Gas three-dimensional extraction and goaf spontaneous combustion ignition coupling test system

A technology of gas drainage and test system, which is applied in the direction of gas emission, fuel oil testing, mining equipment, etc., and can solve the problems that cannot truly reflect the relationship between gas drainage in goafs and coal spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

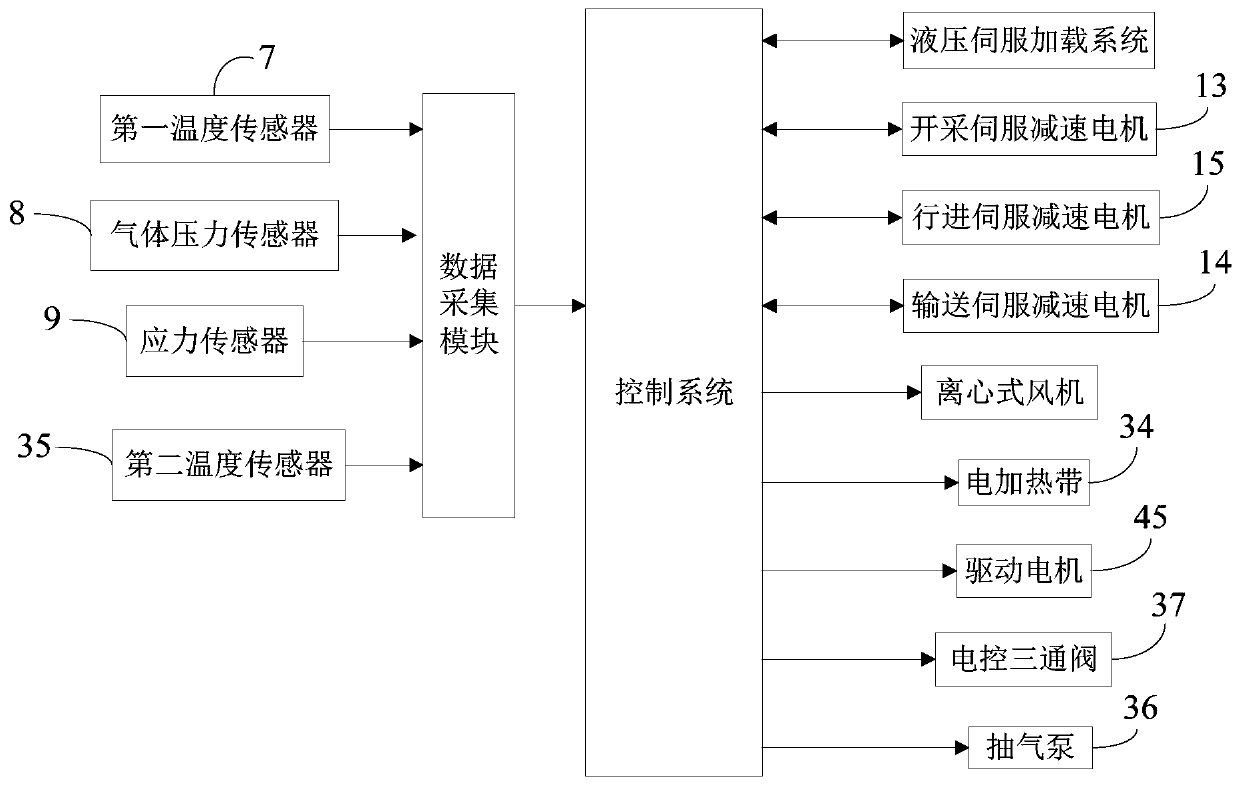

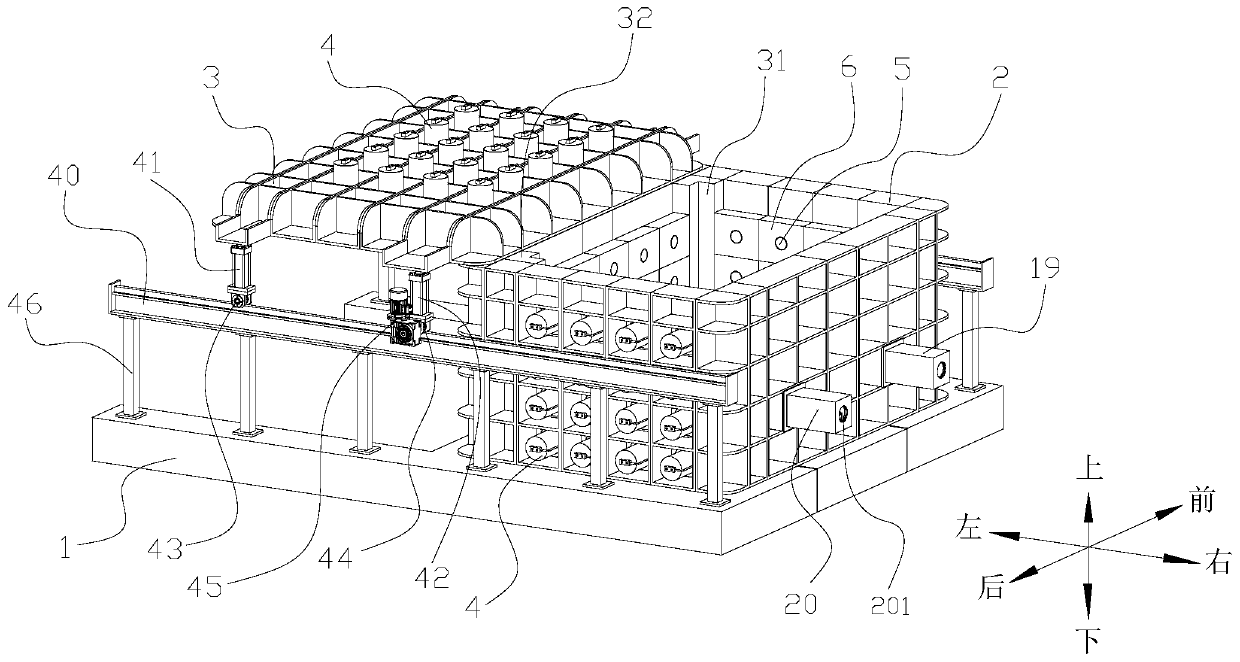

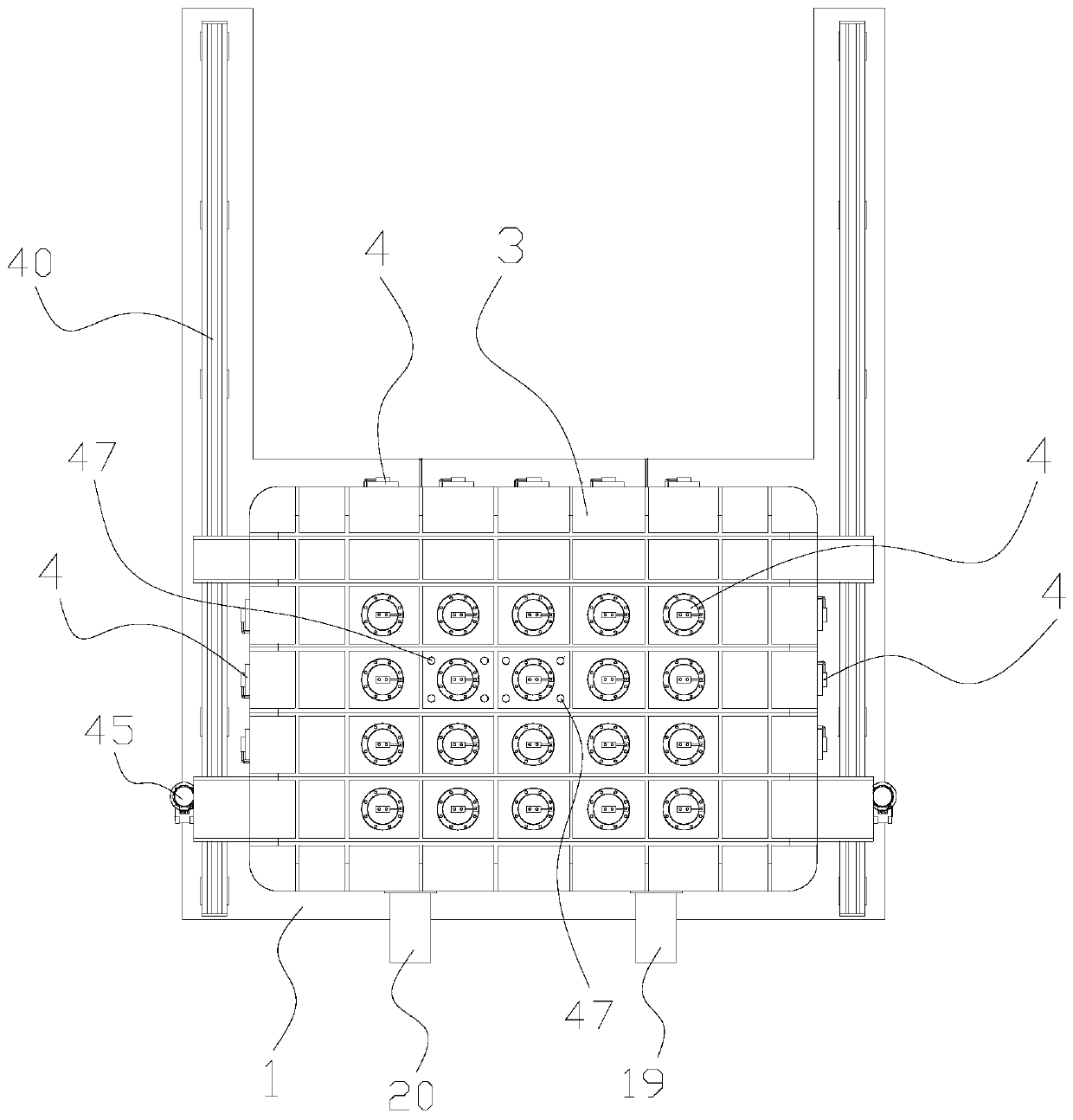

[0033] Such as Figure 1 to Figure 11 The gas three-dimensional drainage and goaf spontaneous combustion coupling test system shown includes a ventilation system, a gas system, a three-dimensional gas drainage system, a data measurement and acquisition system, a control system, a base 1, and a frame fixed on the base 1 2. The top cover 3 that can cover the frame body 2, the heating system that keeps the test sample placed in the test chamber surrounded by the frame body 2 and the top cover 3 at the test temperature, and loads the test sample in the XYZ direction The triaxial stress loading system of the stress and the coal rock excavation system for mining the coal seam in the test sample to form the goaf; the test sample is made of similar materials, and the test sample is a multi-layer structure from top to bottom They are: roof, coal seam and floor.

[0034] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com