Cylinder workpiece double-side grooving machine

A technology of cylindrical workpiece and grooving machine, which is applied in metal processing and other directions, and can solve the problems of slow manual cutting speed, large error of constant grooving, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

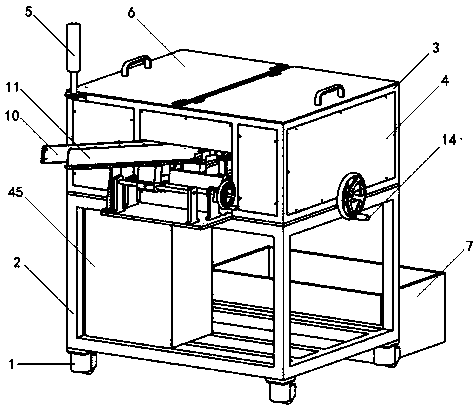

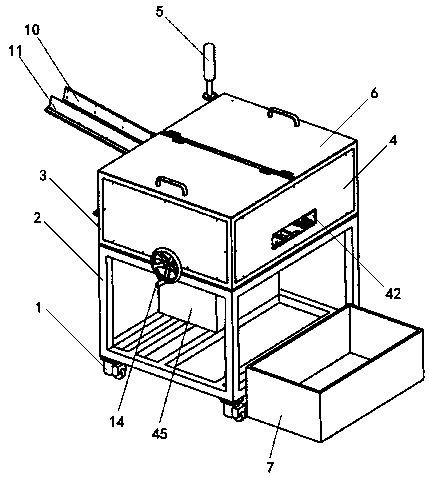

[0043] see Figure 2-4 As shown, a double-sided grooving machine for cylindrical workpieces mainly includes a bottom frame 2, a set of feed components, a set of guide components, two sets of retaining components, two sets of cutting components and an electrical control box 45.

[0044] see Figure 4 with Figure 5 As shown, the feed assembly consists of two fixed feed plate mounting plates 17, a fixed feed plate 10, an adjustable feed plate front driven support mounting frame 8, an adjustable feed plate front driven support 9. An adjustable feed plate rear driven support 15, an adjustable feed plate rear driven support mounting frame 16, an adjustable feed plate 11, an adjustable feed plate active support 12, a The adjustable feeding plate active support mounting frame 13 is composed of an adjustable feeding plate moving hand whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com