Preparation method of curved screen phone tempered glass film

A tempered glass film and curved screen technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of low water resistance and high temperature resistance, difficulty in fully laminating, degumming, etc., and achieve water resistance Good performance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

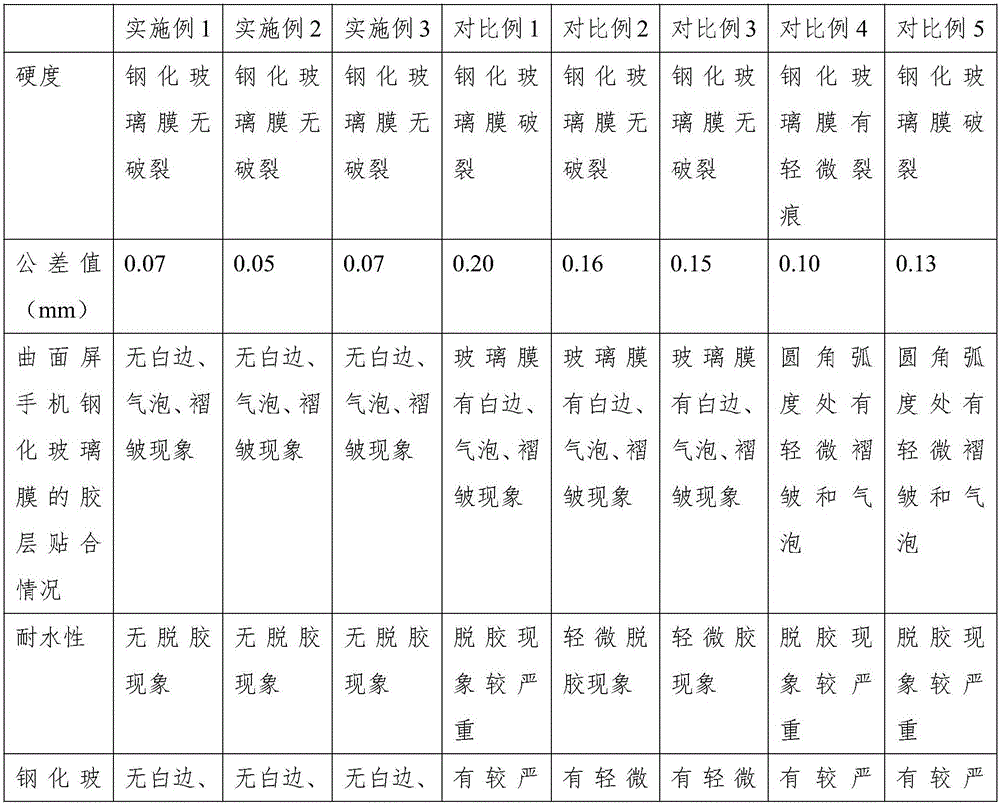

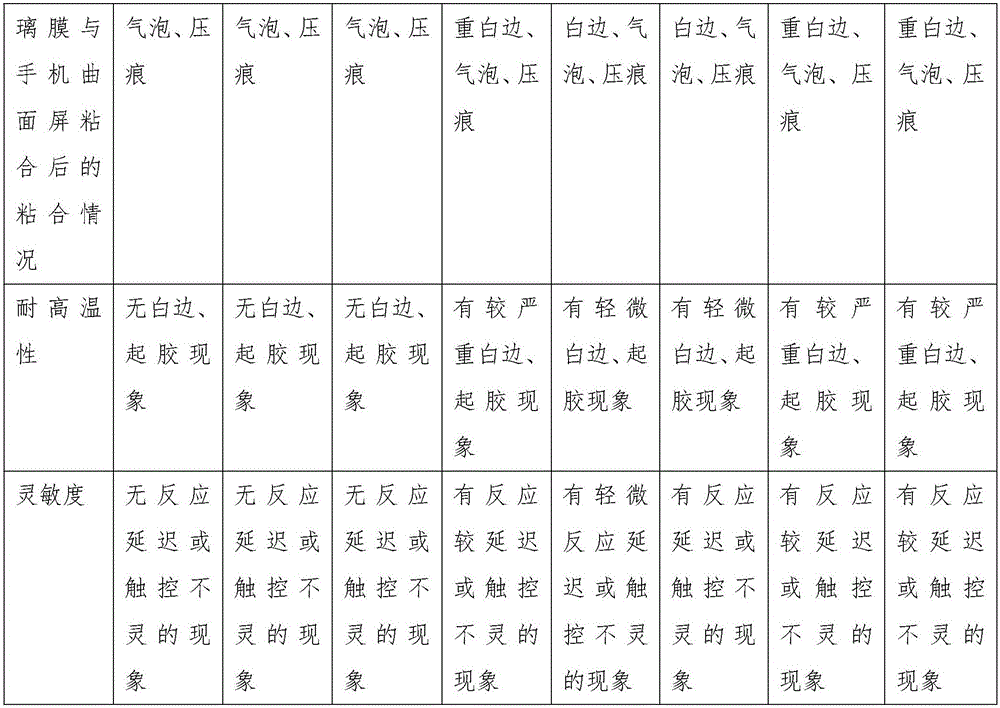

Examples

Embodiment 1

[0027] Example 1. A method for preparing a tempered glass film for a mobile phone with a curved screen

[0028] S1 Take a TPU substrate, apply OCA optical glue with a thickness of 25 μm on the upper surface of the TPU substrate, and apply silica gel with a thickness of 50 μm on the lower surface of the TPU substrate, the thickness of the TPU substrate is 100 μm, The hardness is 85 degrees, and the TPU film is obtained;

[0029] S2 Cut the high-alumina-silicate glass sheet with a thickness of 0.2mm according to the specified size of the curved mobile phone cover plate. After cutting, the size and hole position are processed according to the size of the mobile phone cover plate, and the edge is polished by a grinder to obtain a sheet;

[0030] S3 takes off the mold that is concave in the shape of a mobile phone cover, the upper mold is convex in the shape of a mobile phone cover, and the upper and lower molds are placed in a graphite mobile phone mold in a sealed cavity, and the...

Embodiment 2

[0033] Example 2. A method for preparing a tempered glass film for a mobile phone with a curved screen

[0034] S1 Take a TPU substrate, apply OCA optical glue with a thickness of 45 μm on the upper surface of the TPU substrate, and apply silica gel with a thickness of 80 μm on the lower surface of the TPU substrate. The thickness of the TPU substrate is 120 μm. The hardness is 85 degrees, and the TPU film is obtained;

[0035] S2 Cut the high-alumina-silicate glass sheet with a thickness of 0.3mm according to the specified size of the curved mobile phone cover plate. After cutting, the size and hole position are processed according to the size of the mobile phone cover plate, and the edge is polished by a grinder to obtain a sheet;

[0036] S3 takes off the mold that is concave in the shape of a mobile phone cover, the upper mold is convex in the shape of a mobile phone cover, and the upper and lower molds are placed in a graphite mobile phone mold in a sealed cavity, and then ...

Embodiment 3

[0039] Example 3. A method for preparing a tempered glass film for a mobile phone with a curved screen

[0040] S1 Take a TPU substrate, apply OCA optical glue with a thickness of 70 μm on the upper surface of the TPU substrate, and apply silica gel with a thickness of 100 μm on the lower surface of the TPU substrate. The thickness of the TPU substrate is 150 μm. The hardness is 85 degrees, and the TPU film is obtained;

[0041] S2 Cut the high-alumina-silicate glass sheet with a thickness of 0.5mm according to the specified size of the curved mobile phone cover plate. After cutting, the size and hole position are processed according to the size of the mobile phone cover plate, and the edge is polished by a grinder to obtain the sheet;

[0042] S3 takes off the mold that is concave in the shape of a mobile phone cover, the upper mold is convex in the shape of a mobile phone cover, and the upper and lower molds are placed in a graphite mobile phone mold in a sealed cavity, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com