Biodegradable color master batch and preparation method thereof

A technology of biodegradation and color masterbatch, applied in the field of biodegradable color masterbatch and its preparation, can solve the problems of affecting the biodegradability of degradable plastics, affecting the dispersibility of degradable plastics, uneven color distribution of products, etc. Coloring effect, the effect of increasing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

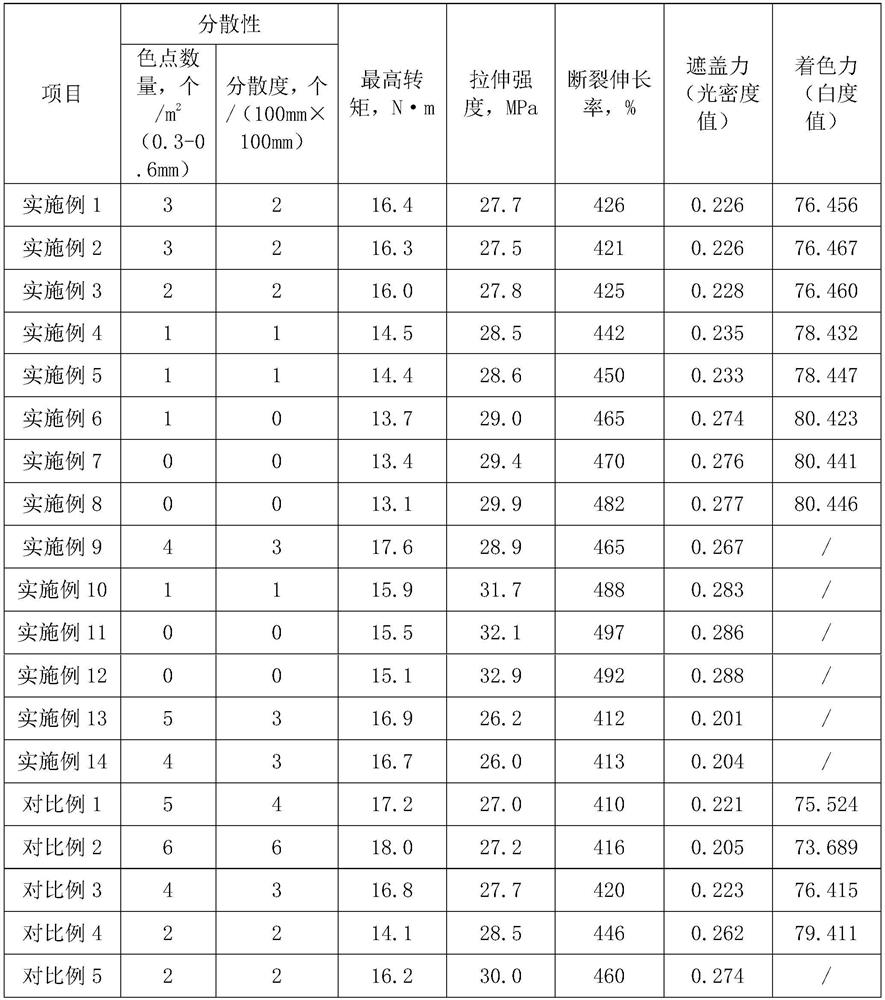

Examples

preparation example 1

[0042]Preparation example 1 of modified titanium dioxide: ① Take calcium silicate, grind and siev it to obtain calcium silicate powder with a particle size of 1-5μm; add 0.1kg of silane to 10kg calcium silicate powder Coupling agent KH570 and 3kg lithium silicate were ground at a speed of 2000r / min for 4h to obtain a silicate mixture;

[0043]②Take the rutile type titanium dioxide, grind it and sieving it to obtain titanium dioxide fine powder with a particle size of 1-5μm; add 0.5kg polycarboxylate sodium salt dispersant and 200kg water to 10kg titanium dioxide fine powder. / min speed, stirring for 30min, obtain titanium dioxide slurry;

[0044]③Add 1-3kg of silicate mixture to the titanium dioxide slurry, stir for 30min at a speed of 2000r / min, and stand for 4-6h at a temperature of 70-80℃ to obtain a titanium dioxide-silicate slurry;

[0045]④Add 30kg, 5wt% aluminum sulfate solution to the titanium dioxide-silicate slurry within 1h. After the dripping is completed, adjust the pH to 7.0, a...

preparation example 2

[0047]Preparation example 2 of modified titanium dioxide: ① Take calcium silicate, grind and siev it to obtain calcium silicate powder with a particle size of 1-5μm; add 0.15kg KH570 to 10kg calcium silicate powder And 4kg lithium silicate, after grinding it at 3000r / min for 3h, a silicate mixture is obtained;

[0048]②Take the rutile titanium dioxide powder, grind it and sieving it to obtain titanium dioxide powder with a particle size of 1-5 μm; add 0.75 kg polycarboxylate sodium salt dispersant and 250 kg of water to 10 kg of titanium dioxide powder. / min speed, stirring for 30min, obtain titanium dioxide slurry;

[0049]③Add 2kg of silicate mixture to the titanium dioxide slurry, stir for 30min at a speed of 2000r / min, and stand for 5h at a temperature of 75°C to obtain a titanium dioxide-silicate slurry;

[0050]④Drop a 35kg, 5wt% aluminum sulfate solution into the titanium dioxide-silicate slurry within 1h. After the dripping is completed, adjust the pH to 7.2 and let stand at room tem...

preparation example 3

[0052]Preparation Example 3 of Modified Titanium Dioxide: ① Take calcium silicate, grind and siev it to obtain calcium silicate powder with a particle size of 1-5μm; add 0.1kg of silane to 10kg calcium silicate powder Coupling agent KH570, 0.1kg silane coupling agent KH791 and 5kg lithium silicate were ground at a speed of 4000r / min for 2h to obtain a silicate mixture;

[0053]②Take the rutile titanium dioxide powder, grind it and sieving it to obtain titanium dioxide powder with a particle size of 1-5μm; add 1kg polycarboxylate sodium salt dispersant and 300kg water to 10kg of titanium dioxide powder, at a rate of 2000r / Min. speed, stirring for 30 minutes to obtain titanium dioxide slurry;

[0054]③Add 3kg of silicate mixture to the titanium dioxide slurry, stir for 30min at a speed of 2000r / min, and stand still for 6h at a temperature of 80°C to obtain a titanium dioxide-silicate slurry;

[0055]④Drop 40kg, 5wt% of aluminum sulfate solution into the titanium dioxide-silicate slurry within...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com