Method for processing stepped nonlinear spiral groove of 16PA6 injection pump plunger

A technology of spiral groove and fuel injection pump, which is applied to metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of reducing work efficiency, affecting the control of oil supply, and not having the conditions for re-testing, and achieves improved surface finish, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

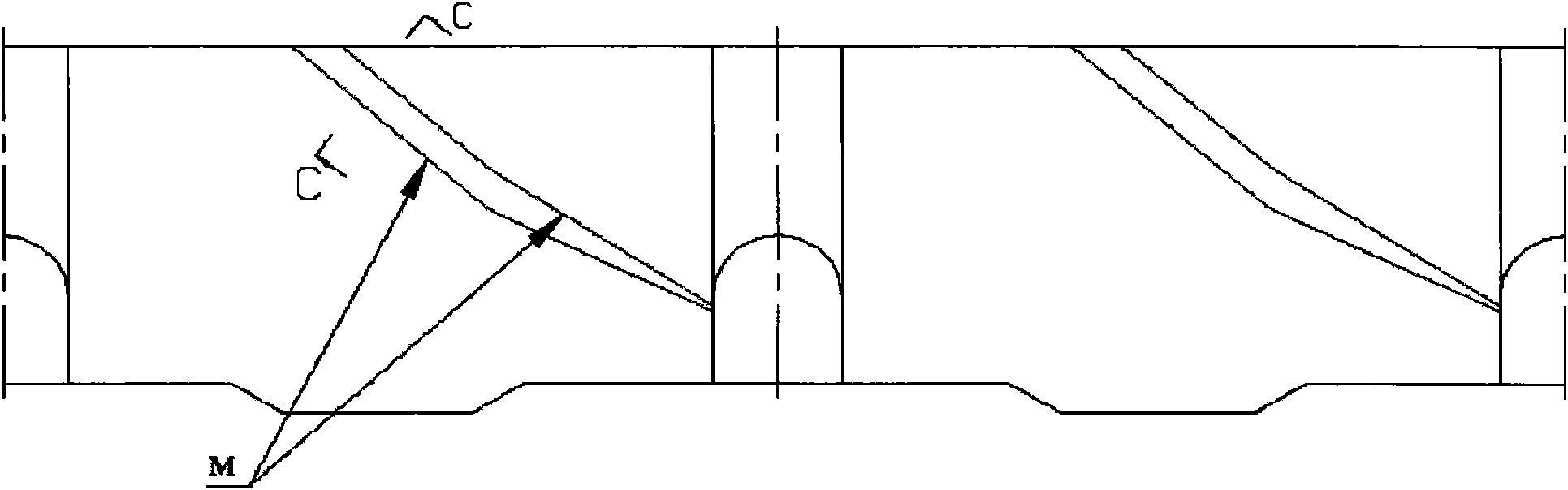

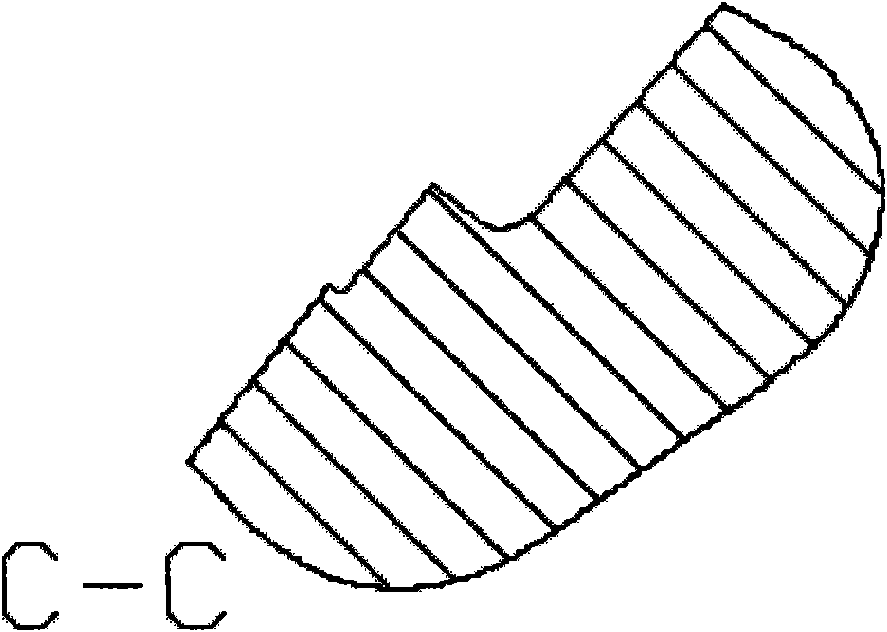

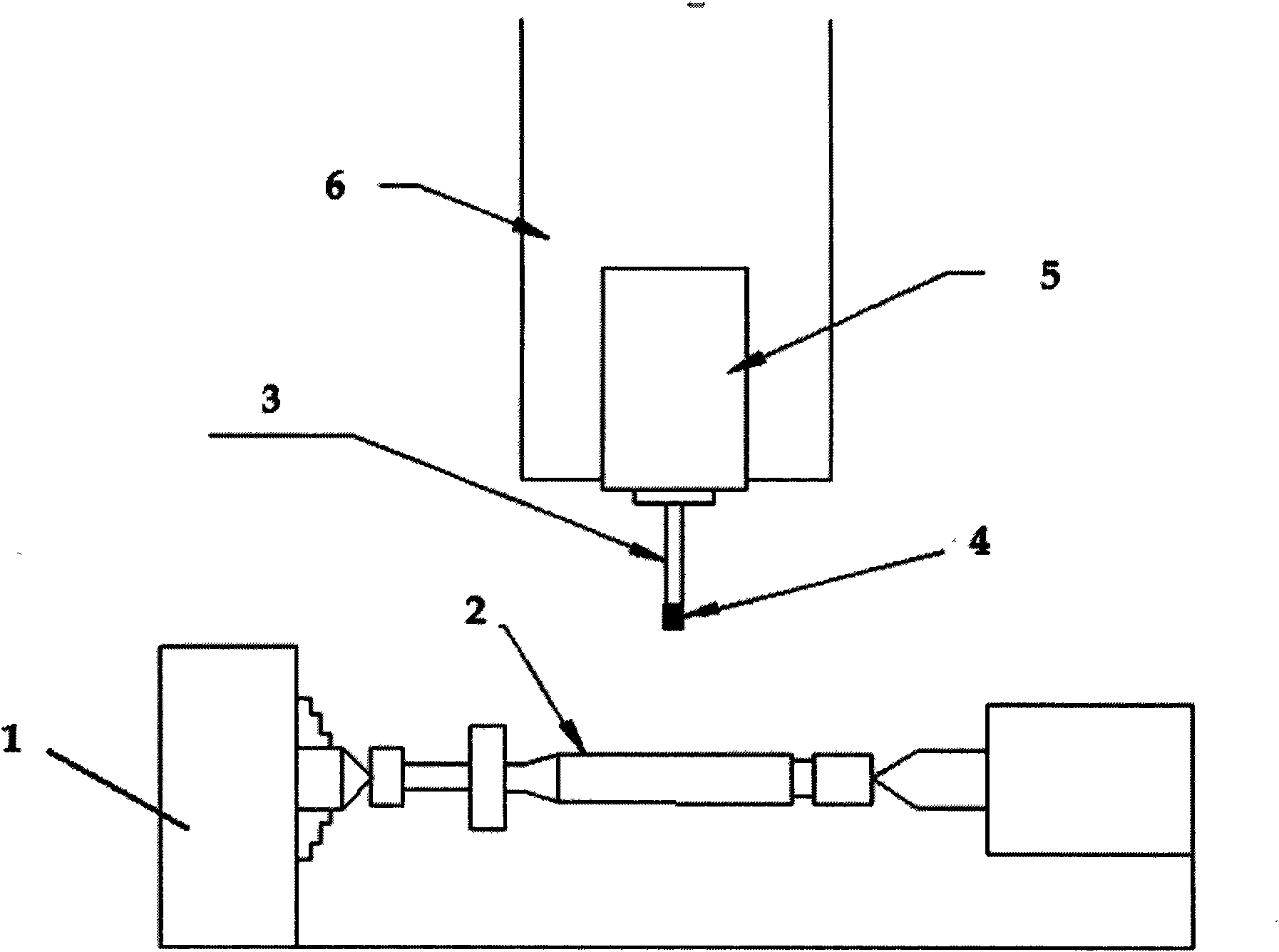

[0023] The method for processing the stepped non-linear spiral groove of the 16PA6 fuel injection pump plunger of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but this should not limit the protection scope of the present invention.

[0024] The improvement of the method of the present invention mainly has two points, one is the adjustment of the processing steps, and the other is the improvement of the processing equipment. details as follows:

[0025] The improved method of processing the stepped non-linear spiral groove of the 16PA6 fuel injection pump plunger of the present invention includes the following steps:

[0026] ①Use a CNC milling machine to roughly machine the spiral groove on the plunger of the 16PA6 fuel injection pump, and leave a machining allowance of 0.05mm. In order to prevent the excessive groove margin when grinding the plunger screw in the subsequent process, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com