A preparation method of aramid lithium battery composite separator

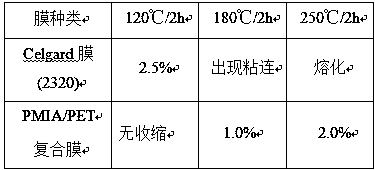

A composite diaphragm and lithium battery technology, which is applied in the preparation of spinning solutions, battery pack components, circuits, etc., can solve the problems of battery short circuit, poor electrolyte affinity, poor thermal dimensional stability at high temperature, etc., and improve thermal stability , The preparation process is simple, the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

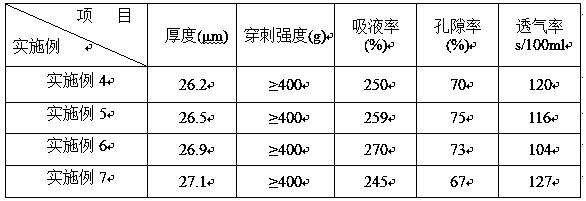

Examples

Embodiment 1

[0018] A preparation method of aramid lithium battery composite diaphragm, comprising the following steps:

[0019] (1) Preparation of N,N-dimethylacetamide / lithium chloride mixed solvent: N,N-dimethylacetamide was dried with 4A molecular sieves and purified by distillation; under nitrogen protection, lithium chloride powder was Add it into N,N-dimethylacetamide, stir with a magnetic stirrer for 10 minutes until completely dissolved, and make N,N-dimethylacetamide / lithium chloride mixed solvent;

[0020] (2) Preparation of PMIA spinning solution: Dry PMIA in a vacuum oven at 120°C for 2 hours, add the dried PMIA to N,N-dimethylacetamide / lithium chloride mixed solvent, and use an oil bath at 80°C Down heating and stirring 10h, until PMIA fiber dissolves completely, PMIA spinning solution promptly prepares; Preparation PMIA concentration is the PMIA spinning solution of 15wt%, wherein the concentration of lithium chloride is 1wt% in the solution;

[0021] (3) Electrospin the pr...

Embodiment 2

[0024] A preparation method of aramid lithium battery composite diaphragm, comprising the following steps:

[0025] (1) Preparation of N,N-dimethylacetamide / lithium chloride mixed solvent: N,N-dimethylacetamide was dried with 4A molecular sieves and purified by distillation; under nitrogen protection, lithium chloride powder was Add it into N,N-dimethylacetamide, stir with a magnetic stirrer for 10 minutes until completely dissolved, and make N,N-dimethylacetamide / lithium chloride mixed solvent;

[0026] (2) Preparation of PMIA spinning solution: Dry PMIA in a vacuum oven at 120°C for 3 hours, add the dried PMIA to the N,N-dimethylacetamide / lithium chloride mixed solvent, and use an oil bath at 80°C Down heating and stirring 10h, until PMIA fiber dissolves completely, PMIA spinning solution promptly prepares; Preparation PMIA concentration is the PMIA spinning solution of 17wt%, wherein the concentration of lithium chloride in the solution is 2wt%;

[0027] (3) Electrospin th...

Embodiment 3

[0030] A preparation method of aramid lithium battery composite diaphragm, comprising the following steps:

[0031] (1) Preparation of N,N-dimethylacetamide / lithium chloride mixed solvent: N,N-dimethylacetamide was dried with 4A molecular sieves and purified by distillation; under nitrogen protection, lithium chloride powder was Add it into N,N-dimethylacetamide, stir with a magnetic stirrer for 10 minutes until completely dissolved, and make N,N-dimethylacetamide / lithium chloride mixed solvent;

[0032] (2) Preparation of PMIA spinning solution: Dry PMIA in a vacuum oven at 120°C for 4 hours, add the dried PMIA to N,N-dimethylacetamide / lithium chloride mixed solvent, and use an oil bath at 80°C Down heating and stirring 10h, until PMIA fiber dissolves completely, PMIA spinning solution promptly prepares; Preparation PMIA concentration is the PMIA spinning solution of 19wt%, wherein the concentration of lithium chloride in the solution is 3wt%;

[0033] (3) Electrospin the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com