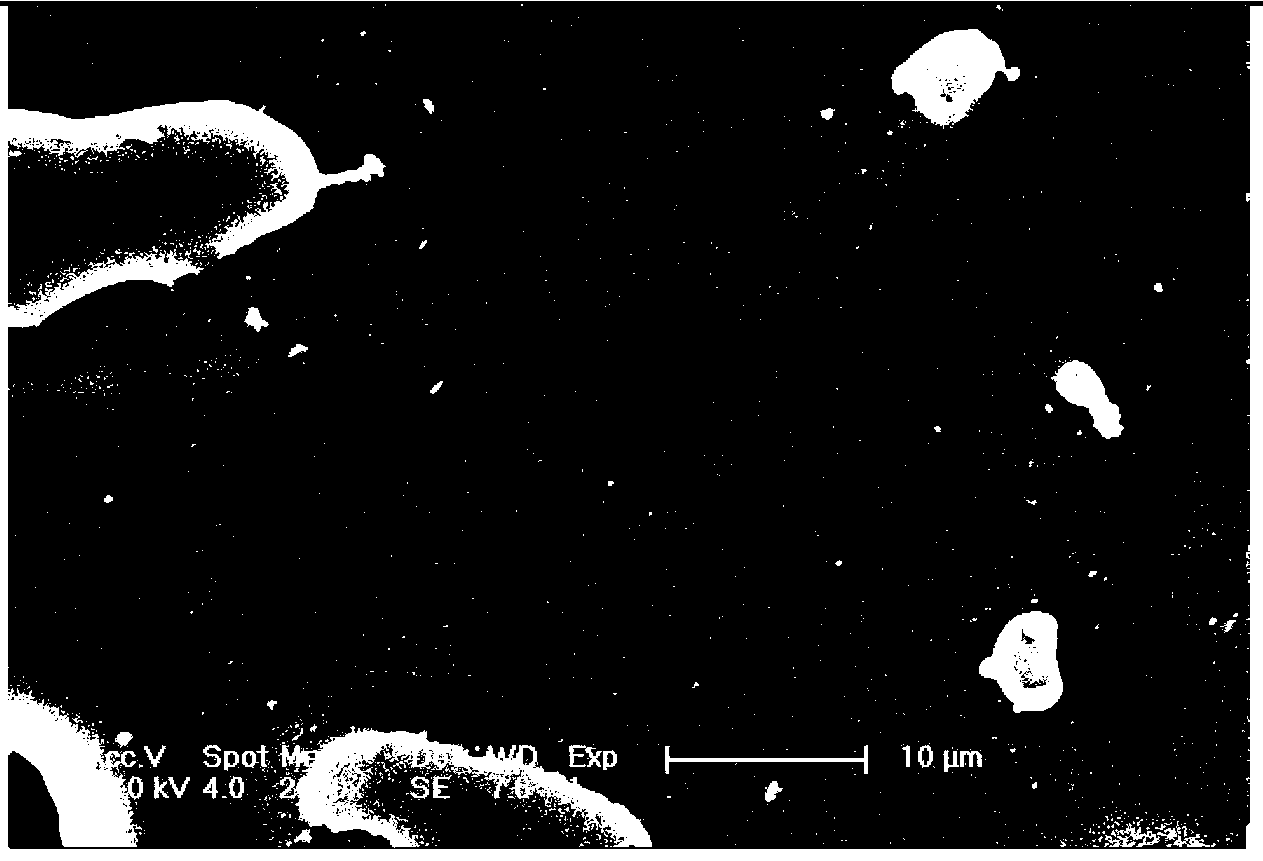

ActiveCN110146531ALarge specific surface areaHigh porosityMaterial analysis using wave/particle radiationPore distributionComposite structure

The invention discloses a large-size double-continuous porous foam bismuth and a preparation method thereof. A material is formed by continuous three-dimensional nanometer bismuth network structures and continuous three-dimensional pores which are connected to each other so as to form a three-dimensional composite structure of a macro dimension. The preparation method of the material comprises thefollowing steps of manufacturing lead-bismuth alloy; using an electrochemical method to carry out de-alloying processing on the lead-bismuth alloy; and cleaning and drying the material after the de-alloying processing to obtain a double-continuous porous foam bismuth material. The preparation method adopts a simple technology, a raw material can be recycled and cost is low. The obtained double-continuous porous foam bismuth material has a large specific surface area, completely continuous two phases, uniform pore distribution, and a continuous bismuth network, a pore size can be controlled inmicrometer and nanometer ranges, and a macroscopic large-sized three-dimensional nano-structure material. The three-dimensional nano-structure material can be applied to fields of a high performancesecondary cell, electro-catalysis, photoelectrocatalysis and the like.

Owner:SUN YAT SEN UNIV

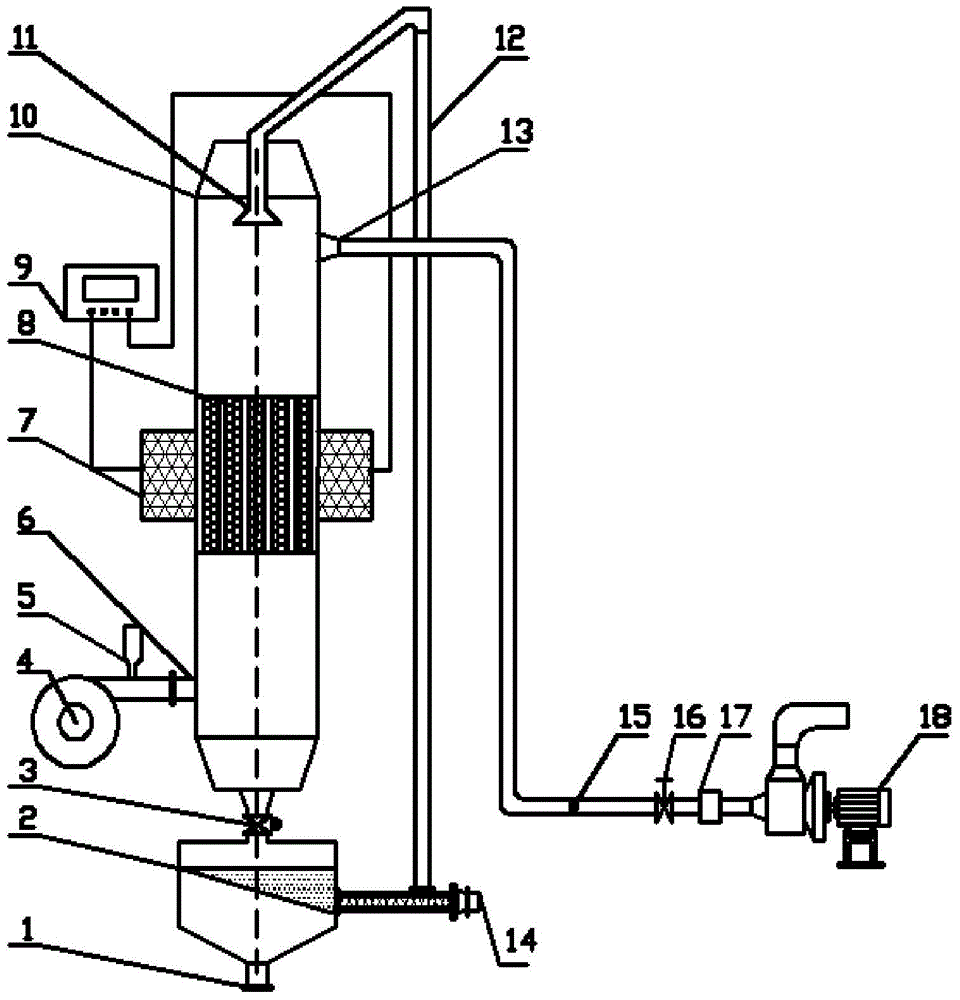

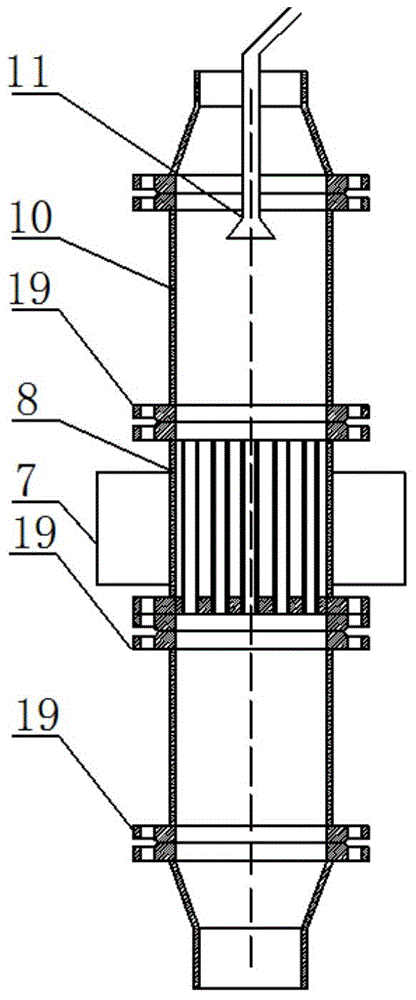

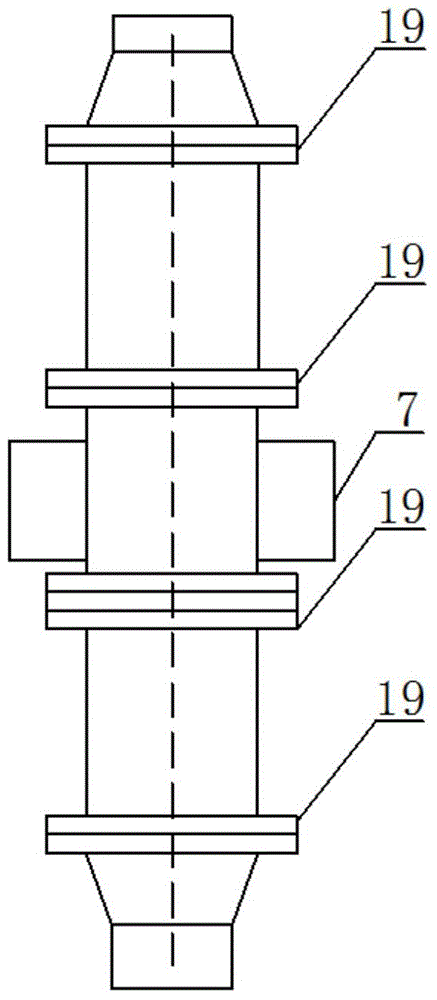

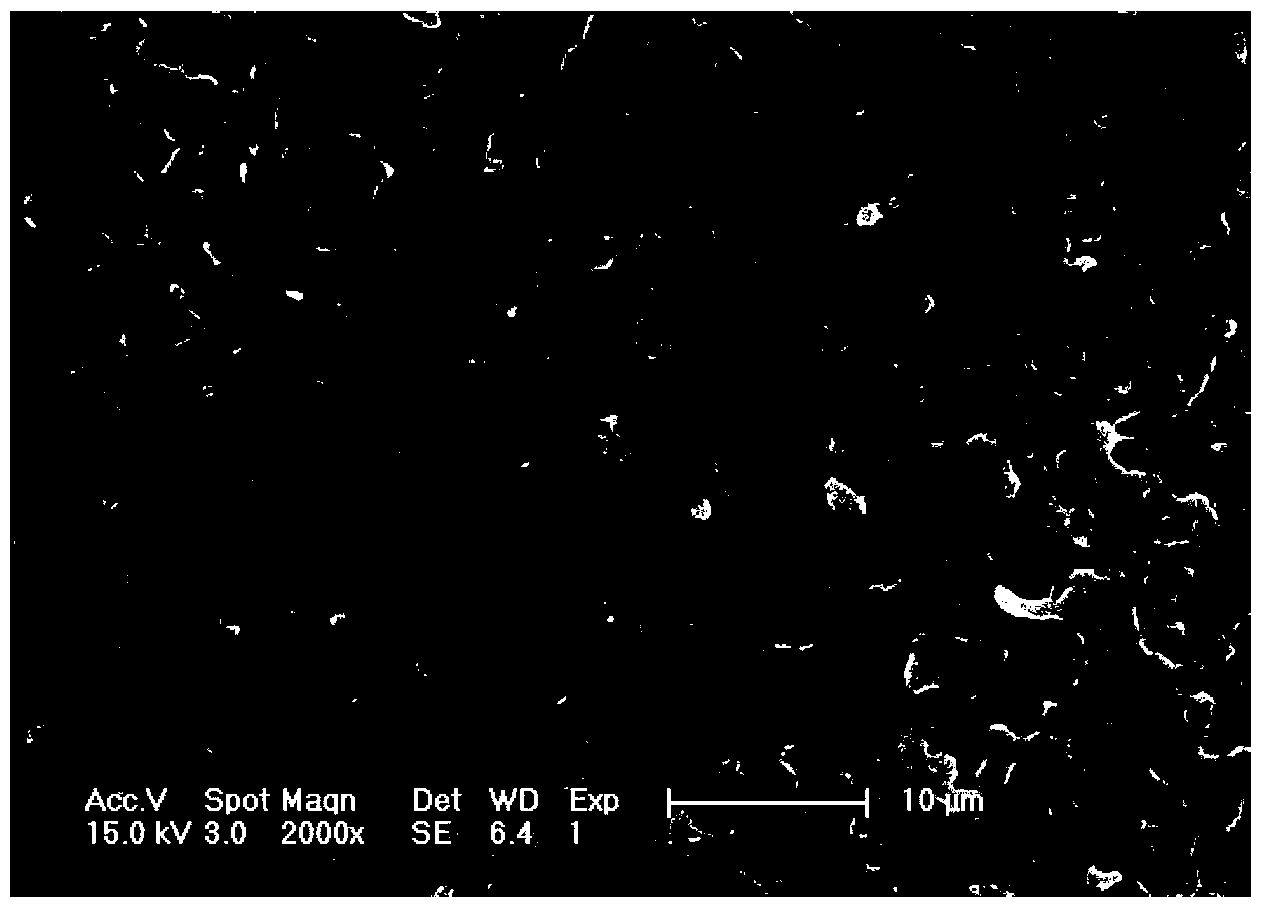

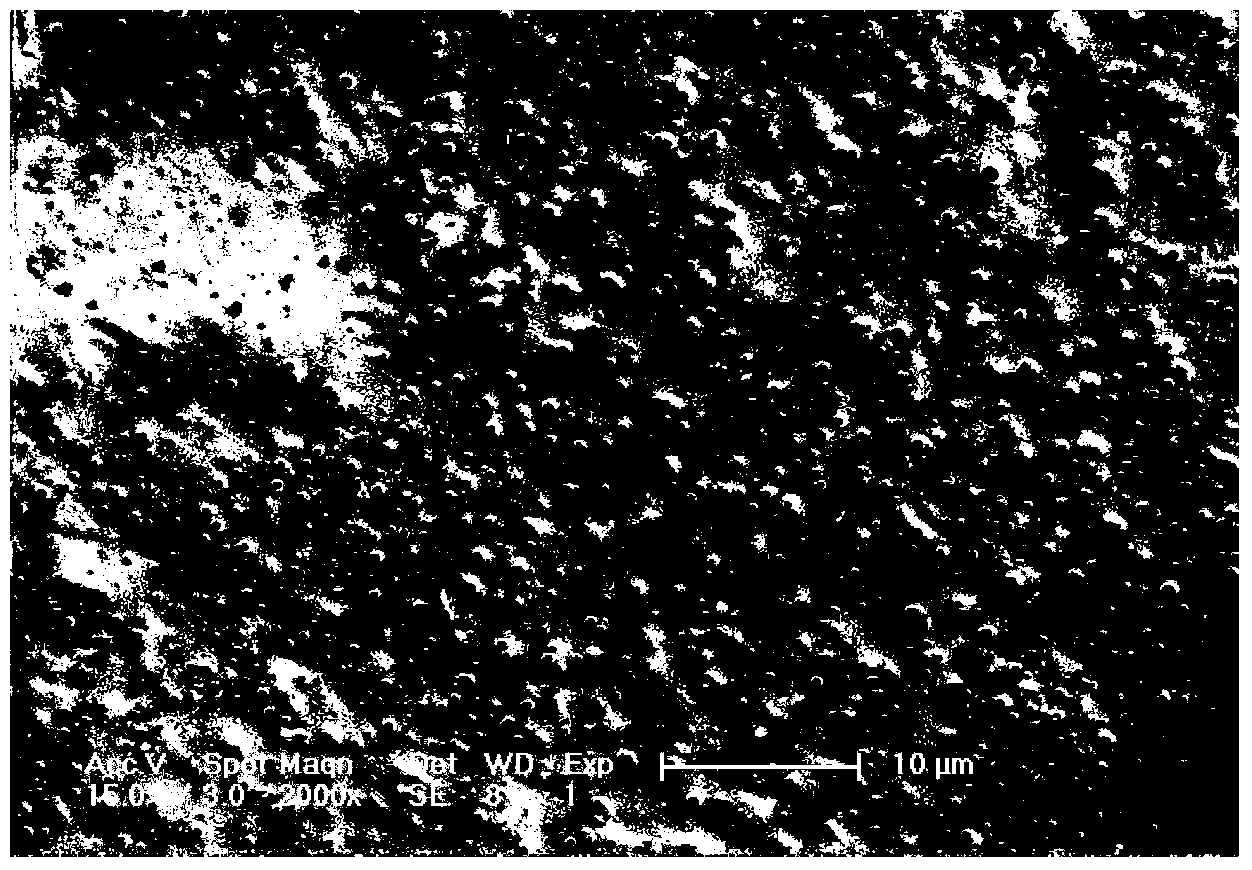

Multi-pipe type high-temperature electromagnetic floating-bed dust remover

ActiveCN104474825APorosity changeLarge adjustment rangeCombination devicesDispersed particle filtrationFlue gasSlurry

The invention relates to a multi-pipe type high-temperature electromagnetic floating-bed dust remover, and aims to provide the dust remover for removing dust in flue gas in high-temperature, high-pressure and high-corrosion occasions; the dust remover disclosed by the invention comprises a dust remover main body; the dust remover main body comprises an upper cylinder, an intermediate cylinder and a lower cylinder; a multi-pipe type floating-bed layer is arranged in the intermediate cylinder; an electromagnetic coil is arranged outside; the electromagnetic coil is connected to a direct-current power supply; the pipes of the multi-pipe type floating-bed layer are filled with magnetic particles; a gas inlet is arranged on the side wall of the lower cylinder; a filter material regeneration tank is arranged at the bottom; an automatic sluice valve plate is arranged between the lower cylinder and the filter material regeneration tank; a waste slurry outlet is arranged at the bottom of the filter material regeneration tank; a spiral conveyor is connected to the side wall of the filter material regeneration tank; a mechanical lifting bucket is connected to the other end of the spiral conveyor; the mechanical lifting bucket is connected to a particle distributor; the particle distributor is in the upper cylinder; and a gas outlet is connected to the side wall of the upper cylinder.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for preparing porous polymer material by selective biodegradation

The invention discloses a method for preparing a porous polymer material by selective biodegradation, belongs to the technical field of a biodegradable high molecular material, and solves the technical problems of a preparation method of the porous polymer material in the prior art that poisons are caused to cells, the connectivity between holes is poor and the porous polymer material cannot be used as a human tissue bracket. The method disclosed by the invention comprises the following steps of: commixing a biodegradable polymer and a non-biodegradable polymer or commixing various biodegradable polymers to obtain a commixed material; and then, carrying out selective degradation on the biodegradable polymers in the commixed material by utilizing the selectivity of a microorganism or an enzyme to obtain the porous polymer material. The preparation method disclosed by the invention is simple in process, moderate, clean and environment-friendly, and strong in selectivity; and the holes of the prepared porous polymer material are controllable and the porous polymer material can be used as a human tissue bracket material.

Owner:吉林省开顺新材料有限公司

Antiviral small nucleic acid and temperature-sensitive type gel preparation and application thereof

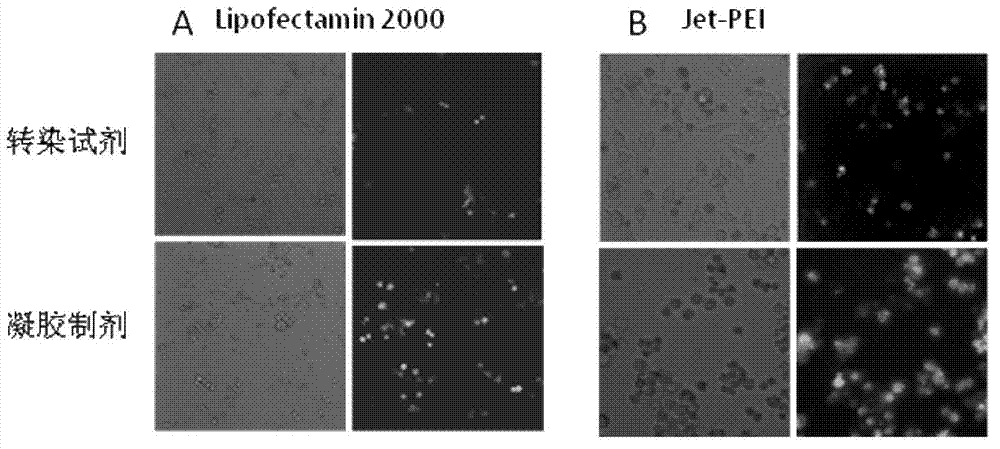

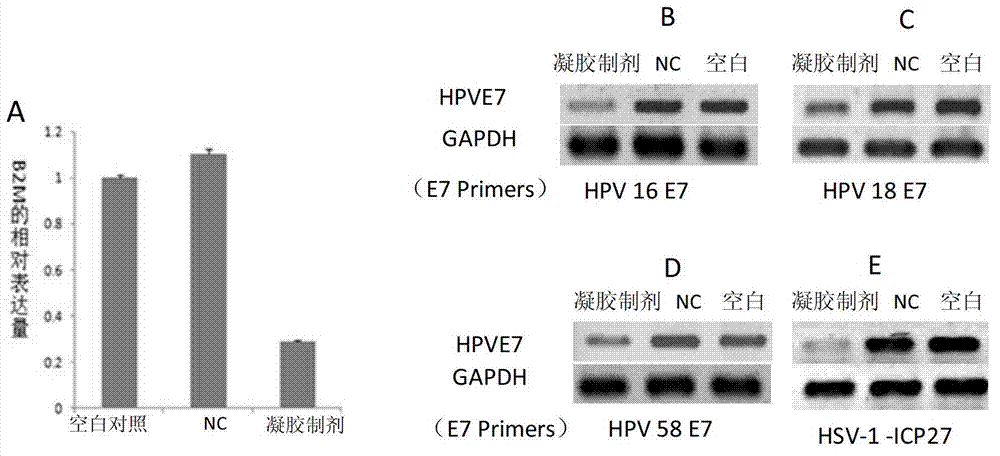

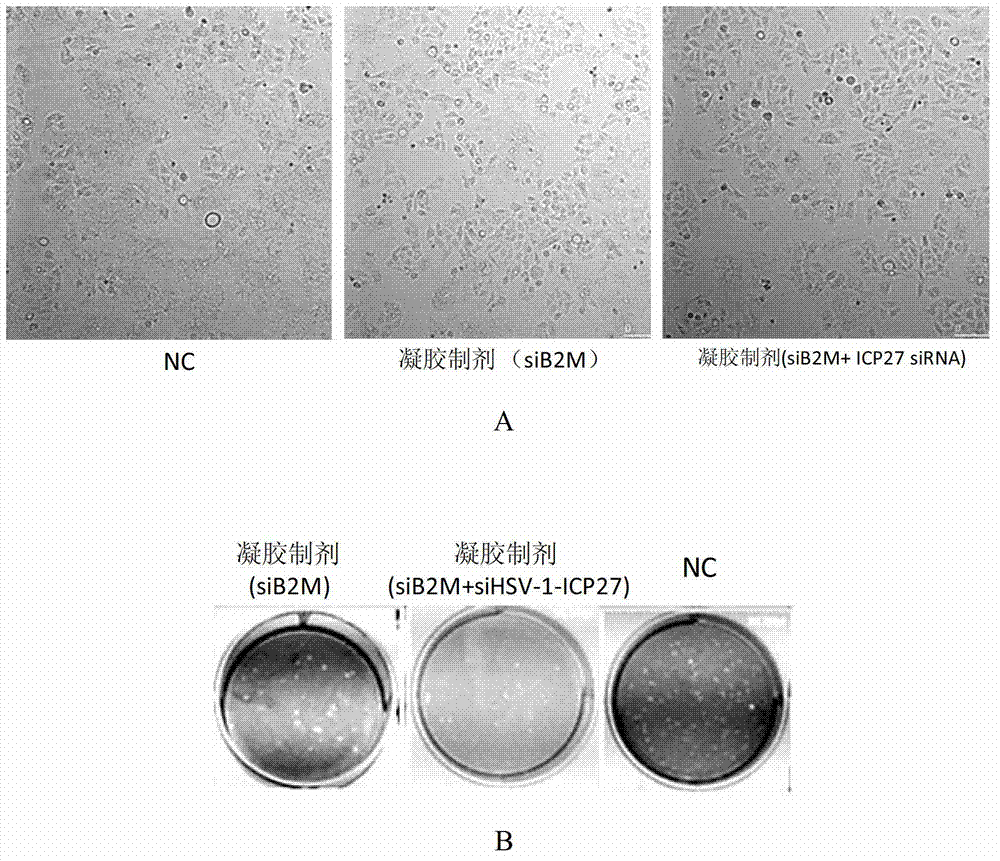

ActiveCN102899327AHigh mechanical strengthNot easy to collapseAerosol deliveryGenetic material ingredientsGeneticsFhit gene

The invention discloses an antiviral small nucleic acid and the application of the small nucleic acid in preparing a medicine for suppressing herpes simplex virus (HSV) and human papilloma virus (HPV). The small nucleic acid is a double strand nucleic acid, the positive-sense strand sequence is 5 in a sequence table, and the antisense strand sequence is 6 in the sequence table; the small nucleic acid can be prepared into a temperature-sensitive type gel preparation; the temperature-sensitive type gel preparation is injected (or sprayed) into irregular cavities such as vagina or mouth, the expression of host B2M genes in epithelial cells at the cavities and the cervix uteri and the expression of externalHPV E7 are suppressed, so that the antiviral small nucleic acid can be used for suppressing the infection of the HPV of the HSV-1 virus and / or for treating the precancerous lesions of uterine cervix caused by the HVP.

Owner:YOUJIA (HANGZHOU) BIOMEDICAL TECH CO LTD

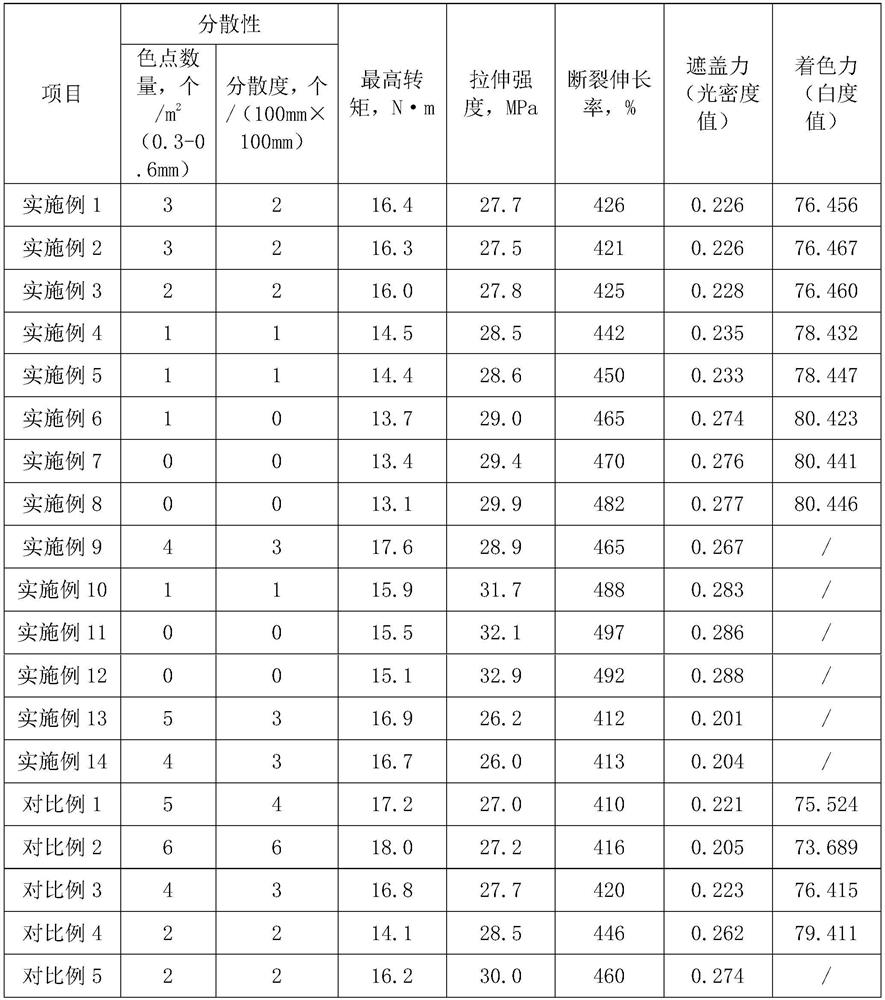

Biodegradable color master batch and preparation method thereof

ActiveCN112143184AReduce crystallinityImprove melt fluidityBio-packagingPolymer sciencePigment dispersion

The invention relates to the field of plastic additives, and particularly discloses a biodegradable color master batch and a preparation method thereof. The biodegradable color master batch is prepared from the following raw materials: poly(butyleneadipate-co-terephthalate), polycaprolactone, a pigment, a plasticizer, a dispersing agent and a compatilizer, wherein the plasticizer is prepared frommicrocrystalline cellulose, ethyl cellulose, tributyl citrate and castor oil in a weight ratio of 3-5:2-4: 1-2: 1-2; the preparation method comprises the following steps: premixing polycaprolactone and the plasticizer, adding the poly(butyleneadipate-co-terephthalate), and carrying out melting, extrusion and granulation to obtain a PBAT premix; and mixing the PBAT premix, the pigment, the dispersing agent and the compatilizer, and carrying out melting, extruding and granulating. The biodegradable color master batch disclosed by the invention can be used for dyeing degradable plastic products,and has the advantages of degradability and high dispersity in the plastic products.

Owner:QINGDAO ZHOUSHI PLASTIC PACKAGE

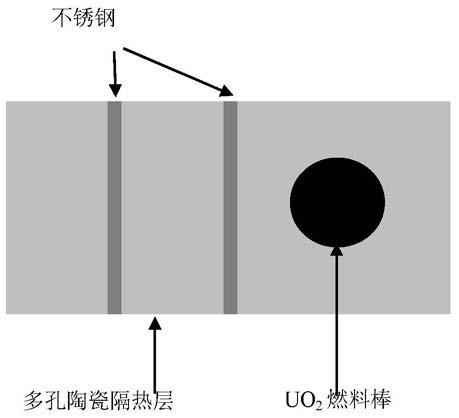

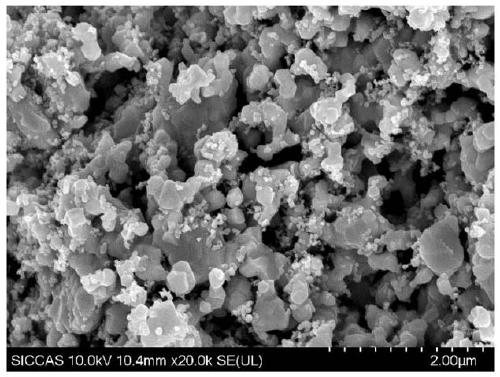

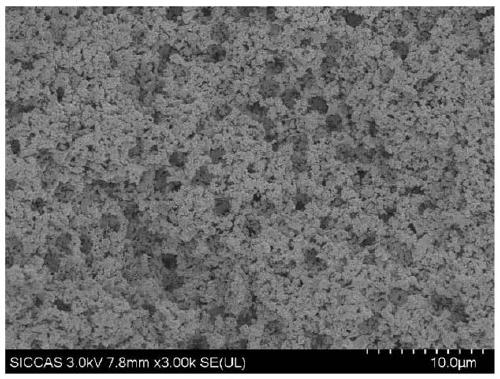

Porous rare earth titanate heat-isolating material and preparation method and application thereof

The invention relates to a porous rare earth titanate heat-isolating material and a preparation method and an application thereof. The porous rare earth titanate heat-isolating material is of a porousstructure and the composition of the material is (Re2O3)X(TiO2)(1-X), wherein Re is at least one of Y and lanthanide elements, and X is equal to 0.2-0.8, preferably 0.4-0.7. The porosity of the porous rare earth titanate heat-isolating material is 10-90% and the pore diameter is 0.1-500 microns.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Seedling culture substrate for improving seedling survival rate and preparation method thereof

InactiveCN107266240AIncrease substrate fertilityImprove water retention capacitySuperphosphatesCalcareous fertilisersMoistureAdditive ingredient

The invention discloses a seedling culture substrate for improving the seedling survival rate. The substrate is prepared from the following ingredients in parts by weight: 18 to 26 parts of humus soil, 8 to 17 parts of bran coat, 6 to 45 parts of turf, 1 to 5 parts of organic fertilizers, 25 to 45 parts of waste fungus rods and 2 to 5 parts of activation powder. The invention also discloses a preparation method of the substrate. The seedling culture substrate can be used for culturing high-quality seedlings; the adaptability of the seedlings is high; the disease and insect pest resistance of the seedlings is relatively improved; the survival rate is high; meanwhile, the soil structure is effectively improved; the soil microbes are activated; the soil fertility is increased; the soil water absorption and soil moisture preservation capability can be improved; the soil aggregate formation is promoted; the rainfall anti-erosion capability of soil is improved.

Owner:兰溪市顺光园艺技术有限公司

Soil conditioner for soil loosening and moisture and fertilizer retention

InactiveCN106281339AImprove permeabilityIncrease the granular structureAgriculture tools and machinesOrganic fertilisersPotassiumSolvent

The invention provides a soil conditioner for soil loosening and moisture and fertilizer retention. The soil conditioner comprises one or more of polyethoxylated fatty alcohol, ethoxylated alkyl ammonium sulfate, polyacrylamide, sodium dodecyl sulfonate, polyglycerol fatty alcohol ester and ethoxyl ether sodium alkyl sulfate and other auxiliaries, and water serves as a solvent. The soil conditioner has the effects of retaining water and fertilizer, loosening soil, fixing nitrogen, decomposing phosphorus, activating potassium, improving saline and alkaline land, enhancing disease resisting and anti-waterlogging performance of crops and growing roots and sprouts. Compared with the effects of existing soil conditioners, the soil conditioner has higher effective active matter content and is friendlier to the environment.

Owner:SICHUAN ANDA CHEM CO LTD

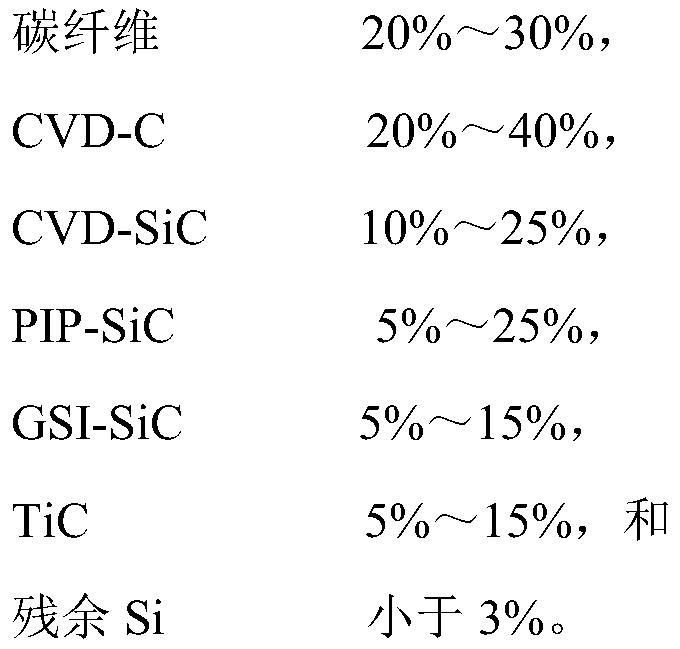

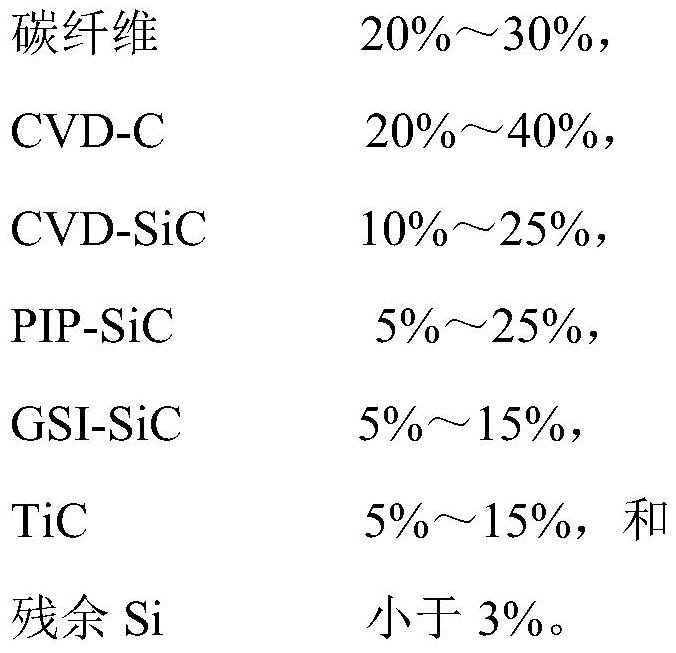

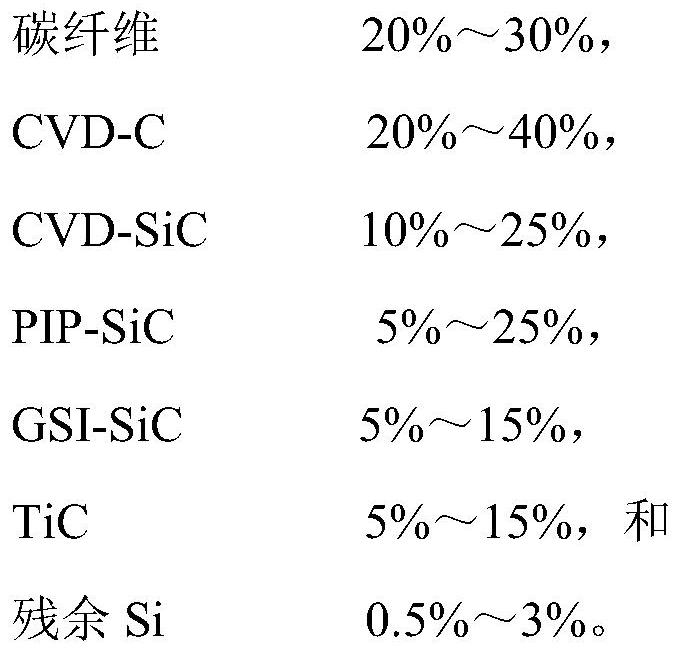

Ceramic-based composite material as well as preparation method and application thereof

ActiveCN112266259AImprove protectionReduce the degree of siliconization damageCarbon fibersWear resistance

The invention discloses a ceramic-based composite material as well as a preparation method and application thereof. The ceramic-based composite material comprises the following components in percentage by mass: 20%-30% of carbon fibers, 20%-40% of C-VDC, 10%-25% of CVD-SiC, 5%-25% of PIP-SiC, 5%-15% of GSI-SiC, 5%-15% of TiC and less than 3% of residual Si. The preparation method sequentially comprises the following steps: deposition of a C layer on a carbon fiber preform; deposition of a SiC layer; impregnation and cracking of a precursor for preparation of SiC; impregnation of asphalt and carbonization; preparation of TiC; and gas-phase siliconizing. The ceramic-based composite material disclosed by the invention has the advantages of excellent friction and wear resistance, mechanical properties and thermal properties, the content of each component can be flexibly designed and adjusted according to actual requirements, and the requirements of the field of high-performance braking andaerospace structural parts on material properties are met.

Owner:中京吉泰(北京)科技有限责任公司

Porous titanium/titanium dioxide nano tube composite flat sheet membrane and preparing method thereof

InactiveCN108251881AAdvantages of preparation methodAdjustable thicknessTransportation and packagingSurface reaction electrolytic coatingSolventNanotube

The invention provides a porous titanium / titanium dioxide nano tube composite flat sheet membrane and a preparing method thereof. The preparing method comprises the following steps that firstly, membrane casting liquid is prepared and comprises following components including, by weight percent, 50%-65% of titanium powder, 4%-7% of a binding agent, 0%-1% of a thickening agent and the balance solvents; secondly, membrane scraping is conducted; thirdly, sintering is conducted; fourthly, cleaning is conducted; fifthly, anodic oxidation is conducted, and a porous titanium flat sheet membrane obtained in the fourth step is subjected to anodic oxidation in a fluorine ion containing organic solution system; and sixthly, heat treatment is conducted, a sample obtained after anodic oxidation in the fifth step is subjected to heat treatment at the temperature ranging from 400 DEG C to 600 DEG C, and the porous titanium / titanium dioxide nano tube composite flat sheet membrane is obtained. The composite flat sheet membrane obtained through the porous titanium / titanium dioxide nano tube composite flat sheet membrane and the preparing method of the porous titanium / titanium dioxide nano tube composite flat sheet membrane can be applied to a filter system and can also be used in the catalysis aspect, operation is simple, cost is low, and industry production can be achieved.

Owner:TIANJIN POLYTECHNIC UNIV

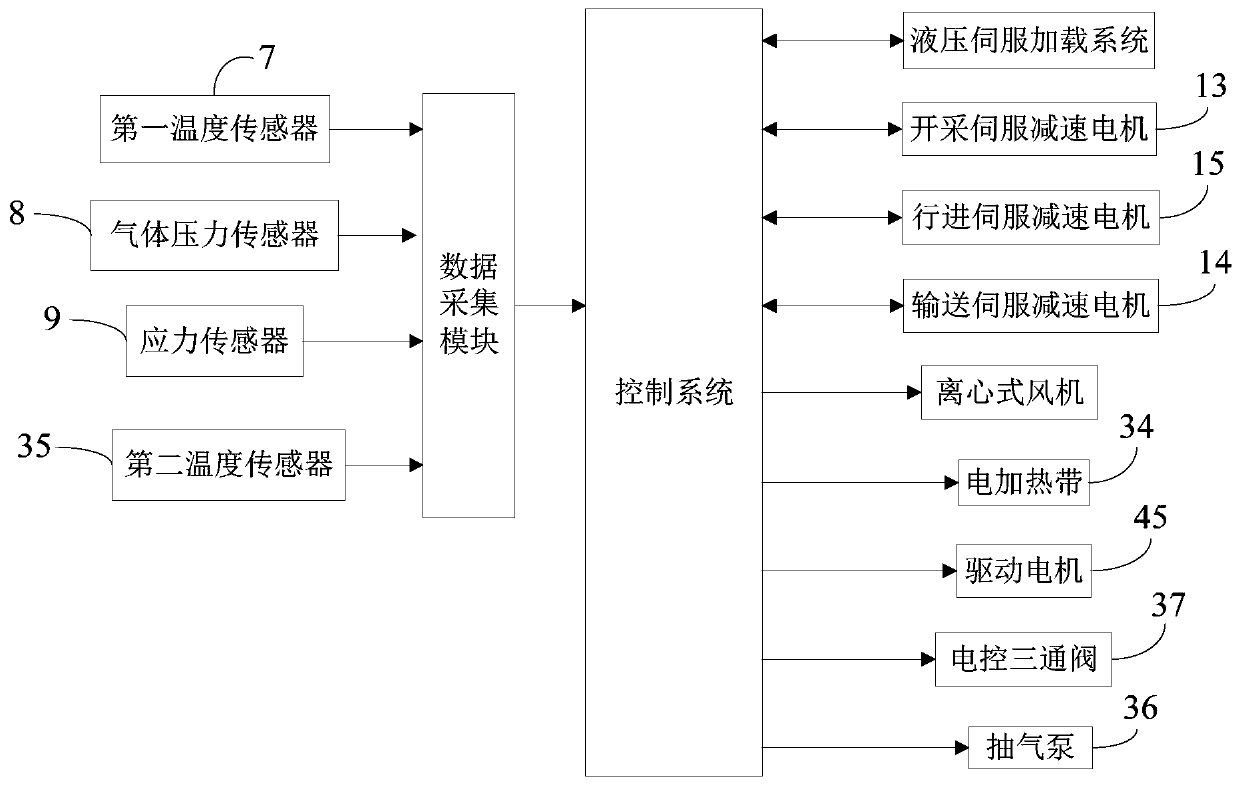

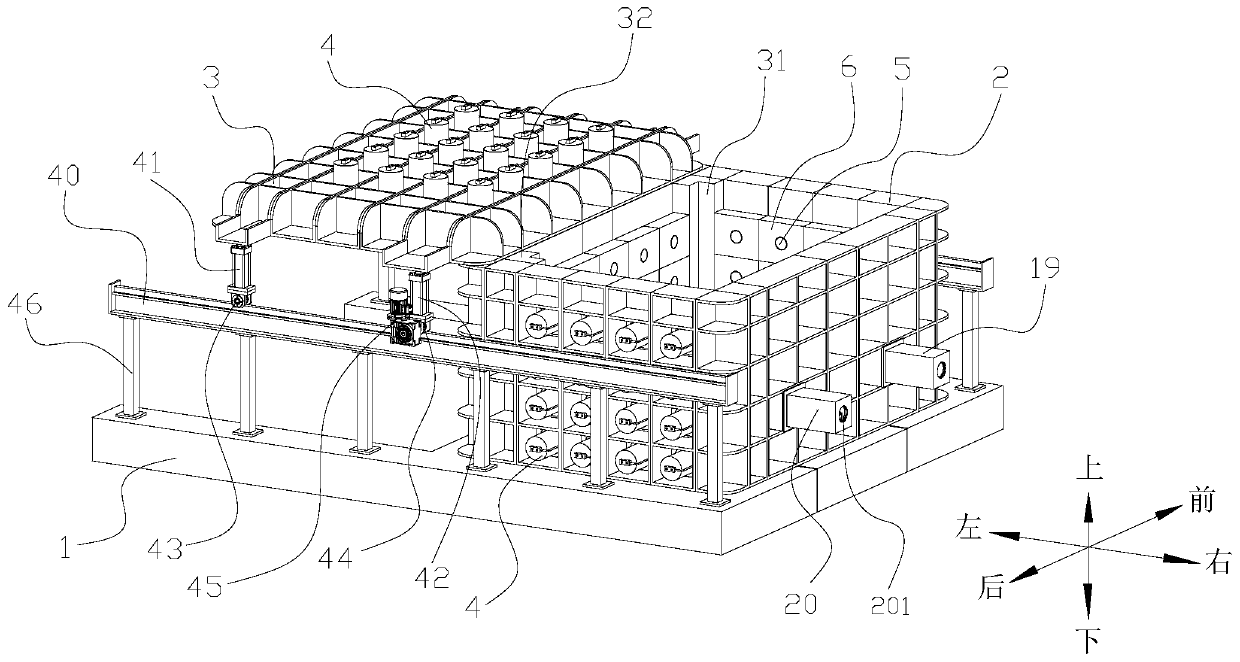

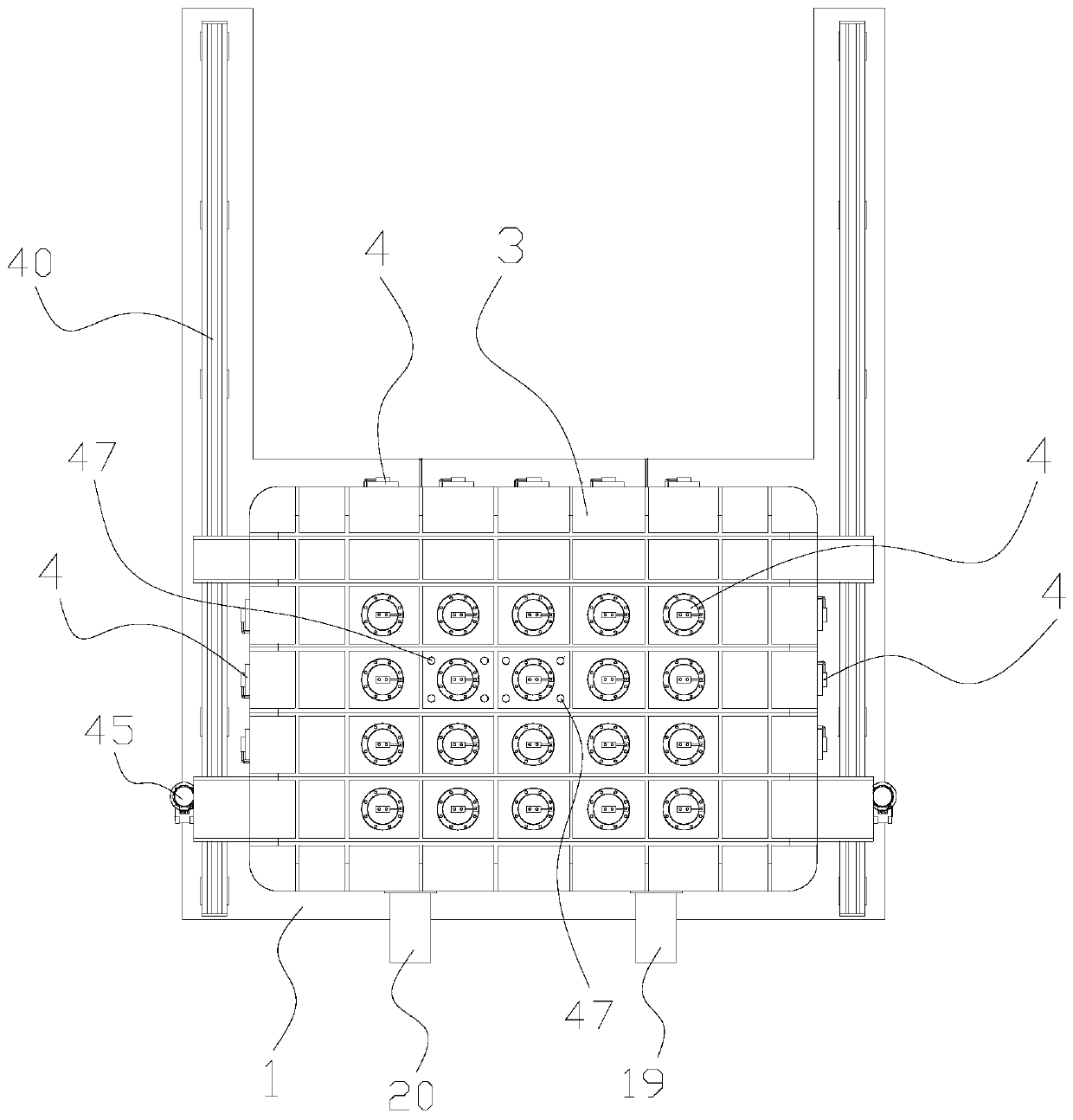

Gas three-dimensional extraction and goaf spontaneous combustion ignition coupling test system

ActiveCN110196315ASimulate the realReal dataComponent separationFuel testingSpontaneous combustionTest sample

The invention discloses a gas three-dimensional extraction and goaf spontaneous combustion ignition coupling test system comprising a ventilation system, a gas system, a three-dimensional gas extraction system, a data measurement and acquisition system and a control system and further comprising a base, a frame body, a top cover, a warming system, a triaxial stress loading system and a coal rock excavation system; the frame body is fixedly arranged on the base, the top cover can cover the frame body, the heating system enables a test sample piece placed in a test cavity defined by the frame body and the top cover to be kept at a test temperature, the triaxial stress loading system is used for loading XYZ-direction stress on the test sample piece, and the coal rock excavation system is usedfor mining a coal bed in the test sample piece to form a goaf. By adoption of the system, the goaf and gas three-dimensional extraction of the actual mine can be simulated more truly, and more accurate and real data is provided for the subsequent coupling relation between gas three-dimensional extraction and spontaneous combustion ignition of the goaf.

Owner:余明高

Organic fertilizer and preparation method thereof

ActiveCN101759451APromote absorptionPromote growth and developmentBio-organic fraction processingOrganic fertiliser preparationPotassiumCompost

The invention provides an organic compost, which comprises the following components in part by weight: 10-50 organic matter, 5-20 humic acid, 0.5-2.0 total-N, 1.0-2.0 total-K and 0.1-0.5 total-P. The organic fertilizer is made by mixing and fermenting heavily polluted condensed water caused by black fluid concentration in the paper making process, crop straws, various plant organic matters or material preparing byproduct. The whole preparing technology is simple. The heavily polluted condensed water generated again in the paper making process and the straws are used to produce the organic fertilizer which is applied to the growing process of the crops again. The newly grown straws can be applied to the paper making industry. The cyclic utilization is the virtuous cycle of the sustainable development of industrial production. The organic compost reduces the soil hardened phenomenon, improves soil granular structure and can effectively promote the root to grow, obviously increase the number and thickness degree of the root, stimulate the crops to grow, strengthen the stress resistant performance of the crops and improve the quality of the crops.

Owner:SHANDONG TRALIN PAPER

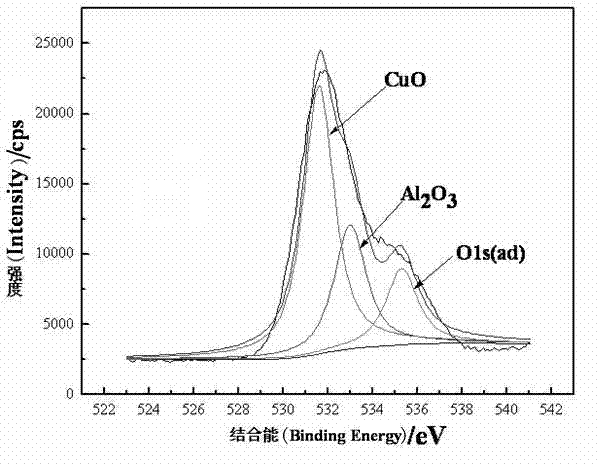

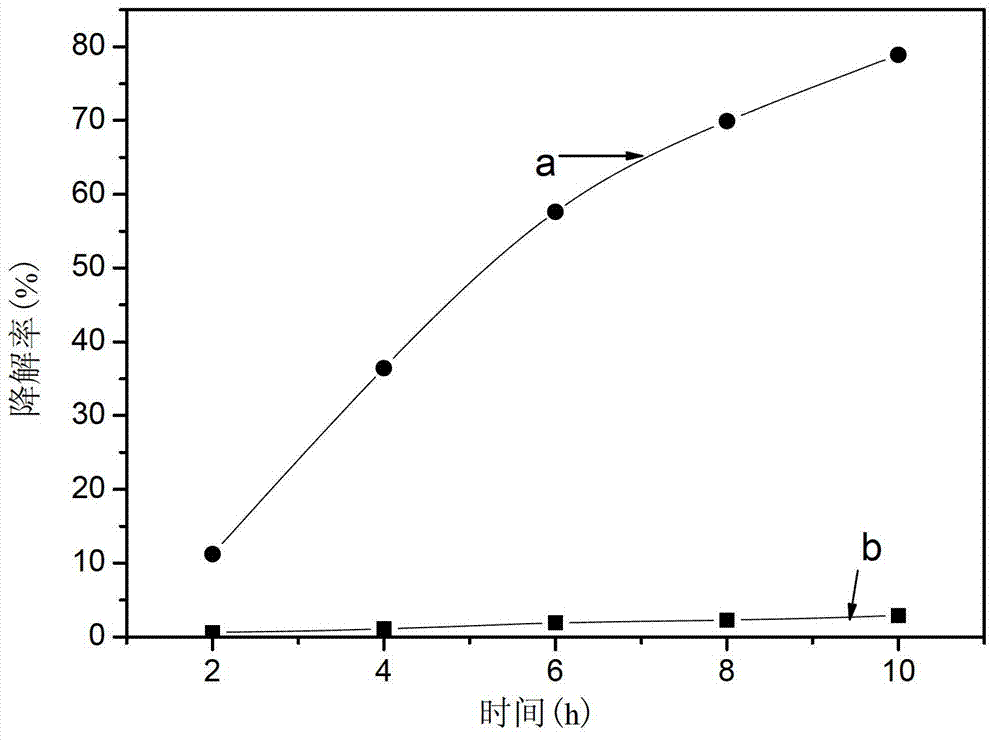

Copper oxide/aluminum oxide composite catalyst and preparation method and special micro-arc oxidation electrolyte thereof

ActiveCN103088387ASimple processImprove efficiencyAnodisationMetal/metal-oxides/metal-hydroxide catalystsElectrolytic agentMicro arc oxidation

The invention relates to the field of preparation of catalysts, and in particular to a copper oxide / aluminum oxide composite catalyst, and a preparation method and a special micro-arc oxidation electrolyte thereof. The preparation method of the copper oxide / aluminum oxide composite catalyst comprises the step of putting a pure aluminum sample into the micro-arc oxidation electrolyte including copper acetate to carry out micro-arc oxidation treatment, thus obtaining the copper oxide / aluminum oxide composite catalyst. The copper oxide / aluminum oxide composite catalyst and the preparation method and the special micro-arc oxidation electrolyte of the copper oxide / aluminum oxide composite catalyst have the advantages that the prepared copper oxide / aluminum oxide composite catalyst film layer is level and smooth in appearance, bonding strength between the active matter CuO and the carrier Al2O3 is good, and the active matter dissolution rate is low, so that the copper oxide / aluminum oxide composite catalyst can be repeatedly used for many times; compared with conventional methods, the copper oxide / aluminum oxide composite catalyst can be prepared by one step, so that the working procedure is reduced and the cost is saved.

Owner:SHAANXI HUAYIN TECH CO LTD

Method for preparing porous polymer material by selective biodegradation

The invention discloses a method for preparing a porous polymer material by selective biodegradation, belongs to the technical field of a biodegradable high molecular material, and solves the technical problems of a preparation method of the porous polymer material in the prior art that poisons are caused to cells, the connectivity between holes is poor and the porous polymer material cannot be used as a human tissue bracket. The method disclosed by the invention comprises the following steps of: commixing a biodegradable polymer and a non-biodegradable polymer or commixing various biodegradable polymers to obtain a commixed material; and then, carrying out selective degradation on the biodegradable polymers in the commixed material by utilizing the selectivity of a microorganism or an enzyme to obtain the porous polymer material. The preparation method disclosed by the invention is simple in process, moderate, clean and environment-friendly, and strong in selectivity; and the holes of the prepared porous polymer material are controllable and the porous polymer material can be used as a human tissue bracket material.

Owner:吉林省开顺新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com