Synchronous pressing synchronous adjusting and digital adjusting mechanism of powder pressing machine

A technology of synchronous adjustment and adjustment mechanism, applied in the field of powder metallurgy, can solve the problems of inability to achieve synchronous adjustment on both sides, affect the stability of pressing, and inconsistent adjustment distance, and achieve the effects of convenient synchronous pressing and adjustment, compact structure and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

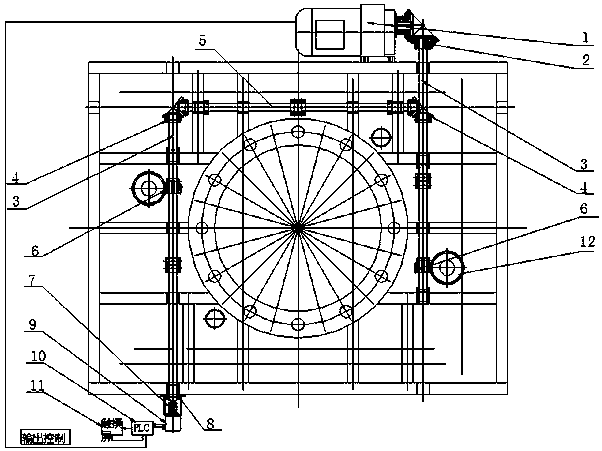

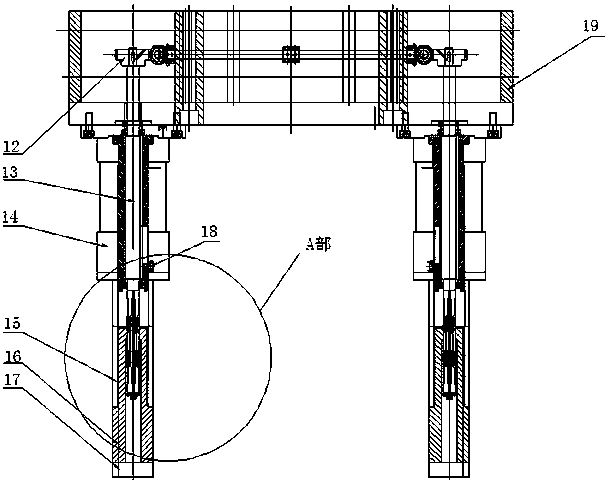

[0021] The present invention includes a synchronous adjustment motor 1, the synchronous adjustment motor 1 drives the front and rear adjustment rod 3 on one side to rotate, and the front and rear adjustment rod 3 on the one side drives the synchronous oil cylinder adjustment rod 13 to rotate through the gear set;

[0022] The front and rear adjustment rods 3 drive the left and right adjustment rods 5 to rotate through the transmission mechanism, and the left and right adjustment rods 5 drive the front and rear adjustment rods 3 on the other side to rotate through the transmission mechanism, and the front and rear adjustment rods 3 on the other side are driven by the gear set Synchronous pressure oil cylinder adjustment rod 13 rotates;

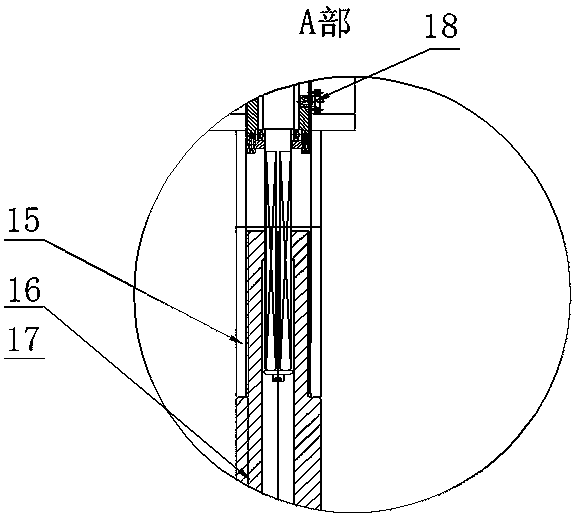

[0023] The adjustment rod 13 of the synchronous oil cylinder is screwed and connected to the pressure head adjustment threaded sleeve 16 and drives it to run. The pressure head adjustment threaded sleeve 16 is screwed to connect with the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com