Double-station sheet cutting connecting rod fracture splitting groove device

A double-station, cracking tank technology, applied in the direction of accessory devices, manufacturing tools, electric processing equipment, etc., can solve the problems of poor processing accuracy and stability, complicated electrode wire winding, and reduced yield, so as to achieve high processing efficiency, The effect of low equipment cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

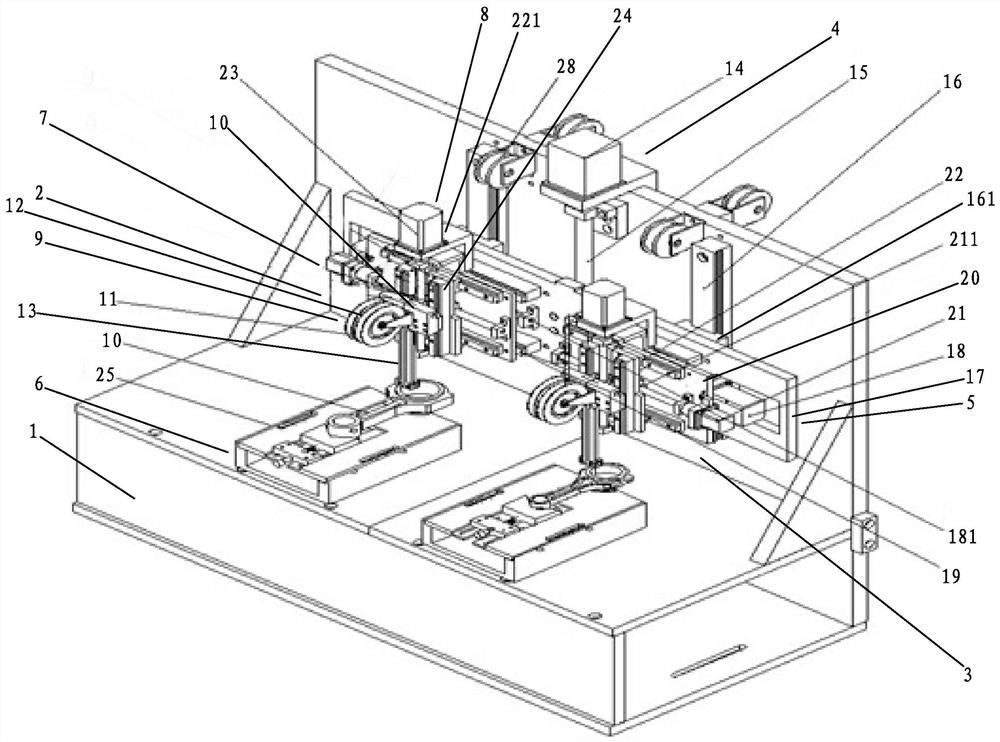

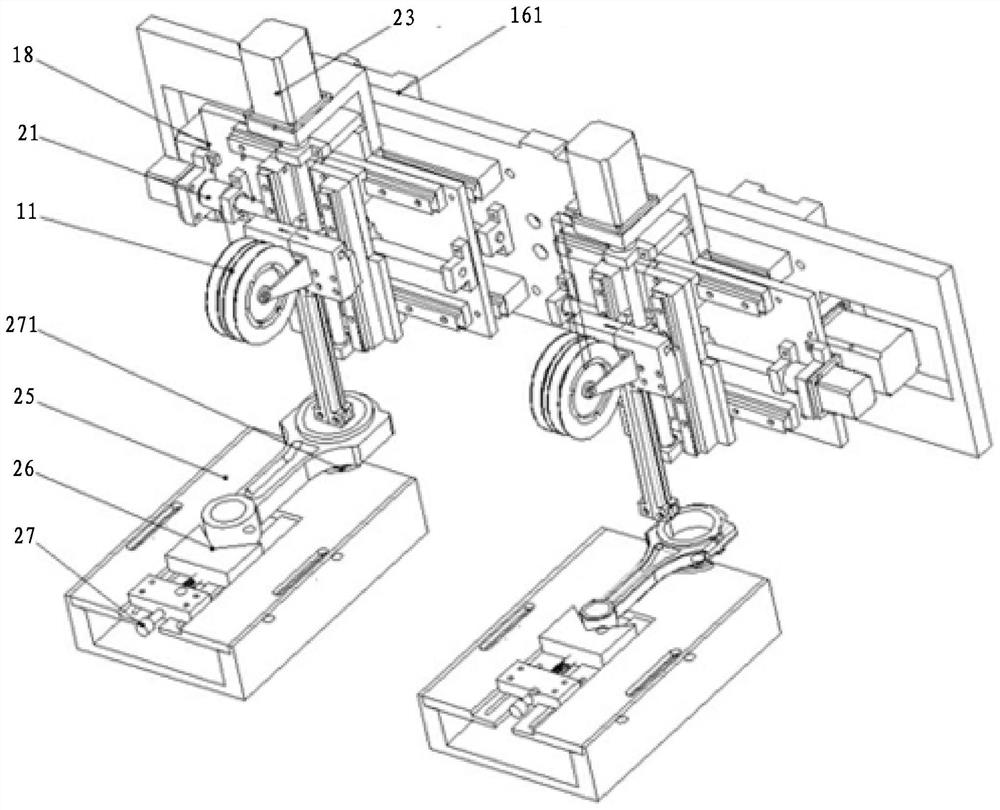

[0027] refer to figure 1 and figure 2 , the present embodiment relates to a double-station sheet cutting connecting rod cracking tank device, including a platform 1, a left-station processing device 2 and a right-station processing device 3 installed on the platform 1, for respectively driving the left-station processing device 2 The secondary vertical driving device 4 and the secondary horizontal driving device 5 sliding in the vertical and horizontal directions with the right station processing device 3, and are used to control the left station processing device 2, the right station processing device 3, the secondary vertical drive The controller of the device 4 and the secondary horizontal driving device 5; the secondary horizontal driving device 5 is installed on the power output end of the secondary vertical driving device 4, and the left station processing device 2 and the right station processing device 3 are installed on On the power output end of the secondary horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com