Copper oxide/aluminum oxide composite catalyst and preparation method and special micro-arc oxidation electrolyte thereof

A composite catalyst and micro-arc oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Complexity, high cost and other issues, to achieve the effect of low dissolution rate of active substances, simple process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] First, weigh the following medicines (0.066mol / L) sodium phosphate, (0.034mol / L) sodium borate, (0.006mol / L) sodium tungstate and (0.005mol / L) sodium silicate, add deionized water to dilute Prepare the electrolyte solution, then add copper acetate (0.015mol / L) into the above solution, and stir evenly.

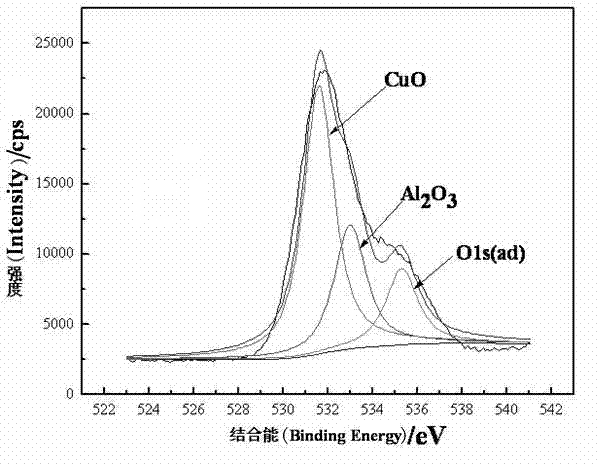

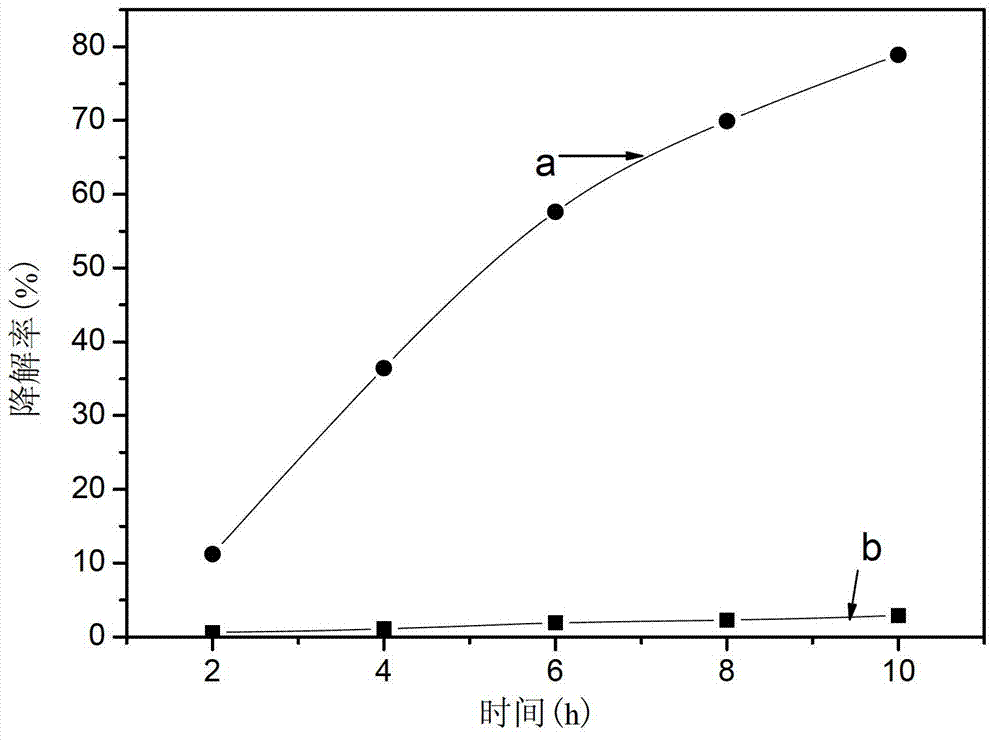

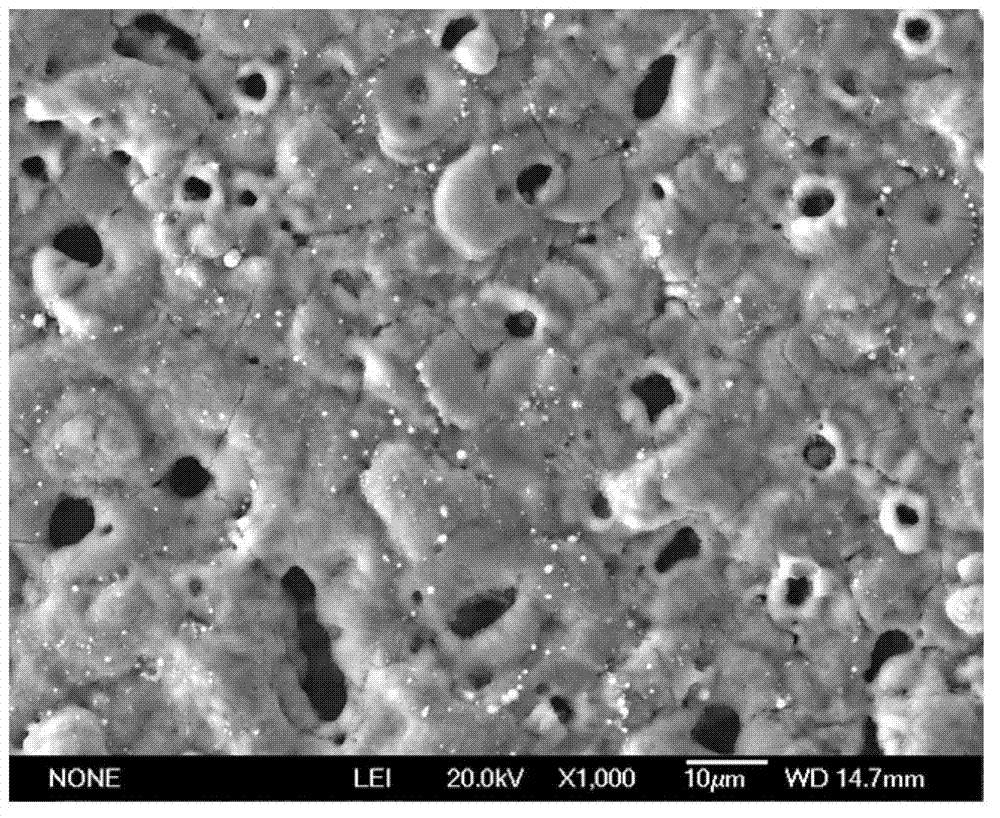

[0044] Put the pure aluminum sample to be treated in the electrolyte for micro-arc oxidation treatment, use the pure aluminum sample as the anode, and the stainless steel plate as the cathode, control the process parameters as shown in Table 1, and the pure aluminum sample can be The surface is formed with a thickness of about 5um and contains CuO / Al 2 o 3 catalytic membrane layer.

[0045] Table 1 Process parameters of pure aluminum micro-arc oxidation

[0046]

Embodiment 2

[0048] First, take the following medicines sodium hexametaphosphate 0.035mol / l, ammonium metavanadate 0.015mol / l, cobalt sulfate 0.005mol / l, sodium silicate 0.12mol / l, add deionized water to dilute the configuration electrolyte, and then Add copper acetate (0.015mol / L) into the above solution and stir evenly.

[0049] Place the pure aluminum sample to be treated in the electrolyte for micro-arc oxidation treatment, use the pure aluminum sample as the anode, and the stainless steel plate as the cathode, and control the process parameters as shown in Table 1 of Example 1, then the pure aluminum The surface of the aluminum sample is formed with a thickness of about 5um containing CuO / Al 2 o 3 catalytic membrane layer.

Embodiment 3

[0051] First, weigh the following medicines (0.066mol / L) sodium phosphate, (0.034mol / L) sodium borate, (0.006mol / L) sodium tungstate and (0.005mol / L) sodium silicate, add deionized water to dilute Prepare the electrolyte solution, then add copper acetate (0.025mol / L) into the above solution, and stir evenly.

[0052] Put the pure aluminum sample to be treated in the electrolyte for micro-arc oxidation treatment, use the pure aluminum sample as the anode, and the stainless steel plate as the cathode, control the process parameters as shown in Table 2, and the pure aluminum sample can be The surface is formed with a thickness of about 10um and contains CuO / Al 2 o 3 catalytic membrane layer.

[0053] Table 2 Process parameters of pure aluminum micro-arc oxidation

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com