Porous titanium/titanium dioxide nano tube composite flat sheet membrane and preparing method thereof

A nanotube composite, titanium dioxide technology, used in metal processing equipment, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve problems such as inability to achieve, achieve high porosity, large specific surface area, and good conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a porous titanium / titanium dioxide nanotube composite flat film, comprising the following steps:

[0028] (1) Prepare casting solution, which is composed of the following components by weight percentage: 50-65% of titanium powder, 4-7% of binder, 0-1% of thickener, and the balance is solvent ;

[0029] (2) scraping the film, using the film-scraping method obtained in step (1) to obtain a wet film, and soaking the formed wet film in water until the solvent is fully separated out, then drying to obtain a film to be sintered;

[0030] (3) Sintering, sintering the film to be sintered obtained in step (2) under the protection of an argon atmosphere, the heating rate during sintering is 1-10°C / min, and the highest sintering temperature is 1000-1200°C, reaching the highest sintering temperature Finally, keep warm for 120-180min and cool naturally to obtain the film to be cleaned;

[0031] (4) cleaning, cleaning the film to be cleaned obtained in step (...

Embodiment 1~5

[0040] The formulations of Examples 1-5 and the pore size range of the porous titanium flat membrane are shown in Table 1 below.

[0041] The concrete sintering process parameter in the step (3) of embodiment 1~5 sees the following table 2, wherein T maxis the maximum sintering temperature, V is the heating rate, and t is the holding time.

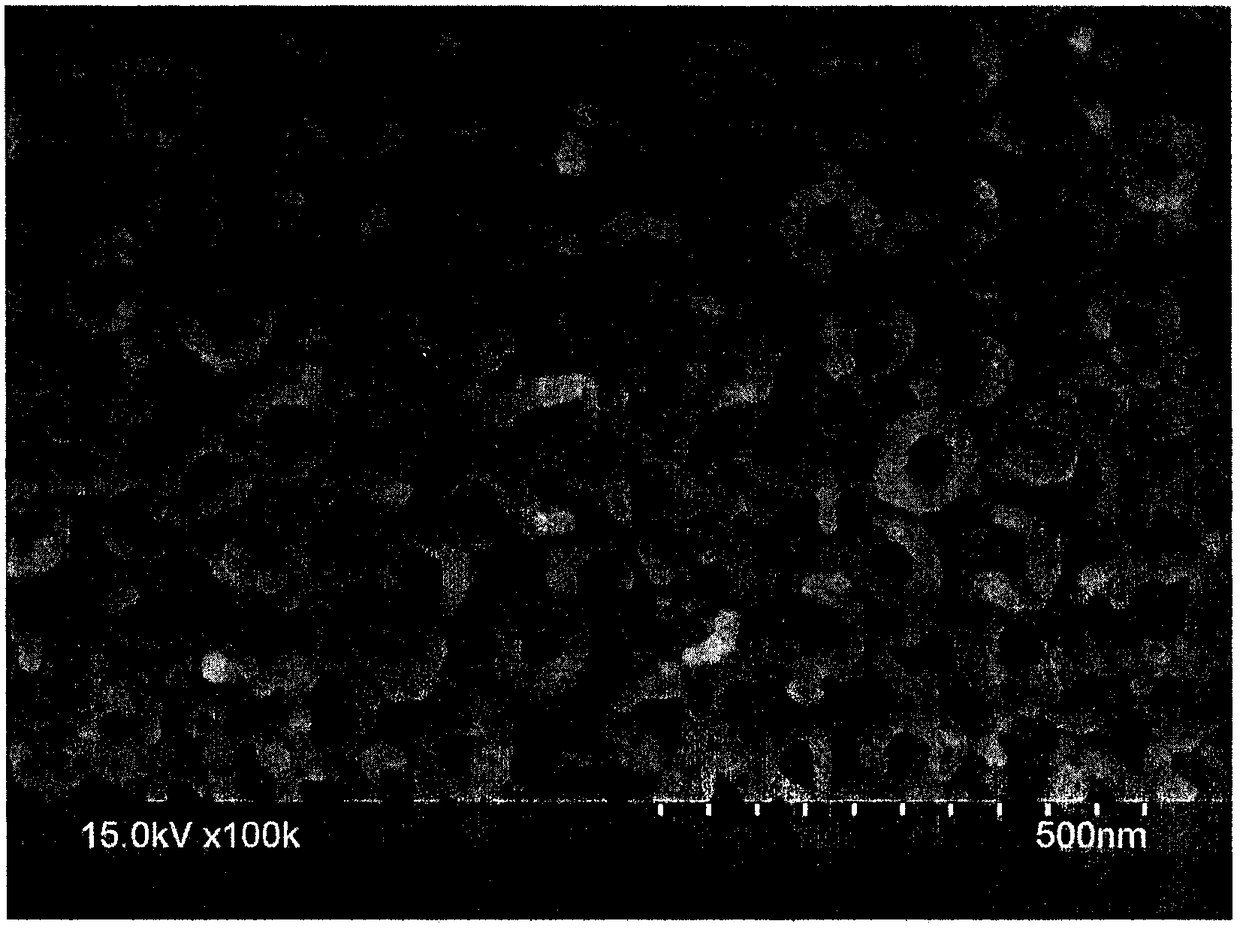

[0042] The anodic oxidation process parameters and the diameter range of titanium dioxide nanotubes in the step (5) of Examples 1-5 are shown in Table 3 below, wherein U is the voltage, and t is the oxidation time.

[0043] Table 1 The formulations of Examples 1 to 5 and the pore diameter range of the porous titanium flat membrane

[0044]

[0045] Table 2 Concrete sintering process parameters in steps (3) of Examples 1 to 5

[0046]

[0047]

Embodiment 1

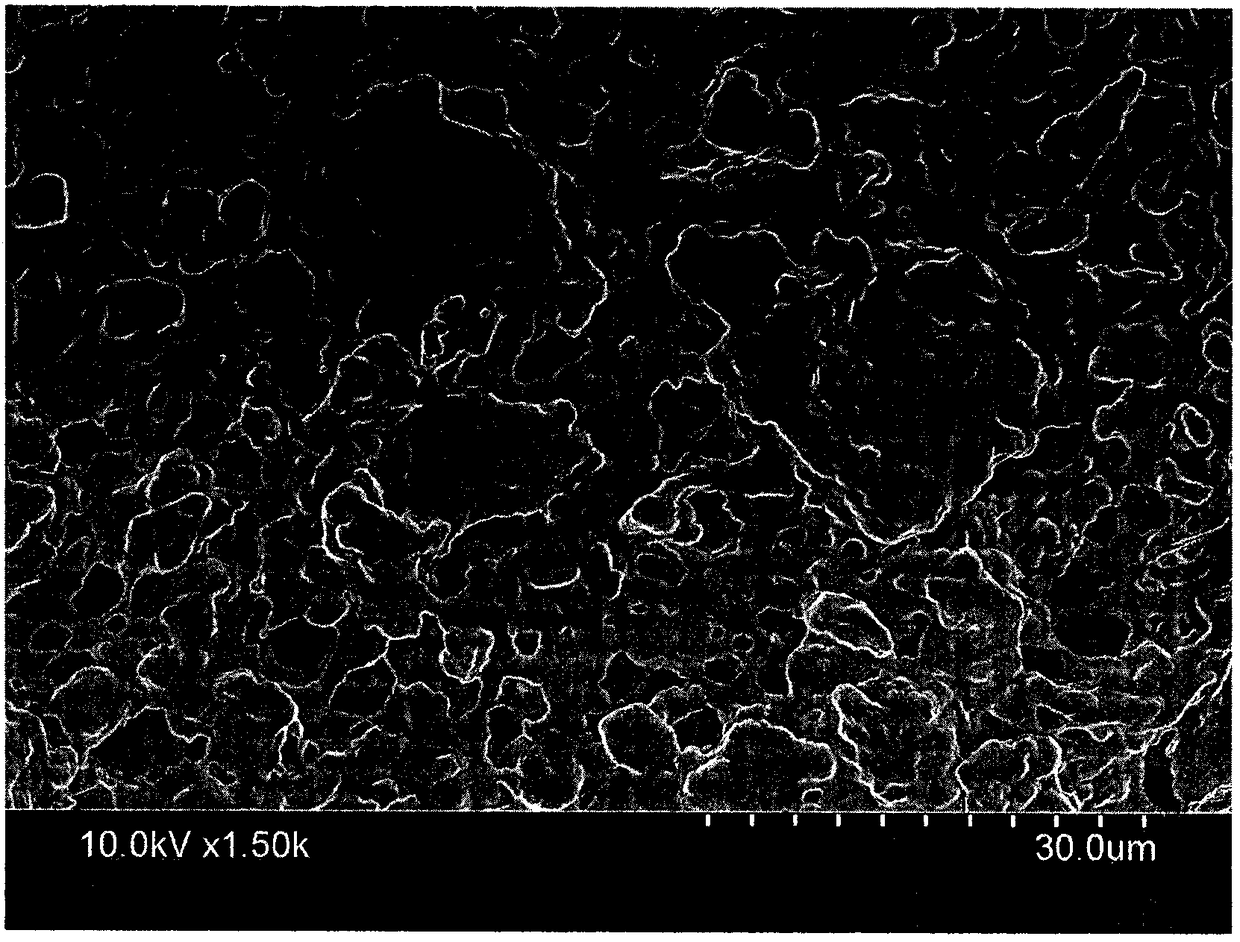

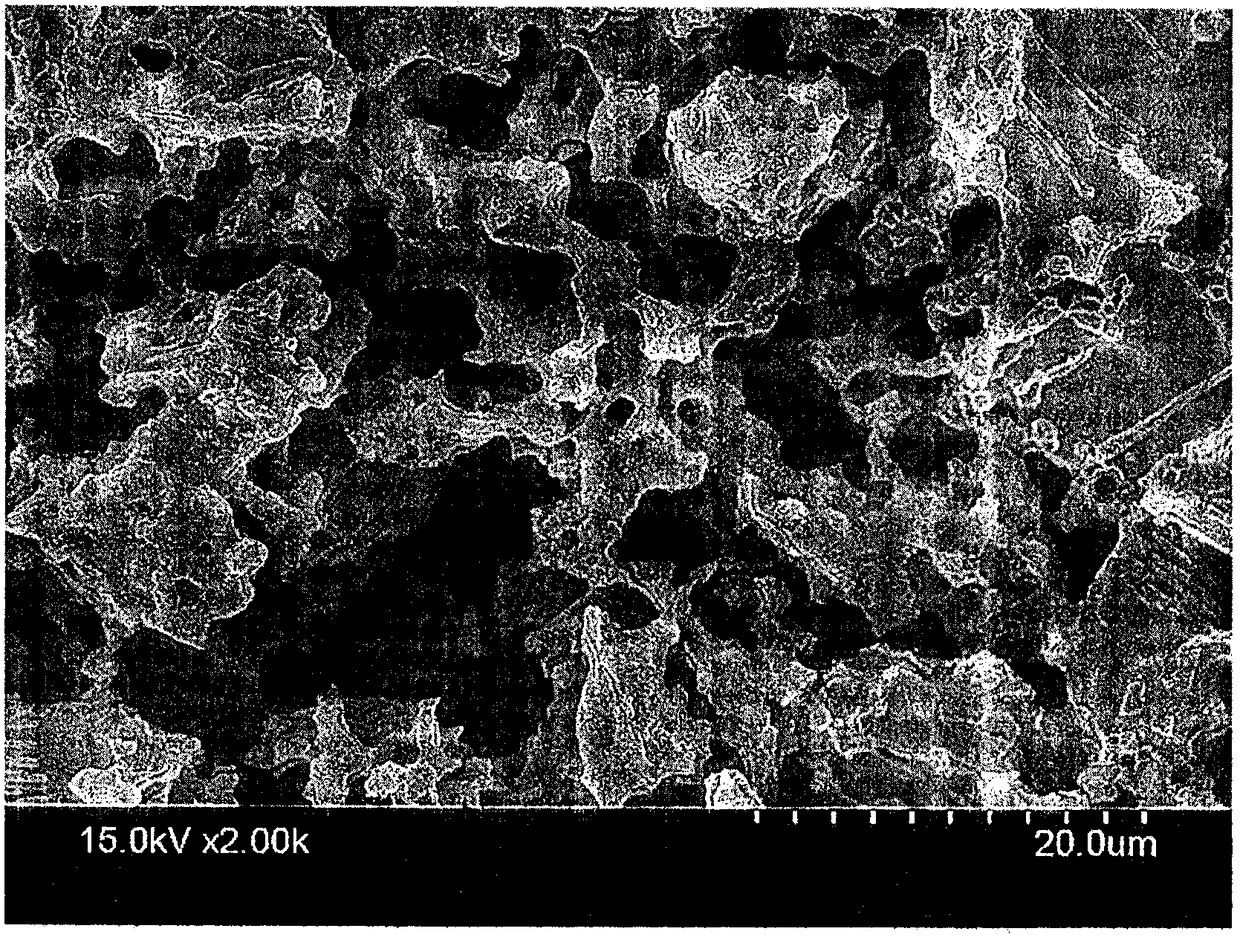

[0050] The surface scanning electron microscope picture of the porous titanium flat film that embodiment 1 obtains is as figure 1 As shown in the figure, it can be seen from the figure that the porous titanium flat membrane prepared by the preparation method provided by the present invention has a complete membrane structure and uniform pores after the raw titanium powder is sintered to form a membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com