Patents

Literature

70results about How to "Change precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

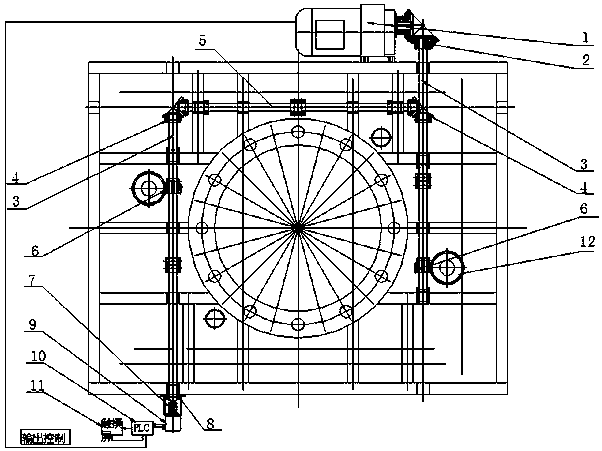

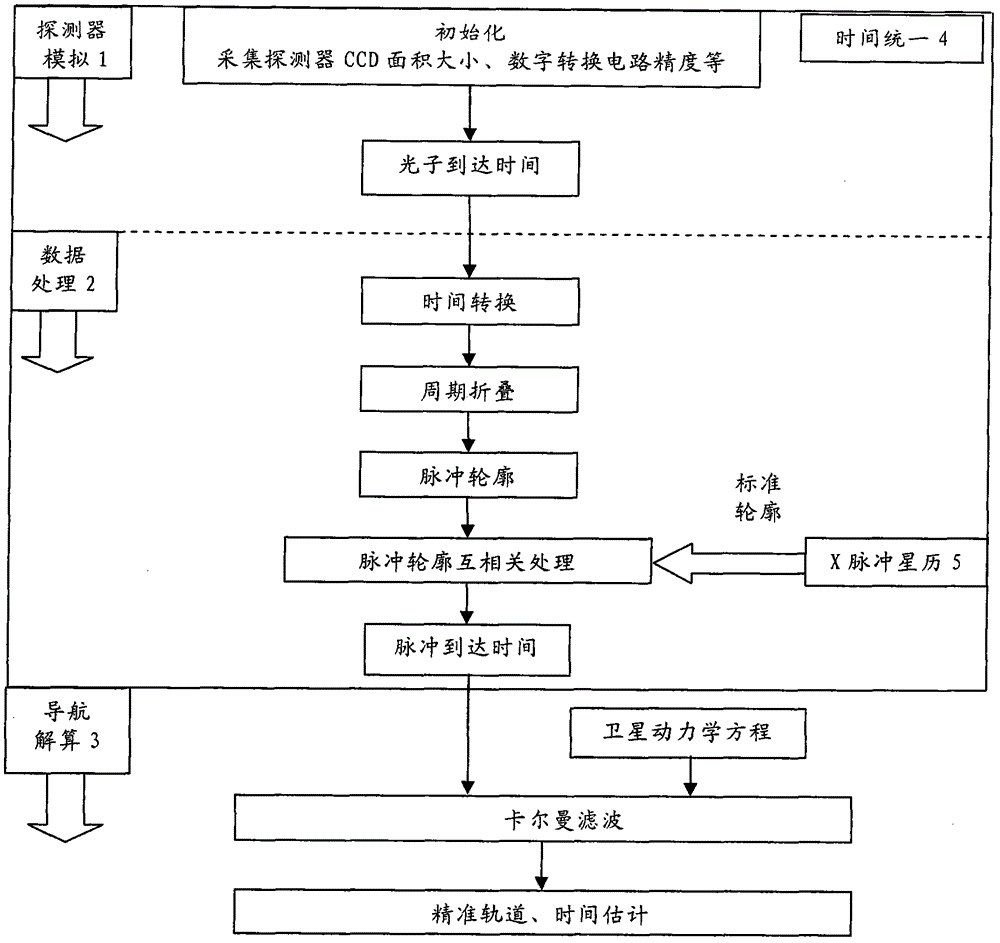

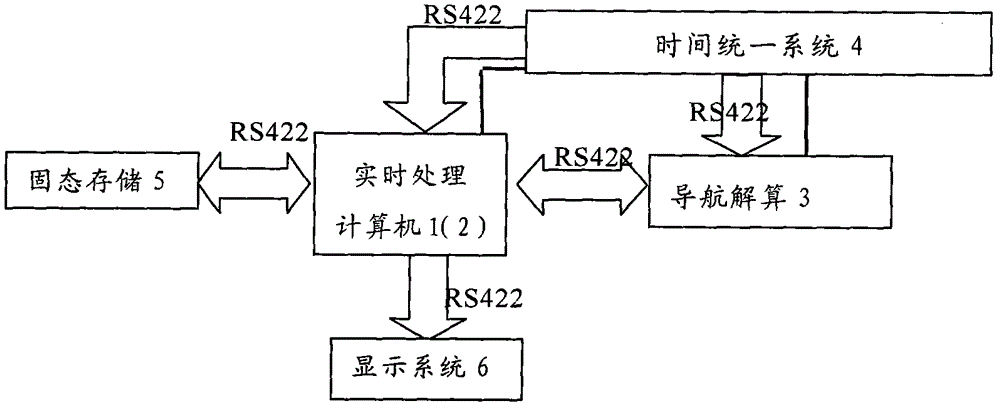

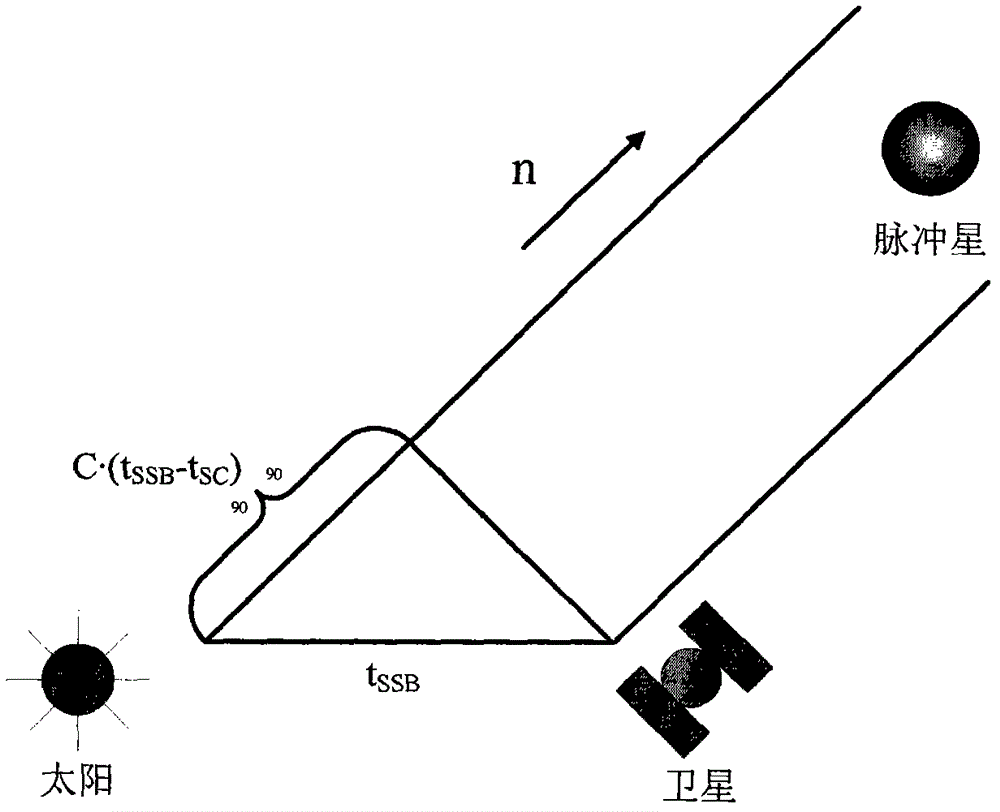

Spacecraft navigation system for equivalent device of X pulsar detector

ActiveCN102175246AChange precisionIncreased accuracy rangeInstruments for comonautical navigationTime informationDynamic equation

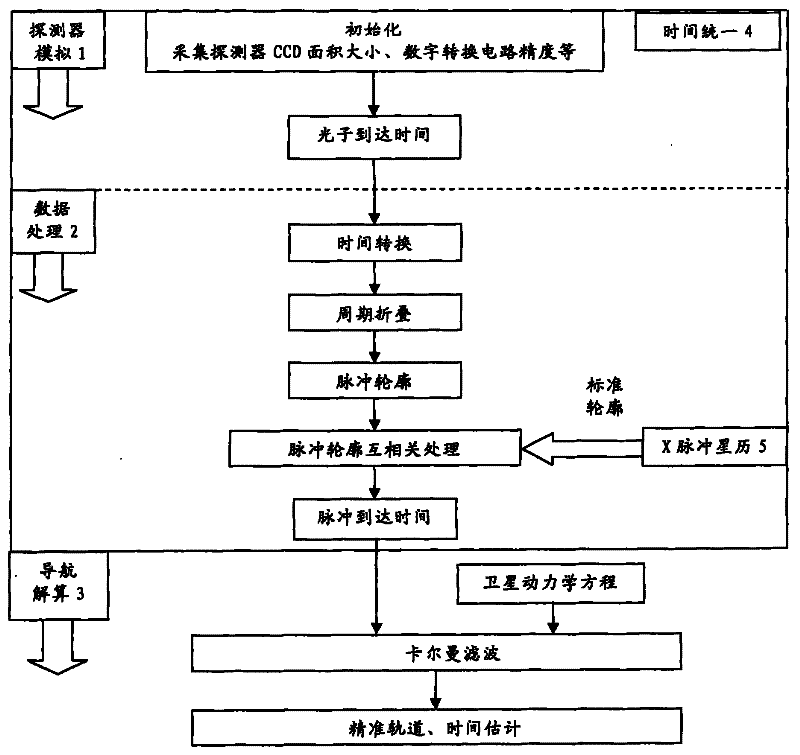

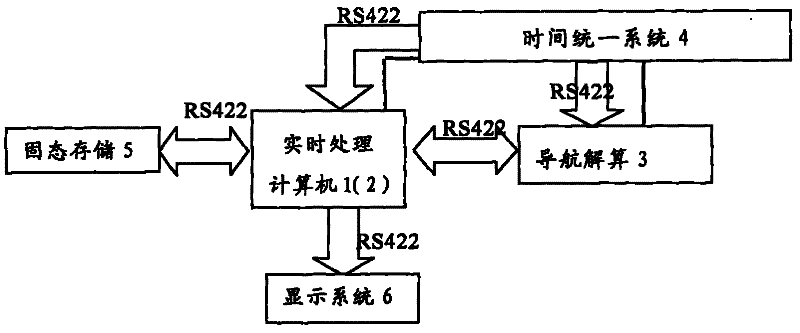

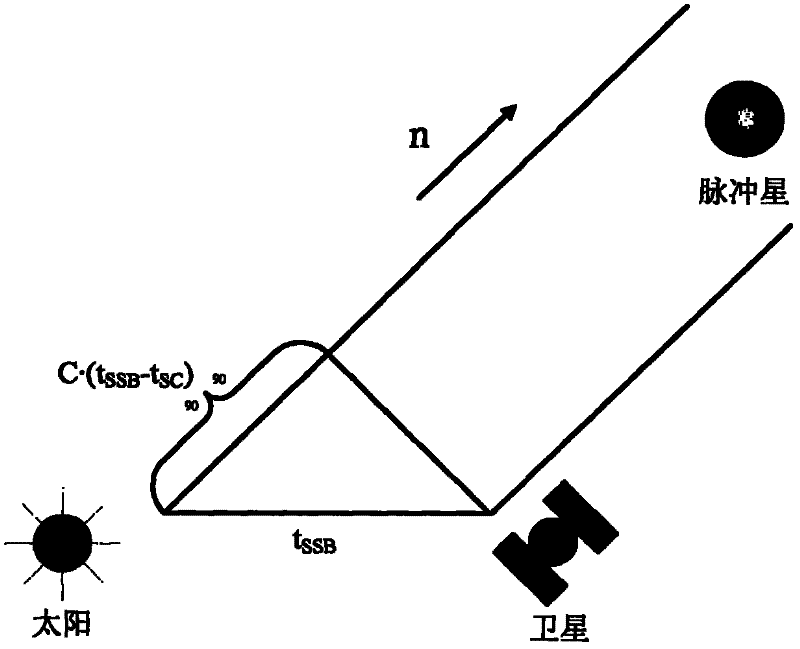

The invention discloses a scheme of a spacecraft navigation based on an X pulsar detection equivalent device. The scheme mainly comprises the following processes of simulating X pulsar emitting photon information detected by an X pulsar detector, and resolving a spacecraft position and speed navigation information. The overall simulation process is divided into three parts, namely detector simulating, data processing and navigation resolving. In the first part, the detector simulates the photon arrival time; in the second part, a data processing system performs cycle folding according to the photon arrival time of the X pulsar, calculates a pulse profile, performs time conversion, and performs pulse profile cross-correlation processing with a standard profile stored by a known ephemeris so as to finish the calculation of the pulse arrival time; and in the third part of navigation resolving, a precise spacecraft orbit and time information are resolved finally by taking the pulse arrival time as measurement information and combining an orbit dynamic equation and kalman filtering. By the X pulsar equivalent device, the influence of various parameters and different algorithms such as a resolution ratio, a view field, time conversion precision, a folding algorithm and the like on the autonomous navigation accuracy of the spacecraft can be analyzed, and necessary technical support is provided for the development of an X pulsar-based autonomous navigation system and the research on combined navigation with other systems.

Owner:山东中宇航空科技发展有限公司

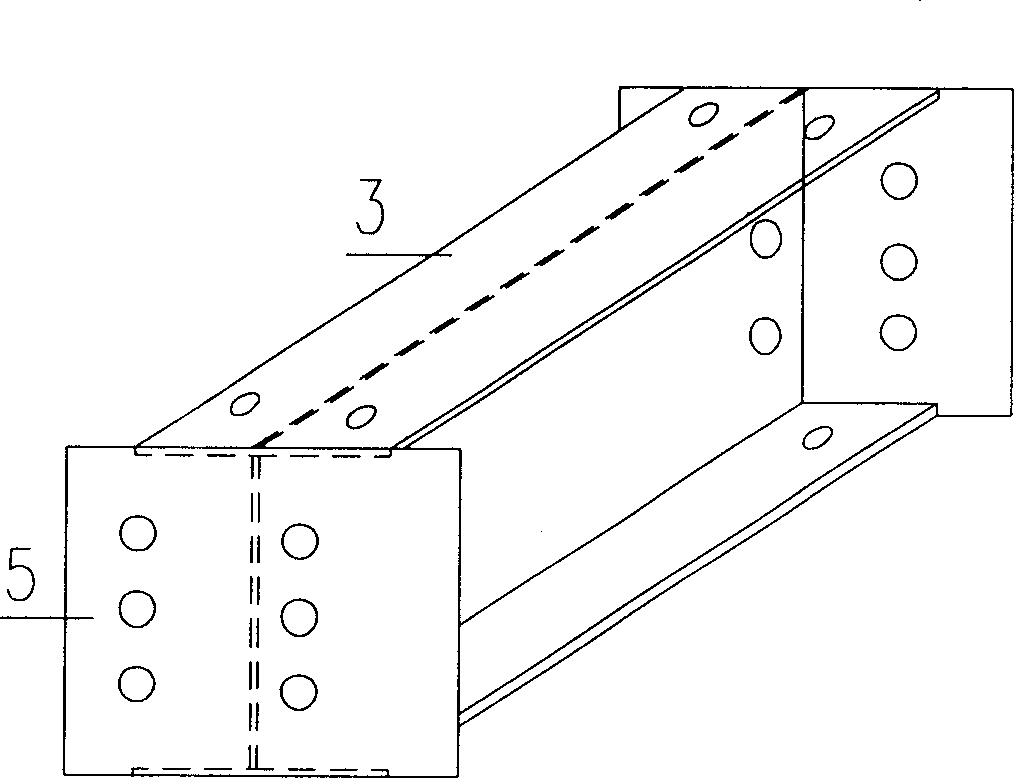

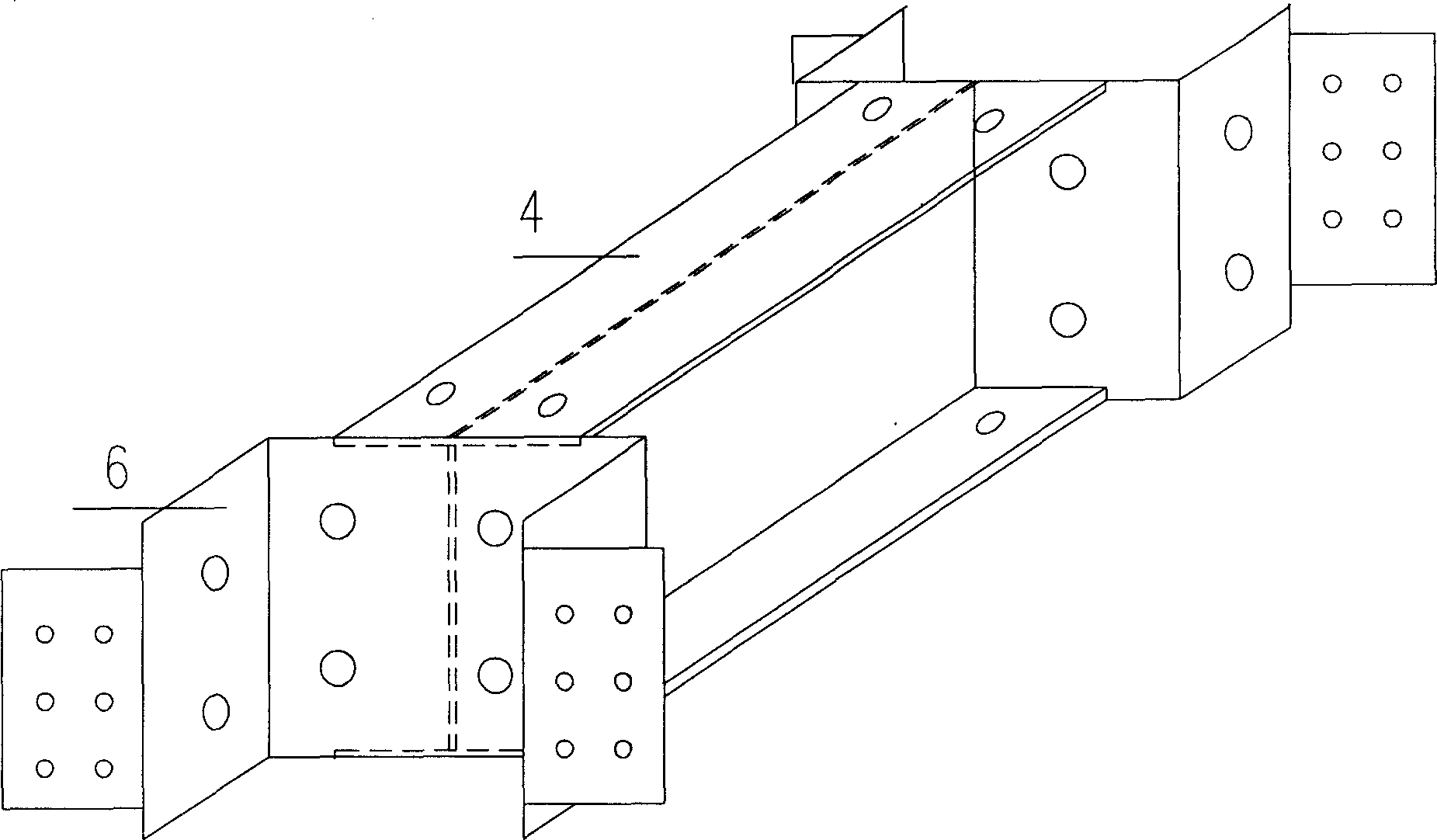

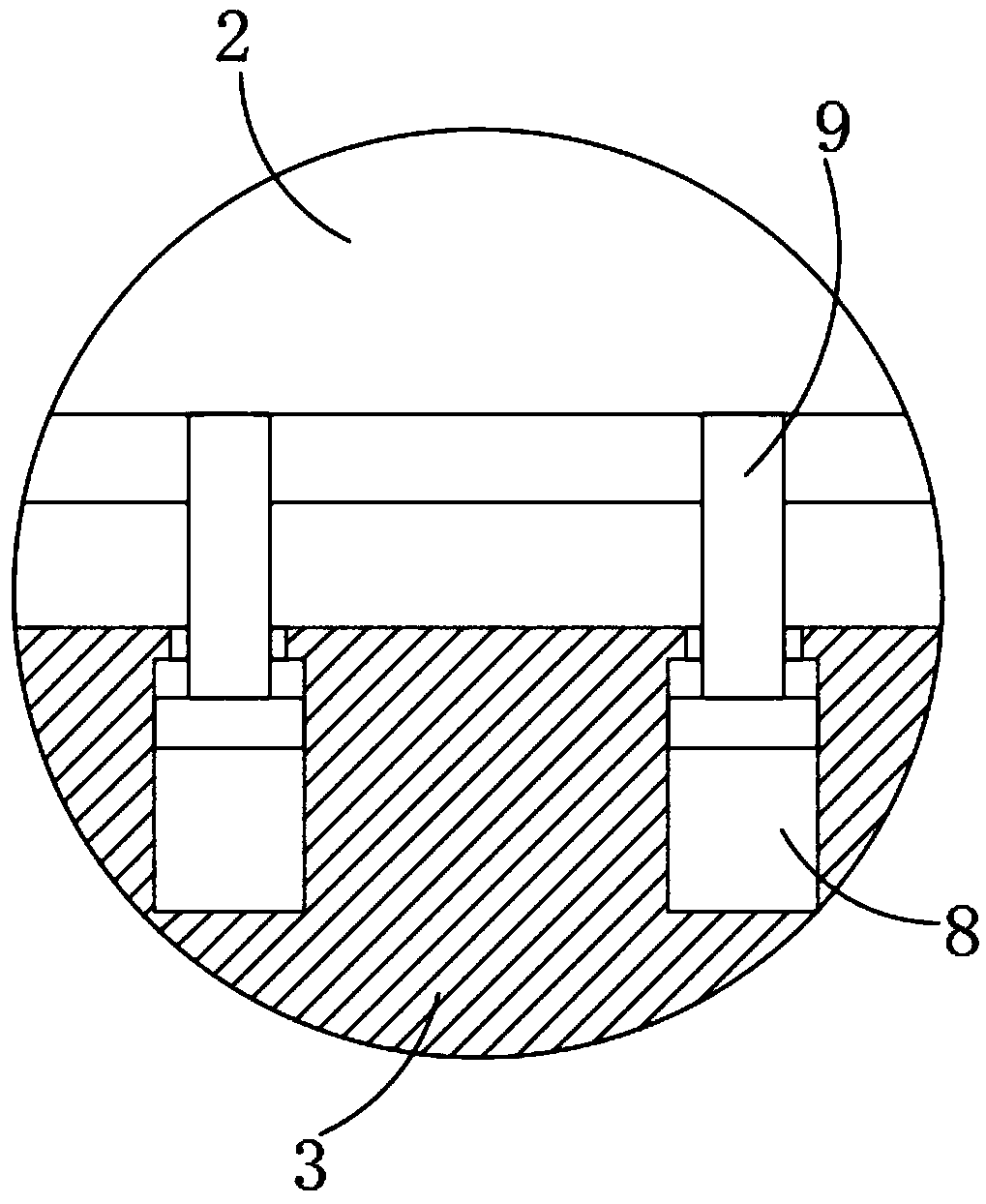

Steel structure beam column joint member

The steel structure beam-column node member is composed of steel upright column and H-beam. The H-beam includes transverse beam and longitudinal beam, on the side surface of steel upright column a screw bolt hole is cut, the upper and lower two sides of said screw bolt hole are quipped with spacing bracket respectively, on the bracket a screw holt hole is cut, on the upper and lower flanges of transverse beam and longitudinal beam and web plate of transverse beam the screw holes are cut, and on the end portion of the transverse beam an end plate is welded, on the end plate a screw hole is cut, on the end portion of the longitudinal beam an ''U'' - shaped clamping hoop plate is welded, and on the clamping hoop plate a screw bolt hole also is cut.

Owner:中原石油勘探局勘察设计研究院

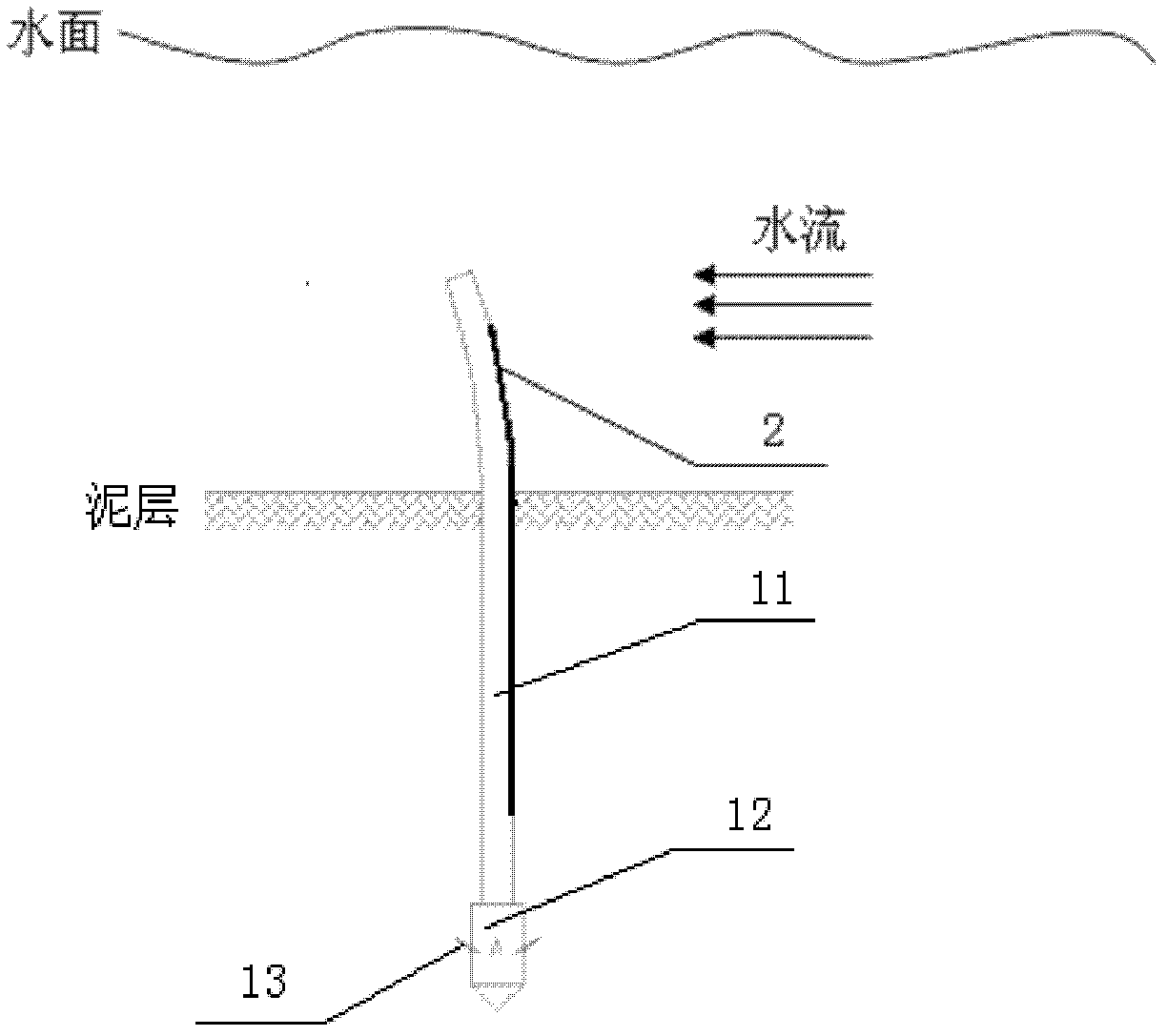

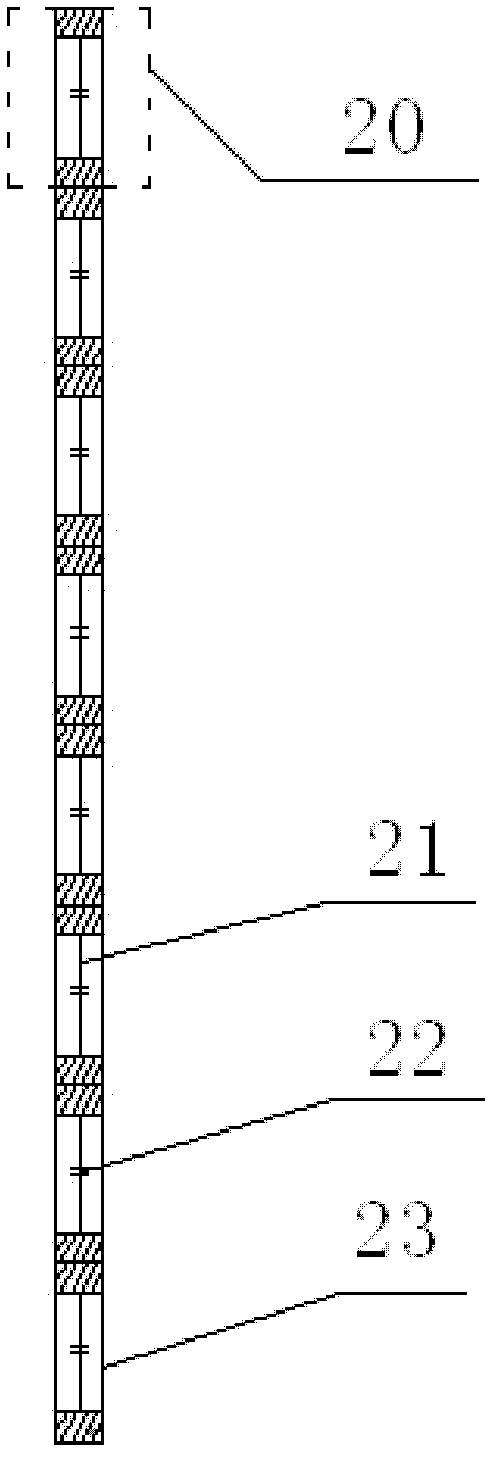

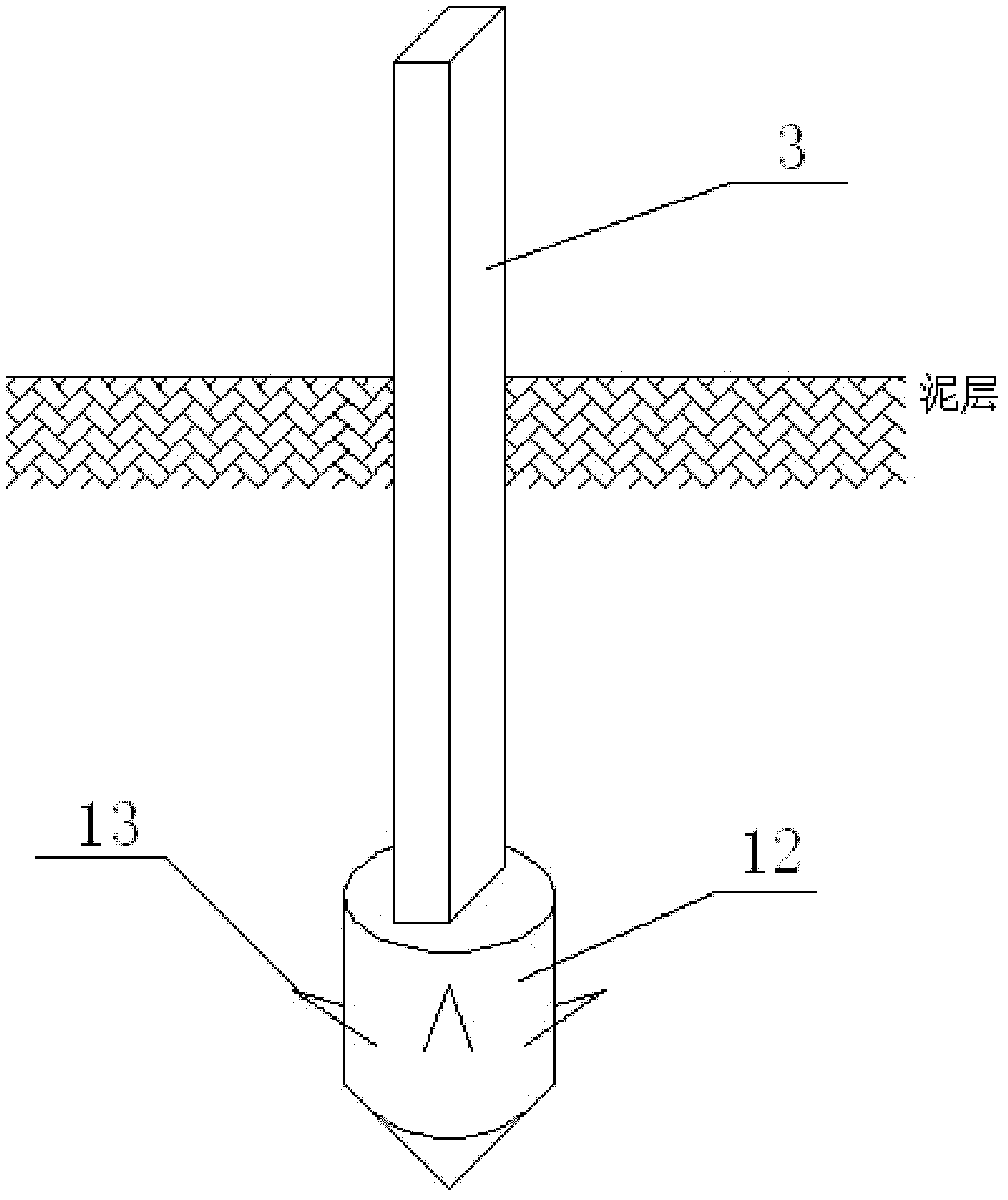

Long-gauge fiber grating scour sensor, manufacturing method thereof, and installation and laying method thereof, and scour monitoring system formed by long-gauge fiber grating scour sensors

InactiveCN102445160AThe flushing principle is simple and reliableNovel test methodUsing optical meansFiberGrating

The invention discloses a long-gauge fiber grating scour sensor, a manufacturing method thereof, and an installation and laying method thereof, and a scour monitoring system formed by the long-gauge fiber grating scour sensors. The long-gauge fiber grating scour sensor comprises an elastic straight rod and a long-gauge fiber grating sensing probe array that is integratedly packaged with the elastic straight rod; and the long-gauge fiber grating sensing probe array is at one side of the elastic straight rod. Besides, the long-gauge fiber grating sensing probe array includes a plurality of long-gauge fiber grating sensing probes that are successively in series connection. According to the invention, the scour principle is simple and reliable and the testing method is novel and ingenious; the manufacturing process of the sensor is simple and costs are relatively low; the sensor has good durability and good environment adaptability; testing precision is good and can reach 0.05m or even smaller, and the precision can be changed according to a concrete requirement; and there is no need to consider a temperature compensation problem, so that the test becomes simple and effective.

Owner:SOUTHEAST UNIV

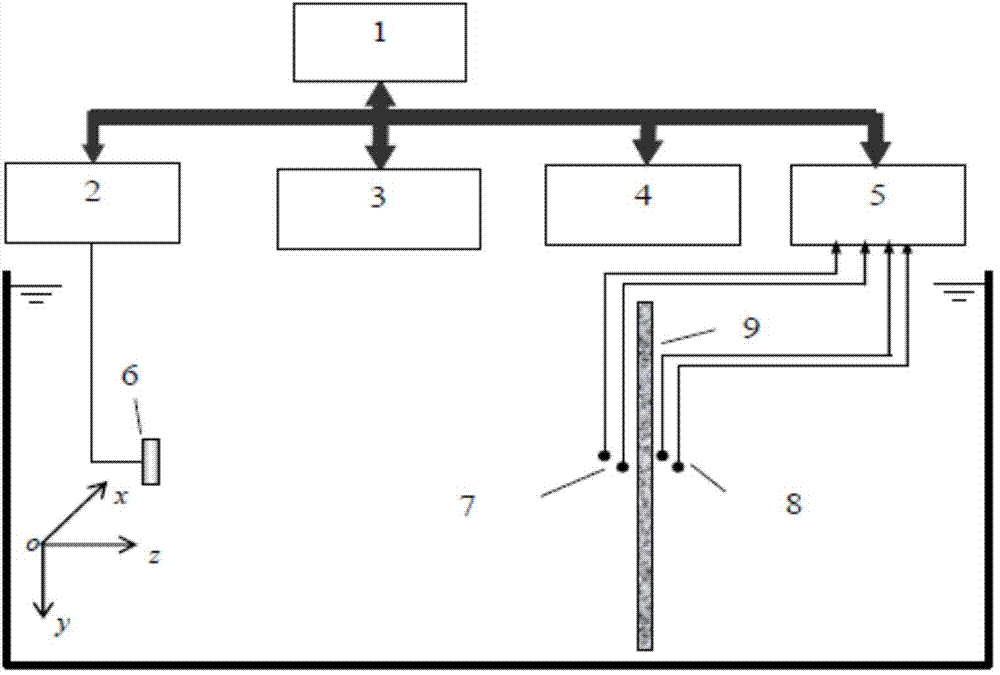

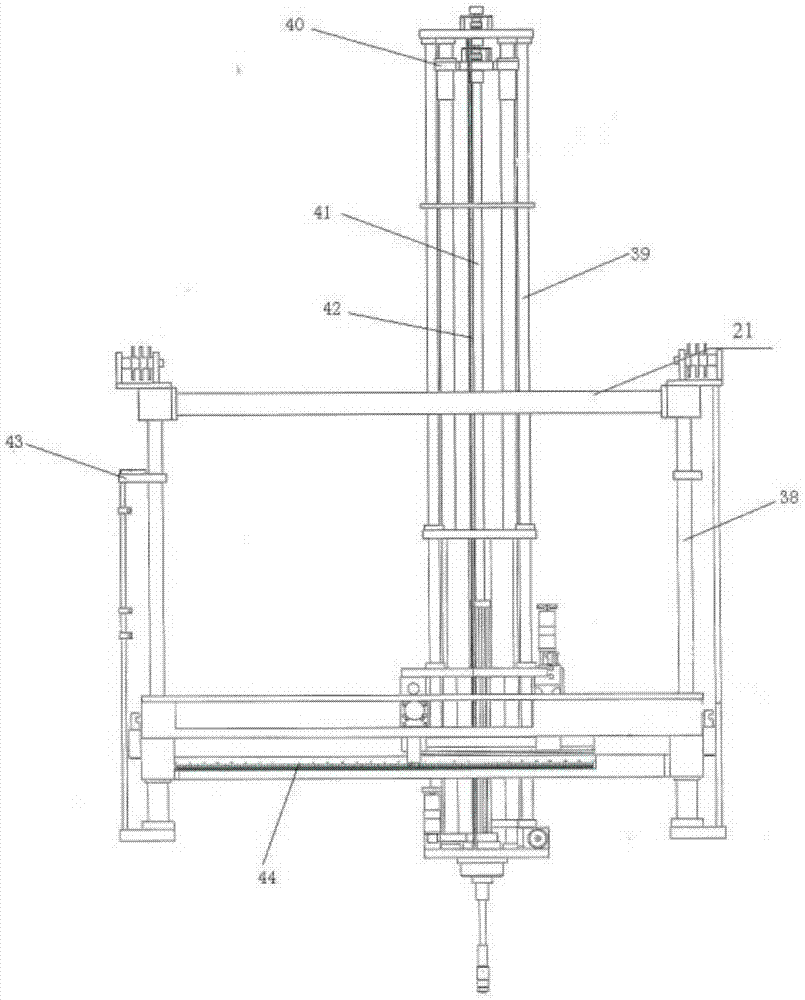

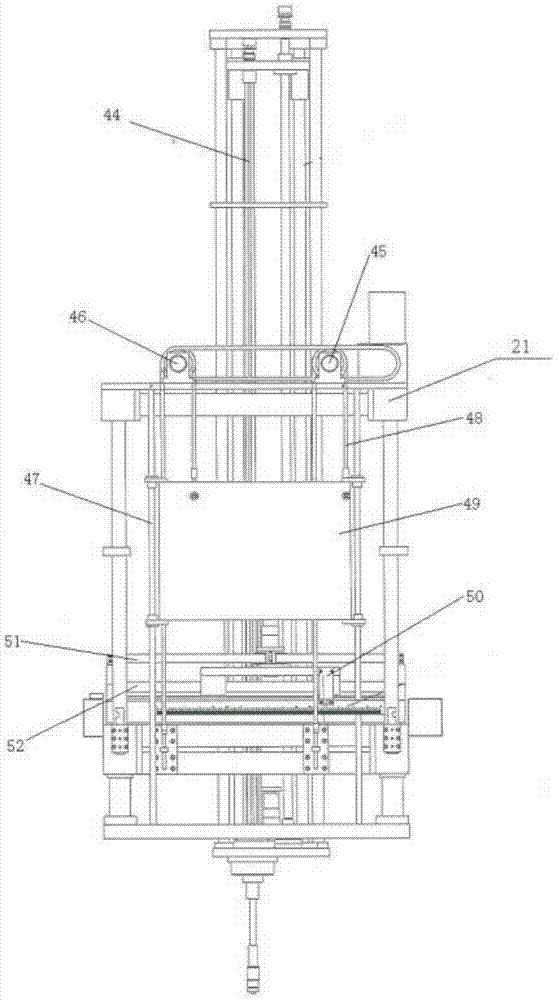

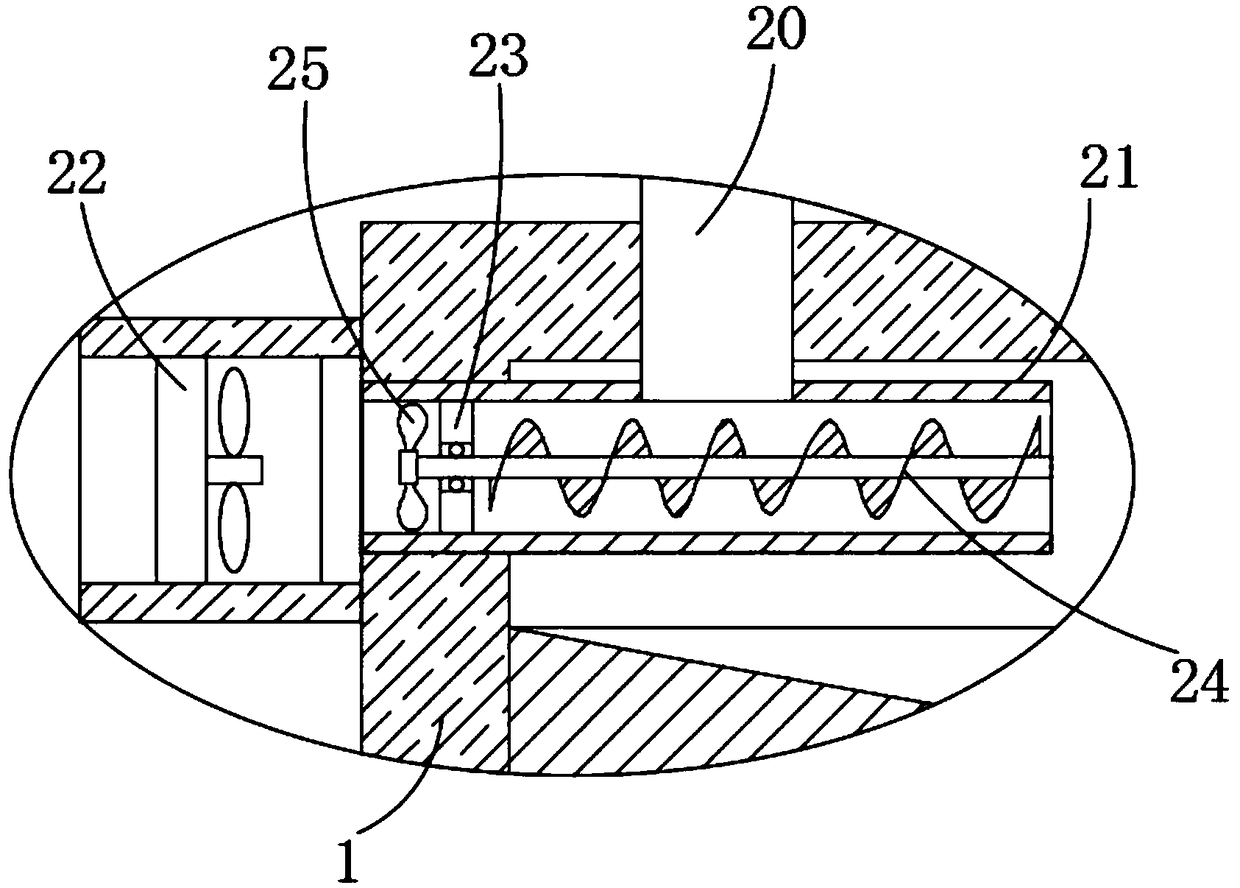

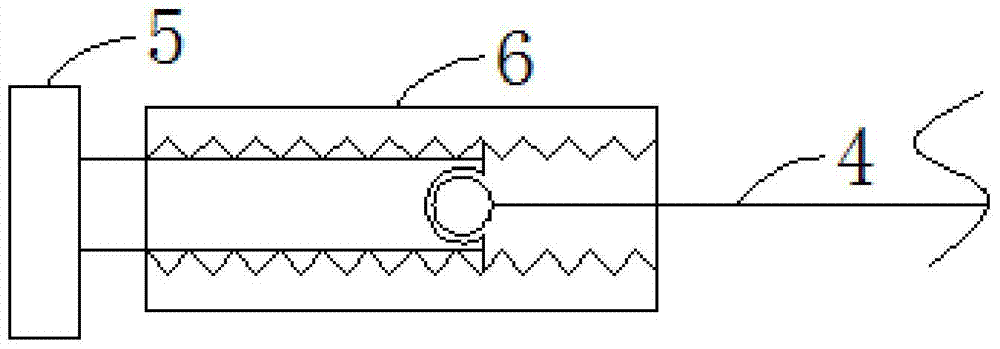

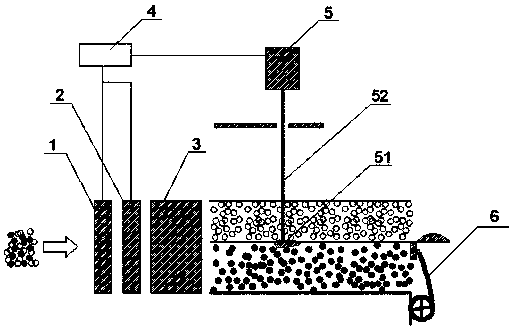

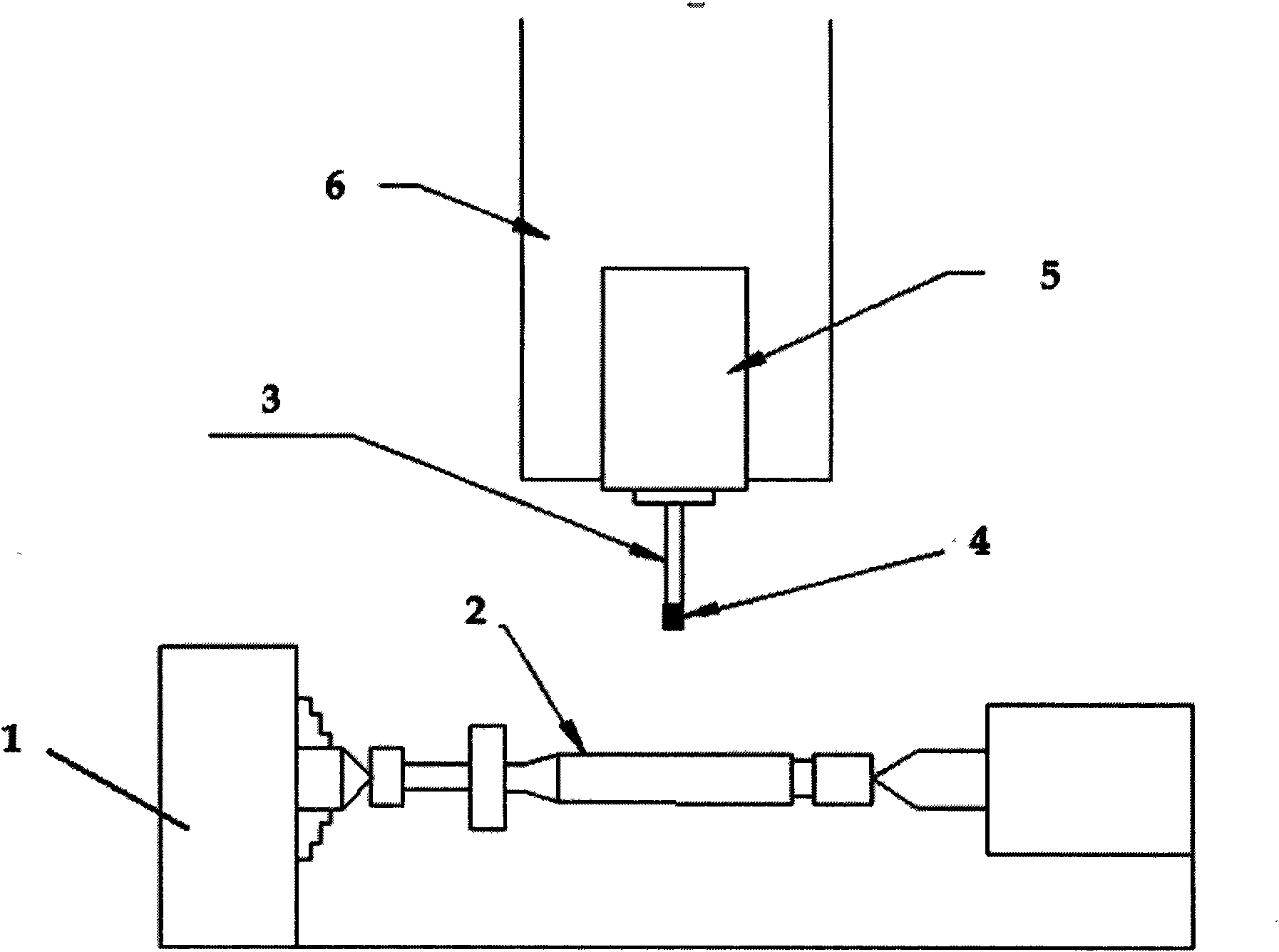

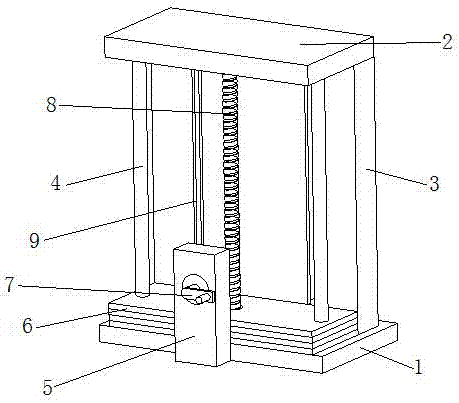

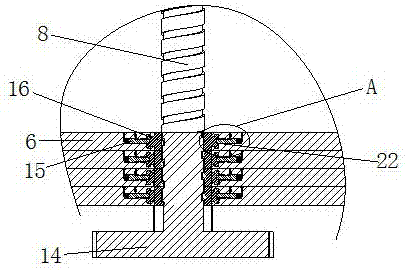

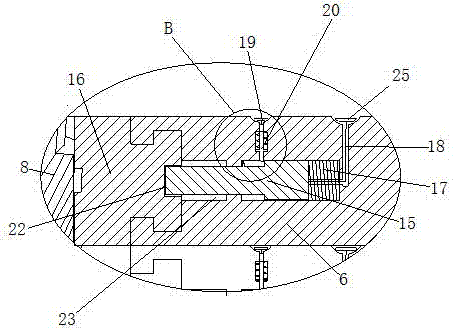

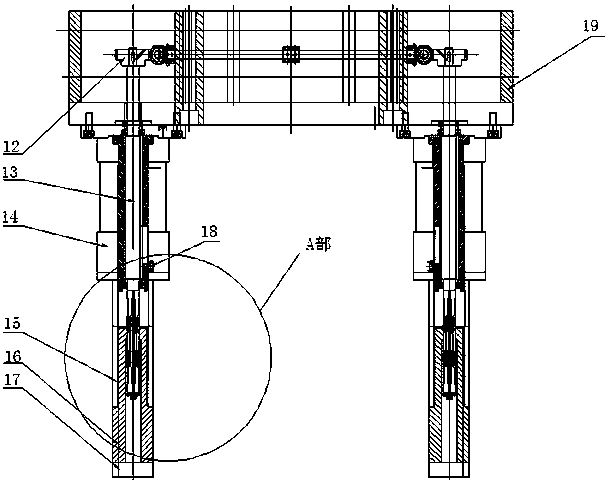

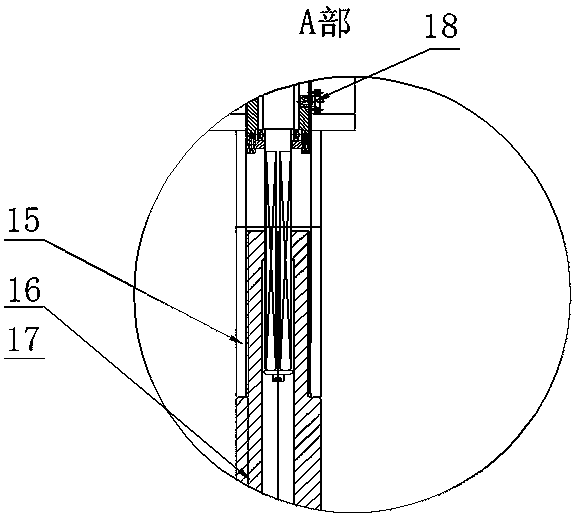

Automatic lifting rotating scanning device of hydrophone

InactiveCN104122543AImprove test accuracyAccelerate development cycleWave based measurement systemsHydrophoneMotor drive

The invention discloses an automatic lifting rotating scanning device of a hydrophone. The automatic lifting rotating scanning device of the hydrophone comprises a rack, the rack is provided with a landing gear, a moving frame, a moving platform, a screw rod, a lifting table and a rotating spindle, the landing gear performs Z-direction lifting movement along the rack, the moving frame performs X-direction translational motion on the landing gear, the moving platform performs Y-direction translational motion on the moving frame, the screw rod is vertically installed on the moving platform, the lifting table is driven by the screw rod to perform lifting movement, the rotating spindle is vertically installed on the lifting table, the rotating spindle and the lifting table are rotatably matched with each other and axially fixed, and the bottom of the rotating spindle is used for suspending the hydrophone or a detected sample which is matched with the hydrophone. A driving mode of the screw rod and the rotating spindle includes that a screw rod driving step motor is mounted on the moving platform, the screw rod driving step motor drives the screw rod to rotate through a screw rod synchronous belt, a rotating sleeve and a step motor are arranged on the moving platform, the step motor drives the rotating sleeve to rotate, the step motor drives the rotating sleeve through a driving belt, and the rotating spindle penetrates the rotating sleeve and is circumferentially positioned and is in axial sliding fit with the rotating sleeve.

Owner:ZHEJIANG UNIV

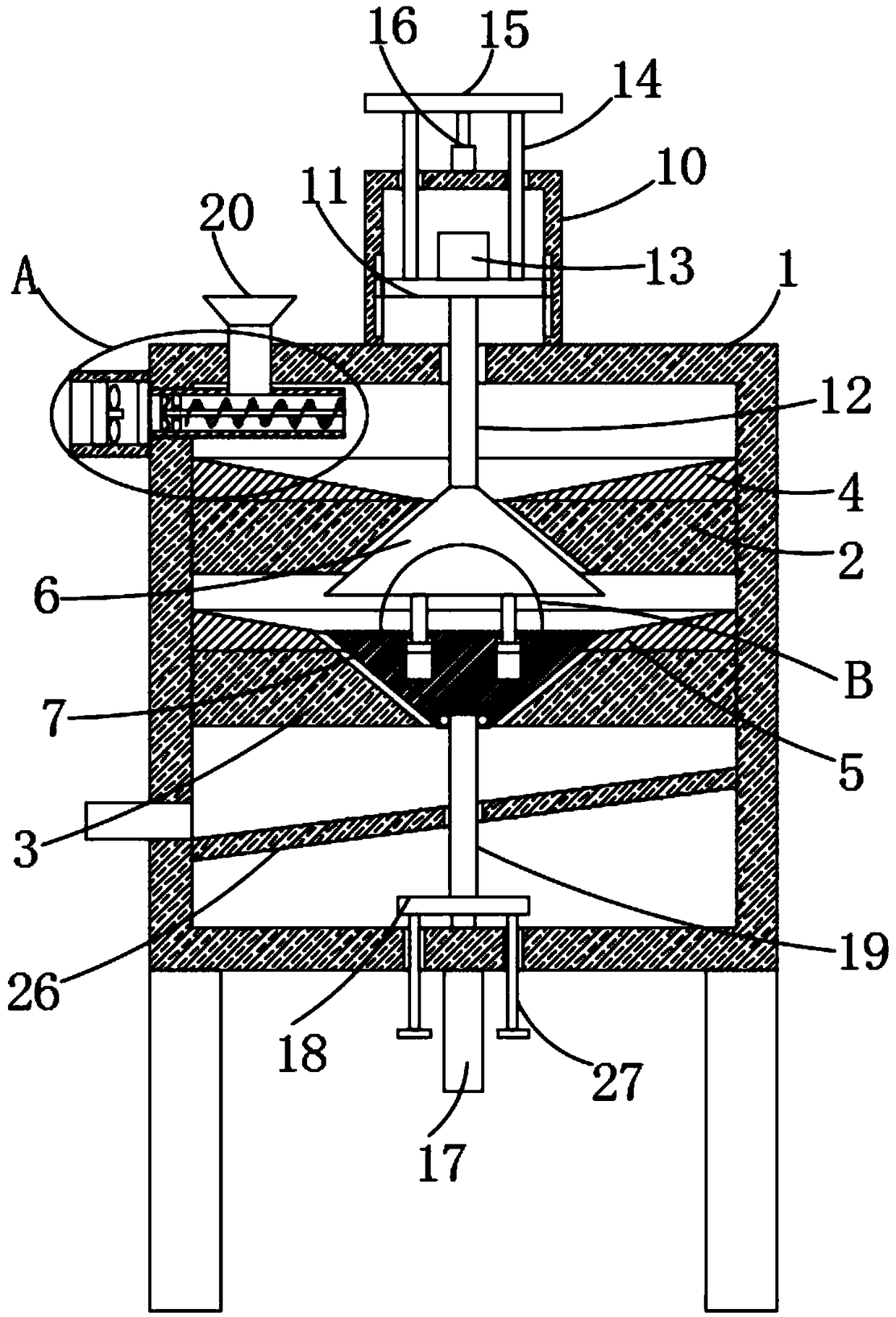

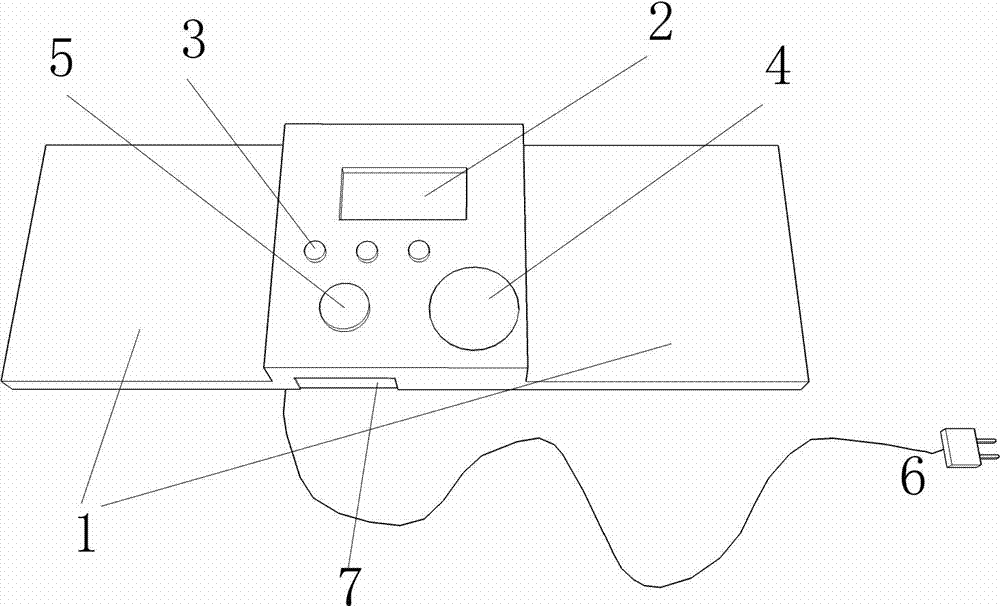

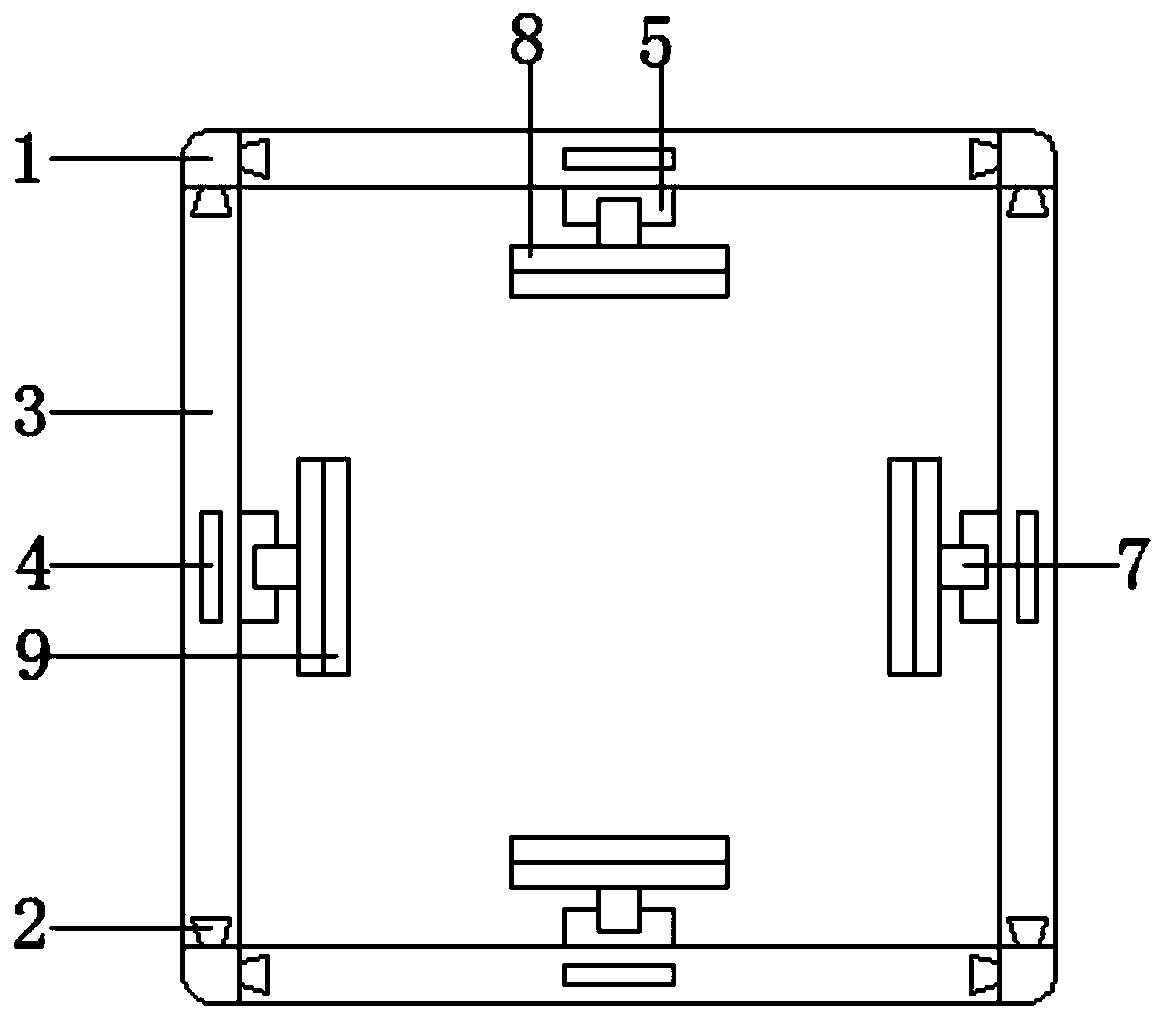

Building coating ingredient grinding device

The invention belongs to the field of building coating production, and particularly discloses a building coating ingredient grinding device. The building coating ingredient grinding device comprises abox body, an upper grinding plate and a lower grinding plate are fixedly connected to the inner wall of the box body in sequence from top to bottom, the sides, close to each other, of the upper grinding plate and the lower grinding plate are each provided with a conical installing port, an upper grinding cone is arranged in the conical installing port of the upper grinding plate, a lower grindingcone is arranged in the conical installing port of the lower grinding plate, and the sides, close to each other, of the upper grinding cone and the lower grinding cone are planes; and limiting grooves are symmetrically formed in the top side of the lower grinding cone, limiting rods are slidably installed in the limiting grooves, and the top ends of the two limiting rods extend to the exterior ofthe limiting grooves and are symmetrically and fixedly connected to the bottom side of the upper grinding cone. According to the building coating ingredient grinding device, the structure is novel, use is convenient, the grinding precision of building coating ingredients can be adjusted, the ingredients can be dried and then can be conveniently ground, and therefore the production efficiency is improved.

Owner:阜阳市金亮涂料有限公司

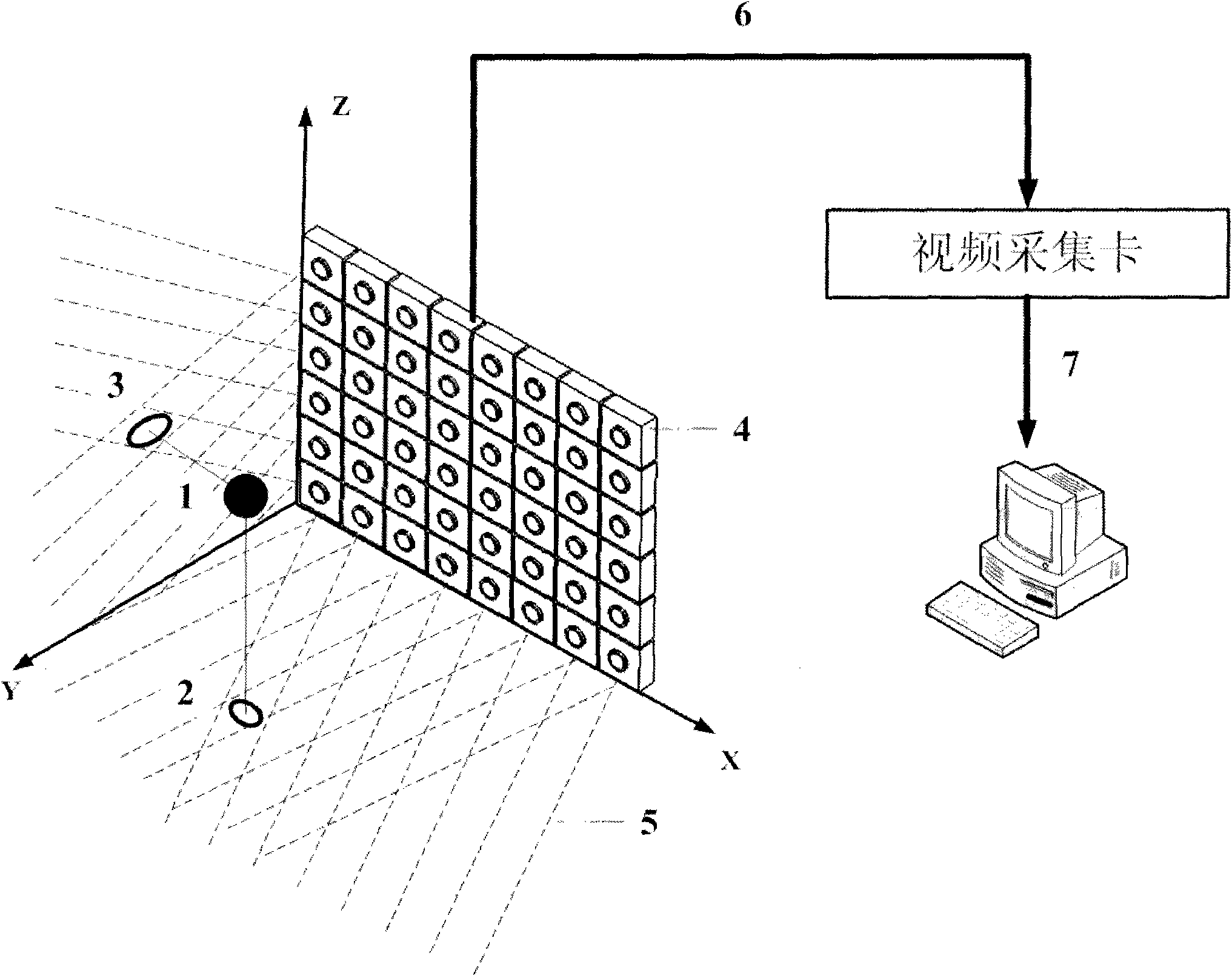

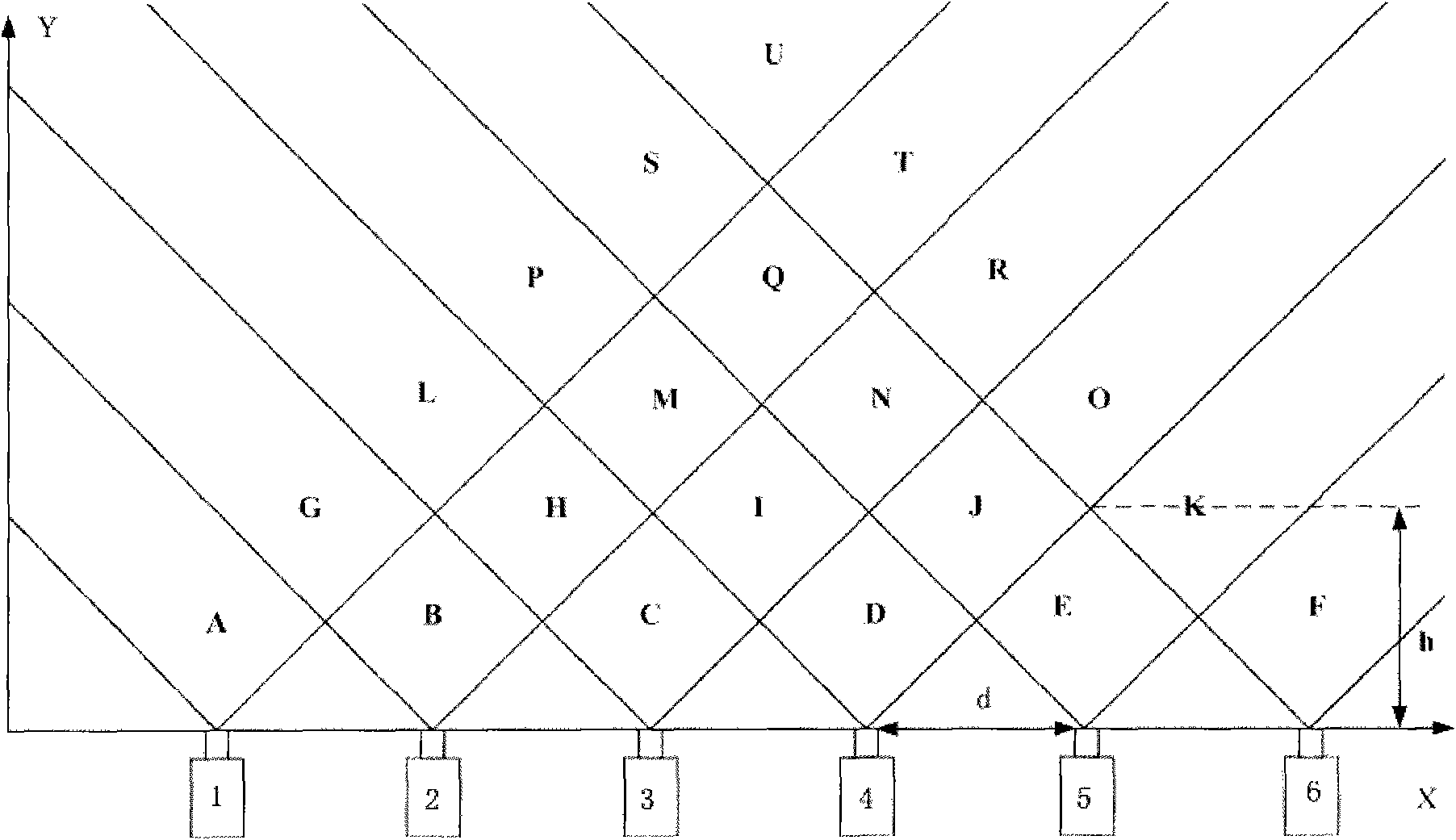

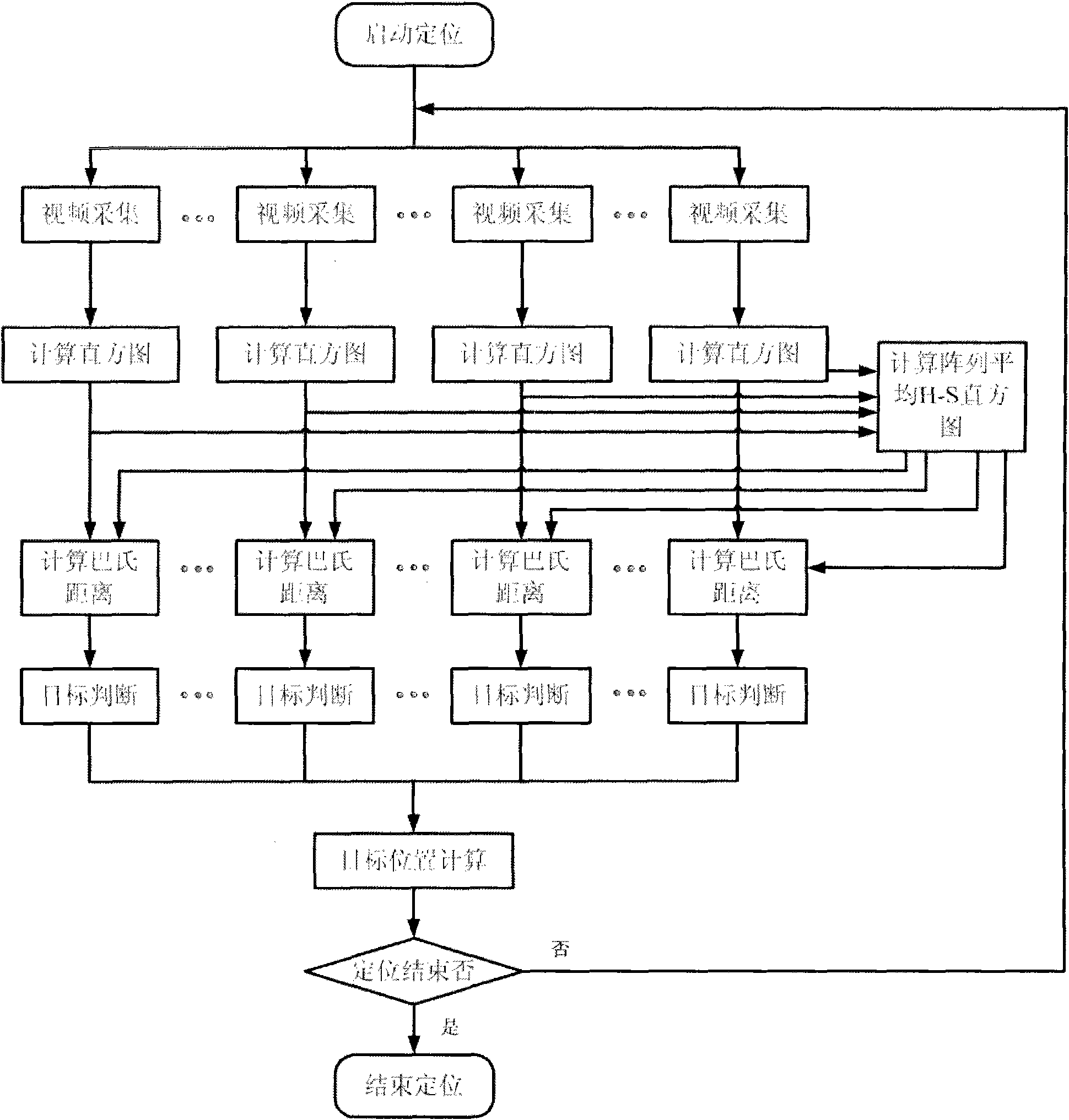

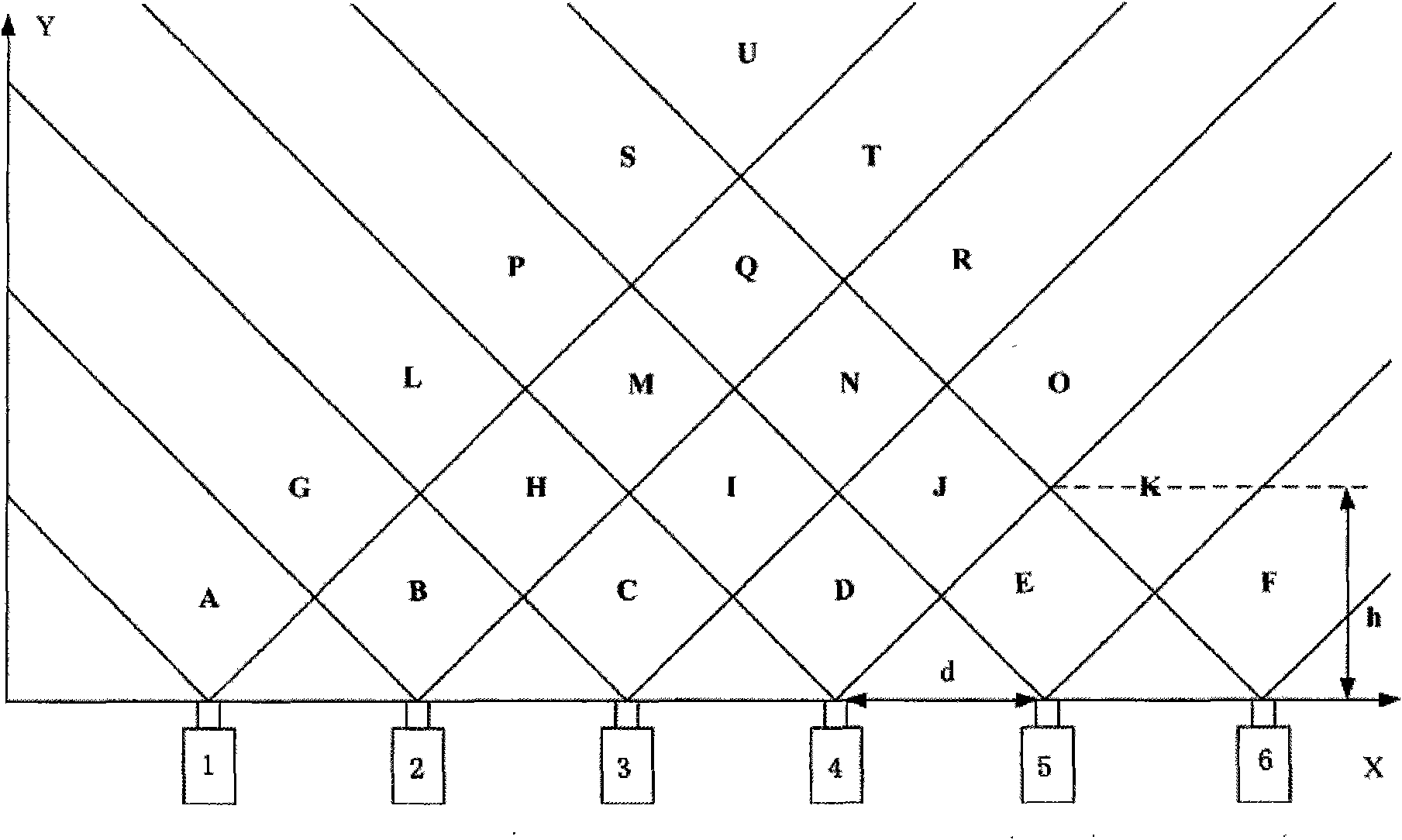

Non-visual geometric camera array video positioning method and system

ActiveCN101782386AReduce sizeEasy to calculateImage analysisUsing reradiationDigital videoVisual field loss

The invention discloses non-visual geometric camera array video positioning method and system. The non-visual geometric camera array video positioning system is arranged on a camera array on a plane board at fixed distance, the focus and visual field angles of all cameras are same, and the whole visual field can be divided into diamond-shaped visual field zones with same shape and shape projection area in the coordinate plane. An analog video signal of each camera is converted into a digital video signal by a video collecting card which is inserted in a computer extension slot. A computer can analyze the digital video information of each path to judge whether the target appears in each video image or not, and can calculate which diamond-shaped visual field zone the target appears in through the serial number of the cameras shooting up the target, and then the target can be quickly positioned.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

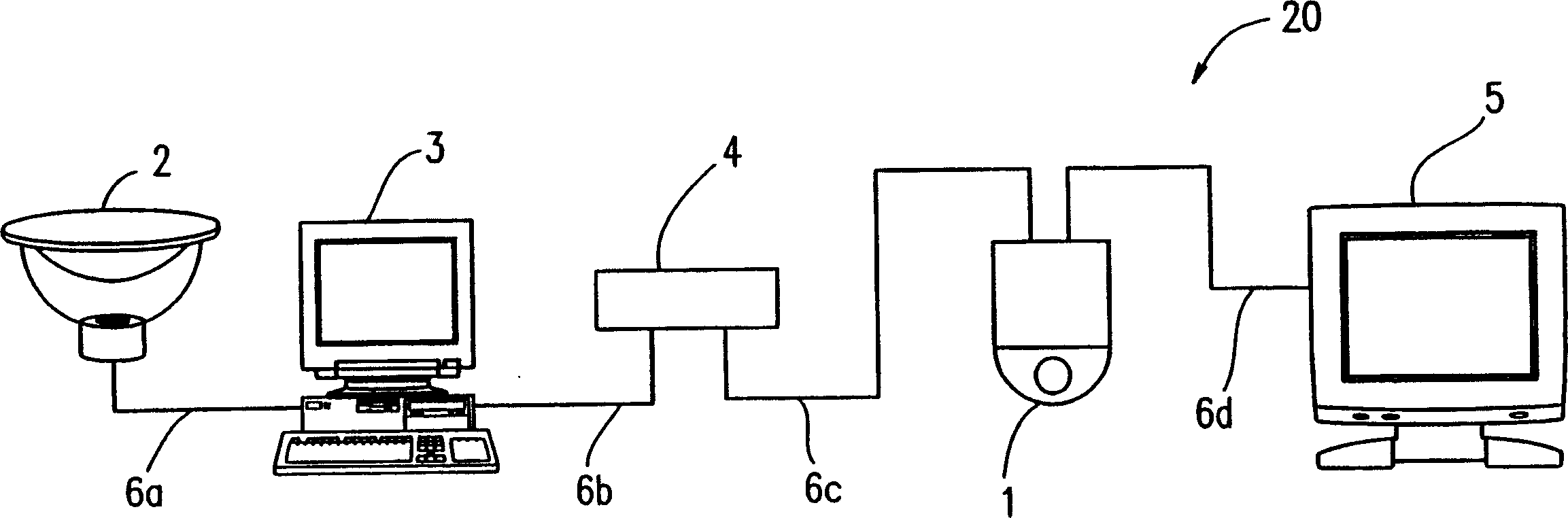

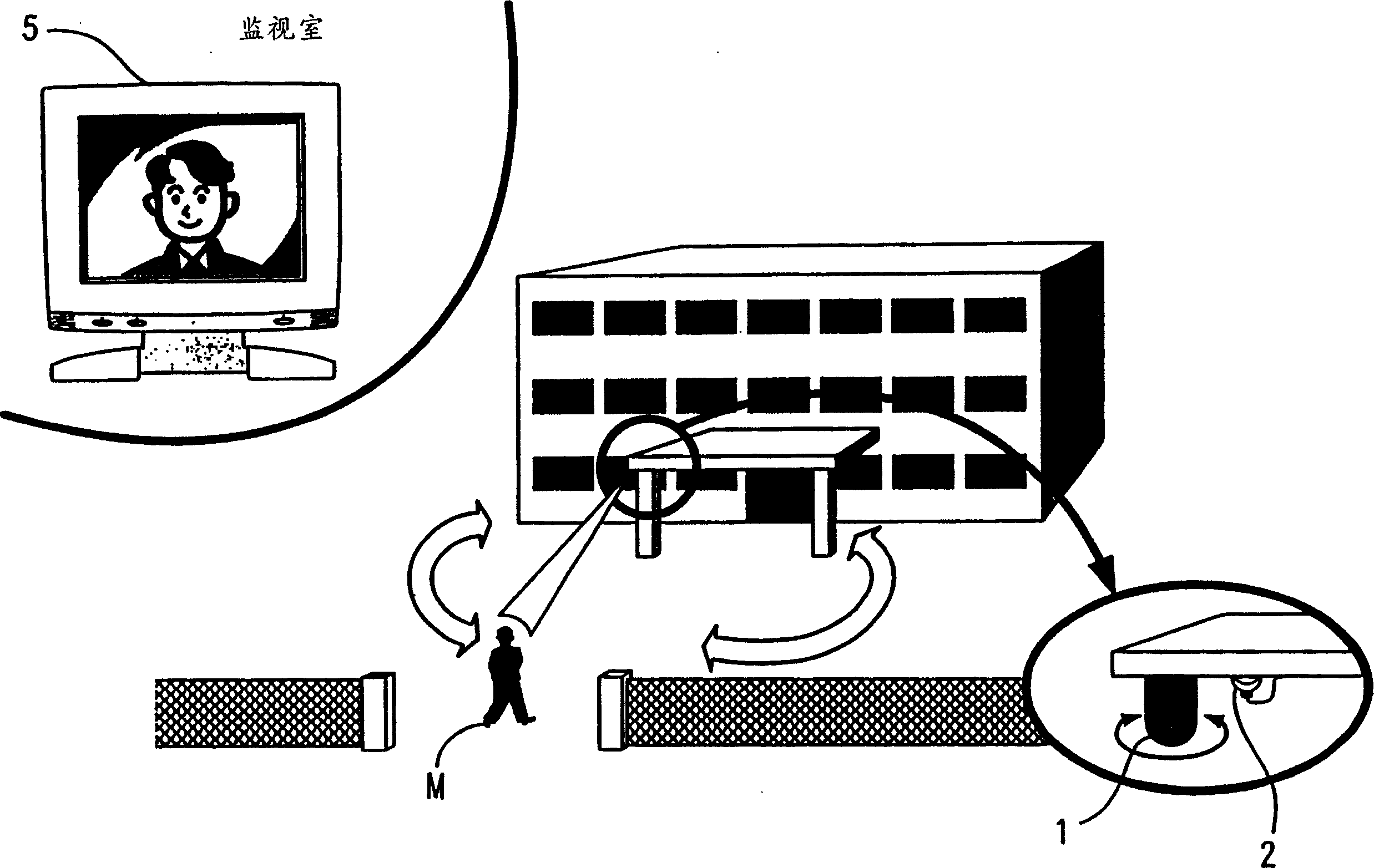

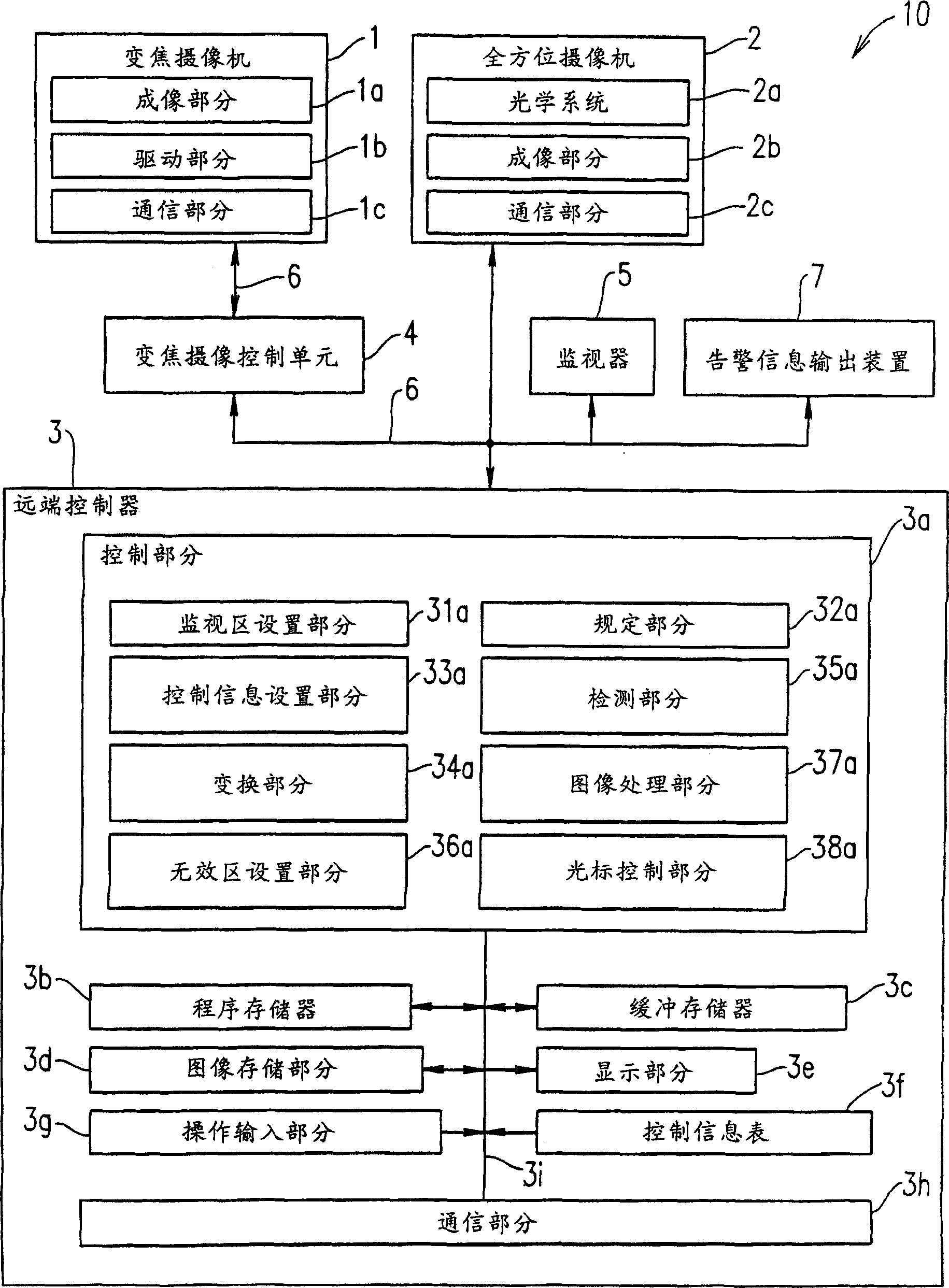

Omnibearing monitoring and control system, omnibearing monitoring and control method, omnibearing monitoring and control program and computer readable record medium

InactiveCN1492280AChange precisionReduce precisionTelevision system detailsColor television detailsOmnidirectional antennaControl system

An omnidirectional monitoring control system includes an omnidirectional camera for taking an omnidirectional image over a viewing angle of a maximum of 360 degrees; at least one zoom camera for performing positional control and magnification ratio control; a control section for rotating the omnidirectional image about a central axis of the omnidirectional image at a prescribed angle such that an apparent reference position of the omnidirectional camera is matched with an apparent reference position for driving the at least one zoom camera, and driving the at least one zoom camera to allow a prescribed monitoring position of omnidirectional image data obtained by the rotation to be photographed by the at least one zoom camera; and a display section for displaying the omnidirectional image taken by the omnidirectional camera and a zoom image taken by the at least one zoom camera.

Owner:SHARP KK

Precision adjustable acceleration transducer

The invention provides a precision adjustable acceleration transducer. The precision adjustable acceleration transducer comprises a light shielding object, a transverse optical path and a vertical optical path. The transverse optical path and the vertical optical path are vertically intersected to form an optical surface, the transverse optical path and the vertical optical path each comprises more than two parallel equally-distanced optical paths, each optical path comprises a luminescence unit and a corresponding photosensitive unit, and each photosensitive unit is used for detecting the shielding condition of the each optical path and is used for transmitting acceleration data. The precision adjustable acceleration transducer is simple in structure and low in cost and can conveniently change the precision of the acceleration transducer.

Owner:嘉兴云泽科技有限公司

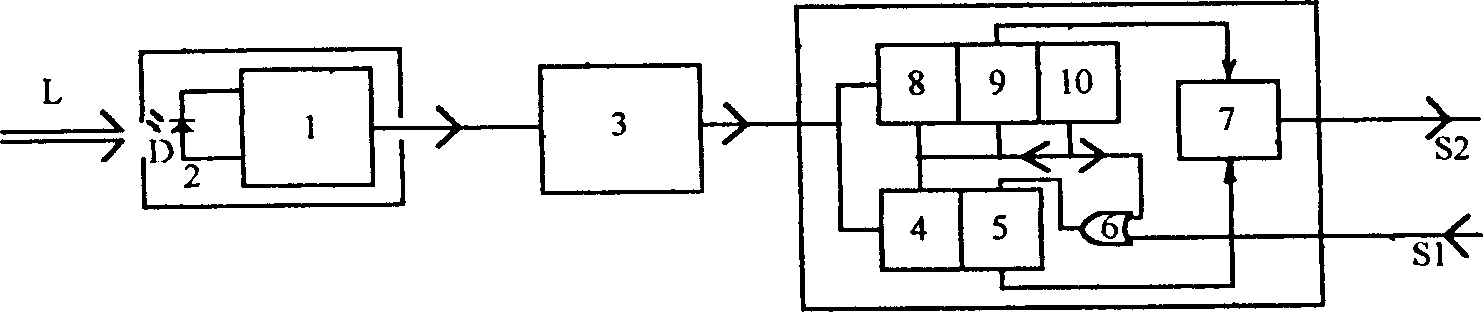

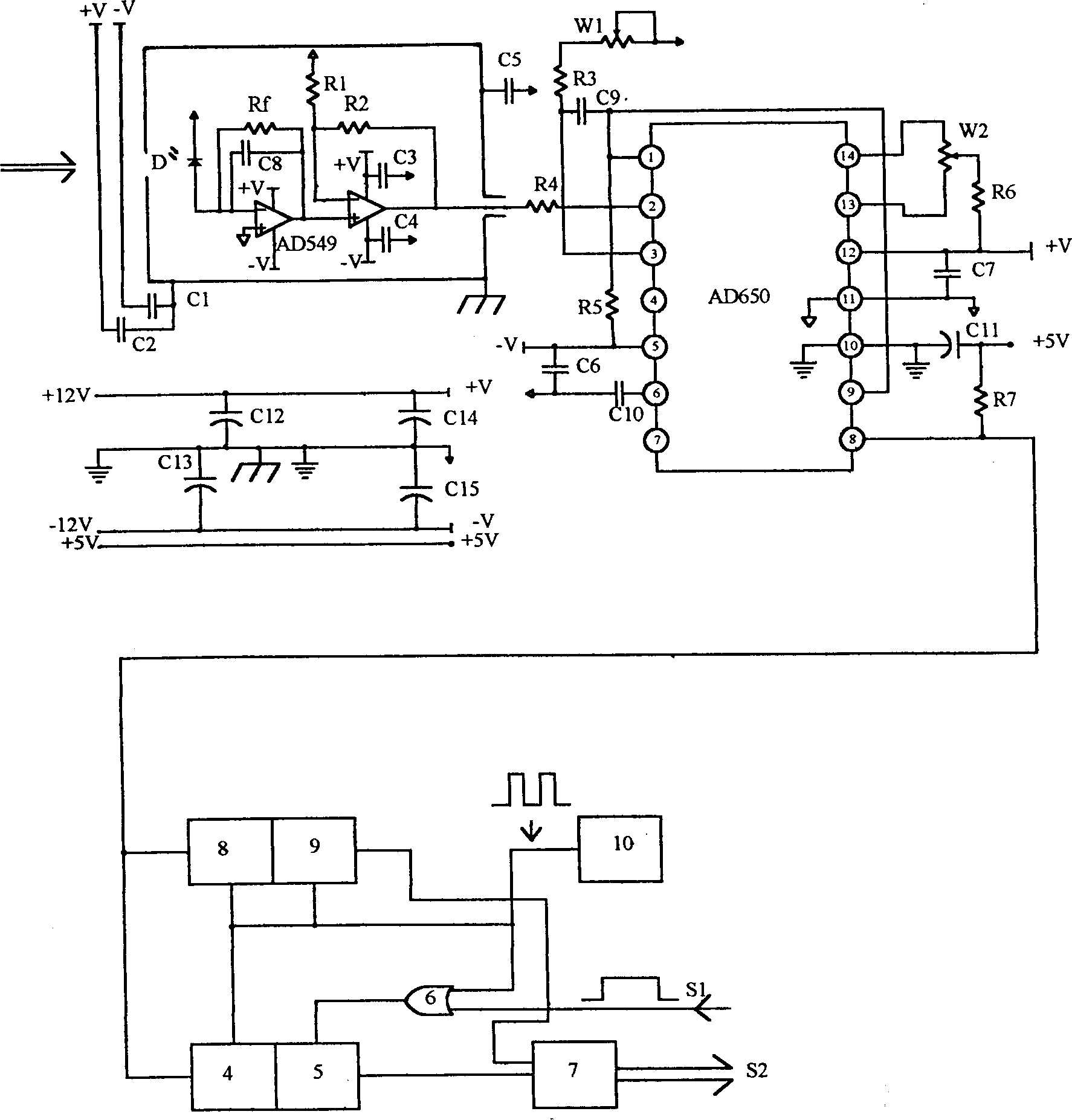

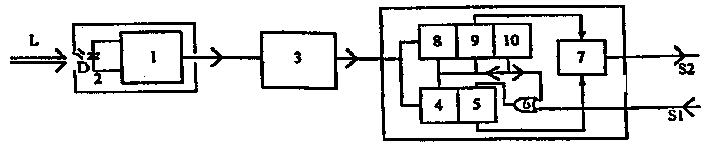

Self-adapting type micro light detection device with high-sensitivity silicon optical diode

InactiveCN1431475AEnhanced inhibitory effectSimple compositionPhotometry using electric radiation detectorsPhysicsData transmission

Based on the silicon optical diode, the device can detect illuminance less than 10 to the power -8 Lx. The silicon optical diode and the magnetifier are installed in the electromagnetic shielding box. The output end of the magnetifier is connected to the input end of the voltage to frequency converter. The decimal data collector with at least 6 digits includes the collection counter, the collection register, the time base generator for the counting gate, the background counter, the background register as well as the OR gate and the full subtracter. The invention provides long-lasting steady work in bad environment, which does not affect the precision, long distance data transmissions well as mini type an low power consumption. The capabilities as of self-adapting and self-starting, satisfy the requirements of no-attendance.

Owner:XIAMEN UNIV

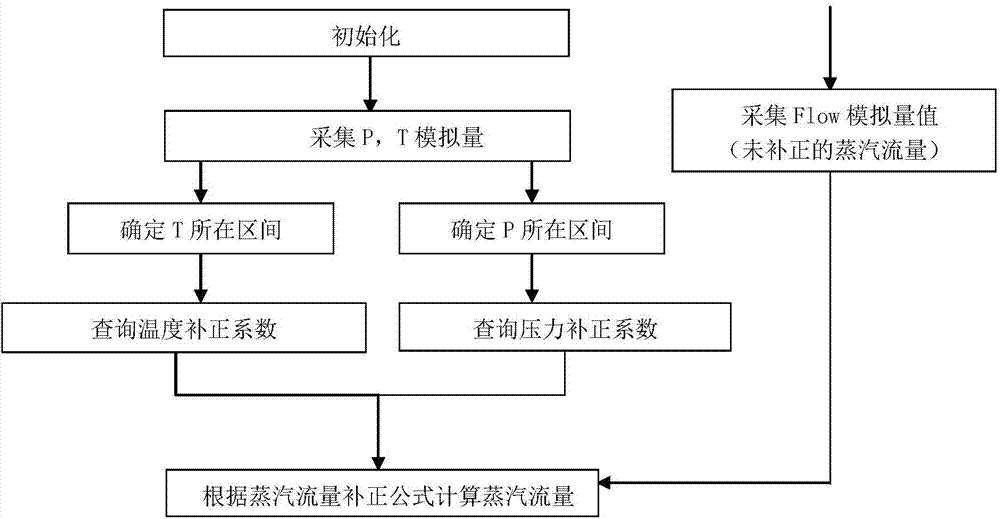

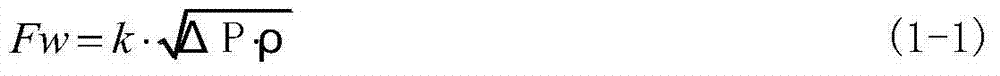

Flow augmenting method of saturated and superheated steam

ActiveCN104764504AReduce storageReduce the amount of calculationVolume meteringCommunications systemProgrammable logic controller

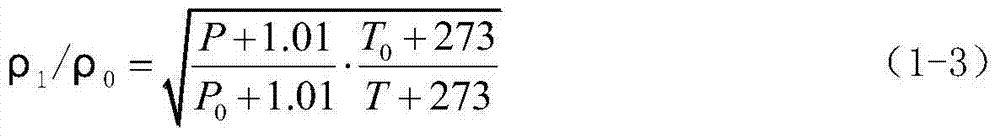

The invention relates to a flow augmenting method of saturated and superheated steam. The method comprises the following steps: 1) dividing the steam into a plurality of temperature intervals according to a common temperature range, wherein each temperature interval corresponds to a temperature augmenting factor r (T, P[0]) / r (T[0], P[0]); dividing the steam into a plurality of pressure intervals according to a common pressure range, wherein each pressure interval corresponds to a pressure augmenting factor r (T[0], P) / r (T[0], P[0]); 2) determining the temperature interval of the steam according to the temperature value of the practical steam, selecting the corresponding temperature augmenting factor, determining the pressure interval of the steam according to the pressure value of the practical steam, and selecting a corresponding pressure augmenting factor; calculating the augmented steam flow by using a formula: FORMULA. Compared with the prior art, the method provided by the invention has the beneficial effects: 1) an ideal gas equation density augmenting formula generally adopted by an existing steel enterprise can be completely replaced to greatly reduce the data storage amount and calculation amount, and is likely to be simply implemented to an industrial PLC (Programmable Logic Controller) or a DCS (Data Communication System) controller; 2) the steam measurement error can be reduced, and the steam metering precision can be improved.

Owner:鞍钢集团工程技术有限公司

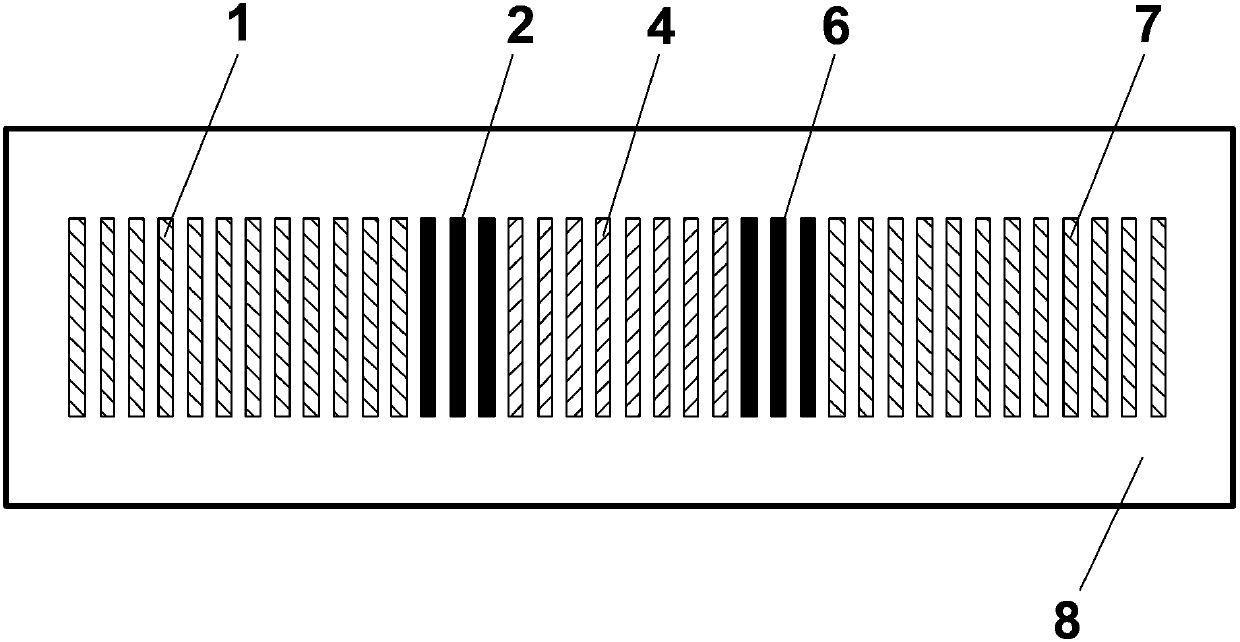

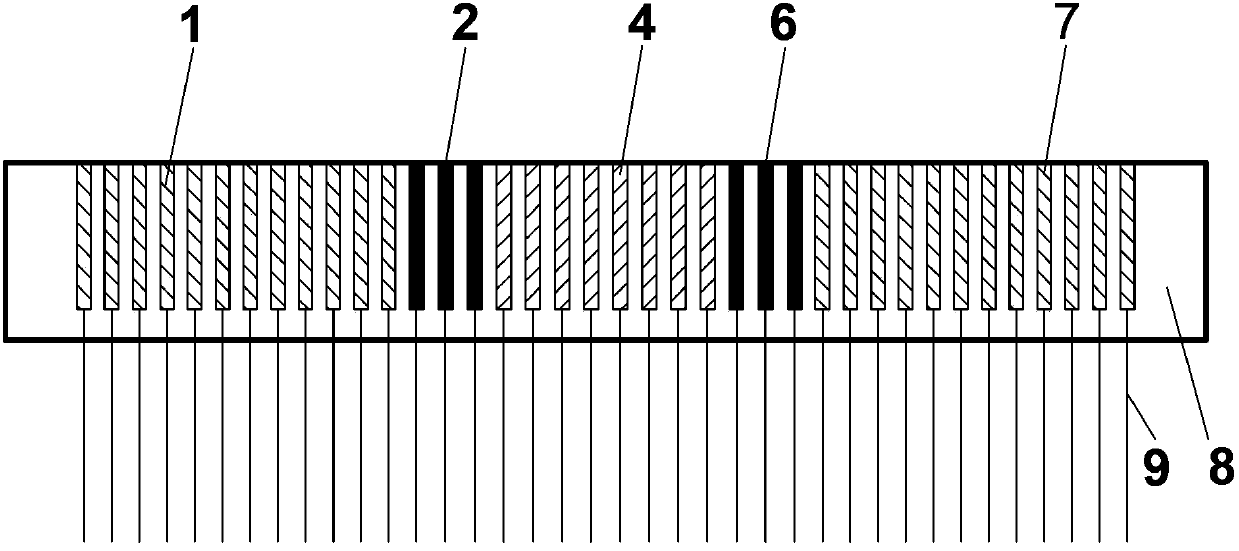

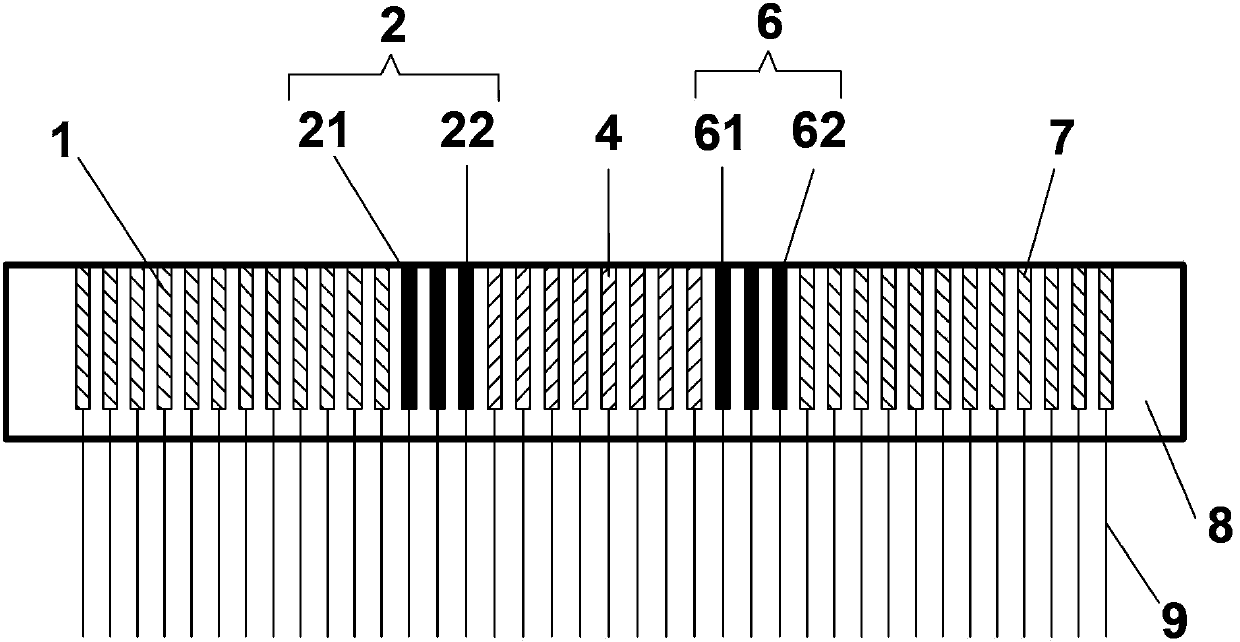

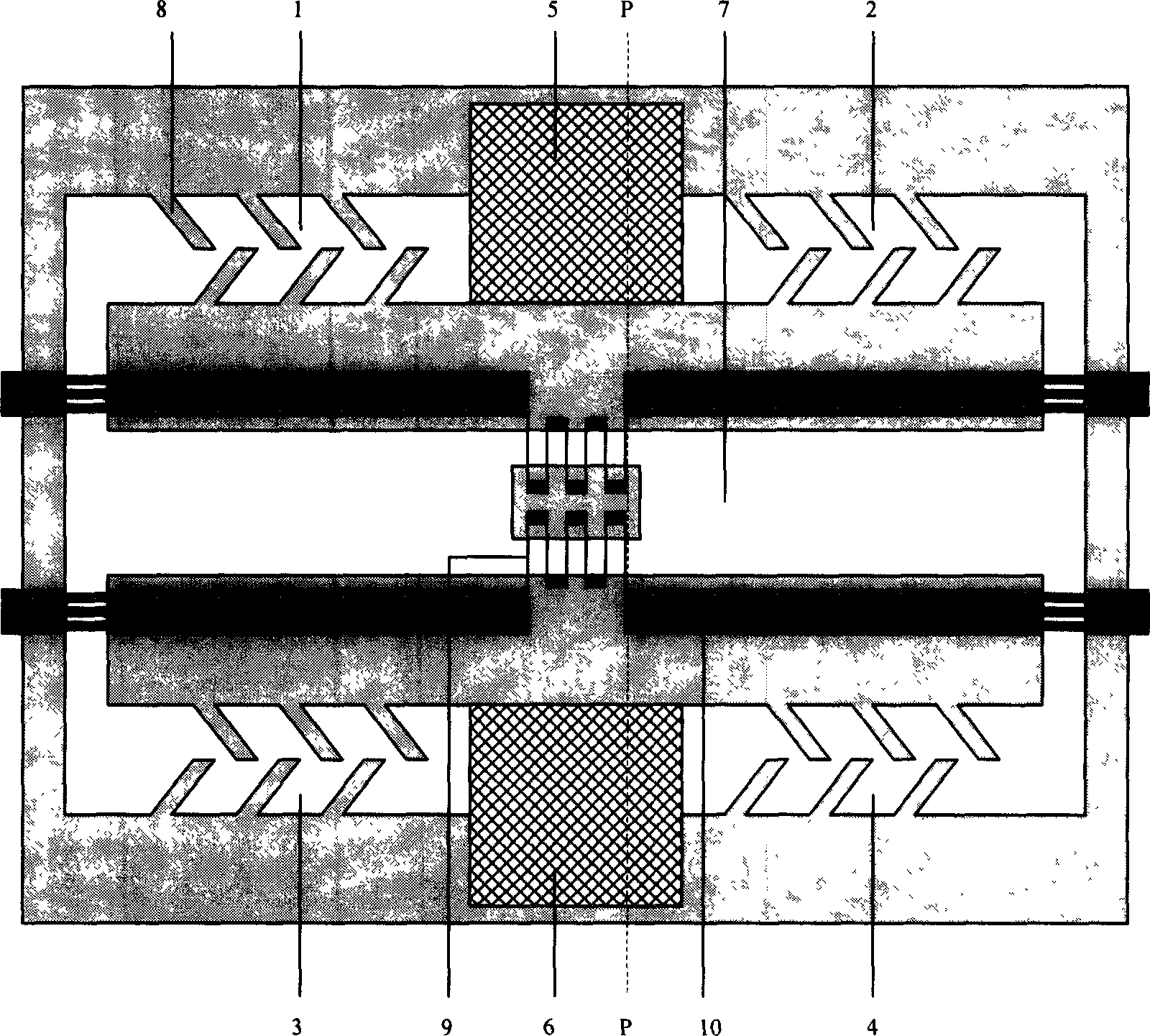

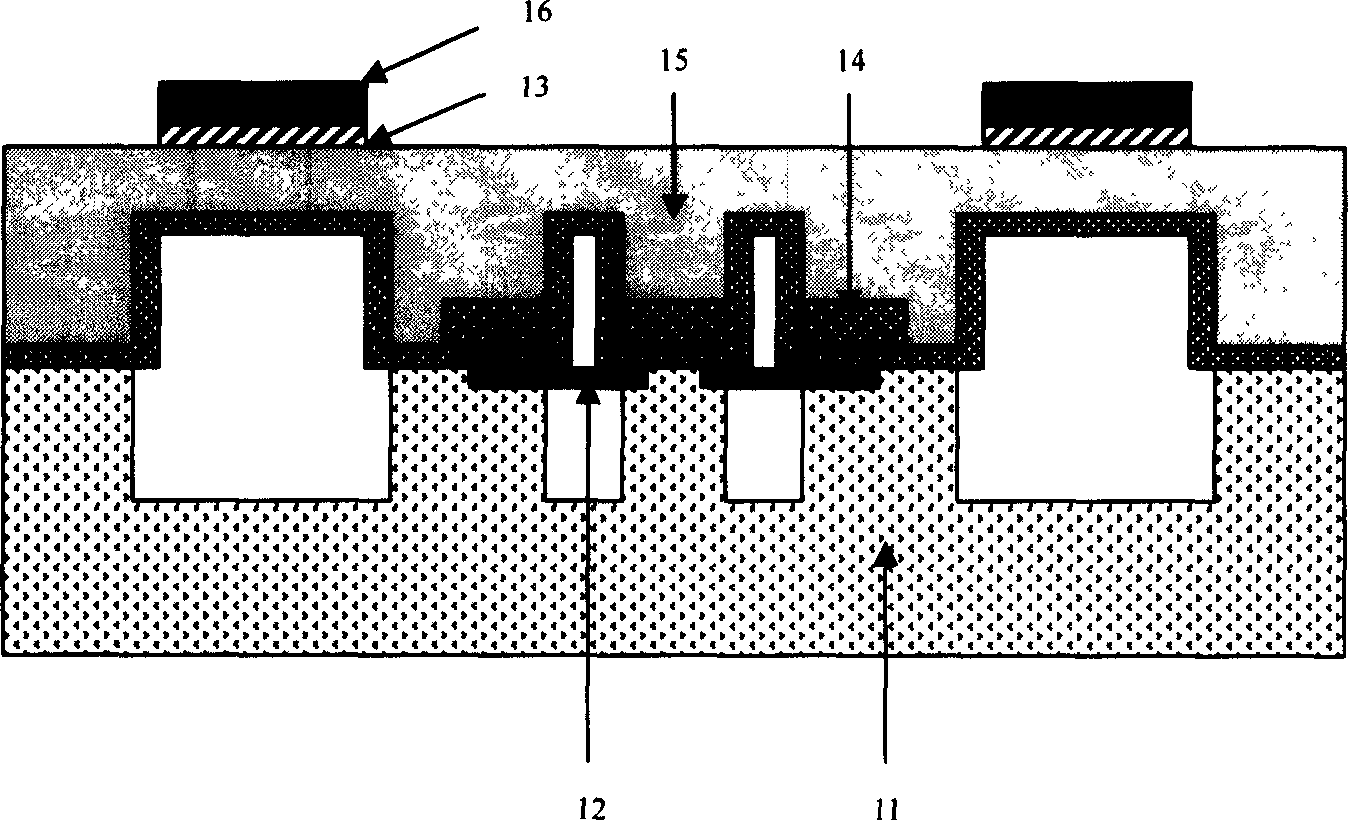

Modularized array electrode of precision simulate welded joint and manufacturing method thereof

InactiveCN103418924AMaintain longitudinal stressAvoid Mixed Electrode SituationsWelding apparatusMicroelectrodeArea ratio

The invention relates to a modularized array electrode of a precision simulate welded joint and a manufacturing method thereof. The modularized array electrode comprises three microelectrode modules: a base metal module, a welding heat affected zone module and a weld metal module, wherein the welding heat affected zone module is arranged between the base metal module and the weld metal module. According to the manufacturing method of the modularized array electrode of the precision simulate welded joint, sample preparations of a base metal zone, a welding heat affected zone, a fusion zone and a weld zone are conducted respectively, the base metal zone, the welding heat affected zone, the fusion zone and the weld zone are recombined and renatured according to the structure features of the welded joint, and therefore the array electrode is manufactured and obtained. The precision simulate welded joint is similar to an actual welded joint in structure and performance and is accurate in simulation and adjustable in area ratio. Through a modularized combination and manufacturing method, an individual test for a certain microelectrode in a certain module can be achieved, coupling tests and scan tests for a certain module or all the modules can be achieved, and the modularized array electrode is especially suitable for galvanic corrosion testing of a multielectrode system.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

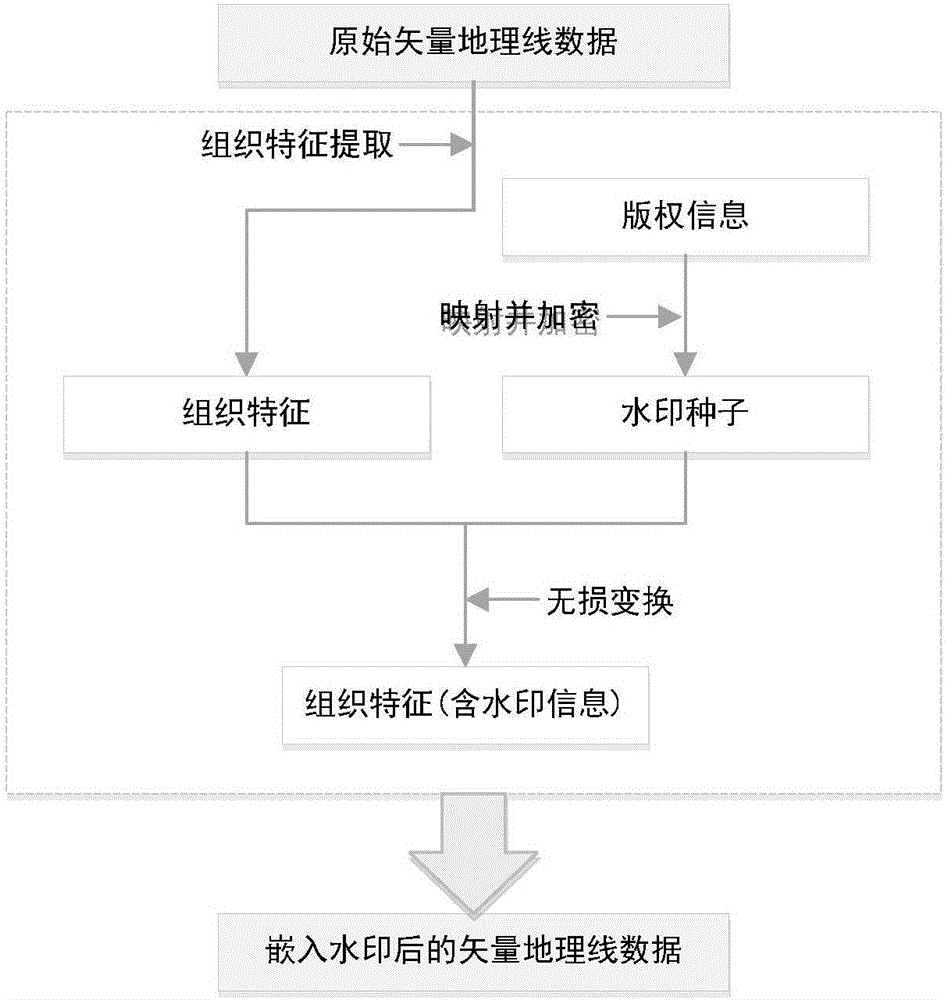

Lossless watermark method based on organization characters of vector geographic line data

ActiveCN106780287AChange precisionAccurate extractionImage data processing detailsInformation embeddingData science

The invention discloses a lossless watermark method based on organization characters of vector geographic line data. The lossless watermark method comprises the following steps: watermark information generation, watermark information embedding and watermark information detecting. The organization characters of the vector geographic line data are utilized fully, and are combined with a robustness watermark technology, so that embedding and detecting of watermarks can be realized under the condition that data precision is not changed. Because watermark information is embedded in invariant of the vector geographic line data, the lossless watermark method can resist attack of almost all common types.

Owner:NANJING NORMAL UNIVERSITY

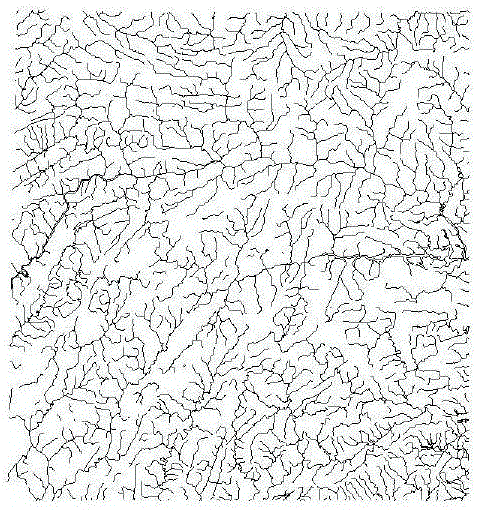

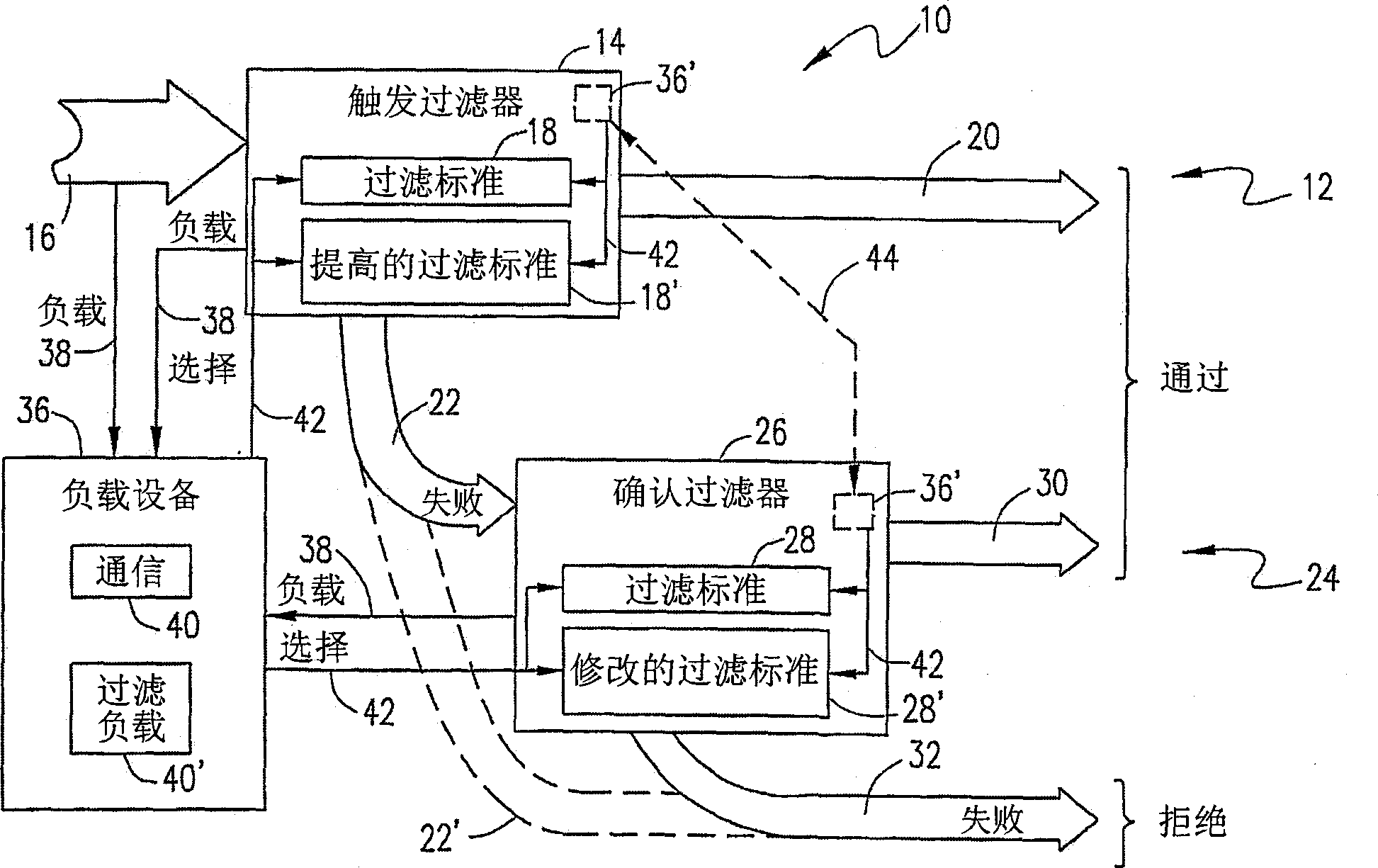

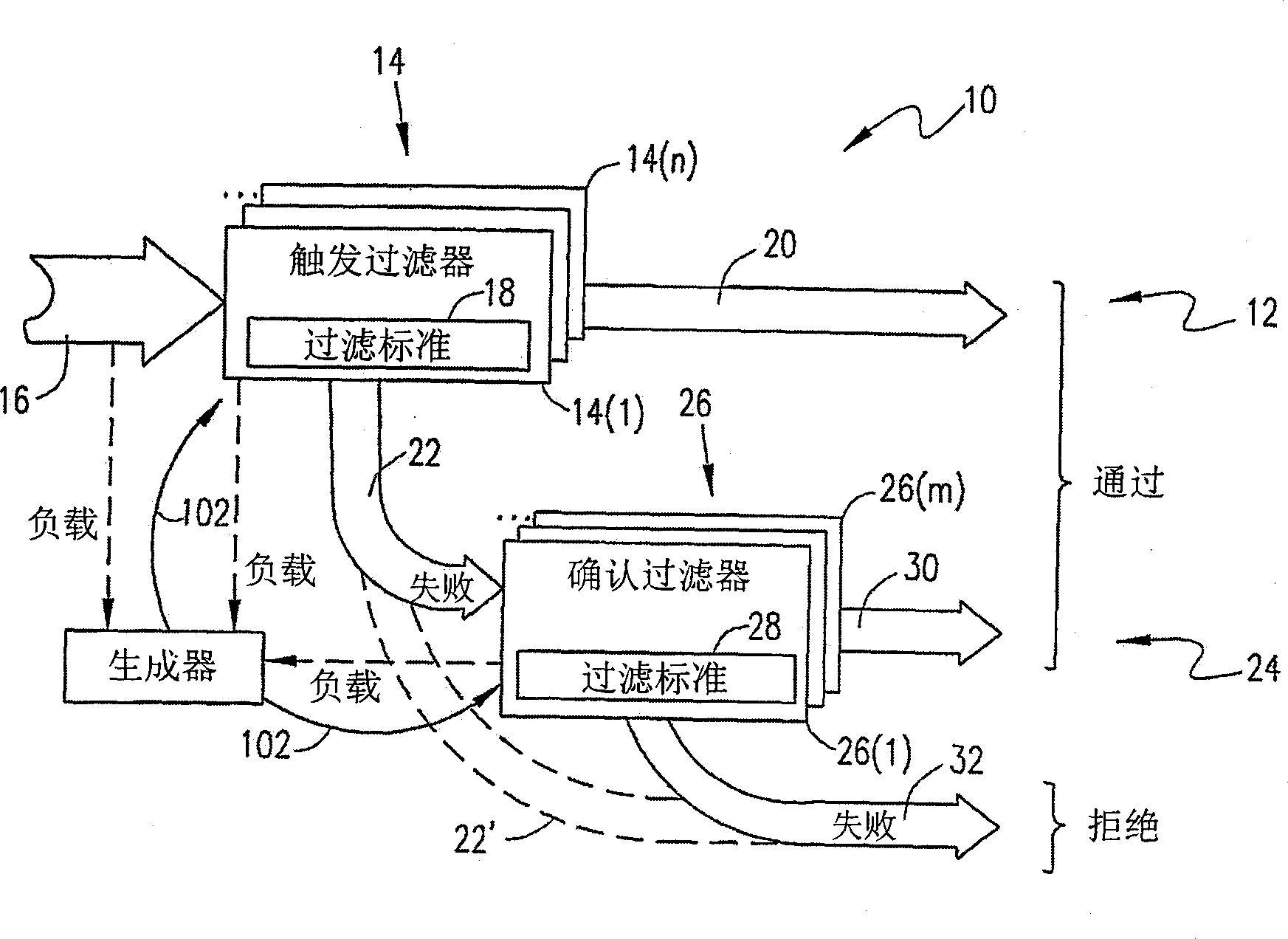

Multi-level packet screening with dynamically selected filtering criteria

InactiveCN1816804AChange complexityChange precisionDigital computer detailsUnauthorized memory use protectionPacket filteringDistributed computing

A packet filtering operation implements a hierarchical technique. Received packet traffic is first filtered with a first filtering criteria. This first filtering action generates a first pass traffic portion and a fail traffic portion from the received packet traffic. The fail traffic portion is then second filtered with a second filtering criteria. This second filtering action generates a second pass traffic portion and a reject traffic portion. The first filtering criteria provide for higher throughput, lower accuracy processing while the second filtering criteria provide for lower throughput, higher accuracy processing. Dynamic adjustments may be made to the first and second filtering criteria to achieve better overall packet filtering performance. For example, load is measured and the filtering criteria adjusted to better balance load between the hierarchical filtering actions.

Owner:HEWLETT PACKARD DEV CO LP

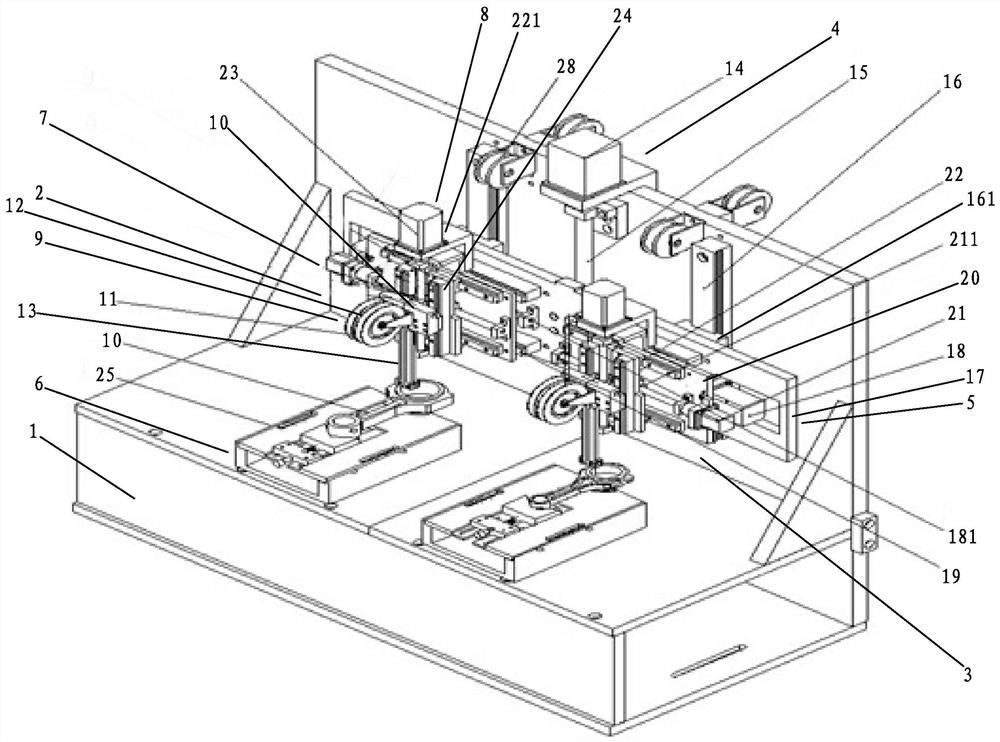

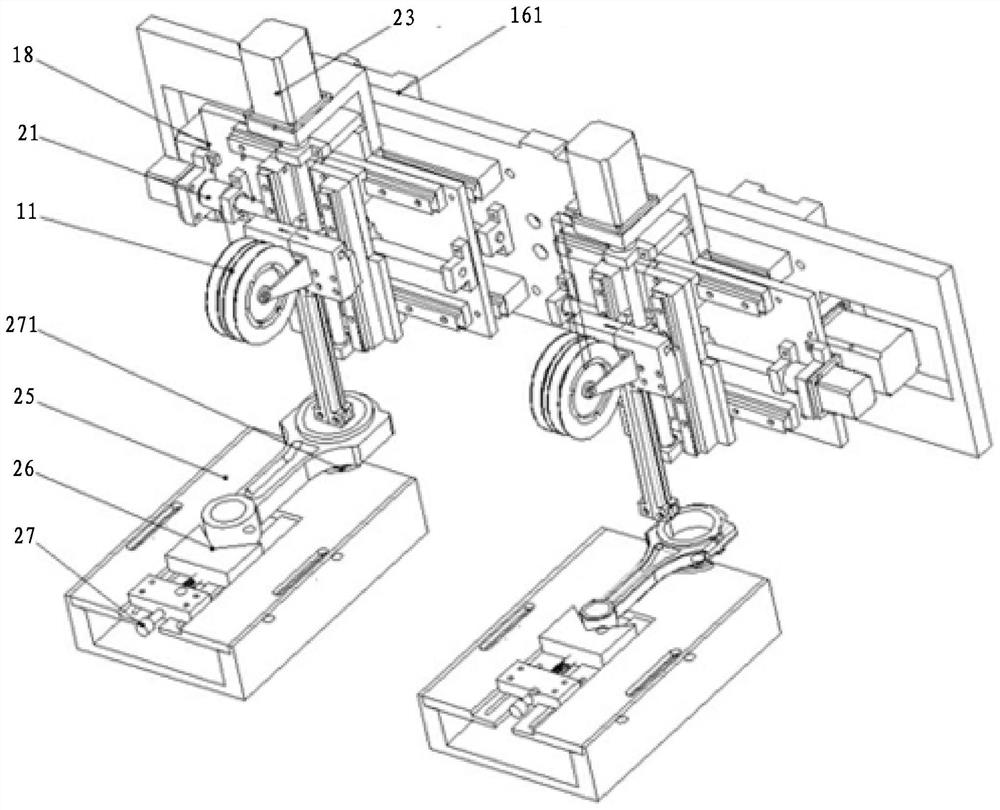

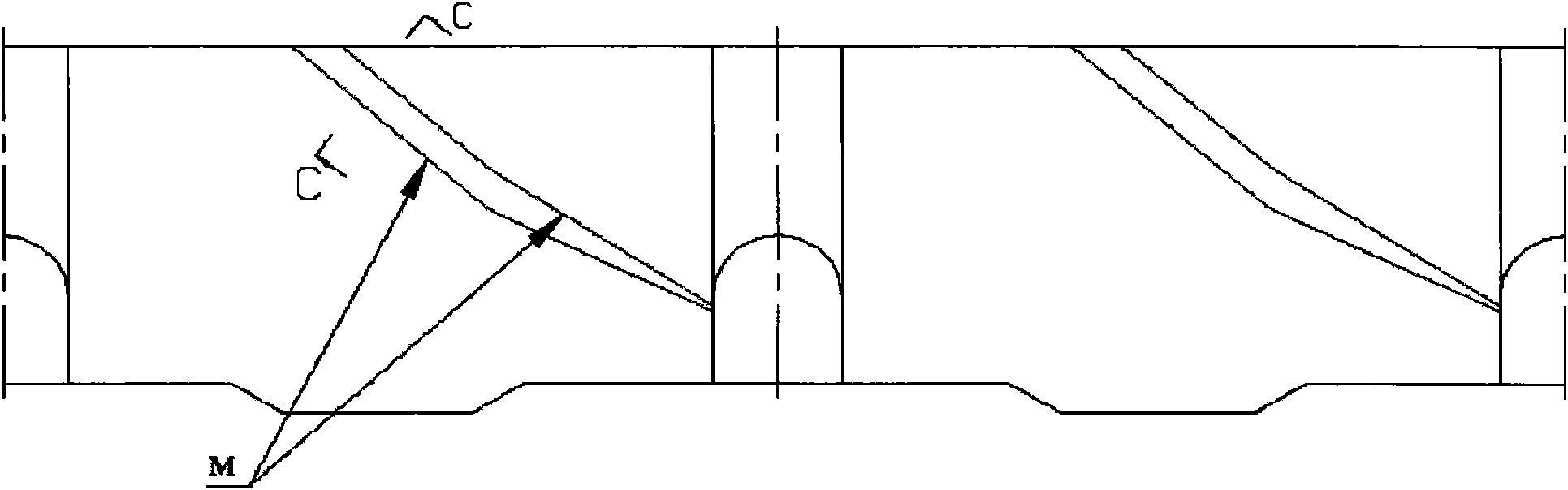

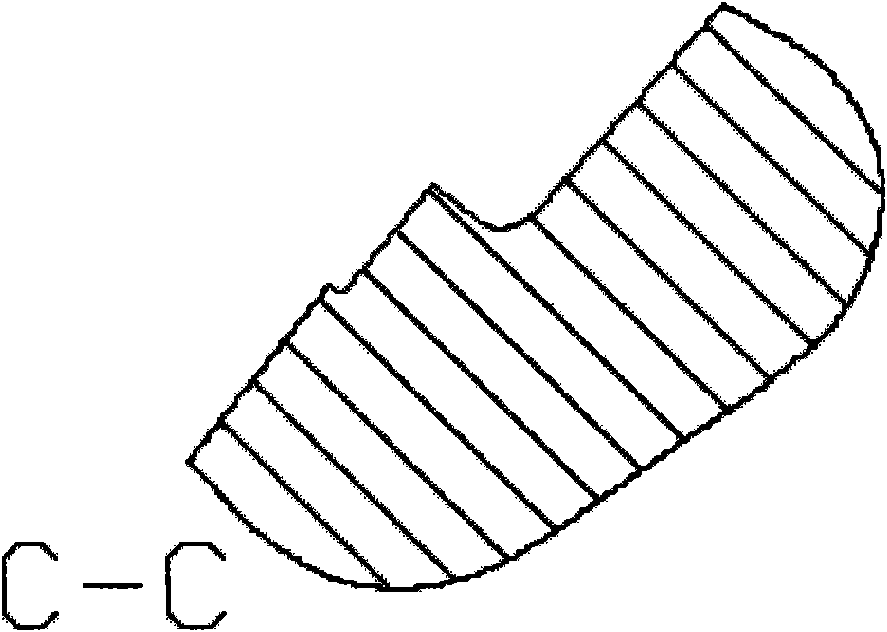

Double-station sheet cutting connecting rod fracture splitting groove device

ActiveCN111992823AAvoid windingImprove processing efficiencyPlastic recyclingElectrical-based machining electrodesReciprocating motionClassical mechanics

The invention discloses a double-station sheet cutting connecting rod fracture splitting groove device which comprises a platform, a left station machining device, a right station machining device, asecondary vertical driving device, a secondary horizontal driving device and a controller. The left station machining device and the right station machining device each comprises a clamp, a main horizontal driving device, a main vertical reciprocating driving device and a machining electrode assembly. Each machining electrode assembly comprises a connecting frame fixedly installed on the main vertical reciprocating driving device, a reel rotatably installed on the connecting frame, a sheet wound on the reel and clamping feet used for clamping the sheet, vertical through holes are formed in theclamping feet, and the sheets are sleeved with the vertical through holes and stretch out of the lower ends of the vertical through holes. The sheets are clamped and tensioned by the clamping feet todo continuous reciprocating motion in the vertical direction, meanwhile, the continuous reciprocating motion in the vertical direction and grooving machining in the horizontal direction form composite machining, continuous reciprocating in the vertical direction is auxiliary motion of grooving machining, and discharging and chip removal are facilitated.

Owner:GUANGDONG UNIV OF TECH

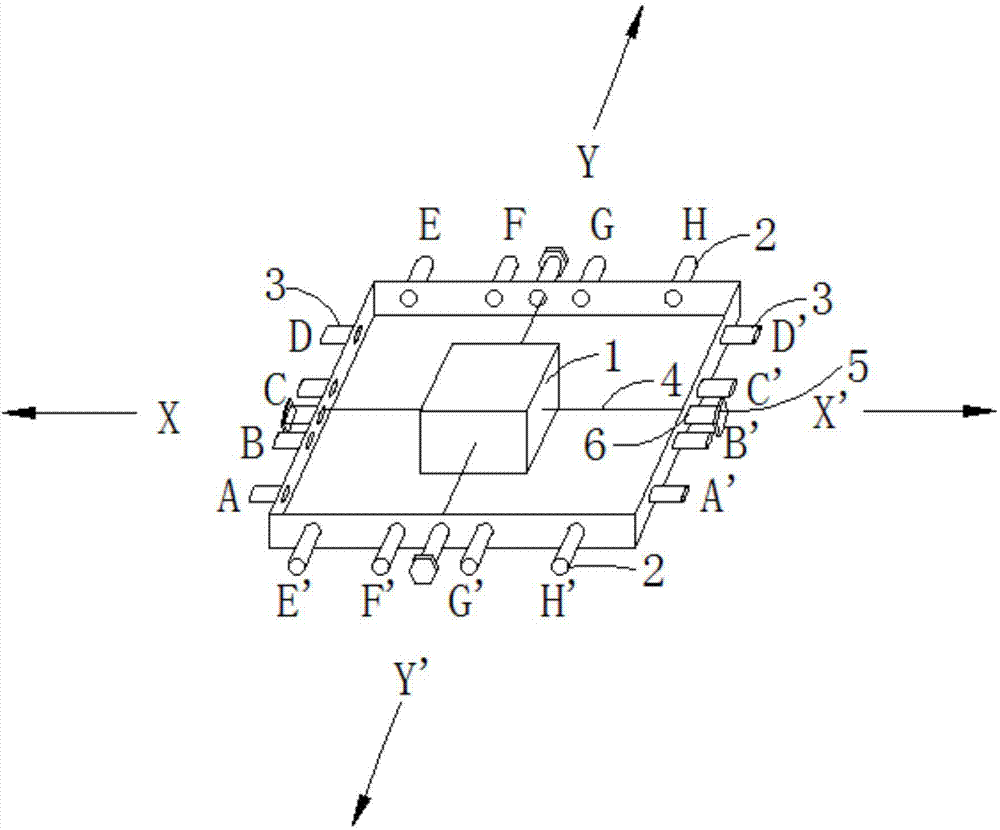

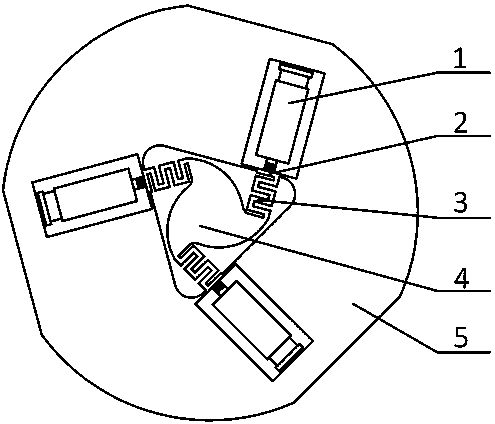

Planar three-degree-of-freedom parallel micro-positioning platform of symmetric structure

InactiveCN103586863AGuaranteed motion accuracyChange the stiffnessProgramme-controlled manipulatorWork benchesKinematic chainElectricity

The invention provides a planar three-degree-of-freedom parallel micro-positioning platform of a symmetric structure. The planar three-degree-of-freedom parallel micro-positioning platform comprises a movable worktable, a fixed platform body and three full-flexible supporting chains connected between the movable worktable and the fixed platform body. The planar three-degree-of-freedom parallel micro-positioning platform is characterized in that the three full-flexible supporting chains are symmetric with the geometrical axis of the movable worktable as the center, each full-flexible supporting chain comprises an elastic moving pair and an elastic folded beam shaped like a Chinese character 'gong', the side face, shaped like the Chinese character 'gong', of each elastic folded beam and the top face of the movable worktable are in the same plane, one end of each elastic folded beam shaped like the Chinese character 'gong' is connected with the movable worktable, the other end of each elastic folded beam shaped like the Chinese character 'gong' is connected with one side face of the corresponding elastic moving pair, the opposite side faces of each elastic moving pair are fixedly connected with the fixed platform body through a piezoelectric ceramic actuator, and the geometrical axes of the three piezoelectric ceramic actuators are in the same plane and do not intersect at one point. The planar three-degree-of-freedom parallel micro-positioning platform of the symmetric structure is made of a piece of a material, and the shortest kinematic chain is adopted, so that the platform has the advantages of being free of assembly errors, compact in structure, high in kinematic accuracy, large in bearing capacity and the like.

Owner:SHANDONG UNIV OF TECH

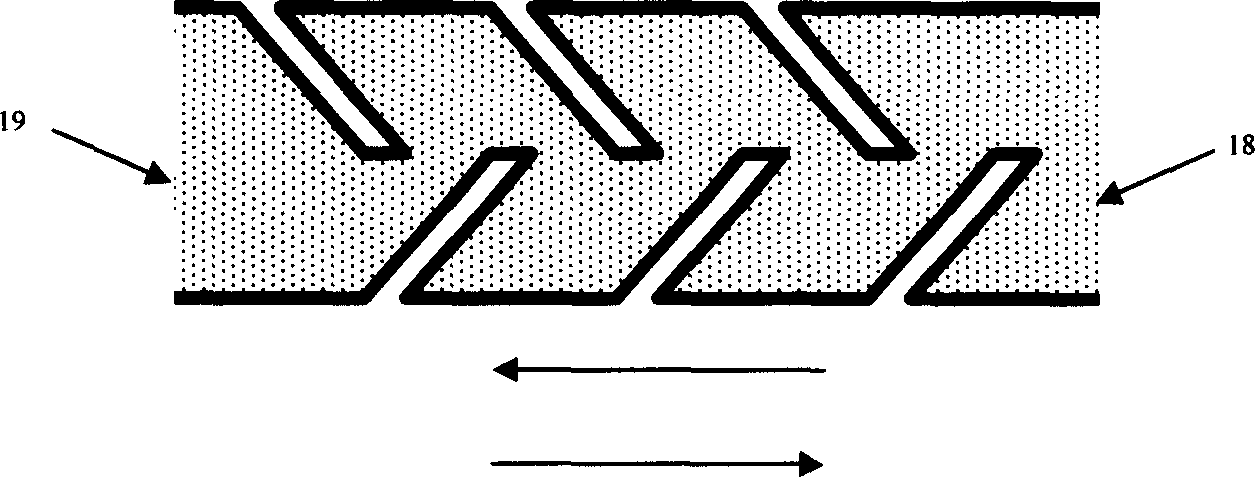

Jet flow angle velocity transducer and method for making same

This invention provides a fluidic angular velocity sensor and its process and belongs to micro electron mechanical system design and its process field. The sensor comprises two vibration chambers; four commute chambers and one detection chamber. The gas in the vibration chamber is driven and recycled and each vibration chamber two sides are located with two commute chambers and the driven gas flows into the detection chamber through the commute chamber and the recycled gas always moves along one direction in the detection chamber. The said detection chamber is symmetrically located with two pieces of heat sensitive resistance wires, which is connected with a Wheatstone bridge. The said commute chamber is needle teeth flow diode, which is composed of several orderly distributed needle teeth block bar.

Owner:PEKING UNIV

Image display device

InactiveCN101627417AImprove the display effectMake up for lack of responsivenessCathode-ray tube indicatorsConversion involving interpolation processesTemporal changeDisplay device

A frame interpolation process circuit (20) performs an interpolation process on a video signal(V1) in a frame unit. A time division gradation process circuit (40) performs a gradation level conversion to distribute luminance of one-frame period to two sub-frame periods: a first half and a latter half. A gradation level change detection circuit (70) detects whether the gradation level has changed between continuous sub-frames for each of pixels. To a pixel which has changed the gradation level, an overshoot process circuit (50) outputs a video signal obtained by performing a gradation level conversion for emphasizing a signal temporal change on an output signal of the frame interpolation process circuit (20) instead of the output signal of the time division gradation process circuit (40). The circuit configuration may further include a predetermined multiplication process circuit to replace the frame interpolation process circuit (20). This improves the dynamic display performance while satisfying the response speed of the display element.

Owner:SHARP KK

Jigging machine self-adaptive buoy device based on machine vision and discharging method

The invention discloses a jigging machine self-adaptive buoy device based on machine vision. The jigging machine self-adaptive buoy device based on machine vision comprises a machine vision instrument, an ash measuring instrument, a jigging machine discharging device, a control processor, a self-adaptive buoy counterweight device and a discharging impeller; the machine vision instrument and the ash measuring instrument are arranged in front of a feeding port of the jigging machine and are connected with the control processor respectively; the jigging machine discharging device is in charge ofsorting and discharging work of coal; the self-adaptive buoy counterweight device is connected with the control processor; the discharging impeller is arranged below a discharging port jigging machinesieve plate; and the control processor controls the rotating speed of the discharging impeller according to a heavy product bed thickness signal acquired by a counterweighted buoy to achieve a good sorting effect. The jigging machine self-adaptive buoy device based on machine vision automatically changes the counterweight of the buoy device by detecting parameters such as variety and density of the coal by the machine vision instrument and the ash measuring instrument so as to detect the thickness of the true bed adapting to different materials, is accurate and reliable, and saves manpower resource.

Owner:CHINA UNIV OF MINING & TECH

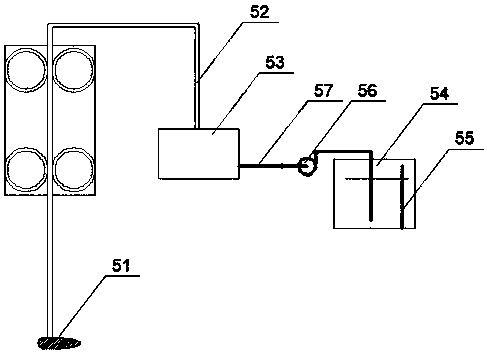

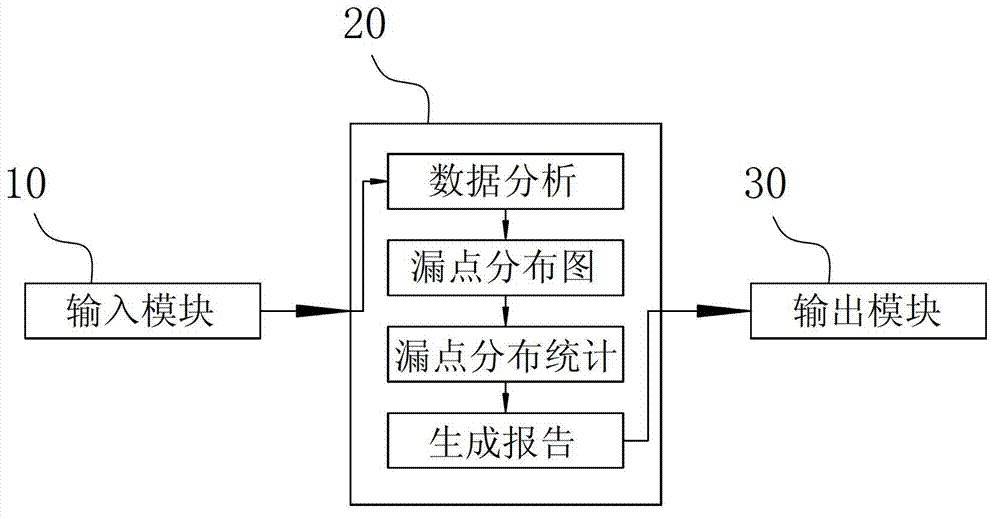

Leak detection processing system based on anti-seepage lining of garbage landfill pool

InactiveCN102853970ATime consuming to changeChange precisionFluid-tightness measurementLeak detectionComputer science

The invention relates to garbage landfill treatment and detection techniques, and particularly relates to a leak detection processing system based on an anti-seepage lining of a garbage landfill pool. The leak detection processing system comprises an input module, a processing module and an output module, wherein an output end of the input module is connected with an input end of the processing module in a single direction; an output end of the processing module is connected with an input end of the output module in the single direction; the processing module obtains detection information led by the input module, carries out data analysis treatment on the information, then forms a leak scatter diagram, obtains leakage statistical data and forms a report to be input into the output module; and the output module displays or prints the information after obtaining the processing information of the processing module. Leak statistics, leak scatter diagram drawing and inspection report issuing or display can be automatically carried out according to the data just by leading the detection data into the processing module in actual use after the processing module and the output module are in coordination. Therefore, time consumption and inaccuracy caused by artificial leak statistics and manual drawing are changed, and the leak detection processing system is convenient and fast to use.

Owner:HEFEI XIANGSHANG ELECTRONICS TECH CO LTD

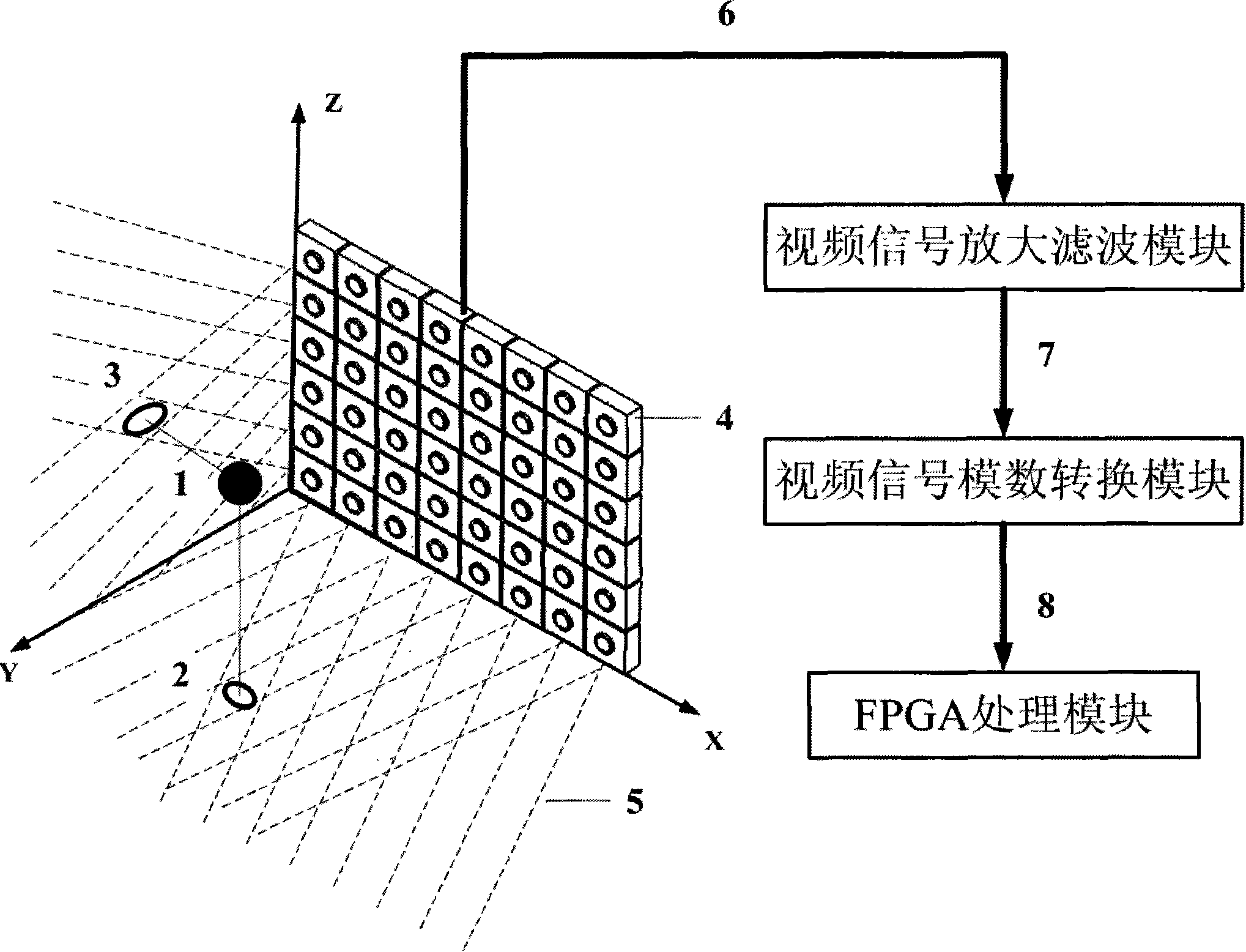

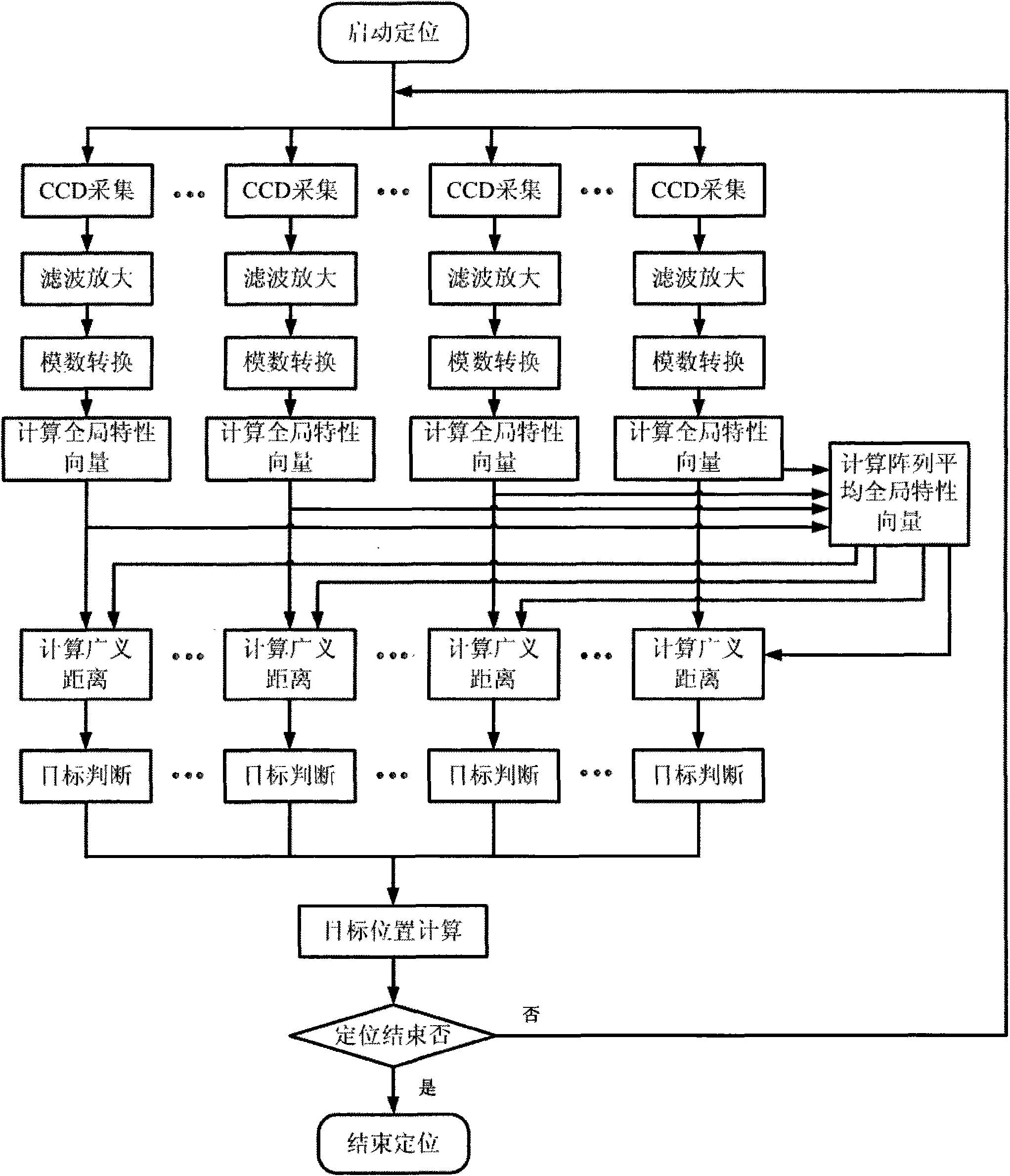

Global property difference-based CCD array video positioning method and system

InactiveCN101778303ARapid positioningReduce sizeTelevision system detailsImage analysisFeature vectorComputer module

The invention discloses a global property difference-based CCD array video positioning method and a system for CCD arrays arranged on a surface plate at fixed intervals. The method comprises the following steps: amplifying and de-noising an analog signal output by each CCD through a video signal amplification and filter module; sending the amplified and de-noised analog signal to a video signal analog-to-digital conversion module, and converting the amplified and de-noised analog signal into a digital signal of YUV format; then adding Y, U and V components in the YUV digital signal of each area array CCD by using an FPGA processing module according to pixels to acquire respective integral characteristic vector respectively; averaging the global property vectors of the whole array; comparing the global property vector of each CCD with the averaged global property vector of the array to judge whether a target appears in a video image of each CCD; and finally, calculating a rhombic vision field area in which the target appears through the sequence number of the shot CCDs of the target so as to position the target quickly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of teflon microporous film baseband

The invention provides a preparation method of a polyfluortetraethylene micro-porous film baseband, belonging to the chemical technical field, particularly relates to the processing technical field of micro-porous polyfluortetraethylene film. The invention comprises the processing steps that polyfluortetraethylene resin powder is mixed with solvent which is number 3 aviation kerosene and isoparaffin; the proportion for uniform mixing among the three ingredients of the polyfluortetraethylene, the number 3 aviation kerosene and the isoparaffin is 1: 0.1-0.15: 0.2-0.3 according to weight percentage; the mixture is statically arranged under the temperature environment of 40-65 DEG C, then dumped into a pre-pressing forming machine, uniformly and slowly pressed into polyfluortetraethylene material rods under the pressure of 50kg-180kg and sent to a thrust press; the mixture then sequentially enters all rollers with the temperature ranging from 30-180 DEG C; the uniformity and width of the thickness of the baseband are adjusted through a baseband uniformity automatic control system to generate the polyfluortetraethylene micro-porous film baseband which is coiled by a coiler. The finished product of the invention has high uniformity and improves the utilization ratio of finished product micro-porous film.

Owner:江西天润天和新材料科技有限公司

Method for processing stepped nonlinear spiral groove of 16PA6 injection pump plunger

InactiveCN101569984AChange precisionChanging the finish is not a good phenomenonGrinding machinesNumerical controlEngineering

The invention relates to a method for processing a stepped nonlinear spiral groove of a 16PA6 injection pump plunger, which is characterized by comprising the following steps: (1), roughly processing the spiral groove on the 16PA6 injection pump plunger by a numerical control milling machine and reserving the working allowance of 0.05mm; (2), performing heat treatment to make the hardness of the spiral groove reach HRC58-62; (3), finely processing the spiral groove on the 16PA6 injection pump plunger to the required size by a numerical control grinder; and (4), grinding an excircle with phi 23mm by the numerical control grinder, and controlling the depth of the spiral groove of the plunger between 0.99 and 1.01mm. The processing method changes the phenomenon of poor precision and smooth finish because the prior numerical control milling machine directly processes the spiral groove, simultaneously eliminates the little deformation influence of quenching on the spiral groove of the plunger, and improves the efficiency of subsequent assembly work and oil tests.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

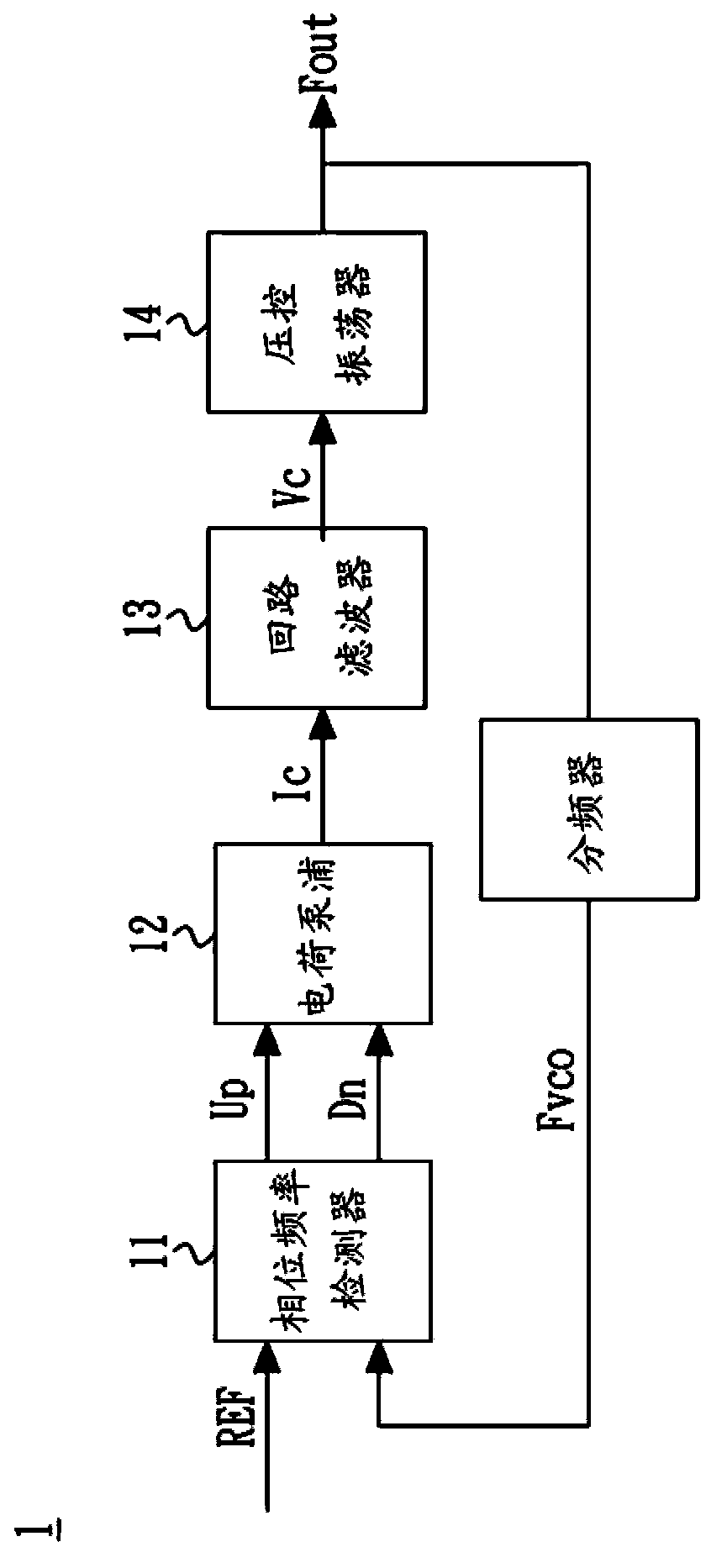

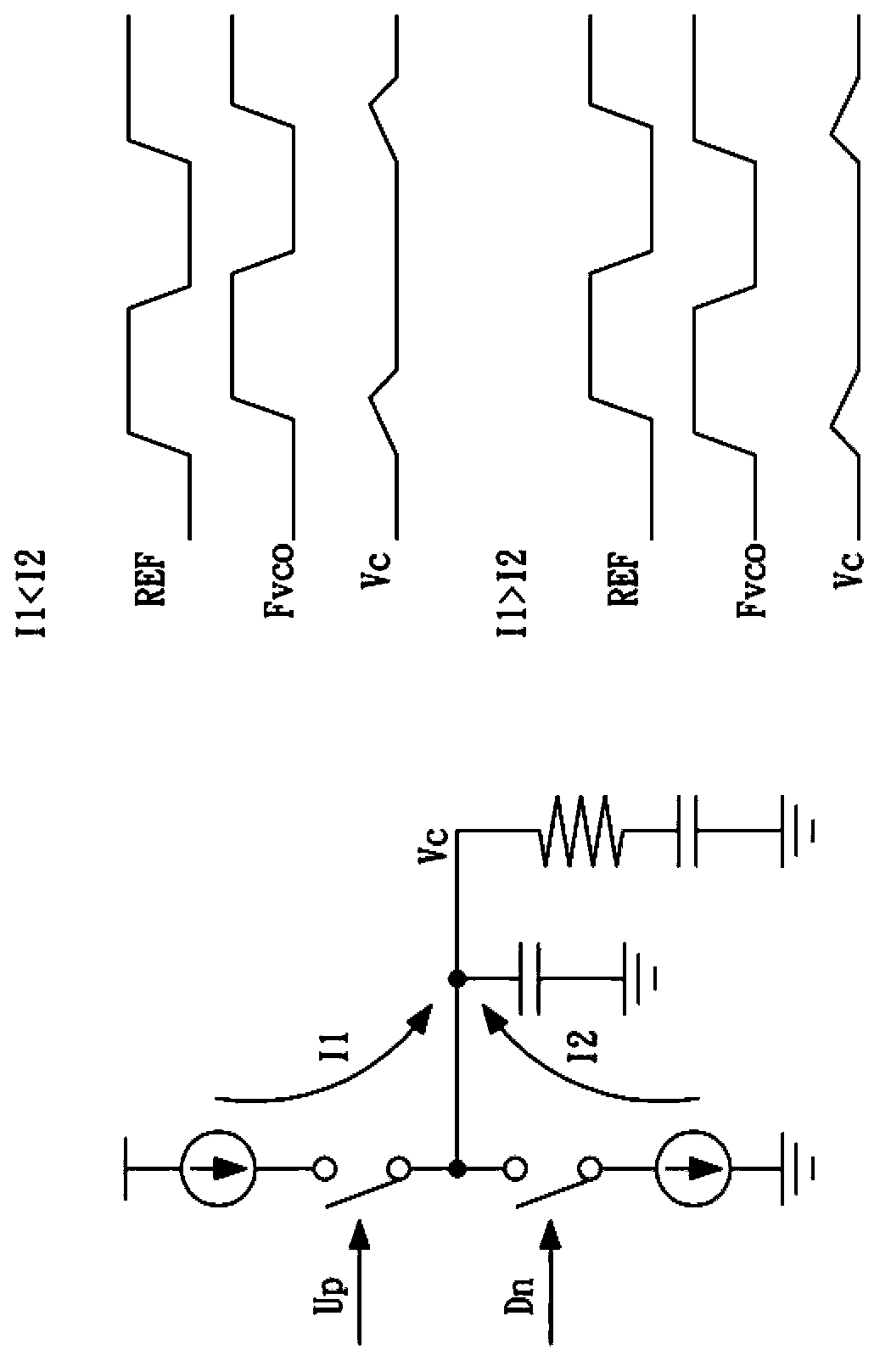

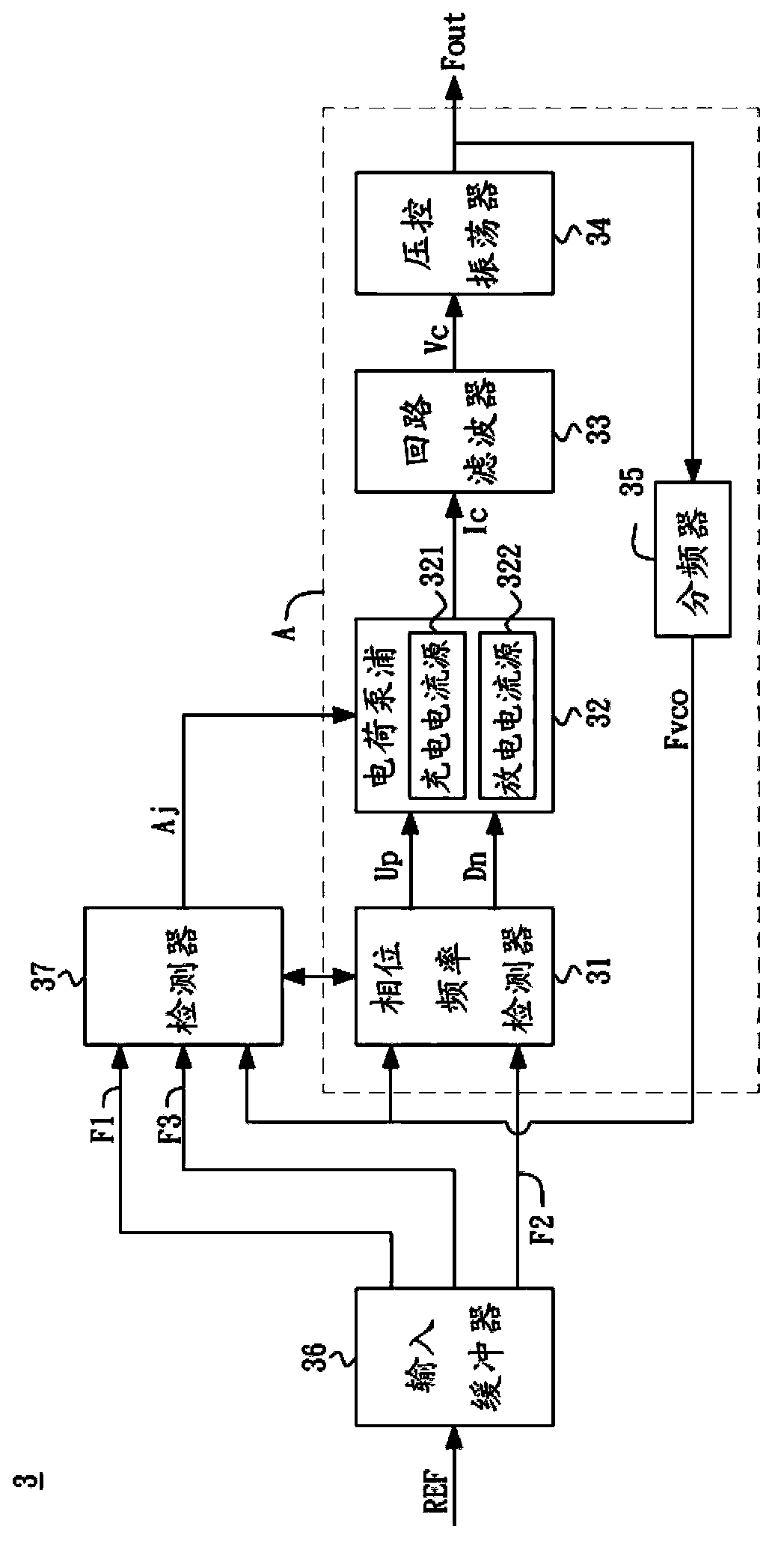

Phase locking loop with current compensation mechanism and method thereof

ActiveCN103856213ASolve the problem of excessive phase differenceSimple structurePulse automatic controlPhase differencePhase-locked loop

The invention discloses a phase locking loop with a current compensation mechanism and a method of the phase locking loop. The phase locking loop comprises an input buffer, an electric charge pumping type phase locking loop body, a detector and a locking judgment device. The input buffer can receive a reference signal so as to generate a first signal, a second signal and a third signal, and the phase delay of the second signal is larger than that of the first signal but smaller than that of the third signal. The locking judgment device can start the detector through a starting signal after detecting that the electric charge pumping type phase locking loop body locks phase difference between a feedback signal and the second signal. The detector executes a sampling program on the feedback signal according to the first signal and the third signal, and an adjustment signal is output to the electric charge pumping type phase locking loop body according to the sampling result so as to adjust the phase position of the feedback signal to be between the first signal and the third signal.

Owner:HIMAX TECH LTD

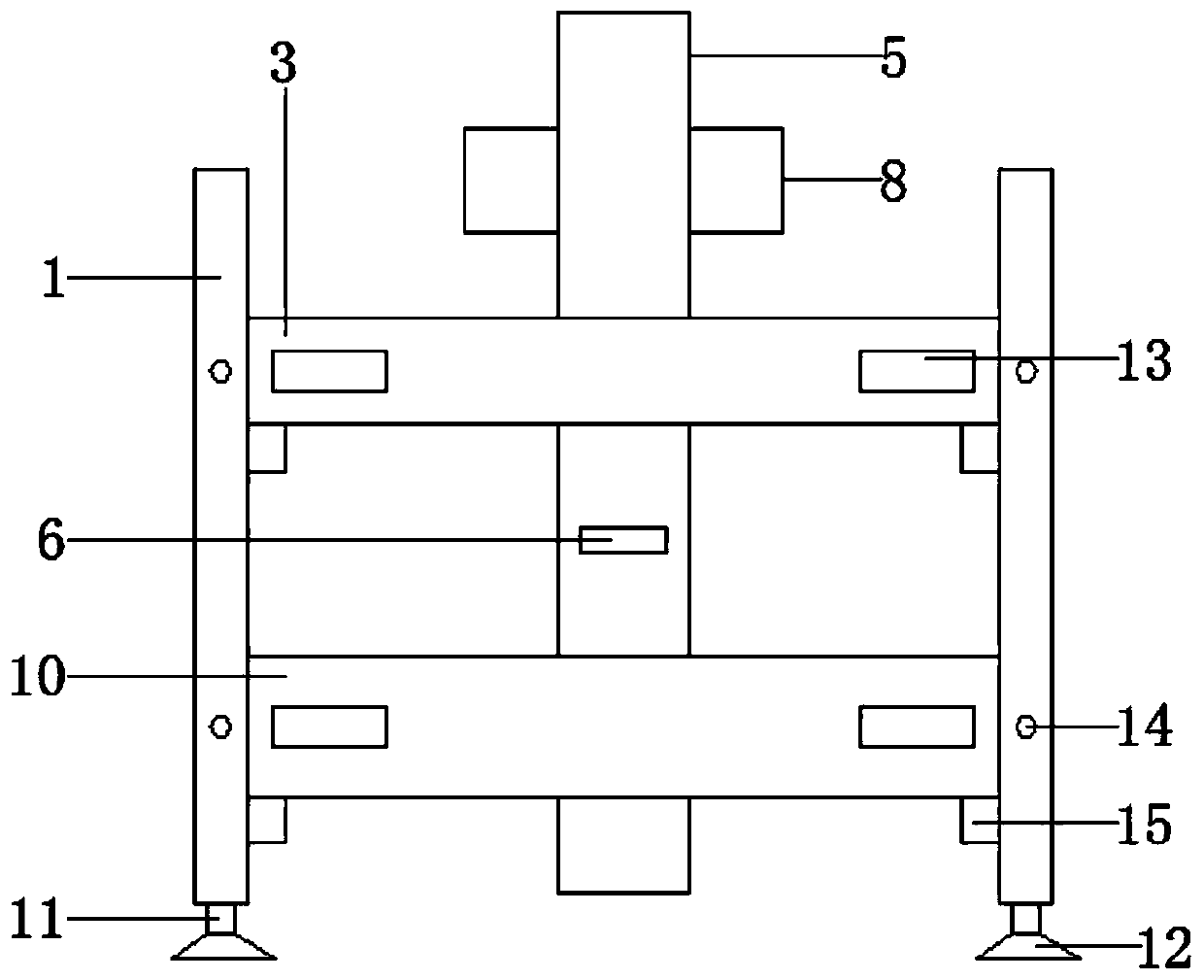

Lifting type multi-layer clamp storage rack

InactiveCN107150327ARotation limitRealize self-locking functionWork tools storageEngineeringScrew thread

Owner:YANGTZE NORMAL UNIVERSITY

Micro landslides prediction instrument

The invention provides a micro landslides prediction instrument. The micro landslides prediction instrument is characterized in that the change of surrounding rock and the development of fracture are continuously monitored through a resistance strain gauge, and the acceleration change characteristic of the surrounding rock instability is sensitively and effectively determined according to the acceleration change of the resistance value, so as to provide a forecast warning for landslides. According to the micro landslides prediction instrument, the landslides prediction technology which is simple, easy to be performed, small in cost, unattended and monitors all the times is provided, which can be applied to the prediction of landslides of underground engineering, safety pre-warning for earthquake proofing and emergency rescuing, and the collapsing prediction of mine, dangerous rock, side slope, dam and the like.

Owner:黄灿

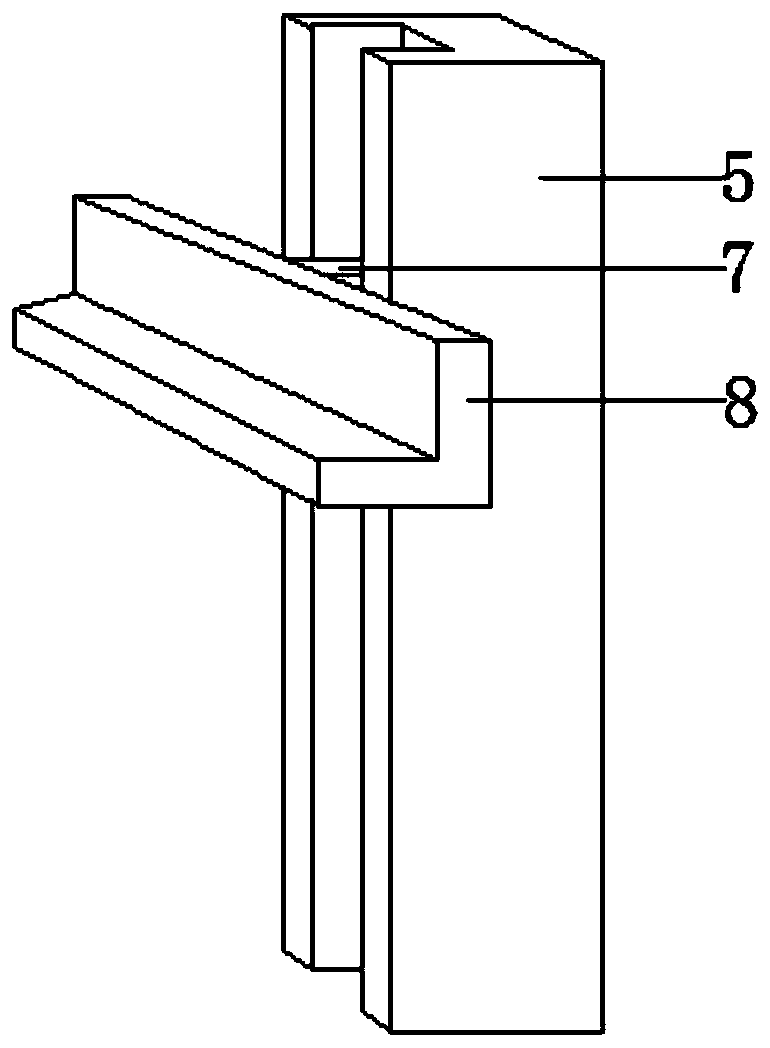

Shock insulation support mounting and positioning rack

PendingCN110306814AEasy to install and disassembleLower requirementBridge structural detailsBridge erection/assemblyEngineeringUltimate tensile strength

The invention relates to a shock insulation support mounting and positioning rack which comprises a mounting rack column. Upper trapezoidal strips are connected to tops on two sides of the mounting rack column, an upper assisted cross beam plate is in clamping and embedding connection to one side of each upper trapezoidal strip, a level bar is fixedly connected to the center of the top of the upper assisted cross beam plate, a damping slideway is arranged on one side of the level bar, a vertical level bar is fixedly connected to the surface of one side of the damping slideway, a positioning slide block is in clamping and embedding connection to an inner cavity of the damping slideway, a support bearing plate is fixedly connected to one side of the positioning slide block, lower trapezoidalstrips are connected to bottoms on two sides of the mounting rack column, and a lower assisted cross beam plate is in clamping and embedding connection to one side of each lower trapezoidal strip. The shock insulation support mounting and positioning rack is convenient to mount and detach, the demand on mounting terrain is reduced greatly, the labor intensity of staff is alleviated, the positioning precision of the mounted shock insulation support mounting and positioning rack is adjustable, the construction quality and the construction efficiency are improved, and the transferring and transporting portability and safety are enhanced.

Owner:YANGZHOU POLYTECHNIC INST

Synchronous pressing synchronous adjusting and digital adjusting mechanism of powder pressing machine

The invention relates to a synchronous pressing synchronous adjusting and digital adjusting mechanism of a powder pressing machine. The mechanism comprises a synchronous adjusting motor, wherein the synchronous adjusting motor drives one front-and-back adjusting rod on one side to rotate, and the front-and-back adjusting rod on one side drives synchronous pressing oil cylinder adjusting rods to rotate through a gear set; the front-and-back adjusting rod on one side drives a left-and-right adjusting rod to rotate through a transmission mechanism, the left-and-right adjusting rod drives anotherfront-and-back adjusting rod on the other side to rotate through the transmission mechanism, and the front-and-back adjusting rod on the other side drives the synchronous pressing oil cylinder adjusting rods to rotate through the gear set; and the synchronous pressing oil cylinder adjusting rods are screwed and connected with pressing head adjusting threaded sleeves and drive the threaded sleevesto operate, the pressing head adjusting threaded sleeves are screwed and connected with adjusting piston rods and drive the adjusting piston rods to operate, and rotation stopping devices for preventing the adjusting piston rods from rotating in the radial directions are arranged on the adjusting piston rods. According to the synchronous pressing synchronous adjusting and digital adjusting mechanism of the powder pressing machine, the structure is reasonable, and stability of pressing can be guaranteed.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

Spacecraft navigation system for equivalent device of X pulsar detector

ActiveCN102175246BChange precisionIncreased accuracy rangeInstruments for comonautical navigationTime informationDynamic equation

The invention discloses a scheme of a spacecraft navigation based on an X pulsar detection equivalent device. The scheme mainly comprises the following processes of simulating X pulsar emitting photon information detected by an X pulsar detector, and resolving a spacecraft position and speed navigation information. The overall simulation process is divided into three parts, namely detector simulating, data processing and navigation resolving. In the first part, the detector simulates the photon arrival time; in the second part, a data processing system performs cycle folding according to the photon arrival time of the X pulsar, calculates a pulse profile, performs time conversion, and performs pulse profile cross-correlation processing with a standard profile stored by a known ephemeris so as to finish the calculation of the pulse arrival time; and in the third part of navigation resolving, a precise spacecraft orbit and time information are resolved finally by taking the pulse arrival time as measurement information and combining an orbit dynamic equation and kalman filtering. By the X pulsar equivalent device, the influence of various parameters and different algorithms such as a resolution ratio, a view field, time conversion precision, a folding algorithm and the like on the autonomous navigation accuracy of the spacecraft can be analyzed, and necessary technical support is provided for the development of an X pulsar-based autonomous navigation system and the research on combined navigation with other systems.

Owner:山东中宇航空科技发展有限公司

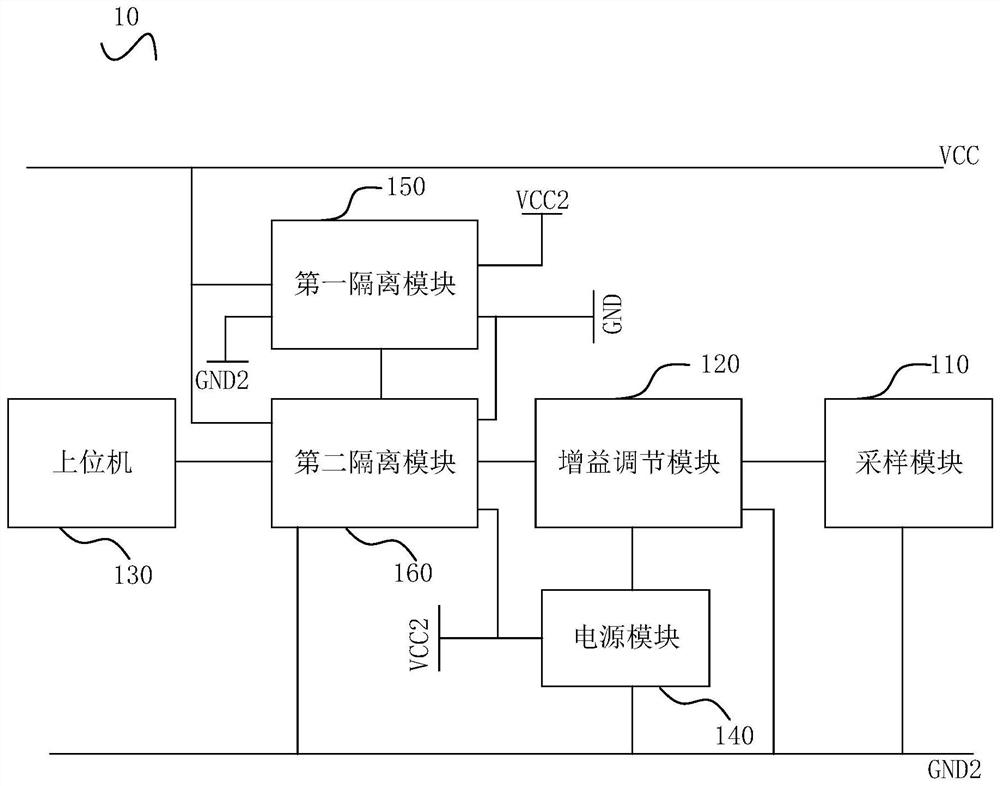

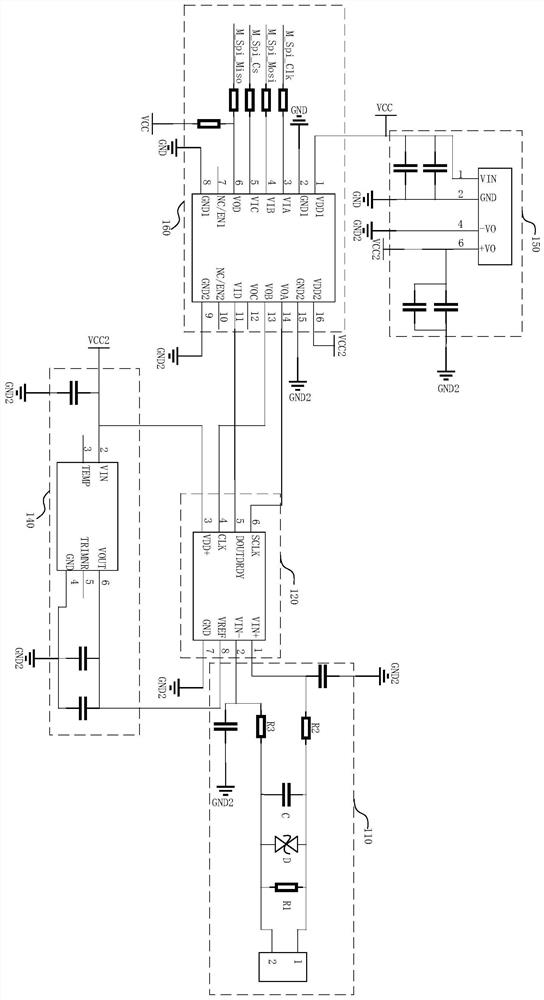

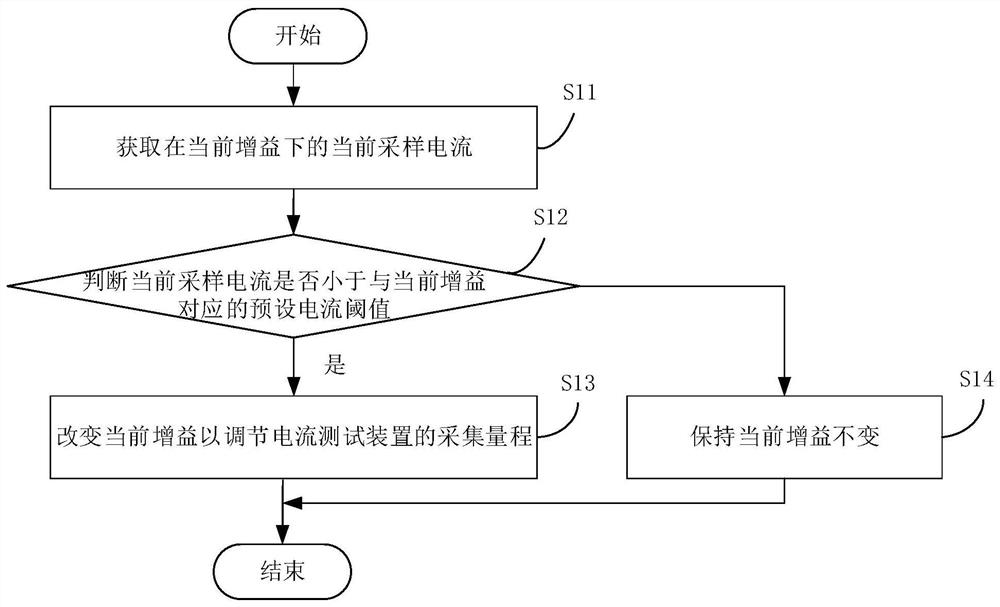

Current testing device, current testing method and electronic equipment

PendingCN112858756AAvoid inaccurate measurementsChange the acquisition rangeCurrent measurements onlyVoltage/current isolationElectrical resistance and conductanceEngineering

The invention discloses a current testing device which comprises a sampling module, a gain adjusting module and an upper computer. The sampling module is used for collecting differential signals at the two ends of the sampling resistor and feeding back the differential signals to the gain adjusting module, and the gain adjusting module is used for determining sampling current according to the differential signals and feeding back the sampling current to the upper computer. The upper computer adjusts the gain of the gain adjusting module according to the sampling current so as to change the acquisition range of the current testing device. According to the current testing device disclosed by the invention, the sampling current is determined according to the differential signals at the two ends of the sampling resistor, and the gain is adjusted according to the sampling current, so that the acquisition range of the current testing device is changed, and meanwhile, the precision of the current testing device can be adjusted, so that the measurement precision corresponds to the acquisition range; under the condition that the current testing device is not replaced, accurate measurement of currents of different magnitudes can be ensured. The invention further discloses a current testing method and electronic equipment.

Owner:GUANGZHOU XIAOPENG MOTORS TECH CO LTD

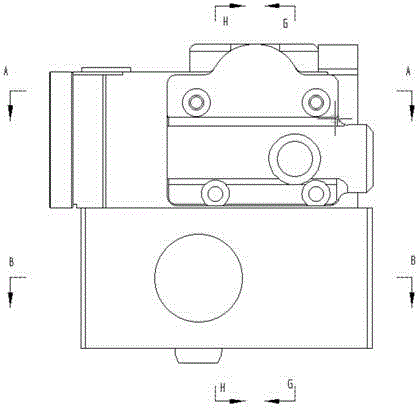

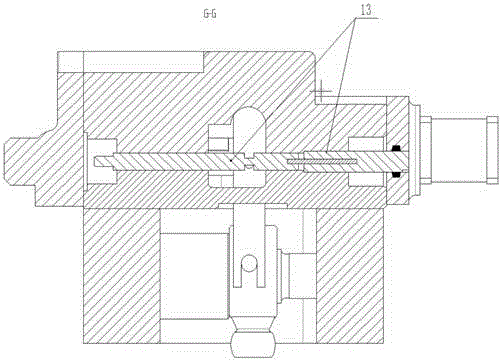

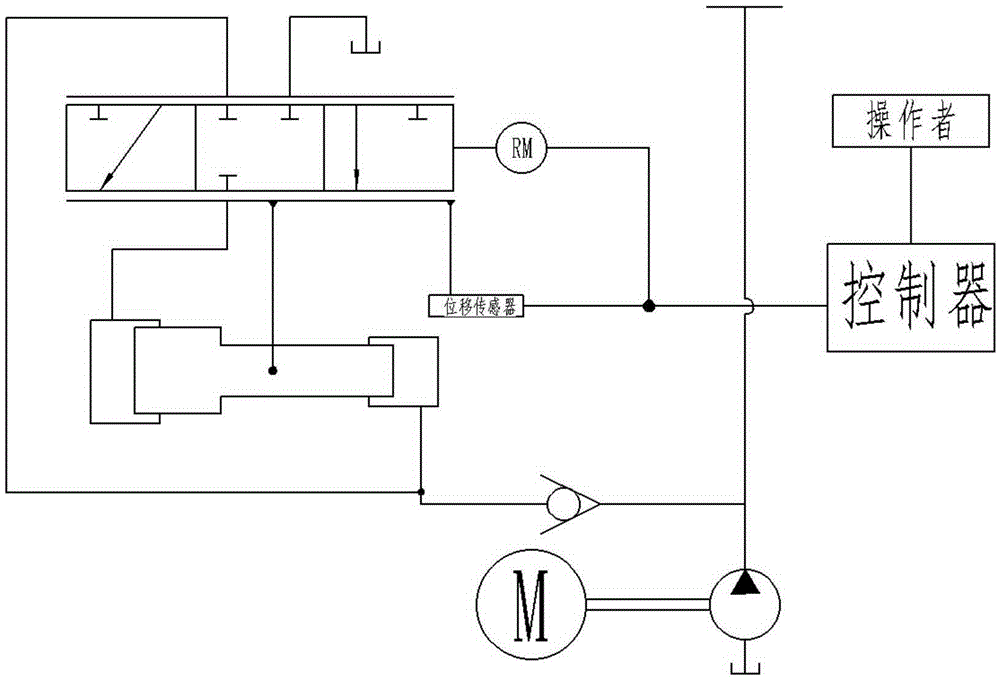

Electro-hydraulic valve control displacement module and using method thereof

ActiveCN105298970AEasy to controlSimple structureOperating means/releasing devices for valvesServomotor componentsMicrocomputerMicrocontroller

The invention relates to an electro-hydraulic valve control displacement module and a using method thereof. The electro-hydraulic valve control displacement module comprises a stepping motor, a transmission rod, a feedback connecting rod, a three-position three-way valve, a linear variable differential transformer, a differential cylinder and a differential cylinder sleeve. The stepping motor is in transmission connection with the transmission rod. The differential cylinder sleeve is fixedly connected with the differential cylinder. The top end of the feedback connecting rod is hinged to the three-position three-way valve, and the bottom end of the feedback connecting rod is hinged to the differential cylinder sleeve. The two sides of the feedback connecting rod are hinged to the transmission rod and the linear variable differential transformer respectively. By means of the linear variable differential transformer and the feedback connecting rod, motion information of the stepping motor and the differential cylinder is fed back to a single-chip microcomputer in real time, by means of accurate calculation of the single-chip microcomputer, the displacement relation between the stepping motor and the differential cylinder can be accurately controlled, an operator can control the displacement relation conveniently and accurately, and therefore accurate adjustment is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com