Patents

Literature

42results about How to "High grooving efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

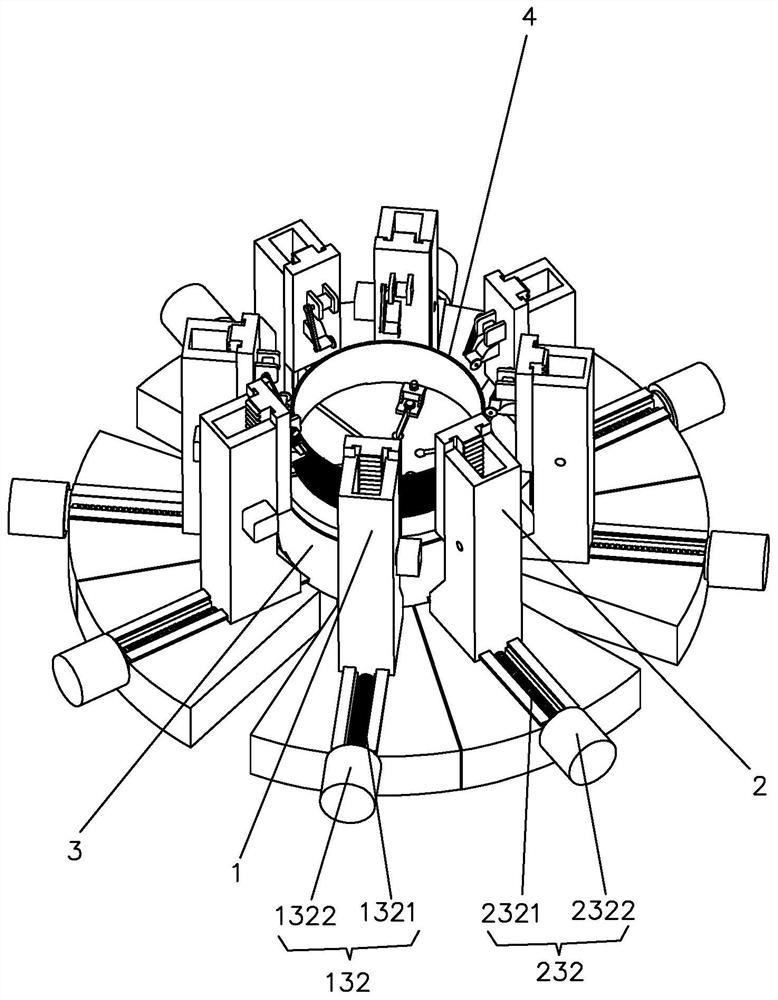

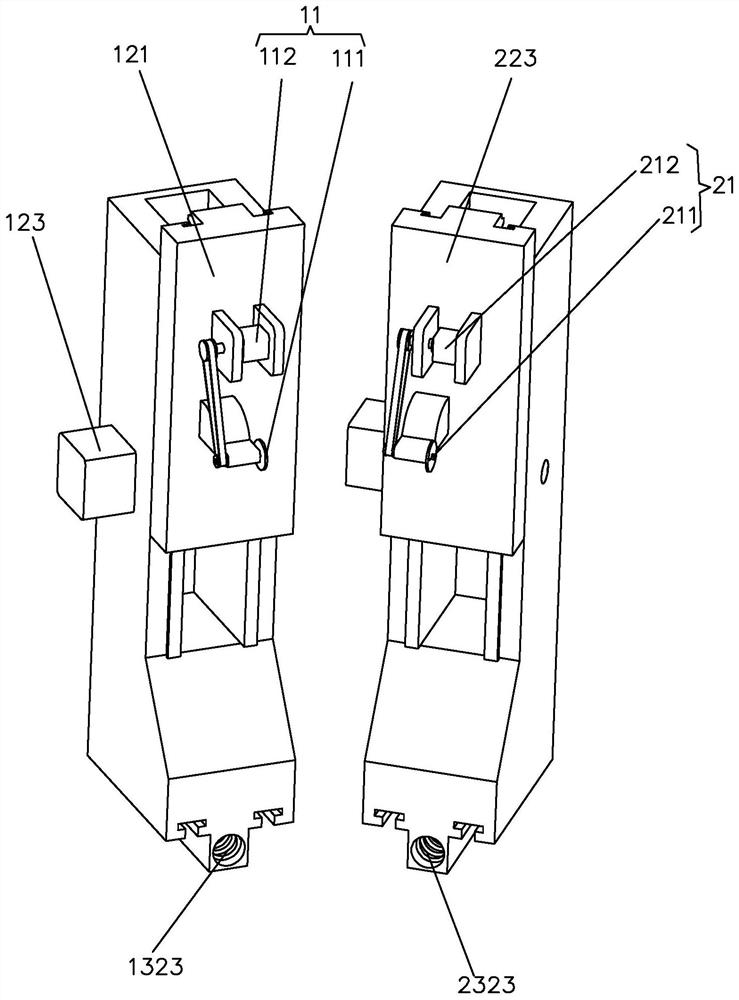

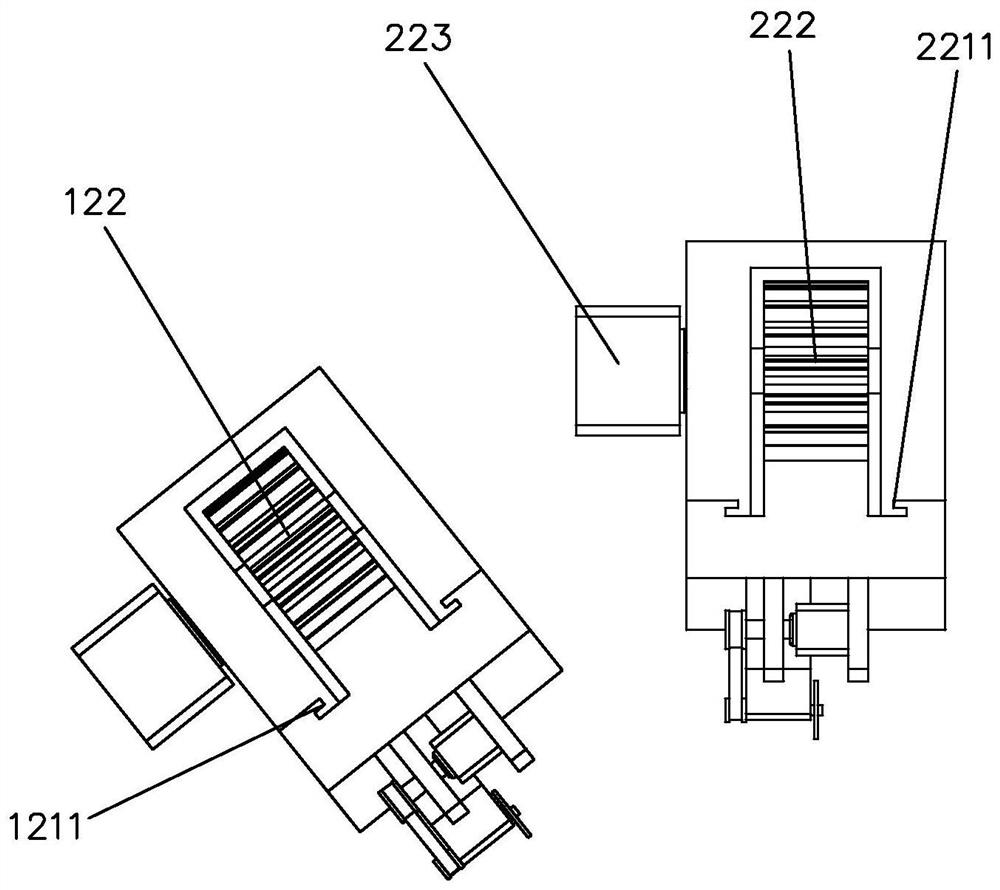

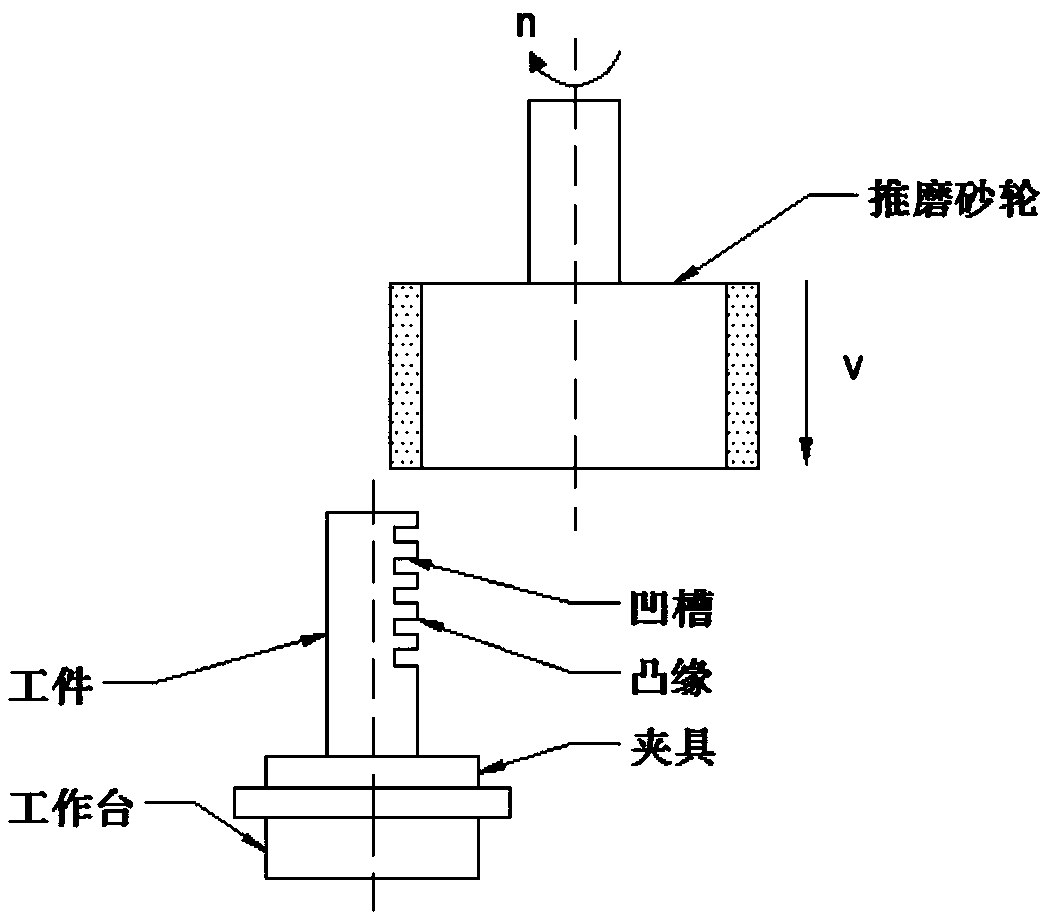

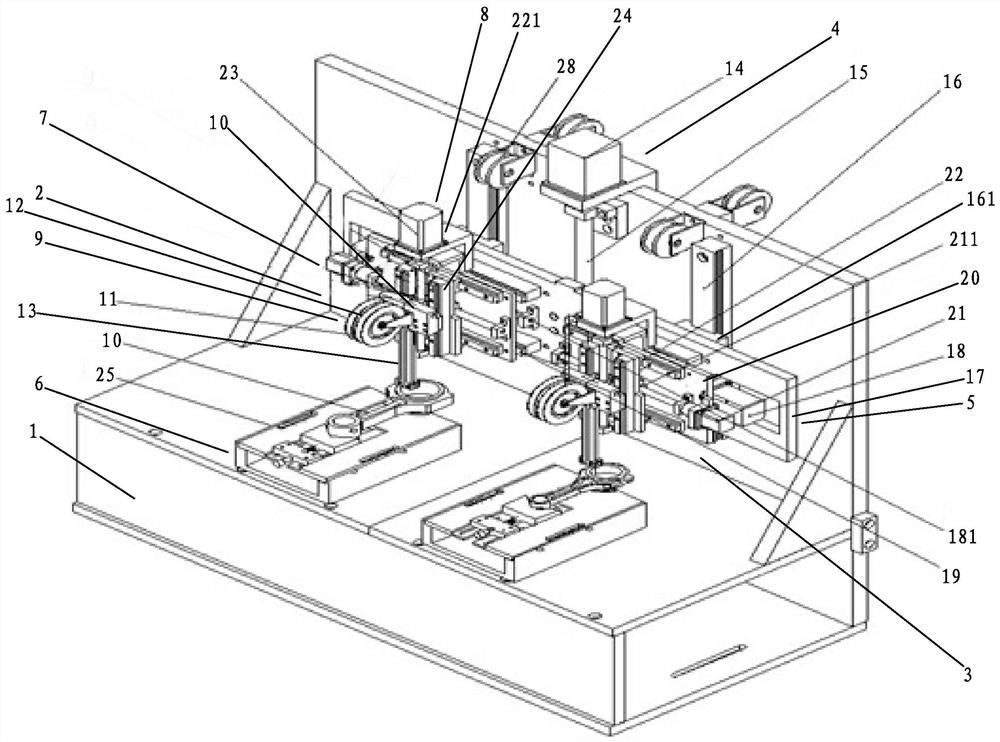

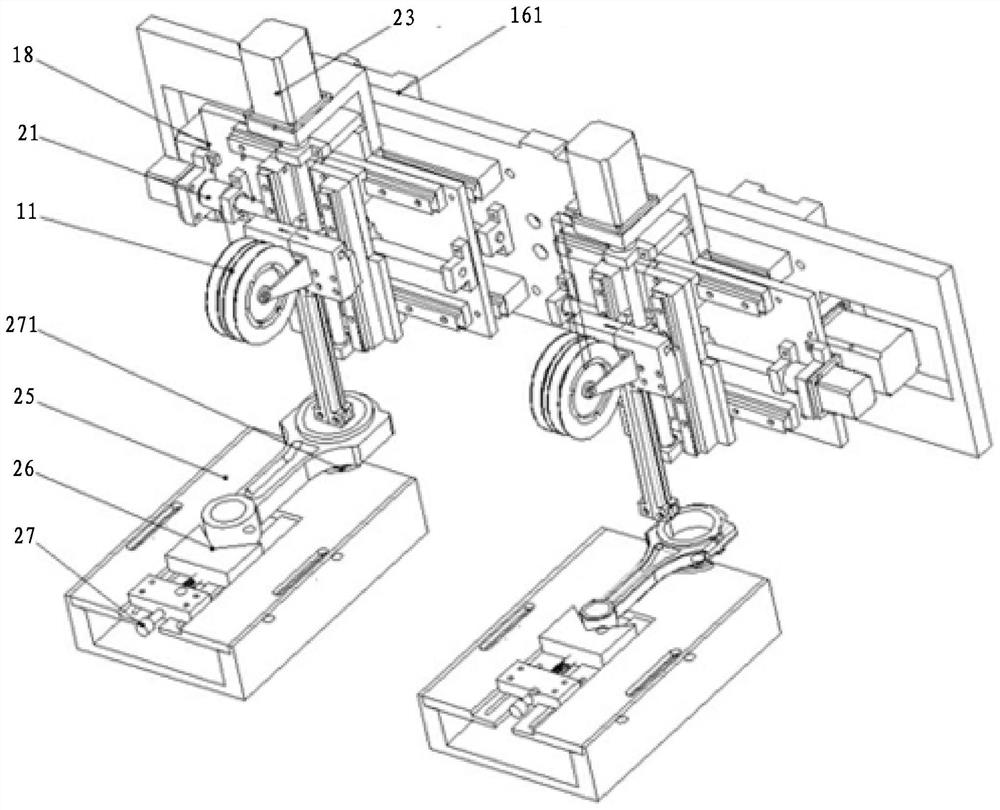

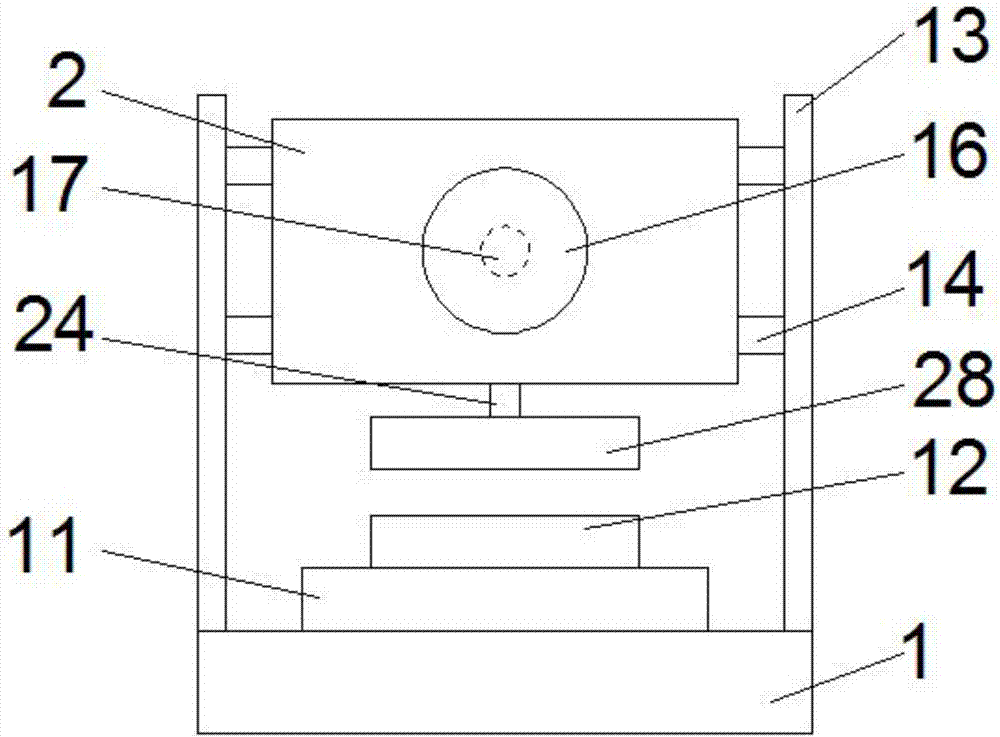

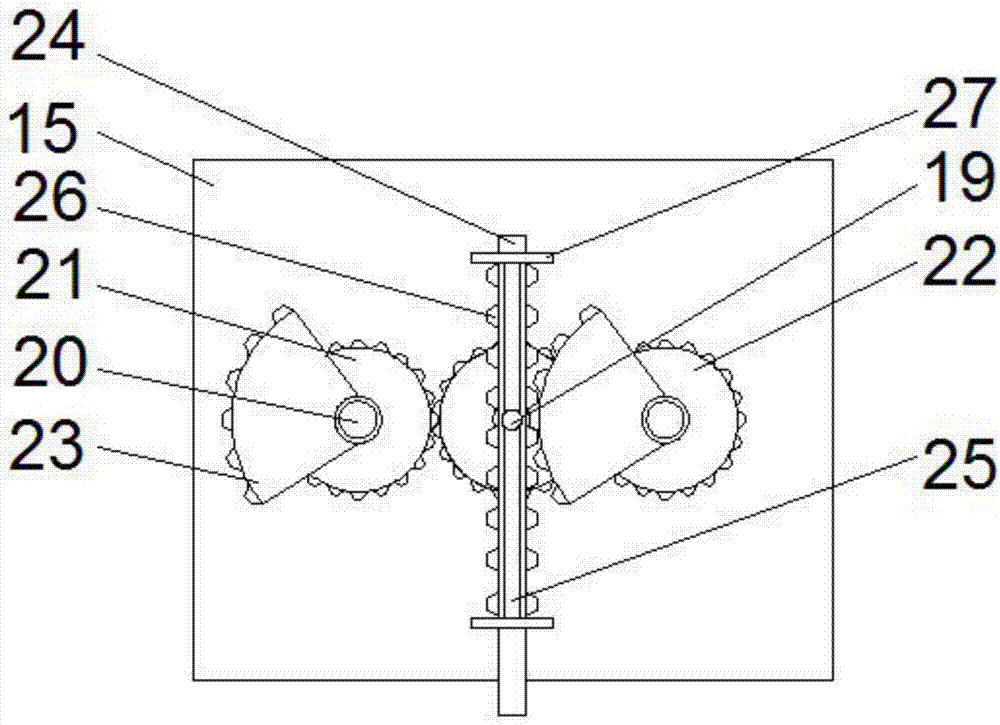

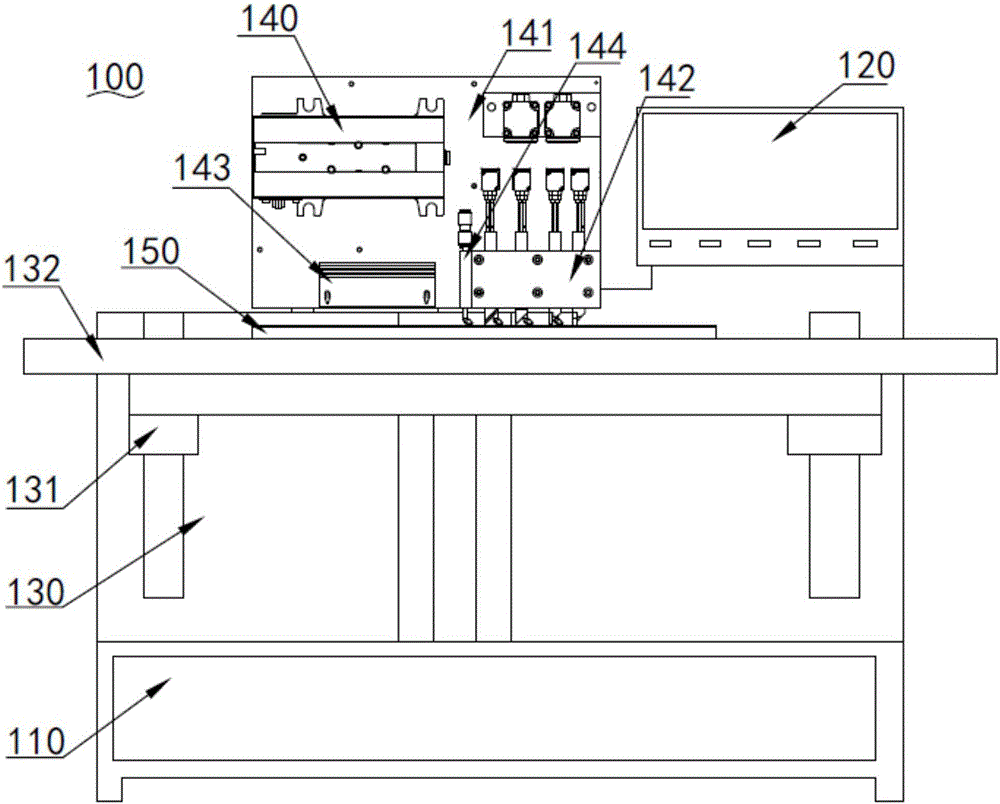

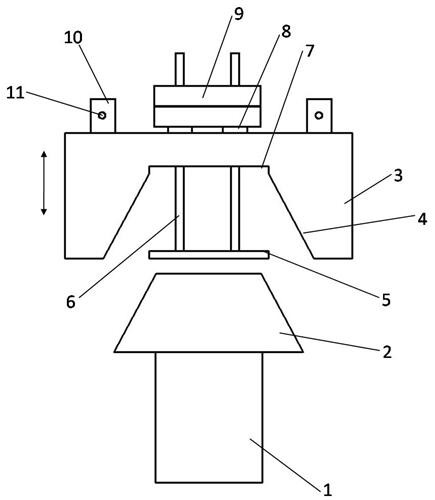

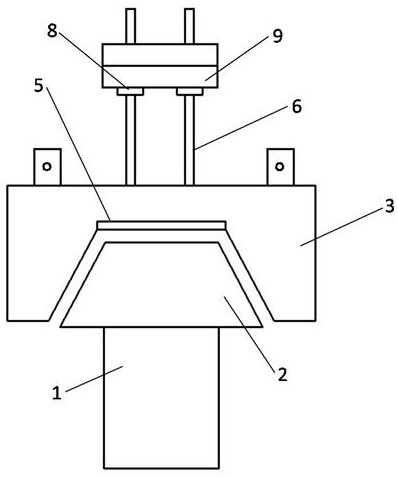

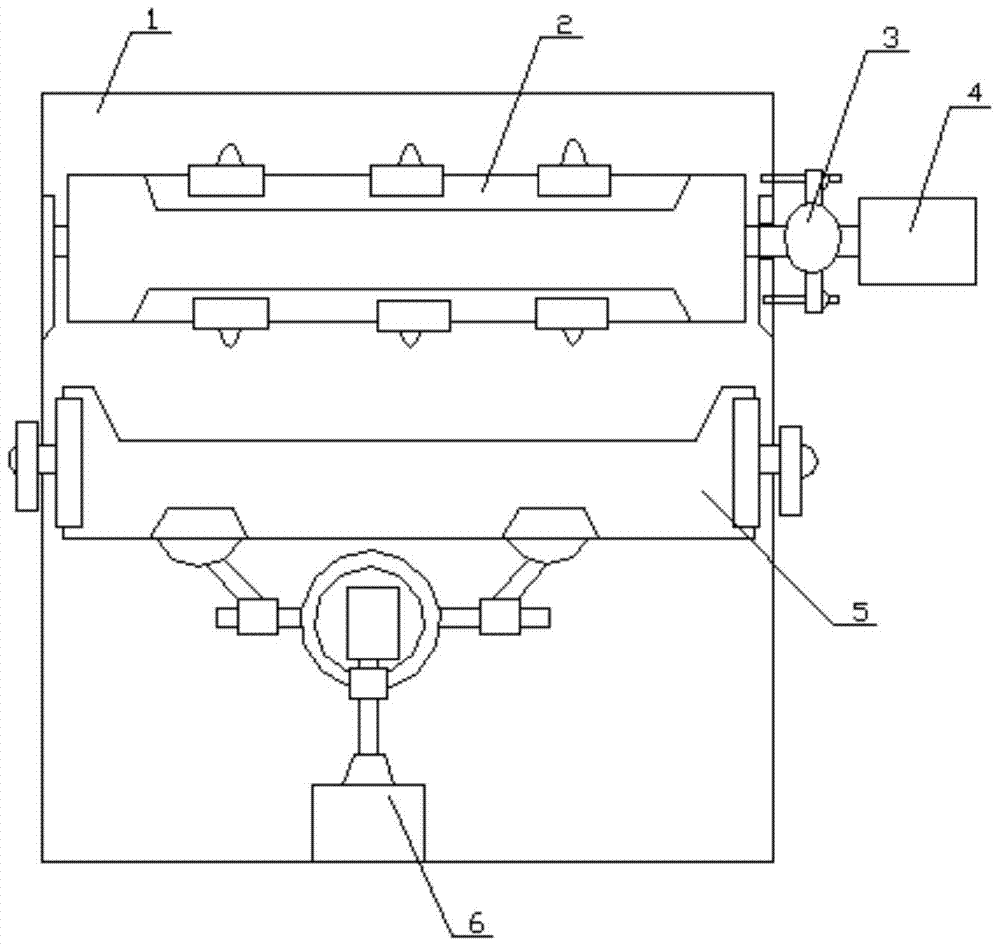

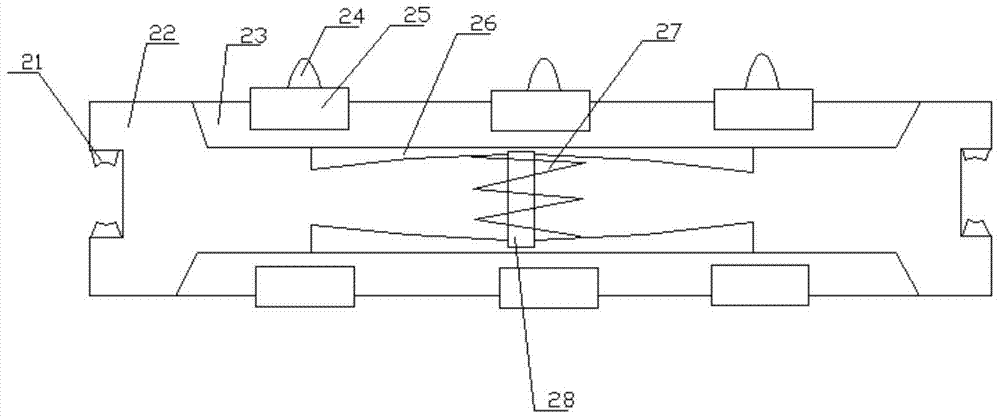

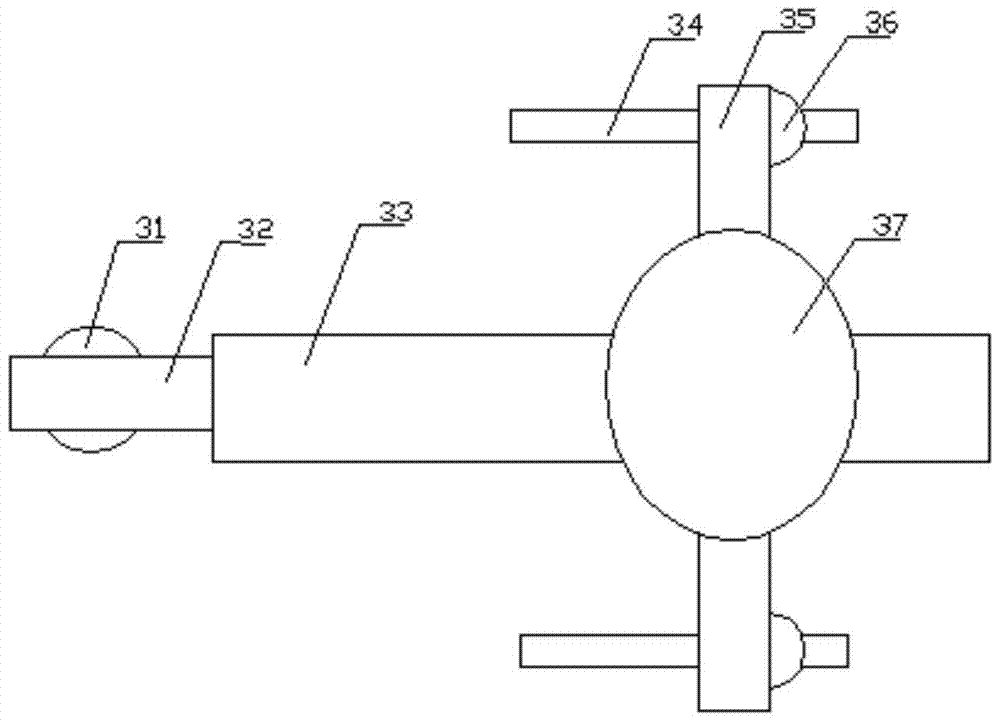

Forming method and device of high-precision circular knitting machine work drum

ActiveCN111660066AIncrease productivityHigh precisionEdge grinding machinesWeft knittingMechanical engineeringPhysics

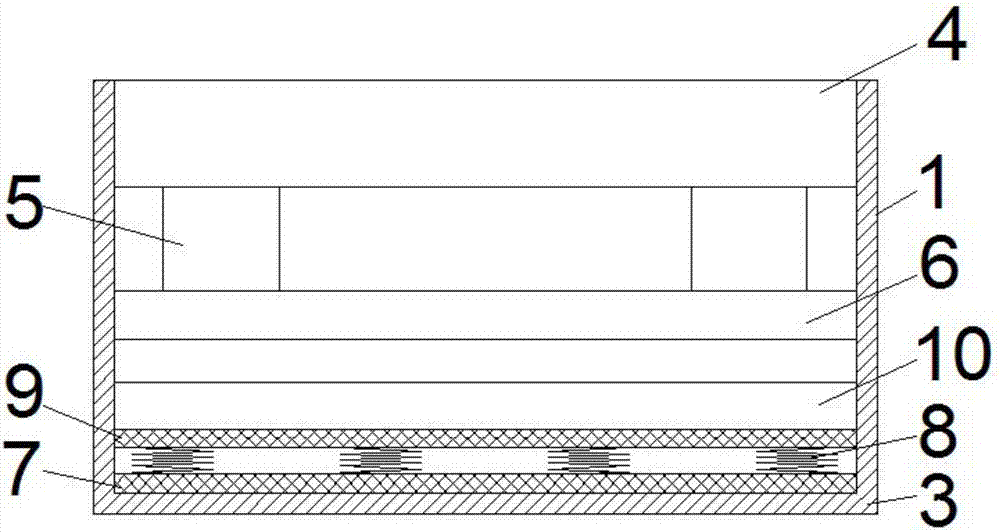

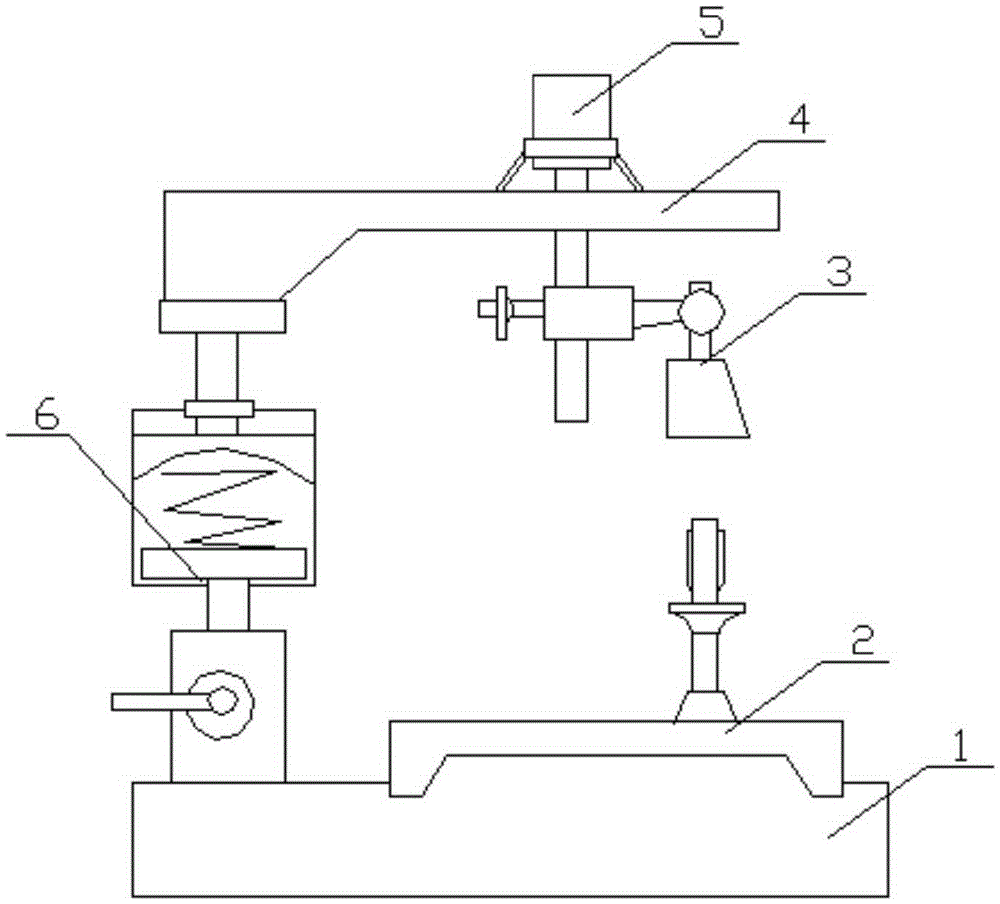

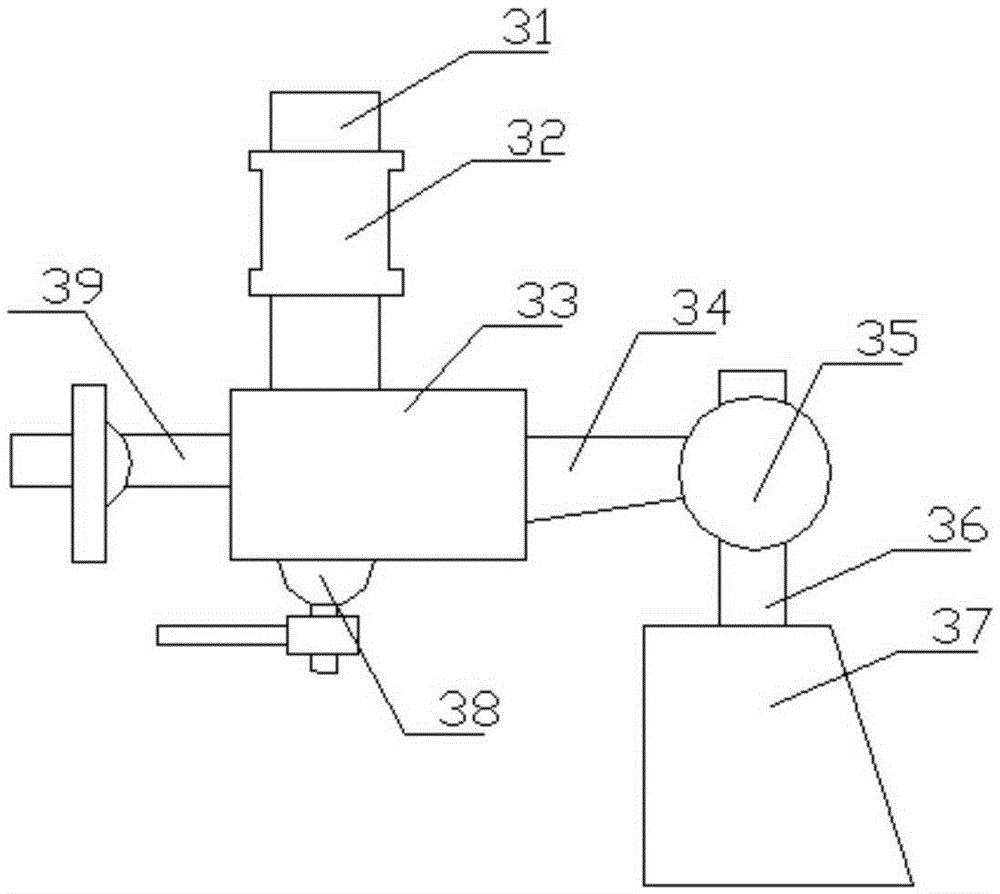

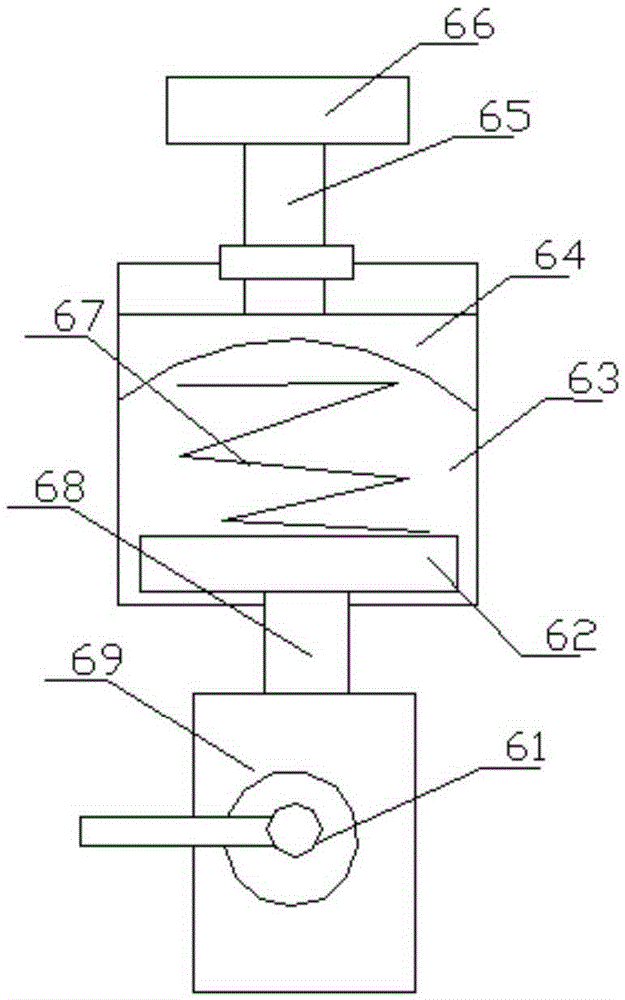

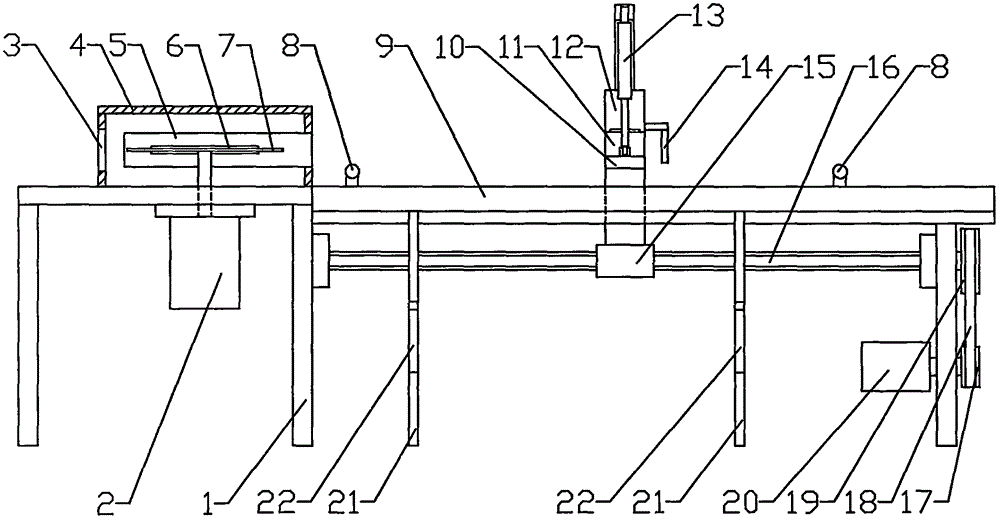

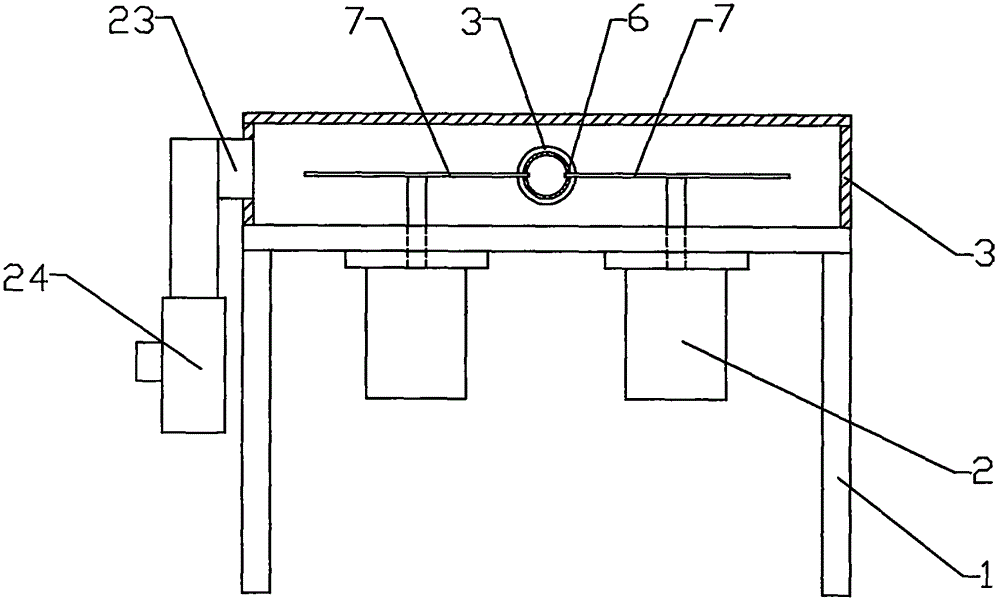

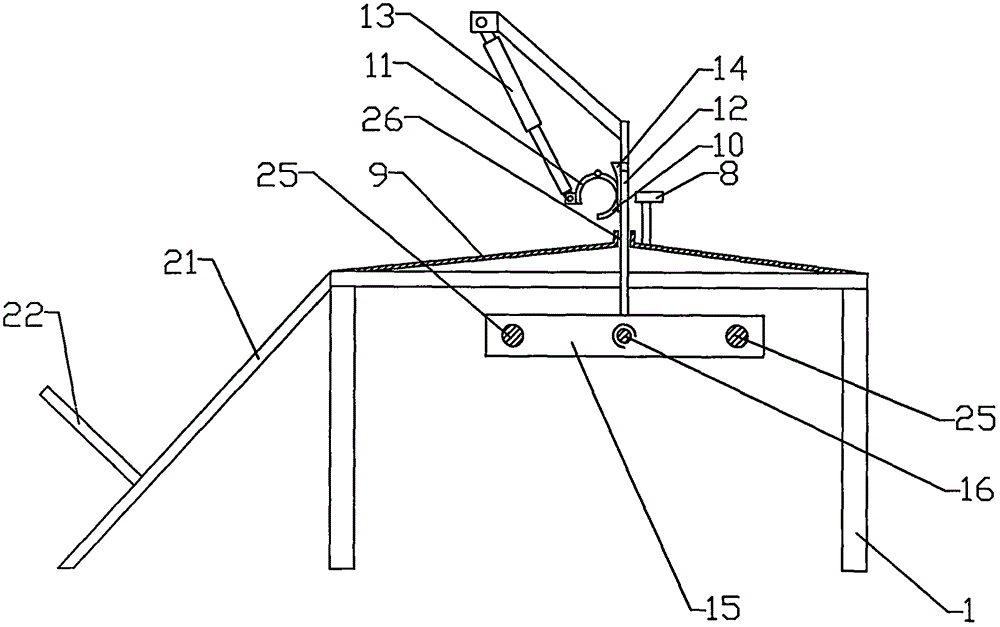

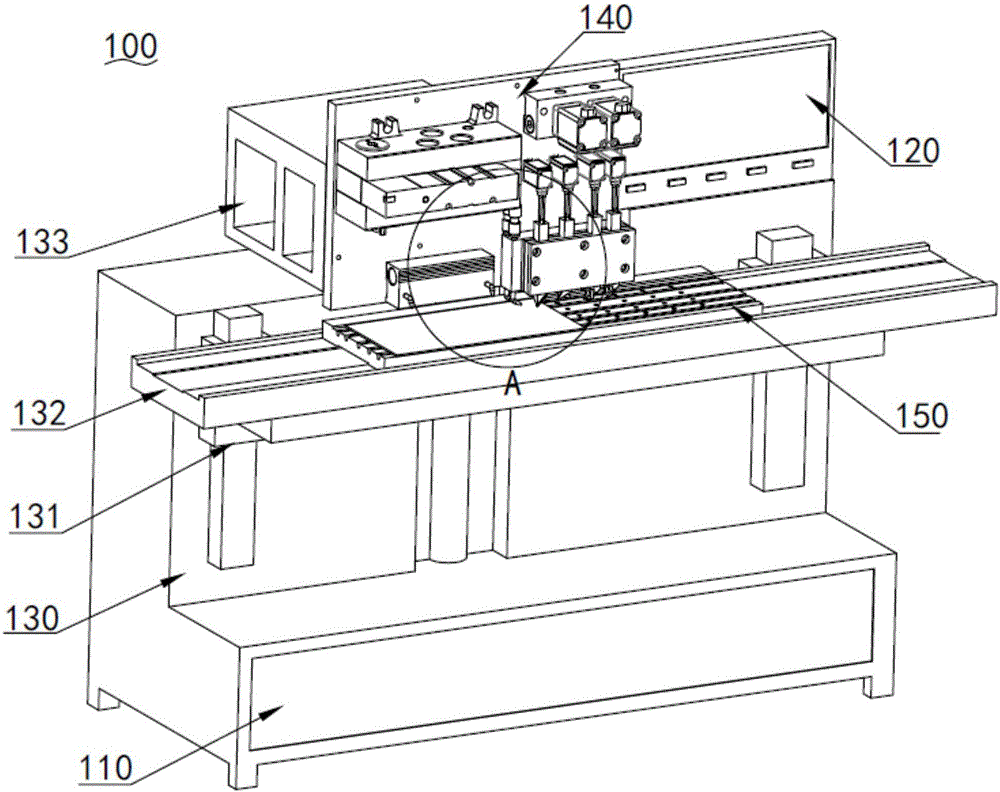

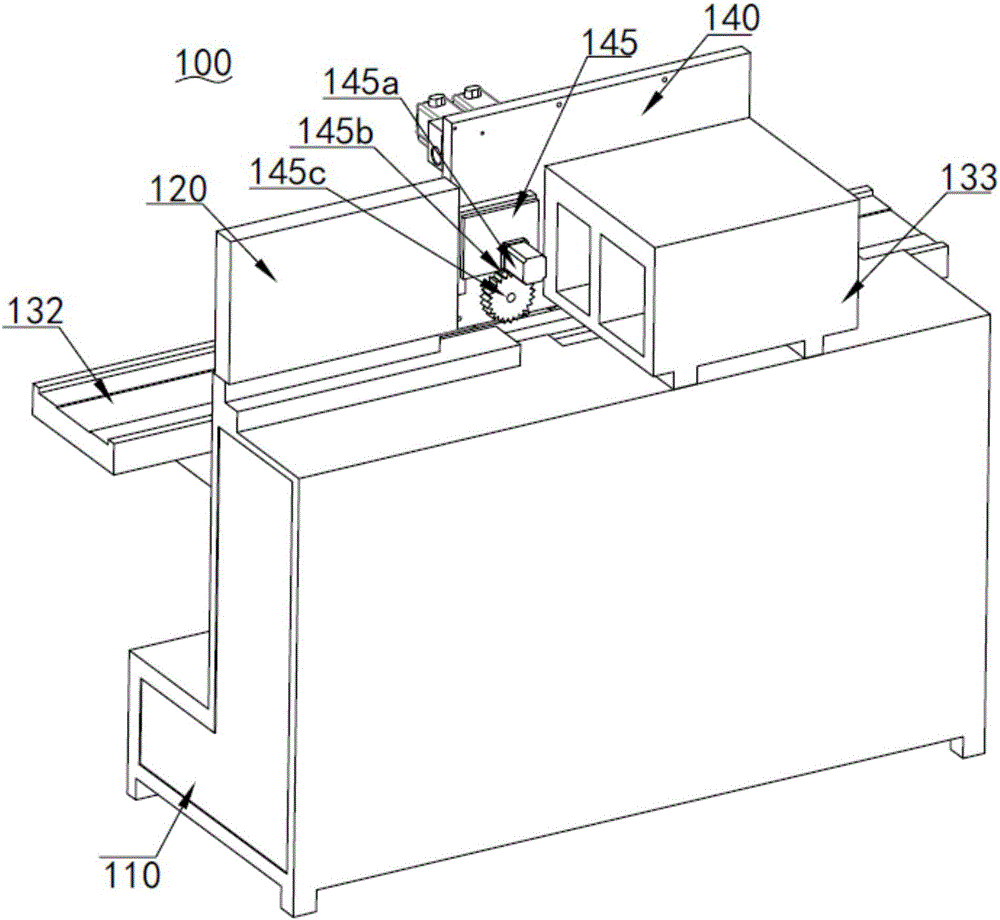

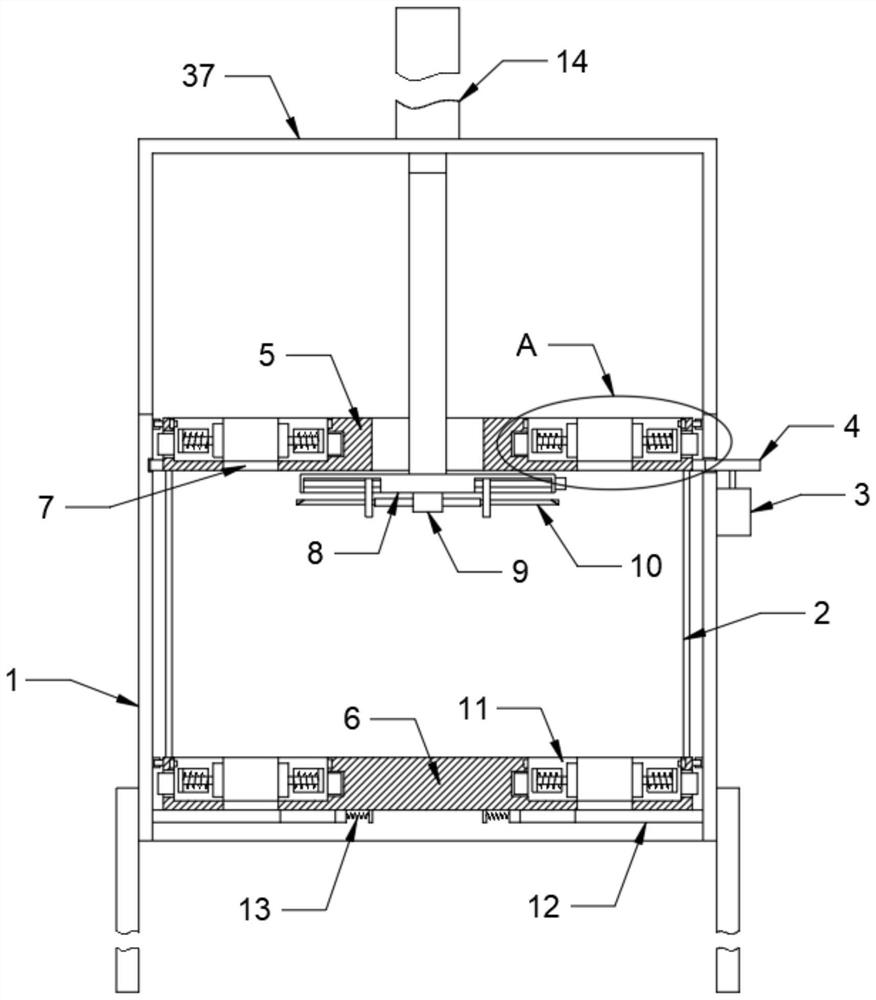

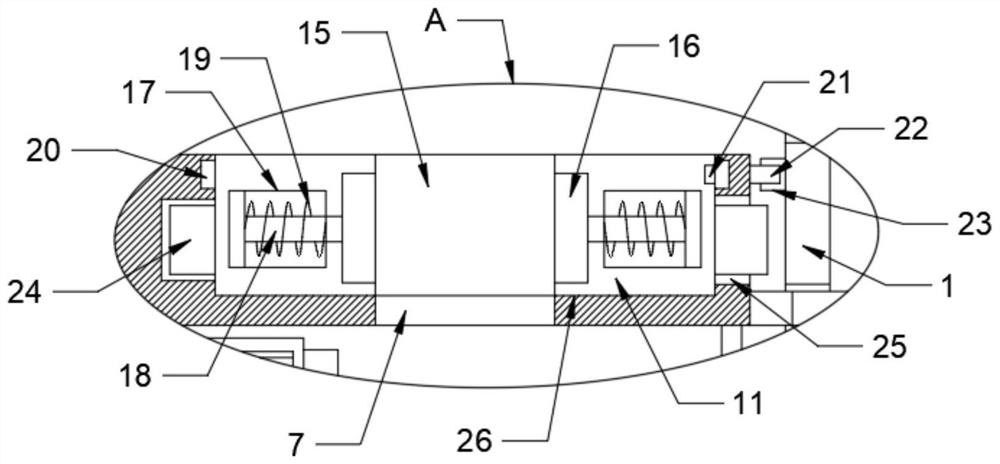

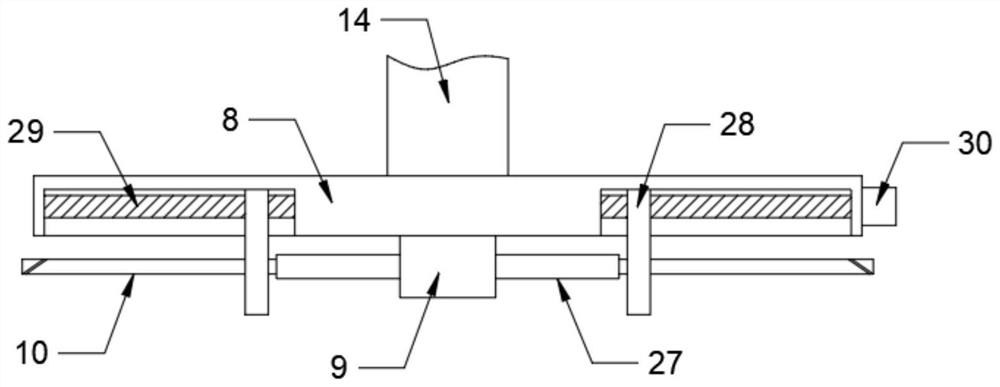

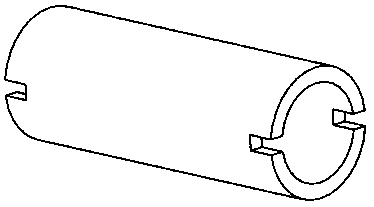

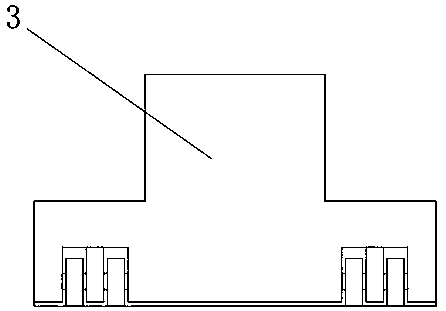

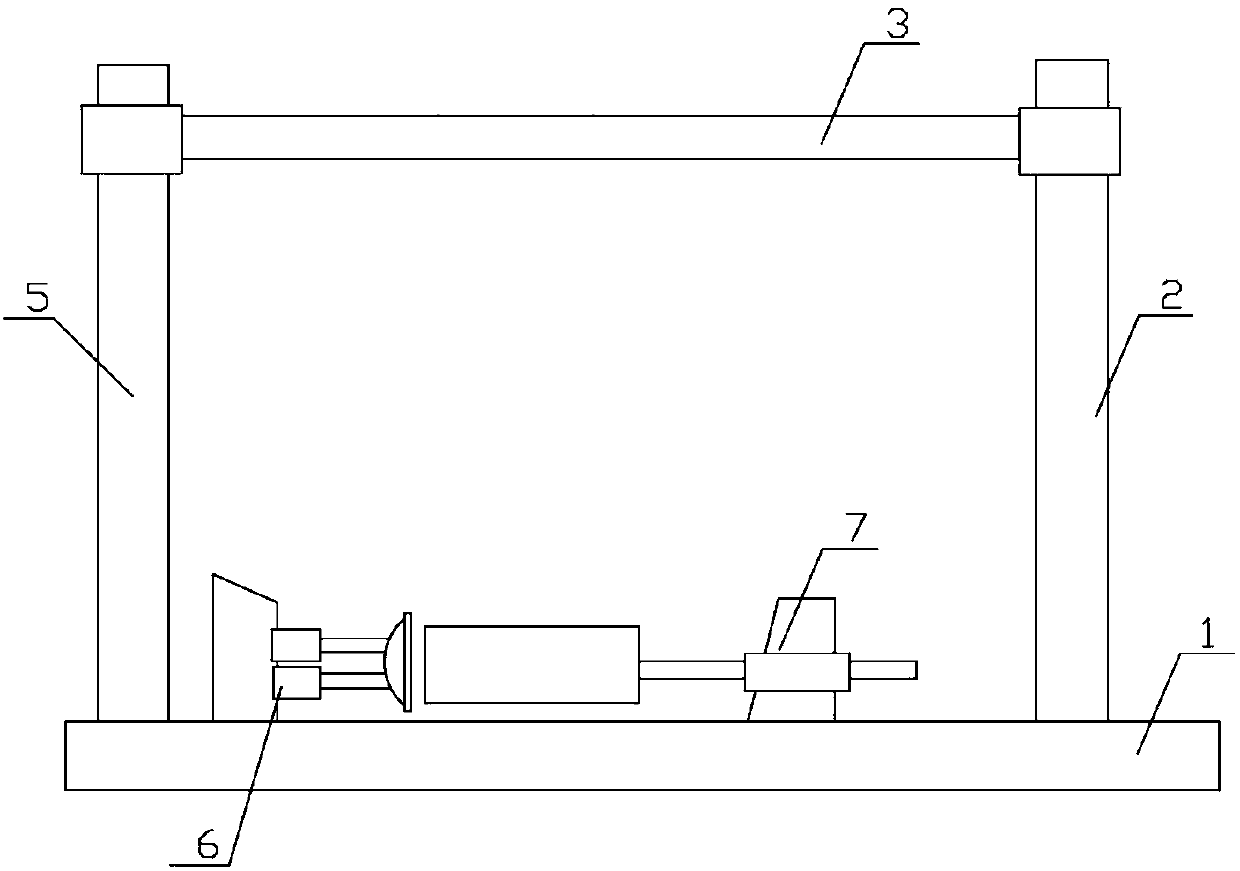

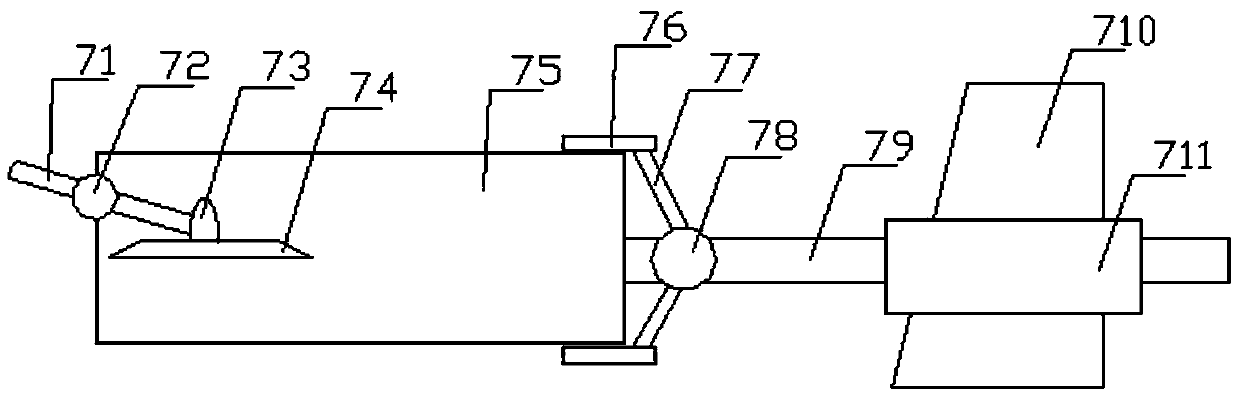

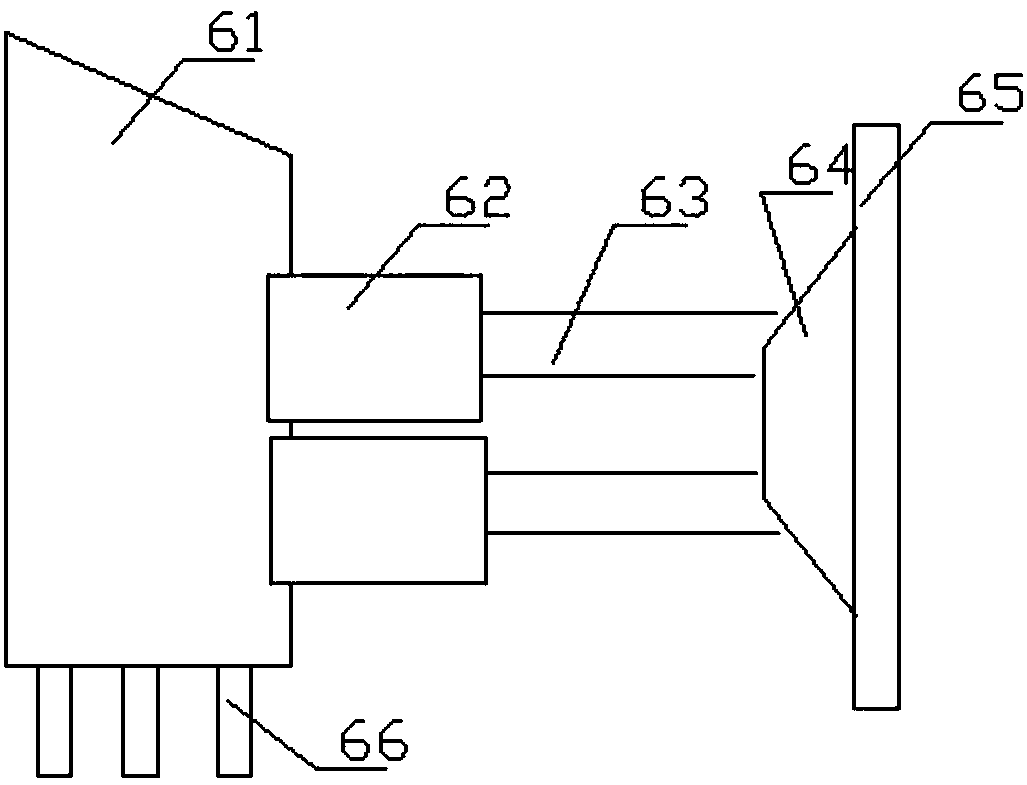

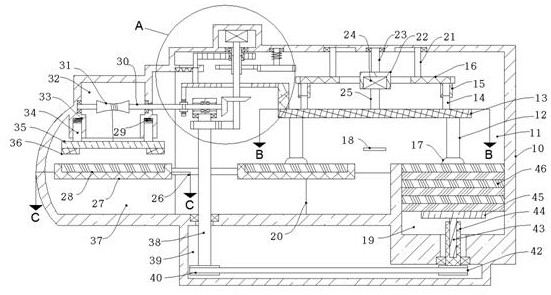

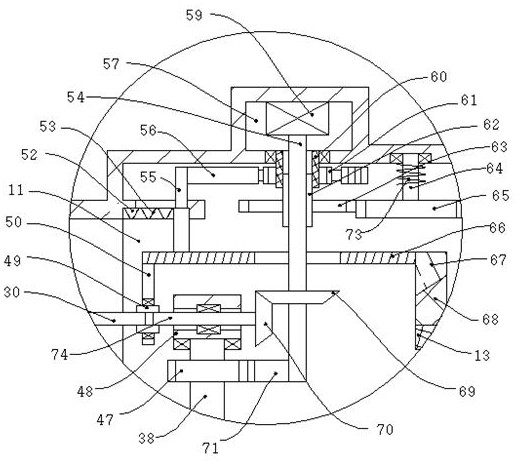

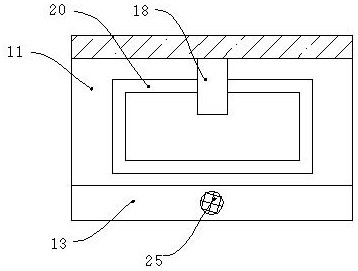

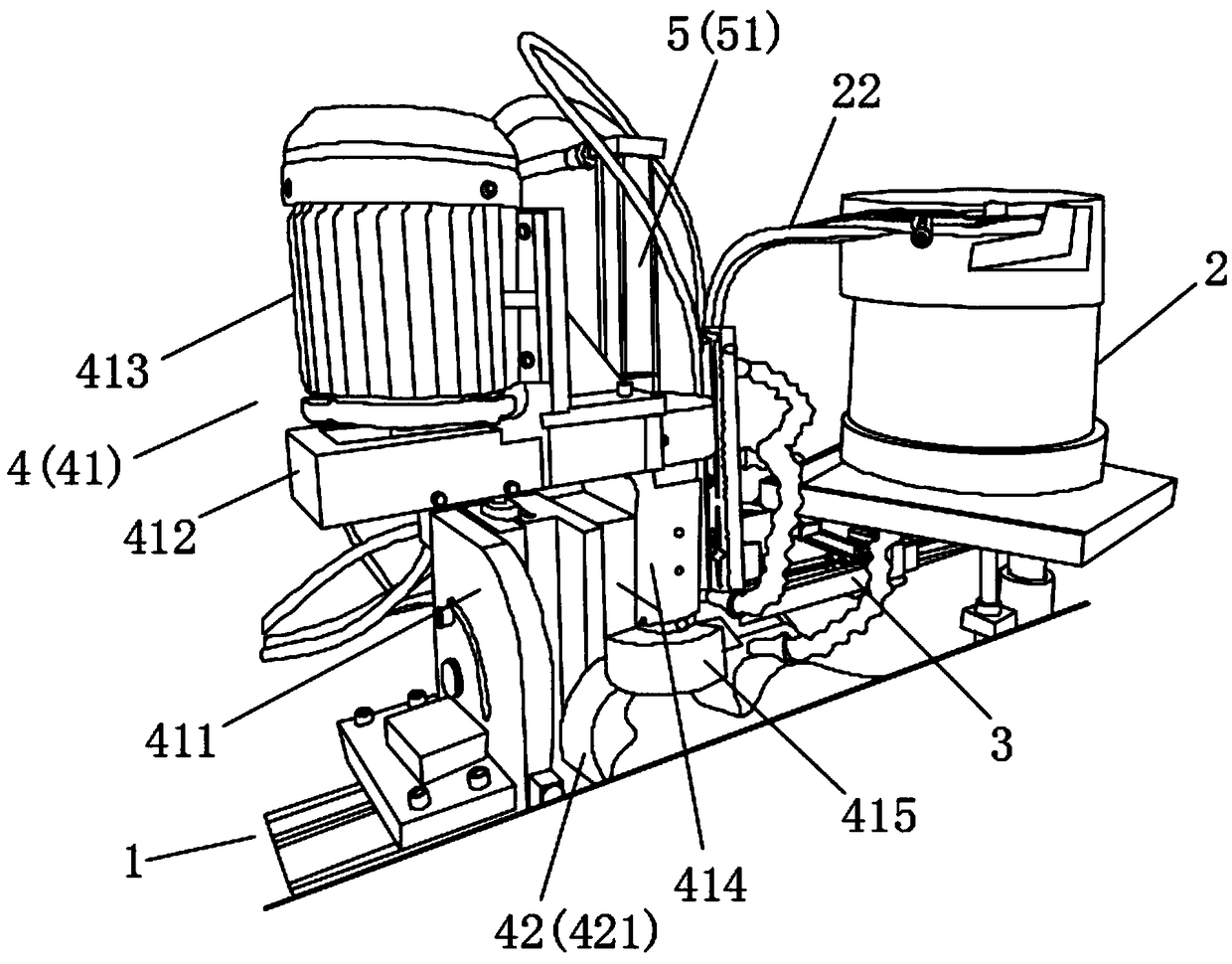

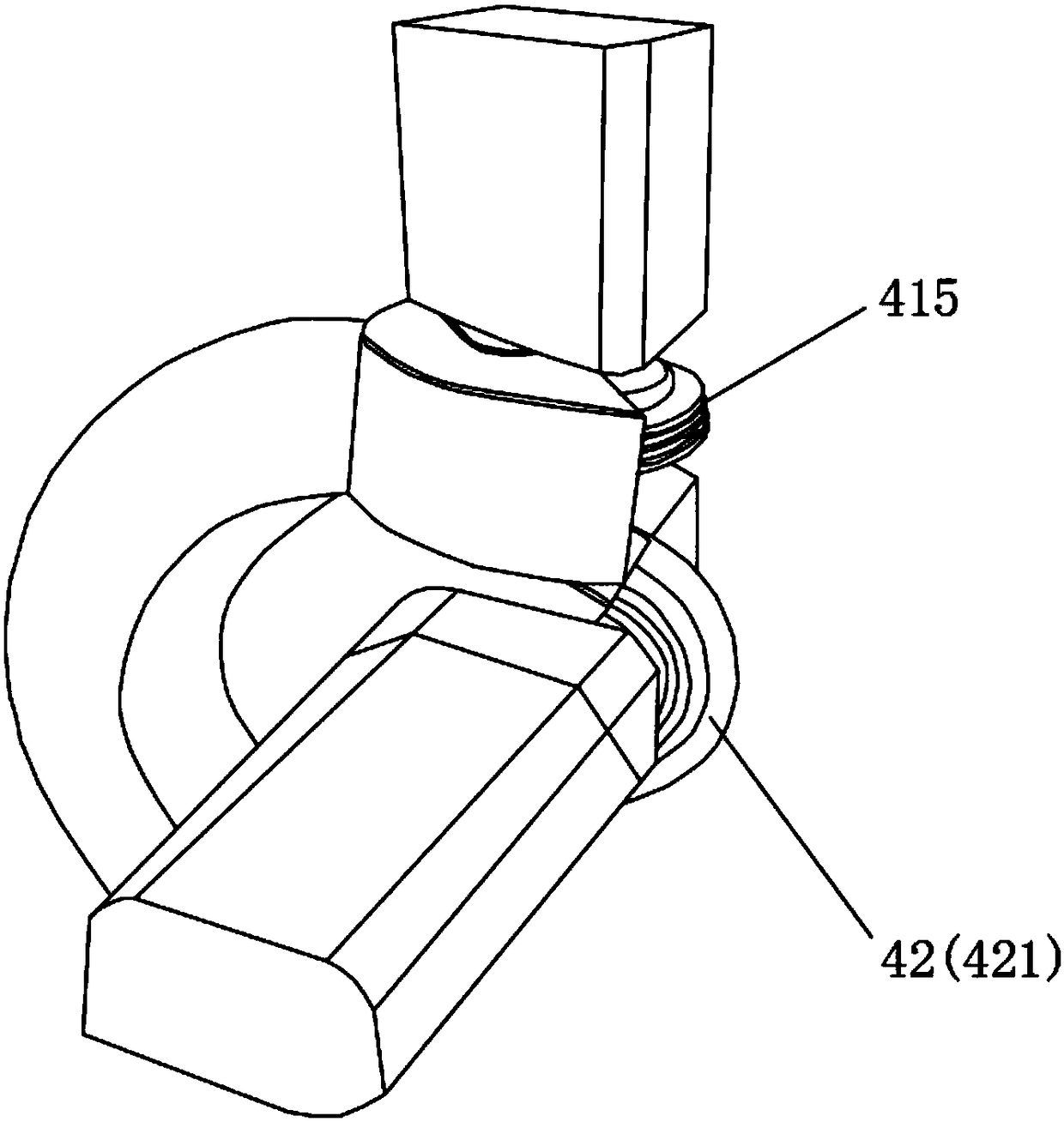

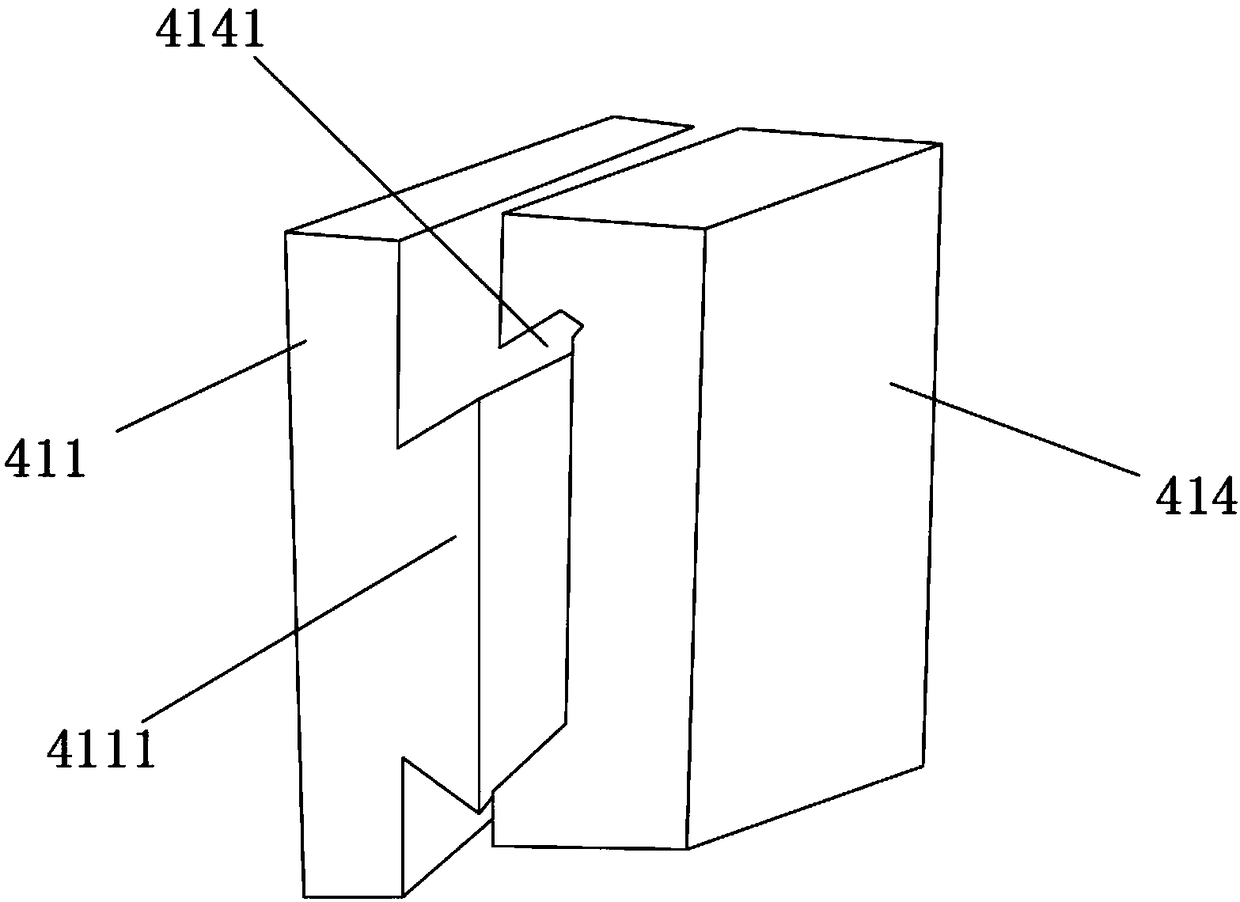

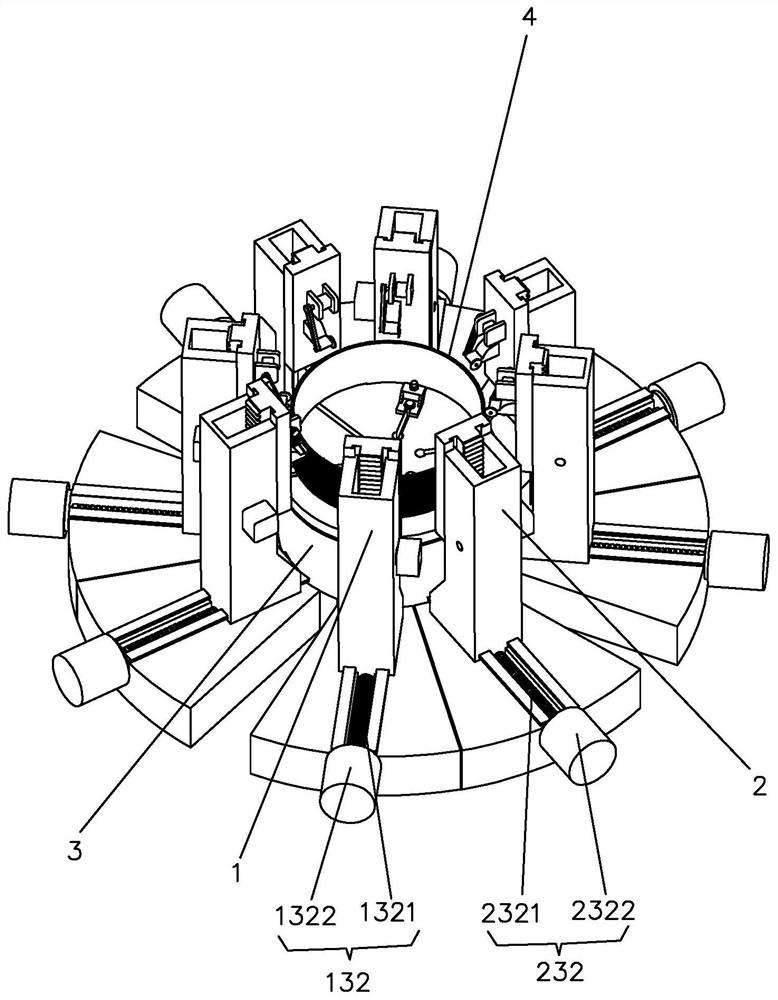

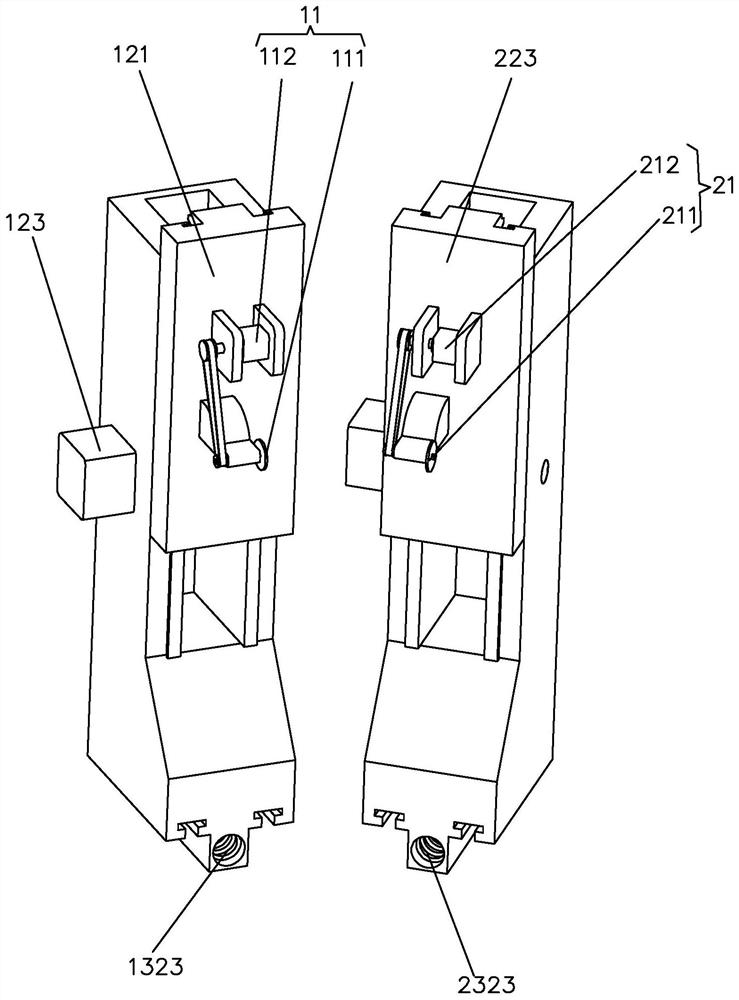

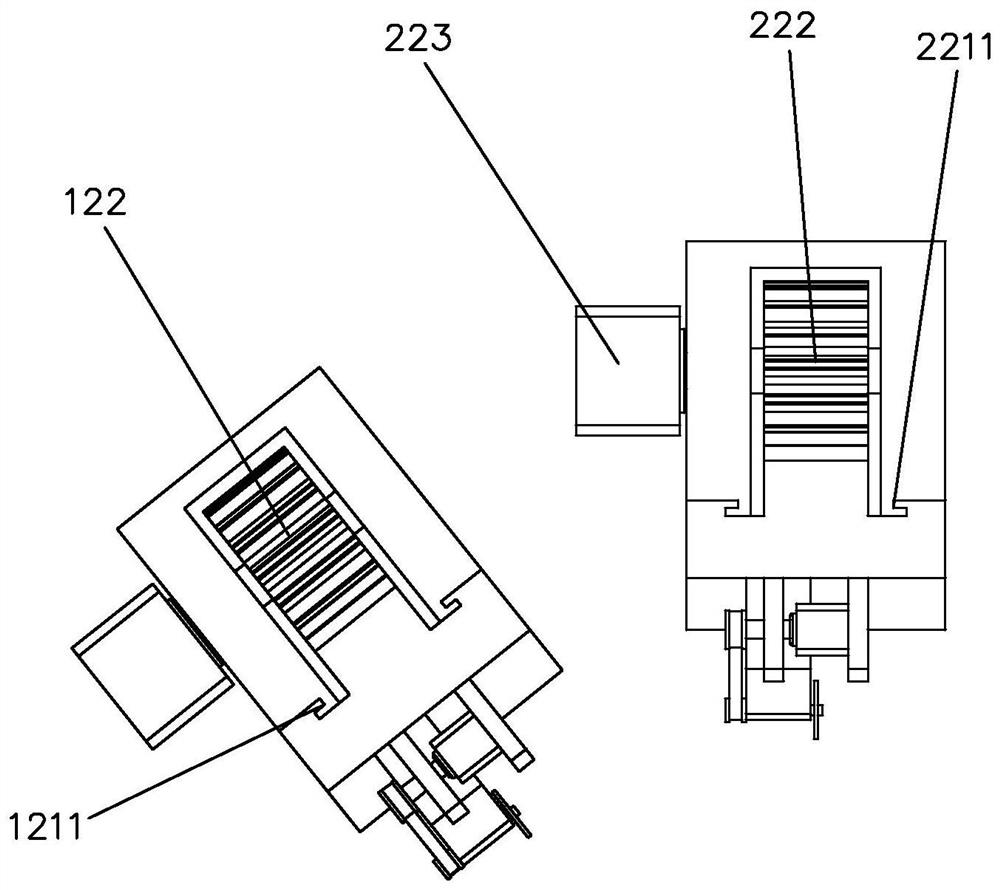

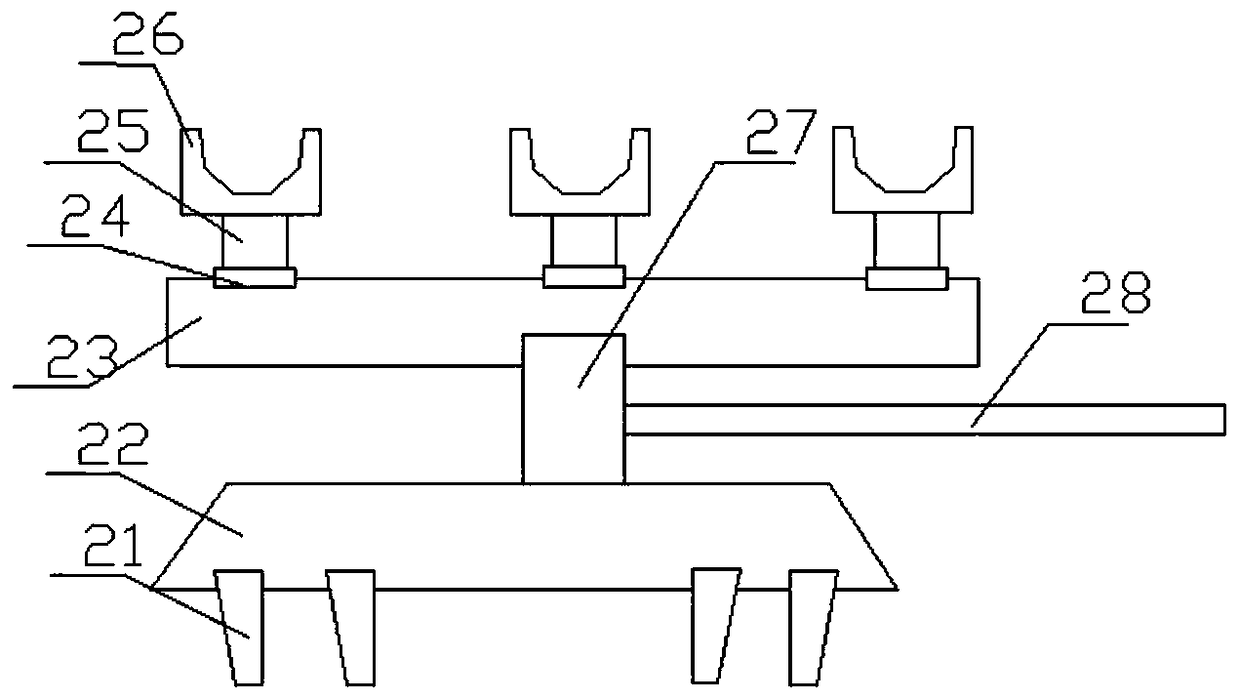

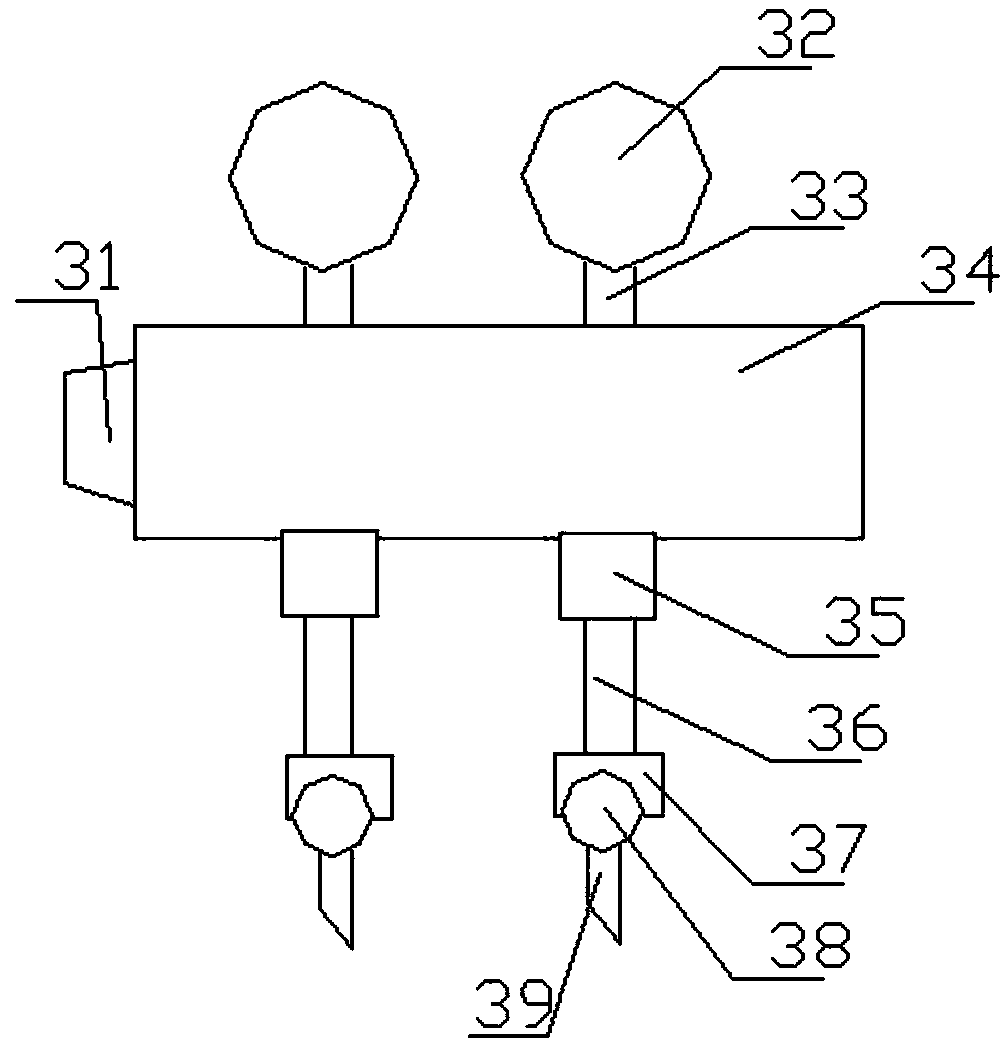

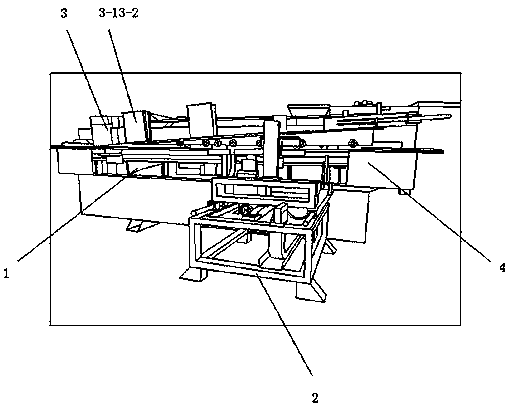

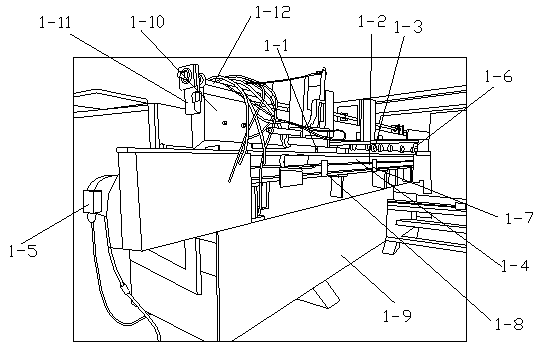

The invention discloses a forming method of a high-precision circular knitting machine work drum. The forming method of the high-precision circular knitting machine work drum comprises the following steps that (1) rough turning is carried out on a blank work drum; (2) fine turning is carried out on the blank work drum after rough turning to form a needle-groove-free work drum; (3) groove milling is carried out on the outer surface of the needle-groove-free work drum; (4) a needle groove formed in step (3) is polished to remove burrs; and (5) the needle groove of the work drum is inspected to determine whether the work drum is qualified or not. The invention further discloses a forming device of the high-precision circular knitting machine work drum to operate the step (3) and the step (4);first, a plurality of grooving devices arranged, around a bearing base, in a grooving forming device simultaneously perform grooving on the work drum, a polishing device immediately follows the grooving devices for fine polishing, the polishing device performs fine polishing on the needle groove when the grooving is carried out, and the problems of low production efficiency, insufficient precision and high scrap rate of existing work drums are solved.

Owner:福建省永宏针纺机械有限公司

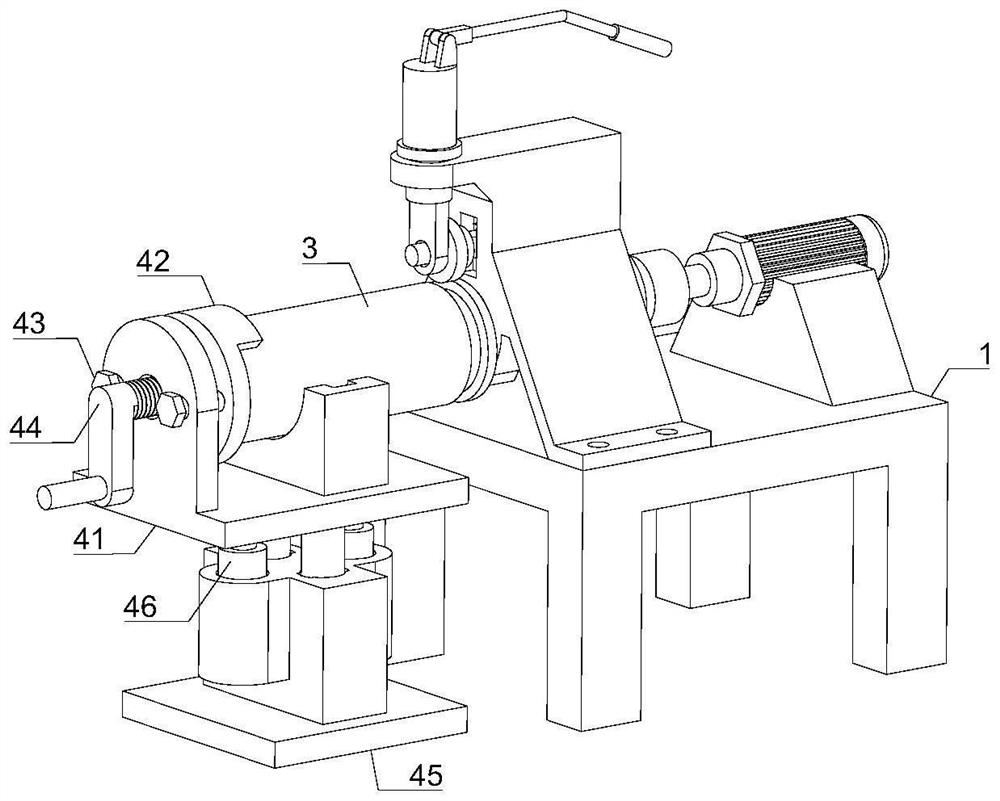

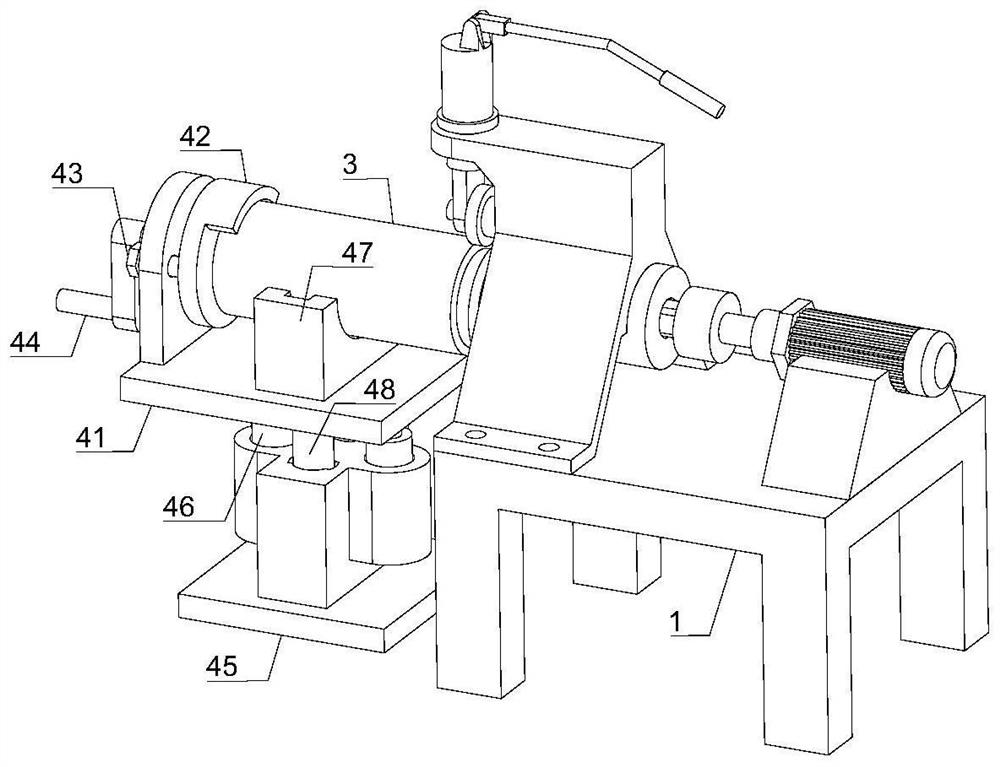

Workpiece fixing device for cutting machine

InactiveCN107671368AEasy to operateEasy to adjustPositioning apparatusMetal-working holdersDetentScrew thread

The invention relates to the technical field of metal processing, in particular to a workpiece fixing device for a cutting machine; the workpiece fixing device for a cutting machine of the present invention includes a base, and the auxiliary fixing frame includes a snap-fit fixing seat, a snap-fit The clamping column at the lower end of the clamping and fixing seat, the extrusion guide cylinder clamped on the side wall of the clamping and fixing seat, and the extrusion guide cylinder are arranged in the extrusion along the axial direction of the extrusion guide cylinder. The extruding rod in the guide cylinder, the integrated frame screwed to the end of the extruded rod through threads, and the extruded plate clamped on the side wall of the integrated frame.

Owner:嘉兴创诺精密五金有限公司

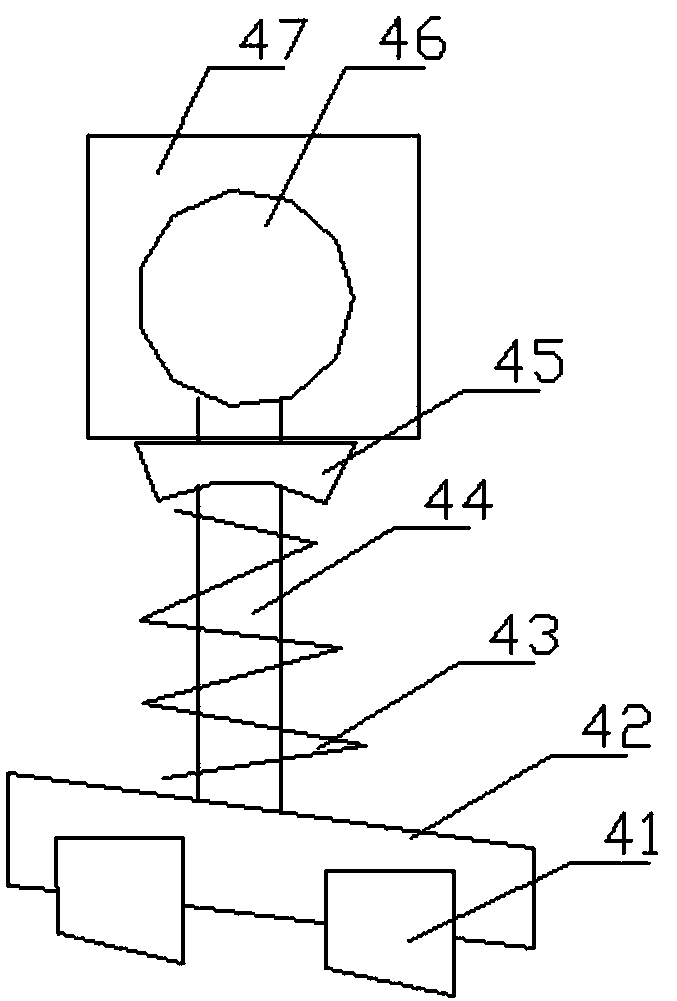

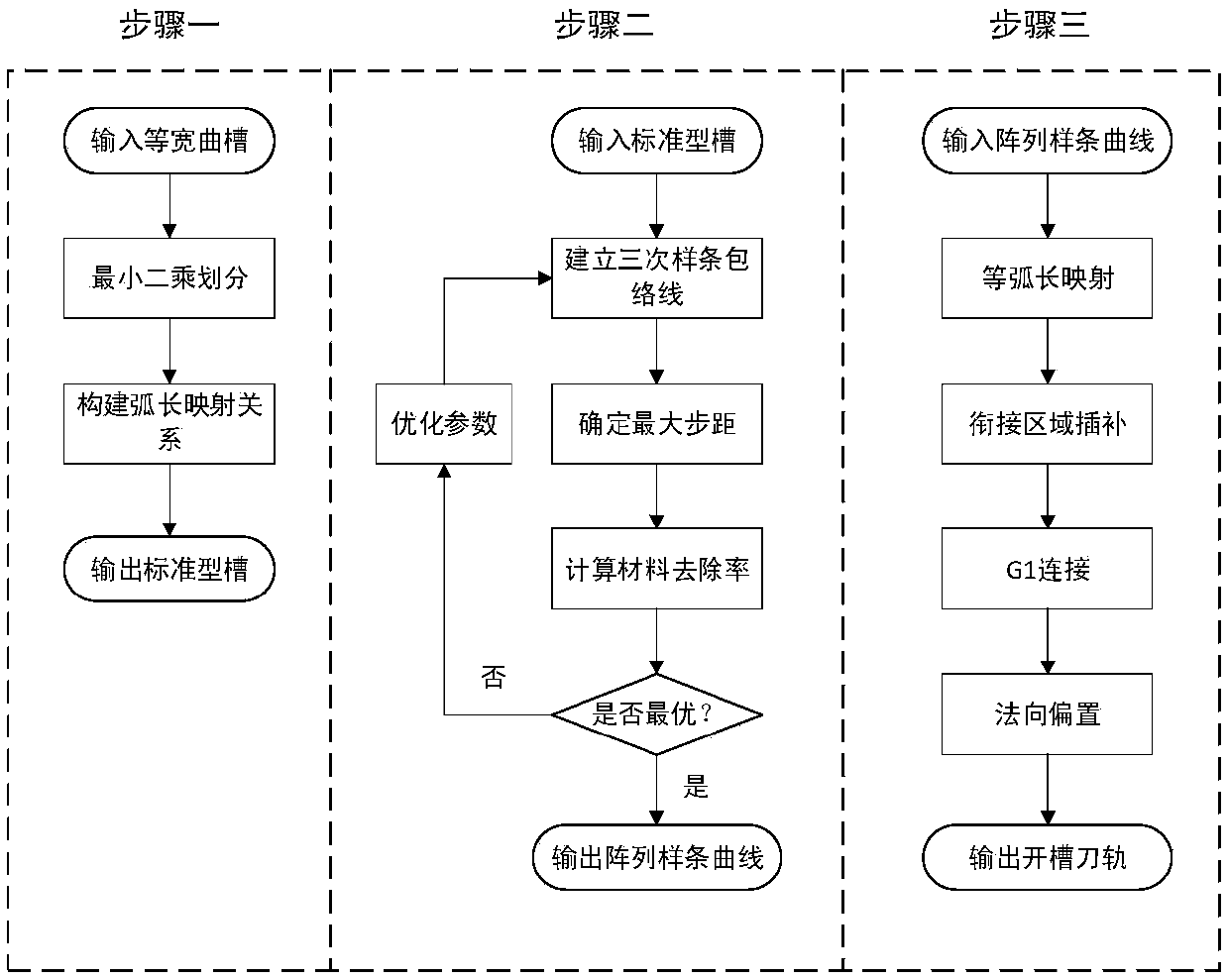

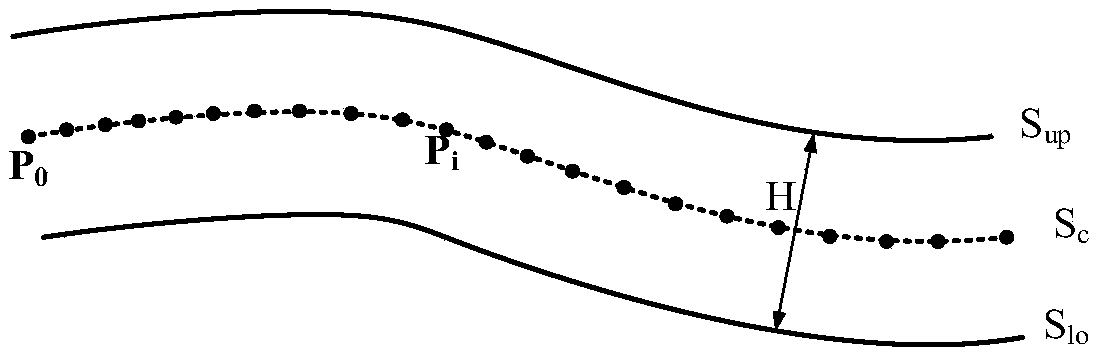

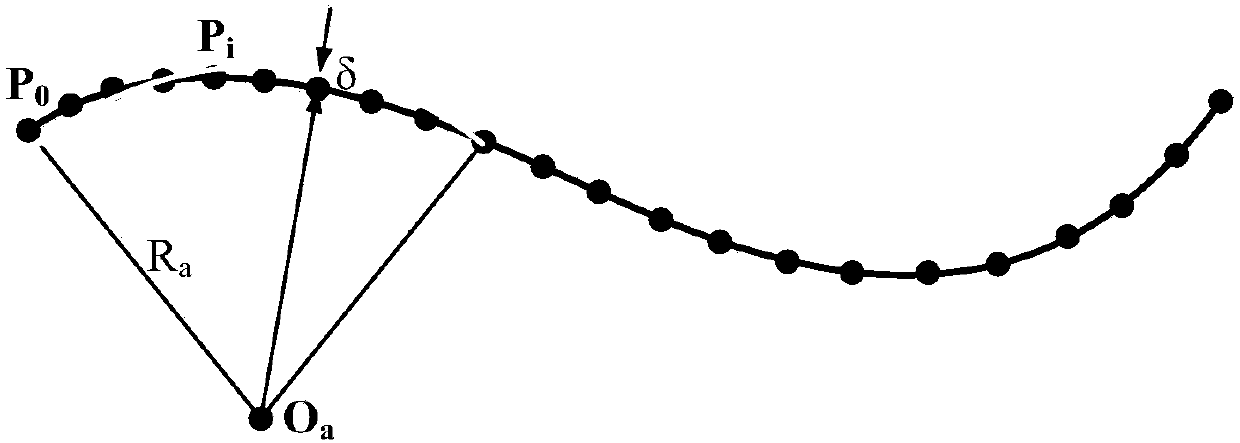

High-efficiency method for generating similar-cycloid milling and slotting tool path

ActiveCN108549326AHigh and stable valueReduce shock loadProgramme controlComputer controlMaterial removalEngineering

The invention relates to a high-efficiency method for generating a similar-cycloid milling and slotting tool path. The method comprises: an equal-width curved slot is divided into a plurality of equal-curvature ring slot and straight slot standard types approximately by using arc least square fitting and an arc length mapping relationship is established; for the equal-curvature ring slot and straight slot standard types, a material boundary line formed by a tool motion envelope is represented by using a cubic spline curve, a maximum step pitch is determined according to a tool contact angle constraint, the cubic spline curve is optimized by using a material removal rate as an objective, and an equal-interval array is generated at a standard type slot; and the obtained material boundary curve array is mapped back to the equal-width curved slot, paired end-to-end connection is carried out form a G1 continuous curve, and normal biasing is carried out on the curve to form a slotting tool path. On the premise that the maximum contact angle meets the condition, the similar-cycloid tool path enables the slotting processing efficiency to be improved obviously.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Abrasive water jet grooving-diamond wheel grinding composite ceramic machining method

InactiveCN109465711AAbrasives are inexpensiveReduce processing costsGrinding machinesPropagation effectAbrasive water jet

The invention provides an abrasive water jet grooving-diamond wheel grinding composite ceramic machining method. The method comprises the following steps that S1, grooving machining is carried out ona flat-plate ceramic workpiece by adopting an abrasive water jet machine tool according to machining requirements to form a parallel flange; and S2, the parallel flanges formed in the step S1 is ground by adopting a diamond grinding wheel until the machining needs are met, wherein abrasive water jet cutting machining mainly consumes water and abrasive particles, no tool is worn in the machining process, the used abrasive is low in cost, and the machining cost can be greatly reduced. In conclusion, the crack propagation effect is utilized so that high-removal rate machining of hard brittle materials such as ceramics can be realized on the premise of higher feeding speed and no tool abrasion.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

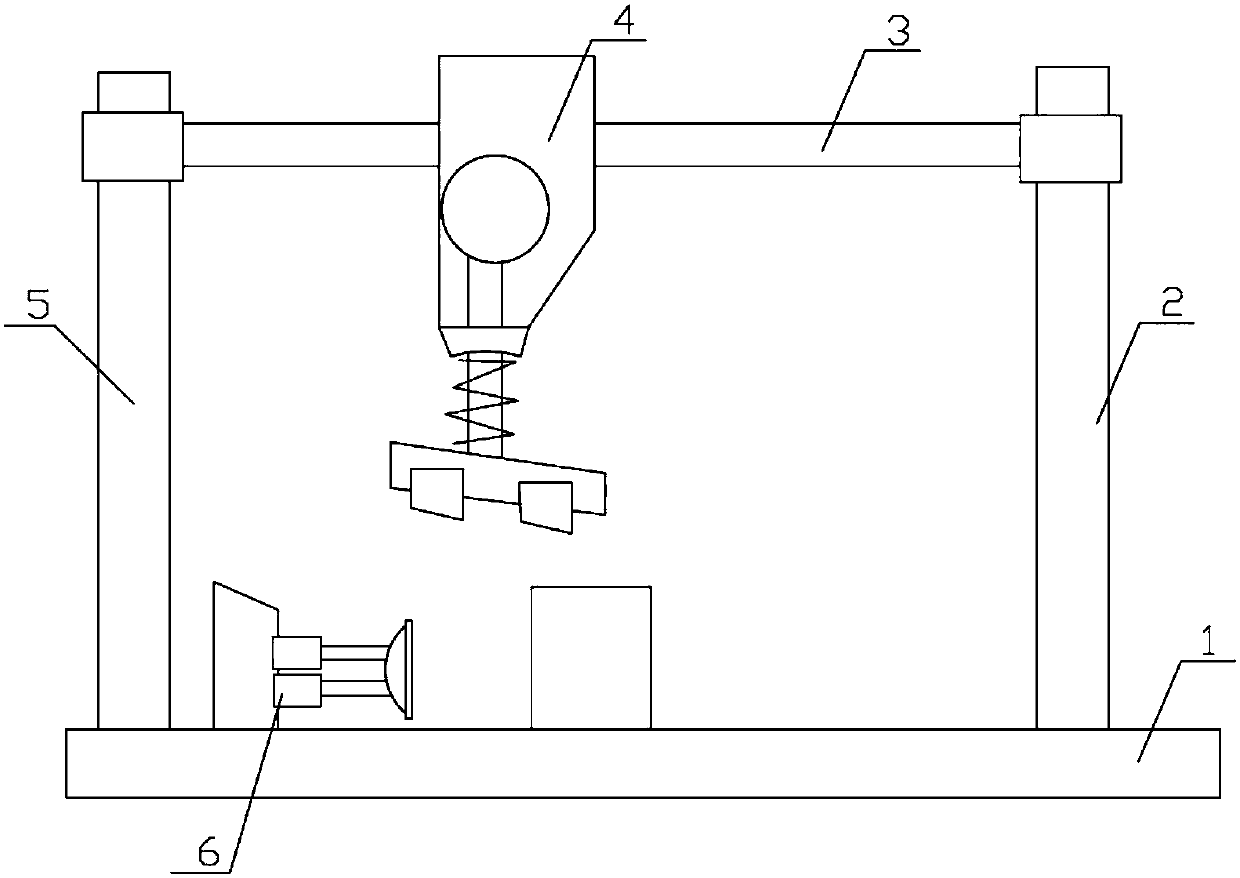

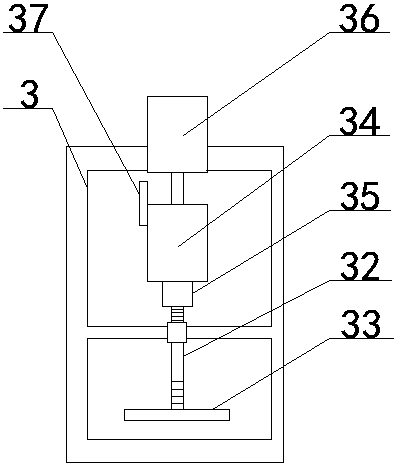

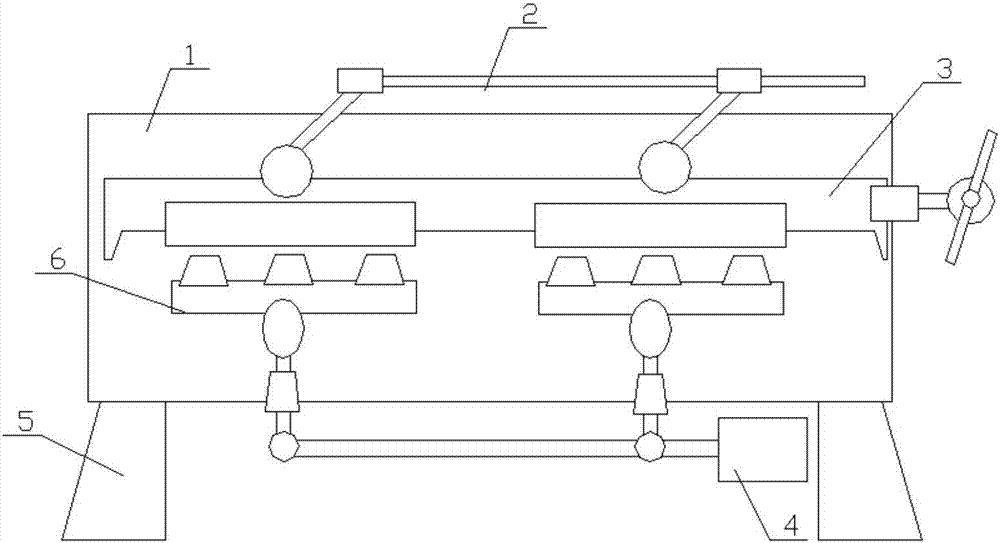

Double-station sheet cutting connecting rod fracture splitting groove device

ActiveCN111992823AAvoid windingImprove processing efficiencyPlastic recyclingElectrical-based machining electrodesReciprocating motionClassical mechanics

The invention discloses a double-station sheet cutting connecting rod fracture splitting groove device which comprises a platform, a left station machining device, a right station machining device, asecondary vertical driving device, a secondary horizontal driving device and a controller. The left station machining device and the right station machining device each comprises a clamp, a main horizontal driving device, a main vertical reciprocating driving device and a machining electrode assembly. Each machining electrode assembly comprises a connecting frame fixedly installed on the main vertical reciprocating driving device, a reel rotatably installed on the connecting frame, a sheet wound on the reel and clamping feet used for clamping the sheet, vertical through holes are formed in theclamping feet, and the sheets are sleeved with the vertical through holes and stretch out of the lower ends of the vertical through holes. The sheets are clamped and tensioned by the clamping feet todo continuous reciprocating motion in the vertical direction, meanwhile, the continuous reciprocating motion in the vertical direction and grooving machining in the horizontal direction form composite machining, continuous reciprocating in the vertical direction is auxiliary motion of grooving machining, and discharging and chip removal are facilitated.

Owner:GUANGDONG UNIV OF TECH

Metal plate notching equipment

InactiveCN107243533ASimple structureStable structureNon-rotating vibration suppressionWorking environmentEngineering

The invention discloses metal plate notching equipment which comprises a damping base and a notching tank located above the damping base. The damping base comprises a first base body and a second base body located in the first base body. The first base body is internally provided with a cavity structure. The first base body is of an open structure. Stand columns are symmetrically arranged on the two sides of the bottom of the second base body. The ends, away from the second base body, of the stand columns are fixedly connected with a first permanent magnet. The metal plate notching equipment has the beneficial effects that the notching equipment is simple in structure and easy to operate, so that the internal structure of the notching equipment is stable, and the notching precision and the notching efficiency are improved; and meanwhile, during working of the notching equipment, mutual vibration between the bottom of the equipment and the ground is reduced to the maximum extent, vibration and noise during working of the notching equipment are greatly weakened or eliminated, components in the equipment are protected, the service life of the equipment is prolonged, the working environment of operators is guaranteed, and the physical and mental health of the operators is protected.

Owner:李天明

Leather grooving machine

The invention relates to the technical field of mechanical equipment, and particularly relates to a leather grooving machine. The leather grooving machine comprises a base, a fixed frame, a lifting piece, a bearing beam, a grooving component and a motor, wherein the fixed frame, the lifting piece, the bearing beam, the grooving component and the motor are arranged on one side of the upper end of the base; the grooving component comprises an integrated seat, a driving shaft, a guide cylinder, a turning piece, a locking piece, a telescopic beam, a first screwing ball, a cutter bar and a cutter; a first positioning ring groove is formed in the side wall of the guide cylinder in a concave mode, and a first guide hole is axially formed through the guide cylinder; a first regulating hole is formed through the integrated seat; a clamping fixed groove is formed in the other side of the integrated seat in the concave mode; a first mounting hole is radially formed through the first screwing ball, and a driving installation groove is formed in the upper part of the cutter. The leather grooving machine has the advantages of convenience in operation and regulation, high grooving efficiency and good grooving quality.

Owner:徐州彭耀家具厂

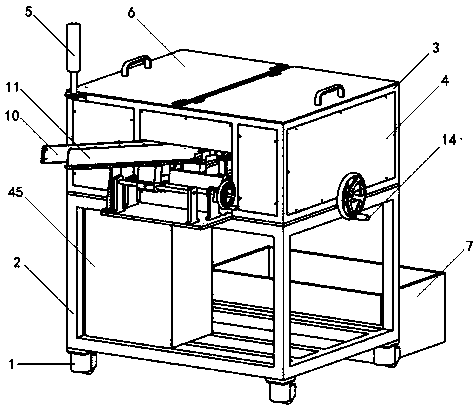

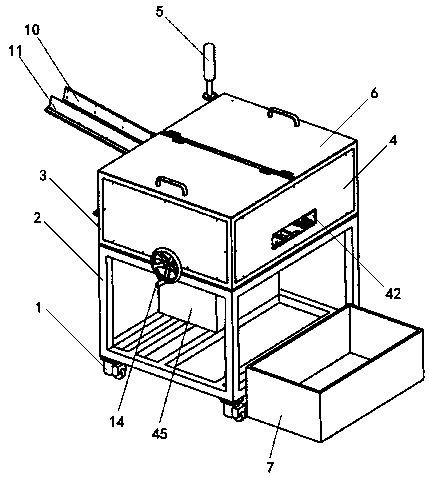

Full-automatic grooving machine

InactiveCN106393237AHigh grooving precisionHigh grooving efficiencyMetal working apparatusHigh volume manufacturingPulp and paper industry

The invention provides a full-automatic grooving machine. The full-automatic grooving machine comprises a rack. A guide barrel is arranged at one end of the rack. Cutters are arranged on the lateral portion of the guide barrel. The guide barrel is provided with through grooves for accommodating the cutters, and the cutters penetrate through the through grooves and are located inside the guide barrel. The full-automatic grooving machine realizes full-automatic cutting of paper tubes, is high in cutting precision, and realizes volume production of paper tubes, and the production efficiency is greatly improved.

Owner:张小良

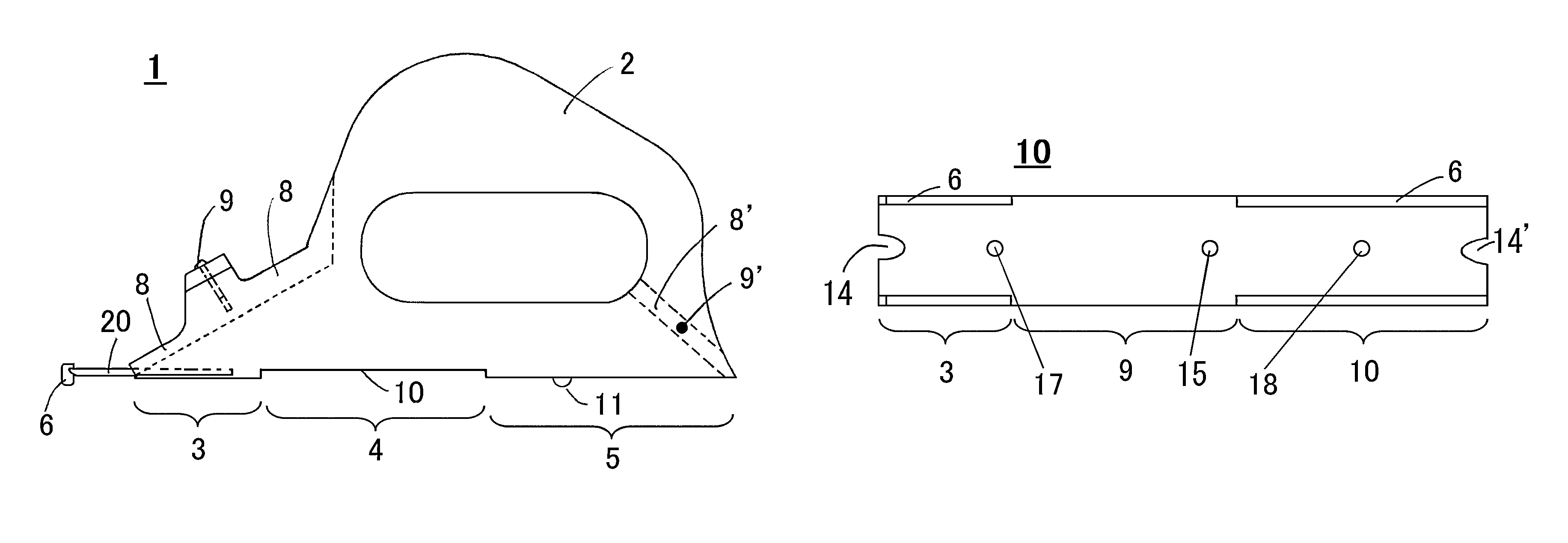

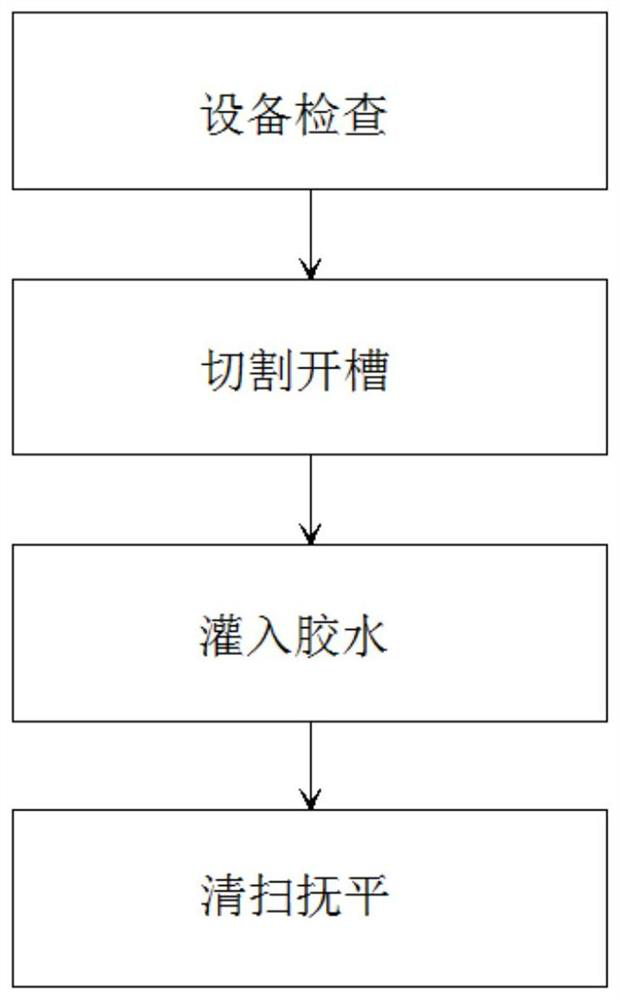

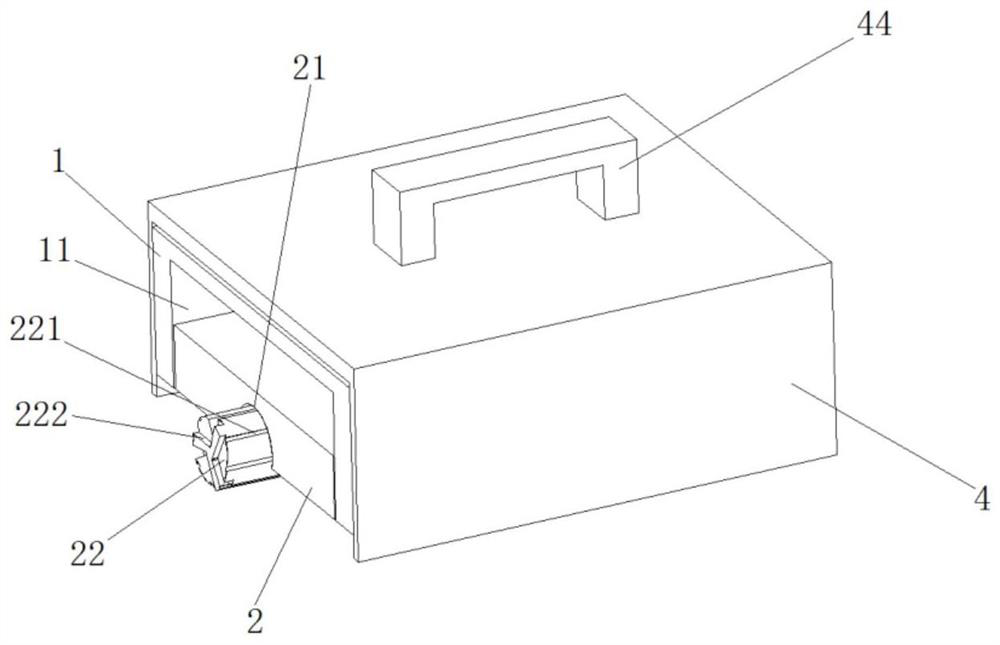

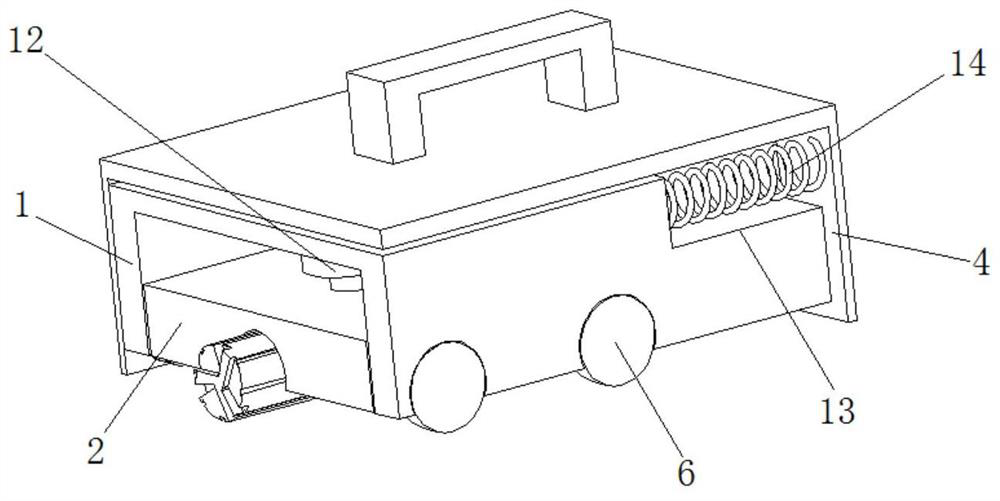

Sheet groove cutter capable of operation without use of ruler

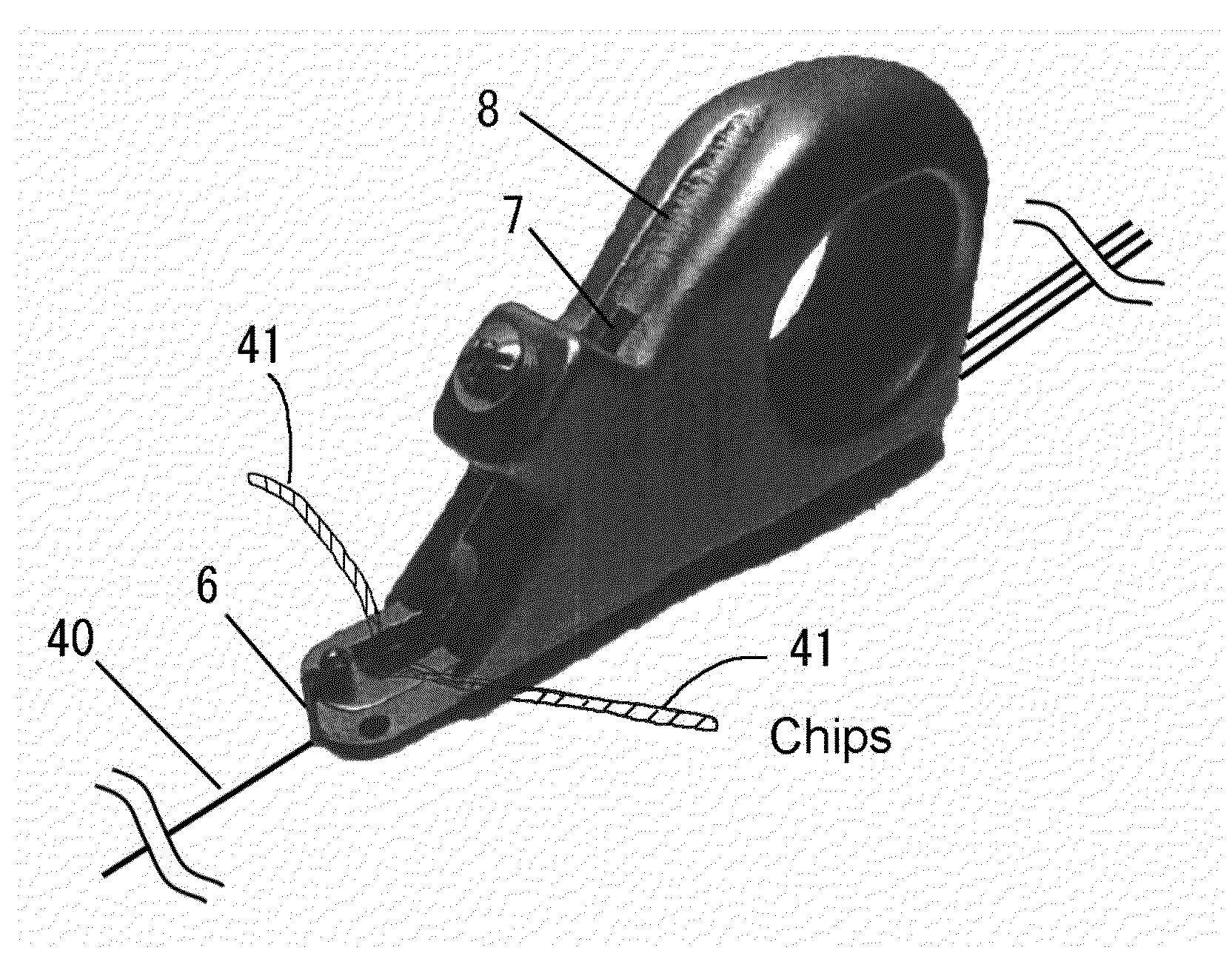

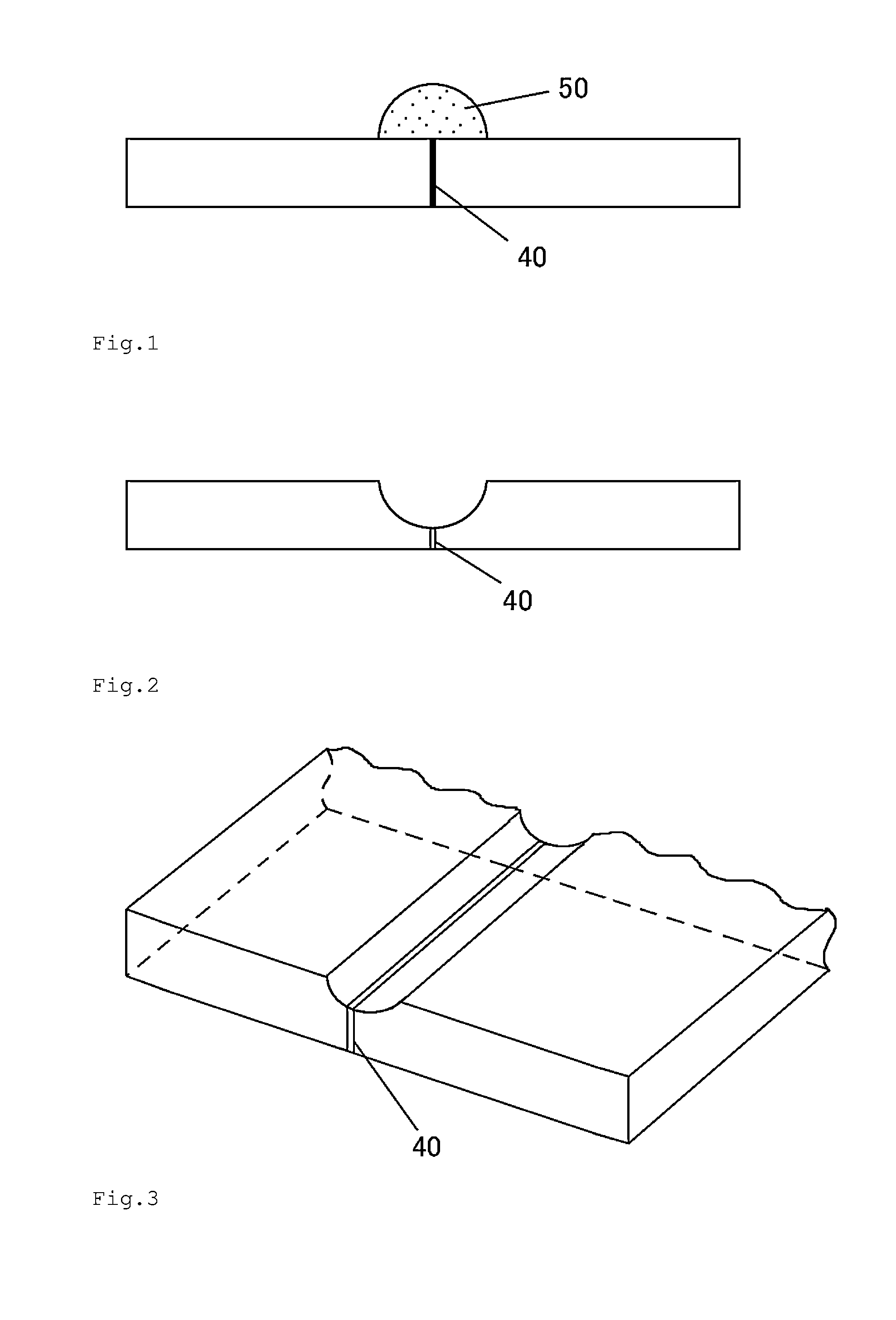

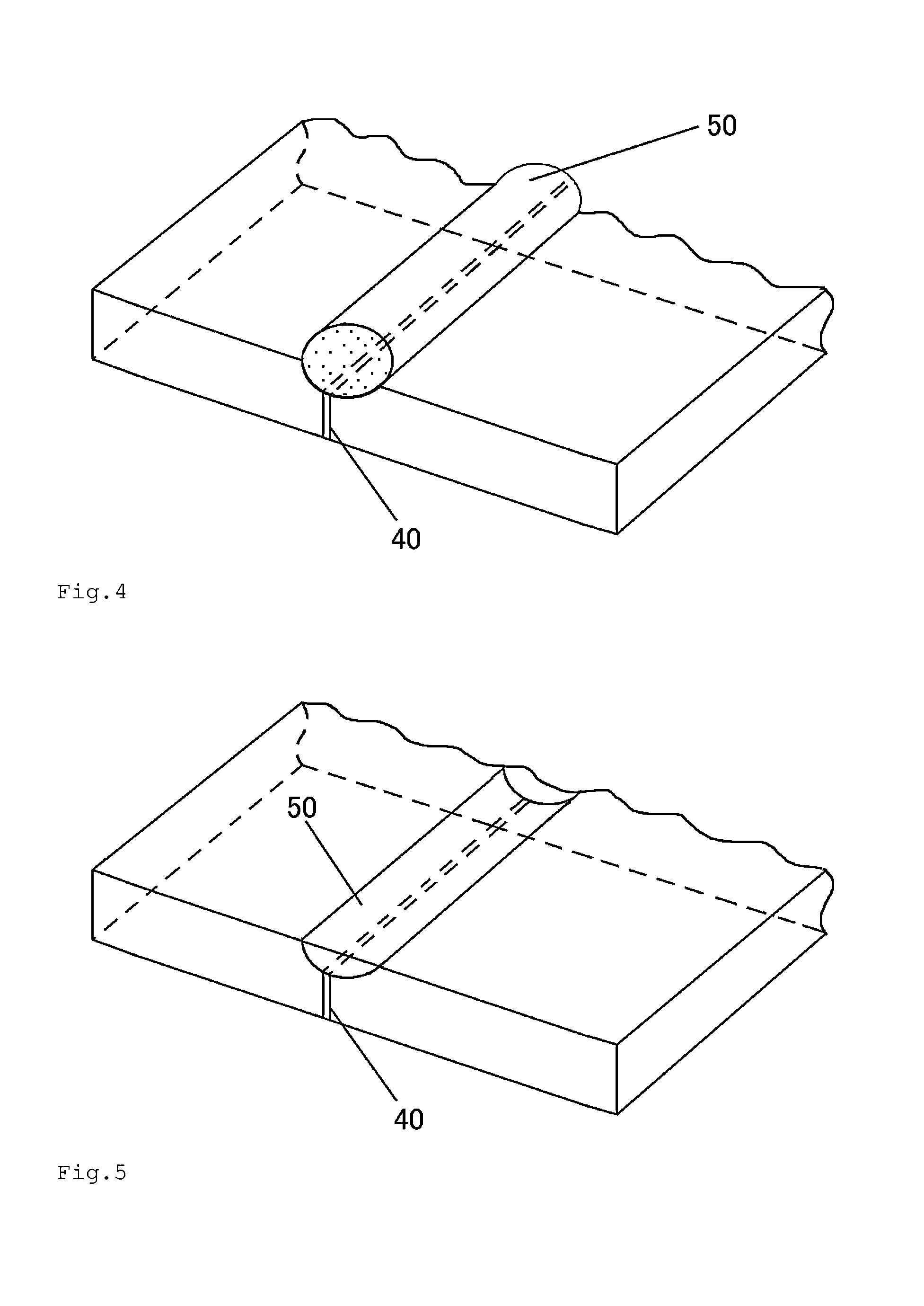

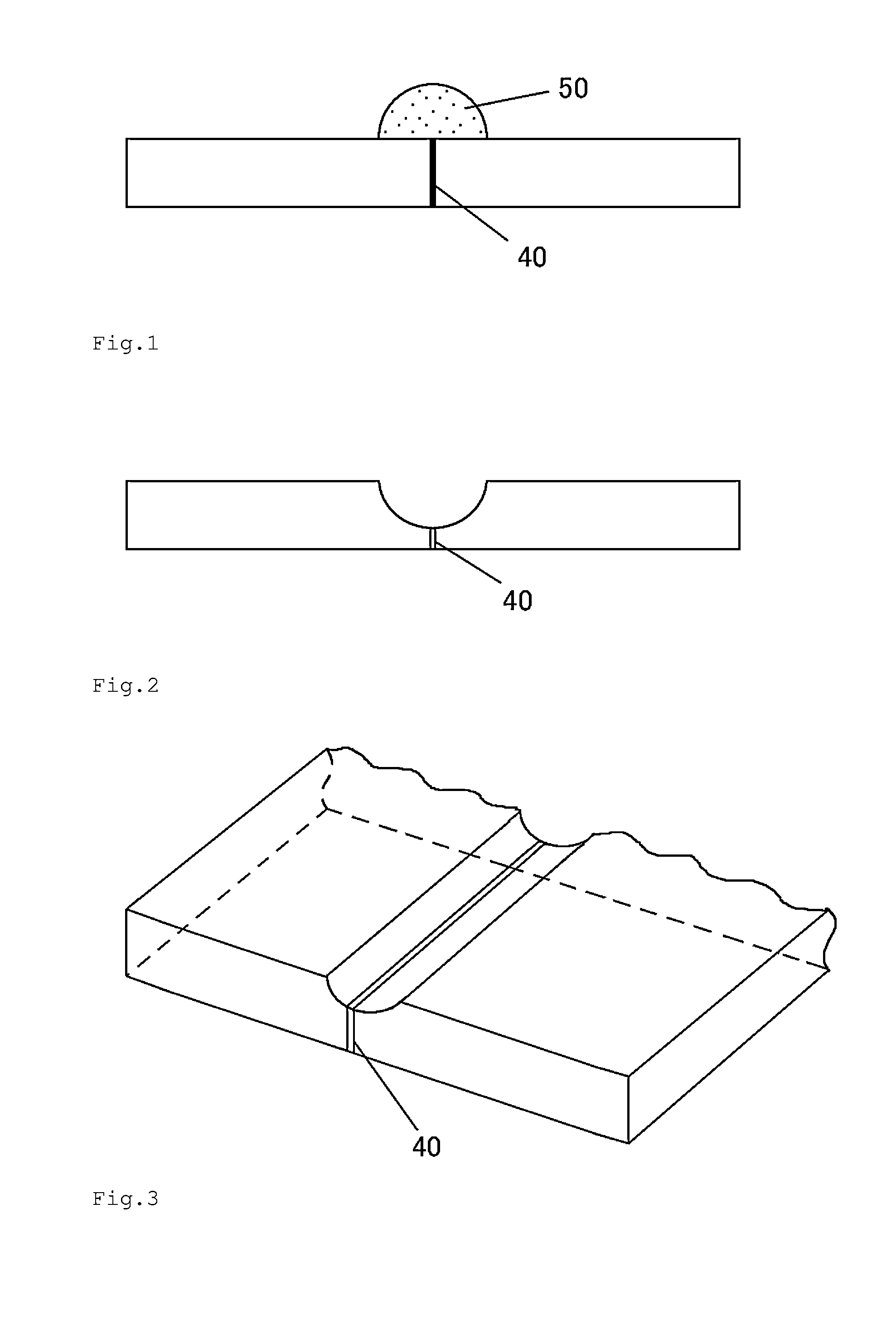

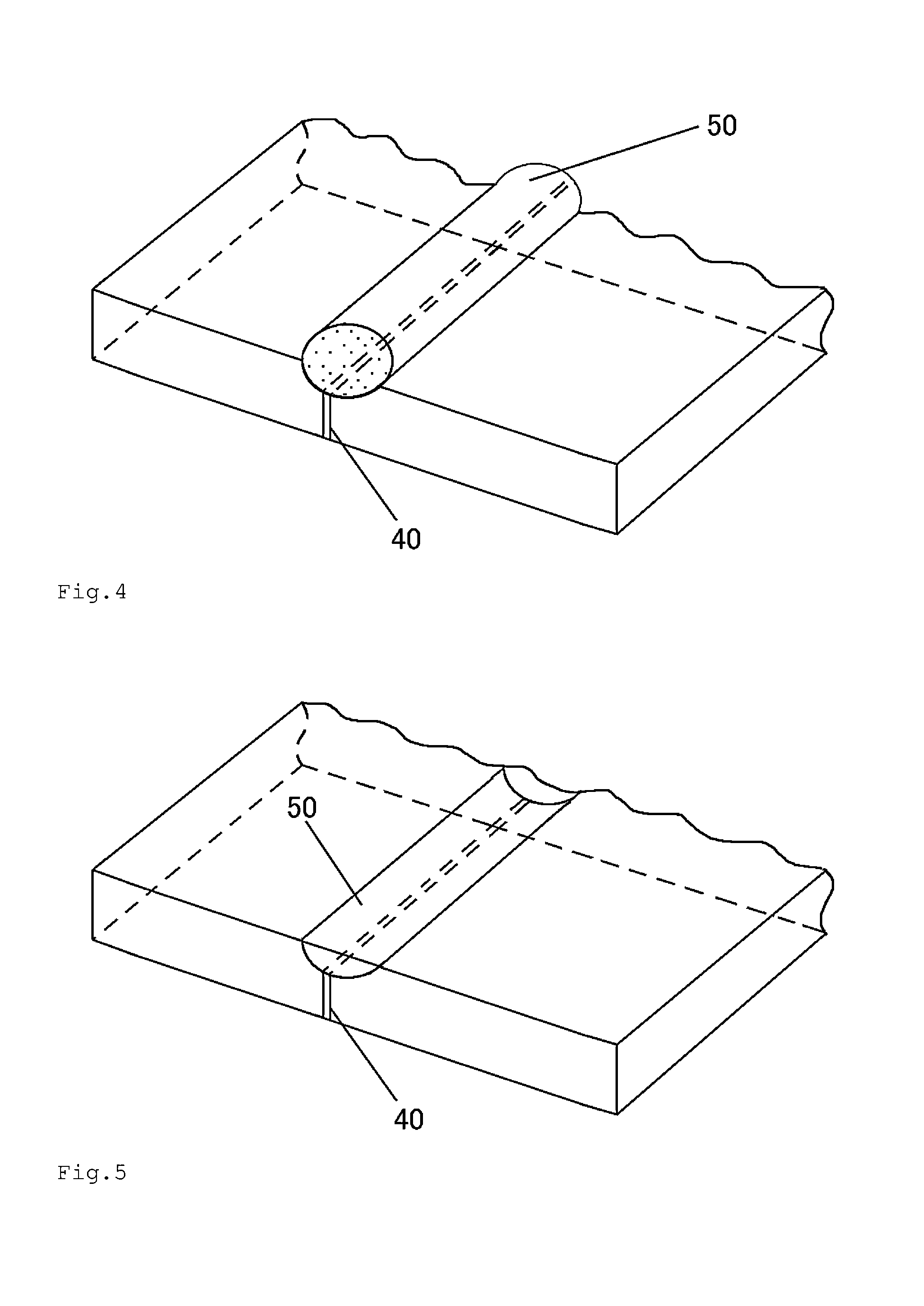

ActiveUS20140260886A1Accurate and easy to obtainHigh grooving efficiencyDomestic articlesAdhesivesEngineeringMechanical engineering

A groove cutter for floor sheets capable of being operated without using a ruler and can cut a seam, which is created when sheets are laid sequentially on the surface of floor base with an adhesive agent, so that a groove formed along the seam can bridge over both adjacent sheets, comprising a front part, a middle part, a rear part, wherein the front part has a thin guide plate, which is to be inserted into the seam and guides the tool along the seam when pushing the tool forward, at the front end, and at least one blade to cut a concave groove at the seam part of the sheet, which is provided behind the guide plate so as to be detachable, and a stabilizing member provided at the rear part, which is to be inserted into the concave groove, to stabilize a direction of movement along the seam.

Owner:IIMORI IKUMI +1

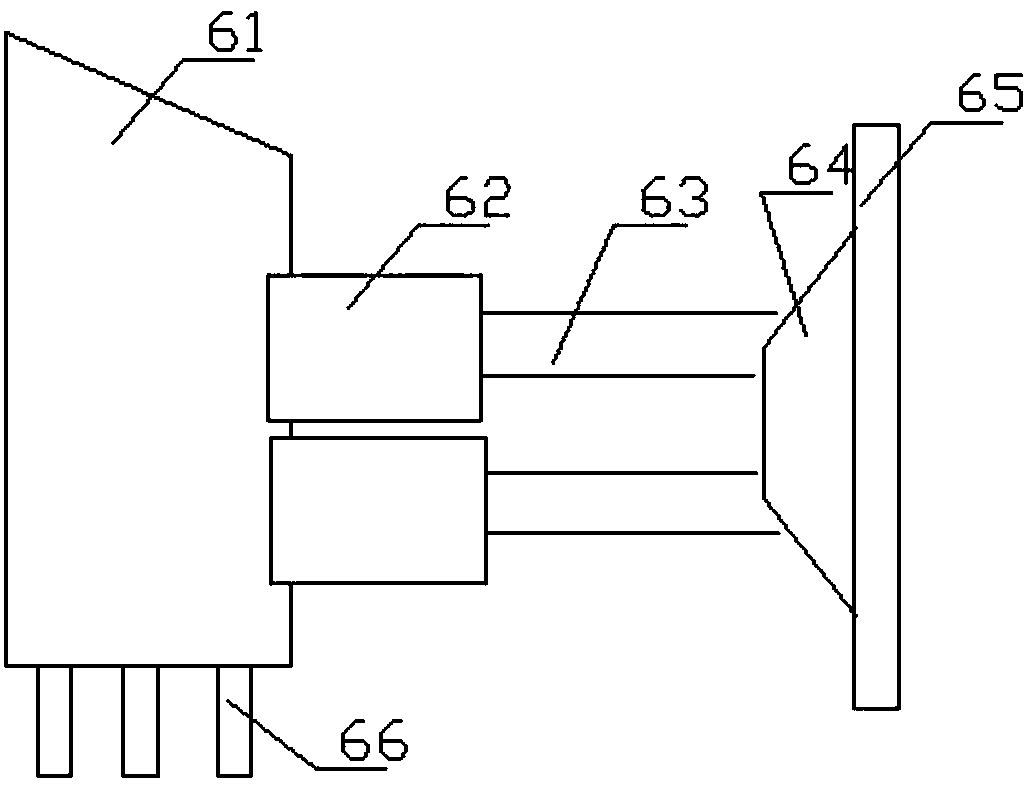

Grooving equipment for processing stainless steel and grooving technology thereof

ActiveCN106825721AImprove cooling effectPlay a fixed effectPlaning/slotting machinesMaintainance and safety accessoriesEngineeringRefrigerant

The invention relates to the field of stainless steel manufacturing and particularly relates to grooving equipment for processing stainless steel and a grooving technology thereof. The grooving equipment comprises a rack, a control assembly, a power assembly and a grooving assembly, wherein the control assembly and the power assembly are arranged on the rack; the power assembly comprises a lifting module, a conveying module and a propelling module; the grooving assembly is arranged on the propelling module; the conveying module is provided with a placement table and is arranged on the lifting module; the grooving assembly comprises an installation plate, a grooving module, a first cooling module, a second cooling module and a rotating module; the first cooling module and the second cooling module are fixed on the installation plate; and the second grooving module is arranged on the second cooling module. A stainless steel plate is grooved through a planer tool, so that the grooving loss is low and the grooving accuracy is high; and a mist refrigerant is ejected through the cooling module to play cooling and chip removal roles in the planer tool, so that the grooving technology is simple and the grooving efficiency is high.

Owner:东莞市梅兴不锈钢钣金科技有限公司

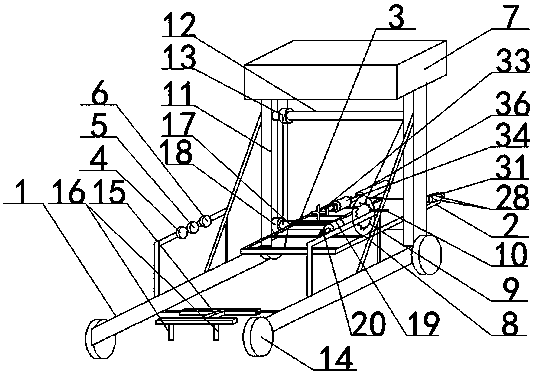

A wall punching and slotting machine

InactiveCN104179331BHigh grooving efficiencyWon't happenBuilding constructionsEngineeringWater tanks

The invention discloses an integrated wall punching and grooving machine. The integrated wall punching and grooving machine comprises a machine body, a groove cutting mechanism and a punching mechanism, wherein the groove cutting mechanism is arranged on the machine body; the punching mechanism is mounted at the upper part of the groove cutting mechanism through a rotary shaft; a grooving switch, a punching switch, a swinging switch, a water tank, a lifting wheel, a toothed disk, a clamping piece, groove guide rails, a rolling shaft, groove rolling wheels, pulleys, an H-shaped fixing plate and supporting columns are arranged on the machine body; a shaft, rotary wheels, a motor, a motor bevel gear, a transmission bevel gear, a swinging rod, a sleeve rod, a connecting rod, sleeves, a cutting bracket, supporting rods, cutting motors, a transmission cutting bevel gear, a cutting motor bevel gear and cutting sheets are arranged on the groove cutting mechanism; a thread rod, a handle, a punching motor, a thread sleeve and a punching sleeve are arranged on the punching mechanism. The integrated wall punching and grooving machine has the advantages that dust cannot be generated, the punching efficiency and the groove cutting efficiency are high, and labor and time are saved.

Owner:尹成东

Bar grooving treatment device for building material processing

PendingCN114433919AHigh grooving efficiencyRealize grooving adjustmentMilling equipment detailsDriving apparatusArchitectural engineeringStructural engineering

The bar grooving treatment device for building material machining comprises a barrel, the barrel is divided into a grooving position, a feeding position and a discharging position in the radial direction, an upper rotating disc and a lower rotating disc are rotationally connected into the barrel, and a plurality of connecting rods are fixedly connected between the upper rotating disc and the lower rotating disc; six grooves are formed in the upper rotary disc and the lower rotary disc in the circumferential direction, every two of the six grooves form a group in the radial direction and correspond to a groove cutting position, a feeding position and a discharging position respectively, limiting rings are rotationally connected into the six grooves, and penetrating openings corresponding to ring openings of the limiting rings are formed in the bottoms of the six grooves. A clamping mechanism capable of clamping the end of a bar is installed in the limiting ring, and opening and closing mechanisms corresponding to the six penetrating openings one to one are installed at the bottom of the lower rotary disc in the circumferential direction. According to the device, the feeding, grooving and discharging processes can be conducted at the same time, the grooving efficiency is high, grooving can be conducted on two bars at a time, and automatic adjustment can be conducted according to the grooving position.

Owner:江苏南通冠仟新材料科技有限公司

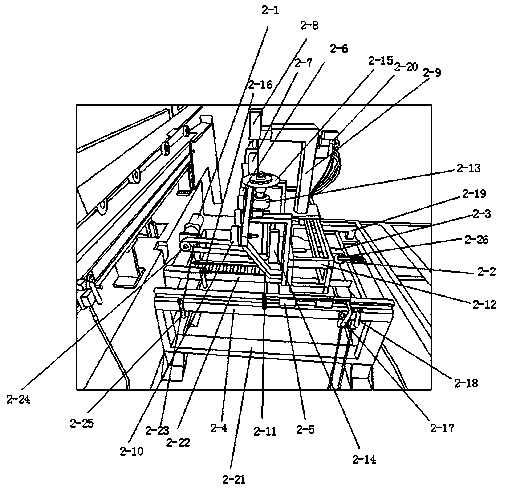

Cylinder workpiece double-side grooving machine

PendingCN109910090ARealize fully automatic batch groovingHigh grooving efficiencyMetal working apparatusElectrical controlEngineering

The invention discloses a cylinder workpiece double-side grooving machine. A bottom rack, a feeding assembly, a material guiding assembly, a stop assembly, a cutting assembly and an electrical controlbox are included. The feeding assembly is composed of a fixing feeding plate, an adjustable feeding plate, fixing feeding plate installing plates, an adjustable feeding plate moving assembly and thelike. The material guiding assembly is composed of a fixing material guiding plate, an adjustable material guiding plate, a fixing material guiding plate installing base, an adjustable material guiding plate moving assembly and the like. The cutting assembly is composed of a grooving workbench, a grooving workbench sliding assembly, a grooving tool installing base, a grooving positioning head, a grooving tool, a grooving tool pushing assembly, reset springs and the like. The stop assembly is composed of a stop hand installing frame, a feeding stop hand drive air cylinder, a feeding stop hand,a grooving positioning stop hand drive air cylinder, a grooving positioning stop hand and the like. The cylinder workpiece double-side grooving machine can finish six procedures including feeding, positioning, clamping, grooving, loosening and discharging at a time, full-automatic batched grooving can be achieved, the grooving efficiency is greatly improved, and the labor cost is saved and is low.

Owner:SUZHOU INST OF INDAL TECH

Slotting device used for production of shell of multi-medium air curtain machine

InactiveCN109175449AHigh grooving efficiencyEfficient collectionEdge grinding machinesCleaning using toolsEngineeringDust collector

The invention relates to the technical field of production of air curtain machines, and discloses a slotting device used for production of a shell of a multi-medium air curtain machine. The slotting device comprises a base. A first sliding groove is formed in the position, close to the center of the bottom, of an inner cavity of the base from right to left. A shell storage plate is fixedly connected to the top of a supporting rod. A vertical plate is vertically and integrally formed at the position, close to the center of the left side, of the top of the base. The right side of a second sliding block is fixedly connected with a motor fixing plate. A motor is fixedly connected to the end, away from the motor fixing plate, of a third sliding block. A dust collector is fixedly mounted on theleft side of the top of the base. According to the slotting device used for production of the shell of the multi-medium air curtain machine, springs, a cleaning bucket and a sealing ring are arrangedon the motor, so that a slotted part of the shell of the air curtain machine is sealed in the slotting process; and scraps in the cleaning bucket can be effectively collected through the dust collection and a ventilation pipe which are arranged in a matched mode, so that the workload of workers is reduced.

Owner:广州成亿电器有限公司

Loading assembly for grooving device

The invention relates to the technical field of metal machining, in particular to a loading assembly for a grooving device. The loading assembly for the grooving device comprises a base, a loading component comprises a basic fixing part, a telescopic barrel, a main telescopic rod, an operation barrel, a second rotary connection ball, a side rod, a clamping plate, an operation barrel, a first rotary connection ball, a handle, a first connection base and a pressing plate, wherein the telescopic barrel is arranged on the basic fixing part in a penetrating mode, the second rotary connection ball is rotationally connected to the main telescopic rod through threads, the clamping plate is clamped to the end of the side rod, the first rotary connection ball is rotationally connected to the side wall of the operation barrel, and the pressing plate is clamped to the lower end of the first connection base. According to the loading assembly for the grooving device, a grooving component and the loading component are convenient to operate and adjust, and high in grooving efficiency.

Owner:嘉兴创诺精密五金有限公司

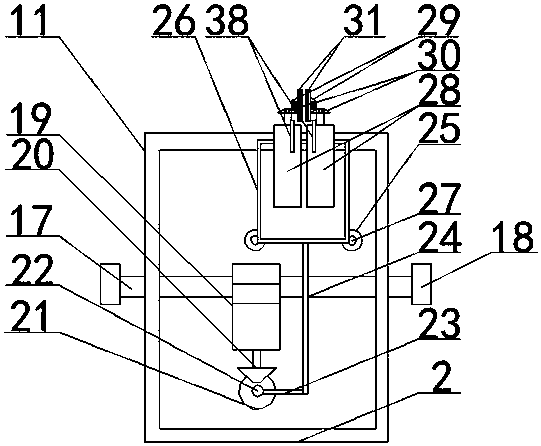

A kind of biochip production equipment

ActiveCN110293598BRealize automatic grooving processingReduce labor intensityMetal working apparatusProcess engineeringBiochip

The invention discloses a biological chip production equipment, which comprises a slotting box and a feeding cavity arranged in the slotting box, a material storage device is arranged in the slotting box, and biochips to be processed are placed in the storage device, The material storage device is equipped with a lifter that can rise; the device is simple in structure and easy to use, and can realize automatic grooving processing of biochips, and the feeding and retrieving of materials in the processing process are all automatically completed, which greatly improves the processing accuracy At the same time, a large number of biochips to be processed can be stored in the storage device of the device, and workers only need to fill in when there is a shortage of materials in the storage device, which realizes batch processing, reduces labor intensity of workers, improves grooving efficiency, and greatly Reduced business costs.

Owner:郑州优铸机械有限公司

Sheet groove cutter capable of operation without use of ruler

ActiveUS9481101B2Accurate and easy to obtainHigh grooving efficiencyGuide fencesDomestic articlesSheet materialClassical mechanics

A groove cutter for floor sheets capable of being operated without using a ruler and can cut a seam, which is created when sheets are laid sequentially on the surface of floor base with an adhesive agent, so that a groove formed along the seam can bridge over both adjacent sheets, comprising a front part, a middle part, a rear part, wherein the front part has a thin guide plate, which is to be inserted into the seam and guides the tool along the seam when pushing the tool forward, at the front end, and at least one blade to cut a concave groove at the seam part of the sheet, which is provided behind the guide plate so as to be detachable, and a stabilizing member provided at the rear part, which is to be inserted into the concave groove, to stabilize a direction of movement along the seam.

Owner:IIMORI IKUMI +1

Groove pressing structure of plate bending machine

InactiveCN111790778AHigh grooving efficiencyQuality improvementHydraulic cylinderStructural engineering

The invention discloses a pressing groove structure of a plate bending machine, comprising a fixed pressing table and a movable pressing head, wherein the fixed pressing table is arranged on a workbench of the plate bending machine, and the movable pressing head moves towards or away from the fixed pressing table. A fixed pressing head is arranged at the upper end of the fixed pressing table, a matching groove matched with the fixed pressing head is formed in the movable pressing head, four through holes are formed in the groove bottom of the matching groove, slidable connecting rods are arranged in the through holes, the lower ends of the connecting rods are connected with a vertical pressing plate, shaft rings are formed on the upper portions of the connecting rods, and the shaft rings axially limit the connecting rods. According to the invention, the movable pressing head is connected with a cylinder rod of a hydraulic cylinder through a connector; the movable pressing head is driven by the cylinder rod to move towards the fixed pressing head, the matching groove in the movable pressing head is matched with the fixed pressing head to achieve groove pressing, in the process, thevertical pressing plate is always matched with the fixed pressing head to press the groove bottom of a formed groove of a plate, the pressure applied by the vertical pressing plate is the sum of the gravity of a balance weight plate, the connecting rods and the vertical pressing plate, and groove pressing efficiency is high, and the quality is good.

Owner:津阳创展(天津)金属科技有限公司

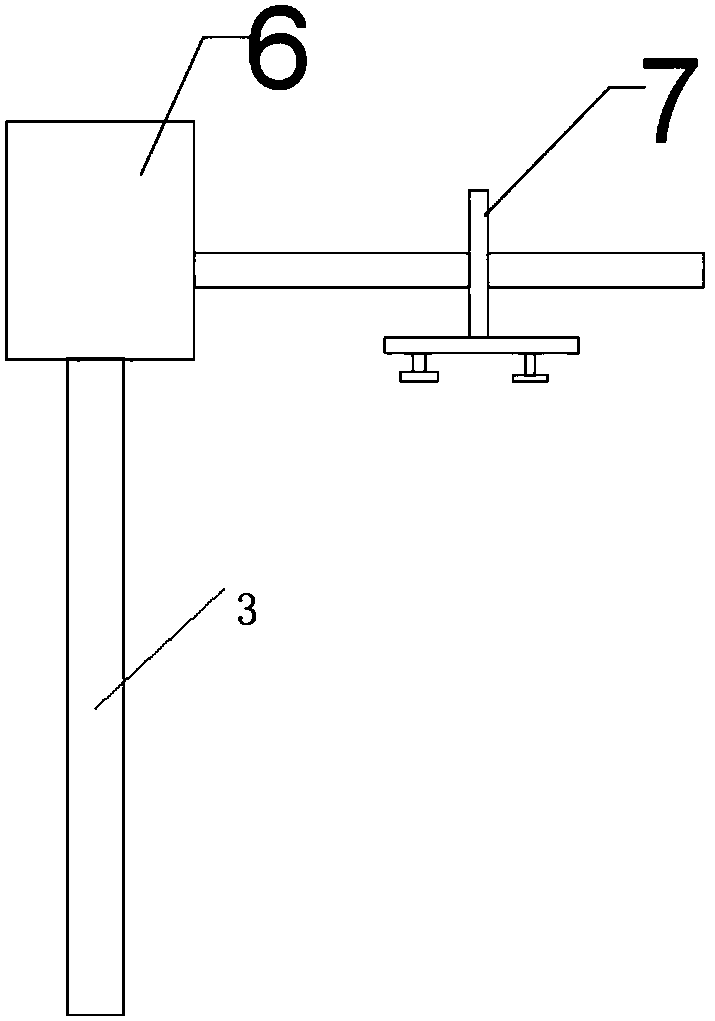

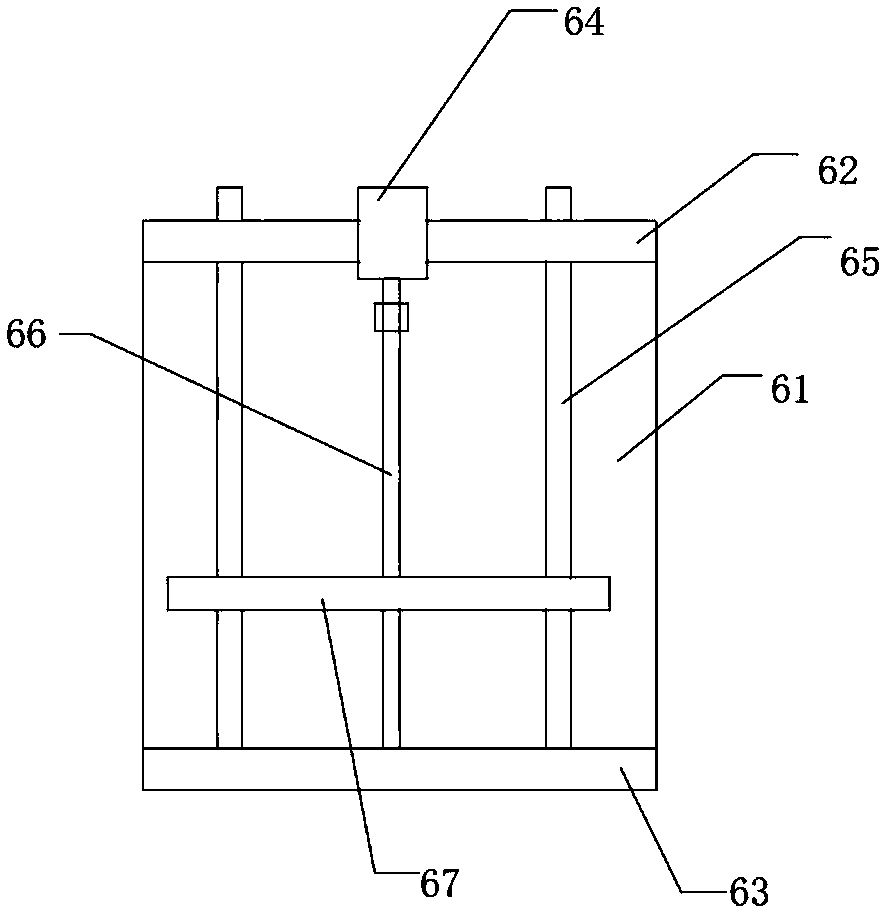

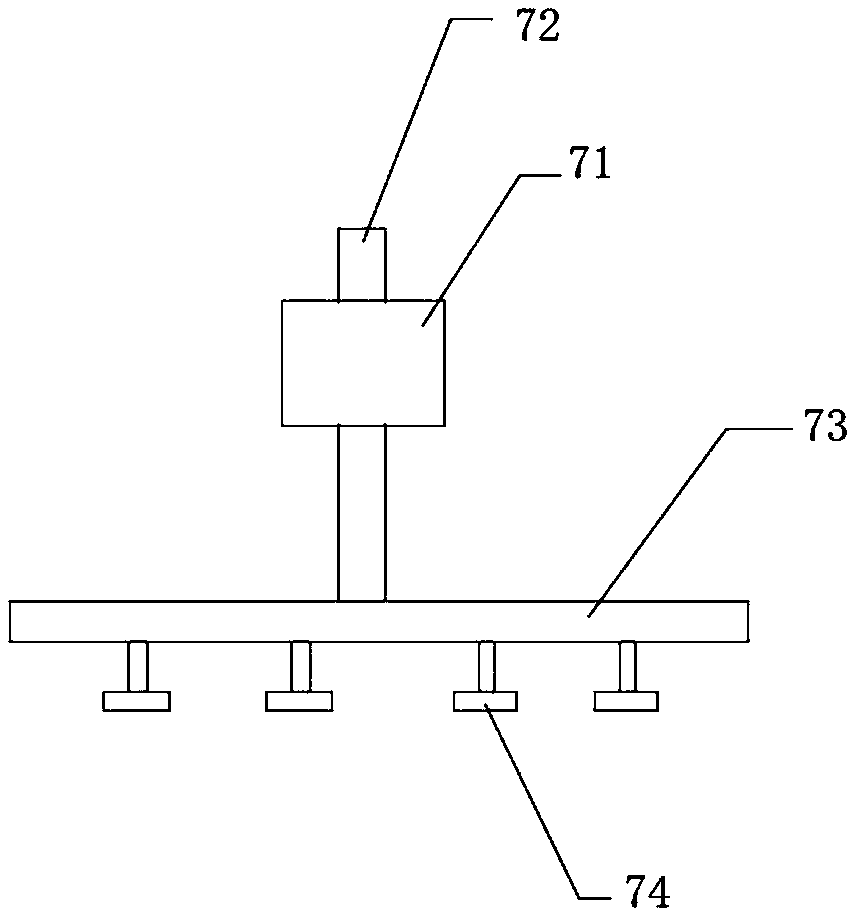

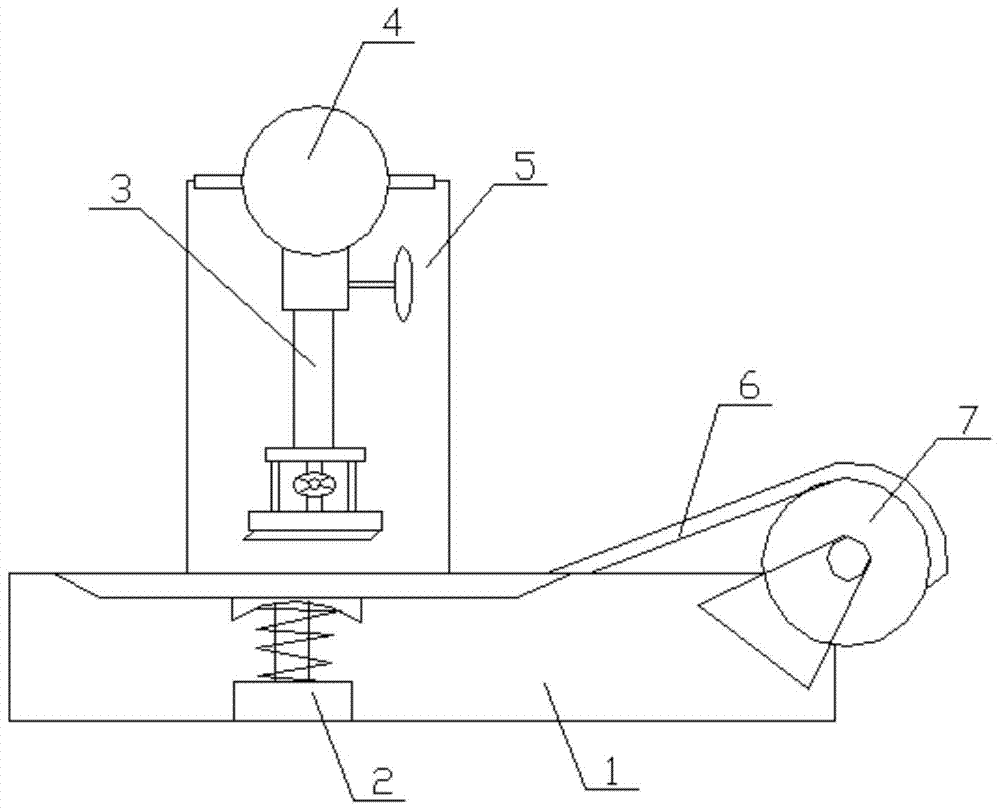

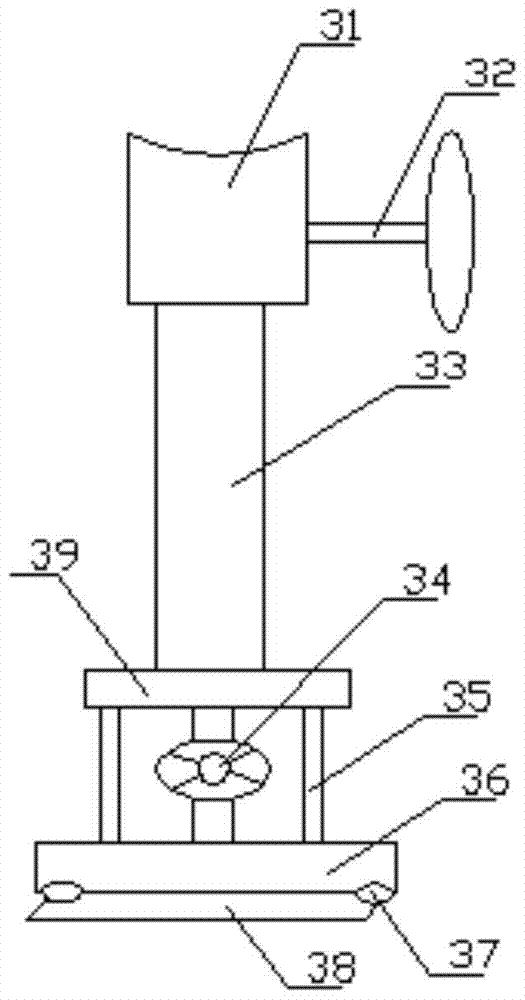

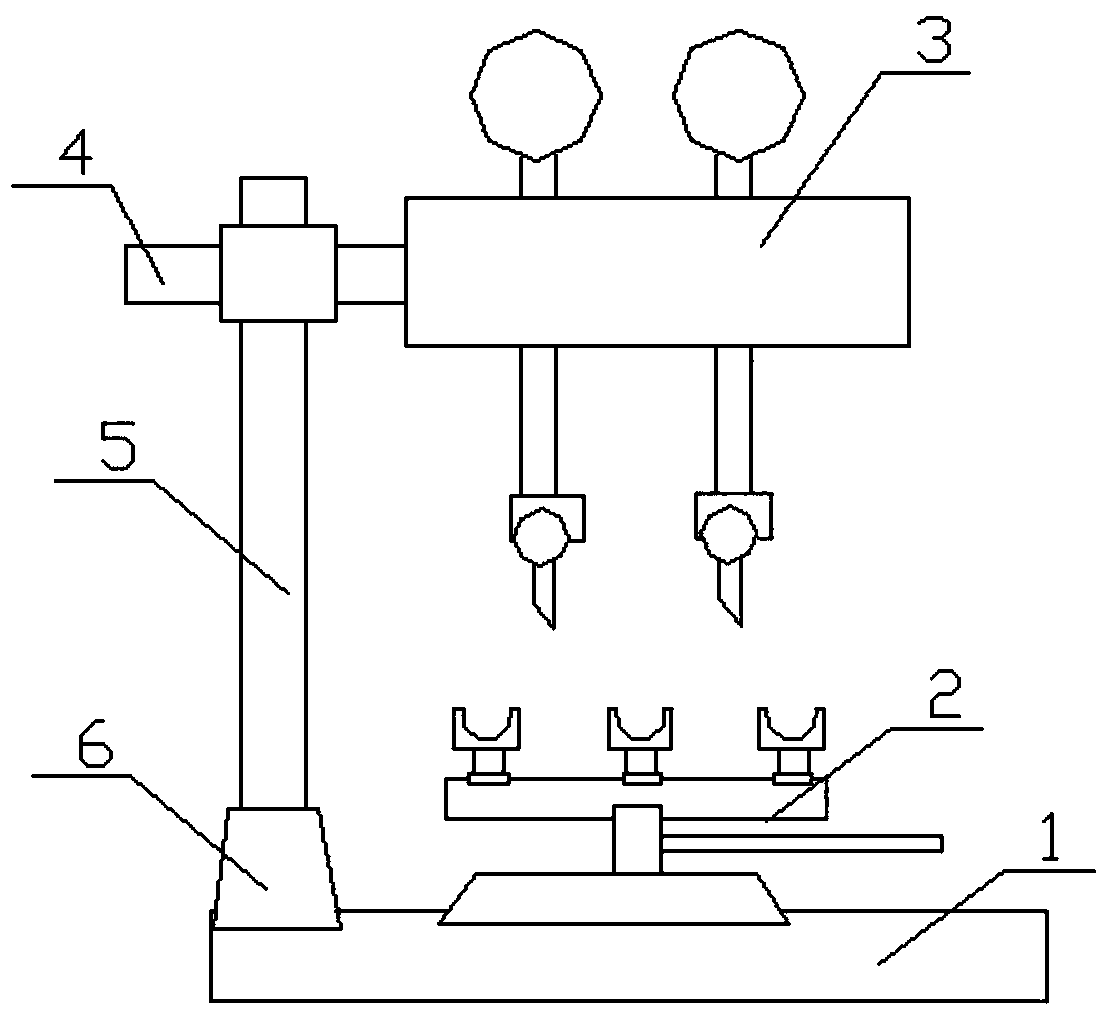

Lifting and grooving component for production of paper board

InactiveCN108582895AInnovative designIngenious structureMechanical working/deformationCardboardMechanical equipment

The invention relates to the field of mechanical equipment and discloses a lifting and groove grooving component for production of a paper board. The lifting and grooving component comprises a supporting column, a lifting component and a groove component, wherein the lifting component is spirally connected to the upper part of the supporting column through screw threads; and the grooving componentis arranged at the lifting component. The lifting and grooving component is novel in design, ingenious in structure, beneficial for improving the grooving efficiency, good in grooving effect and highin adjustability.

Owner:浙江新峰包装材料有限公司

a slotting machine

ActiveCN105252065BEasy to adjustEasy to operateShearing machinesShearing machine accessoriesDrive shaftAgricultural engineering

The present invention relates to the technical field of mechanical equipment, in particular to a slotting machine; the slotting machine of the present invention includes a base, a frame, a first driving part, a slotting part, a supporting part, a second driving part and a transmission Parts; the grooving part includes a main transmission rod, a transmission seat, an adjustment knob, a first mounting plate, a lifting adjustment member, a second mounting plate, an auxiliary lifting rod, a main cutting knife and a fine-tuning device arranged on the main cutting knife parts; the grooving machine of the present invention is easy to operate, convenient to adjust, and has high grooving efficiency.

Owner:ZHEJIANG SANLIN METALS PROD

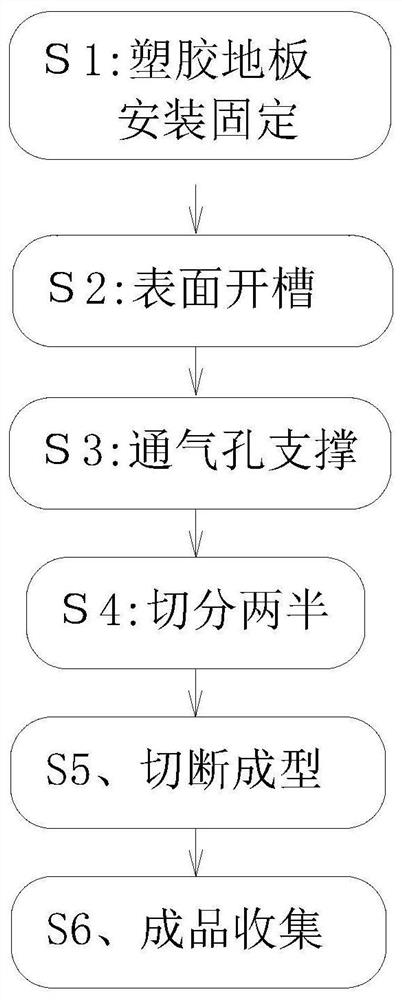

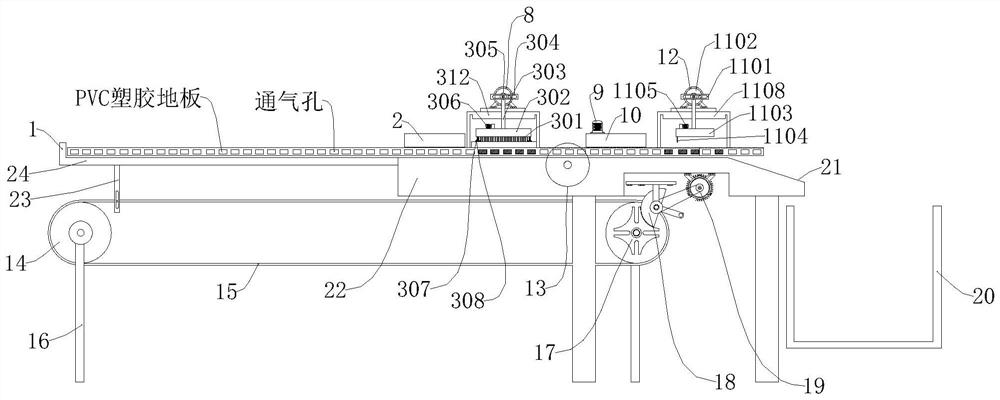

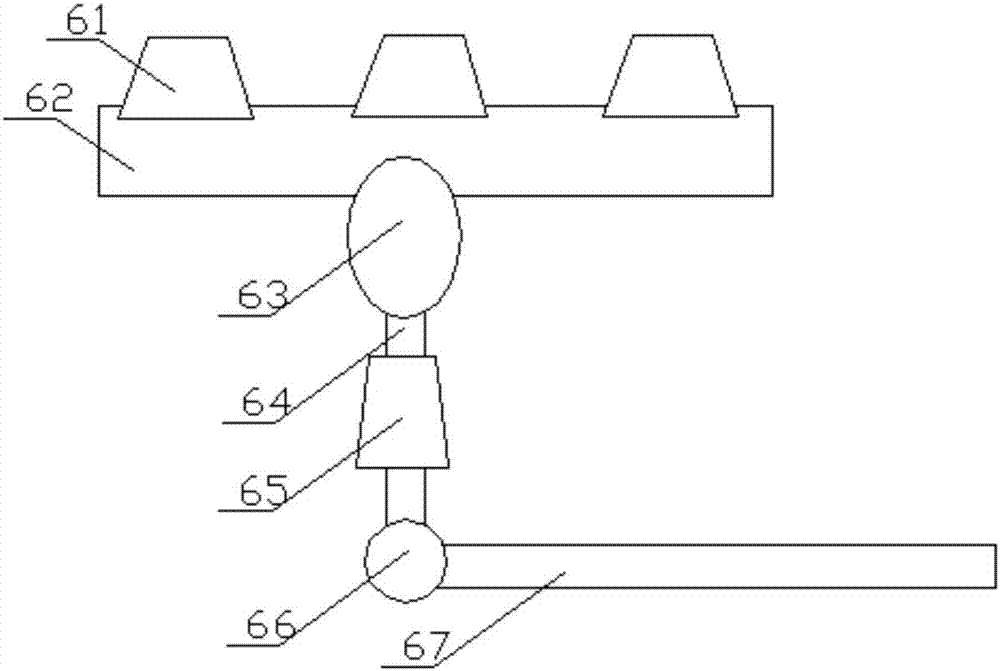

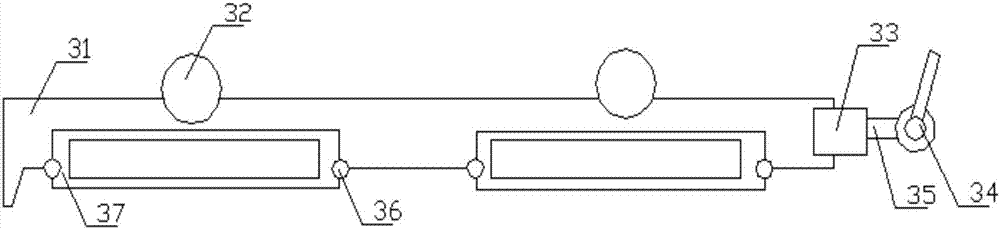

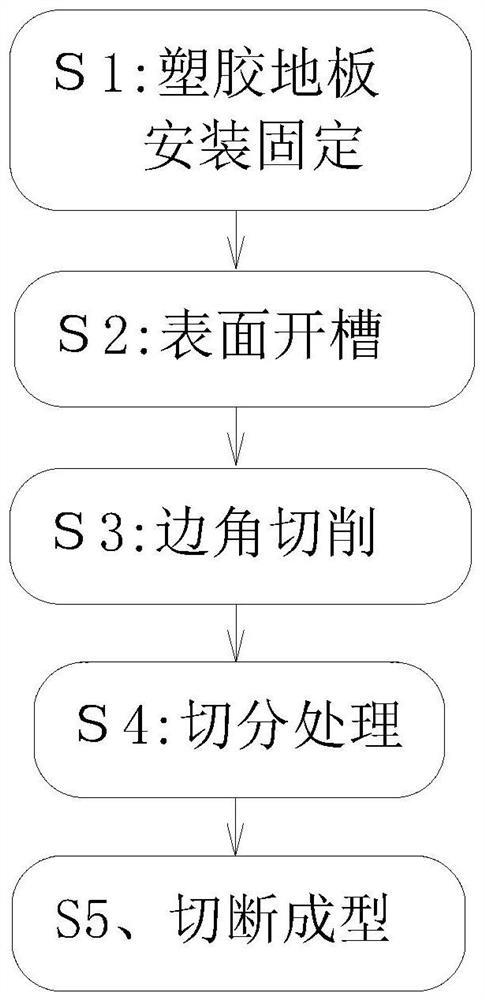

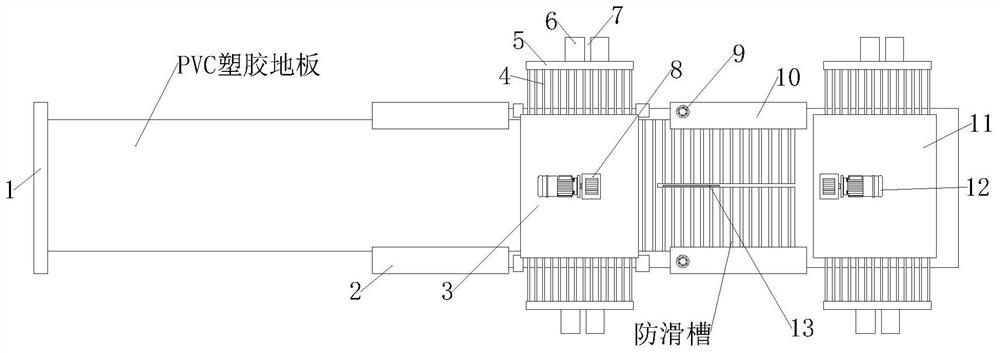

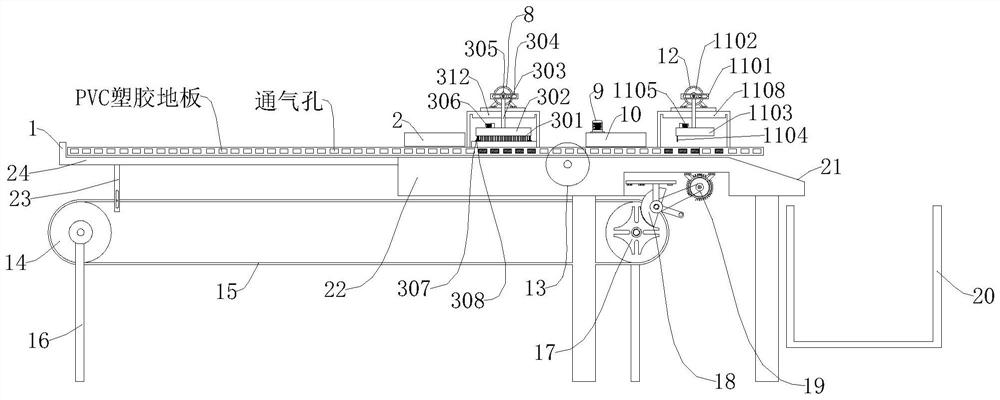

A kind of pvc plastic floor molding process

ActiveCN112894987BEasy to installImprove structural strengthMetal working apparatusWater flowWater spray

The invention provides a PVC plastic floor molding process, which relates to the technical field of plastic floor production and processing. S1. Installation and fixing of the plastic floor: installing and fixing the PVC plastic floor to be formed on a PVC plastic floor forming device; S2. Grooving the surface: Grooving the surface of the PVC plastic floor installed and fixed on the PVC plastic floor molding device in step S1, by arranging multiple rows of circularly rotating cutter teeth on the top surface of the PVC plastic floor at equal intervals to open the top surface of the PVC plastic floor Groove, control slotting depth; S3, ventilation hole support: in step S2, in the process of carrying out equidistant slotting on the top surface of PVC plastic floor; , each No. 1 water nozzle reciprocates and oscillates on the side wall of the brush seat, and the water flow reciprocatingly oscillates on the ground inside the pigsty wall, which is conducive to quickly cleaning up the feces adhered to the ground and improving the protection against feces. cleaning speed.

Owner:ZHEJIANG TIANZHEN BAMBOO & WOOD DEV

A metal plate grooving equipment

ActiveCN104907378BHigh grooving efficiencyGood groove effectMetal-working apparatusEngineeringMetal sheet

The present invention relates to the technical field of mechanical equipment, in particular to a metal plate grooving equipment; the metal plate grooving equipment of the present invention includes a main frame, and also includes a second driving part, a supporting part, a spinning roller, a transmission part and a first The driving part; the spinning roller includes a main cylinder, a fixed side plate, a main mounting seat, a pressure head, an inner pressure plate, an inner tensioning rod, a tensioning spring, a transmission chamber and a screw seat; the metal plate grooving equipment of the present invention The groove pressing efficiency is high, the groove pressing effect is good, the operation is convenient, and the adjustment is convenient.

Owner:徐州欧普莱斯工业机械有限公司

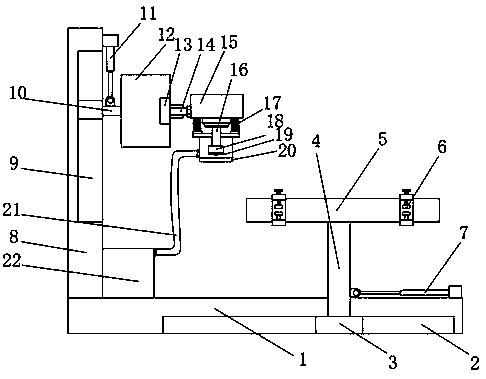

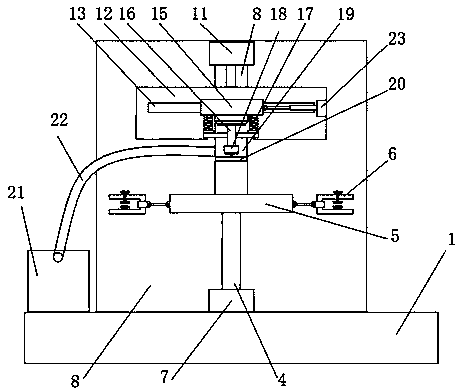

Automatic grooving machine for conductive fixing blocks for circuit boards for automobiles

The invention discloses an automatic grooving machine for conductive fixing blocks for circuit boards for automobiles. The automatic grooving machine comprises a machine table, a feeding device, a pushing device, a bidirectional grooving device and a longitudinal shifting device, wherein the pushing device is arranged on the machine table and is located below the tail end of the feeding device, the bidirectional grooving device is arranged on the machine table and is located on the side edge of the pushing device, the longitudinal shifting device is arranged on the machine table and is movablyarranged between the pushing device and the bidirectional grooving device, and the bidirectional grooving device comprises a transverse grooving mechanism and a longitudinal grooving mechanism. The automatic grooving machine for the conductive fixing blocks for the electric circuit boards for the automobiles has the advantages that bidirectional, automatic and accurate grooving can be carried outon the conductive fixing blocks, the action accuracy is high, the mutual action cooperation is accurate, tight and smooth, the automation degree is high, the grooving precision can be improved, the product quality can be improved, and the grooving working efficiency can be greatly improved.

Owner:DONGGUAN LUXIN HARDWARE PROD

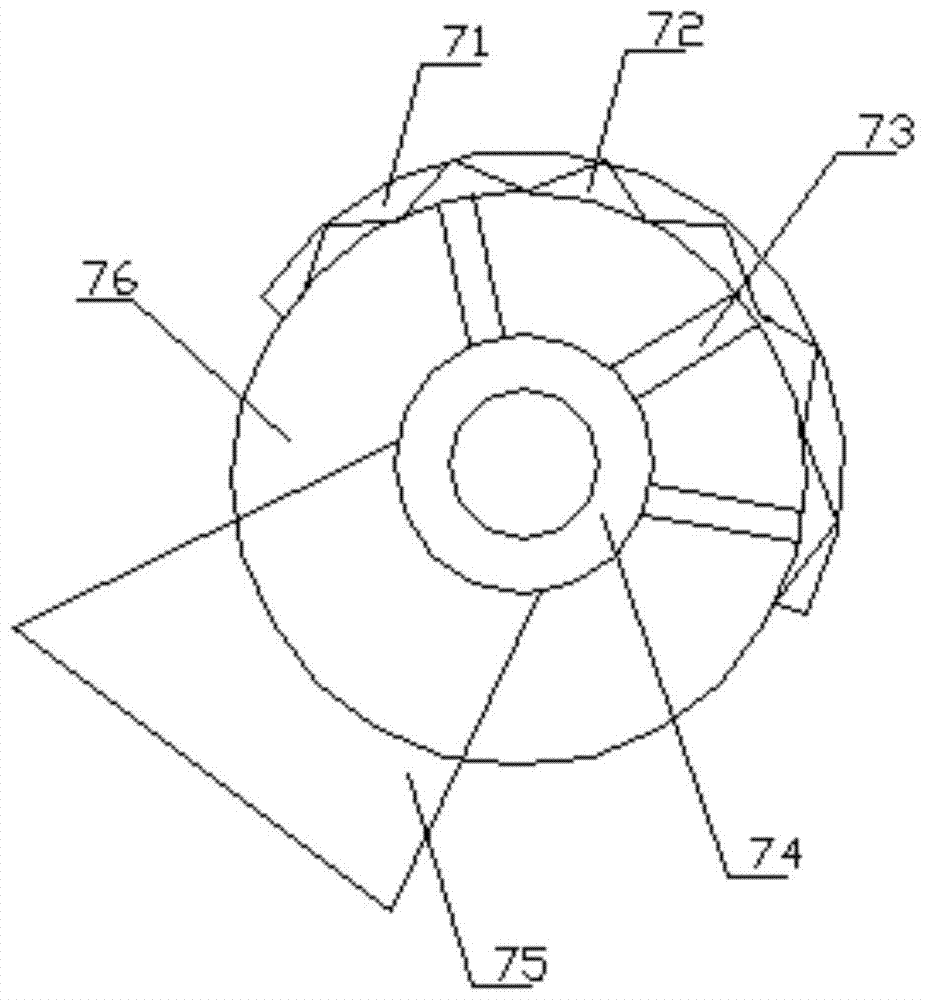

A multi-knife grooving machine

ActiveCN105563541BEasy to adjustEasy to operateMetal working apparatusEngineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a multi-cutter groove rolling machine. The multi-cutter groove rolling machine comprises a main machine frame and landing legs arranged on the lower side of the main machine frame. The multi-cutter groove rolling machine further comprises groove rolling components, a motor, a conveying component and an adjusting component. Each groove rolling component comprises a collecting disc, groove rolling cutters, an inner rotating piece, a first shaft section, a rotation adjusting piece, a transmission ball and a second shaft section, wherein a clamping cutter groove is formed in the upper portion of the collecting disc in a concave manner. A drive installing groove is formed in the lower portion of each collecting disc in a concave manner. A first output hole penetrates each inner rotating piece in the radial direction of the inner rotating piece. Each rotation adjusting piece is in a cylindrical shape, wherein a first rotating guiding hole penetrates the rotation adjusting piece in the axial direction of the rotation adjusting piece. Each transmission ball is in a ball shape, wherein a second output hole penetrates the transmission ball in the radial direction of the transmission ball. The multi-cutter groove rolling machine is convenient to operate and adjust, high in groove rolling efficiency and good in groove rolling quality.

Owner:山东鑫阳专用汽车制造有限公司

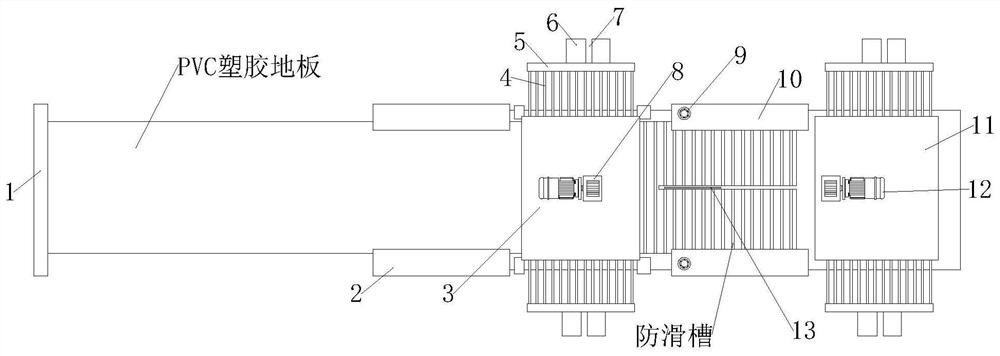

A kind of pvc plastic floor manufacturing process

ActiveCN112917581BEasy to installImprove structural strengthMetal working apparatusMachining processSupport plane

The invention provides a PVC plastic floor manufacturing process, which relates to the technical field of plastic floor production and processing. The PVC plastic floor manufacturing process is specifically completed by a PVC plastic floor manufacturing process device. The PVC plastic floor forming device It includes a device frame, the top surface of the device frame is a plane, and the bottom end of the device frame is fixed with a support frame upright on the ground; the left side of the device frame is slidably connected to a slide plate, and the slide plate The top surface is flat, and a raised push rod is fixed on the left side of the top surface of the skateboard; the side cutting knife is used to cut from the front and back sides of the PVC plastic floor, so that the PVC plastic floor will slide against the PVC plastic floor during the sliding process on the top surface of the device frame. The front and rear sides of the plastic floor are cut, thereby effectively improving the efficiency of forming and processing the corners of the PVC plastic floor, avoiding the need to change the station of the PVC plastic floor due to cutting the front and rear sides of the PVC plastic floor, and avoiding secondary Clamping.

Owner:ZHEJIANG TIANZHEN BAMBOO & WOOD DEV

A kind of construction treatment method of house waterproof membrane

ActiveCN111550019BHigh grooving efficiencyImprove waterproof performanceBuilding constructionsHydraulic cylinderFloor slab

The present invention relates to the field of building construction, in particular to a construction treatment method for house waterproof coiled materials, which uses a construction treatment device, the construction treatment device includes a machine body and a movable base, the bottom end of the machine body is provided with a lifting groove, and the movable base The seat is inserted in the lifting groove, and a hydraulic cylinder is fixedly connected in the lifting groove, and the output end of the hydraulic cylinder is fixedly connected to the top of the movable base, and the bottom of the movable base is provided with a rotating groove, and a cutting roller is inserted in the rotating groove. The inner wall of the rotating groove is symmetrically fixed with a T-shaped limiting ring, and the outer side of the cutting roller is symmetrically provided with limiting grooves. The limiting grooves are symmetrically arranged with the limiting ring and meshed with each other. The movable base is fixedly connected with a rotating motor, and the output end of the rotating motor is fixedly connected with a transmission gear. The invention can improve the groove-cutting efficiency of prefabricated floor slabs, and at the same time ensure the depth and orderliness of the cut-out grooves, and is suitable for popularization.

Owner:重庆创设建筑工程有限公司

A high-precision circular knitting machine needle cylinder molding method and molding equipment

ActiveCN111660066BIncrease productivityHigh precisionEdge grinding machinesWeft knittingStructural engineeringManufacturing engineering

The invention discloses a method for forming a needle cylinder of a high-precision circular knitting machine, which comprises the following steps: (1) performing rough turning on a blank needle cylinder; (2) performing finish turning on the blank needle cylinder after rough turning to form a needle cylinder without needle grooves. Needle cylinder; (3) milling the outer surface of the needle cylinder without needle groove to form needle groove; (4) grinding the needle groove formed in step (3) to remove burrs; (5) grinding the needle cylinder The needle grooves are inspected to determine whether they are qualified; the invention also discloses a high-precision large circular knitting machine needle cylinder forming equipment to operate steps (3) and (4); firstly, a plurality of groove forming devices arranged around the bearing base are used The grooving device in the machine simultaneously grooves the needle barrel, and the grinding device follows the grooving device for fine grinding. While grooving, the grinding device finely grinds the needle groove. The problems of low production efficiency, insufficient precision and high scrap rate of existing syringes are solved.

Owner:福建省永宏针纺机械有限公司

A multi-station plate grooving equipment

The present invention relates to the technical field of new plate processing, in particular to a multi-station new plate grooving equipment; the multi-station new plate grooving equipment of the present invention includes a base and an operating frame clamped on the upper end of the base , a fixed seat clamped on the edge of the upper end of the base, a vertical rod screwed to the upper end of the fixed seat along the axial direction of the fixed seat, a beam and a slidable sleeve sleeved on the fixed seat The grooved part on the beam; the operating frame includes a clamping seat, a fixed block, an upper bearing column screwed to the clamping base along the axial direction of the clamping base, and an upper bearing column along the bearing The radial direction of the column is screwed to the adjustment rod on the bearing column, the top plate clamped to the upper end of the bearing column, the locking ring clamped to the upper end of the top plate, the connecting rod and screwed to the An operating seat at the upper end of the connecting rod.

Owner:浙江华创融盛商业展示有限公司

Two-side groove cutting nail door stop machine for door pocket plate

InactiveCN109397423ACentralized processingWon't hurtMetal sawing devicesStapling toolsCutting nailsEngineering

The invention discloses a two-side groove cutting nail door stop machine for a door pocket plate, particularly relates to the technical field of mechanical equipment. A positioning groove-cutting device with the left side capable of achieving automatic linear forward and backward walking is arranged on the front side of a main-body linear feeding device, and a door stop nail nailing device is arranged on the upper portion of one side of the main-body linear feeding device; and a door stop two-layer feeding device is arranged on the lower portion of the side opposite to the door stop nail nailing device, and a reverse-side door pocket plate right-side groove cutting device and a nail nailing device connecting base are arranged on the back of the main-body linear feeding device. By means ofthe door pocket groove cutting device, automatic door pocket plate two-side groove cutting can be achieved, and automatic door stop nailing is completed at a time. The groove cutting efficiency is high, and the labor and cost are saved; and damage to workers cannot be caused in the groove cutting process, and a groove cutting saw blade is provided with a dust hood, so that centralized dust processing is achieved, and the device is environmentally friendly, safe and convenient.

Owner:刘占明

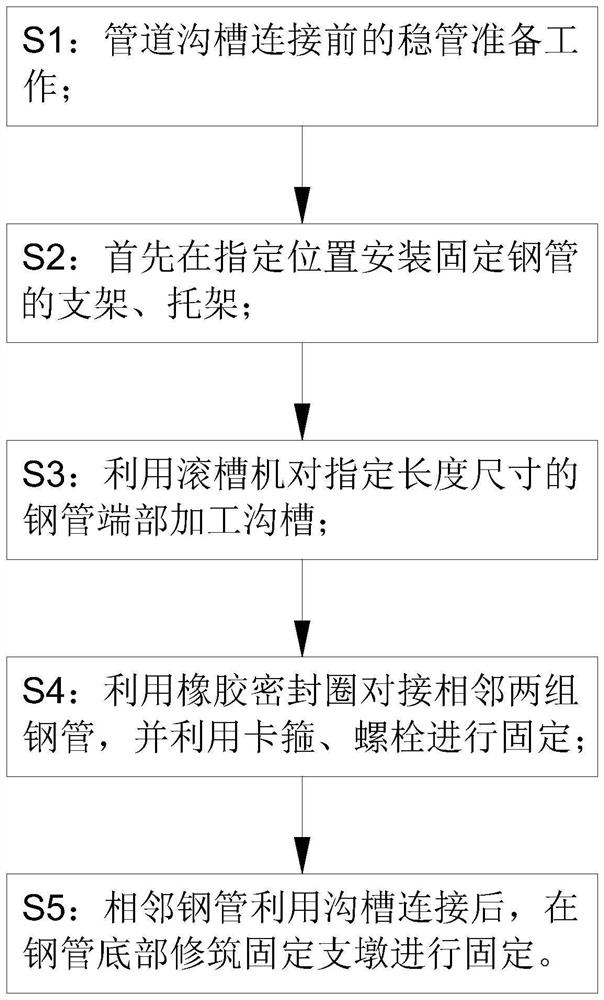

Construction method for pipeline groove connection

PendingCN114378535AAvoid water seepageImprove Grooving EfficiencyPositioning apparatusMaintainance and safety accessoriesButtressButt joint

The invention belongs to the technical field of pipeline groove connection, and particularly relates to a construction method for pipeline groove connection, which comprises the following steps: S1, pipe stabilizing preparation work before pipeline groove connection; s2, firstly, a support and a bracket for fixing the steel pipe are installed at the designated position; s3, a groove is machined in the end of the steel pipe with the specified length size through a channeling machine; s4, two adjacent groups of steel pipes are in butt joint through rubber sealing rings and are fixed through hoops and bolts; s5, after the adjacent steel pipes are connected through the grooves, fixing buttresses are built at the bottoms of the steel pipes for fixing; the construction method for pipeline groove connection is systematically and strictly formulated through the steps S1 to S5, so that when groove connection is conducted on pipelines, rigorous construction can be conducted according to the construction method, and the phenomenon that due to imperfection of many details, pipeline connection is not tight, the sealing performance is poor, and water seepage is caused in later use is avoided.

Owner:BEIJING URBAN CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com